Metallurgical Effect of Rare-Earth Lanthanum Fluoride and Boride in the Composite Coating of Wires in the Arc Welding of Bainitic-Martensitic and Austenitic Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. REE Compound Properties

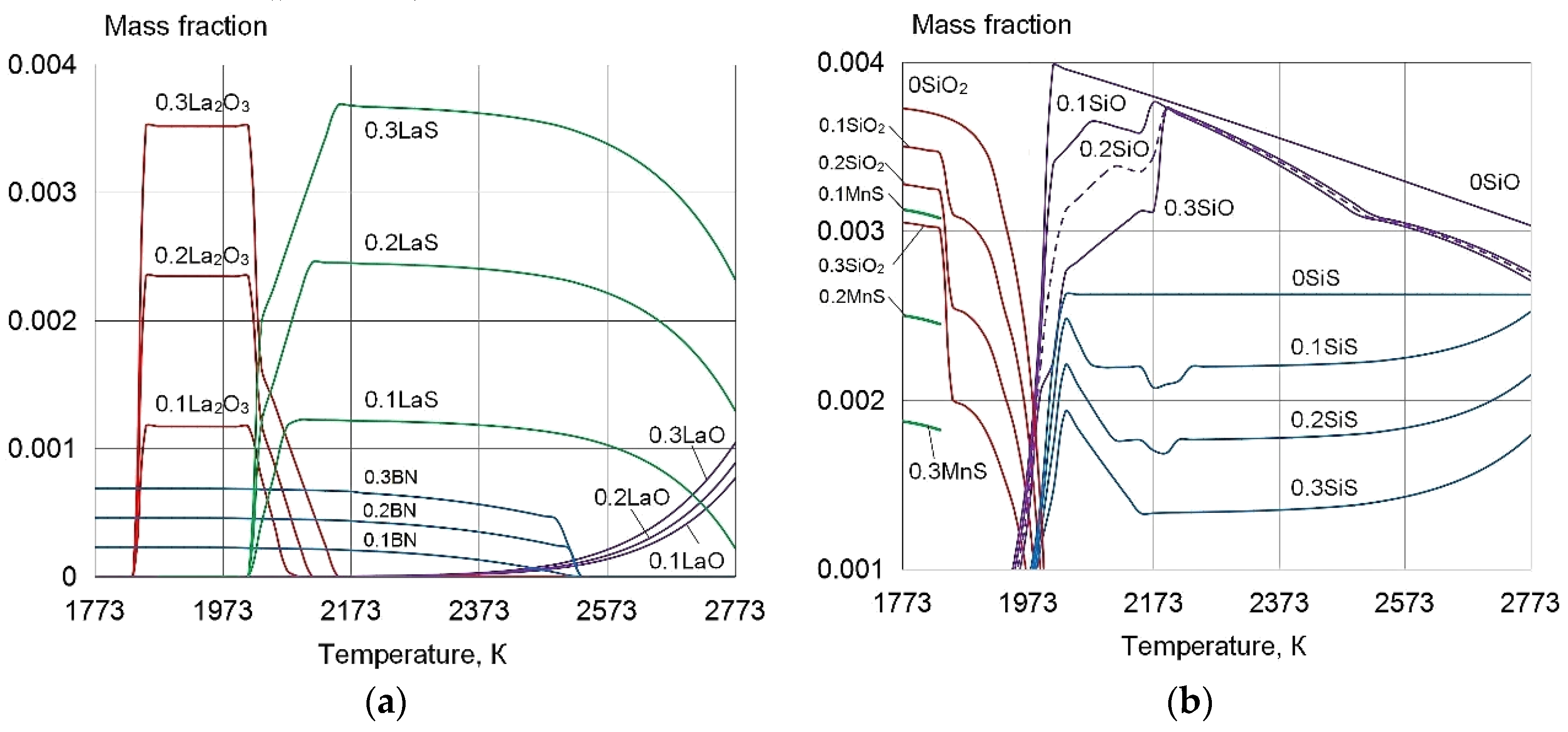

3.2. Metallurgical Reactions in the Weld Pool

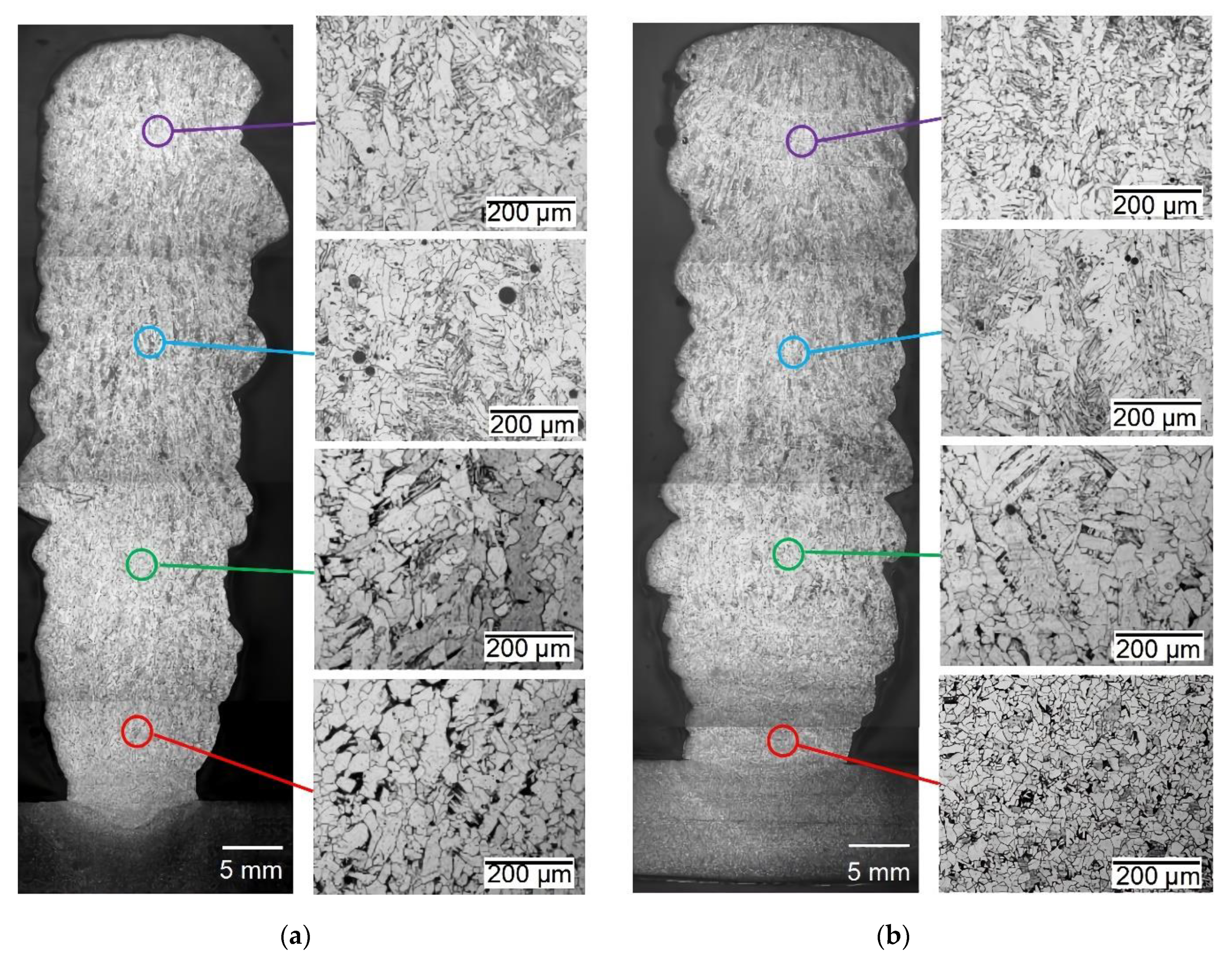

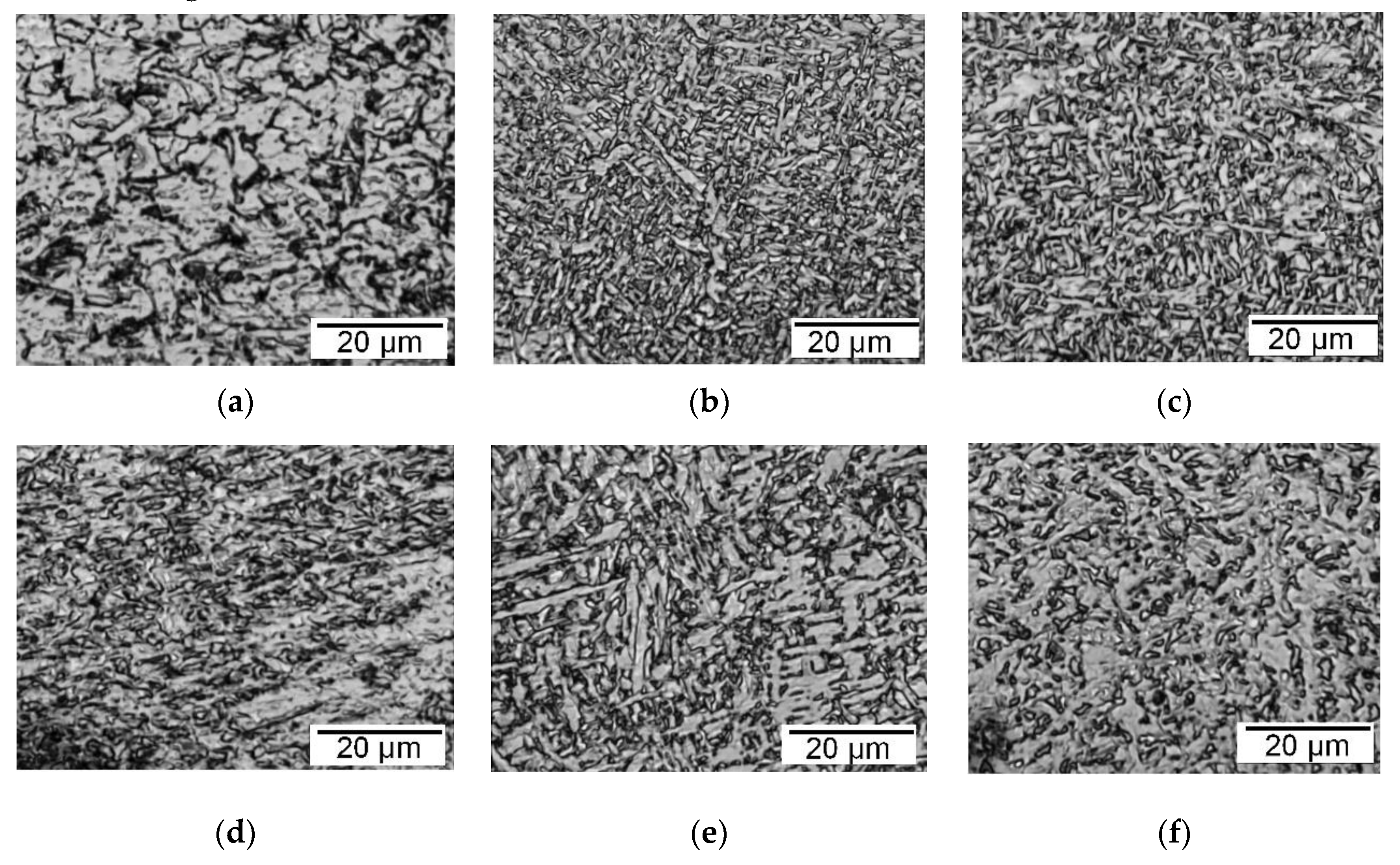

3.3. Wires with Composite Coating

4. Conclusions

- (1)

- The advanced design of steel wire with a micro-composite coating of a nickel matrix and nanoparticles of REE compounds allows improvement of the microstructure and the properties of the welds during arc welding or wire-arc additive manufacturing of high-strength and cold-resistant steels. Adding LaF3 and LaB6 into the matrix of the composite coating of the wire at a content of 0.4 wt% increases the transition coefficient of lanthanum from the wire to the weld pool, and the metallurgical effect of REE on the nucleation mechanism of the nonmetallic inclusions.

- (2)

- The REE and boron transition from the wire composite coating to the weld pool leads to strong metallurgical reactions, the formation of refractory sulphides and oxides of REEs and boron nitride, and a decrease in the content of low-melting and brittle sulphides and oxides. The maximum solubility of O, N and S, and the addition of 0.3 wt% La in the weld pool of G3Si1 pearlitic steel or 316 L austenitic steel, leads to an increase in the content of the refractory compounds La2O3, LaO2, and LaS to 0.0035 wt% each, which allows reduction of the content of SiO2, SiO, MnO, and MnS to 0.001–0.002 wt%, or by 3.3–3.5 times, and the SiS content by 1.6–2.2 times.

- (3)

- As a result, the pearlitic, bainitic, and austenitic microstructural refinement enables a reduction of the average grain size by 1.3–2 times, decreasing the width of the grain boundaries. The application of wires with a composite coating of LaF3 and LaB6 particles in the welding of S960QL bainitic-martensitic steel offers an increase in the impact toughness of the weld by 1.2–1.4 times, and in the welding of X70 API bainitic steel by 1.17–1.6 times.

Funding

Acknowledgments

Conflicts of Interest

References

- Lippold, J.C. Welding Metallurgy and Weldability, 1st ed.; Wiley: New York, NY, USA, 2014. [Google Scholar]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley: New Jersey, NJ, USA, 2003. [Google Scholar]

- Efimenko, N.G. Rare-Earth Metals in Welding Materials, 1st ed.; Collegium: Kharkov, Ukraine, 2017. (In Russian) [Google Scholar]

- Turkdogan, E.T. Fundamentals of Steelmaking, 1st ed.; Institute of Materials: London, UK, 1996. [Google Scholar]

- Abson, D.J. Acicular ferrite and bainite in C-Mn and low-alloy steel arc weld metals. Sci. Technol. Weld. Join. 2018, 23, 635–648. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Q.; Jiang, Z.; Yi, Y.; Yi, J.; Niu, B.; Ma, J.; Hu, H. Effect of rare-earth elements on the corrosion resistance of flux-cored arc-welded metal with 10CrNi3MoV steel. Int. J. Corros. 2018, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Pan, F.; Zhang, J.; Chen, H.L.; Su, Y.H.; Kuo, C.L.; Su, Y.H.; Chen, S.H.; Lin, K.J.; Hsieh, P.H.; Hwang, W.S. Effects of rare earth metals on steel microstructures. Materials 2016, 9, 417. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Y.C.; Zhang, S.H.; Li, H.; Wang, S.B. Effects of rare earth lanthanum on the solidification structure and hot ductility of Fe-43Ni expansion alloy. High Temp. Mater. Process. 2018, 37, 261–269. [Google Scholar] [CrossRef]

- Wang, A.-Q.; Li, M.; Ma, D.-Q.; Wu, Q.-J.; Xie, J.-P. Effect of lanthanum on microstructures and properties of ASTM A216 steel. Kem. U Ind. 2016, 65, 11–16. [Google Scholar] [CrossRef]

- Guerra, F.V.; Bedolla-Jacuide, A.; Zuno-Silva, J.; Ortiz-Dominguez, M.; Ruiz-López, I.; Cardoso-Legorreta, E. Fatigue resistance improvement of a forging medium carbon steel using mishmetal (rare earths) as inclusions (MnS) modifier element. Nova Sci. 2016, 8, 97–125. [Google Scholar]

- Kimanov, B.M. Removing oxide and sulfide inclusions from molten steel by filtration. Steel Transl. 2008, 38, 641–646. [Google Scholar] [CrossRef]

- Hao, F.; Liao, B.; Li, D.; Dan, T.; Ren, X.; Yang, Q. Effects of rare earth oxide on hardfacing metal microstructure of medium carbon steel and its refinement mechanism. J. Rare Earths 2011, 29, 609–613. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, J.; Chen, H.L.; Su, Y.H.; Su, Y.H.; Hwang, W.S. Thermodynamic calculation among cerium, oxygen and sulfur in liquid iron. Sci. Rep. 2016, 6, 1–6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torkamani, H.; Raydan, S.; Garcia-Mateo, C.; Rassizadehghani, J.; Vivas, J.; Palizdar, Y.; San-Martin, D. The influence of La and Ce addition on inclusion modification in cast niobium microalloyed steels. Metals 2017, 7, 377. [Google Scholar] [CrossRef] [Green Version]

- Bhadeshia, H.K.D.H. Bainite in steels. In Theory and Practice, 3rd ed.; CRC Press: Boca Raton, USA, 2015. [Google Scholar]

- Wang, M.X.; He, L.X. Effect of boron on structure and properties of low carbon bainitic steels. ISIJ Int. 2002, 42, 38–46. [Google Scholar] [CrossRef]

- Da Rosa, G.; Maugis, P.; Portavoce, A.; Drillet, J.; Valle, N.; Lentzen, E.; Hoummada, K. Grain-boundary segregation of boron in high-strength steel studied by nano-SIMS and atom probe tomography. Acta Mater. 2020, 182, 226–234. [Google Scholar] [CrossRef]

- Kataoka, T.; Ikeda, R.; Ono, M.; Yasuda, K.; Hirata, Y. Effect of REM addition of wire on CO2 gas shielded arc phenomenon. Weld. Int. 2009, 23, 517–522. [Google Scholar] [CrossRef]

- Methong, T.; Yamaguchi, T.; Shigeta, M.; Tanaka, M.; Ikeda, R.; Matsushita, M.; Poopat, B. Effect of rare earth metal on plasma properties in GMAW using CO2 shielding gas. Welding in the World 2017, 61, 1039–1047. [Google Scholar] [CrossRef]

- Li, E.; Wang, N.; Wan, S. Application of lanthanum oxide and cerium oxide in E4303 electrode. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 5th Annual International Conference on Material Engineering and Application, Wuhan, China, 14–16 December 2018; IOP Publishing: Bristol, UK, 2019; Volume 484, pp. 1–7. [Google Scholar]

- Kataoka, T.; Ikeda, R.; Yasuda, K.; Amano, K. Effect of microalloying elements of wire on spatter generation in CO2 arc welding. Prepr. Natl. Meet. Jpn. Weld. Soc. 2003, 72, 80–81. (In Japanese) [Google Scholar]

- Parshin, S.G. Welding Metallurgy, 1st ed.; Politech-Press: Saint Petersburg, Russia, 2020. (In Russian) [Google Scholar]

- Goldstein, Y.E.; Mizin, V.G. Modification and Microalloying of Iron and Steel, 1st ed.; Metallurgia: Moscow, Russia, 1986. (In Russian) [Google Scholar]

- Gao, J.; Fu, P.; Liu, H.; Li, D. Effects of rare earth on the microstructure and impact toughness of H13 steel. Metals 2015, 5, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Bartlett, L.N.; Avila, B.R. Grain refinement in lightweight advanced high-strength steel castings. Int. J. Met. 2016, 10, 401–420. [Google Scholar] [CrossRef]

- Haakonsen, F.; Solberg, J.K.; Klevan, O.S.; Eijk, C.V.D. Grain refinement of austenitic manganese steels. In AISTech 2011 Proceedings. Iron and Steel Technology Conference and Exhibition; AIST: Indianapolis, IN, USA, 2011; Volume 2, pp. 763–771. [Google Scholar]

- Ji, Y.; Zhang, M.-X.; Ren, H. Roles of lanthanum and cerium in grain refinement of steels during solidification. Metals 2018, 8, 884. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.; Yan, B. Effects of cerium on weld solidification crack sensitivity of 441 ferritic stainless steel. Metals 2019, 9, 372. [Google Scholar] [CrossRef] [Green Version]

- Chase, M.W. (Ed.) NIST-JANAF Thermochemical Tables, 4th ed.; NIST: New York, NY, USA, 1998.

- Gurvich, L.V.; Veits, I.V.; Medvedev, V.A.; Bergman, G.A.; Yungman, V.S.; Khachkuruzov, G.A.; Iorish, V.S.; Dorofeeva, O.V.; Osina, E.A.; Tolmach, P.I.; et al. (Eds.) Thermodynamic properties of individual substances. In Handbook. Tables of Thermodynamic Properties, 1st ed.; Volume 4. Part 2; Nauka: Moscow, Russia, 1982. (In Russian) [Google Scholar]

- Belov, G.V.; Trusov, B.G. Thermodynamic Modeling of Chemically Reacting Systems, 1st ed.; Bauman Moscow State Technical University: Moscow, Russia, 2013. (In Russian) [Google Scholar]

- Haynes, W.M. (Ed.) CRC Handbook of Chemistry and Physics, 97th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Brown, D.; Wedemeyer, H. Th Thorium: Compounds with S, Se, Te and B, 1st ed.; Springer: Berlin, Germany, 2013. [Google Scholar]

- Samsonov, G.V.; Vinitsky, I.M. Refractory Compounds; Metallurgia: Moscow, Russia, 1976. (In Russian) [Google Scholar]

- Samsonov, G.V.; Borisova, A.L.; Zhidkova, T.G. Physical and chemical properties of oxides. In Handbook, 1st ed.; Metallurgia: Moscow, Russia, 1978. (In Russian) [Google Scholar]

| Root Pass | S960QL with Union X96 1.0 mm | X70 API with G3Si1 1.2 mm | ||||

| I, A | U, V | V, m/min | I, A | U, V | V, m/min | |

| 170 | 24 | 7.8 | 160 | 20 | 5.5 | |

| Filling passes | 210 | 26 | 8.5 | 200 | 25 | 6.5 |

| Weld deposition | Multilayer deposition with 316L 1.0 mm (45 layers) | Multilayer deposition with G3Si1 1.2 mm (45 layers) | ||||

| I, A | U, V | V, m/min | I, A | U, V | V, m/min | |

| 64 | 12.9 | 2.2 | 92 | 13.3 | 2.1 | |

| REE Compound | Melting Temperature, °C | Density, g/cm3 | REE Compound | Melting Temperature, °C | Density, g/cm3 |

|---|---|---|---|---|---|

| La2O3 | 2304 | 6.51 | Ce2O3 | 2250 | 6.2 |

| Y2O3 | 2439 | 5.03 | CeO2 | 2480 | 7.21 |

| Nd2O3 | 2233 | 7.24 | ThO2 | 3350 | 10 |

| REE Compound | Melting Temperature, °C | Density, g/cm3 | REE Compound | Melting Temperature, °C | Density, g/cm3 |

|---|---|---|---|---|---|

| LaS | 2300 | 5.61 | Y2S3 | 1925 | 3.87 |

| La2S3 | 2110 | 4.9 | NdS | 2200 | 6.23 |

| CeS | 2445 | 5.9 | Nd2S3 | 2207 | 5.46 |

| Ce2S3 | 2450 | 5.02 | ThS | 2335 | 9.56 |

| YS | 2060 | 4.92 | Th2S3 | 2300 | 7.88 |

| Coating | Ni | La | F | B |

|---|---|---|---|---|

| Ni–LaF3 | 58.08 | 23.57 | 15.30 | – |

| Ni–LaB6 | 61.9 | 31.3 | – | 16.5 |

| Base metal | C | Si | Mn | Cr | Mo | Ni | Al |

| 0.13–0.16 | 0.4–0.5 | 1.7–1.8 | 1.2–1.36 | 0.46–0.6 | 0.8–1.1 | <0.07 | |

| V | Cu | Ti | La | B | P | S | |

| <0.16 | 0.4–0.51 | <0.01 | – | <0.001 | <0.008 | <0.003 | |

| Weld metal | C | Si | Mn | Cr | Mo | Ni | Al |

| 0.08–0.11 | 0.6–0.63 | 1.94–2.1 | 0.49–0.7 | 0.5–0.56 | 1.1–1.4 | <0.05 | |

| V | Cu | Ti | La | B | P | S | |

| <0.016 | 0.13–0.18 | <0.02 | 0.01–0.04 | <0.005 | <0.01 | <0.008 |

| Wire | Yield Strength, MPa | Tensile Strength, MPa | Impact Toughness, KCV−40, J | Hardness, HV10 Test Force: 98,07 N Test Time: 4 s | ||

|---|---|---|---|---|---|---|

| Weld Metal | Base Metal | Weld Metal | HAZ | |||

| Union X96 standard wire | 930–970 950 | 1048–1152 1100 | 38–52 45 | 297–335 316 | 367–385 376 | 252–281 266 |

| Union X96 wire with Ni-LaF3 coating | 950–990 970 | 1035–1125 1080 | 50–58 54 | 302–355 328,5 | 365–404 384,5 | 269–286 277,5 |

| Union X96 wire with Ni-LaB6 coating | 1033–1059 1046 | 1133–1199 1166 | 62–70 66 | 308–358 333 | 392–403 397,5 | 282–292 287 |

| Base metal | C | Si | Mn | Cr | Mo | Ni | Al |

| 0.09–0.12 | 0.28–0.32 | 1.62–1.7 | 0.03–0.04 | <0.01 | 0.02–0.04 | 0.04–0.05 | |

| V | Cu | Ti | La | B | P | S | |

| 0.03–0.05 | 0.16–0.19 | 0.01–0.02 | – | – | <0.007 | <0.006 | |

| Weld metal | C | Si | Mn | Cr | Mo | Ni | Al |

| 0.08–0.1 | 0.8–1.1 | 1.3–1.4 | 0.01–0.03 | <0.01 | 0.16–0.21 | <0.005 | |

| V | Cu | Ti | La | B | P | S | |

| <0.008 | 0.01–0.03 | <0.002 | 0.01–0.034 | <0.005 | <0.007 | <0.02 |

| Wire | Yield Strength, MPa | Tensile Strength, MPa | Elongation, % | Impact Toughness, KCV–20, J | Hardness, HV10 Test Force: 98,07 N Test Time: 4 s | |||

|---|---|---|---|---|---|---|---|---|

| Weld Metal | HAZ | Base Metal | Weld Metal | HAZ | ||||

| G3Si1 standard wire | 519–533 526 | 574–589 581.5 | 10.9–11.3 11.1 | 84–90 87 | 116–170 143 | 193–212 202 | 189–193 191 | 208–241 224 |

| G3Si1 wire with Ni-LaF3 coating | 546–574 560 | 600–620 610 | 11.8–15.5 13.6 | 100–104 102 | 134–174 154 | 204–217 210 | 199–214 206 | 223–236 229 |

| G3Si1 wire with Ni-LaB6 coating | 560–584 572 | 609–670 639.5 | 12.5–19.5 16 | 127–160 143.5 | 150–198 174 | 201–224 212 | 202–210 206 | 213–247 230 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parshin, S.G. Metallurgical Effect of Rare-Earth Lanthanum Fluoride and Boride in the Composite Coating of Wires in the Arc Welding of Bainitic-Martensitic and Austenitic Steel. Metals 2020, 10, 1334. https://doi.org/10.3390/met10101334

Parshin SG. Metallurgical Effect of Rare-Earth Lanthanum Fluoride and Boride in the Composite Coating of Wires in the Arc Welding of Bainitic-Martensitic and Austenitic Steel. Metals. 2020; 10(10):1334. https://doi.org/10.3390/met10101334

Chicago/Turabian StyleParshin, Sergey G. 2020. "Metallurgical Effect of Rare-Earth Lanthanum Fluoride and Boride in the Composite Coating of Wires in the Arc Welding of Bainitic-Martensitic and Austenitic Steel" Metals 10, no. 10: 1334. https://doi.org/10.3390/met10101334

APA StyleParshin, S. G. (2020). Metallurgical Effect of Rare-Earth Lanthanum Fluoride and Boride in the Composite Coating of Wires in the Arc Welding of Bainitic-Martensitic and Austenitic Steel. Metals, 10(10), 1334. https://doi.org/10.3390/met10101334