In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography

Abstract

1. Introduction

2. Materials and Methods

2.1. L-PBF Processsing Conditions

2.1.1. Machine and Material

2.1.2. Description of the Specimen and Processing Parameters

2.2. In-Situ Monitoring by Thermograpy and Optical Tomography

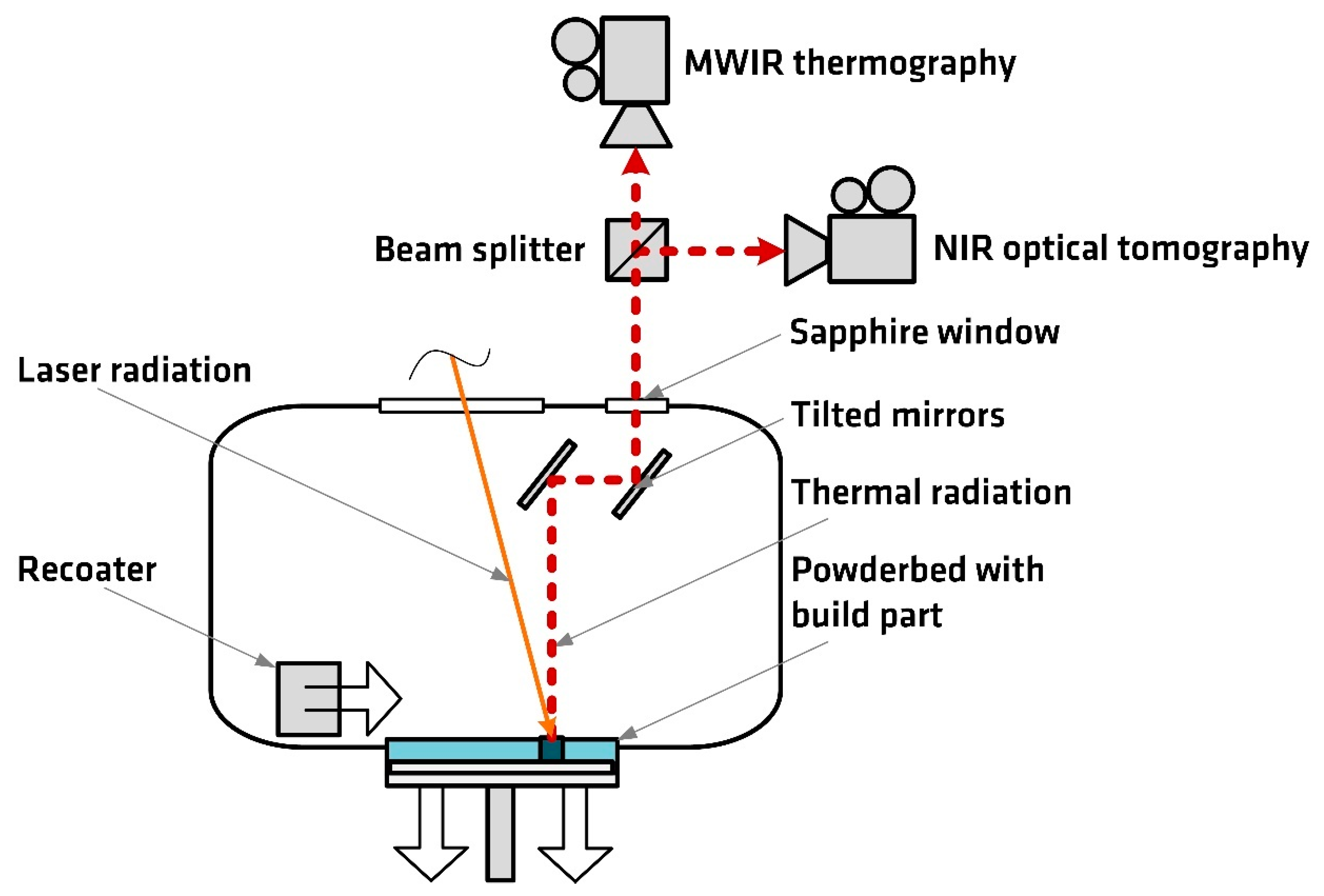

2.2.1. Optical Setup

2.2.2. Data Acquisition

2.3. Ex-Situ Inspection by Computed Tomography, Metallography and Data Integration

3. Results and Discussion

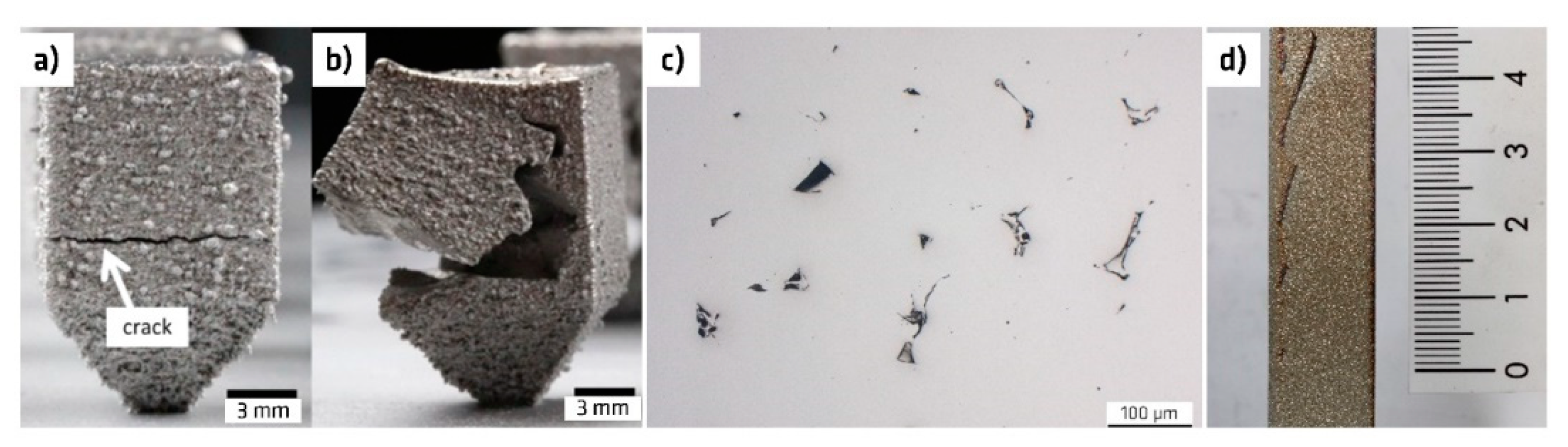

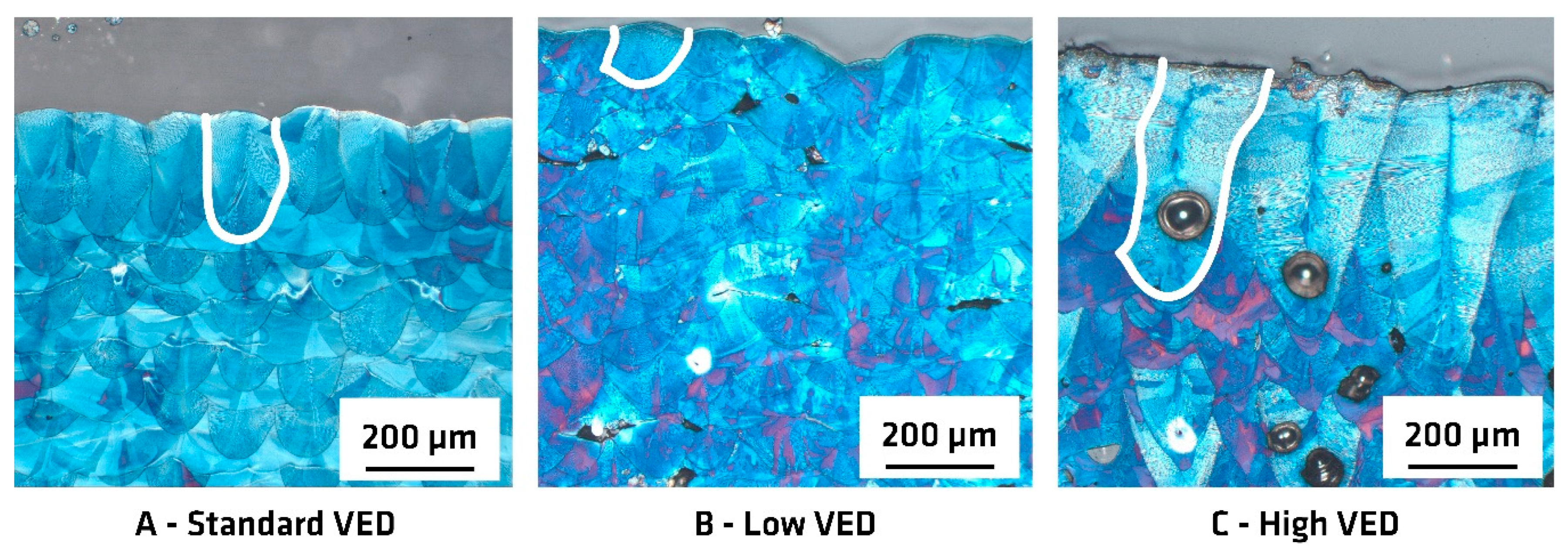

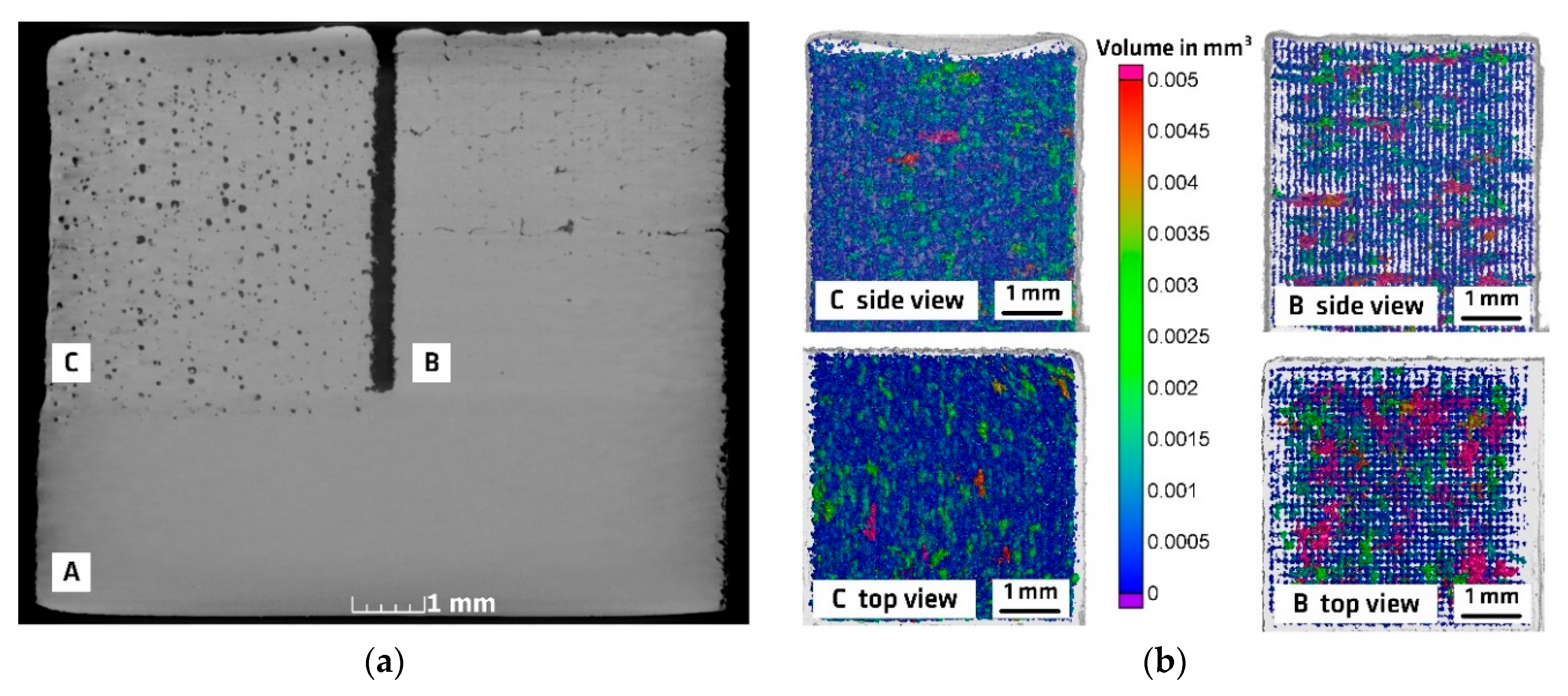

3.1. Influence of Processing Parameters Analysed by µCT and Metallography

3.2. In-Situ Monitoring

3.2.1. Data analysis Concepts

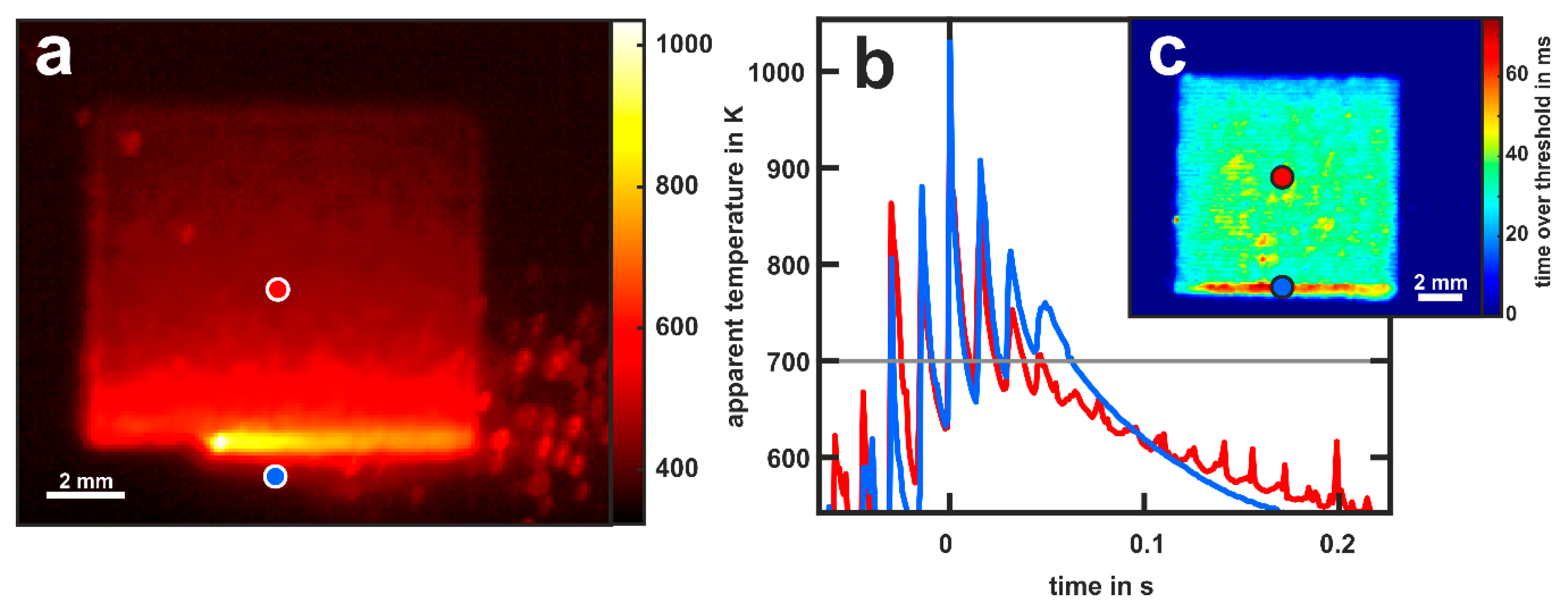

Thermography–Apparent Temperatures

Thermography–Time over Threshold (TOT)

Optical Tomography

3.2.2. Influence of Processing Parameters on In-Situ Monitoring Signatures

Standard Process Parameters

Comparison between Standard, High and Low VED Settings

3.2.3. In-Situ Monitoring for Defect Detection

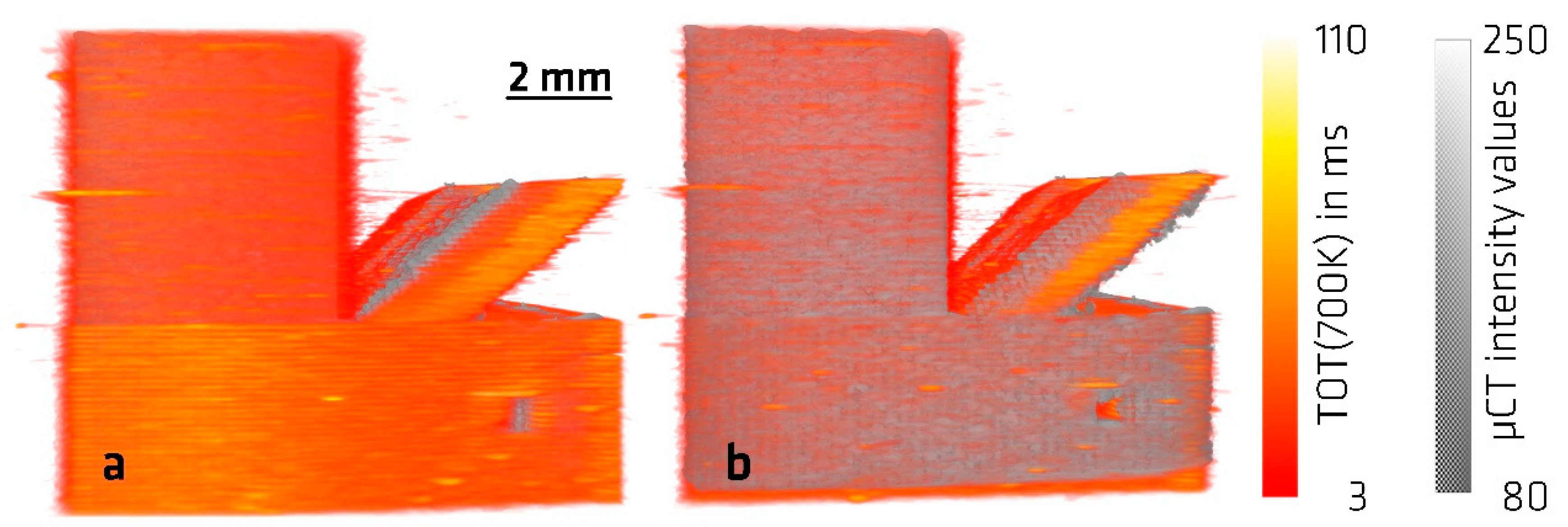

Processing Parameters Related Defects

Artificial Defects with Standard Process Parameters

3.3. Automation of Data Handling

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kruth, J.P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wohlers, T.T.; Campbell, I.; Diegel, O.; Kowen, J.; Caffrey, T. Wohlers Report. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates, Inc.: Fort Collins, CO, USA, April 2007. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Karg, M.; Ahuja, B.; Kuryntsev, S.; Gorunov, A.; Schmidt, M. Processability of high strength Aluminium-Copper alloys AW-2022 and 2024 by Laser Beam Melting in Powder Bed. In Proceedings of the 25th Annual International Solid Freeform Symposium, Austin, TX, USA, 4–6 October 2014. [Google Scholar]

- Mohr, G.; Johannsen, J.; Knoop, D.; Gärtner, E.; Hummert, K.; Emmelmann, C. Processing of a high-strength Al-Fe-Ni alloy using laser beam melting and its potential for in-situ graded mechanical properties. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Tapia, G.; Elwany, A. A review on process monitoring and control in metal-based additive manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 1–25. [Google Scholar] [CrossRef]

- Rehme, O.; Emmelmann, C. Reproducibility for properties of selective laser melting products. In Proceedings of the Third International WLT-Conference on Lasers in Manufacturing, Munich, Germany, 13–16 June 2005. [Google Scholar]

- O’Regan, P.; Prickett, P.; Setchi, R.; Hankins, G.; Jones, N. Metal Based Additive Layer Manufacturing: Variations, Correlations and Process Control. Procedia Comput. Sci. 2016, 96, 216–224. [Google Scholar] [CrossRef]

- Zerbst, U.; Hilgenberg, K. Damage development and damage tolerance of structure maanufactuired by selective laser melting—A review. Procedia Struct. Integr. 2017, 7, 141–148. [Google Scholar] [CrossRef]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by Selective Laser Melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Sharratt, B. Non-Destructive Techniques and Technologies for Qualification of Additive Manufactured Parts and Processes: A Literature Review; Contract Report No. DRDC-RDDC-2015-C035 [Online]; Sharratt Research and Consulting Inc.: Victoria, BC, Canada, 2015. [Google Scholar]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integrating Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar]

- Alberts, D.; Schwarze, D.; Witt, G. High speed melt pool & laser power monitoring for selective laser melting (SLM®). In 9th International Conference on Photonic Technologies LANE; Bayrisches Laserzentrum GmbH: Fürth, Germany, 2016; Volume 2016. [Google Scholar]

- Neef, A.; Seyda, V.; Herzog, D.; Emmelmann, C.; Schönleber, M.; Kogel-Hollacher, M. Low coherence interferometry in selective laser melting. Phys. Procedia 2014, 56, 82–89. [Google Scholar] [CrossRef]

- Ali, U.; Mahmoodkhani, Y.; Imani Shahabad, S.; Esmaeilizadeh, R.; Liravi, F.; Sheydaeian, E.; Huang, K.Y.; Marzbanrad, E.; Vlasea, M.; Toyserkani, E. On the measurement of relative powder-bed compaction density in powder-bed additive manufacturing processes. Mater. Des. 2018, 155, 495–501. [Google Scholar] [CrossRef]

- Grasso, M.; Demir, A.G.; Previtali, B.; Colosimo, B.M. In situ monitoring of selective laser melting of zinc powder via infrared imaging of the process plume. Robot. Comput.-Integr. Manuf. 2018, 49, 229–239. [Google Scholar] [CrossRef]

- Anwar, A.B.; Pham, Q.-C. Study of the spatter distribution on the powder bed during selective laser melting. Addit. Manuf. 2018, 22, 86–97. [Google Scholar] [CrossRef]

- Mohr, G.; Seeger, S.; Hilgenberg, K. Measurement of particle emissions in Laser Powder Bed Fusion (L-PBF) processes and its potential for in-situ process monitoring. In Proceedings of the Euro PM 2019, Maastricht, The Netherlands, 13–16 October 2019. [Google Scholar]

- Dunbar, A.J. Analysis of the Laser Powder Bed Fusion Additive Manufacturing Process through Experimental Measurement and Finite Element Modeling; Open Access: State College, PA, USA, 2016. [Google Scholar]

- Craeghs, T.; Clijsters, S.; Kruth, J.P.; Bechmann, F.; Ebert, M.C. Detection of Process Failures in Layerwise Laser Melting with Optical Process Monitoring. Phys. Procedia 2012, 39, 753–759. [Google Scholar] [CrossRef]

- Zenzinger, G.; Bamberg, J.; Ladewig, A.; Hess, T.; Henkel, B.; Satzger, W. Process monitoring of additive manufacturing by using optical tomography. In Proceedings of the AIP Conference Proceedings, Boise, ID, USA, 20–25 July 2014; Volume 1650, pp. 164–170. [Google Scholar]

- Bartlett, J.L.; Heim, F.M.; Murty, Y.V.; Li, X. In situ defect detection in selective laser melting via full-field infrared thermography. Addit. Manuf. 2018, 24, 595–605. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Krauss, H. Qualitätssicherung beim Laserstrahlschmelzen durch schichtweise thermografische In-Process-Überwachung; Herbert Utz Verlag: Munich, Germany, 2017; Volume 325. [Google Scholar]

- Bamberg, J.; Zenzinger, G.; Ladewig, A. In-process control of selective laser melting by quantitative optical tomography. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Gögelein, A.; Ladewig, A.; Zenzinger, G.; Bamberg, J. Process Monitoring of Additive Manufacturing by Using Optical Tomography. In Proceedings of the 14th Quantitaitve InfraRed Thermography Conference, Berlin, Germany, 25–29 June 2018. [Google Scholar]

- Mitchell, J.A.; Ivanoff, T.A.; Dagel, D.; Madison, J.D.; Jared, B. Linking pyrometry to porosity in additively manufactured metals. Addit. Manuf. 2020, 31, 100946. [Google Scholar] [CrossRef]

- Oesch, T.; Weise, F.; Meinel, D.; Gollwitzer, C. Quantitative In-situ Analysis of Water Transport in Concrete Completed Using X-ray Computed Tomography. Transp. Porous Media 2019, 127, 371–389. [Google Scholar] [CrossRef]

- Klein, S.; Staring, M.; Murphy, K.; Viergever, M.A.; Pluim, J.P. Elastix: a toolbox for intensity-based medical image registration. IEEE Trans. Med. Imaging 2009, 29, 196–205. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Li, Y.; Bai, Q. Defect formation mechanisms in selective laser melting: A review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Hunnewell, T.S.; Walton, K.L.; Sharma, S.; Ghosh, T.K.; Tompson, R.V.; Viswanath, D.S.; Loyalka, S.K. Total Hemispherical Emissivity of SS 316L with Simulated Very High Temperature Reactor Surface Conditions. Nucl. Technol. 2017, 198, 293–305. [Google Scholar] [CrossRef]

- Lough, C.S.; Wang, X.; Smith, C.C.; Adeniji, O.; Landers, R.G.; Bristow, D.A.; Kinzel, E.C. Use of SWIR Imaging to Monitor Layer-to-Layer Part Quality during SLM of 304L Stainless Steel. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Mattes, D.; Haynor, D.R.; Vesselle, H.; Lewellyn, T.K.; Eubank, W. Nonrigid multimodality image registration. In Medical Imaging 2001: Image Processing; Sonka, M., Hanson, K.M., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 2001; pp. 1609–1620. [Google Scholar]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

| Parameters of Sections | A | B | C |

|---|---|---|---|

| Parameter Set | Standard volumetric energy density (VED) | Low VED | High VED |

| VED in J/mm³ | 65.5 | 35.7 | 152.7 |

| Laser Power PL in W | 275 | 150 | 275 |

| Scanning Velocity vs in mm/s | 700 | 700 | 300 |

| Camera System | Thermography | Optical Tomography |

|---|---|---|

| Camera | Infratec ImageIR8300 | DALSA Genie Nano-M4020 |

| Detector | cooled InSb-focal-plane array | CMOS |

| Detector Size | 640 × 512 pixels | 4112 × 3012 pixels |

| Used Detector Elements | 192 × 176 pixels | 4112 × 3012 pixels |

| Lens Focal Length | 100 mm | 50 mm |

| Resulting Optical Resolution | 100 µm/pixel | 50 µm/pixel |

| Framerate and Exposure Time | 900 Hz, 90 µs | bulb exposure of layer expositions |

| Effective Sensitive Spectral Range | 2 µm–5.7 µm | 855 nm–905 nm |

| Black Body Calibration Range | 623 K–973 K | no calibration |

| Melt Pool Depth and Porosity in Different Sections | A | B | C |

|---|---|---|---|

| Parameter Set | Standard VED | Low VED | High VED |

| Melt Pool Depth in µm | 213 ± 19 | 117 ± 14 | 471 ± 54 |

| Pore Volume in % of Part Volume Measured by µCT | <0.1 | 2.7 * | 7.4 |

| Volume | A | B | C |

|---|---|---|---|

| Parameter Set | Standard VED | Low VED | High VED |

| Mean TOT(700 K) in ms | 28.1 | 14.5 | 280 |

| Mean OT Signal in Digital Values (DV) | 816 | 483 | 2860 * |

| Overlap of Signals and Defects | All Pores, 0 Layers Shifted | All Pores, 1 Layer Shifted | Pores > 0.001 mm³, 0 Layers Shifted | Pores > 0.001 mm³, 1 Layer Shifted |

|---|---|---|---|---|

| Micro-CT pores overlapped by thermography anomalies | 3.1% | 3.1% | 35.1% | 29.9% |

| Micro-CT pores overlapped by OT anomalies | 0.7% | 0.5% | 14.3% | 11.7% |

| Thermography anomalies overlapped by micro-CT pores | 71.4% | 55.5% | 33.3% | 30.2% |

| OT anomalies overlapped by micro-CT pores | 17.1% | 15.1% | 11.0% | 8.8% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals 2020, 10, 103. https://doi.org/10.3390/met10010103

Mohr G, Altenburg SJ, Ulbricht A, Heinrich P, Baum D, Maierhofer C, Hilgenberg K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals. 2020; 10(1):103. https://doi.org/10.3390/met10010103

Chicago/Turabian StyleMohr, Gunther, Simon J. Altenburg, Alexander Ulbricht, Philipp Heinrich, Daniel Baum, Christiane Maierhofer, and Kai Hilgenberg. 2020. "In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography" Metals 10, no. 1: 103. https://doi.org/10.3390/met10010103

APA StyleMohr, G., Altenburg, S. J., Ulbricht, A., Heinrich, P., Baum, D., Maierhofer, C., & Hilgenberg, K. (2020). In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals, 10(1), 103. https://doi.org/10.3390/met10010103