Recent Advances in the Laser Forming Process: A Review

Abstract

:1. Introduction

2. Laser Bending of Monolithic Sheets

3. Laser Bending of Bi-Layer and Tailored Blanks

4. Laser Forming of Composite Sheets

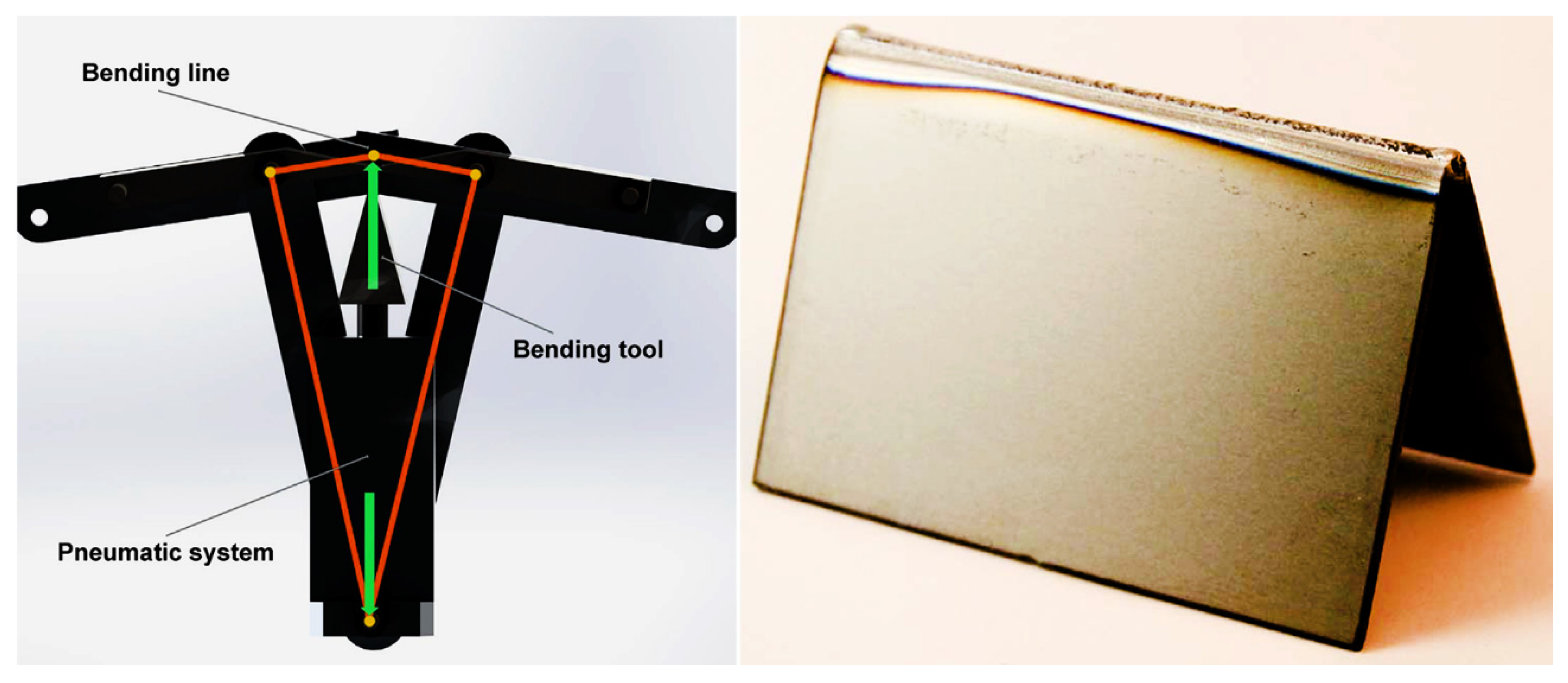

5. Force Assisted Laser Bending

6. Laser Tube Bending

7. Optimization

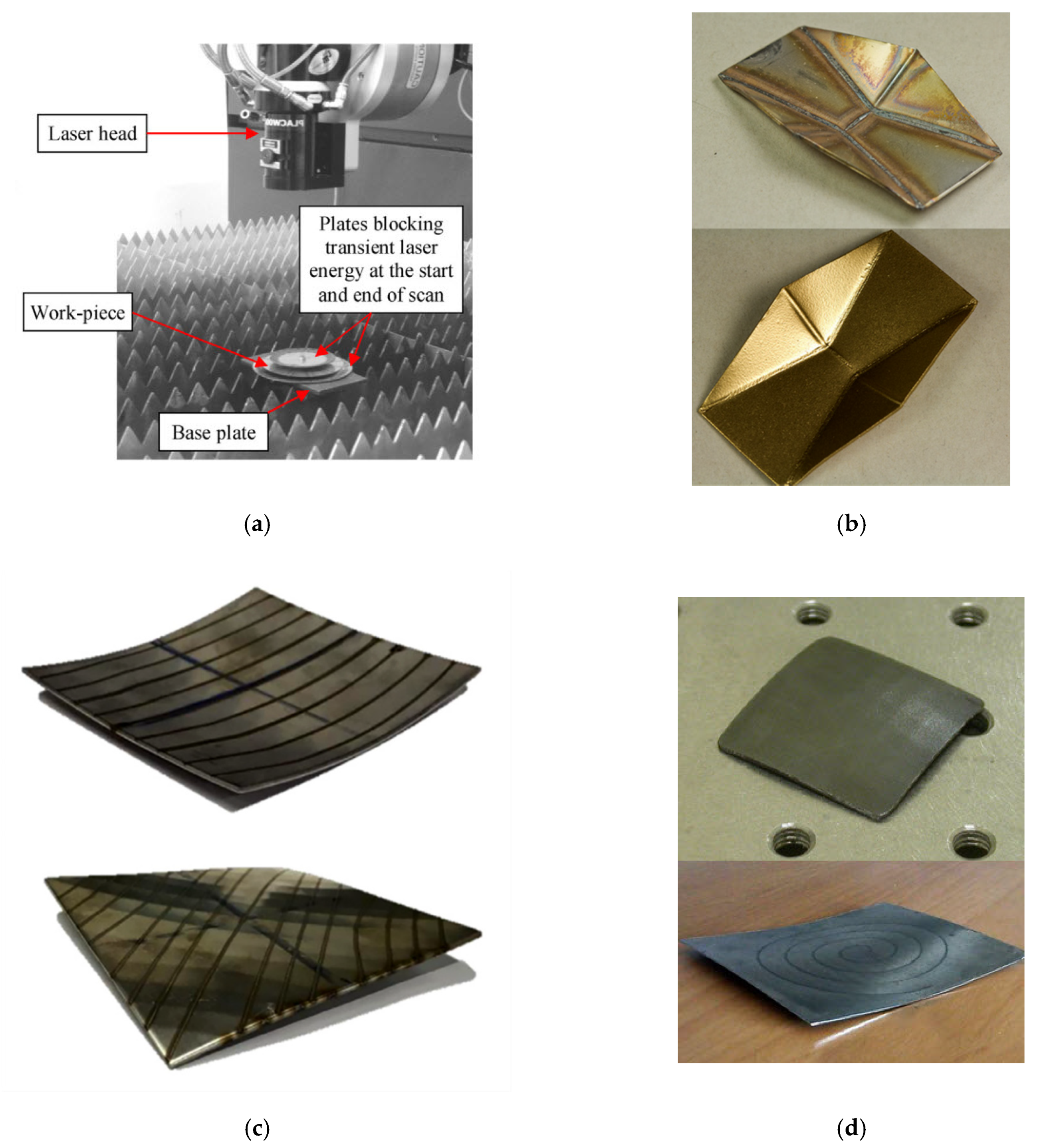

8. Doubly Curved Parts

9. Analytical Approaches

10. Other Applications of Laser Beam Technology

11. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dixit, U.S.; Joshi, S.N.; Kant, R. Laser forming systems: A review. Int. J. Mechatr. Manuf. Sys. 2015, 8, 160–205. [Google Scholar] [CrossRef]

- Das, B.; Biswas, P. A review of plate forming by line heating. J. Ship. Prod. Des. 2018, 34, 155–167. [Google Scholar] [CrossRef]

- Kant, R.; Bhuyan, P.M.; Joshi, S.N. Experimental Studies on TGM and BM Dominated Curvilinear Laser Bending of Aluminum Alloy Sheets. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi, S., Dixit, U., Eds.; Springer: New Delhi, India, 2015; pp. 69–91. [Google Scholar] [CrossRef]

- Roohi, A.H.; Moslemi Naeini, H.; Hoseinpour Gollo, M.; Shahbazi Karami, J.; Imani Shahabad, S. Effects of temperature gradient magnitude on bending angle in laser forming process of aluminium alloy sheets. J. Comput. Appl. Res. Mech. Eng. 2016, 5, 97–109. [Google Scholar] [CrossRef]

- Xu, L.; Li, W.; Wang, X.; Wan, M.; Jiang, M. Plastic deformation behavior in laser bending of elastic preloaded metal plate. Inte. J. Adv. Manuf. Tech. 2017, 90, 3397–3406. [Google Scholar] [CrossRef]

- Rattan, A.; Jasra, Y.; Saxena, R.K. Prediction of bending behavior for laser forming of lime coated plain carbon steel using finite element method. Materials today: Proc. 2020, 28, 1943–1950. [Google Scholar] [CrossRef]

- Abedi, H.R.; Hoseinpour Gollo, M. An experimental study of the effects of surface roughness and coating of Cr2O3 layer on the laser-forming process. Opt. Laser Technol. 2019, 109, 336–347. [Google Scholar] [CrossRef]

- Fidder, H.; Admiraal, J.P.J.; Ocelík, V.; De Hosson, J.T.M. In situ digital image correlation observations of laser forming. Metals 2020, 10, 17. [Google Scholar] [CrossRef] [Green Version]

- Gautam, S.S.; Singh, S.K.; Dixit, U.S. Laser Forming of Mild Steel Sheets Using Different Surface Coatings. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi, S., Dixit, U., Eds.; Springer: New Delhi, India, 2015; pp. 17–39. [Google Scholar] [CrossRef]

- Fetene, B.N.; Dixit, U.S.; Liao, H. Laser bending of friction stir processed and cement-coated sheets. Mater. Manuf. Process. 2017, 32, 1628–1634. [Google Scholar] [CrossRef]

- Maji, K.; Pratihar, D.K.; Nath, A.K. Numerical and Experimental Studies on Pulsed Laser Forming of Sheet Metal. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi, S., Dixit, U., Eds.; Springer: New Delhi, India, 2015; pp. 55–67. [Google Scholar] [CrossRef]

- Kristiansen, E.; Kristiansen, M.; Endelt, B.; Thomsen, A.N. Investigation of the profile of laser bends with variable scan distance. Proc. Manuf. 2019, 36, 192–199. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, W.; Qiao, Y.; Zhang, C. Edge effect investigation of DP980 steel sheet in multiple laser scanning process. Int. J. Precis. Eng. Manuf. 2019, 20, 319–326. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Kim, J.; Song, J.H.; Lee, G.A.; Lee, H.J.; Lee, N.K. FEM analysis for laser bending process of DP980 steel sheet. Int. J. Precis. Eng. Manuf. 2015, 16, 315–321. [Google Scholar] [CrossRef]

- Maji, K.; Pratihar, D.K.; Nath, A.K. Experimental investigations, modeling, and optimization of multi-scan laser forming of AISI 304 stainless steel sheet. Int. J. Adv. Manuf. Technol. 2016, 83, 1441–1455. [Google Scholar] [CrossRef]

- Song, J.H.; Lee, G.A.; Jung, K.H.; Park, S.J. Laser irradiated bending characteristics of the ultra-high strength steel sheets. Int. J. Automot. Techn. 2015, 16, 89–96. [Google Scholar] [CrossRef]

- Dixit, U.S.; Fetene, B.N. A finite element modelling of laser bending of friction stir welded aluminium 5052-H32 sheets. Int. J. Mechatr. Manuf. Sys. 2016, 9, 215–236. [Google Scholar] [CrossRef]

- Fetene, B.N.; Kumar, V.; Dixit, U.S.; Echempati, R. Numerical and experimental study on multi-pass laser bending of AH36 steel strips. Opt. Laser Technol. 2018, 99, 291–300. [Google Scholar] [CrossRef]

- Mjali, K.V.; Els-Botes, A.; Mashinini, P.M. The Effects of Laser and Mechanical Forming on the Hardness and Microstructural Layout of Commercially Pure Grade 2 Titanium Alloy Plates. In Volume 2: Additive Manufacturing; Materials, Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; Paper No: MSEC2017-2603; p. V002T03A009. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-bstract/MSEC2017/50732/V002T03A009/269465 (accessed on 3 November 2020). [CrossRef]

- Akinlabi, S.; Mashinini, M.; Akinlabi, E. Effect of Temperature on the Evolved Microstructure During Laser Beam Forming of Sheet Steels. In Volume 2: Advanced Manufacturing; Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; Paper No: IMECE2017-72044; p. V002T02A069. Available online: https://asmedigitalcollection.asme.org/IMECE/proceedings-abstract/IMECE2017/58356/V002T02A069/265599 (accessed on 3 November 2020). [CrossRef]

- Mjali, K.V.; Els-Botes, A.; Mashinini, P.M. Residual stress distribution and the concept of total fatigue stress in laser and mechanically formed commercially pure grade 2 titanium alloy plates. ASME. J. Manuf. Sci. Eng. 2018, 140, 061005–061014. [Google Scholar] [CrossRef]

- Kant, R.; Joshi, S.N. Thermo-mechanical studies on bending mechanism, bend angle and edge effect during multi-scan laser bending of magnesium M1A alloy sheets. J. Manuf. Process. 2016, 23, 135–148. [Google Scholar] [CrossRef]

- Kotobi, M.; Honarpisheh, M. Experimental and numerical investigation of through-thickness residual stress of laser-bent Ti samples. J. Strain Anal. Eng. 2017, 52, 347–355. [Google Scholar] [CrossRef]

- Paramasivan, K.; Das, S.; Marimuthu, S.; Misra, D. Increment in laser bending angle by forced bottom cooling. Int. J. Adv. Manuf. Technol. 2018, 94, 2137–2147. [Google Scholar] [CrossRef]

- Kant, R.; Joshi, S.N. A Numerical Investigation into the Effect of Forced Convection Cooling on the Performance of Multi-scan Laser Bending Process. In Application of Lasers in Manufacturing, Proceeding of the 6th International and the 27th All India Manufacturing Technology, Design and Research (AIMTDR 2016) conference, Pune, India, 16–18 December 2016; Dixit, U., Joshi, S., Davim, J., Eds.; Springer: Singapore, 2019; pp. 21–43. [Google Scholar] [CrossRef]

- Fetene, B.N.; Dixit, U.S. Finite Element Simulations of Laser Bending of Small Sized Sheets. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; Joshi, S., Dixit, U., Eds.; Springer: New Delhi, India, 2015; pp. 41–53. [Google Scholar] [CrossRef]

- Safari, M.; Ebrahimi, M. Numerical investigation of laser bending of perforated sheets. J. Adv. Des. Manuf. Technol. 2016, 9, 53–60. [Google Scholar]

- Lambiase, F.; Di Ilio, A.; Paoletti, A. Productivity in multi-pass laser forming of thin AISI 304 stainless steel sheets. Int. J. Adv. Manuf. Technol. 2016, 86, 259–268. [Google Scholar] [CrossRef]

- Safari, M.; Mostaan, H.; Farzin, M. Laser bending of tailor machined blanks: Effect of start point of scan path and irradiation direction relation to step of the blank. Alex. Eng. J. 2016, 55, 1587–1594. [Google Scholar] [CrossRef] [Green Version]

- Safari, M.; Joudaki, J. Prediction of bending angle for laser forming of tailor machined blanks by neural network. Iranian J. Mater. Form. 2018, 5, 47–57. [Google Scholar] [CrossRef]

- Seyedkashi, S.M.H.; Abazari, H.D.; Gollo, M.H.; Woo, Y.Y.; Moon, Y.H. Characterization of laser bending of SUS304L/C11000 clad sheets. J. Mech. Sci. Technol. 2019, 33, 3223–3230. [Google Scholar] [CrossRef]

- Kotobi, M.; Honarpisheh, M. Through-depth residual stress measurement of laser bent steel–titanium bimetal sheets. J. Strain Anal. Eng. 2018, 53, 130–140. [Google Scholar] [CrossRef]

- Kotobi, M.; Mansouri, H.; Honarpisheh, M. Investigation of laser bending parameters on the residual stress and bending angle of St-Ti bimetal using FEM and neural network. Opt. Laser Technol. 2019, 116, 265–275. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Luo, Y. Numerical simulation of stainless steel-carbon steel laminated plate considering interface in pulsed laser bending. Materials 2019, 12, 1410. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Wang, X. Analytical model for estimating bending angle in laser bending of 304 stainless steel/Q235 carbon steel laminated plate. J. Laser Appl. 2019, 31, 042012-1–042012-12. [Google Scholar] [CrossRef]

- Wang, X.; Ma, X.; Li, Z.; Wang, R. A study of thickening phenomenon in laser bending zone of a metal laminated plate. Proc. CIRP. 2016, 42, 454–459. [Google Scholar] [CrossRef]

- D’ Souza, A.; Palani, I.A.; Naikwad, S.; Padmanabhan, R.; Shanmugam, S.; Natu, H. Parametric Investigation in Laser Forming of 8 mm FE-410 Plate Using High Power CO2 Laser and Its Bend Angle Prediction. Mater. Today Proc. 2015, 2, 2013–2021. [Google Scholar] [CrossRef]

- Seyedkashi, S.M.H.; Hoseinpour Gollo, M.; Biao, J.; Moon, Y.H. Laser bendability of SUS430/C11000/SUS430 laminated composite and its constituent layers. Met. Mater. Int. 2016, 22, 527–534. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X. Numerical simulation of warping deformation on metal composite plate during laser bending. J. Inf. Laser Eng. 2018, 47, 506004–0506010. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, W.; Gau, J.T.; Shen, Z.; Ma, Y.; Zhang, G.; Wang, X. Feature size effect on formability of multilayer metal composite sheets under microscale laser flexible forming. Metals 2017, 7, 275. [Google Scholar] [CrossRef] [Green Version]

- Gisario, A.; Mehrpouya, M.; Rahimzadeh, A.; De Bartolomeis, A.; Barletta, M. Prediction model for determining the optimum operational parameters in laser forming of fiber-reinforced composites. Adv. Manuf. 2020, 8, 242–251. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M. Laser forming of glass laminate aluminium reinforced epoxy (GLARE): On the role of mechanical, physical and chemical interactions in the multi-layers material. Opt. Laser. Eng. 2018, 110, 364–376. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Y.; Yao, Z. Shape prediction for laser peen forming of fiber metal laminates by experimentally determined eigenstrain. J. Manuf. Sci. Eng. 2017, 139, 041004–041013. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Y.; Yao, Z. An Experiment-Based Model to Determine Eigenstrain in Fibre Metal Laminates Induced by Laser Peen Forming. In Volume 1: Processing, Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, USA, June 27–July 1 2016; Paper No: MSEC2016-8544; p. V001T02A027. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2016/49897/V001T02A027/268523 (accessed on 3 November 2020). [CrossRef]

- Gisario, A.; Mehrpouya, M.; Venettacci, S.; Barletta, M. Laser-assisted bending of titanium grade-2 sheets: Experimental analysis and numerical simulation. Opt. Laser. Eng. 2017, 92, 110–119. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S. Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys. Opt. Laser Technol. 2016, 86, 46–53. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. Laser-assisted bending of sharp angles with small fillet radius on stainless steel sheets: Analysis of experimental set-up and processing parameters. Laser. Manuf. Mater. Process. 2015, 2, 57–73. [Google Scholar] [CrossRef] [Green Version]

- Nowak, Z.; Nowak, M.; Widłaszewski, J.; Kurp, P. Experimental and Numerical Investigation on Laser-Assisted Bending of Pre-Loaded Metal Plate. In AIP Conference Proceedings Vol. 1922, Proceedings of the 22nd International Conference on Computer Methods in Mechanics, Lublin, Poland, 13–16 September 2017; AIP Publishing: New York, NY, USA; p. 140006. [CrossRef]

- Ponticelli, G.S.; Guarino, S.; Giannini, O. A fuzzy logic-based model in laser-assisted bending springback control. Int. J. Adv. Manuf. Technol. 2018, 95, 3887–3898. [Google Scholar] [CrossRef]

- Fetene, B.N.; Shufen, R.; Dixit, U.S. FEM-based neural network modeling of laser-assisted bending. Neural. Comput. Appl. 2018, 29, 69–82. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Sun, G.; Li, C. Study on reducing edge effects by using assistant force in laser forming. J. Mater. Process. Tech. 2016, 227, 169–177. [Google Scholar] [CrossRef]

- Dutta, P.P.; Kalita, K.; Dixit, U.S.; Liao, H. Magnetic-force-assisted straightening of bent mild steel strip by laser irradiation. Laser Manuf. Mater. Process. 2017, 4, 206–226. [Google Scholar] [CrossRef]

- Dutta, P.P.; Kalita, K.; Dixit, U.S. Electromagnetic-force-assisted bending and straightening of ah36 steel strip by laser irradiation. Laser Manuf. Mater. Process. 2018, 5, 201–221. [Google Scholar] [CrossRef]

- Safari, M. A study on the laser tube bending process: Effects of the irradiating length and the number of irradiating passes. Iranian J. Mater. Form. 2020, 7, 46–53. [Google Scholar] [CrossRef]

- Khandandel, S.E.; Seyedkashi, S.M.H.; Moradi, M. A novel path strategy design for precise 2D and 3D laser tube forming process; experimental and numerical investigation. Optik 2020, 206, 164302. [Google Scholar] [CrossRef]

- Li, F.; Liu, S.; Shi, A.; Shi, Q.; Li, Y. Research on laser thread form bending of stainless steel tube. Int. J. Precis. Eng. Manuf. 2019, 20, 893–903. [Google Scholar] [CrossRef]

- Imhan, K.I.; Baharudin, B.T.H.T.; Zakaria, A.; Ismail, M.I.S.B.; Alsabti, N.M.H.; Ahmad, A.K. Improve the material absorption of light and enhance the laser tube bending process utilizing laser softening heat treatment. Opt. Laser Technol. 2018, 99, 15–18. [Google Scholar] [CrossRef] [Green Version]

- Imhan, K.I.; Baharudin, B.T.H.T.; Zakaria, A.; Ismail, M.I.S.B.; Alsabti, N.M.H.; Ahmad, A.K. Investigation of material specifications changes during laser tube bending and its influence on the modification and optimization of analytical modeling. Opt. Laser Technol. 2017, 95, 151–156. [Google Scholar] [CrossRef]

- Che Jamil, M.S.; Imam Fauzi, E.R.; Juinn, C.S.; Sheikh, M.A. Laser bending of pre-stressed thin-walled nickel micro-tubes. Opt. Laser Technol. 2015, 73, 105–117. [Google Scholar] [CrossRef]

- Keshtiara, M.; Golabi, S.; Tarkesh Esfahani, R. Multi-objective optimization of stainless steel 304 tube laser forming process using GA. Eng. Comput. 2019, 1–17. [Google Scholar] [CrossRef]

- Folkersma, G.; Brouwer, D.; Römer, G. Microtube laser forming for precision component alignment. ASME. J. Manuf. Sci. Eng. 2016, 138, 081012-1–081012-6. [Google Scholar] [CrossRef]

- Kumar, V.; Dixit, U.S. Selection of process parameters in a single-pass laser bending process. Eng. Optimiz. 2018, 50, 1609–1624. [Google Scholar] [CrossRef]

- Lambiase, F.; Di Ilio, A.; Paoletti, A. Optimization of multi-pass laser bending by means of soft computing techniques. Proc. CIRP 2015, 33, 502–507. [Google Scholar] [CrossRef] [Green Version]

- Omidvar, M.; Kashiry Fard, R.; Sohrabpoor, H.; Teimouri, R. Selection of laser bending process parameters for maximal deformation angle through neural network and teaching–learning-based optimization algorithm. Soft. Comput. 2015, 19, 609–620. [Google Scholar] [CrossRef]

- Kant, R.; Joshi, S.N.; Dixit, U.S. An integrated FEM-ANN model for laser bending process with inverse estimation of absorptivity. Mech. Adv. Mater. Mod. Process. 2015, 1, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Shen, H.; Zheng, Y.; Wang, H.; Yao, Z. Heating position planning in laser forming of single curved shapes based on probability convergence. ASME. J. Manuf. Sci. Eng. 2016, 138, 091003-1–091003-7. [Google Scholar] [CrossRef]

- Nejati, M.R.; Gollo, M.H.; Tajdari, M.; Ghaffarian, H. Input value prediction of parameters in laser bending using fuzzy and PSO. Soft. Comput. 2018, 22, 2189–2203. [Google Scholar] [CrossRef]

- Maji, K.; Chakraborty, S.S.; Pratihar, D.K.; Nath, A.K. Inverse analysis and multi-objective optimization of coupling mechanism based laser forming process. Sadhana Acad. P. Eng. S. 2020, 45, 8. [Google Scholar] [CrossRef]

- Boonpuang, R.; Mongkolwongroj, M.; Sakulkalavek, A.; Sakdanuphab, R. Empirical modeling and optimization of laser bending process parameters using the central composite design method for HDD slider PSA/RSA adjustment. Laser Manuf. Mater. Process. 2020, 7, 290–304. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Guarino, S.; Giannini, O.; Tagliaferri, F.; Venettacci, S.; Ucciardello, N.; Baiocco, G. Springback control in laser-assisted bending manufacturing process by using a fuzzy uncertain model. Proc. CIRP 2020, 88, 491–496. [Google Scholar] [CrossRef]

- Behera, A.; Sahu, P.S.; Patel, S.K. Application of Taguchi methodology for optimization of process parameters in laser bending of Al sheet. Mater. Today Proc. 2020, 26, 2323–2327. [Google Scholar] [CrossRef]

- Cook, F.; Celentano, D.; Ramos-Grez, J. Experimental-numerical methodology for the manufacturing of cranial prosthesis via laser forming. Int. J. Adv. Manuf. Technol. 2016, 86, 2187–2196. [Google Scholar] [CrossRef]

- Gisario, A.; Mehrpouya, M.; Venettacci, S.; Mohammadzadeh, A.; Barletta, M. Laser Origami (LO) of three-dimensional (3D) components: Experimental analysis and numerical modelling. J. Manuf. Process. 2016, 23, 242–248. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Huang, H.; Venettacci, S.; Gisario, A. Laser Origami (LO) of three-dimensional (3D) components: Experimental analysis and numerical modeling-part II. J. Manuf. Process. 2019, 39, 192–199. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. Progress in tridimensional (3d) laser forming of stainless steel sheets. Laser Manuf. Mater. Process. 2015, 2, 148–163. [Google Scholar] [CrossRef] [Green Version]

- Safari, M.; Alves de Sousa, R.; Joudaki, J. Fabrication of saddle-shaped surfaces by a laser forming process: An experimental and statistical investigation. Metals 2020, 10, 883. [Google Scholar] [CrossRef]

- Safari, M.; Farzin, M. A new method for production of double-curvature dome-shaped part: Statistical analysis of the effects of process parameters on the radius of curvature of obtained dome shape. J. Ship. Prod. Des. 2018, 34, 85–93. [Google Scholar] [CrossRef]

- Safari, M.; Farzin, M.; Mostaan, H. A novel method for laser forming of two-step bending of a dome shaped part. Iranian J. Mater. Form. 2017, 4, 1–14. [Google Scholar] [CrossRef]

- Safari, M. A novel and comprehensive method for laser forming of cylindrical surfaces with arbitrary radius of curvature. Modares Mech. Eng. 2016, 15, 9–16. [Google Scholar]

- Safari, M.; Farzin, M. Experimental investigation of laser forming of a saddle shape with spiral irradiating scheme. Opt. Laser Technol. 2015, 66, 146–150. [Google Scholar] [CrossRef]

- Safari, M. Experimental and numerical investigation of laser forming of a doubly curved saddle shape with spiral irradiating scheme. J. Adv. Manuf. Technol. 2015, 9, 51–60. [Google Scholar]

- Safari, M.; Farzin, M. A study on laser bending of tailor machined blanks with various irradiating schemes. J. Mater. Process. Technol. 2014, 214, 112–122. [Google Scholar] [CrossRef]

- Safari, M.; Farzin, M.; Ghaei, A. Investigation into the effects of process parameters on bending angle in the laser bending of tailor machined blanks based on a statistical analysis. J. Laser Appl. 2013, 25, 052001-1–052001-10. [Google Scholar] [CrossRef]

- Safari, M.; Mostaan, H. Experimental and numerical investigation of laser forming of cylindrical surfaces with arbitrary radius of curvature. Alex. Eng. J. 2016, 55, 1941–1949. [Google Scholar] [CrossRef] [Green Version]

- Dehghan, S.H.; Loh-Mousavi, M.; Farzin, M.; Safari, M. Laser forming of metallic dome-shaped parts using spiral and radial-circular scan paths. J. Adv. Manuf. Technol. 2016, 10, 29–44. [Google Scholar]

- Hoseinpour Gollo, M.; Nadi, G.; Mehdi, M.; Abbaszadeh, M. Experimental and numerical study of spiral scan paths on cap laser forming. J. Laser Appl. 2015, 27, 012002-1–012002-9. [Google Scholar] [CrossRef]

- Abolhasani, D.; Seyedkashi, S.M.H.; Hoseinpour Gollo, M.; Moon, Y.H. Effects of laser beam parameters on bendability and microstructure of stainless steel in three-dimensional laser forming. Appl. Sci. 2019, 9, 4463. [Google Scholar] [CrossRef] [Green Version]

- Kant, R.; Bhuyan, P.M.; Joshi, S.N. Experimental Studies on Curvilinear Laser Bending of Thin Sheets. Proceedings of the International Conference on Advanced Technologies for Societal Applications (Techno-Societal 2016), Pandharpur, India, 20–21 December 2016; Pawar, P., Ronge, B., Balasubramaniam, R., Seshabhattar, S., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Navarrete, Á.; Celentano, D. Effect of workpiece geometry using circular scan patterns in sheet laser forming processes. Int. J. Adv. Manuf. Technol. 2018, 96, 1835–1846. [Google Scholar] [CrossRef]

- Navarrete, Á.; Cook, F.; Celentano, D.; Cruchaga, M.; García-Herrera, C. Numerical simulation and experimental validation of sheet laser forming processes using general scanning paths. Materials 2018, 11, 1262. [Google Scholar] [CrossRef] [Green Version]

- Abolhasani, D.; Seyedkashi, S.M.H.; Kim, Y.T.; Hoseinpour Gollo, M.; Moon, Y.H. A double raster laser scanning strategy for rapid die-less bending of 3D shape. J. Mater. Res. Technol. 2019, 8, 4741–4756. [Google Scholar] [CrossRef]

- Chakraborty, S.S.; Racherla, V.; Nath, A.K. Thermo-mechanical finite element study on deformation mechanics during radial scan line laser forming of a bowl shaped surface out of a thin sheet. J. Manuf. Process. 2018, 31, 593–604. [Google Scholar] [CrossRef]

- Liu, C.; Yao, Y.L. FEM-based process design for laser forming of doubly curved shapes. J. Manuf. Process. 2005, 7, 109–121. [Google Scholar] [CrossRef]

- Na, S.J.; Kim, J.T. 3D laser forming strategies for sheet metal by geometrical information. Int. J. Mater. Form. 2008, 1, 1367–1370. [Google Scholar] [CrossRef]

- Kim, J.; Na, S.J. 3D laser-forming strategies for sheet metal by geometrical information. Opt. Laser Technol. 2009, 41, 843–852. [Google Scholar] [CrossRef]

- Gao, H.; Sheikholeslami, G.; Dearden, G.; Edwardson, S.P. Reverse analysis of scan strategies for controlled 3D laser forming of sheet metal. Proc. Eng. 2017, 183, 369–374. [Google Scholar] [CrossRef]

- Shahabad, S.I.; Naeini, H.M.; Roohi, A.H.; Soltanpour, M.; Tavakoli, A. Height prediction of dome-shaped products in laser forming process. Int. J. Adv. Manuf. Technol. 2017, 88, 2227–2236. [Google Scholar] [CrossRef]

- Shahabad, S.I.; Naeini, H.M.; Roohi, A.H.; Tavakoli, A.; Nasrollahzade, M. Experimental investigation of laser forming process to produce dome-shaped products. Int. J. Adv. Manuf. Technol. 2017, 90, 1051–1057. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, W.; Wang, H. Laser forming of doubly curved plates using minimum energy principle and comprehensive strain control. Int. J. Mech. Sci. 2018, 145, 42–52. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Zhou, W. Process modelling in laser forming of doubly-curved sheets from cylinder shapes. J. Manuf. Process. 2018, 35, 373–381. [Google Scholar] [CrossRef]

- Maji, K.; Pratihar, D.K.; Nath, A.K. Laser forming of a dome shaped surface: Experimental investigations, statistical analysis and neural network modeling. Opt. Laser Eng. 2014, 53, 31–42. [Google Scholar] [CrossRef]

- Liu, F.R.; Chan, K.C.; Tang, C.Y. Theoretical analysis of deformation behavior of aluminum matrix composites in laser forming. Mater. Sci. Eng. A 2005, 396, 172–180. [Google Scholar] [CrossRef]

- Eideh, A.; Dixit, U.S.; Echempati, R. A Simple Analytical Model of Laser Bending Process. In Lasers Based Manufacturing, Topics in Mining, Metallurgy and Materials Engineering. Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 1–15 December 2014; Joshi, S., Dixit, U., Eds.; Springer: New Delhi, India, 2015. [Google Scholar] [CrossRef]

- Mulay, S.; Paliwal, V.; Babu, N.R. Analytical model for prediction of bend angle in laser forming of sheets. Int. J. Adv. Manuf. Technol. 2020, 109, 699–715. [Google Scholar] [CrossRef]

- Kumar, V.; Dixit, U.S. Estimation of temperature-dependent yield strength and modulus of elasticity during laser bending. Measurement 2020, 154, 107515. [Google Scholar] [CrossRef]

- Kumar, V.; Dixit, U.S. A model for the estimation of hardness of laser bent strips. Opt. Laser Technol. 2018, 107, 491–499. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, Y.; Wang, X.; Sun, R.; Bing, Z. An analytical model of laser bending angle under preload. Int. J. Adv. Manuf. Technol. 2020, 108, 2569–2577. [Google Scholar] [CrossRef]

- Imam Fauzi, E.R.; Jamil, M.S.C.; Samad, Z.; Sheikh, M.A.; Najib, A.M. Influence of non-conventional beam profile on edge effects in laser forming of AISI 304 stainless steel plate. Int. J. Adv. Manuf. Technol. 2019, 104, 1593–1601. [Google Scholar] [CrossRef]

- Joudaki, J.; Sedighi, M. Effect of material’s behavior on residual stress distribution in elastic–plastic beam bending: An analytical solution. P. I. Mech. Eng. L-J. Mat. 2017, 231, 361–372. [Google Scholar] [CrossRef]

- Manouchehry nya, R.; Peirovi, S.; Alipour, R.; Farokhi Nejad, A. Finite element analysis of micro scale laser bending of a steel sheet metal subjected to short pulse shock wave. Proc. Manuf. 2015, 2, 397–401. [Google Scholar] [CrossRef]

- Bucher, T.; Cardenas, S.; Verma, R.; Li, W.; Lawrence Yao, Y. Laser forming of sandwich panels with metal foam cores. ASME. J. Manuf. Sci. Eng. 2018, 140, 111015-1–111015-12. [Google Scholar] [CrossRef] [Green Version]

- Roohi, A.H.; Moslemi Naeini, H.; Hoseinpour Gollo, M.; Soltanpour, M.; Bruschi, S.; Ghiotti, A. Forming of closed-cell aluminum foams under thermal loadings: Experimental investigation. Int. J. Adv. Manuf. Technol. 2018, 95, 3919–3928. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, C.; Huang, Y.; Zou, T. Bending processing and mechanism of laser forming pure aluminum metal foam. Int. J. Adv. Manuf. Technol. 2018, 94, 1849–1856. [Google Scholar] [CrossRef]

- Zhang, M.; Jun Chen, C.; Brandal, G.; Bian, D.; Lawrence Yao, Y. Experimental and numerical investigation of laser forming of closed-cell aluminum foam. ASME. J. Manuf. Sci. Eng. 2016, 138, 021006-1–021006-8. [Google Scholar] [CrossRef]

- Bucher, T.; Young, A.; Zhang, M.; Chen, C.J.; Lawrence Yao, Y. Thermally induced mechanical response of metal foam during laser forming. ASME. J. Manuf. Sci. Eng. 2018, 140, 041004-1–041004-12. [Google Scholar] [CrossRef] [Green Version]

- Bucher, T.; Young, A.; Zhang, M.; Chen, C.J.; Yao, L.Y. Bending Mechanism Analysis for Laser Forming of Metal Foam. In Volume 1: Processes. Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; Paper No: MSEC2017-3026; p. V001T02A060. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2017/50725/V001T02A060/268607 (accessed on 3 November 2020). [CrossRef]

- Mohammad Shahid, R.; Srinu, T.; Datta, S.; Saha, P. Investigating the Effect of Process Parameters and Scan Strategy During Laser Forming of Thin Open Celled Aluminium Foam. In Volume 4: Processes. Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, TX, USA, 18–22 June 2018; Paper No: MSEC2018-6591; p. V004T03A059. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2018/51388/V004T03A059/277111 (accessed on 3 November 2020). [CrossRef]

- Bucher, T.; Zhang, M.; Chen, C.J.; Verma, R.; Li, W.; Lawrence Yao, Y. Laser forming of metal foam sandwich panels: Effect of panel manufacturing method. ASME. J. Manuf. Sci. Eng. 2019, 141, 051006-1–051006-11. [Google Scholar] [CrossRef]

- Bucher, T.; Finn, C.; Verma, R.; Li, W.; Lawrence Yao, Y. 3D laser forming of metal foam sandwich panels. ASME. J. Manuf. Sci. Eng. 2020, 142, 081008-1–081008-11. [Google Scholar] [CrossRef]

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi, G. Analyses of effects of process parameters on laser bending of stiffened panels. Int. J. Precis. Eng. Manuf. 2018, 19, 593–604. [Google Scholar] [CrossRef]

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi, G. Laser forming of the panel with crossed reinforcing bars. Int. J. Precis. Eng. Manuf. 2017, 92, 3673–3692. [Google Scholar] [CrossRef]

- Fu, S.; Yang, L.; Zhang, H.; Wang, Y.; Chi, G.; Ding, Y. Numerical simulation of the twist deformation for the stiffened panel with laser forming. Int. J. Precis. Eng. Manuf. 2018, 19, 1569–1582. [Google Scholar] [CrossRef]

- Hu, Y.; Xie, Y.; Wu, D.; Yao, Z. Quantitative evaluation of specimen geometry effect on bending deformation of laser peen forming. Int. J. Mech. Sci. 2019, 150, 404–410. [Google Scholar] [CrossRef]

- Luo, M.; Hu, Y.; Qian, D.; Yao, Z. Numerical modeling and mechanism analysis of hybrid heating and shock process for laser-assisted laser peen forming. ASME. J. Manuf. Sci. Eng. 2018, 140, 111009-1–111009-10. [Google Scholar] [CrossRef]

- Sagisaka, Y.; Yamashita, K.; Ueta, H. Efficiency improvement of thin-sheet-metal bending by femtosecond laser peen forming. Proc. Manuf. 2018, 15, 1314–1321. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, M.; Yao, Z. Increasing the capability of laser peen forming to bend titanium alloy sheets with laser-assisted local heating. Mater. Design. 2016, 90, 364–372. [Google Scholar] [CrossRef]

- Hu, Y.; Zheng, X.; Wang, D.; Zhang, Z.; Xie, Y.; Yao, Z. Application of laser peen forming to bend fibre metal laminates by high dynamic loading. J. Mater. Process. Tech. 2015, 226, 32–39. [Google Scholar] [CrossRef]

- Peng, C.; Xiao, Y.; Wang, Y.; Guo, W. Effect of laser shock peening on bending fatigue performance of AISI 9310 steel spur gear. Opt. Laser Technol. 2017, 94, 15–24. [Google Scholar] [CrossRef]

- Shen, N.; Ding, H. Surface integrity analysis of laser peen micro-bending without protective coating. Proc. CIRP 2016, 45, 315–318. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.; Chen, Y.; Feng, Z.; Hou, W.; Fan, W.; Lin, X. A real-time method to detect the deformation behavior during laser solid forming of thin-wall structure. Metals 2020, 10, 508. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Li, C.; Ma, Y.; Shen, Z.; Sun, X.; Sha, C.; Gao, S.; Li, L.; Liu, H. An experimental study on micro clinching of metal foils with cutting by laser shock forming. Materials 2016, 9, 571. [Google Scholar] [CrossRef] [Green Version]

- Lazarus, N.; Smith, G.L. Laser folding in a roll-to-roll manufacturing process. Lasers Manuf. Mater. Process. 2018, 5, 237–247. [Google Scholar] [CrossRef]

- Chakraborty, S.S.; More, H.; Racherla, V.; Nath, A.K. Modification of bent angle of mechanically formed stainless steel sheets by laser forming. J. Mater. Process. Tech. 2015, 222, 128–141. [Google Scholar] [CrossRef]

- Thomsen, A.N.; Kristiansen, M.; Kristiansen, E.; Endelt, B. Online measurement of the surface during laser forming. Int. J. Adv. Manuf. Technol. 2020, 107, 1569–1579. [Google Scholar] [CrossRef]

| Reference | Material | Laser Specification | Blank Dimensions |

|---|---|---|---|

| Zhang et al. [13] | DP980 steel | 220 W laser; 2.5 mm spot diameter; 20 mm/min scan speed | 80 mm × 80 mm, 1.8 mm thickness |

| Zhang et al. [14] | DP980 steel | 750–1250 W laser; 5.2 mm spot diameter; 2–5 m/min scan speed | 100 mm × 50 mm, 1.4 mm thickness |

| Maji et al. [15] | AISI 304 stainless steel | 225–275 W laser; 0.5–0.75 mm spot diameter; 250–283 mm/s scan speed | 120 mm × 40 mm, 0.5 mm thickness |

| Song et al. [16] | Ultra-high strength steel sheet SPFC1180Y | 500–1000 W laser; 5 mm spot diameter; 2–10 m/min scan speed | 100 mm × 50 mm, 1.2 mm thickness |

| Fetene et al. [18] | AH36 (mild) steel | 500–700 W laser; 7.6–11.4 mm spot diameter; 800–1000 mm/min scan speed | 120 mm length, 20–40 mm width, 1–2 mm thickness |

| Mjali et al. [19,21] | Commercially pure grade 2 titanium alloy | 1500–3500 W laser; 12 mm spot diameter; 1.6–2.6 m/min scan speed | 200 mm × 50 mm, 3 mm thickness |

| Kant and Joshi [22] | Magnesium M1A alloy | 300–500 W laser; 3.87–7.74 mm spot diameter; 1–3 m/min scan speed | 70 mm × 40 mm, 1.9 mm thickness |

| Kotobi and Honarpisheh [23] | Commercially pure grade 2 titanium alloy | 1600 W laser; 3 mm spot diameter; 6 m/min scan speed | 70 mm × 40 mm, 0.6 mm thickness |

| Reference | Fabricated Shape | Irradiation Scheme | Material | Laser Specification | Blank Dimensions |

|---|---|---|---|---|---|

| Chakraborty et al. [92] | bowl-shaped surface | Radial scan | AISI 304 stainless steel | 350 W laser; 2.8 mm spot diameter; 0.45 mm/min scan speed | φ100 mm, 1 mm thickness |

| Liu and Yao [93] | pillow and saddle-shaped surfaces | Calculated paths | 1010 mild steel | 1000–1500 W laser; 6 mm spot diameter; 20–60 mm/s scan speed | 140 mm × 80 mm × 0.89 mm |

| Na and Kim [94] and Kim and Na [95] | saddle-shaped surface | Calculated paths | mild steel | 100 W laser; 2 mm spot diameter; 4–10 mm/s scan speed | 30 mm × 30 mm × 0.8 mm |

| Gao et al. [96] | ship hull shape | Calculated paths | S275 steel | 400–500 W laser; 3–5 mm spot diameter; 20–40 mm/s scan speed | 100 mm × 100 mm × 1.5 mm |

| Imani Shahabad et al. [97,98] | Dome-shaped surface | Spider scanning paths | AA 6061-T6 aluminum alloy | 2500–3000 W laser; 5–7 mm spot diameter; 60–100 mm/s scan speed | φ150 mm, 2 mm thickness |

| Shen et al. [99,100] | Pillow, warped and saddle shape | Computational scanning path | 304 stainless steel | 200 W laser; 1.7 mm spot diameter | 100 mm × 100 mm × 2 mm; 100 mm × 100 mm × 1 mm |

| Maji et al. [101] | Dome-shaped surface | Cross (axial and diagonal) scanning paths | AISI 304 stainless steel | 400–500 W laser; 2–3 mm spot diameter; 30–40 mm/s scan speed | 60 mm × 60 mm × 1 mm; 90 mm × 90 mm × 1 mm; 120 mm × 120 mm × 1 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safari, M.; Alves de Sousa, R.; Joudaki, J. Recent Advances in the Laser Forming Process: A Review. Metals 2020, 10, 1472. https://doi.org/10.3390/met10111472

Safari M, Alves de Sousa R, Joudaki J. Recent Advances in the Laser Forming Process: A Review. Metals. 2020; 10(11):1472. https://doi.org/10.3390/met10111472

Chicago/Turabian StyleSafari, Mehdi, Ricardo Alves de Sousa, and Jalal Joudaki. 2020. "Recent Advances in the Laser Forming Process: A Review" Metals 10, no. 11: 1472. https://doi.org/10.3390/met10111472

APA StyleSafari, M., Alves de Sousa, R., & Joudaki, J. (2020). Recent Advances in the Laser Forming Process: A Review. Metals, 10(11), 1472. https://doi.org/10.3390/met10111472