Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

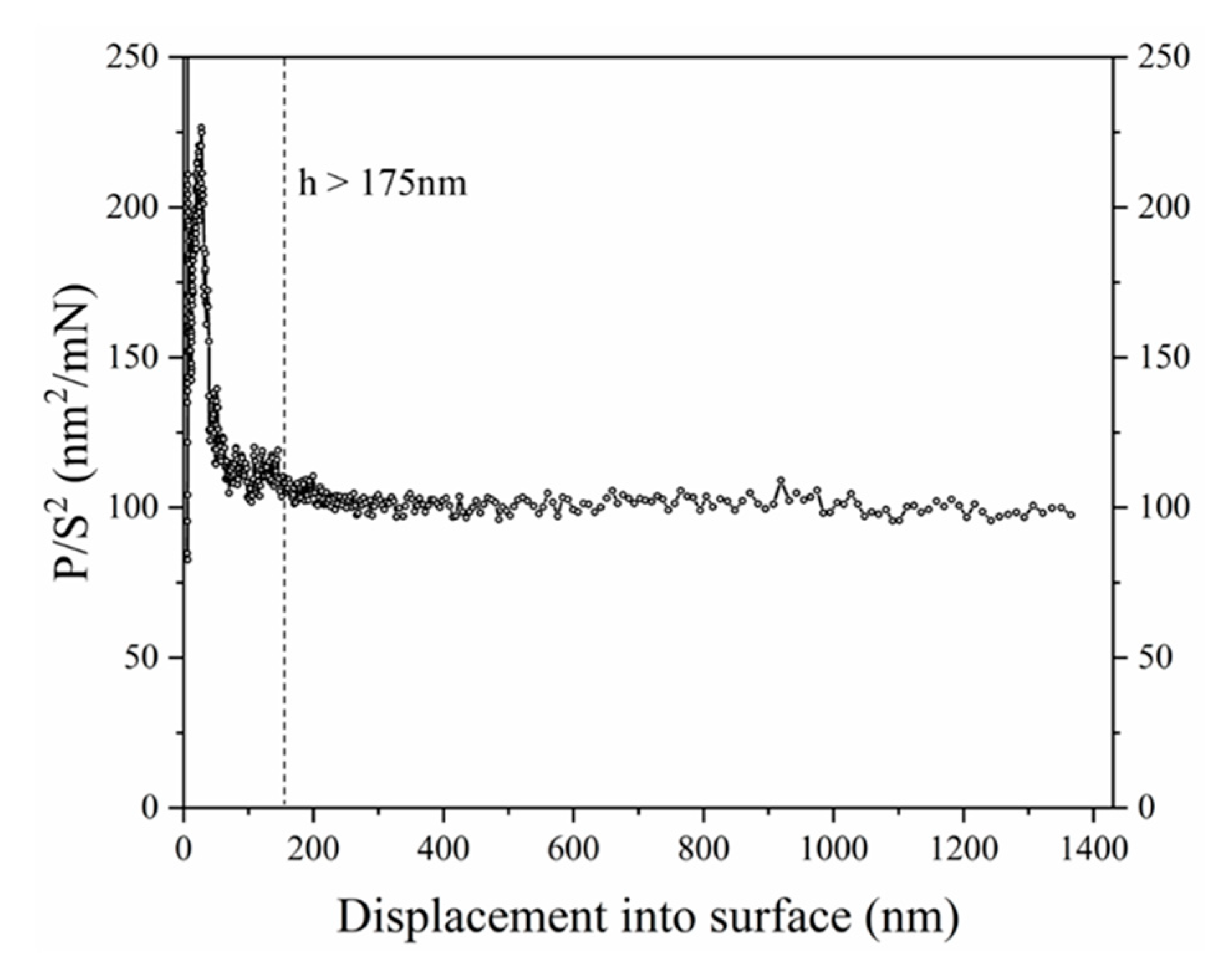

2.2. Assessment of Small-Scale Mechanical Properties and Statistical Analysis

3. Results and Discussions

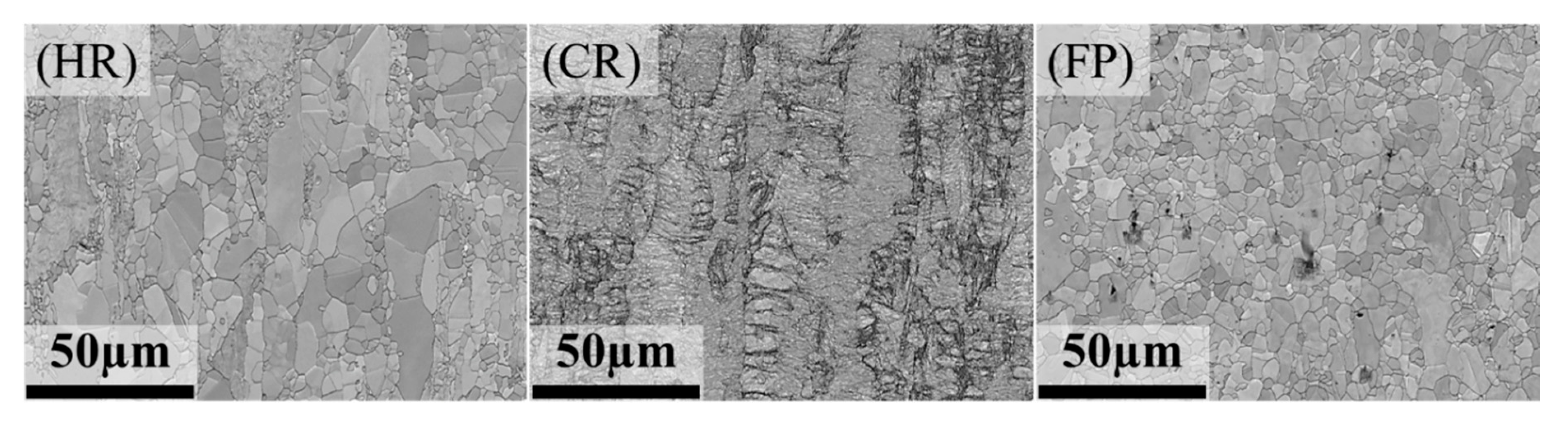

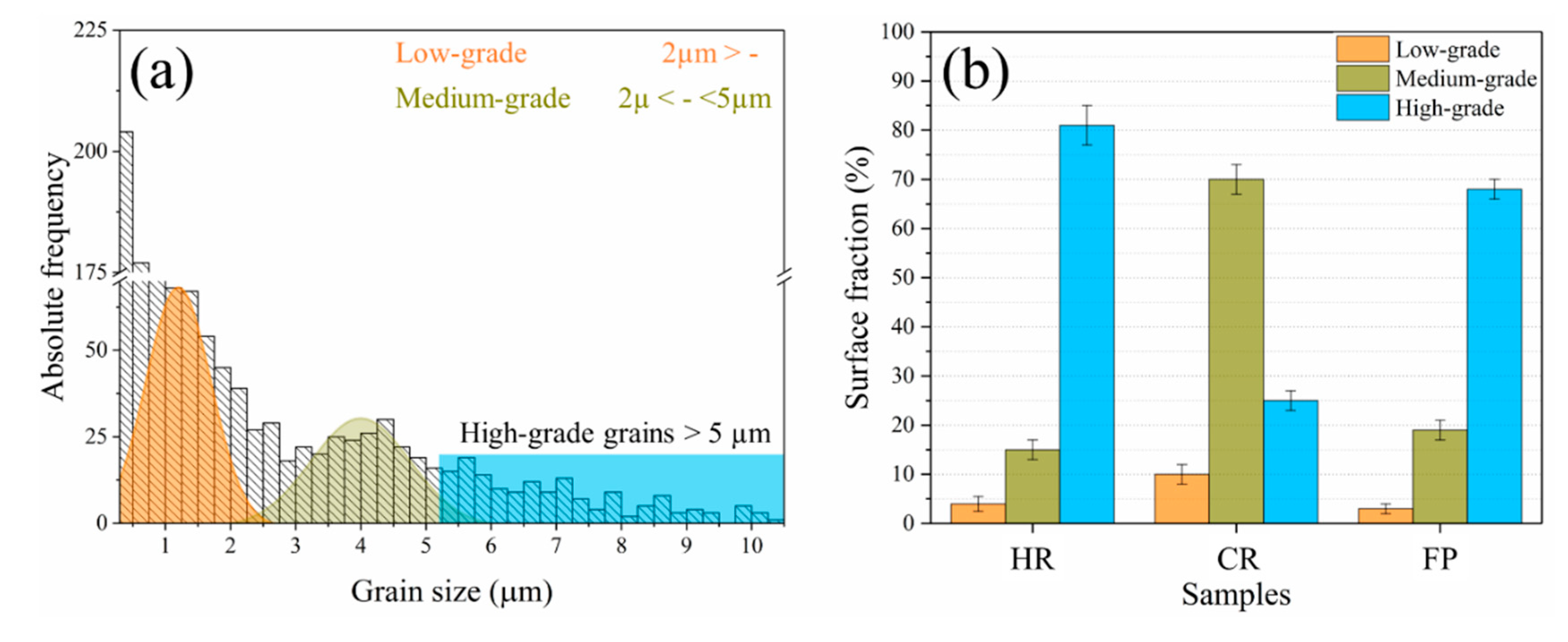

3.1. Microstructural Characterization

3.2. Micromechanical Properties

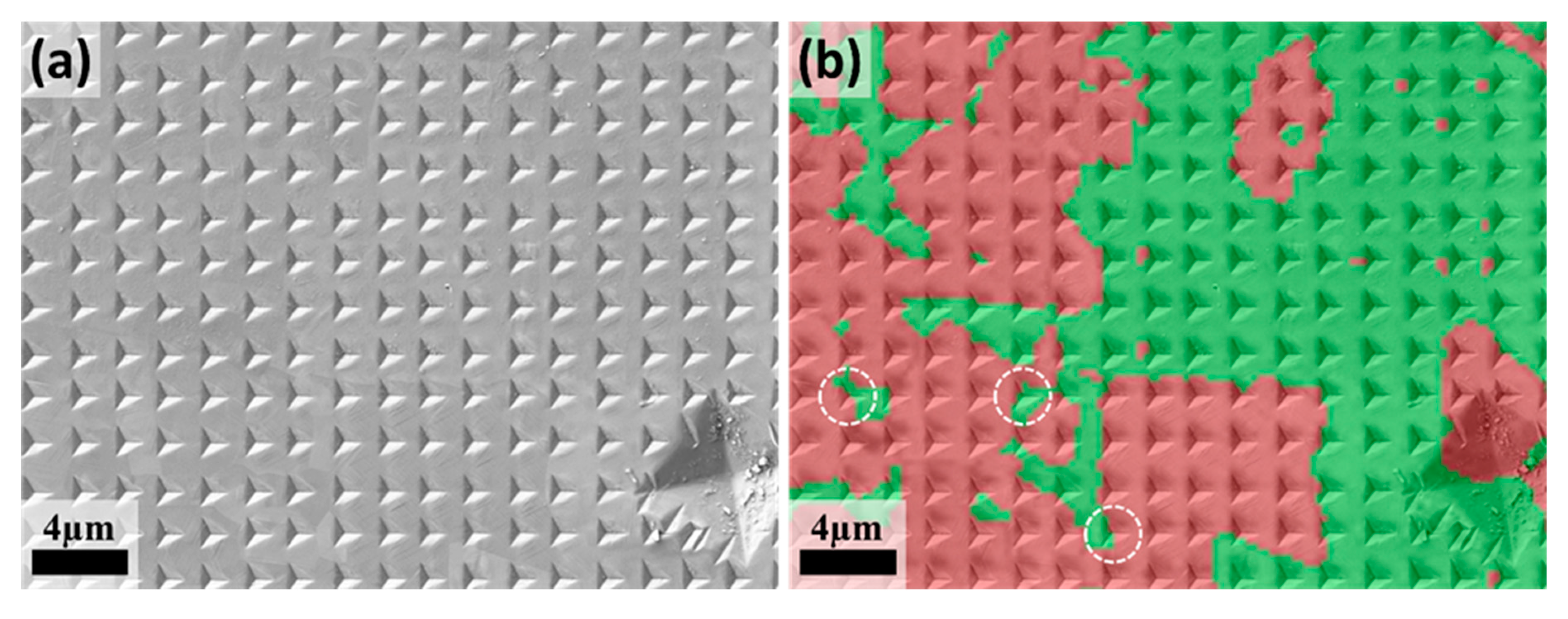

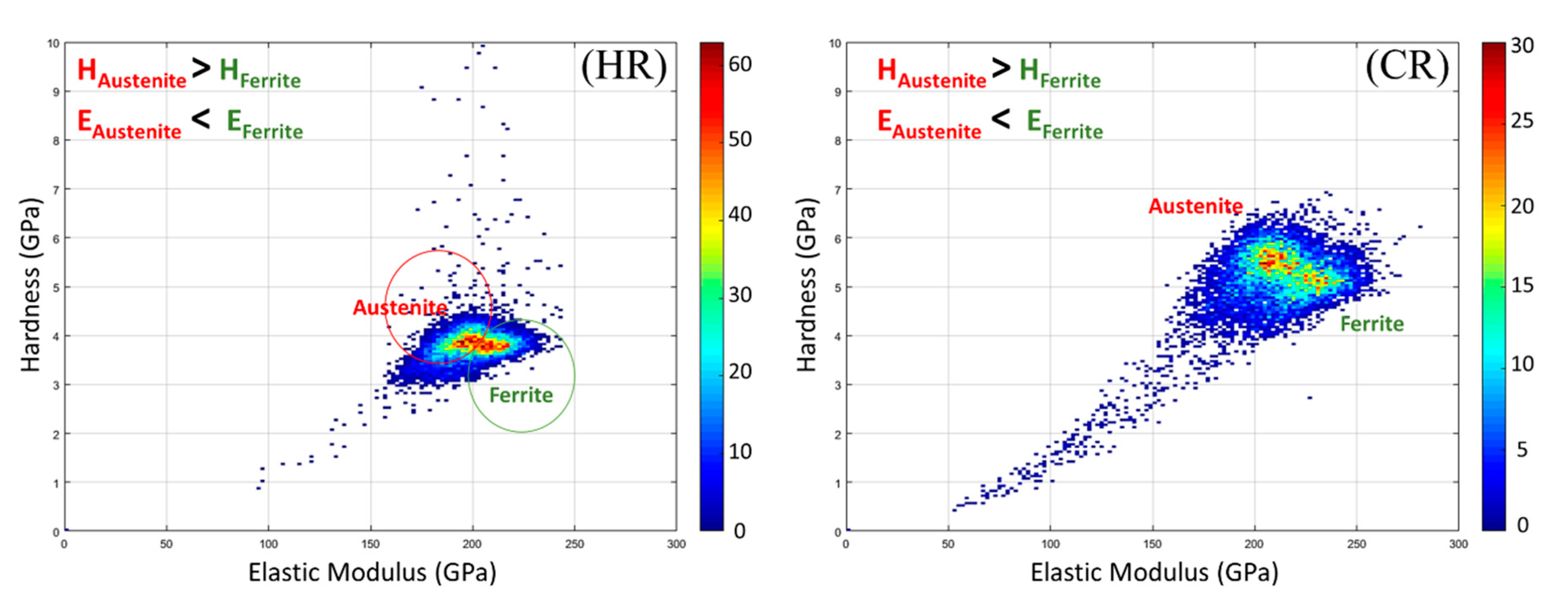

3.2.1. Micromechanical Properties–Microstructure Correlation: Cartography Maps

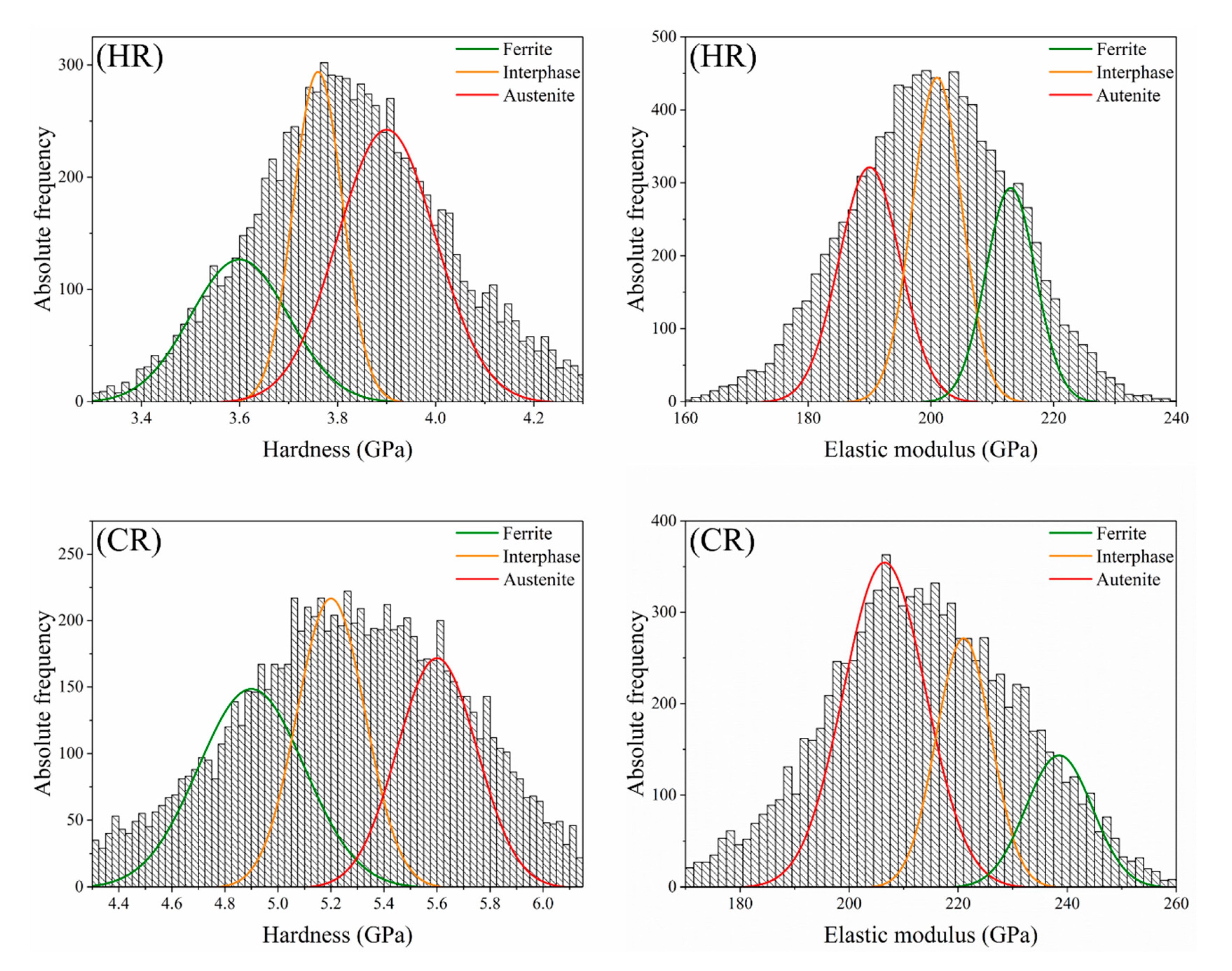

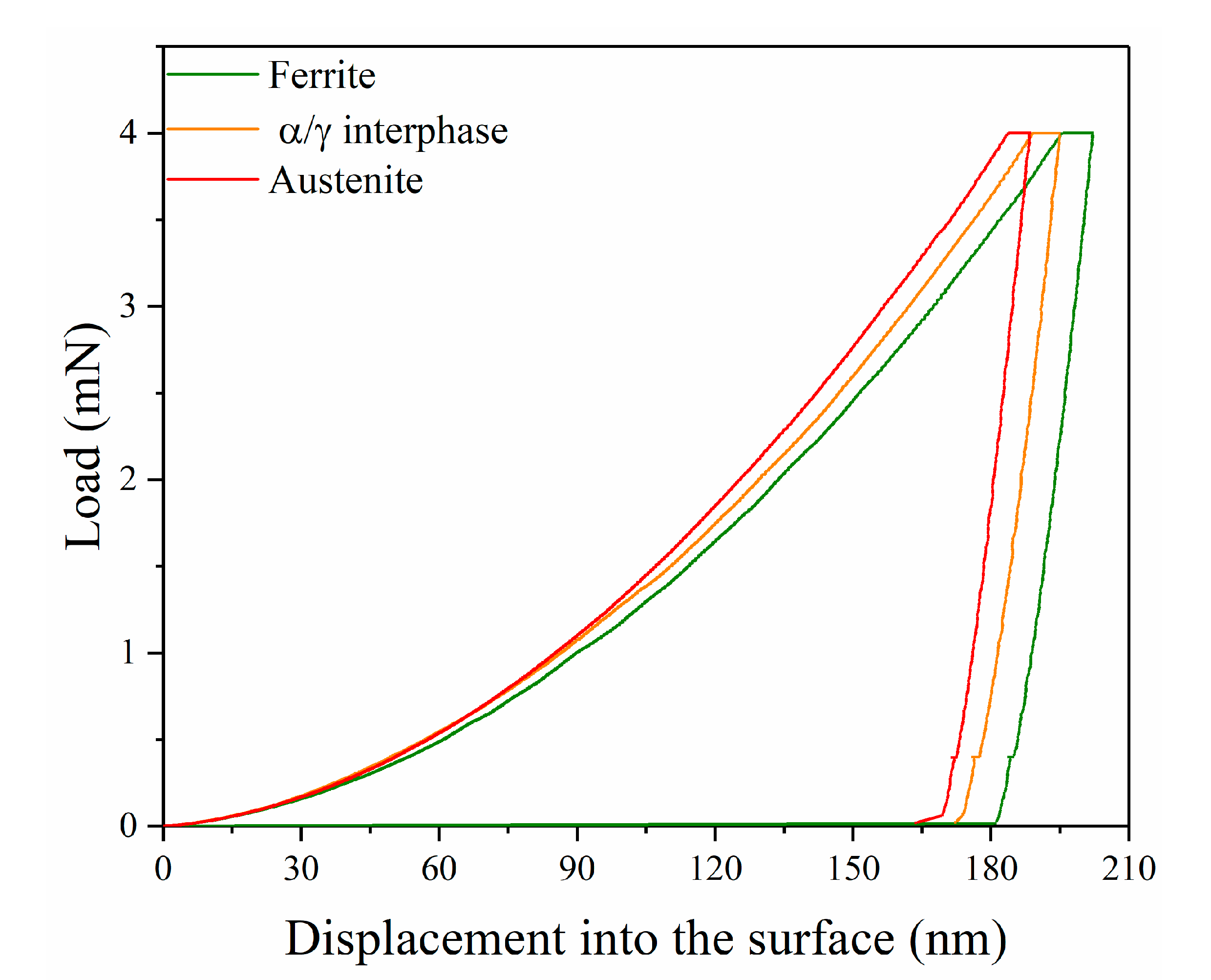

3.2.2. Small-Scale Mechanical Properties of Each Constitutive Phase: Statistical Analysis

4. Conclusions

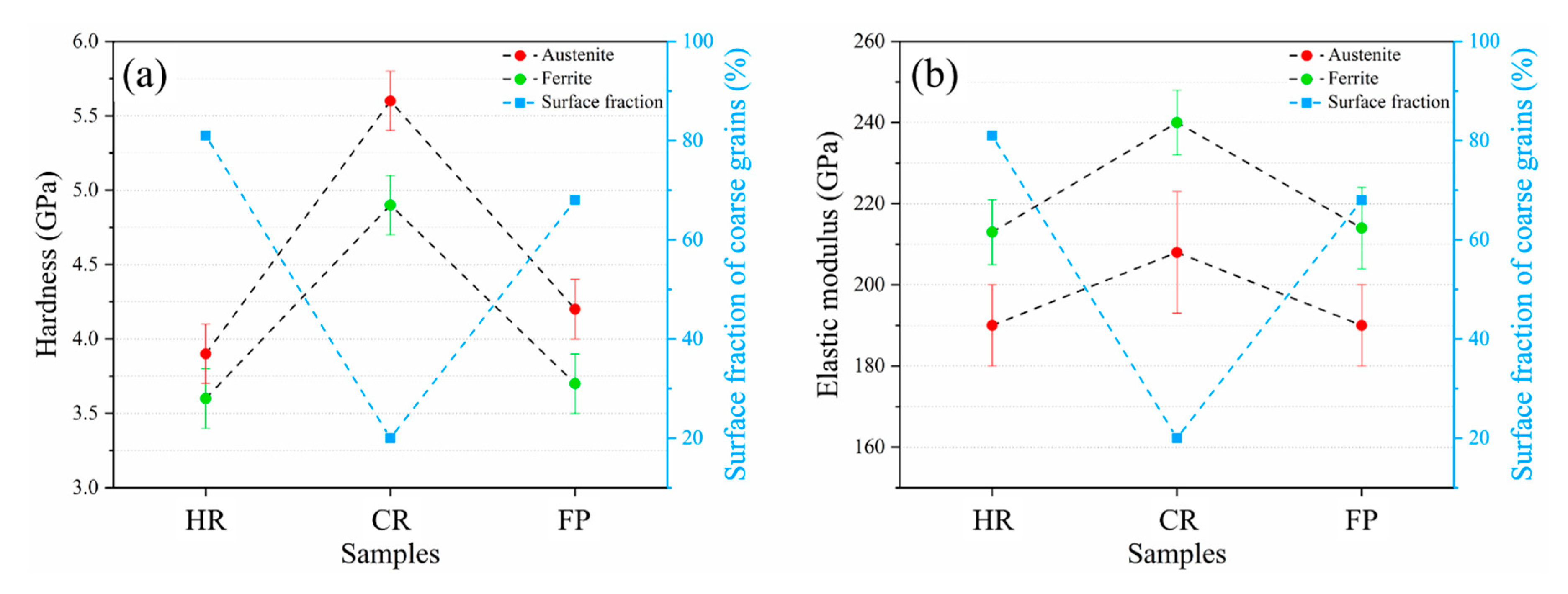

- The surface fraction occupied by medium- and large-sized grains demonstrated a high sensitivity to cold work. Grains were significantly refined during cold work via the elongation and fragmentation of grains. Subsequent annealing treatment activated recovery and recrystallization of the grains, which caused a higher surface fraction of coarser grains.

- Hardness and elastic modulus cartography maps provided a satisfactory correlation between micromechanical properties and constitutive phases (confirmed by EBSD analysis). The accuracy and definition of such a relationship were increased by using H/E maps. Therefore, the H/E ratio is proposed as an appropriated and reliable parameter for mechanically distinguishing between phases with relatively similar properties.

- The different processing routes investigated here have similar effects on the mechanical properties of both phases. For the DSS here studied (with an intermediate N content of 0.15 in %wt), the austenitic phase demonstrated higher hardness and lower elastic modulus compared with the ferritic one.

- Cold work resulted in higher values of hardness and elastic modulus for both austenite and ferrite phases, as compared to the hot-rolled as well as the annealed (final product) ones. Such relative changes assessed in the small-scale properties are expected to be related to work hardening and deformation texture effects. Further research is here recalled for a deeper understanding of these correlations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Solomon, H.D.; Devine, T.M., Jr. Proc. Conf. on duplex stainless steels. Am. Soc. Met. Met. Park. 1983, 1, 693–756. [Google Scholar]

- Guha, P.; Clark, C. Properties and applications of high-chromium duplex stainless steels. In Duplex Stainless Steels; Lula, R.A., Ed.; American Society for Metals: Ceauga, OH, USA, 1983; pp. 355–369. [Google Scholar]

- Nilsson, J.-O. Super duplex stainless steels. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Olsson, J.; Snis, M. Duplex—A new generation of stainless steels for desalination plants. Desalination 2007, 205, 104–113. [Google Scholar] [CrossRef]

- Sotomayor, M.; De Kloe, R.; Levenfeld, B.; Varez, A. Microstructural study of duplex stainless steels obtained by powder injection molding. J. Alloys Compd. 2014, 589, 314–321. [Google Scholar] [CrossRef]

- Gunn, R.N. Duplex Stainless Steels; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Tahchieva, A.B.; Llorca-Isern, N.; Cabrera-Marrero, J.-M. Duplex and Superduplex Stainless Steels: Microstructure and Property Evolution by Surface Modification Processes. Metals 2019, 9, 347. [Google Scholar] [CrossRef] [Green Version]

- Hertzman, S.; Charles, J. On the effect of nitrogen on duplex stainless steels. Rev. De Métallurgie 2011, 108, 413–425. [Google Scholar] [CrossRef]

- Horvath, W.; Prantl, W.; Stroißnigg, H.; Werner, E. Microhardness and microstructure of austenite and ferrite in nitrogen alloyed duplex steels between 20 and 500 °C. Mater. Sci. Eng. A 1998, 256, 227–236. [Google Scholar] [CrossRef]

- Malta, P.O.; Dias, F.L.; De Souza, A.C.M.; Santos, D.B. Microstructure and texture evolution of duplex stainless steels with different molybdenum contents. Mater. Charact. 2018, 142, 406–421. [Google Scholar] [CrossRef]

- Song, J.; Bate, P. Plastic Anisotropy in A Superplastic Duplex Stainless Steel. Acta Mater. 1997, 45, 2747–2757. [Google Scholar] [CrossRef]

- Sarkar, A.; Sanyal, S.; Bandyopadhyay, T.; Mandal, S. Influence of annealing parameters on phase evolution and recrystallization kinetics of a Mn-Al-Si alloyed duplex steel. Mater. Charact. 2017, 134, 213–224. [Google Scholar] [CrossRef]

- Fargas, G.; Anglada, M.; Mateo, A. Effect of the annealing temperature on the mechanical properties, formability and corrosion resistance of hot-rolled duplex stainless steel. J. Mater. Process. Technol. 2009, 209, 1770–1782. [Google Scholar] [CrossRef]

- Martins, M.; Casteletti, L.C. Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure. Mater. Charact. 2005, 55, 225–233. [Google Scholar] [CrossRef]

- Hutchinson, W.B.; Ushioda, K.; Runnsjö, G. Anisotropy of tensile behaviour in a duplex stainless steel sheet. Mater. Sci. Technol. 1985, 1, 728–736. [Google Scholar] [CrossRef]

- Rodrigues, D.G.; Maria, G.G.B.; Viana, N.A.L.; Santos, D. Effect of low cold-rolling strain on microstructure, texture, phase transformation, and mechanical properties of 2304 lean duplex stainless steel. Mater. Charact. 2019, 150, 138–149. [Google Scholar] [CrossRef]

- Mateo, A. Anisotropy effects on the fatigue behaviour of rolled duplex stainless steels. Int. J. Fatigue 2003, 25, 481–488. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.; Han, W.; Ma, C.; Zhou, L. Influence of duplex ageing on secondary α precipitates and mechanical properties of the near β-Ti alloy Ti-55531. Mater. Charact. 2018, 144, 1–8. [Google Scholar] [CrossRef]

- Cabrera-Marrero, J.-M. Hot deformation of duplex stainless steels. J. Mater. Process. Technol. 2003, 143, 321–325. [Google Scholar] [CrossRef]

- Hosseini, A.; Karlsson, V.; Örnek, L.; Reccagni, C.; Wessman, P.; Engelberg, D.S. Microstructure and functionality of a uniquely graded super duplex stainless steel designed by a novel arc heat treatment method. Mater. Charact. 2018, 139, 390–400. [Google Scholar] [CrossRef]

- Moallemi, M.; Zarei-Hanzaki, A.; Kim, S.J.; Alimadadi, H. On the microstructural-textural characterization and deformation analysis of a nano/ultrafine grained Fe-20Cr-8Mn-0.3N duplex alloy with superior mechanical properties. Mater. Charact. 2019, 156, 109878. [Google Scholar] [CrossRef]

- Wang, X.F.; Yang, X.P.; Guo, Z.D.; Zhou, Y.C.; Song, H.W. Nanoindentation Characterization of Mechanical Properties of Ferrite and Austenite in Duplex Stainless Steel. Adv. Mater. Res. 2007, 26, 1165–1170. [Google Scholar] [CrossRef]

- Fargas, G.; Akdut, N.; Anglada, M.; Mateo, A. Microstructural Evolution during Industrial Rolling of a Duplex Stainless Steel. ISIJ Int. 2008, 48, 1596–1602. [Google Scholar] [CrossRef] [Green Version]

- Tao, P.; Gong, J.; Wang, Y.-F.; Jiang, Y.; Li, Y.; Cen, W.-W. Characterization on stress-strain behavior of ferrite and austenite in a 2205 duplex stainless steel based on nanoindentation and finite element method. Results Phys. 2018, 11, 377–384. [Google Scholar] [CrossRef]

- Zhang, Q.; Singaravelu, A.S.S.; Zhao, Y.; Jing, T.; Chawla, N. Mechanical properties of a thermally-aged cast duplex stainless steel by nanoindentation and micropillar compression. Mater. Sci. Eng. A 2019, 743, 520–528. [Google Scholar] [CrossRef]

- Olanipekun, A.T.; Nthabiseng, M.; Ayodele, O.O.; Mphahlele, M.; Mampuya, B.M.; Olubambi, P.A. Datasets on the measurement of mechanical properties of ferrite and austenite constitutive phases using nanoindentation and micro hardness techniques. Data Brief. 2019, 27, 104551. [Google Scholar] [CrossRef]

- Tromas, C.; Stinville, J.; Templier, C.; Villechaise, P. Hardness and elastic modulus gradients in plasma-nitrided 316L polycrystalline stainless steel investigated by nanoindentation tomography. Acta Mater. 2012, 60, 1965–1973. [Google Scholar] [CrossRef]

- Taylor, M.; Choi, K.; Sun, X.; Matlock, D.; Packard, C.E.; Xu, L.; Barlat, F. Correlations between nanoindentation hardness and macroscopic mechanical properties in DP980 steels. Mater. Sci. Eng. A 2014, 597, 431–439. [Google Scholar] [CrossRef]

- Roa, J.; Fargas, G.; Mateo, A.; Jimenez-Pique, E. Dependence of nanoindentation hardness with crystallographic orientation of austenite grains in metastable stainless steels. Mater. Sci. Eng. A 2015, 645, 188–195. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.-J.; Van Vliet, K. On the use of nanoindentation for cementitious materials. Mater. Struct. 2003, 36, 191–196. [Google Scholar] [CrossRef]

- Constantinides, G.; Chandran, K.R.; Ulm, F.-J.; Van Vliet, K. Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng. A 2006, 430, 189–202. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.-J. The nanogranular nature of C–S–H. J. Mech. Phys. Solids 2007, 55, 64–90. [Google Scholar] [CrossRef]

- Ulm, F.-J.; Vandamme, M.; Bobko, C.; Ortega, J.A.; Tai, K.; Ortiz, C. Statistical Indentation Techniques for Hydrated Nanocomposites: Concrete, Bone, and Shale. J. Am. Ceram. Soc. 2007, 90, 2677–2692. [Google Scholar] [CrossRef] [Green Version]

- Roa, J.; Jimenez-Pique, E.; Verge, C.; Tarragó, J.; Mateo, A.; Fair, J.; Llanes, L. Intrinsic hardness of constitutive phases in WC–Co composites: Nanoindentation testing, statistical analysis, WC crystal orientation effects and flow stress for the constrained metallic binder. J. Eur. Ceram. Soc. 2015, 35, 3419–3425. [Google Scholar] [CrossRef]

- De Bono, D.M.; London, T.; Baker, M.; Whiting, M. A robust inverse analysis method to estimate the local tensile properties of heterogeneous materials from nano-indentation data. Int. J. Mech. Sci. 2017, 123, 162–176. [Google Scholar] [CrossRef] [Green Version]

- Besharatloo, H.; De Nicolas, M.; Roa, J.; Dios, M.; Mateo, A.; Ferrari, B.; Gordo, E.; Llanes, L. Assessment of mechanical properties at microstructural length scale of Ti(C,N)–FeNi ceramic-metal composites by means of massive nanoindentation and statistical analysis. Ceram. Int. 2019, 45, 20202–20210. [Google Scholar] [CrossRef]

- Besharatloo, H.; Gordon, S.; Rodriguez-Suarez, T.; Can, A.; Oliver, W.; Llanes, L.; Roa, J. Small-scale mechanical properties of constitutive phases within a polycrystalline cubic boron nitride composite. J. Eur. Ceram. Soc. 2019, 39, 5181–5189. [Google Scholar] [CrossRef]

- Besharatloo, H.; De Nicolas, M.; Wheeler, J.; Mateo, A.; Ferrari, B.; Gordo, E.; Llanes, L.; Roa, J. Carbon addition effects on microstructure and small-scale hardness for Ti(C.,N)-FeNi cermets. Int. J. Refract. Met. Hard Mater. 2019, 85, 105064. [Google Scholar] [CrossRef]

- De Nicolás, M.; Besharatloo, H.; Wheeler, J.; De Dios, M.; Alvaredo, P.; Roa, J.; Ferrari, B.; Llanes, L.; Gordo, E. Influence of the processing route on the properties of Ti(C,N)-Fe15Ni cermets. Int. J. Refract. Met. Hard Mater. 2020, 87, 105046. [Google Scholar] [CrossRef]

- Xiao, Y.; Besharatloo, H.; Gan, B.; Maeder, X.; Spolenak, R.; Wheeler, J.M. Combinatorial investigation of Al–Cu intermetallics using small-scale mechanical testing. J. Alloy. Compd. 2020, 822, 153536. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W. A critical assessment of the effect of indentation spacing on the measurement of hardness and modulus using instrumented indentation testing. Mater. Des. 2019, 164, 107563. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering; John Wiley & Sons: Hoboken, NY, USA, 2011. [Google Scholar]

- Metallographic determination of microstructure. Part 2: Measurement of WC grain size, in: ISO 4499-2 2008, Hardmetals, Geneva, 2008.

- Gadelrab, K.R.; Li, G.; Chiesa, M.; Souier, T. Local characterization of austenite and ferrite phases in duplex stainless steel using MFM and nanoindentation. J. Mater. Res. 2012, 27, 1573–1579. [Google Scholar] [CrossRef] [Green Version]

- Shamanth, V.; Kumar, P.; Ravishankar, K. Effect of Heat Treatment on the High Cycle Fatigue Behaviour of S2205 Duplex Stainless Steels. Mater. Today Proc. 2017, 4, 10798–10802. [Google Scholar] [CrossRef]

- Schwarm, S.C.; Kolli, R.P.; Aydogan, E.; Mburu, S.; Ankem, S. Characterization of phase properties and deformation in ferritic-austenitic duplex stainless steels by nanoindentation and finite element method. Mater. Sci. Eng. A 2017, 680, 359–367. [Google Scholar] [CrossRef] [Green Version]

- Malta, P.O.; Condé, B.L.; Assumpção, R.F.; Perasoli, D.B.; Sicupira, D.C.; Santos, D.B. Effect of Annealing Temperature on Mechanical Behavior, Pitting Resistance and Grain Boundary Character of a 2304 Lean Duplex Stainless Steel. Met. Mater. Trans. A 2019, 50, 2665–2677. [Google Scholar] [CrossRef]

- Breda, M.; Brunelli, K.; Grazzi, F.; Scherillo, A.; Calliari, I. Effects of Cold Rolling and Strain-Induced Martensite Formation in a SAF 2205 Duplex Stainless Steel. Met. Mater. Trans. A 2014, 46, 577–586. [Google Scholar] [CrossRef]

- Zhou, T.; Xiong, Y.; Yue, Y.; Lu, Y.; Chen, Y.-N.; He, T.-T.; Ren, F.-Z.; Singh, H.; Kömi, J.; Huttula, M.; et al. Controlled cold rolling effect on microstructure and mechanical properties of Ce-modified SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 2019, 766, 138352. [Google Scholar] [CrossRef]

- Cooke, B.A.; Jones, A.R.; Ralph, B. Recrystallization of microduplex steels. Met. Sci. 1979, 13, 179–186. [Google Scholar] [CrossRef]

- Blicharski, M. Structure of deformed ferrite–Austenite stainless steel. Met. Sci. 1984, 18, 92–98. [Google Scholar] [CrossRef]

- Padilha, A.F.; Plaut, R.L.; Rios, P.R. Annealing of Cold-worked Austenitic Stainless Steels. ISIJ Int. 2003, 43, 135–143. [Google Scholar] [CrossRef]

- Johannsen, D.L.; Kyröläinen, A.; Ferreira, P. Influence of annealing treatment on the formation of nano/submicron grain size AISI 301 Austenitic stainless steels. Met. Mater. Trans. A 2006, 37, 2325–2338. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mahata, D.; Roychaudhuri, R.; Mondal, R. Effect of rolling deformation and solution treatment on microstructure and mechanical properties of a cast duplex stainless steel. Bull. Mater. Sci. 2012, 35, 839–846. [Google Scholar] [CrossRef] [Green Version]

- Moura, A.; Favarato, L.; Filho, A.I.; Alcântara, C.M.; Cunha, M.; Oliveira, T.; Machado, M. Study of the recrystallization and crystallographic texture evolution during final annealing of UNS S32304 Lean Duplex stainless steel. Mater. Charact. 2017, 130, 39–49. [Google Scholar] [CrossRef]

- Farnoush, H.; Momeni, A.; Dehghani, K.; Mohandesi, J.A.; Keshmiri, H. Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases. Mater. Des. 2010, 31, 220–226. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, Z.; Dou, R.; Zhou, G.; Li, Z. Evolution of microstructure and mechanical properties of cold-rolled SUS430 stainless steel during a continuous annealing process. Mater. Sci. Eng. A 2014, 598, 22–27. [Google Scholar] [CrossRef]

- Rezaei, H.; Ghazani, M.S.; Eghbali, B. Effect of post deformation annealing on the microstructure and mechanical properties of cold rolled AISI 321 austenitic stainless steel. Mater. Sci. Eng. A 2018, 736, 364–374. [Google Scholar] [CrossRef]

- Sun, G.; Du, L.; Hu, J.; Zhang, B.; Misra, R.D.K. On the influence of deformation mechanism during cold and warm rolling on annealing behavior of a 304 stainless steel. Mater. Sci. Eng. A 2019, 746, 341–355. [Google Scholar] [CrossRef]

- Fonseca, I.; Benito, J.; Mejía, I.; Jorba, J.; Roca, A. Variación del módulo de Young en el acero C45E (norma EN 10083) tratado térmicamente. Rev. De Met. 2002, 38, 249–255. [Google Scholar] [CrossRef] [Green Version]

- Pérez, R.; Benito, J.; Prado, J.M. Study of the Inelastic Response of TRIP Steels after Plastic Deformation. ISIJ Int. 2005, 45, 1925–1933. [Google Scholar] [CrossRef] [Green Version]

- Mejía, I.; Maldonado, C.; Benito, J.A.; Jorba-Peiro, J.; Vallmajor, A.R. Determination of the Work Hardening Exponent by the Hollomon and Differential Crussard-Jaoul Analyses of Cold Drawn Ferrite-Pearlite Steels. Mater. Sci. Forum 2006, 509, 37–42. [Google Scholar] [CrossRef]

- Yamada, Y.; Kuwabara, T. Materials for Springs; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Kizu, T.; Okuda, K.; Nagataki, Y.; Urabe, T.; Seto, K. Influence of Tensile Strain on Young’s Modulus in High-strength Cold-rolled Steel Sheets. ISIJ Int. 2015, 55, 1502–1511. [Google Scholar] [CrossRef] [Green Version]

| C | Mn | P | S | Si | Cr | Ni | Mo | N | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.023 | 2.55 | 0.026 | 0.006 | 0.45 | 22.62 | 5.92 | 3.02 | 0.158 | Bal. |

| Samples | Hardness, H (GPa) | Elastic modulus, E (GPa) | ||||

|---|---|---|---|---|---|---|

| α | α/γ Interphase | γ | α | α/γ Interphase | γ | |

| HR | 3.6 ± 0.2 | 3.8 ± 0.1 | 3.9 ± 0.2 | 213 ± 8 | 201 ± 8 | 190 ± 10 |

| CR | 4.9 ± 0.2 | 5.2 ± 0.2 | 5.6 ± 0.2 | 240 ± 8 | 220 ± 10 | 208 ± 15 |

| FP | 3.7 ± 0.2 | 3.9 ± 0.2 | 4.2 ± 0.2 | 215 ± 10 | 202 ± 7 | 190 ± 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Besharatloo, H.; Carpio, M.; Cabrera, J.-M.; Mateo, A.M.; Fargas, G.; Wheeler, J.M.; Roa, J.J.; Llanes, L. Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel. Metals 2020, 10, 1352. https://doi.org/10.3390/met10101352

Besharatloo H, Carpio M, Cabrera J-M, Mateo AM, Fargas G, Wheeler JM, Roa JJ, Llanes L. Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel. Metals. 2020; 10(10):1352. https://doi.org/10.3390/met10101352

Chicago/Turabian StyleBesharatloo, Hossein, Marcel Carpio, José-María Cabrera, Antonio Manuel Mateo, Gemma Fargas, Jeffrey Martin Wheeler, Joan Josep Roa, and Luis Llanes. 2020. "Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel" Metals 10, no. 10: 1352. https://doi.org/10.3390/met10101352

APA StyleBesharatloo, H., Carpio, M., Cabrera, J.-M., Mateo, A. M., Fargas, G., Wheeler, J. M., Roa, J. J., & Llanes, L. (2020). Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel. Metals, 10(10), 1352. https://doi.org/10.3390/met10101352