Abstract

Economic and societal changes and technological development guide the focus of tribology research. “Classical” tasks, such as the improvement of materials or the tuning of a lubricant, have long been replaced by a function-oriented aggregate design, including specifications defined by needs arising from production and the environment. Tribology faces, among other remarkable changes, a paradigm shift according to the tendency to replace classic internal combustion engine (ICE) drivetrains with electric drives. How tribology will develop, and which research topics will prevail in the future, are being explored by several studies based on the experience of experts. The variety of contributions to journals and conferences provide an indicator of the importance of such tasks or topics. Here, a report on the ECOTRIB 2019—7th European Conference on Tribology held in Vienna, Austria, is presented. From the available information, an even stronger integration of other disciplines into tribology is noticeable, with certain hype in the fields of advanced material technology, sensor integration and the implementation of data science. Measures to rethink tribology from both an organizational and scientific point of view to cope with future tasks are being targeted and comprehensively implemented in the current research program “InTribology”, operated by the Austrian Center of Competence for Tribology (AC²T) in Wiener Neustadt, Austria.

1. Introduction

Like many other fields of research in the technological, economic, and social sphere, tribology faces the challenge of steadily adjusting its aims and methodologies. Advanced electronics, micro and nanotechnology, biochemistry, and materials technology offer unprecedented possibilities. In particular, technical development accelerated by information technology has changed people’s behavior when dealing with modern equipment. The saying is that “technology has the solutions, the task or need for it is yet to be found”. Certain disciplines, including tribology, are of special importance as techniques of everyday life. Against the background of interdisciplinarity, as well as increasingly important transdisciplinarity in tribology, it is exciting to find answers to the question of what the tasks, goals, and methods of tribology will be in the next 10–15 years. Studies by experts from recognized institutions have attempted to provide such answers. However, the influence of the development of economic framework conditions and political steering cannot be estimated with sufficient accuracy despite medium or longer-term plans, as recent events following the COVID-19 pandemic have shown. Furthermore, the ideas of researchers and technicians are not only influenced by current conditions, but also create facts within their own dynamics which may, after a certain “induction period”, influence the reality of social development.

The current state of research is significantly reflected by scientific technical events. They enable insight not only into the top research activities at the time, but also facilitate the estimation of important topics in the future. While the submission of papers as contributions to congresses or journals is influenced by several reasons, the number of papers assigned to specific topic groups is an indicator of how “hot” a particular topic is. As an example, we can consider the content arrangement of the European Conference on Tribology 2019.

An interesting look at current developments in tribology is generated by combining tribological expertise with recent methods provided by data science. The orientation of the Austrian tribology research program “InTribology” is given here as an example. The program was recently launched (April 2020) by the Austrian Center of Competence for Tribology in cooperation with worldwide partners, predominantly from Europe, with support by public funding. The core of the scientific-technical research scope of this program is precisely oriented towards a pronounced intertwining of tribology and data science. Broadband application and tribology driven by developments in digitalization will be carried out under the keyword “Synaptic Tribology” during the next four years, with a possible extension for another four years.

2. The Age of Changes—Including for Tribology

The highly sophisticated and universal definition of tribology as the “science and engineering of interacting surfaces in relative motion” has provided an obstacle for the engineering community to become acquainted with its utility. Thus, it is no surprise that even H. Peter Jost, the “father of tribology”, who remained highly committed to promoting the benefits of tribology applications in industry, referred to tribology as the “generic, physics based science and technology of friction and wear” in the last years of his life [1]. The special appeal of tribology lies in its interdisciplinarity, which also contributes to its complexity and the strong influence of natural and technical sciences. Due to recent social, economic, and technical changes, tribologists and tribology-minded people, including scientists, engineers, and increasingly, economists, are faced with numerous challenges. Highly specialized scientific methods are available, and ambitious research approaches are being applied by tribologists to create results that support solutions for the various tasks emerging from product engineering and related branches, as well as from modern industrial technologies in connection with the concept of Industry 4.0. New technologies, integrated design, tailored materials, novel lubrication concepts, and ecological requirements, as well as the comprehensive changes related to already applied or expected technical solutions in the field of drive technology (keyword: e-mobility), provide the scope, challenge and opportunity for tomorrow’s tribo(techno)logists.

2.1. Tribology’s Position in Global Technology Trends

In view of the essential social challenges in the field of transport and mobility, as well as the digitalization of the world of work, tribology is also about to rethink itself. Keywords such as e-mobility and autonomous driving, data management and the Internet of Things illustrate the current technological and economic trends that create new conditions in the field of activity for tribologists. For example, tighter ecological regulations increasingly draw attention to environmentally friendly lubricants and additives. Safety aspects and the scarcity of resources literally force greater efforts towards the monitoring of machines and their essential tribosystems (including lubricants in use) in order to increase the lifetime of components and prevent sudden failure. Friction reduction to increase energy efficiency is a key issue in the context of decarbonization.

In various disciplines, as well as in tribology, attempts are repeatedly being made to determine emerging trends in economics and technology in order to predict the future “hot” topics of research or possible impacts due to applied knowledge. Such observations and conclusions in tribology have been compiled by experts in their various fields of expertise, e.g., [2,3,4], but are also a strategic task of relevant institutions, e.g., [5,6,7]. In several countries, studies have recently been performed to identify the current profile of tribology and its background, mainly in terms of industrial needs (driven by requests from the market and by political targets and regulations).

A sound investigation of the actual research and technological needs related to tribology was conducted by the Society of Tribologists and Lubrication Engineers (STLE) [8], together with McKinley Advisors in 2017, after having previously presented an Emerging Trends report in 2014. The updated report was based on the responses of more than 900 respondents to an initial stage survey and subsequent interviews with approximately 30 of the survey respondents. Six field discipline areas of primary interest from a tribological point of view were identified in the investigation as transportation, medical/health, energy, manufacturing, communication and data management, and atomistic processes. For each of the areas, the main short-term trends (relevant for the next 5 to 10 years) and long-term trends (significant for 10 years and further into the future) were compiled. The findings of the analyses were compiled in the form of a matrix for each of the areas, highlighting the importance and development of the area with respect to tribology. The findings were roughly classified under the areas of: governmental regulations; impact on and requirements of safety and environment; and relevant human needs. Saving energy and material resources, avoiding emissions, increasing product safety, and making education in tribology attractive are seen to be the major issues to overcome by the tribology community.

A second example for such an investigation: A group of German tribologists—viz. members of the Board of the German Society of Tribology—authored a study, [9], in which the focus was laid on the relevance of tribology and its applications on ecological aspects, such as CO2 emission reduction and saving resources. The transportation sector, a major field, has seen potentially positive progress in reduction of friction. The relevance of this development becomes clear when the energy consumption and poor efficiency in this field is considered: energy losses due to friction are quantified at 23% of the primary energy input, with an estimated potential to reduce it by 8.6%. Another important effect of applied tribology is the air pollution control by reduction or prevention of exhaust gas and particle emissions. Transition to e-mobility, the use of eco-friendly fuels, and restriction of harmful substances, e.g., in lubricants, have consequences for tribology and other similar research topics. These boundary conditions will lead to modified or completely new technical solutions, especially for drives, drivetrains and lubricants, and consequently to the development of engineering materials—including surface treatments and coatings—and lubrication technology.

A third example for the topic of “tribology of the future” is based on the use of modern data science tools [10]. There is a ranking of trends based on the development of the number of patents and publications in this field during the last ten years, and especially in the last two years. Additionally, a huge number of documents (about 50 million articles, patents, and wiki pages) were reviewed using a special software based on a search query, for instance, using the word “tribology”, which delivered a cloud of frequently-used, related “trendy” words. Relative frequency of word combinations can be weighted indicating mainstream trends, also considering “trends around a trend”. Efficient software tools like Percipio big data analytics software [11] can support researchers to find highly topical themes. Based on the word “tribology”, a number of terms are found to be trendy, such as “biotribology”, “modelling biotribological systems”, and “rail-wheel contact”, and details about technology and properties of “diamond-like carbon”, or “carbon nanomaterials”.

Nevertheless, these two facts should be kept in mind: firstly, studies, including data evaluation, are based on personal expertise of people being familiar with the domain, and secondly, experiences and documents in literature reflect the past. It is up to the creativity of tribologists to open the window to the future.

Each scientific discipline has its own scale-related view of the phenomena that occur in contact between surfaces that relatively move to each other. Tribology uses atomistic processes to deal with effects that appear in the macroscopically perceivable world but have their origin in the nanoscale. Thus, the behavior of giant mechanical systems, such as power plants for the generation of electrical energy from renewable sources (wind and water power plants), are as much a field of interest as tribological properties of materials on the nano-scale (e.g., graphene, nitrides from boron or gallium). Challenges for tribology in the coming years are to be met by emphasizing cross-scale and cross-disciplinary approaches in tribology with the aim of closer integration of the nanocosmos and the macroscopic world.

2.2. A Congress as a Reflection of Current Research Efforts

After the successful (second) World Tribology Congress 2001 in Vienna, the first formal preparations to organize a European tribology congress started in 2005. Subsequently, the respective national tribology societies from Slovenia, Italy, and Austria formed the “ECOTRIB consortium” (European COnference on TRIBology). The first to start the conference cycle was Ljubljana, Slovenia, in 2007; in the same year, Switzerland entered the consortium. In 2011 the fourth ECOTRIB took place in Vienna, and 7th ECOTRIB was organized in 2019 in Vienna again.

The founding members of the ECOTRIB consortium laid emphasis on obtaining solutions to the issues pertaining to economy and ecology (“ECO”) through advancements in tribology science and technology. A pronounced aim of ECOTRIB was and is to provide a platform for the presentation of R&D activities, not only from academic and research institutions, but also from the industry. Economy, social structures and political positions have changed considerably over the last 10–15 years. These conditions seem to have had a much stronger influence on the technological progress (and the research work behind them) than, conversely, the research results being adopted by policy makers. Therefore, it is still extremely important to emphasize the achievements of the scientific communities, particularly those of the tribologists. Tribologists should be aware that they can decisively contribute to answers to urgent energy problems; to questions related to the design of sustainable products; and to issues deriving from reliability and safety requirements of technical devices and equipment. Tribologists’ contributions will be even the more effective, the more the specific micro- and nano-conditions and processes of a tribocontact are understood. These—together with their interaction with the macro-conditions in a specific application and evidenced by specific analysis techniques—might be considered a “tribotope”, i.e., a set of such “entities” (term coined by AC²T for its unique research approach towards a unified characterization or classification of the tribosystem’s complexity [12]).

Tribology currently does not elicit the same attentive response like the other catchwords, such as nanotechnology, Industry 4.0, graphene, digitalization, or artificial intelligence. However, tribology has a distinct application relevance, which can be enhanced if relevant findings and methods from other fields of knowledge are incorporated into engineering tribology. A paradigm shift is evident in the fields of energy conversion, mobility, and production processes. These changes result in new challenges for tribology, claiming to use a wide variety of pre-existing, emerging or even revolutionary new working methods.

ECOTRIB 2019 offered a platform for the communication between scientists and engineers, for presentations and discussions of current research activities and results. It was also an excellent opportunity for young tribologists to present their own research work, and at the same time become acquainted with a multitude of up-to-date tribotechnical approaches. In addition, “MaTri”—the Austrian-Indian Conference on Materials Engineering and Tribology—that was held several times in Austria, and was included as a part of the 2019 conference. The participants had an opportunity to attend presentations, and visit research institutions and their laboratories at the Technology and Research Centre Wiener Neustadt (“tfz”), Lower Austria, about 45 km south of Vienna. A highlight of this visit was the Austrian Center of Competence for Tribology (AC2T research GmbH), one of the largest private research institutions specially devoted to tribology.

The relevance of tribology for the industry and the importance of further education of engineers and technicians convinced the technical group “Metal Technology Austria” of the Austrian Economic Chamber to offer their conference area to hold ECOTRIB 2019 in the center of Vienna.

The President of the International Tribology Council (ITC), Dr. Ali Erdemir (formerly Argonne National Laboratory, Lemont, IL, USA, now Professor at the Texas A&M University, College of Engineering, College Station, TX, USA) was present to give the welcome speech and also a plenary address (see Figure 1), where he presented some insights and a review of the latest successes in the use of materials and surface coatings with regard to superlubricity, i.e., the possibility of realizing ultra-low coefficients of friction, also in daily practice.

Figure 1.

Dr. Ali Erdemir (International Tribology Council (ITC)), at his plenary talk. Source: ÖTG/F. Franek.

Other plenary lectures also addressed the “hot topics” of tribology:

Prof. Ashlie Martini (University of California Merced, Merced, CA, USA) focused her presentation on reactive molecular dynamic simulations by reactive force fields (reaxFF) in tribochemistry, and the current progress, challenges and possibilities of this tool to understand the mode of action of tribofilms.

Prof. emer. Gwidon W. Stachowiak (Tribology Gold Medalist, Curtin University, Bentley, Australia) dealt with whether progress is possible without tribology—a question highly topical in view of the social, economic, and ecological challenges facing today’s society.

Prof. Maria-Isabel De Barros Bouchet (Ecole Centrale de Lyon, Laboratory of Tribology and System Dynamics, Lyon, France) presented the mechanisms of action of so-called gas phase lubrication (GPL) and related investigations as a novel approach in tribochemistry to contribute to efficient and sustainable lubrication technologies.

Prof. Hannes Hick (Graz University of Technology—Institute of Machine Components and Methods of Development, Graz, Austria) addressed the future challenges of tribology arising from current trends in automotive mobility (e-mobility), e.g., for powertrain systems.

Dr. Helena Ronkainen (VTT Technical Research Centre of Finland, Espoo, Finland) presented her and her co-authors’ studies on multiscale modelling to estimate the mechanical and tribological behavior of surface layers with regard to wear reduction by simulation methods and the far-reaching possibilities thereof to support a targeted material design.

Altogether, about 150 papers (submitted by scientists and by people from industry were scheduled in the final program [13]), and tribologists and experts of related disciplines—about 260 people from more than 30 countries—participated in the thematic sessions. The number of papers presented in each session can be considered as an indicator of the current fields of interest and the relevance of topics among the scientific community. This is presented in Table 1.

Table 1.

Main topics of sessions and presentations allocated to these sessions. Not included are the ECOTRIB plenary papers, MaTri keynote papers and the technical presentations at “tfz Wiener Neustadt”.

2.3. Tribology in The Age of Digitalization

Digitalization and data science can accelerate research and knowledge generation; the topics presented at the ECOTRIB 2019 supported these booming fields. This was evident in the number of papers and their content in the sessions “Fundamentals of tribology”, “Materials, coatings & thin films”, and “Modelling & simulation”.

The “digital revolution” often addressed by people from economy and politics affects wide areas of economic, social, work, and private lives and, of course, technology. Tribology, with its numerous diverse fields of application and tasks, its complexity and interdisciplinarity, seems to be an ideal field to make use of the efficiency of digitalization and to profit from the latest developments in this field.

Considering the huge amount of information via the various data sources available worldwide, despite the confidentiality of sensitive data, usable analyses of tribologically relevant material developments, lubrication approaches, test methods, design solutions, and online system monitoring, as well as maintenance strategies, are expected to be possible or already done under the conditions of “big data”. This enables targeted research and evaluation and offers the possibility of more rapid development of customized system solutions.

Finding and using data is associated with some risks and requires profound tribological system knowledge. It also requires knowledge of the proper generation of relevant data, e.g., from different sources, such as practical applications, laboratory analyses, and experimental and/or mathematical simulation. Generation of adequate and appropriate data makes use of modern methods of system and process modelling as well as of sensorics and analytics. These represent valuable and very direct information about system functionality, performance and “health” and therefore support data analyses from web-based sources and finally the holistic design approach in the sense of tribology.

The topic “digitalization” in the context of tribology and tribosensorics is under comprehensive discussion among experts of tribology. The integration of specific sensor technology and information technology determines the challenges and opportunities that result from the comprehensive efforts of this wave of digitalization for tribology and its solution approaches. Yet, the limitations and threats related to these technological possibilities should not be forgotten: the quality and applicability of models defined based on tribology knowledge depend largely on the quality of available data.

3. “InTribology”—The New Austrian Tribology Research Program

Shortly before the ECOTRIB 2019 event, an official decision was made to support Austrian tribology activities with public money within the framework of the governmental funding initiative “Competence Centers for Excellent Technologies” (COMET) [14]. The corresponding umbrella project is called “InTribology” and is focused on “Customized Tribology for Industrial Innovations”. The operating organization for the “InTribology” project is the Austrian Center of Competence for Tribology (AC2T research GmbH, AC²T) in Wiener Neustadt, a research subsidiary of the Austrian Tribology Society (ÖTG). AC²T—founded in 2002—is located at the Technology and Research Centre Wiener Neustadt (tfz), Niederösterreich (Lower Austria), and was also responsible for previous tribology umbrella projects.

The “InTribology” project proposal was prepared in autumn 2018 on the basis of more than 100 declarations of support from corporate and scientific partners, and submitted to the Austrian Research Promotion Agency (FFG). The project exposé and the hearing in front of a jury of international experts convinced the decision-makers to unanimously recommend “InTribology” for funding in the period from April 2020 to March 2024, with the option of an extension until 2028. The total planned budget is approx. EUR 43 million, of which the monetary contribution of the public sector is defined as 50%. Nevertheless, the indispensable prerequisite for the allocation of public financial resources is that companies from the business sector, but also institutions from the research sector such as universities contribute a corresponding share in cash and materials to the individual research projects.

Several projects have already been predefined with partners, especially long-term projects in the fields of industrial research, experimental development, and related fundamental research topics. Partners from industry and science can take part regardless of the size of the organization, the industry, or the geographical location. Thus, within the given budget, international project partners can also participate in the research program on a pro rata basis and benefit from the funding conditions.

3.1. Strategic Position of The Research Program

In the first period from 2020 to 2024, InTribology will drastically influence the process of designing and developing tribological components and systems through data-driven methods, thereby enabling customized solutions and fostering industrial innovation with focus on Europe.

InTribology will be a prominent lighthouse project leading tribology into an era of digital transformation; it will contribute significantly to an important global challenge, viz. decarbonization, since this is a technological, economic and social goal in many advanced countries, and also agreed on European level as the “Green Deal” [15].

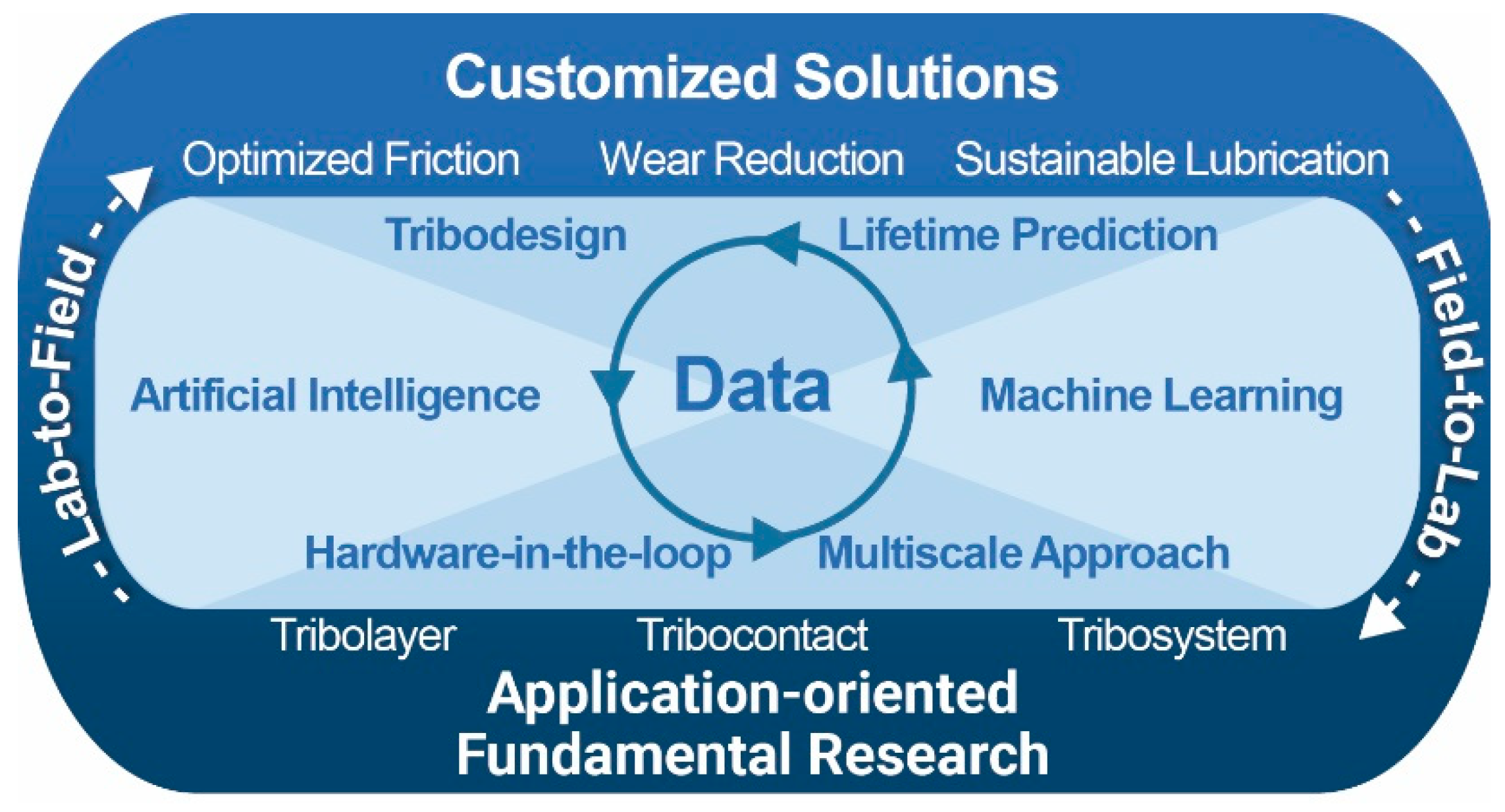

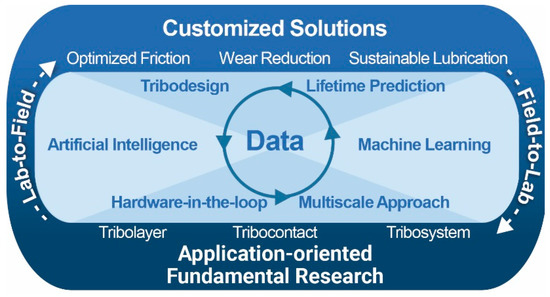

InTribology research route is based, among others, on well-founded tribological knowledge, adequate tribological reasoning, proper planning and interdisciplinary creativity as provided by the capacity of the Austrian Centre of Competence for Tribology—or in terms of the COMET InTribology project: Excellence Centre of Tribology—to create innovations in tribology. The assets of InTribology are the augmentation of long-standing experience, vast expertise, and solid knowledge in tribology combined with data science and artificial intelligence, as represented in Figure 2. A number of outstanding topics will extend the research focus of AC²T, considering the dramatic changes in technology (e.g., digitalization, additive manufacturing, and electrification), global trends in economy (e.g., by globalization), and challenges due to ever increasing needs on the part of ecology (e.g., decarbonization).

Figure 2.

General InTribology research approach—augmentation of tribology expertise by sound integration of data science and artificial intelligence. Source: AC2T research GmbH [16].

3.2. Research Areas

The overall goal of InTribology is to elaborate customized solutions in the field of tribology and related disciplines by means of transdisciplinary application of information and digital technologies in research and engineering. The focus on industrial innovations is supported by application-oriented research, and the project topics, goals and research activities are structured into three “Areas” based on important functional issues of tribosystems:

- Area 1: “Friction Optimized Devices” conducts research on customized surface and material design of energy-efficient and functional (mechanical) components, clearly focusing on reliability by a novel R&D approach viz. augmenting the field-to-lab/lab-to-field loop by a special view on tribosystems and the targeted application of data science.

- Area 2: “Wear Reduction Strategies for Industry” mainly deals with tribosystems under harsh environments, wear resistant materials, and monitoring and maintenance techniques. Ecological and economic sustainability are major concerns in the respective projects.

- Area 3: “Sustainable Lubrication” responds in its research to the current technological and ecological challenges of industrial applications, particularly, mobility. This Area–from a holistic point of view–pays special attention to designing future lubricants, lubrication, and maintenance concepts, essentially guided by “Green Tribology”.

Common tasks and advanced methods needed in the research work in the Areas mentioned above are bundled in more fundamental-oriented research projects assigned to a Strategic Area:

- Area 4: “Synaptic Tribology” establishes the basis for the InTribology research program by adopting state-of-the-art methods of statistics and information technology and combining them with multiscale simulations, sophisticated experimental techniques and advanced chemical/physical analytical methods. This Area supports and complements the projects running in the other Areas and is responsible for the comprehensive application and method development of digitalization and data science in tribology.

The research focus of “InTribology” will extensively make use of digitalization to solve tribological challenges, mainly deriving from industry. In addition to data-driven approaches, simulations will play a key role in the research. These range from simulations at the atomistic level to digital twins of products and entire production processes, thus enabling the simulative/virtual representation of reality.

3.3. Scheme and Objectives of InTribology Research

The overall motto of InTribology is: “From Tribology Research to Industrial Innovation”. Main steps and objectives in reaching this goal are as follows:

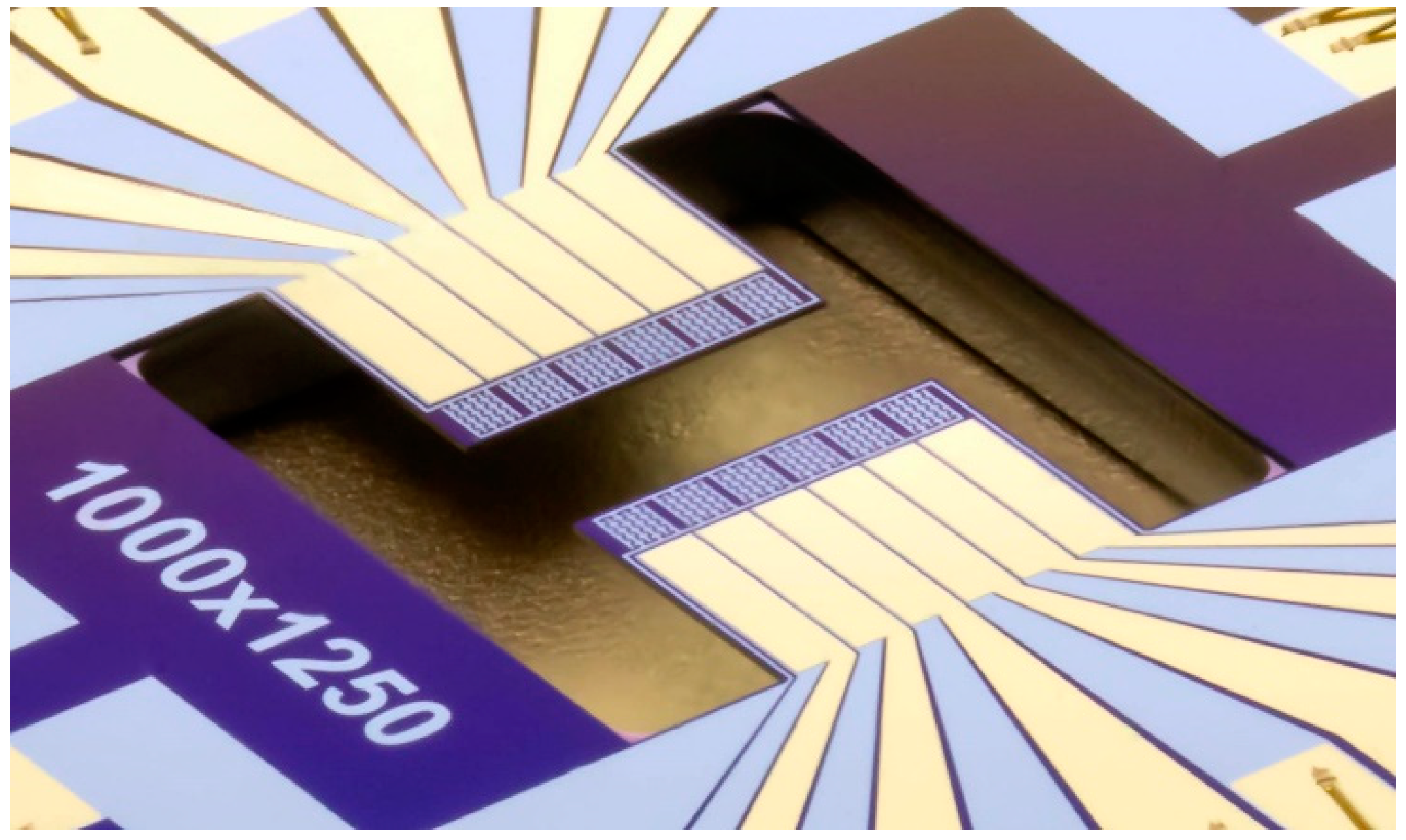

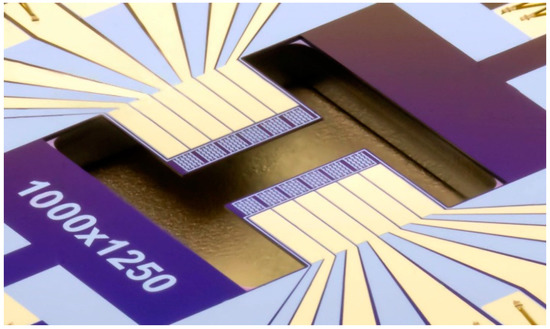

- Discovering correlations in data: Phenomenological approaches to predict friction and wear are not always available. New theories and models must be developed to go beyond the traditional way of data generation and interpretation. The capability of prediction using current tribological knowledge has to be extended by making use of modern data science, AI techniques—such as deep neural networks—and advanced sensor technology. Modern production processes are increasingly establishing condition-based and predictive maintenance; this significantly reduces machine downtime, and increases productivity and operational reliability. This requires customized sensors characterized by high robustness, low space requirements and low power consumption for the continuous measurement of critical properties (see Figure 3). Machine learning algorithms and statistical models help implementing ‘intelligence’ to predict behavior of tribosystems and thus of the reliability of the respective aggregates.

Figure 3. Piezoelectrically-driven MEMS cantilevers can accumulate particles such as wear debris and varnish precursors. Source: Pfusterschmied—TU Wien [13].

Figure 3. Piezoelectrically-driven MEMS cantilevers can accumulate particles such as wear debris and varnish precursors. Source: Pfusterschmied—TU Wien [13].

- Creating models from fundamental research: Data-driven knowledge goes beyond the current level of tribology. The additional knowledge enables the creation of novel tribological models or improve existing ones by combining them with well-established tribological principles. Parameter studies involving these models are performed for their verification and validation. For example, classical molecular dynamics provides insight into the behaviour of films between sliding surfaces that cannot be probed experimentally. Since the bonding between atoms, i.e., chemical bonds, are predefined here, chemical reactions of the lubricant with the surfaces cannot be captured. To overcome these limitations, reactive molecular dynamics simulations are performed using ReaxFF, one of the most used reactive potentials (cf. e.g., [17]).

- Simulating reality: Increased efficiency of machines such as vehicles and their components are challenging tasks for tribology research and development. New materials, new surface designs and lubricants are the key technologies to face this challenge. But state-of-the-art R&D processes for new materials and their application in tribological components and systems are very time consuming and costly. To accelerate the development a new approach based on “materials up-scaling” development environment is used. Down-scaling and up-scaling in tribology will be served by the introduction and implementation of such approaches for both industrial and academic challenges via developments of digital twins combined with experimental model tests and their characterization data. Tribological material behavior of a new material can be already predicted in a very early component development stage.

- Designing customized solutions: Customized solutions are built from reliable data correlations, fundamental models, and experimentally validated system performance. One such particular challenge is to functionalize components with light-weight structure; this may be fabricated from light alloy by 3D printing to increase wear resistance by embedding hard and wear resistant particles in a metallic matrix layer. Such coatings, along with self-lubricating phases for controlled friction behavior, can be fabricated using high power laser cladding. Furthermore, sensor integration in such hybrid components will allow online monitoring of tribologically relevant parameters or alerts, e.g., tension, pressure, friction forces. This way, the fields of application of those parts are considerably expanded.

4. Concluding Remarks

In the current period of significant changes in the social and technological environment, tribology is to be seen as an “enabling technology”. People working in tribology—as a domain of engineering creativity—will consistently apply their generic knowledge with all its features (tribophysics, tribochemistry, engineering tribology, etc.), but also adopt and effectively implement knowledge from other disciplines. Experts and institutions constantly bring out studies on the future of tribology. Scientific-technical events give an overview of the current “hot topics”; detailed information can be gained using data science methods on scientific, technical, and patent literature on the internet. Thereby, the trends of current fields of research can be made out more clearly, especially when comparing the development of thematic publications over time. The understanding of tribosystems and their processes too can profit from making use of the efficiency of digitalization and the latest developments in this field, thus enabling the rethinking of tribology.

The Austrian Center of Competence for Tribology (AC²T), Austria, recently started a 4-year research period within the framework of the governmental COMET program. The corresponding umbrella project “InTribology” precisely addresses the consequent application, adoption, and further development of tribology to respond to industrial needs within a reasonable timeframe and with predictable accuracy. AC²T and its 140 scientific and technical staff members are now executing the targeted tribology research program for and with more than 120 COMET partners from industry and scientific institutions; members of the project consortia each will benefit from cost reduction and process optimization, shorter R&D cycles, intelligent maintenance, and customized products and processes.

Funding

The research performed in the “InTribology” project is funded by the Austrian governmental COMET program, project no. 872176, via the Austrian Research Promotion Agency (FFG) and the respective partner institutions of the federal states Niederösterreich and Vorarlberg.

Acknowledgments

The organization team of the ECOTRIB 2019 gratefully acknowledges the technical group “Metal Technology Austria” of the Austrian Economic Chamber for the opportunity to hold the congress in their conference area, and for the financial support of the congress. The authors thank Harsha Raghuram for editing the language of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jost, H.P. Opening Address. In Proceedings of the 20th International Colloquium Tribology—Industrial and Automotive Lubrication, Technische Akademie Esslingen—TAE, Stuttgart/Ostfildern, Germany, 12–14 January 2016. [Google Scholar]

- Hasegawa, T. (Ed.) Tribology Research Trends; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2008. [Google Scholar]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Spencer, N.D. The Cutting Edge of Tribology, a Decade of Progress in Friction, Lubrication, and Wear; World Scientific: Singapore, 2015. [Google Scholar]

- NN. 12 Disruptive Business and Technology Trends for 2020, (TNXTOutlook 2020, The Next Organization, NL). Available online: https://www.consultancy.eu/news/4000/12-disruptive-business-and-technology-trends-for-2020 (accessed on 3 May 2020).

- Briggs, B.; Buchholz, S. Deloitte Insights—Tech Trends 2020. Available online: www.deloitte.com/insights/tech-trends (accessed on 3 May 2020).

- Müller, J.; Potters, L. Future Technology for Prosperity—Horizon Scanning by Europe’s Technology Leaders; European Commission: Brussels, Belgium, 2019; ISBN 978-92-76-09509-5. Available online: https://op.europa.eu/en/publication-detail/-/publication/ae785b63-dba9-11e9-9c4e-01aa75ed71a1/language-en/format-PDF/source-116042367 (accessed on 24 July 2020).

- NN. Report on Emerging Issues and Trends in Tribology and Lubrication Engineering; STLE—Society of Tribologists and Lubrication Engineers: Park Ridge, IL, USA, 2017. [Google Scholar]

- Woydt, M.; Gradt, T.; Hosenfeldt, T.; Luther, R.; Rienäcker, A.; Wetzel, F.-J.; Wincierz, C. Tribologie in Deutschland—Querschnittstechnologie zur Minderung von CO2-Emissionen und zur Ressourcenschonung; GfT—Gesellschaft für Tribologie e. V.; DE: Jülich, Germany, 2019; Available online: https://www.gft-ev.de/wp-content/uploads/GfT-Studie-Tribologie-in-Deutschland.pdf (accessed on 24 July 2020).

- Reynvaan, C. Trends in Tribology Discovered by a Sematic Big Data Analysis, Proceedings, ÖTG Symposium 2917; Austrian Tribology Society (Österreichische Tribologische Gesellschaft—ÖTG): Wiener Neustadt (AT), Austria, 2017; ISBN 978-3-901657-56-6. [Google Scholar]

- Duh, A.; Korošak, D. Percipio Big Data Analytics Software, Version 2017. Available online: https://percipio-big-data.com/#about (accessed on 29 April 2020).

- Franek, F.; Dörr, N.; Badisch, E.; Jech Vernes, A. An Advanced View on Tribosystems: TriboTope Approach, Supplementary Presentation. In Proceedings of the ECOTRIB 2019—7th European Conference on Tribology, Vienna (AT), Austria, 12–14 June 2019; Österreichische Tribologische: Wiener Neustadt (AT), Austria, 2019. [Google Scholar]

- Dörr, N.; Gachot, C.; Franek, F.; Kalin, M.; Ciulli, E.; Crockett, R. (Eds.) Book of Abstracts, ECOTRIB 2019—7th European Conference on Tribology with the Special Event MaTri ‘19—4th Austria-India-Symposium on Materials Engineering and Tribology, Vienna (AT), Austria, 12–14 June 2019; Österreichische Tribologische Gesellschaft (Austrian Tribology Society): Wiener Neustadt (AT), Austria, 2019; ISBN 978-3-901657-60-3. [Google Scholar]

- COMET—Competence Centers for Excellent Technologies, The Austrian Research Promotion Agency (FFG). Available online: https://www.ffg.at/en/comet-competence-centers-excellent-technologies (accessed on 4 May 2020).

- “The European Green Deal”, Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://ec.europa.eu/info/sites/info/files/european-green-deal-communication_en.pdf, cf. https://en.wikipedia.org/wiki/European_Green_Deal (accessed on 15 May 2020).

- Badisch, E.; Dörr, N.; Pirker, F.; Franek, F.; Pauschitz, A. Customized Tribology for Industrial Innovations: InTribology—Research Perspectives 2020–2028, Proceedings, p. 11–18, ÖTG-Symposium 2019 “Tribology in Industry and Research—Tribology Impulses through Digitalization?”, Dornbirn (AT), Austria, 21 November 2019; Österreichische Tribologische Gesellschaft (Austrian Tribology Society): Wiener Neustadt (AT), Austria, 2019; ISBN 978-3-901657-62-7. [Google Scholar]

- Mohammadtabar, K.; Eder, S.J.; Bedolla, P.O.; Dörr, N.; Martini, A. Reactive Molecular Dynamics Simulation of Thermal Film Growth from Di-tert-butyl Disulfide on a Fe(100) surface. Langmuir 2018, 34, 15681–15688. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).