High-Frequency Heat Treatment of AISI 1045 Specimens and Current Calculations of the Induction Heating Coil Using Metal Phase Transformation Simulations

Abstract

:1. Introduction

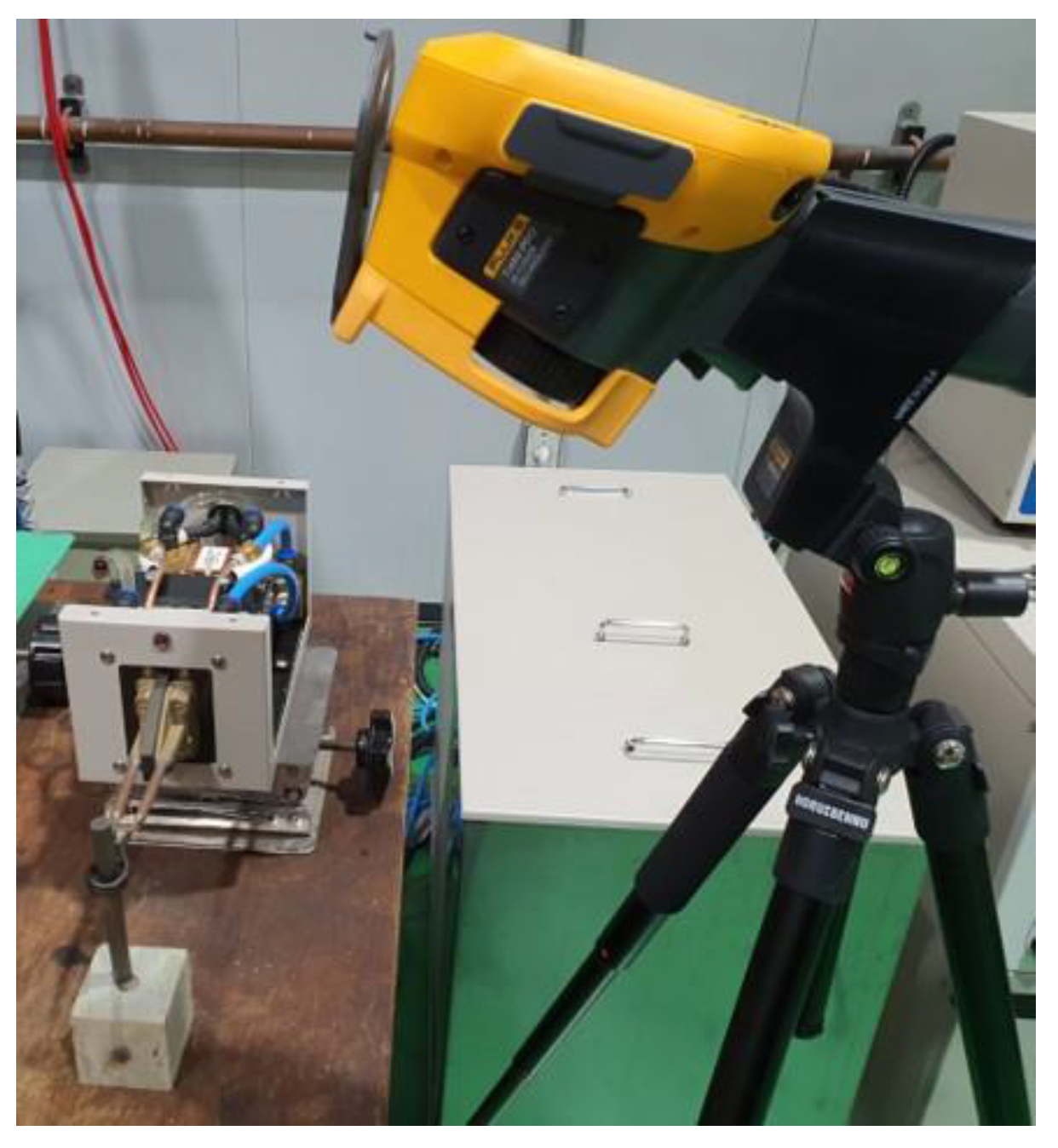

2. High-Frequency Induction Hardening Process of the AISI 1045 Specimen

2.1. High-Frequency Induction Hardening Procedure

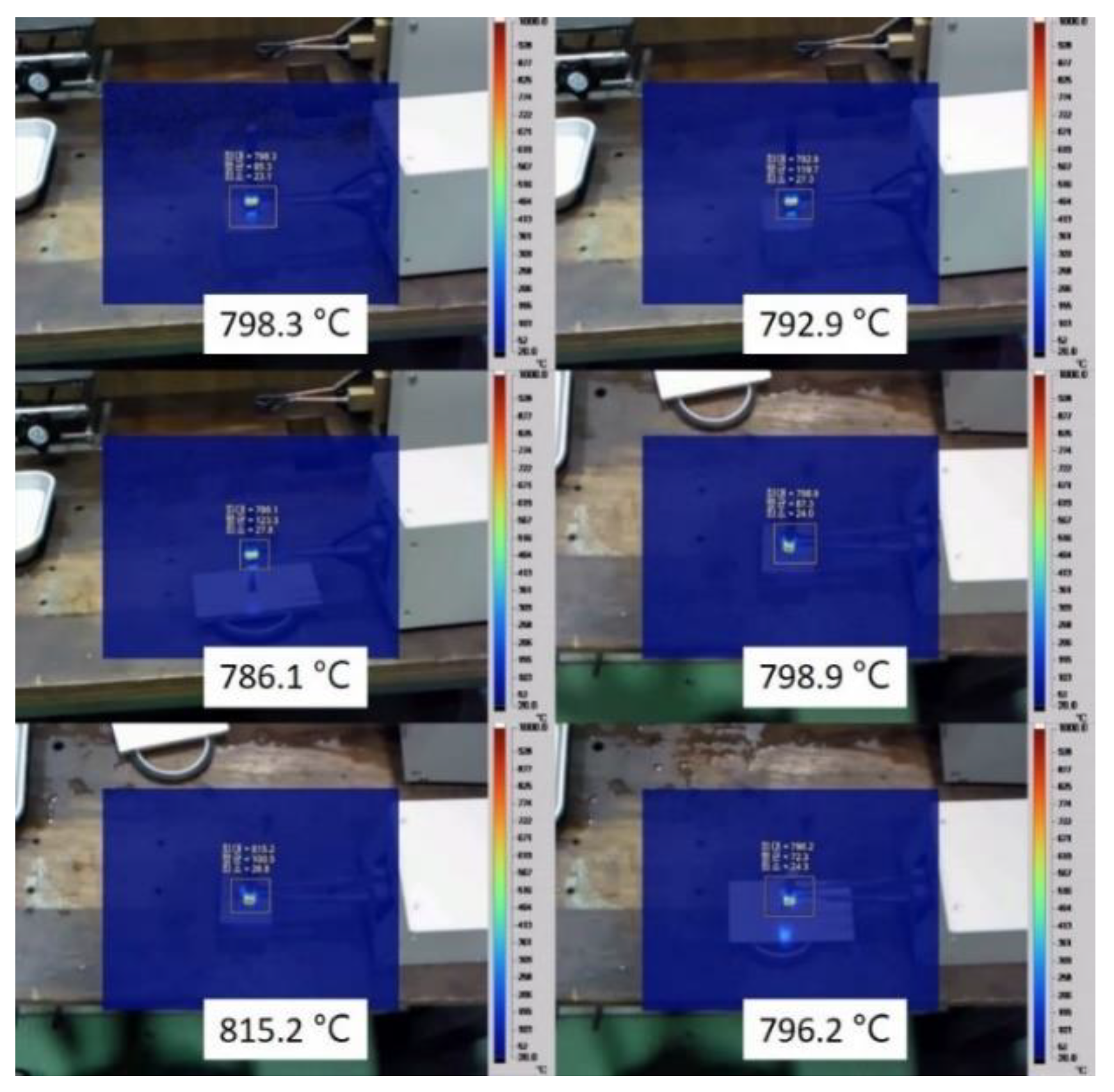

2.2. High-Frequency Induction Hardening Results

3. Calculation of Induction Coil Current

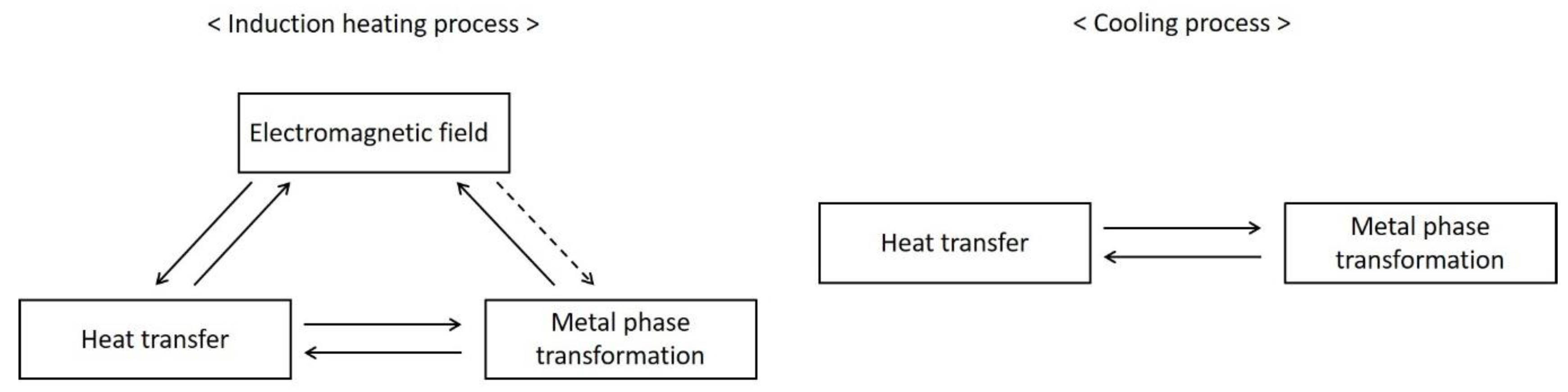

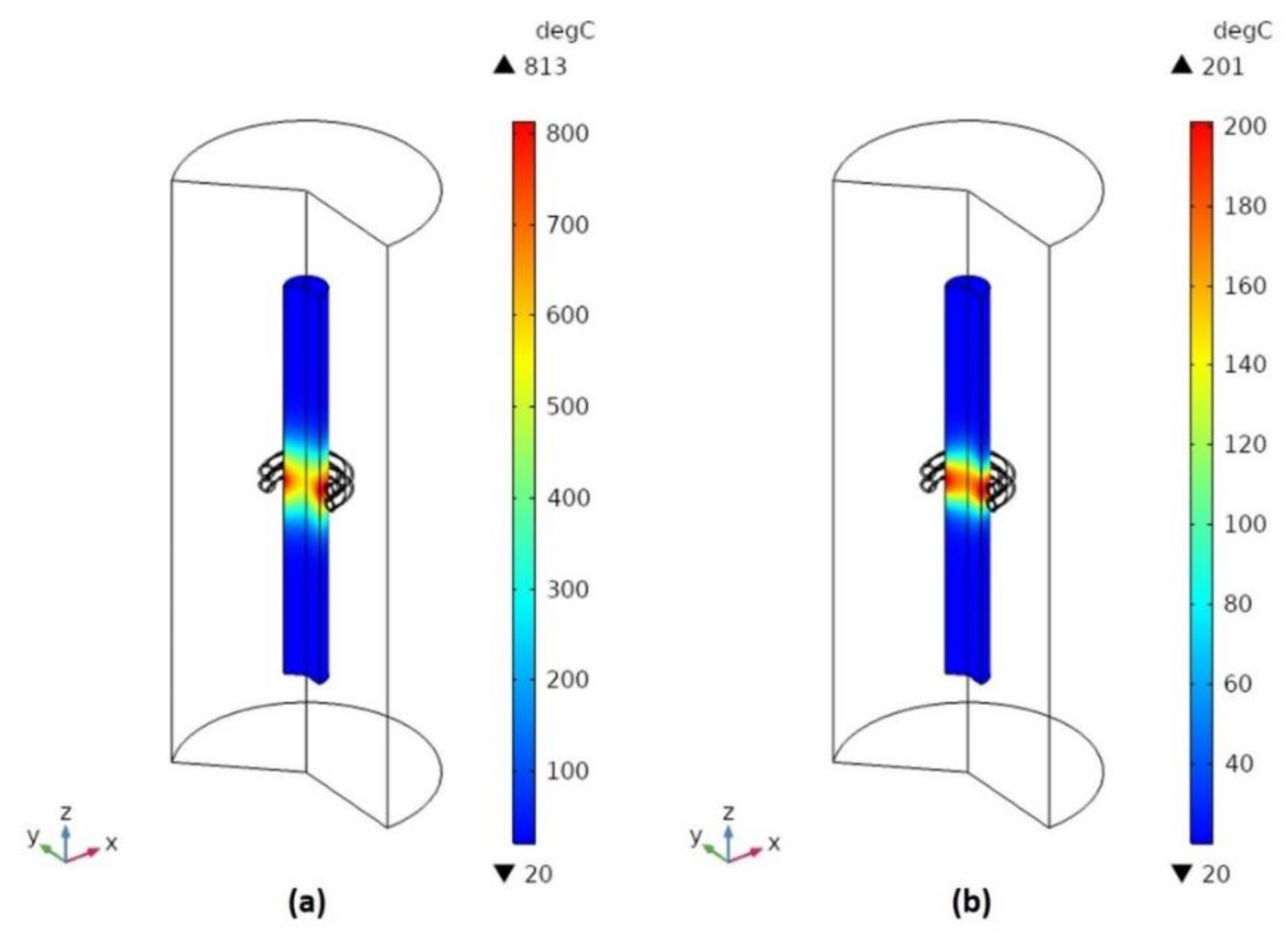

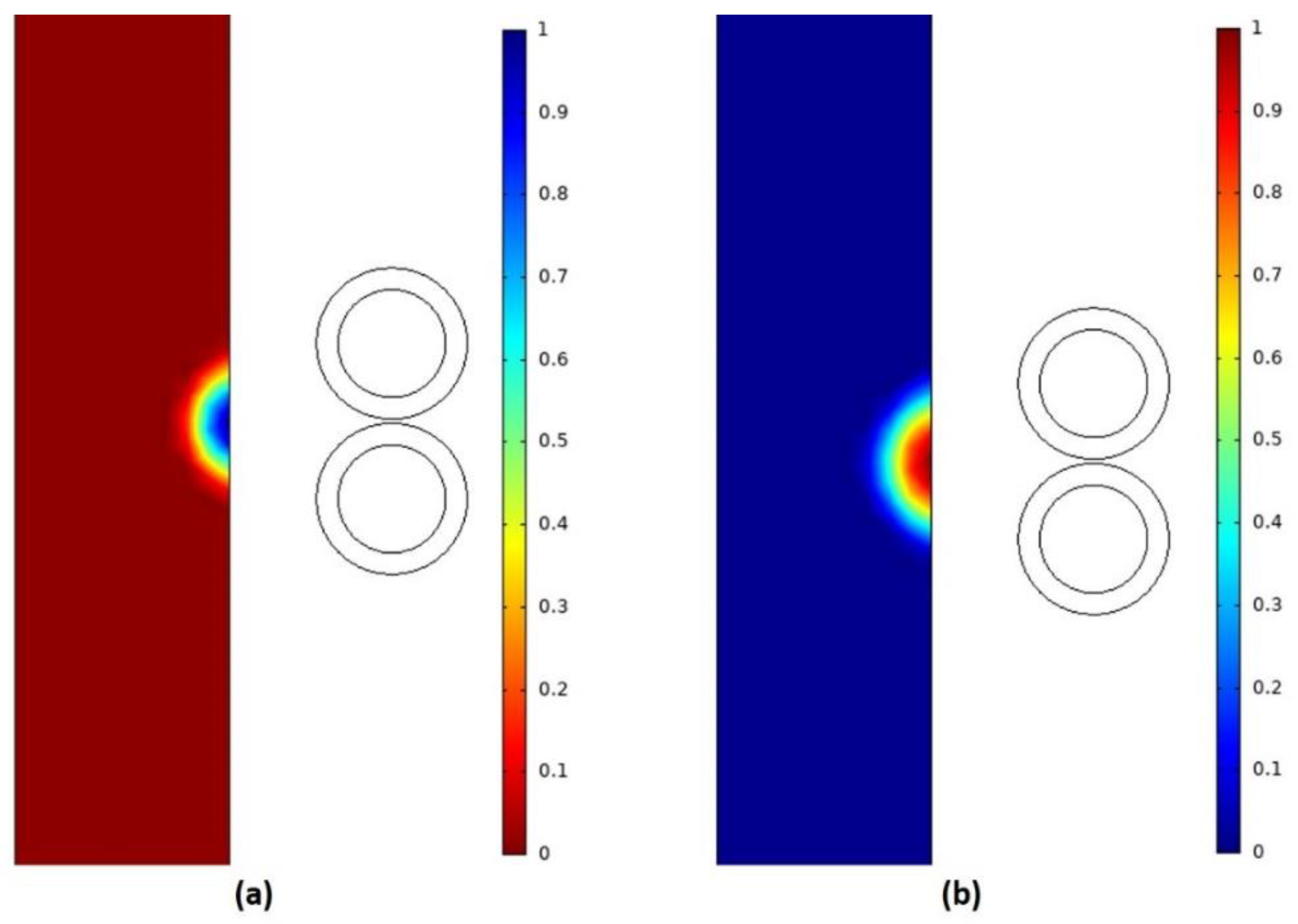

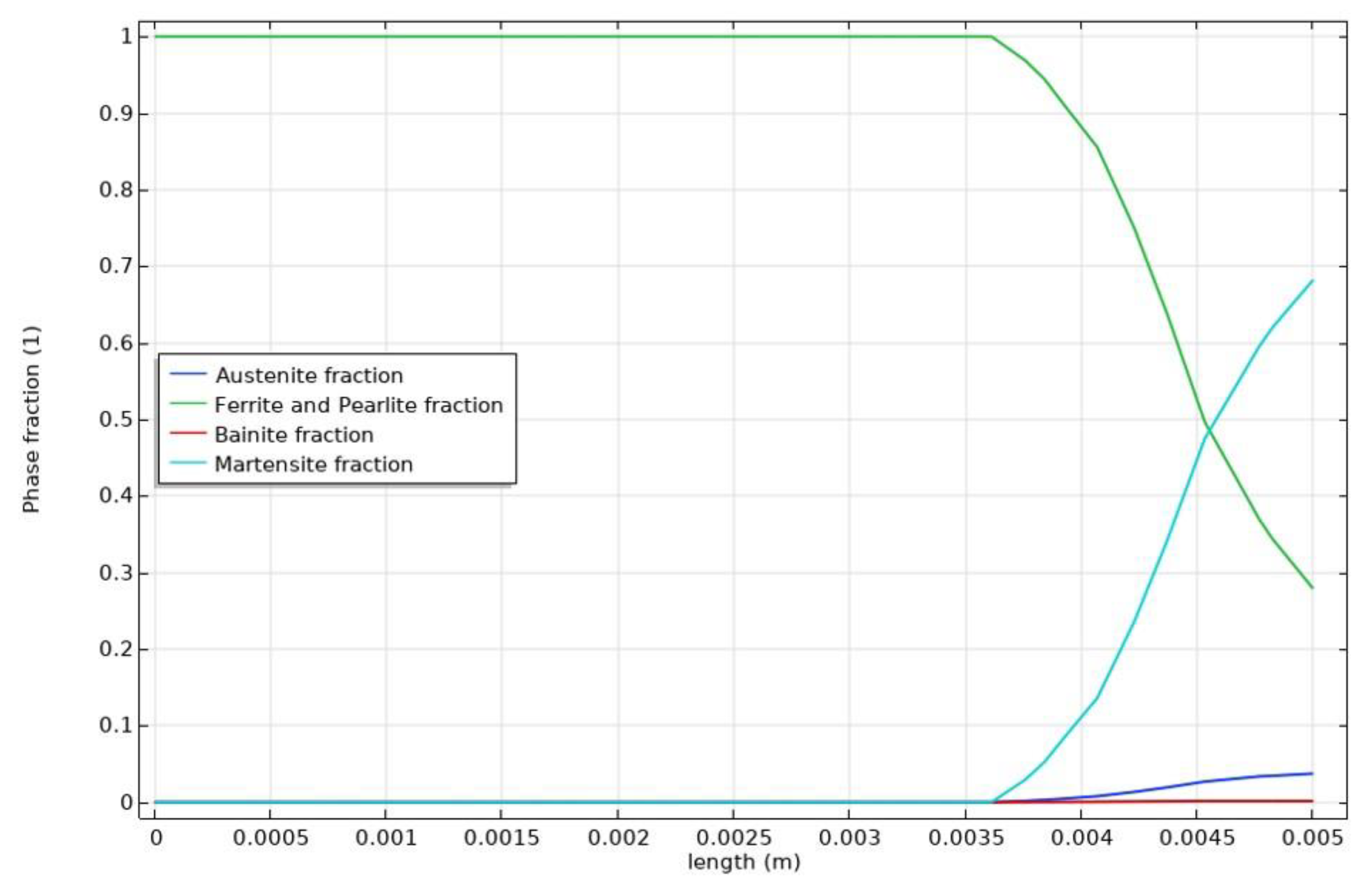

4. Simulations of the High-Frequency Induction Hardening Process

5. Comparative Verification of Experiment and Simulation Results

6. Conclusions

- After converting the high-frequency induction heating system to the RLC circuit, the AC current (708 A) flowing through the induction heating coil was calculated and simulated. The temperature of the induction heating experiment of the AISI 1045 specimens was 797.9 °C and the simulated temperature was 813 °C.

- To verify the hardening depth obtained by simulations, experiments were conducted, which produced the same 0.8 mm hardening depth.

- As a result of comparing the experiment and simulation, it was confirmed that the accuracy of the simulation is high. Phase transformation simulations were more intuitive and efficient than previous simulations which predicted the curing area using only the existing heating and cooling temperatures [7,8]. It is expected that the high-frequency heat treatment and the heating coil shape can be further optimized through high-frequency heat treatment considering metal phase transformation simulations.

Author Contributions

Funding

Conflicts of Interest

References

- Han, Y.; Yu, E.; Zhang, H.; Huang, D. Numerical analysis on the medium-frequency induction heat treatment of welded pipe. Appl. Therm. Eng. 2013, 51, 212–217. [Google Scholar] [CrossRef]

- Li, H.; He, L.; Gai, K.; Jiang, R.; Zhang, C.; Li, M. Numerical simulation and experimental investigation on the induction hardening of a ball screw. Mater. Des. 2015, 87, 863–876. [Google Scholar] [CrossRef]

- Lee, I.; Tak, S.; Pack, I.; Lee, S. Comparative Study on Numerical Analysis using Co-simulation and Experimental Results for High Frequency Induction Heating on SCM440 Round Bar. J. Soc. Aerosp. Syst. Eng. 2017, 11, 1–7. [Google Scholar] [CrossRef]

- Oh, D.-W.; Kim, T.H.; Do, K.H.; Park, J.M.; Lee, J. Design and Sensitivity Analysis of Design Factors for Induction Heating System. J. Korean Soc. Heat Treat. 2013, 26, 233–240. [Google Scholar] [CrossRef] [Green Version]

- Ji, H.; Wang, B.; Fu, X. Study on the induction heating of the workpiece before gear rolling process. In Proceeding of the 20th International ESAFORM Conference on Material Forming, Dublin, Ireland, 26–28 April 2017; Volume 1896, pp. 1–6. [Google Scholar] [CrossRef]

- Tak, S.-M.; Kang, H.-B.; Baek, I.-S.; Lee, S.-S. Improved workability using preheating in the electromagnetic forming process. J. Mech. Sci. Technol. 2019, 33, 2809–2815. [Google Scholar] [CrossRef]

- Choi, J.-K.; Park, K.-S.; Lee, S. Predicting the hardening depth of a sprocket by finite element analysis and its experimental validation for an induction hardening process. J. Mech. Sci. Technol. 2018, 32, 1235–1241. [Google Scholar] [CrossRef]

- Choi, J.-K.; Park, K.-S.; Lee, S. Prediction of High-Frequency Induction Hardening Depth of an AISI 1045 Specimen by Finite Element Analysis and Experiments. Int. J. Precis. Eng. Manuf. 2018, 19, 1821–1827. [Google Scholar] [CrossRef]

- Tong, D.; Gu, J.; Totten, G.E. Numerical simulation of induction hardening of a cylindrical part based on multi-physics coupling. Model. Simul. Mater. Sci. Eng. 2017, 25, 035009. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R.; Black, M. Handbook of Induction Heating; Marcel Dekker: New York, NY, USA, 2003; p. 19. [Google Scholar]

- Korean Agency for Technology and Standards. KS D 0027, Methods of Measuring Case Depth for Steel Hardened by Flame or Induction Hardening Process; KATS: Maengdong-myeon, Korea, 2002.

- Alexander, C.; Sadiku, M.O. Fundamentals of Electric Circuits; McGraw-Hill: New York, NY, USA, 2012; pp. 613–673. [Google Scholar]

- Gao, K.; Qin, X.; Wang, Z.; Chen, H.; Zhu, S.; Liu, Y.; Song, Y. Numerical and experimental analysis of 3D spot induction hardening of AISI 1045 steel. J. Mater. Process. Technol. 2014, 214, 2425–2433. [Google Scholar] [CrossRef]

- Leblond, J.; Devaux, J. A new kinetic model for anisothermal metallurgical transformations in steels including effect of austenite grain size. Acta Metall. 1984, 32, 137–146. [Google Scholar] [CrossRef]

- Koistinen, D.; Marburger, R. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Edelbauer, W.; Zhang, D.; Kopun, R.; Stauder, B. Numerical and experimental investigation of the spray quenching process with an Euler-Eulerian multi-fluid model. Appl. Therm. Eng. 2016, 100, 1259–1273. [Google Scholar] [CrossRef]

| Depth (mm) | Vickers Hardness (Hv) | Rockwell Hardness (HrC) |

|---|---|---|

| 0.05 | 520 | 50.5 |

| 0.10 | 573 | 53.8 |

| 0.15 | 580 | 54.2 |

| 0.20 | 600 | 55.3 |

| 0.30 | 584 | 54.4 |

| 0.40 | 590 | 54.7 |

| 0.50 | 485 | 48.1 |

| 0.60 | 498 | 49 |

| 0.70 | 492 | 48.6 |

| 0.80 | 500 | 49.1 |

| 0.90 | 431 | 43.8 |

| 1.00 | 409 | 41.8 |

| AC Voltage (V) | Frequency (kHz) | |

|---|---|---|

| Measurement Section 1 | 130 ± 5.3% | 241.7 ± 0.8% |

| Measurement Section 2 | 194 ± 6.7% | 242 ± 0.6% |

| Temperature (°C) | K (l/s) | L (l/s) |

|---|---|---|

| 750 | 0.22 | 1 |

| 770 | 0.53 | 1 |

| 790 | 1.05 | 0.97 |

| 810 | 2.02 | 0.94 |

| 830 | 4.55 | 0.87 |

| 840 | 5.6 | 0.76 |

| 860 | 7.37 | 0.45 |

| 880 | 10.77 | 0 |

| 900 | 20 | 0 |

| Temperature (°C) | F (l/s) | G (l/s) |

|---|---|---|

| 340 | 0 | |

| 350 | 0.014 | |

| 450 | 0.067 | 0 |

| 550 | 0 | 0.067 |

| Temperature Rate (K/h) | H (l) |

|---|---|

| −43,000 | 0.2 |

| −15,000 | 1 |

| −7200 | 1.5 |

| −1500 | 0.22 |

| −700 | 0.1 |

| −70 | 0.0044 |

| Parameter | Value |

|---|---|

| MS | 370 (°C) |

| β | 0.011 (1/K) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.; Lee, S. High-Frequency Heat Treatment of AISI 1045 Specimens and Current Calculations of the Induction Heating Coil Using Metal Phase Transformation Simulations. Metals 2020, 10, 1484. https://doi.org/10.3390/met10111484

Choi J, Lee S. High-Frequency Heat Treatment of AISI 1045 Specimens and Current Calculations of the Induction Heating Coil Using Metal Phase Transformation Simulations. Metals. 2020; 10(11):1484. https://doi.org/10.3390/met10111484

Chicago/Turabian StyleChoi, Jinkyu, and Seoksoon Lee. 2020. "High-Frequency Heat Treatment of AISI 1045 Specimens and Current Calculations of the Induction Heating Coil Using Metal Phase Transformation Simulations" Metals 10, no. 11: 1484. https://doi.org/10.3390/met10111484

APA StyleChoi, J., & Lee, S. (2020). High-Frequency Heat Treatment of AISI 1045 Specimens and Current Calculations of the Induction Heating Coil Using Metal Phase Transformation Simulations. Metals, 10(11), 1484. https://doi.org/10.3390/met10111484