The Impact of Lubricant Film Thickness and Ball Bearings Failures †

Abstract

:1. Introduction

2. Empirical Equations for Life

3. Tribological Predictions of Life

4. First Parametric Study

5. Second Parametric Study

6. Conclusions

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Number of revolutions before 10% chance of failure | |

| SKF | Svenska Kullagerfabriken |

| RMS | Root Mean Square |

References

- Stachowiak, G.; Batchelor, A. Engineering Tribology, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Gohar, R. Elastohydrodynamics; World Scientific Publishing Company: Singapore, 2002. [Google Scholar]

- Ranger, A.; Ettles, C.; Cameron, A. The solution of the point contact elasto-hydrodynamic problem. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1975, 346, 227–244. [Google Scholar] [CrossRef]

- Blau, P. On the nature of running-in. Tribol. Int. 2005, 38, 1007–1012. [Google Scholar] [CrossRef]

- Hu, Y.; Li, N.; Tønder, K. A dynamic system model for lubricated sliding wear and running-in. J. Tribol. 1991, 113, 499–505. [Google Scholar] [CrossRef]

- Suzuki, M.; Ludema, K. The wear process during the “running-in” of steel in lubricated sliding. J. Tribol. 1987, 109, 587–591. [Google Scholar] [CrossRef]

- Endo, K.; Kotani, S. Observations of steel surfaces under lubricated wear. Wear 1973, 26, 239–251. [Google Scholar] [CrossRef]

- Nanbu, T.; Yasuda, Y.; Ushijima, K.; Watanabe, J.; Zhu, D. Increase of traction coefficient due to surface microtexture. Tribol. Lett. 2008, 29, 105–118. [Google Scholar] [CrossRef]

- Wong, P.; Huang, P.; Wang, W.; Zhang, Z. Effect of geometry change of rough point contact due to lubricated sliding wear on lubrication. Tribol. Lett. 1998, 5, 265–274. [Google Scholar] [CrossRef]

- Cann, P.; Spikes, H. In-contact IR spectroscopy of hydrocarbon lubricants. Tribol. Lett. 2005, 19, 289–297. [Google Scholar] [CrossRef]

- Jiang, P.; Li, X.M.; Guo, F.; Chen, J. Interferometry measurement of spin effect on sliding EHL. Tribol. Lett. 2009, 33, 161–168. [Google Scholar] [CrossRef]

- Reddyhoff, T.; Spikes, H.A.; Olver, A.V. Compression heating and cooling in elastohydrodynamic contacts. Tribol. Lett. 2009, 36, 69–80. [Google Scholar] [CrossRef]

- Timken Manual 10424, October 2016. Available online: https://www.timken.com/resources/timken-engineering-manual/ (accessed on 13 April 2019).

- Svenska Kullager Fabriken AB. SKF Bearing Calculator. 2017. Available online: http://webtools3.skf.com/BearingCalc/selectProduct.action (accessed on 23 April 2019).

- SKF Bearing Maintenance Handbook; SKF Group: Gothenburg, Sweden, 2011; ISBN 978-91-978966-4-1.

- Zaretsky, E.V. Rolling Bearing Life Prediction, Theory, and Application; NASA Technical Report. Available online: https://ntrs.nasa.gov/search.jsp?R=20160013905 (accessed on 10 September 2018).

- Zaretsky, E.V. A. Palmgren Revisited a Basis for Bearing Life Prediction; NASA Technical Memorandum; Lewis Research Center: Clevelend, OH, USA, 1997. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19970025228.pdf (accessed on 10 September 2018).

- Rolling Bearings: Dynamic Load Ratings and Rating Life; International Organization for Standardization (DIN): Berlin, Germany, 2007; Available online: https://www.iso.org/standard/38102.html (accessed on 10 September 2018).

- Greenwood, J.; Williamson, J. Contact of nominally flat surfaces. Proc. R. Soc. Lond. A 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Bush, A.; Gibson, R.; Keogh, G. The limit of elastic deformation in the contact of rough surfaces. Mech. Res. Commun. 1976, 3, 169–174. [Google Scholar] [CrossRef]

- Carbone, G. A slightly corrected Greenwood and Williamson model predicts asymptotic linearity between contact area and load. J. Mech. Phys. Solids 2009, 57, 1093–1102. [Google Scholar] [CrossRef]

- McCool, J. Comparison of models for the contact of rough surfaces. Wear 1986, 107, 37–60. [Google Scholar] [CrossRef]

- Bush, A.; Gibson, R.; Thomas, T. The elastic contact of a rough surface. Wear 1975, 35, 87–111. [Google Scholar] [CrossRef]

- Persson, B. Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 2006, 61, 201–227. [Google Scholar] [CrossRef] [Green Version]

- Finkin, E. Applicability of Greenwood-Williamson theory to film covered surfaces. Wear 1970, 15, 291–293. [Google Scholar] [CrossRef]

- Cann, P.; Ioannides, E.; Jacobson, B.; Lubrecht, A. The lambda ratio—A critical Re-examination. Wear 1994, 175, 177–188. [Google Scholar] [CrossRef]

- Marko, M. Friction of Tungsten-based coatings of steel under sliding contact. Lubricants 2019, 7, 14. [Google Scholar] [CrossRef]

- Crook, A. The lubrication of rollers. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1958, 250, 387–409. [Google Scholar] [CrossRef]

- Archard, J. The temperature of rubbing surfaces. Wear 1958, 2, 438–455. [Google Scholar] [CrossRef]

- Jaeger, J. Moving sources of heat and the temperature at sliding contact. Proc. R. Soc. N. S. W. 1942, 76, 203–224. [Google Scholar]

- Blok, H. Theoretical study of temperature rise at surfaces of actual contact under oiliness conditions. Proc. Inst. Mech. Eng. Gen. Discuss. Lubr. 1937, 2, 222–235. [Google Scholar]

- Cameron, A.; Gohar, R. Theoretical and experimental studies of the oil film in lubricated point contact. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 291, 520–536. [Google Scholar] [CrossRef]

- Hamrock, B.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts, III Fully Flooded Results; NASA Tech. Note; National Aeronautics and Space Administration: Washington, DC, USA, 1976; p. D-8317.

- Hamrock, B.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts, I Theoretical Formulation; NASA Tech. Note; National Aeronautics and Space Administration: Washington, DC, USA, 1975; p. D-8049.

- Hamrock, B.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts, IV Starvation Results; NASA Tech. Note; National Aeronautics and Space Administration: Washington, DC, USA, 1976; p. D-8318.

- Dowson, D. Elastohydrodynamic and micro-elastohydrodynamic lubrication. Wear 1995, 190, 125–138. [Google Scholar] [CrossRef]

- Nam, J.; Ryou, H.; Cho, S. A numerical model of rotating bearings for thermo-mechanical coupled analysis. Proc. Int. Conf. Simul. Exp. Heat Transf. Appl. 2016, 106, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Lugt, P.M.; Velichov, S.; Tripp, J.H. On the chaotic behavior of grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 581–590. [Google Scholar] [CrossRef]

- Van Zoelen, M.; Venner, C.; Lugt, P. Prediction of film thickness decay in starved elasto-hydrodynamically lubricated contacts using a thin layer flow model. J. Eng. Tribol. 2009, 223, 541–552. [Google Scholar] [CrossRef]

- Venner, C.H.; Popovici, G.; Lugt, P.M.; Organisciak, M. Film thickness modulations in starved elastohydrodynamically lubricated contacts induced by time varying lubricant supply. ASME J. Tribol. 2008, 130, 041501. [Google Scholar] [CrossRef]

- Venner, C.; van Zoelen, M.; Lugt, P. Thin layer flow and film decay modeling for grease lubricated rolling bearings. Tribol. Int. 2012, 47, 175–187. [Google Scholar] [CrossRef]

- Fillot, N.; Berro, H.; Vergne, P. From continuous to molecular scale in modelling elastohydrodynamic lubrication: Nanoscale surface slip effects on film thickness and friction. Tribol. Lett. 2011, 43, 257–266. [Google Scholar] [CrossRef]

- Guo, F.; Wong, P.L.; Geng, M.; Kaneta, M. Occurrence of wall slip in elastohydrodynamic lubrication contacts. Tribol. Lett. 2009, 34, 103–111. [Google Scholar] [CrossRef]

- Krupka, I.; Bair, S.; Kumar, P.; Svoboda, P.; Hartl, M. Mechanical degradation of the liquid in an operating EHL contact. Tribol. Lett. 2011, 41, 191–197. [Google Scholar] [CrossRef]

- Marko, M. The Tribological Effects of Lubricating Oil Containing Nanometer-Scale Diamond Particles. Ph.D. Thesis, Columbia University, New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Marko, M.; Kyle, J.P.; Wang, Y.S.; Terrell, E.J. Tribological investigations of the load, temperature, and time dependence of wear in sliding contact. PLOS ONE 2017, 12, e0175198. [Google Scholar] [CrossRef] [PubMed]

- Marko, M.D.; Kyle, J.P.; Branson, B.; Terrell, E.J. Tribological improvements of dispersed nano-diamond additives in lubricating mineral oil. J. Tribol. 2015, 137, 011802. [Google Scholar] [CrossRef]

- Marko, M.D.; Kyle, J.P.; Wang, Y.S.; Branson, B.; Terrell, E.J. Numerical and experimental tribological investigations of diamond nanoparticles. J. Tribol. 2016, 138, 032001. [Google Scholar] [CrossRef]

- Johnson, K. Contact Mechanics; Cambridge University Press: New York, NY, USA, 1987. [Google Scholar]

- Einstein, A. Neue Bestimmung der molekuldimensionen. Ann. Phys. 1906, 19, 289–306. [Google Scholar] [CrossRef]

- Pabst, W. Fundamental considerations on suspension rheology. Ceram. Silik. 2004, 48, 6–13. [Google Scholar]

- So, B.; Klaus, E. Viscosity-pressure correlation of liquids. ASLE Trans. 1980, 23, 409–421. [Google Scholar] [CrossRef]

- ASTM D341-09, Standard Practice for Viscosity-Temperature Charts for Liquid Petroleum Products; ASTM-International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 21 January 2013).

- Cengel, Y. Heat Transfer, a Practical Approach, 2nd ed.; Mcgraw-Hill: Boston, MA, USA, 2002. [Google Scholar]

- Abdel-Aal, H. A remark on the flash temperature theory. Int. Commun. Heat Mass Transf. 1997, 24, 241–250. [Google Scholar] [CrossRef]

- Barber, J. Distribution of heat between sliding surfaces. J. Mech. Eng. Sci. 1967, 9, 351–354. [Google Scholar] [CrossRef]

- Blok, H. The flash temperature concept. Wear 1963, 6, 483–494. [Google Scholar] [CrossRef]

- Archard, J.; Rowntree, R. The temperature of rubbing bodies; Part 2, the distribution of temperatures. Wear 1988, 128, 1–17. [Google Scholar] [CrossRef]

- White, F. Fluid Mechanics, 5th ed.; McGraw-Hill: Boston, MA, USA, 2003. [Google Scholar]

| Model | d (mm) | (kN) | (mm) | H (mm) | E (mm) | D (mm) | |

|---|---|---|---|---|---|---|---|

| 1 | 29418 | 90 | 820 | 98.9 | 148 | 137 | 190 |

| 2 | 29320 | 100 | 462 | 108.1 | 141 | 134 | 170 |

| 3 | 29420 | 100 | 1020 | 108.8 | 164 | 151 | 210 |

| 4 | 29322 | 110 | 604 | 118.6 | 157 | 149 | 190 |

| 5 | 29422 | 110 | 1200 | 120.3 | 180 | 167 | 230 |

| 6 | 29324 | 120 | 768 | 128.5 | 172 | 163 | 210 |

| 7 | 29424 | 120 | 1390 | 131.6 | 197 | 182 | 250 |

| 8 | 29326 | 130 | 852 | 140.3 | 186 | 177 | 225 |

| 9 | 29426 | 130 | 1600 | 142.4 | 213 | 197 | 270 |

| 10 | 29328 | 140 | 970 | 148.9 | 199 | 188 | 240 |

| 11 | 29428 | 140 | 1640 | 152.8 | 223 | 207 | 280 |

| 12 | 29330 | 150 | 993 | 159.5 | 209 | 198 | 250 |

| 13 | 29430 | 150 | 1860 | 163.5 | 238 | 222 | 300 |

| 14 | 29332 | 160 | 1190 | 170.5 | 225 | 213 | 270 |

| 15 | 29432 | 160 | 2100 | 175 | 255 | 237 | 320 |

| 16 | 29334 | 170 | 1230 | 179.2 | 235 | 223 | 280 |

| 17 | 29434 | 170 | 2380 | 184.8 | 270 | 251 | 340 |

| 18 | 29336 | 180 | 1430 | 190.7 | 251 | 238 | 300 |

| 19 | 29436 | 180 | 2660 | 197.6 | 286 | 267 | 360 |

| 20 | 29338 | 190 | 1620 | 202.2 | 268 | 253 | 320 |

| 21 | 29438 | 190 | 3040 | 205.5 | 303 | 281 | 380 |

| 22 | 29340 | 200 | 1880 | 213.3 | 284 | 269 | 340 |

| 23 | 29440 | 200 | 3210 | 217 | 317 | 295 | 400 |

| 24 | 29344 | 220 | 1950 | 231.6 | 303 | 288 | 360 |

| 25 | 29444 | 220 | 3350 | 237.8 | 339 | 317 | 420 |

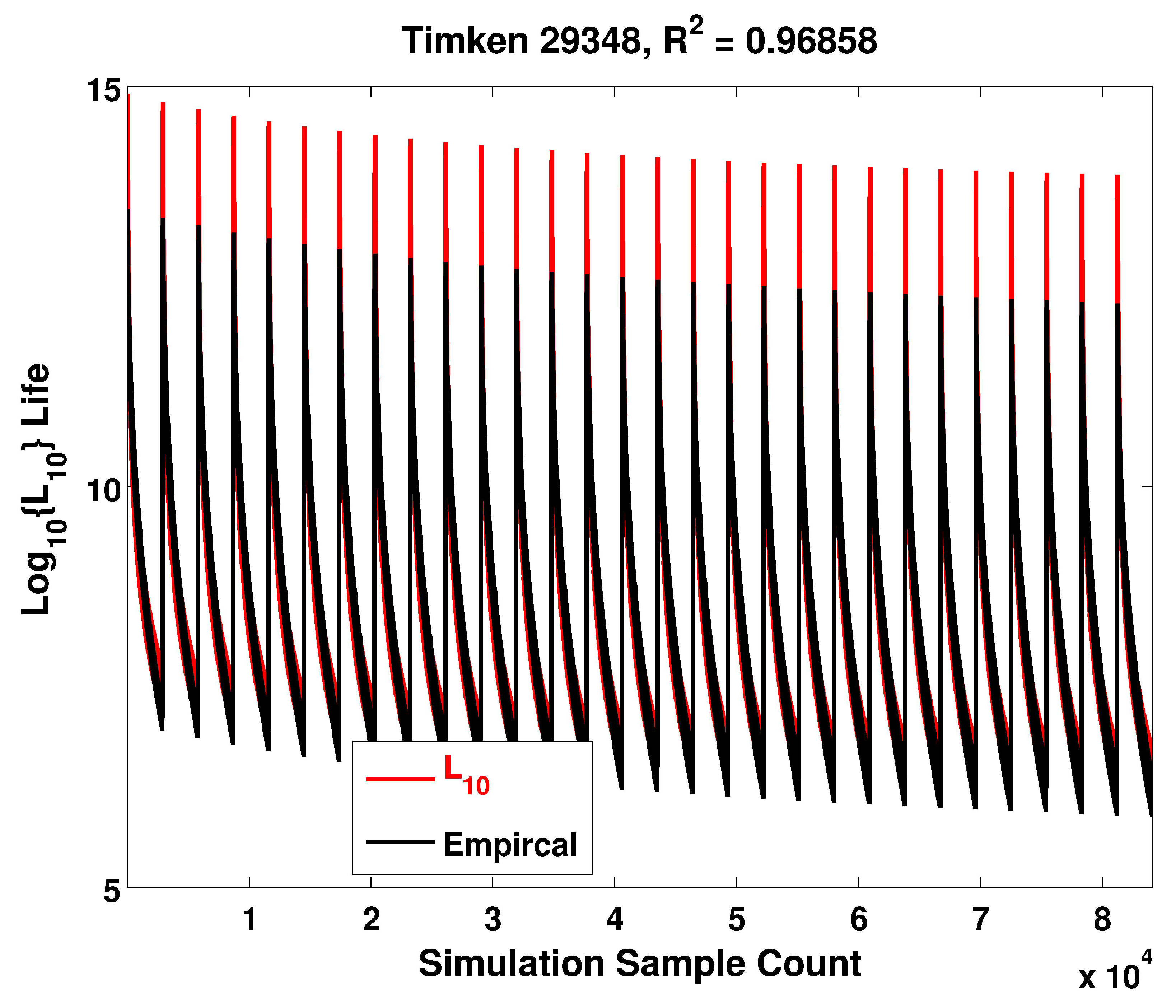

| 26 | 29348 | 240 | 2040 | 251.9 | 323 | 308 | 380 |

| 27 | 29448 | 240 | 3410 | 259 | 360 | 338 | 440 |

| 28 | 29352 | 260 | 2580 | 275.7 | 356 | 340 | 420 |

| 29 | 29452 | 260 | 4160 | 279.2 | 391 | 367 | 480 |

| 30 | 29356 | 280 | 2580 | 296.8 | 376 | 360 | 440 |

| 31 | 29456 | 280 | 4920 | 300.6 | 423 | 397 | 520 |

| 32 | 29360 | 300 | 3150 | 315.6 | 407 | 388 | 480 |

| 33 | 29460 | 300 | 4990 | 321.1 | 443 | 418 | 540 |

| 34 | 29364 | 320 | 2830 | 333.3 | 427 | 407 | 500 |

| 35 | 29464 | 320 | 5155 | 320 | 469 | 444 | 580 |

| 36 | 29368 | 340 | 3120 | 365.8 | 463 | 443 | 540 |

| 37 | 29468 | 340 | 5922 | 340 | 500 | 473 | 620 |

| 38 | 29372 | 360 | 3632 | 360 | 476 | 457 | 560 |

| 39 | 29472 | 360 | 5440 | 360 | 528 | 498 | 640 |

| 40 | 29376 | 380 | 4295 | 380 | 507 | 486 | 600 |

| 41 | 29476 | 380 | 6493 | 380 | 546.1 | 518 | 670 |

| 42 | 29380 | 400 | 3850 | 400 | 534 | 510 | 620 |

| 43 | 29480 | 400 | 7333 | 400 | 577.1 | 547 | 710 |

| 44 | 29284 | 420 | 2682 | 420 | 513.1 | 498 | 580 |

| 45 | 29384 | 420 | 4040 | 420 | 561 | 537 | 650 |

| 46 | 29484 | 420 | 6780 | 420 | 608 | 576 | 730 |

| 47 | 29388 | 440 | 4530 | 440 | 585 | 561 | 680 |

| 48 | 29488 | 440 | 8606 | 440 | 635 | 602 | 780 |

| 49 | 29392 | 460 | 4820 | 460 | 614 | 589 | 710 |

| 50 | 29492 | 460 | 8120 | 460 | 666 | 631 | 800 |

| 51 | 29396 | 480 | 4820 | 480 | 635 | 610 | 730 |

| 52 | 29496 | 480 | 9320 | 480 | 700 | 662 | 850 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marko, M.D. The Impact of Lubricant Film Thickness and Ball Bearings Failures. Lubricants 2019, 7, 48. https://doi.org/10.3390/lubricants7060048

Marko MD. The Impact of Lubricant Film Thickness and Ball Bearings Failures. Lubricants. 2019; 7(6):48. https://doi.org/10.3390/lubricants7060048

Chicago/Turabian StyleMarko, Matthew David. 2019. "The Impact of Lubricant Film Thickness and Ball Bearings Failures" Lubricants 7, no. 6: 48. https://doi.org/10.3390/lubricants7060048

APA StyleMarko, M. D. (2019). The Impact of Lubricant Film Thickness and Ball Bearings Failures. Lubricants, 7(6), 48. https://doi.org/10.3390/lubricants7060048