Abstract

Aluminum alloys can be used in the fabrication of intricate geometry and curved parts for a wide range of uses in aerospace and automotive sectors, where high stiffness and low weight are necessitated. This paper outlines a review of various research investigations on the superplastic behavior of aluminum alloys that have taken place mainly over the past two decades. The influencing factors on aluminum alloys superplasticity, such as initial grain size, deformation temperature, strain rate, microstructure refinement techniques, and addition of trace elements in aluminum alloys, are analyzed here. Since grain boundary sliding is one of the dominant features of aluminum alloys superplasticity, its deformation mechanism and the corresponding value of activation energy are included as a part of discussion. Dislocation motion, diffusion in grains, and near-grain boundary regions being major features of superplasticity, are discussed as important issues. Moreover, the paper also discusses the corresponding values of grain size exponent, stress exponent, solute drag creep and power law creep. Constitutive equations, which are essential for commercial applications and play a vital role in predicting and analyzing the superplastic behavior, are also reviewed here.

1. Introduction

Superplasticity is a process in which polycrystalline materials undergo several hundred to several thousand percent of tensile elongation at an appropriate temperature and strain rate. It is greatly effective in reducing the weight and production cost by minimizing the processing steps of machining and joining. Furthermore, superplasticity can also be defined as the capacity of materials to be plastically deformed up to and exceeding 1000% without breaking [1]. Generally, in order to achieve the superplastic behavior of materials, temperature should be more than homologous temperature (T/Tm > 0.5; T: deformation temperature; Tm: melting point), where deformation mechanism deviates from dislocation activity to thermally activated mechanisms [2,3,4]. Likewise, to achieve better superplasticity, grain size should be less than 10 µm and strain rate interval in the tensile test should be within 1 × 10−5 s−1 to 1 × 10−1 s−1 [5]. Under superplastic conditions, deformation resistance is decreased while plasticity of materials is increased, resulting in a 50–80% decrease in energy compared to the conventional process, 50–90% cut down equipment expenses, and 20–50% reduction in raw materials consumption [6]. Moreover, compared to the conventional fabrication method, number of parts and joints decreases, along with their weight and cost, and intricate geometry can be fabricated.

As grains in the polycrystalline matrix grow easily at an elevated temperature, therefore it is difficult to achieve smaller grain size at homologous temperature. Furthermore, the physics underlying this process is extremely complicated [7,8]. These restrictions resulted in increased attention in the research and the development of severe plastic deformation (SPD). Over the last two decades, alternative approaches are available for grain refinement through the application of SPD techniques [8,9]. SPD is an innovative and effective metal forming process where ultra-high plastic strain is introduced on a bulk metal in order to make ultra-fine grained metals [10,11,12,13]. SPD causes the formation of grain size in submicrometer to nanometer range, which results in the enhanced mechanical performance of the metals [11,12]. SPD techniques such as equal channel angular pressing (ECAP) [14,15,16,17,18,19,20], friction stir process (FSP) [21,22], high-pressure torsion (HPT) [23,24,25], accumulative roll bonding (ARB), and cryorolling, as well as asymmetric rolling are used for producing ultrafine grained materials.

Aluminum alloys can be used in aero engines to manufacture compressor casing, cone, and inlet ring while aluminum composites are used in fan blades, fan casing, and cowls [26]. Superplasticity of aluminum alloys reduces manufacturing cost and has the ability to form parts of intricate geometry which would be difficult or even impossible to fabricate by other means. Xing et al. [27] pointed out that aluminum alloys can be used in the fabrication of complex shapes and curved parts for a wide range of uses in aerospace and automotive sectors, architectural design and small scale structural elements, where high stiffness and low weight are necessitated. Furthermore, superplasticity of aluminum alloys can be used for facade elements, automobile parts, uncritical parts, and mass-produced sheets [28].

With the development of several SPD techniques, exceptional grain refinement has led to enhanced superplastic property at low temperatures and high strain rates, which is impossible to attain using conventional processing techniques. Recently, Avtokratova et al. [29] achieved an exceptional superplastic elongation of 4100% at high strain rate in an Al-Mg-Sc-Zr alloy after processing by ECAP. Moreover, the recent development of nanoidentation technique, which requires limited sample volume is effective to measure the mechanical property [30]. In addition, quick superplastic forming technology, which was developed recently, improves the low production efficiency of traditional superplasticity by combining traditional superplastic forming and hot drawing technology. It not only reduces the production cycle but also decreases the manufacturing cost [31]. Likewise, García-Infanta et al. [32] used a small punch testing device, which requires a small amount of sample, to analyze the superplastic behavior of HPT processed Al alloy.

The purpose of this review is to introduce the recent developments in Al alloys superplasticity, their mechanisms and the factors influencing the superplastic characteristics.

2. Influencing Factors on Al Alloys Superplasticity

Studies on superplasticity of metals have a long history since Pearson [33] reported a noteworthy tensile elongation of 1950% in Pb-Sn eutectic alloy. Since then, multitudinous research has been reported in superplasticity of metals like aluminum, magnesium, iron, titanium and nickel-based alloys [34]. Generally, superplasticity can be experienced both at a lower and higher temperature. Presnyakov [35] achieved a maximum elongation of 650% in Al-Zn (eutectoid composition) at 250 °C. Lee [36] achieved maximum elongation to failure 2100% in the Mg-Al eutectic alloy at 400 °C. Ishikawa et al. [37] observed a maximum tensile strain of 2900% in Zn-22% Al eutectoid at a testing temperature of 200 °C and grain size of 2.5 μm, which was the highest strain reported in a superplastic material at that time. Likewise, single phase AA2004 aluminum alloy exhibited excellent superplastic behavior. Subsequently, reports on the superplasticity of alloys stronger than AA2004, particularly, high strength aerospace alloys of the 7000 series were published. The high cost of fuel in the late 1970s and enhanced mechanical properties of these alloys appropriate to aerospace applications attracted much more attention in the aluminum alloys superplasticity. As a result, superplastic research on aluminum alloys like AA7075 and AA7475 was undertaken in many laboratories around the world. Researchers were investigating the alloy composition that can replace the airframe alloys and have low density and high stiffness than existing airframe alloys. Excellent superplastic properties of these aluminum alloys not only attracted the researchers but also encouraged companies like TI Group, Rockwell Company to manufacture and sell engineering components from aluminum sheet [38]. As a result, Horiuchi et al. [39] reported a tensile elongation of more than 600% in Al-Cu-Mg alloy and Wadsworth et al. [40] achieved the best elongation to failure of 1035% in Al-3Li-0.5Zr at 370 °C. Highashi et al. [41] experienced exceptional superplastic elongation of 5500% in aluminum bronze at 800 °C and 6.3 × 10−3 s−1 strain rate. Exceptional grain refinement by SPD process was initiated 30 years ago. Valiev et al. [9] utilized high-pressure torsion HPT to process Al-Cu-Zr alloy and obtained elongation of 250% at a low temperature of 220 °C while Wang et al. [42] took advantage of ECAP to process Al-3Mg alloy and achieved the grain size of 0.2 µm. In addition to these two SPD processes, several other processes have been developed since then but the two procedures receiving most interest are ECAP and HPT [34]. Table 1 lists some experiments on the superplasticity of Al alloys performed by different researchers over the past 20 years. It can be inferred from the Table 1 that generally superplastic elongation increases with decrease in grain size.

Table 1.

Development of superplasticity in Al alloys in recent years.

2.1. Effect of Initial Grain Size on the Superplasticity of Al Alloys

In order to achieve the better mechanical properties of the superplastic alloy, the alloys should possess fine grain size and it should remain stable during deformation [50]. A fine-grained microstructure has a greater number of grains and grain boundaries than that of a coarse grain counterpart and is typically less than 10 µm. However, finer microstructure requires high severity processing than coarser ones during SPD, and consequently more energy is stored in the material. This stored energy gives rise to high nucleation density followed by rapid grain growth at elevated temperatures. Therefore, stored energy during SPD process is the driving force for abnormal grain growth at high temperatures. This lowers the maximum temperature where grain boundary sliding (GBS) can operate homogeneously in finer microstructure than for coarser microstructure [51,52]. It is well accepted that grain boundary migration due to extensive GBS results in strain induced grain growth in fine grained polycrystalline materials. Moreover, elevated test temperature and low strain rate can enhance grain growth during superplastic deformation process [53]. In addition, grain growth at high temperature results in strain hardening to stabilize neck free plasticity, determines the limit of ductility and increases the flow stress. It is generally believed that the possible microscopic grain growth mechanism is either grain boundary migration accelerated by superplasticity and/or rotation and coalescence of grains. Masuda et al. [54] proposed that a pair of neighboring grains should slide, rotate, and coalesce with each other in order to align in the tensile axis. Furthermore, change in the shape of grain and dynamic grain growth can also occur to avoid the formation of cavities during superplastic deformation [55].

In order to realize better superplastic property, grain shape should be equiaxed because the grain sliding mechanism cannot operate smoothly in a matrix with an elongated grain structure. Grain refinement not only increases the range of strain rate but also decreases the temperature for GBS mechanism [56]. Likewise, to achieve better superplasticity, grain boundaries should be of high angle character, because low angle boundaries are not able to slide. However, in some cases low angled grain boundaries can be changed to high by either by a static discontinuous recrystallization process prior to severe plastic deformation or through a continuous recrystallization process in the early stages of superplastic deformation [57,58,59]. With reduction in grain size, strain rate sensitivity increases, and optimum superplastic elongation can be realized at comparatively lower strain rate and/or temperature. Further, it is well known that deformation occurs mainly at boundaries and decreasing the grain size will increase the grain boundaries, which leads to higher elongation. Nevertheless, at relatively larger grain size, transition to GBS and dislocation creep does not occur at high strain rate, as a result superplastic property cannot be realized [60]. Further information on a range of aspects of grain size and grain growth may also be found in grimes et al. [38], Masuda et al. [54], Li et al. [61], and Tan et al. [60].

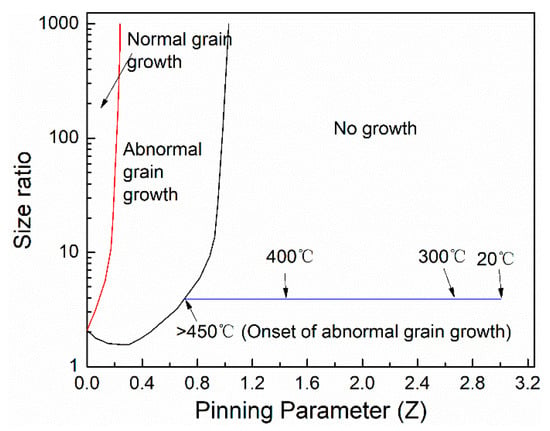

An equally significant aspect of superplastic deformation process is abnormal grain growth. Grain growth during superplastic deformation process is generally ascribed to grain boundary sliding or dislocation creep or diffusion creep. Since grain boundary migration, diffusion creep, and dislocation creep are temperature dependent, grain grows with an increase in temperature. Grain growth at high temperature results in strain hardening, consequently increasing the flow stress [55]. However, abnormal grain growth is a process through which few energetic grains grow at the expense of the finer matrix grains. In general, abnormal grain growth is more likely to occur when the usual grain growth of the matrix grain stagnates, when the second phase particles are unstable and when there is strong texture [62,63]. Charit et al. [64] claimed that the reduction of pinning force due to dissolution of particles and anisotropy in grain boundary energy and mobility promotes abnormal grain growth. Abnormal grain growth becomes a possibility when the pinning parameter, Z, lies within the range 0.25 < Z < 1 (Z = 3 FvR/d, where Fv is the volume fraction of particles, R is the average grain radius, and d is the average particle diameter). Charit et al. [65] found that FSP 7475Al did not display superplastic elongation due to abnormal grain growth. Figure 1 elucidates the relation between pinning parameter Z and grain size ratio of FSP7475Al alloy. It can be inferred from the Figure 1 that Z value decreases continuously with an increase in temperature up to 450 °C, owing to the coarsening and dissolution of MgZn2 precipitates. The authors suggested that abnormal grain growth must be restricted to enhance superplastic elongation. Moreover, inhomogeneous pattern during FSP also promotes the abnormal grain growth during superplastic deformation process. Second phase particles are effective in inhibiting the abnormal grain growth, which is described in detail in Section 2.6.

Figure 1.

A microstructural stability map demonstrating the transition of microstructure from no growth to abnormal grain growth, reproduced from [65], with permission from Elsevier, 2002.

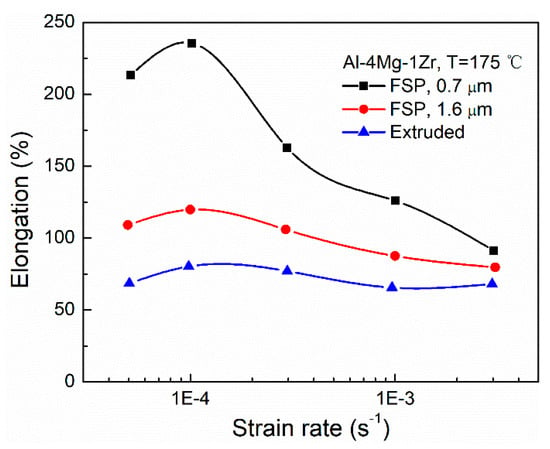

Mahidhara [66] compared the ductility of 7475 aluminum alloy with grain sizes ranging between 9 and 35 µm at 457 °C and 517 °C at the same strain rate of 10−4 s−1. They found that at temperature 517 °C, ductility decreases with increase in grain size until grain size reached 20 µm, beyond this, there was no appreciable drop in ductility whereas at temperature 457 °C, initially ductility increases with an increase in grain size until grain size reached 14 µm; beyond this ductility decreased with increase in grain size. This anomalous behavior of alloy at 457 °C is due to a high nucleation rate of cavities. In another experiment, Ma et al. [67] looked into the effect of grain size on Al-4Mg-1Zr alloy at 175 °C and 0.7–1.6 µm. The results suggested that a decrease in grain sizes improves the ductility of the alloy as displayed in Figure 2. Similarly, Caballero et al. [68] analyzed Al-Zn-Mg-Cu alloy at two different cooling rates and grain sizes (0.5 µm and 0.2 µm). At the temperature 400 °C and strain rate 10−2 s−1, the uncooled material with a grain size of 0.5 µm reached maximum elongation to failure 511%, whereas the cooled material with the grain size of 0.3 µm reached same maximum elongation to failure at 350 °C. Increase in maximum elongation to failure at relatively small grain size confirms the dependence of elongation on the grain size of the grain boundary sliding equation.

Figure 2.

Variation of elongation with strain rate and grain size, reproduced from [67], with permission from Elsevier, 2005.

2.2. Effect of Temperature on the Superplasticity of Al Alloys

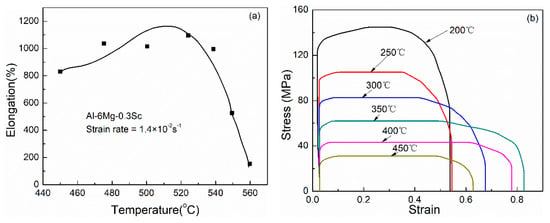

Superplastic deformation temperature plays a vital role in enhancing the mechanical property of superplastic alloy. Research suggests that superplastic deformation temperature should be more than the homologous temperature to achieve better mechanical properties [69,70]. With an increase in temperature, the viscous force within the grain boundary decreases gradually, which makes grain boundaries unstable. This causes GBS, which is the basic requirement for superplasticity. However, an excessive increase in temperature softens the grain boundary and grain boundary binding force, which declines the elongation [71]. Alhamidi et at. [72] studied the superplastic behavior of AA2024 alloy at 400 °C and concluded that elongation to failure increases with an increase in temperature till it reaches its peak, after which an increase in temperature decreases the elongation to failure. They claimed that the former increase in elongation with temperature is due to GBS but at a temperature higher than 400 °C, the contribution of GBS to total strain decreases because of grain growth and a decrease in grain boundary fraction. Figure 3 further supports the interrelation between maximum elongation to failure and temperature at a specific strain rate. Dramatic reduction in elongation to failure in Figure 3a is due to the presence of excessive liquid phase at grain boundaries, which causes grain boundary separation under tension. In another experiment conducted by Li et al. [73], the authors examined the superplastic behavior of Al-4.5Mg at 450–570 °C and strain rates from 10−6–10−2 s−1. Through their observations, it was concluded that elongation increases with temperature. However, the maximum elongation achieved was only 282% due to cavitation. Furthermore, Caballero et al. [51] found that flow stress decreases with increase in temperature in Al7075 alloy, which can be inferred from Figure 3b.

Figure 3.

(a) Relation between temperature and elongation to failure Al-6Mg-0.3Sc (Left) reproduced from [70], with permission from Elsevier, 1998; (b) True stress-true strain curves at different temperatures for the overaged 7075 alloy, reproduced from [51], with permission from Elsevier, 2017.

An equally significant aspect of aluminum superplasticity is low temperature superplasticity, which is normally less than 300 °C. Noda et al. [74] carried out a low-temperature experiment on Al-Mg alloy by multi-axial alternative forging, which resulted in a grain size of 0.8 µm. Through their observations, elongation of 340% was found at temperature 200 °C and 2.8 × 10−3 s−1 strain rate. It was inferred from the microstructure evaluation that intragranular deformation due to dislocation movement and GBS were the main deformation mechanism of superplastic deformation at 200 °C. Ota et al. [75] conducted a series of experiments employing ECAP process on three different Al-3%Mg alloys containing 0.2% Sc, 0.2% Fe, and 0.1% Zr separately at 250 and 300 °C. Al-3%Mg-0.2%Sc alloy yielded maximum elongation of 640% when tested at 250 °C and 3.3 × 10−4 s−1 while 1280% when tested at 300 °C and 1 × 10−2 s−1. Such a large elongation at 300 °C was possible due to the stable fine-grained structure at high temperatures.

2.3. Effect of Strain Rate on the Superplasticity of Al Alloys

Strain rate significantly influences the superplastic deformation behavior of Al alloys. Optimum superplastic behavior is generally observed at strain rates from 10−4 s−1 to 5 × 10−3 s−1, and tensile elongation tends to decrease at lower and higher strain rates [76]. Generally, GBS and dislocation creep contribute significantly to deformation at low strain rates, but these processes are too slow to contribute to total deformation at high strain rates. Consequently, at high strain rate deformation occurs mainly due to dislocation creep [60]. According to Equation (1), true stress is dependent on the strain rate, which infers that stain rate also plays a key role in the superplasticity of Al alloys.

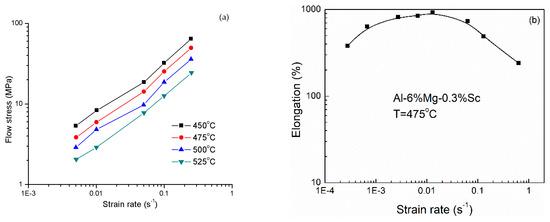

Where is true stress, is strain rate, m is strain rate sensitivity, and K is the material parameter. In Figure 4a, it is shown that the sigmoidal relation exists between flow stress and strain rate, i.e., maximum flow stress declines with decrease in strain rate [72,77,78]. Likewise, Ma et al. [79] concluded that Al-Mg-Zr alloy shows superplastic behavior even at a higher strain rate. It can be inferred from Figure 4b that elongation increases with an increase in strain rate and reaches a peak over an intermediate range of strain rate but decreases with further increase in strain rate [70]. Elongation is low at strain rates < 10−2 s−1 due to relatively longtime for dynamic recrystallization, which causes grain growth. Likewise, elongation decreases at strain rate > 10−2 s−1 because dynamic recrystallization does not occur due to short time of deformation that makes grain boundary difficult to slide. Moreover, Le et al. [80] compared the grain sizes after fracture at different strain rates and confirmed that grain size decreases with an increase in initial strain rate. To some extent microstructure after deformation can be determined by strain rates. Low strain rates could result into coarse microstructure while high strain rates lead to relatively fine microstructure, attributed to recovery and dynamic recrystallization process.

Figure 4.

(a) Flow stress as a function of strain rate, reproduced from [78], with permission from Elsevier, 2016; (b) Elongation as a function of strain rate reproduced from [70], with permission from Elsevier, 1998.

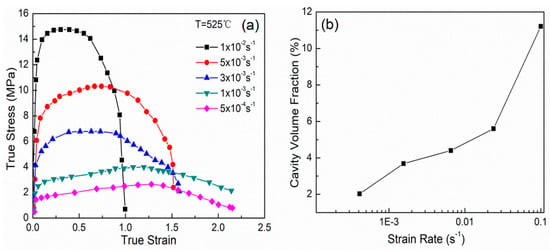

Generally, flow stress and rate of flow hardening increase with an increase in strain rate. A glance at Figure 5a reveals true stress rises steeply and then hold constant or decrease after attaining the peak value with increasing strain rate. In addition, the span length of strain during which nearly constant flow behavior appears increases with decreasing strain rate. Rapid increase in the stress at the beginning of the deformation is due to increase in deformation density. Nevertheless, constant or decrease in stress after attaining peak value is due to dynamic softening arising from a recrystallization process. Moreover, flow stress increases with increasing strain rate because of lack of time for diffusion and accommodation process [78,81]. Charit et al. [82] observed a monotonic increase in cavity volume fraction with an increase in strain rate as displayed in Figure 5b. At low strain rates, comparatively small stress is accumulated at the grain boundaries and also the stress has more time to relax, thereby decreasing the possibility of cavity nucleation.

Figure 5.

(a) Effect of strain rates on true strain-true stress curves, reproduced from [81], with permission from Elsevier, 2009. (b) Variation of cavity volume fraction with strain rate, reproduced from [82], with permission from Cambridge University Press, 2004.

Strain rate interval at which superplasticity normally occurs (<1 × 10−2 s−1) is often too slow from the viewpoint of industrial applications. Strain rate > 1 × 10−2 s−1 is suitable for industrial applications and would satisfy the current industrial manufacturing speed [83]. Mikhaylovskaya et al. [84] evaluated the impacts of high strain rate on two Al-Zn-Mg-Zr-Sc alloys distinguished by the presence and absence of Al9FeNi particles. Alloy with Al9FeNi particles displayed elongation to failure up to 915% while alloy without Al9FeNi particles exhibited maximum elongation of 310% at strain rates up to 1 × 10−2 s−1 and a temperature of 480 °C. The partially recrystallized structure was observed in alloy without Al9FeNi particles and superplastic indicators were significantly lower. Charit and Mishra [85] evaluated the effect of high strain rate on AA2024 alloy prepared by FSP. Superplastic experiments conducted at a strain rate of 10−2 s−1 and 430 °C and resulted in a maximum elongation of 525%. It is important to note that, even at a high strain rate of 10−1 s−1, the elongation to failure was >280%. Very fine grain size (3.9 µm) and high angle disorientation of grain boundaries were largely responsible for the enhanced superplastic response at high strain rate. Straumal et al. [86] claimed that prewetting or premelting of the grain boundary is responsible for high strain rate superplasticity in Al-Mg alloys.

It is, however, important to note that the highest strain rate to obtain superplasticity in Al alloys is roughly 1 s−1. Musin et al. [77] achieved an elongation to failure of about 500% at a strain rate of 1.2 s−1 in Al-Mg-Sc alloy. Such high elongation was attributed to the ultrafine grain structure (1 µm) produced by Equal Channel Angular Extrusion (ECAE) process and the presence of coherent Al3Sc dispersoids. Likewise, Ma et al. [79] attained a maximum elongation of~ 450% in FSP Al-1Mg-4Zr alloy ascribed to fine microstructure with a grain size of 1.5 µm and uniform distribution of fine Al3Zr dispersoids. It can be seen from the above analysis that high strain rate superplasticity (100–103 s−1) might be interesting and would satisfy the current industrial manufacturing speed.

2.4. Effect of Strain Rate Sensitivity on the Superplasticity of Al Alloys

Strain rate sensitivity (m) is an indicator of a material of its superplastic potential and its value is derived from applied stress and corresponding strain rate [87,88]. For a material to exhibit superplastic properties, strain rate sensitivity should be more than or equal to 0.3. The higher value of strain rate sensitivity indicates that the material is more stable against the local strain rate increase and thus exhibits higher superplastic elongation. Experimental studies have shown that the value of strain rate sensitivity depends on temperature, strain rate, and strain [77,89].

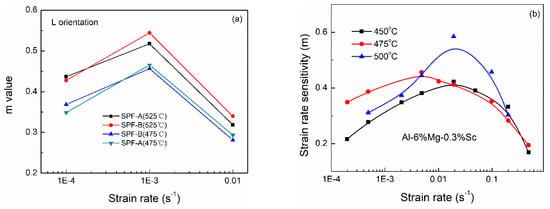

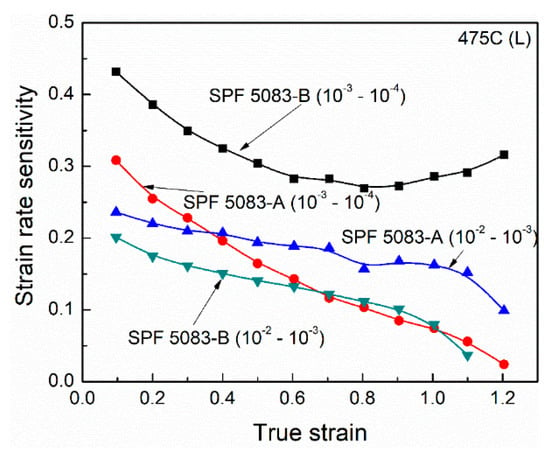

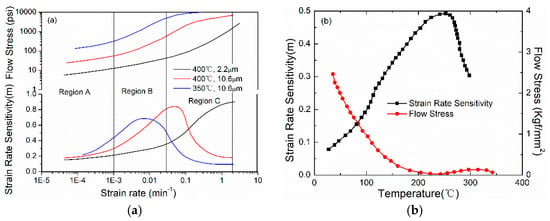

Arieli et al. [90] analyzed the relationship between strain rate sensitivity and strain rate and concluded that strain rate sensitivity decreases rapidly at low and high strain rates as the strain rate increases, whereas the rate of decrease is slower at intermediate strain rates. Similarly, Friedman et al. [91] evaluated the influence of strain rate sensitivity and strain rate on AA5083 alloy at 5% elongation and found that deformation at lower strain rate is controlled by diffusional accommodation at grain boundaries but the deformation at relatively higher strain rate is controlled by thermally assisted dislocation motion. However, at the intermediate strain rate, where the ‘m’ value peaks, it is presumed that both diffusional accommodation at grain boundaries and thermally assisted dislocation mechanisms are associated, as shown in Figure 6a. Likewise, 6b elucidate that strain rate sensitivity increases with an increase in temperature. Moreover, Figure 7 illustrates that strain rate sensitivity shows significantly higher value of m at the strain rates of 1 × 10−4 and 1 × 10−5 than at 1 × 10−3 and 1 × 10−2. With increasing the strain, strain rate sensitivity decreases due to grain growth as well as damage accumulation in the form of cavity nucleation.

Figure 6.

(a) Relation between strain rate sensitivity and strain rate for Superplastic Forming (SPF) 5083 alloys in longitudinal orientation, reproduced from [91], with permission from Springer Nature, 2004; (b) variation of strain rate sensitivity at different temperatures and strain rates for the Al-6Mg-0.3Sc alloy, reproduced from [70], with permission from Elsevier, 1998.

Figure 7.

Strain rate sensitivity as a function of true strain at 475 °C [91].

2.5. Effect of Microstructure Refinement Techniques on the Superplasticity of Al Alloys

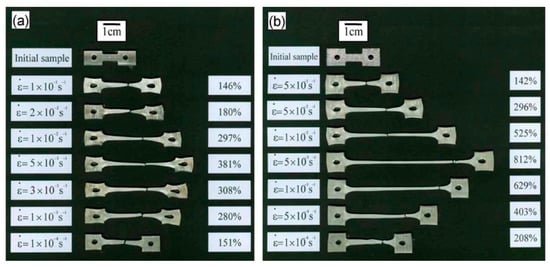

Superplastic deformation mechanism and mechanical properties differ with change in microstructure refinement techniques. Alloys with almost similar composition exhibit different mechanical properties because of different refinement techniques. Loucif et al. [92] prepared AA7075 alloy by HPT while Caballero et al. [51] prepared AA7075 alloy by FSP and they performed superplastic deformation test in the temperature range from 200–450 °C and strain rate from 1 × 10−4–1 × 10−1 s−2. Loucif et al. attained maximum elongation up to 400% at 350 °C and 10−1 s−2 while Caballero et al. obtained a maximum elongation of 126% at the same temperature and strain rate. In another experiment, Chentouf et al. [93] analyzed the superplastic behavior of AA5083 by hot and cold preform, whose average grain size was determined to be 8.32 and 7.95 µm respectively. They concluded that the number of cavities in the hot preform case were less than in the cold preform case and hot preformed samples led to an increase in the nucleation of subsurface discontinuities. Nevertheless, the average cavity size of hot preformed sample was higher than cold preformed sample. Large cavity sizes are susceptible to the formation of large sized voids and cracking. Furthermore, Smolej et al. [47] compared superplastic behavior of Al-4.5Mg-0.35Sc-0.15Zr alloy by rolling and FSP and claimed that in the temperature range from 350–500 °C and strain rate from 1 × 10−2 s−1–1 s−1, the elongation of the FSP-processed alloy is 7, 2.5 times higher than those of the rolled alloy. Rolled samples underwent incipient hardening followed by softening at higher strains whereas FSP samples exhibited smooth and rising hardening during the initial superplastic flow. Superior elongation of FSP samples was possible because of stable microstructure at high temperature, which was ensured by the addition of Sc and Zr.

Wang et al. [94] claimed exceptionally high elongation of 3250% using Al-Zn-Mg-Cu alloy. The alloy was prepared by FSP, which resulted in an equiaxed grain size of 6.2 µm. The tensile test was done in the temperature range of 500–535 °C and at a strain rate of 10−2 s−1, which resulted in elongation of 3250% at 535 °C. Such high elongation was obtained due to the presence of a small amount of liquid phase at the grain boundaries, which helped remove the stress concentration and suppress the appearance of cavities during deformation. Further, relatively stable grain size at high temperature due to the pinning of a high-density Cr bearing dispersoids was responsible for high elongation. Park et al. [95] studied the superplasticity of a commercial Al-Mg alloy subjected to ECAP and ECAP + post rolling. The high strain rate superplastic elongation was remarkably enhanced during Post-ECAP rolling, as shown in Figure 8. ECAP + post rolled samples’ microstructure consisted of elongated band structure delineated by lamellar boundaries and deformation was dominated by GBS whereas ECAP sample was governed by dislocation viscous glide. Post rolling after ECAP enhanced elongation by increasing the portion of high angle boundaries which changed the deformation mechanism from dislocation viscous glide to GBS.

Figure 8.

(a) Equal channel angular pressing (ECAP)-processed sample, (b) ECAP + post rolled samples, reproduced from [95], with permission from Elsevier, 2005.

SPD techniques provide an opportunity to achieve remarkable grain refinement by imposing large strain without any significant change in the overall dimensions of the sample, which leads to the occurrence of superplasticity not only at low temperatures but also at high strain rates. SPD techniques have the capability of altering the grain orientation by transforming the low angle boundaries to a large proportion of high angle grain boundaries. Nevertheless, the mechanisms underlying different SPD processing techniques are different. The evolution of dislocation cell structures and its transformation into a new grain structure with a large proportion of high angle grain boundaries in the process of straining is also different for different SPD techniques [96]. ECAP technique increases the mechanical strength of the metallic material by pressing it through a die constrained within a channel bent through a sharp angle near the center of the die [97]. In FSP, the friction between the rotating pin and metal surface results in a stirred zone with fine grain size [98,99]. HPT involves the application of a very high hydrostatic pressure on the material, which plays a major role in grain refinement [100,101]. Moreover, special rolling techniques for grain refinement like ARB, cryorolling, asymmetric rolling are affected by the amount of thickness reduction in each pass and the level of rolling friction [102]. ARB comprises deformation and bonding process, which on repetition can produce SPD of bulky materials [103,104]. Asymmetric rolling encompasses compressive and shear strain to maintain a high degree of friction between the sheet and the rolls. It not only decreases the rolling force and rolling torque but also improves the formability of the material [105,106,107]. Furthermore, cryorolling produces ultrafine grain microstructure in the light metals and alloys that require a comparatively lower load to induce severe strain for producing the sub-microcrystalline structure [108,109,110].

2.6. Effect of Addition of Trace Elements in Alloys on the Superplasticity of Al Alloys

In general, single phase materials do not exhibit superplastic behavior because grain grows rapidly at high temperatures. However, the addition of trace elements like Sc, Zr, Mg, Li, Cu [81] form nanoscale coherent Al3Zr, Al3Sc, Al3ScxZr1-x precipitates at grain boundaries and within the grain interiors to resist grain growth during recrystallization at elevated temperature. Thermally stable second phase particles stabilize grain boundaries, subgrain boundaries, and dislocation by the Zener pinning effect [111,112]. Trace elements have strong interactions with dislocations and have ability to increase the dislocation production rate during deformation, which leads to higher strain hardening and subsequently to an increased ductility. Trace elements not only interact with all types of structural defects like void formation, stacking faults, dislocations but also modify the collective behavior of these defects [113]. The addition of trace elements not only influences the process of lattice dislocation incorporation into the grain boundary but also can change rate of boundary sliding through grain boundary segregation [114]. To achieve better superplasticity, size of the second phase should be fine (<1 µm) and its distribution should be uniform. Furthermore, the second phase must be able to deform with the matrix in order to avoid stress concentration and early fracture [57]. In addition, segregation of impurity atoms at grain boundaries not only contribute to grain boundary sliding but also influence the cavitation by decreasing the surface and grain boundary energy, further details can be found in [115]. Al alloys can provide good high-temperature properties using coherent intermetallic precipitates for strengthening.

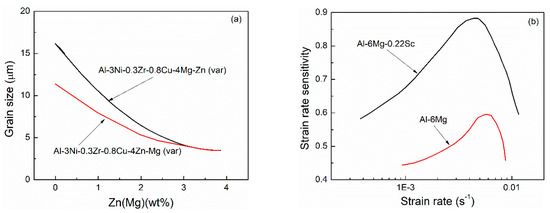

The addition of Mg in Al as an alloying element helps to improve the mechanical properties like work hardening characteristics of Al. In an experiment conducted by Kishchik et al. [116], mechanical behavior of Al-Mg-Mn-Cr was analyzed by varying the Mg content and stipulated that grain size decreases with an increase in Mg content from 3 to 6.8%, beyond this, grain size increases due to formation conglomerates of chromium-manganese particles. Decrease in grain size was attributed to increase in the amount of magnesium oxide entering the melt upon fusion, which serves as a substrate for the nucleation of new grains upon recrystallization. Likewise, Kotov et al. [117] carried out an experiment on Al-Zn-Mg-Cu-Ni-Zr alloy and the experimental result suggested that with an increase in the amount of Zn and Mg from 0–4%, grain size as well as yield stress decreases as shown in Figure 9a while elongation to failure increases. The addition of Zn and Mg not only reduces the average size of recrystallized grains but also prevented the reconfiguration of the dislocation structure by the formation of Al3Zr dispersed particles.

Figure 9.

(a) Effect of concentration of Mg and Zn in alloys, (b) effect of addition of Sc in Al-Mg alloy [117,118].

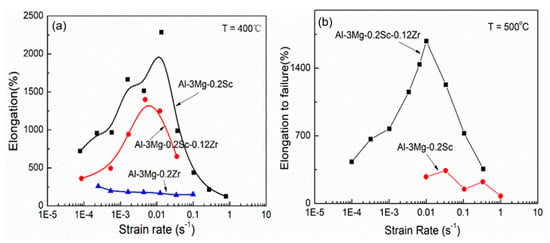

Peng et al. [119] compared the superplastic deformation behavior of two aluminum Al-Mg-Mn alloys with Sc and Zr addition and it was concluded that alloy with Sc and Zr exhibits lower flow stress, higher m value, refined grain structure, high elongation and restrict grain growth. Addition of Sc and Zr in Al-Mg alloys form Al3Si and Al3(Sc1−xZrx), which not only refines the grain structure but also pin the sub-grain boundaries and dislocations, restricts grain growth and stabilize deformation structure at high temperature, that causes the excellent superplasticity as demonstrated in Figure 9b [118]. Lee et al. [112] performed experiment on three different Al-3%Mg alloys, which contained 0.2% Sc or 0.2% Zr or 0.2% Sc + 0.12% Zr. ECAP method was applied for grain refinement and the final grain size was in the range of 0.2–0.3 µm for all three alloys. They concluded that Al-Mg–Zr alloy did not exhibit superplastic ductility because its grain was not stable at high temperatures due to the non-uniform distribution of Al3Zr, which is essential for superplastic flow. Al-Mg–Sc and Al-Mg–Sc–Zr alloys both exhibited better superplastic properties at 300 °C and 400 °C whereas at temperature 500 °C only Al-Mg–Sc–Zr alloy exhibited excellent superplasticity, as displayed in Figure 10. Al-Mg–Sc displayed better superplastic behavior at 300 °C and 400 °C due to Al3Sc precipitates which prevents grain growth but Al-Mg–Sc–Zr showed excellent superplasticity at 500 °C because Al3(ZrxSc1-x) precipitates appeared to be more stable than Al3Sc precipitates at 500 °C [120].

Figure 10.

Elongation to failure vs. strain rate reproduced from [112], with permission from Elsevier, 2002: (a) Elongation to failure versus initial strain rate for the alloys tested at 400 °C; (b) Elongation to failure versus initial strain rate for the Al-Mg-Sc-Zr and Al-Mg-Sc alloys tested at 500 °C.

The addition of Cu as an alloying element improves the heat treatability of alloy and at the same time decreases the eutectic temperature as well as melting point of the alloy. Furthermore, copper forms CuAl2 phase and many other intermetallic compounds, which improves the strength of the casting parts [121,122,123,124]. Hossain et at. [125] studied the effect of addition of Cu in Al-6Si-0.5 Mg alloy and authors reported an increase in tensile strength and decrease in ductility of the alloy. They further elaborated that an addition of 2% of Cu showed maximum strength. Increase in tensile strength is attributed to the precipitation of copper rich precipitates and decrease in ductility to the formation of void and its coalescence. Moreover, Watanabe et al. [126], in another test, put emphasis on finding superplastic behavior of Al alloys with the addition of Copper. Their work revealed that finely dispersed particles in copper containing alloy inhibit subgrain growth during continuous recrystallization, which in turn results in finely recrystallized grain structures. The addition of 0.6% of copper in Al-5% Mg resulted in an increase in the value of m, enhanced the corrosion resistivity and increased total elongation by about 500%.

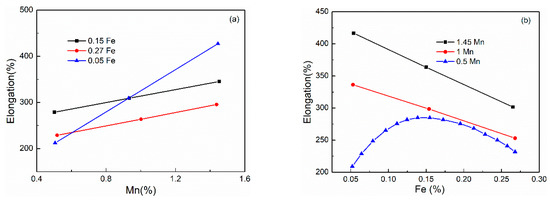

Irina and Haiou [127] evaluated the influence of Mn and Fe on Al-Mg-Mn-Fe alloy by changing the composition of Mn and Fe. The addition of Mn and Fe was in the range of 1.5% and 0.05% respectively for grain refinement. Figure 11a indicates that Mn content can be increased beyond 1.5% but it is difficult to prepare it by casting due to the risk of precipitation of primary intermetallic crystals whereas Figure 11b illustrates that formability reduces with an increase in Fe content. Highest elongation to failure of Al-4.5 Mg-1.5 Mn-0.05 Fe-<0.1 Si alloy was 400% at 475 °C and 10−3 s−1. During casting, coarse Al6Mn constituent particles were formed and fine dispersoids Al6Mn particles during homogenization and hot rolling, which in the presence of Fe formed Al6 (Fe, Mn). These fine Al6 (Fe, Mn) particles inhibited the grain growth at high temperature by zener pinning effect, which is essential and beneficial to superplasticity. Likewise, Henager et al. [114] performed an experiment on Al-Mg-Mn-Sc-Sn alloy and suggested that the addition of Sn reduces cavitation by allowing a redistribution of stress at critical hetero-junctions (sites at which cavities nucleate) in the alloys.

Figure 11.

Total elongation vs. (a) Mn and (b) Fe content [127].

3. Superplastic Deformation Mechanism of Al Alloys

Superplastic deformation can be defined by two S-shaped and peak shaped curves. S-shaped curve describes the relationship between logarithmic flow stress log(σ) and logarithmic strain rate , whereas the peak-shaped curve describes the relationship between strain rate sensitivity m and . Figure 12 shows the comparative effects of temperature, grain size, and strain rate.

Figure 12.

(a) Variation of strain rate, flow stress and strain rate sensitivity (m) at different temperatures and grain sizes, reproduced from [36], with permission from Elsevier, 1969; (b) relation between flow stress, strain rate sensitivity, and temperature, reproduced from [128], with permission from Elsevier, 1982.

Figure 12a demonstrates that with a decrease in grain size, the flow stress decreases, and strain rate sensitivity increases whereas experimental results of Figure 12b shows that the flow stress decreases with an increase in the temperature and the maximum value of strain rate sensitivity is obtained at a critical temperature (Tc). Lowest flow stress and the highest sensitivity at critical temperature make it the best working temperature [128].

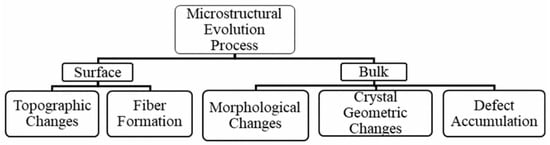

Superplastic performance, properties, and deformation mechanism are affected by the microstructural changes occurring during the superplastic forming as shown in Figure 13.

Figure 13.

Dependence of the microstructural evolution process on different factors.

The microstructural process at the surface depends on various factors, such as strain, strain rate, temperature, back pressure, and strain path. Morphological changes are determined by phase or grain growth, phase spatial distribution and phase shape changes. Crystal geometric changes depend on texture changes and grain boundary changes. Similarly, cavitation and dislocation structure are factors responsible for defect accumulation [129].

3.1. Superplastic Deformation Mechanisms

Plenty of research has been done to find dominant microstructural features and results of those research have indicated that GBS is the most important feature of aluminum alloys superplasticity [130,131]. However, dislocation motion, diffusion in grains, and near-grain boundary region are also major features of superplasticity. The theoretical models for GBS are divided into two categories, namely intrinsic GBS and extrinsic GBS. Grain boundaries slide freely in intrinsic GBS and are not hindered by any external factors such as the triple grain junctions, grain boundary ledges, and the second phase at grain boundaries. Generally, GBS in bicrystal is intrinsic GBS. Likewise, in extrinsic GBS, the sliding at grain boundaries is hindered by triple grain junctions and other structural factors [132]. GBS must be accommodated to prevent the formation of a void in the microstructure. Accommodation mechanisms can be divided into three groups as (i) diffusion accommodation, (ii) accommodation by dislocation motion, and (iii) combination of dislocation and diffusional accommodation [76].

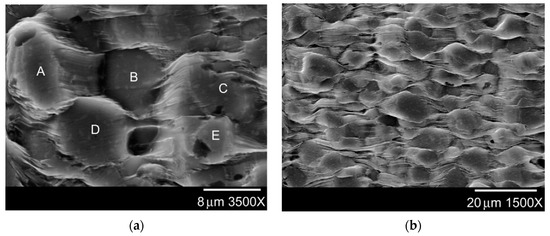

When tensile stress is applied to polycrystalline metal, it may deform either by dislocation processes occurring within the grains or by the stress flow of vacancies, which is known as diffusion creep. Langdon [133] presented an extrinsic sliding model and claimed that dislocation is moved by a combination of glide and climb along the GB leading to sliding of the grains along the boundary. It was also concluded in [133] that climb velocity is slower than that of glide and it controls the GBS rate. Lin and McLean [134] presented evidence which suggested that dislocation primarily originates within the grains and enters the boundary region by slip. Furthermore, Crossman and Ashby [135] assumed that the grain creep obeys the power-law creep and grain boundaries slide in a Newtonian viscous way. Through their calculations, it was displayed that at high stress or strain-rate, grain deforms rapidly and the contribution of GBS is a negligible fraction to the total deformation. However, GBS contribution increases with decrease in stress and the deformation become non-uniform. SEM micrographs of the FSP 7075Al alloy deformed at 490 °C and 3 × 10−3 s−1 strain rate, resulted in elongation of 200% and 400% as shown in Figure 14a,b, respectively. It can be seen in Figure 14a that surface grains A, B, C, D, and E move apart due to GBS. With further increase in strain to an elongation of 400%, the GBS became more distinct and the grains were elongated along the tensile direction [136].

Figure 14.

SEM micrographs showing surface morphologies of FSP 7075Al superplastically deformed to (a) an elongation of 200% and (b) an elongation of 400% [136].

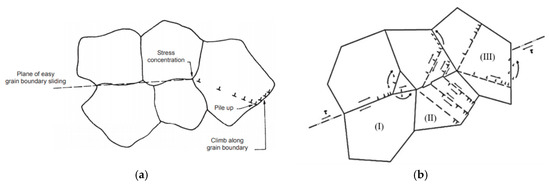

Ball and Hutchison [137] proposed the first model to explain GBS accommodated by dislocation movement. Ball and Hutchison proposed that during superplastic deformation a group of grains, whose boundaries are suitably aligned tends to slide as a unit until unfavorably oriented grains obstruct the process. As shown in Figure 15a, dislocation pile up at grain boundaries and continuation of sliding requires climb by the leading dislocation toward annihilation sites. Soon after the Ball and Hutchison model, Mukherjee [138] put forward a modification of Ball and Hutchison model that explained the fact that grains slide individually rather than in group and grain boundary ledges can act as dislocation sources. In Mukherjee’s model, adjacent grains need not have to slide as groups and the distance climbed by dislocation at the grain boundary for the purpose of annihilation is likely to be of the order of the grain diameter. Later Gifkins [139] presented a slightly different model known as the core and mantle model to explain the mechanism of GBS. In core and mantle model, grain was considered as the core and the regions adjacent to the grain boundary as the mantle. Gifkins considered the fact that sliding takes place by the motion of grain boundary dislocations which pile up at the triple point. Shear stress on the whole group concentrates on any grain that obstructs the movement of the group and is relaxed by dislocation motion in the blocking grains as illustrated in Figure 16a. A model was presented in which grain boundary sliding is accommodated by the deformation fold. Figure 15b illustrates the dislocation mechanisms involved in the relaxation of stress concentrations resulting from grain boundary sliding proposed by Ball and Hutchison, Mukherjee and Gifkins.

Figure 15.

(a) Illustration of the Ball–Hutchison model of grain boundary sliding (GBS) accommodated by dislocation movement, [140]. (b) Slip accommodation of GBS proposed by (I) Gifkins, (II) Mukherjee, and (III) Ball and Hutchinson [76].

Figure 16.

(a) GBS and its accommodation proposed by Gifkins [139]. (b) A unified model for Rachinger GBS originated by Langdon [141].

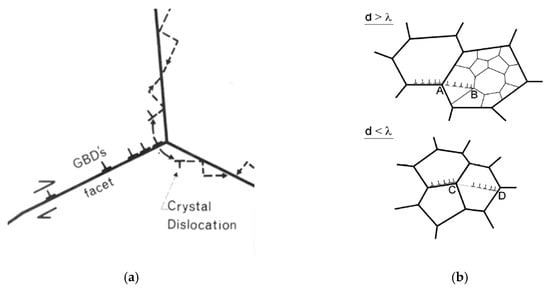

Polycrystalline material under the action of external stress may also deform by the flow of vacancies known as diffusion creep. Lifshitz [142] proposed a theory, which is also known as Lifshitz sliding, that individual grains become elongated and grains are moved with respect to each other so that sharp offsets become visible. However, Rachinger [143] claimed that grains retain essentially their original shape and are displaced with respect to each other to contribute increase in their number along the tensile axis. Langdon developed a unified model for Rachinger sliding at all grain sizes by employing a single model for both the large and small grain size ranges as demonstrated in Figure 16b [141]. The difference between Lifshitz GBS and Rachinger GBS is that Lifshitz sliding is itself an accommodation process for conventional diffusion creep whereas Rachinger sliding requires accommodation by intragranular slip.

Figure 16b shows the process of GBS, where d and λ are grain size and subgrain size, respectively. Coarse grain samples at high temperatures get divided into arrays of subgrain having an average size of λ. When λ > d, grains move and rotate in response to external forces and the stress concentration is at triple point C due to GBS. This stress concentration is accommodated by intragranular slip in the adjacent grain but in the absence of any subgrain, dislocation moves to grain boundary at D. When λ < d, grain exhibits small displacement with respect to the adjacent grain and sliding makes a minor contribution to the total elongation [30,141]. GBS is controlled and accompanied by dislocation motion with the grains [36,139]. Furthermore, creep behavior of Al-Mg solid solution comprises of glide on slip planes and climb over physical obstacles. This process is a sequential process and its overall creep rate is determined by the slower process for sequential glide and climb as expressed in Equation (2):

where, , , and represent overall creep rate, climb controlled creep rate, and glide controlled creep rate respectively [144]. Ashby and Verrall [145] proposed a model to describe the process of superplasticity as a transition between the diffusion-accommodated flow at low strain rates, and dislocation creep at high strain rates. This model gave vivid description on experimentally observed switching of equiaxed grains throughout deformation. Ashby and Verrall claimed that grains switch their neighbors and do not change their shape much during diffusion accommodated flow. The equation below is a general constitutive law for lattice-diffusion controlled dislocation creep in polycrystalline metals of high stacking fault energy metals.

where is total deformation rate, is dislocation creep strain rate and is strain rate due to grain boundary sliding. Substituting the value of and , Equation (3) can be written in the form

where is lattice diffusivity, b is the Burger’s vector, is the mean linear intercept grain size, and E is the modulus of elasticity [146]. In Equation (4), the first term on the right side is independent of grain size whereas the second term is dependent on grain size. The decrease in the value of L increases the second term on the right side, which in turn increases total deformation. Thus, grain size refinement improves superplastic mechanisms.

Equation (5) is the phenomenological equation for high temperature creep where A is a constant that depends on the material and the dominant deformation mechanism, D is a diffusion coefficient (=, where Do is a frequency factor, Qs is the activation energy for the appropriate diffusion process), G is shear modulus, b is the magnitude of the Burgers vector, d is the grain size, p is the grain-size exponent, R is the universal gas constant, n is stress exponent (=1/m, where m is strain rate sensitivity), and is strain rate. In order to establish a constitutive relationship for a material, it is essential to compute the value of the material parameters like p, n, and Qs, which can help to identify the rate controlling mechanism. The grain size exponent, n, is in the range of 2–3 under GBS creep, 0–1 under power law creep, and 0 under solute drag creep. Likewise, stress exponent, n, is around 2 under GBS creep, close to 5 under power law creep, and solute drag creep has an average n value of about 3 [76,147,148]. Moreover, the superplastic deformation mechanism can also be predicted by calculating the activation energy (Q). Q value of 84 kJ/mol indicates GBS, 123–135 kJ/mol denotes solute drag mechanism and 142 kJ/mol represents lattice diffusion [149]. McNelley et al. [56] reported that the Solute Drag Creep mechanism is dominant at higher strain rate (~10−1 s−1) whereas governing deformation mechanism at lower strain rate (~10−1 s−1) is GBS. Further information on a range of aspects of superplastic deformation mechanism may also be found in Grimes et al. [38], Stevens et al. [150], Prabu et al. [151], Mukherjee et al. [152], and Sergueeva et al. [153].

3.2. Constitutive Equations of Superplasticity

Constitutive equations play a vital role in predicting and analyzing the superplastic behavior as well as reflect the dynamic response to the thermal parameters in the superplastic processing. Moreover, constitutive equations are essential for commercial applications and can be used for the process as well as product design through superplastic forming processes [28,154]. Different constitutive equations are proposed corresponding to different situations, some of the typical forms are reviewed and listed in Table 2. The superplastic constitutive equation, which is shown in Equation (6) is affected by strain hardening exponent [155]. Constitutive equation is analyzed at a relatively lower temperature by Rossard [156] (Equation (7)) and at high temperature by Backofen et al. [157] (Equation (8)). The constitutive equation at lower temperature indicates that the process combines strain hardening with strain rate hardening whereas equation at higher temperature indicates that the process is mainly influenced by strain rate sensitivity exponent m.

where σ is the true stress, is the true strain, the strain rate, n is the strain-hardening exponent, and K is a parameter for the material. The value of m decreases with an increase in grain size, which in turn decreases the superplastic behavior whereas decreasing the grain size increases the ‘m’ value and also moves to higher strain rate [158]. Larger the strain rate sensitivity, greater the superplastic elongation will be [156] and its value more than 0.3 is considered to be superplastic [159]. Likewise, small grain size and particle size helps to minimize the cavitation [160]. Ma et al. [161] performed an experiment on Al 7075 alloy to investigate the relationship between grain size and cavitation. Through their observation, it was concluded that a decrease in grain size results in a decrement of size, density and volume fraction of cavities. However, density, size and volume fraction of cavities increased with an increase in initial strain rates from 1 × 10−2 to 1 × 10−1 s−1 but cavity density was decreased with an increase in temperature from 450 to 510 °C. Nieh et al. found that presence of a small amount of liquid phase at grain boundary at higher temperature reduces the cavitation by assisting GBS accommodation and thus delays the appearance of internal cavitation [94,162].

Table 2.

Superplastic Constitutive Equations.

In Table 2, values of m and n in [157] and [163] are regarded as constant but they should vary with the microstructural change, so they cannot precisely represent the superplastic behavior. Song et al. [164] proposed an equation with varying m and n based on Backofen equation for superplastic flow. Churyumov et al. [165] further modified the Backofen equation and included the factor that characterizes the influence of particles of excessive phase on yield stress. Similarly, Mabuchi and Higashi [166] developed an equation to represent the superplastic behavior of aluminum matrix composite with Si3N4 whiskers and concluded that stress-strain relation for the composites and alloy without crackers was almost the same. Likewise, the bottom two equations [167,168] explain the superplastic behavior of the respective alloy at different conditions.

4. Summary and Prospect

Al alloys superplasticity not only reduces manufacturing cost but also has an ability to form parts of intricate geometry which would be difficult to fabricate by other means. The processing of Al alloys through the application of SPD leads to exceptional grain refinement and provides new opportunities for achieving excellent superplastic properties. Of late, several SPD techniques have been developed, however, it has been found that two procedures have received the maximum interest, i.e., ECAP and HPT. Considering the superplastic behavior of Al alloys, some investigations were performed to analyze the factors that influence the superplasticity of Al alloys. The results showed that alloys with almost similar composition exhibit different mechanical properties due to different refinement techniques. Besides, it was also observed that lower the size of the grain, higher is the elongation. Furthermore, elongation to failure is higher if the temperature is more than the homologous temperature and the strain rate is in the range of 1 × 10−5 s−1–1 × 10−1 s−1. Elongation increases with increase in temperature and strain rate, reaches a peak over an intermediate range but decreases with further increase in temperature and strain rate. Fine, equiaxed, and high angle grain structures that remains stable during deformation enhances the superplastic property. Moreover, to achieve better superplasticity, the size of the second phase particles should be fine and their distribution should be uniform. Generally, the superplastic deformation mechanism in Al alloy is operated by GBS, where a group of grains whose boundaries are suitably aligned tends to slide as a unit. Moreover, the dominant deformation mechanism can be predicted by constitutive equations.

In addition to basic research, if adequate research is carried out in the domain of advancement of computer modeling and simulation, it would lead to an intelligent adaptive tool to analyze the deformation process in detail. With further research on high strain rate, superplasticity will significantly contribute to industrial applications in the future. Rapid progress in the superplastic field can be achieved by suitable blending of material research and mechanical engineering. Further, there is a need to develop low-temperature and high strain rate superplastic deformation techniques and materials. Cryogenic deformation technique can also be used to produce ultrafine-grained materials, whose superplastic deformation capability should be studied.

Author Contributions

Conceptualization, H.Y.; formal analysis, L.B.; investigation, L.B.; writing—original draft preparation, L.B., H.Y.; writing—review and editing, A.P., A.P.Z., P.T., C.K., H.Y.; supervision, H.Y.; project administration, H.Y.; funding acquisition, A.P., A.P.Z., P.T. and H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (Grant number: 51674303), National Youth Thousand Plan Program of China, Huxiang High-Level Talent Gathering Project of HUNAN Province (Grant number: 2018RS3015), Innovation Driven Program of Central South University (Grant number: 2019CX006), the Research Fund of the Key Laboratory of High Performance Complex Manufacturing at Central South University, the Ministry of Science and Higher Education of Russia Federation for financial support (Grant number: 14.Z50.31.0043), and the Department of Science & Technology, Ministry of Science and Technology, Government of India (Grant number: INT/RUS/RFBR/P-349).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Smolej, A.; Skaza, A.; Slacek, E. Superplasticity of the 5083 Aluminum alloy with the addition of Scandium. Mater. Technol. 2009, 14, 299–302. [Google Scholar]

- Edalati, K.; Masuda, T.; Arita, M.; Furui, M.; Sauvage, X.; Horita, Z.; Valiev, R.Z. Room-Temperature Superplasticity in an Ultrafine-Grained Magnesium Alloy. Sci. Rep. 2017, 7, 2662. [Google Scholar] [CrossRef] [PubMed]

- Kaibyshev, O.A. Superplasticity of Alloys, Intermetallides and Ceramics, 1st ed.; Springer: New York, NY, USA, 1992. [Google Scholar]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press: Cambridge, CA, USA, 1997. [Google Scholar]

- Smolej, A.; Skaza, B.; Markoli, B.; Klobčar, D.; Dragojević, V.; Slaček, E. Superplastic Behaviour of AA5083 Aluminium Alloy with Scandium and Zirconium. Mater. Sci. Forum 2012, 709, 395–401. [Google Scholar] [CrossRef]

- Li, Z.Q.; Zhu, H.L. Industrial applications of superplastic forming technology in China. Mater. Sci. Forum 2001, 357, 53–58. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Lorimer, G.W. Thermomechanical Processing of Aluminium Alloys. Adv. Light Alloy. Compos. 1998, 59, 343–353. [Google Scholar]

- Pereira, P.H.R.; Huang, Y.; Kawasaki, M.; Langdon, T.G. An examination of the superplastic characteristics of Al–Mg–Sc alloys after processing. J. Mater. Res. 2017, 32, 4541–4553. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Kuznetsov, R.I.; Kaibyshev, O.A.; Musalimov, R.S.; Tsenev, N.K. Low-temperature superplasticity of metallic materials. Sov. Phys. Dokl. 1988, 33, 626. [Google Scholar]

- Kapoor, R. Severe Plastic Deformation of Materials. In Materials under Extreme Conditions; Tyagi, A.K., Banerjee, S., Eds.; Elsevier: Mumbai, India, 2017; pp. 717–754. [Google Scholar]

- Zrnik, J.; Dobatkin, S.V.; Mamuzi, I. Processing of metals by severe plastic deformation (SPD)-Structure and mechanical properties respond. Metalurgija 2008, 47, 211–216. [Google Scholar]

- Kawasaki, M.; Langdon, T.G. Developing Superplasticity in Ultrafine-Grained Metals. Acta Phys. Pol. A 2015, 128, 470–478. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. Cirp Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Review Processing of metals by equal-channel angular pressing. J. Mater. Sci. 2001, 36, 2835–2843. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Baumgart, C. Influence of Mg content, grain size and strain rate on mechanical properties and DSA behavior of Al-Mg alloys processed by ECAP and annealing. Mater. Sci. Forum 2014, 794–796, 870–875. [Google Scholar] [CrossRef]

- Kapoor, R.; Chakravartty J, K. Deformation behavior of an ultrafine-grained Al–Mg alloy produced by equal-channel angular pressing. Acta Mater. 2007, 55, 5408–5418. [Google Scholar] [CrossRef]

- Huarte, B.; Luis, C.J.; Puertas, I.; Leon, J.; Luri, R. Optical and mechanical properties of an Al–Mg alloy processed by ECAE. J. Mater. Process. Technol. 2005, 162, 317–326. [Google Scholar] [CrossRef]

- Horita, Z.; Fujinami, T.; Nemoto, M.; Langdon, T.G. Equal-channel angular pressing of commercial aluminum alloys: Grain refinement, thermal stability and tensile properties. Metall. Mater. Trans. A 2000, 31, 691–701. [Google Scholar] [CrossRef]

- Chen, Y.C.; Huang, Y.Y.; Chang, C.P.; Kao, P.W. The effect of extrusion temperature on the development of deformation microstructures in 5052 aluminium alloy processed by equal channel angular extrusion. Acta Mater. 2003, 51, 2005–2015. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Butt Welding. U.S. Patent PCT/GB92/02203, October 1995. [Google Scholar]

- García-Bernal, M.A.; Mishra, R.S.; Verma, R.; Hernández-Silva, D. Influence of friction stir processing tool design on microstructure and superplastic behavior of Al-Mg alloys. Mater. Sci. Eng. A 2016, 670, 9–16. [Google Scholar] [CrossRef]

- Eskandarzade, M.; Masoumi, A.; Faraji, G.; Mohammadpour, M.; Yan, X.S. A new designed incremental high pressure torsion process for producing long nanostructured rod samples. J. Alloys Compd. 2017, 695, 1539–1546. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Kulagin, R.; Fedorov, V.; Mazilkin, A.; Scherer, T.; Baretzky, B.; Hahn, H. High Pressure Torsion Extrusion as a new severe plastic deformation process. Mater. Sci. Eng. A 2016, 664, 247–256. [Google Scholar] [CrossRef]

- Edalati, K.; Lee, S.; Horita, Z. Continuous high-pressure torsion using wires. J. Mater. Sci. 2012, 47, 473–478. [Google Scholar] [CrossRef]

- Serra, D. Superplastic Forming Applications on Aero Engines. A Review of ITP Manufacturing Process. In Proceedings of the 6th EUROSPF Conference, Carcassonne, France, 3–5 September 2008; pp. 1–10. [Google Scholar]

- Xing, H.L.; Wang, C.W.; Zhang, K.F.; Wang, Z.R. Recent development in the mechanics of superplasticity and its applications. J. Mater. Process. Technol. 2004, 151, 196–202. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, Y.; Zhou, Y.; Jin, Q. Superplastic forming of aluminum alloy car body panels. Mater. Sci. Forum 2005, 475, 3025–3028. [Google Scholar] [CrossRef]

- Avtokratova, E.; Sitdikov, O.; Markushev, M.; Mulyukov, R. Extraordinary high-strain rate superplasticity of severely deformed Al–Mg–Sc–Zr alloy. Mater. Sci. Eng. A 2012, 538, 386–390. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. Superplasticity in Ultrafine-Grained Materials. Rev. Adv. Mater. Sci. 2018, 54, 46–55. [Google Scholar] [CrossRef]

- Wang, G.; Jia, H.; Gu, Y.; Liu, Q. Research on Quick Superplastic Forming Technology of Industrial Aluminum Alloys for Rail Traffic. Defect Diffus. Forum 2018, 385, 468–473. [Google Scholar] [CrossRef]

- García-Infanta, J.M.; Zhilyaev, A.P.; Sharafutdinov, A.; Ruano, O.A.; Carreñoa, F. An evidence of high strain rate superplasticity at intermediate homologous temperatures in an Al–Zn–Mg–Cu alloy processed by high-pressure torsion. J. Alloys Compd. 2009, 473, 163–166. [Google Scholar] [CrossRef]

- Pearson, C.E. The viscous properties of extruded eutectic alloys of lead-tin and bismuth-tin. J. Inst. Met. 1934, 54, 111–123. [Google Scholar]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998–6010. [Google Scholar] [CrossRef]

- Underwood, E.E. A review of Superplasticity. J. Met. 1962, 14, 914–919. [Google Scholar]

- Lee, D. The Nature of Superplastic Deformation in the MgAl Eutectic. Acta Metall. 1969, 17, 1057–1069. [Google Scholar] [CrossRef]

- Ishikawa, H.; Mohamed, F.A.; Langdon, T.G. The influence of strain rate on ductility in the superplastic Zn–22% Al eutectoid. Philos. Mag. 1975, 32, 1269–1271. [Google Scholar] [CrossRef]

- Grimes, R. Superplastic forming of advanced Metallic Materials. Woodhead Publ. 2011, 2011, 247–271. [Google Scholar]

- Horiuchi, R.; El-Sebai, A.B.; Otsuka, M. Superplasticity in the Ternary Eutectic Alloys, Al-33%Cu-7%Mg and Al-25%Cu-11%Mg. Scr. Metall. 1973, 7, 1101–1104. [Google Scholar] [CrossRef]

- Wadsworth, J.; Palmer, I.G.; Crooks, D.D. Superplasticity in Al-Li Based Alloys. Scr. Metall. 1983, 17, 347–352. [Google Scholar] [CrossRef]

- Higashi, K.; Ohnishi, T.; Nakatani, Y. Superplastic Behavior of Commercial Aluminum Bronze. Scr. Metall. 1985, 19, 821–823. [Google Scholar] [CrossRef]

- Wang, J.; Horita, Z.; Furukawa, M.; Nemoto, M.; Tsenev, N.K.; Valiev, R.Z.; MA, Y.; Langdon, T.G. An investigation of ductility and microstructural evolution in an Al-3% Mg alloy with submicron grain size. J. Mater. Res. 1993, 8, 2810–2818. [Google Scholar] [CrossRef]

- Shagiev, M.; Motohashi, Y.; Musin, F.; Kaibyshev, R.; Itoh, G. Superplastic Behavior in Al–Li–Mg–Cu–Sc Alloy Sheet. Mater. Trans. 2003, 44, 1694–1697. [Google Scholar] [CrossRef][Green Version]

- Haoyan, D.; Rehan, Q.; Tingting, W.; Shasha, Z.; Chaoli, M. Superplastic Behavior of Coarse-Grained Al-Mg Alloy. Int. J. Mod. Phys. Conf. Ser. 2012, 6, 401–406. [Google Scholar]

- Prasad, V.J.; Mohanarao, N.; Kamaluddin, S.; Bhattacharya, S.S. Development of superplasticity in an Al–Mg alloy through severe plastic deformation. Int. J. Adv. Manuf. Technol. 2018, 94, 2973–2979. [Google Scholar] [CrossRef]

- Luo, T.; Nia, D.R.; Xue, P.; Li, Y.Z.; Xiao, B.L.; Ma, Z.Y.; Fu, M.J.; Li, X.H.; Zeng, Y.S. Low-temperature superplasticity of nugget zone of friction stir welded Al-Mg alloy joint. Mater. Sci. Eng. A 2018, 727, 177–183. [Google Scholar] [CrossRef]

- Smolej, A.; Klobčar, D.; Skaza, B.; Nagode, A.; Slaček, E.; Dragojević, V.; Smolej, S. Superplasticity of the rolled and friction stir processed Al–4.5 Mg–0.35Sc–0.15Zr alloy. Mater. Sci. Eng. A 2014, 590, 239–245. [Google Scholar] [CrossRef]

- Xu, C.; Furukawa, M.; Horita, Z.; Langdon, T.G. Developing High Strain Rate Superplasticity in Aluminum Alloys. Mater. Sci. Forum 2015, 475, 2949–2954. [Google Scholar]

- Moguchevaa, A.; Yuzbekovab, D.; Kaibyshev, R. Superplasticity in a 5024 aluminium alloy subjected to ECAP and subsequent cold rolling. Mater. Sci. Forum 2016, 838, 428–433. [Google Scholar] [CrossRef]

- Valle, J.A.D.; Ruano, O.A. Influence of grain size fluctuations on ductility of superplastic magnesium alloys processed by severe plastic deformation. Mater. Sci. Technol. 2008, 24, 1238–1244. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Álvarez, M.; Hidalgo-Manrique, P.; Cepeda-Jiménez, C.M.; Ruano, O.A.; Carreno, F. Grain size versus microstructural stability in the high strain rate superplastic response of a severely friction stir processed Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2017, 680, 329–337. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Mcqueen, H.J. Grain growth and stabilisation of nanostructured aluminium at high temperatures: Review. Mater. Sci. Technol. 2015, 31, 1016–1034. [Google Scholar] [CrossRef]

- Liew, K.M.; Tan, M.J.; Tan, H. Analysis of Grain Growth during Superplastic Deformation. Mech. Adv. Mater. Struct. 2007, 14, 541–547. [Google Scholar] [CrossRef]

- Masuda, H.; Kanazawa, T.; Tobe, H.; Sato, E. Dynamic anisotropic grain growth during superplasticity in Al–Mg–Mn alloy. Scr. Mater. 2018, 149, 84–87. [Google Scholar] [CrossRef]

- Ma, Z.; Mishra, R.S. (Eds.) High-Strain-Rate Superplasticity; Friction Stir Superplasticity for Unitized Structures: Oxford, UK, 2014; pp. 7–18. [Google Scholar]

- Mcnelley, T.R.; Oh-Ishi, K.; Zhilyaev, A.P.; Krajewski, P.E.; Swaminathan, S.; Taleff, E.M. Characteristics of the Transition from Grain-Boundary Sliding to Solute Drag Creep in Superplastic AA5083. Metall. Mater. Trans. A 2007, 39, 50–64. [Google Scholar] [CrossRef]

- Krauss, G. Deformation Processing and Structure. In Proceedings of the 1982 ASM Materials Science Seminar, St. Louis, MO, USA, 23–24 October 1982. [Google Scholar]

- Sherby, O.D.; Caligiuri, R.D.; Kayali, E.S.; White, R.A. Fundamentals of Superplasticity and Its Application; Bruke, J.J., Mehrabian, R., Weissm, V., Eds.; Advances in Metal Processing 1981; Springer: Boston, UK, 1981; pp. 133–171. [Google Scholar]

- Wadsworth, J.; Oyama, T.; Sherby, O.D. Advances in Materials Technology in the Americas. In Proceedings of the 6th Inter-American Conference on Materials Technology 1980, San Francisco, CA, USA, 12–15 August 1980. [Google Scholar]

- Tan, M.J.; Liew, K.M.; Tan, H. Cavitation and grain growth during superplastic forming. J. Achiev. Mater. Manuf. Eng. 2007, 24, 307–314. [Google Scholar]

- Li, S.; Huang, Z.; Jin, S. Superplastic Behavioral Characteristics of Fine-Grained 5A70 Aluminum Alloy. Metals 2019, 9, 62. [Google Scholar] [CrossRef]

- kh Hassan, A.A.; Norman, A.F.; Price, D.A.; Prangnell, P.B. Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment. Acta Mater. 2003, 51, 1923–1936. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Abnormal grain growth in friction stir processed alloys. Scr. Mater. 2008, 58, 367–371. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S.; Mahoney, M.W. Multi-sheet structures in 7475 aluminum by friction stir welding in concert with post-weld superplastic forming. Scr. Mater. 2002, 47, 631–636. [Google Scholar] [CrossRef]

- Mahidharar, K. Effect of Grain Size on the Superplastic Behavior of a 7475 Aluminum Alloy. J. Mater. Eng. Perform. 1995, 4, 674–678. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S. Development of ultrafine-grained microstructure and low temperature (0.48 Tm) superplasticity in friction stir processed Al–Mg–Zr. Scr. Mater. 2005, 53, 75–80. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Cepeda-Jiménez, C.M.; Hidalgo-Manrique, P.; Rey, P.; Gesto, D.; Verdera, D.; Ruano, O.A.; Carreño, F. Lowering the temperature for high strain rate superplasticity in an Al-Mg-Zn-Cu alloy via cooled friction stir processing. Mater. Chem. Phys. 2013, 142, 182–185. [Google Scholar] [CrossRef]

- Liu, F.C.; Ma, Z.Y.; Chen, L.Q. Low-temperature superplasticity of Al–Mg–Sc alloy produced by friction stir processing. Scr. Mater. 2009, 60, 968–971. [Google Scholar] [CrossRef]

- Nieh, T.G.; Hsiung, L.M.; Wadsworth, J.; Kaibyshev, R. High Strain Rate Superplasticity in a Continuously Recrystallized Al-6%Mg-0.3%Sc Alloy. Acta Mater. 1998, 46, 2789–2800. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Y.Q.; Hou, H.L.; Zhang, Y.L.; Dong, X.M.; Li, Z.Q. Superplastic deformation behavior of 7B04 Al alloy. J. Mater. Eng. 2017, 45, 27–33. [Google Scholar] [CrossRef]

- Alhamidi, A.; Horita, Z. Grain refinement and high strain rate superplasticity in aluminium 2024 alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 622, 139–145. [Google Scholar] [CrossRef]

- Li, F.; Roberts, W.T.; Bate, P.S. Superplasticity and the Development of Dislocation Structures in an Al-4.5%Mg Alloy. Acta Mater. 1996, 44, 217–233. [Google Scholar] [CrossRef]

- Noda, M.; Hirohashi, M.; Funami, K. Low Temperature Superplasticity and Its Deformation Mechanism in Grain Refinement of Al-Mg Alloy by Multi-Axial Alternative Forging. Mater. Trans. 2003, 44, 2288–2297. [Google Scholar] [CrossRef]

- Ota, S.; Akamatsu, H.; Neishi, K.; Furukawa, M.; Horita, Z.; Langdon, T.G. Low-Temperature Superplasticity in Aluminum Alloys Processed by Equal-Channel Angular Pressing. Mater. Trans. 2002, 43, 2364–2369. [Google Scholar] [CrossRef]

- Giuliano, G. Superplastic Forming of Advanced Metallic Materials; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–33. [Google Scholar]

- Musin, F.; Kaibyshev, R.; Motohashi, Y.; Itoh, G. High strain rate superplasticity in a commercial Al–Mg–Sc alloy. Scr. Mater. 2004, 50, 511–516. [Google Scholar] [CrossRef]

- Xu, G.F.; Cao, X.W.; Zhang, T.; Duan, Y.L.; Peng, X.Y.; Deng, Y.; Yin, Z.M. Achieving high strain rate superplasticity of an Al-Mg-Sc-Zr alloy by a new asymmetrical rolling technology. Mater. Sci. Eng. A 2016, 672, 98–107. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S.; Mahoney, M.W.; Grimes, R. High strain rate superplasticity in friction stir processed Al-Mg-Zr alloy. Mater. Sci. Eng. A 2003, 351, 148–153. [Google Scholar] [CrossRef]

- Li, M.; Pan, Q.; Shi, Y.; Suna, X.; Xiang, H. High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling. Mater. Sci. Eng. A 2017, 687, 298–305. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, X.; Zheng, D.; Liu, S.; Tang, J. Superplastic behavior of an Al–Mg–Li alloy. J. Alloys Compd. 2009, 487, 109–115. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Evaluation of microstructure and superplasticity in friction stir processed 5083 Al alloy. J. Mater. Res. 2004, 19, 3329–3342. [Google Scholar] [CrossRef]

- Lei, J.; Xiaolu, W.; Hui, L.; Yutao, Z.; Yonggang, Y.; Jianchao, C. High strain rate superplasticity of in situ Al3Zr/6063Al composites. Rare Metal Mat. Eng. 2016, 45, 2798–2803. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Cheverikin, V.V.; Kotov, A.D.; Portnoy, V.K. Superplastic behaviour of Al-Mg-Zn-Zr-Sc-based alloys at high strain rates. Mater. Sci. Eng. A 2016, 659, 225–233. [Google Scholar] [CrossRef]

- Charit, I.; Mishra R, S. High strain rate superplasticity in a commercial 2024 Al alloy via friction stir processing. Mater. Sci. Eng. A 2003, 359, 290–296. [Google Scholar] [CrossRef]

- Straumal, B.B.; López, G.A.; Mittemeijer, E.J.; Gust, W.; Zhilyaev, A.P. Grain Boundary Phase Transitions in the Al–Mg System and Their Influence on High-Strain Rate Superplasticity. Defect Diffus. Forum 2003, 216, 307–312. [Google Scholar] [CrossRef]

- Hedworth, J.; Stowell, M.J. The Measurement of Strain-Rate Sensitivity in Superplastic Alloys. J. Mater. Sci. 1971, 6, 1061–1069. [Google Scholar] [CrossRef]

- Vairis, A. Superplasticity Effects and Strain Rate Dependency in A Material Joining Process. J. Eng. Sci. Technol. Rev. 2008, 1, 28–32. [Google Scholar] [CrossRef]

- Nazzal, M.A.; Khraisheh, M.K.; Abu-Farha, F.K. The effect of strain rate sensitivity evolution on deformation stability during superplastic forming. J. Mater. Process. Technol. 2007, 191, 189–192. [Google Scholar] [CrossRef]

- Arieli, A.; Mukherjee, A. Factors Affecting the Maximum Attainable Ductility in a Superplastic Titanium Alloy. Mater. Sci. Eng. 1980, 43, 47–54. [Google Scholar] [CrossRef]

- Friedman, P.A.; Copple, W.B. Superplastic response in Al-Mg sheet alloys. J. Mater. Eng. Perform. 2004, 13, 335–347. [Google Scholar] [CrossRef]

- Loucif, A.; Huang, Y.; Helbert, A.L.; Baudin, T.; Sabbaghianrad, S.; Langdon, T.G. Microtextural changes and superplasticity in an Al-7075 alloy processed by high-pressure torsion. Mater. Sci. Forum 2015, 838, 445–450. [Google Scholar] [CrossRef]

- Chentouf, S.M.; Belhadj, T.; Bombardier, N.; Brodusch, N.; Gauvin, R.; Jahazi, M. Influence of predeformation on microstructure evolution of superplastically formed Al 5083 alloy. Int. J. Adv. Manuf. Technol. 2017, 88, 2929–2937. [Google Scholar] [CrossRef]

- Wang, K.; Liu, F.C.; Ma, Z.Y.; Zhang, F.C. Realization of exceptionally high elongation at high strain rate in a friction stir processed Al–Zn–Mg–Cu alloy with the presence of liquid phase. Scr. Mater. 2011, 64, 572–575. [Google Scholar] [CrossRef]

- Park, K.T.; Lee, H.J.; Lee, C.S.; Shin, D.H. Effect of post-rolling after ECAP on deformation behavior of ECAPed commercial Al–Mg alloy at 723 K. Mater. Sci. Eng. A 2005, 393, 118–124. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Segal, V.M. Engineering and commercialization of equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 2004, 386, 269–276. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Lynch, S.P. Friction-Stir Processing; Defense Technical Information Center: California, CA, USA, 2006. [Google Scholar]

- Mishra, R.S.; Mahoney, M.W. Friction stir processing: A new grain refinement technique to achieve high strain rate superplasticity in commercial alloys. Superplast. Adv. Mater. 2001, 357, 507–514. [Google Scholar] [CrossRef]