Effect of Radial Forging on the Microstructure and Mechanical Properties of Ti-Based Alloys

Abstract

:1. Introduction

- -

- The choice of thermal treatment modes for forged semiproducts, which meet the technical requirements to the structure and mechanical characteristics;

- -

- The elaboration of algorithms for the deformation of rods and alignment of the RFM tool using data acquired during the analysis of structural and mechanical properties, which obeys requirements to the geometrical sizes and surface quality.

2. Materials and Methods

3. Results

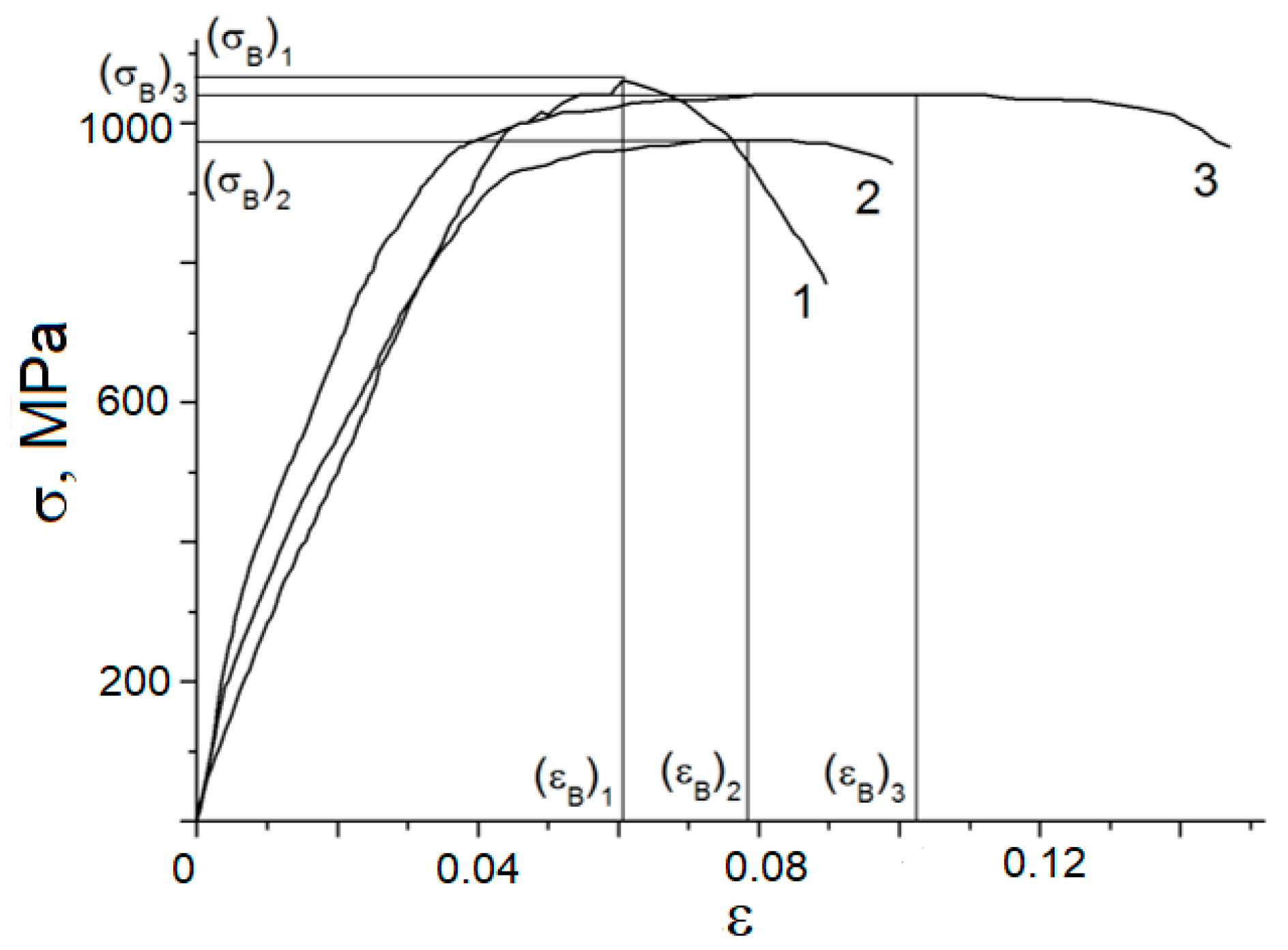

3.1. Mechanical Properties of Ti-Al-Mo-V Alloy after Hot Pressing

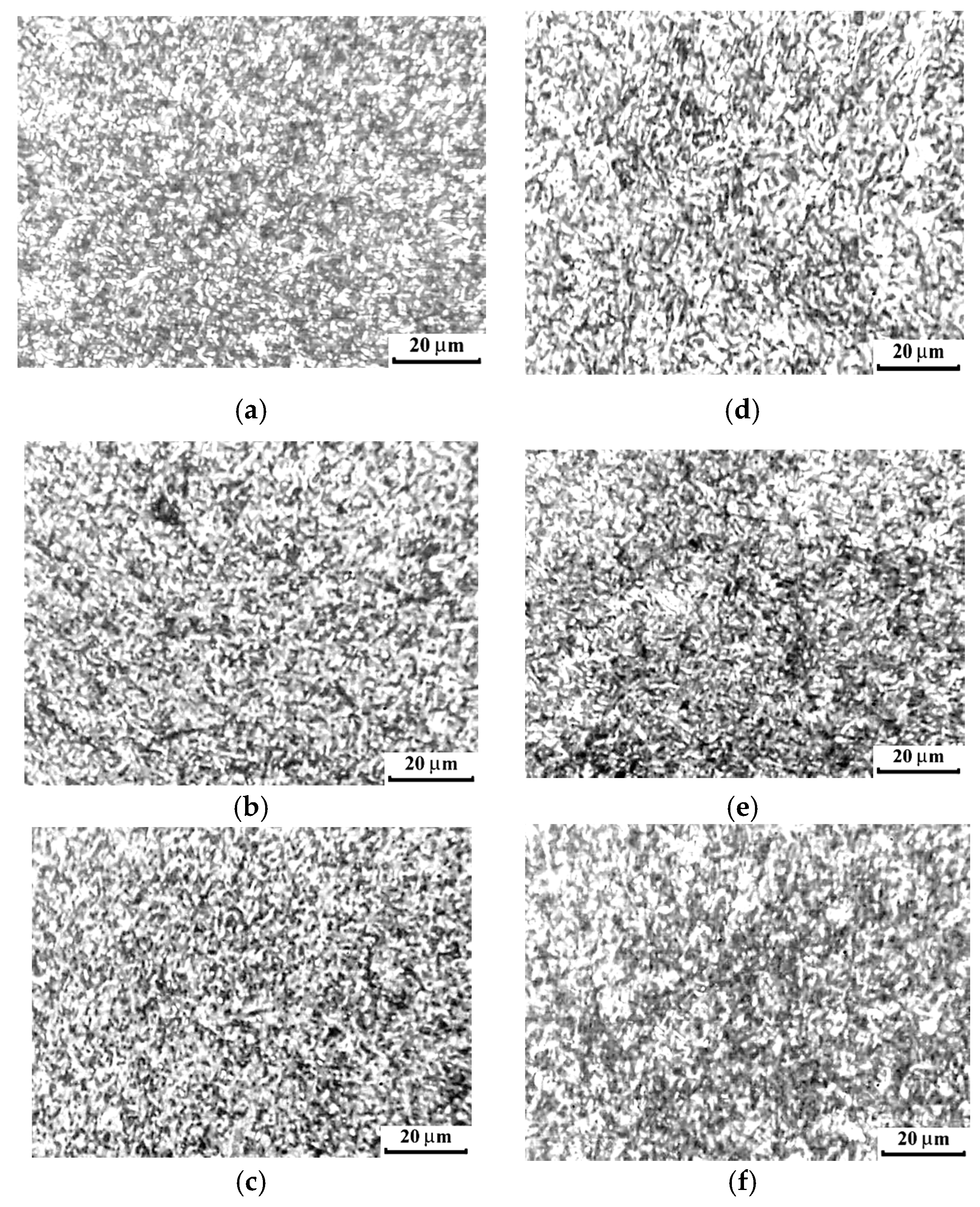

3.2. Structure of of Ti-Al-Mo-V Alloy after Radial Forging

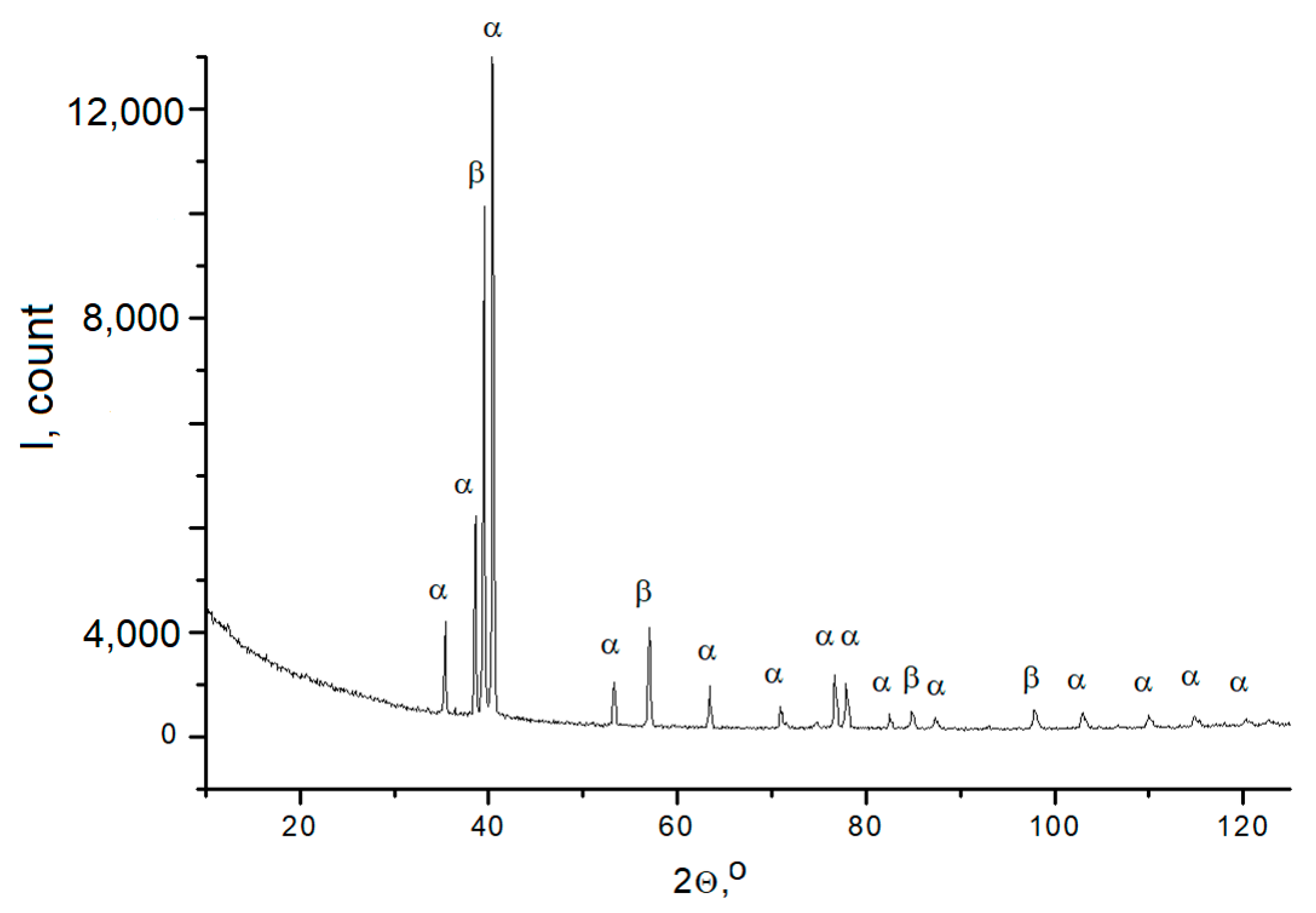

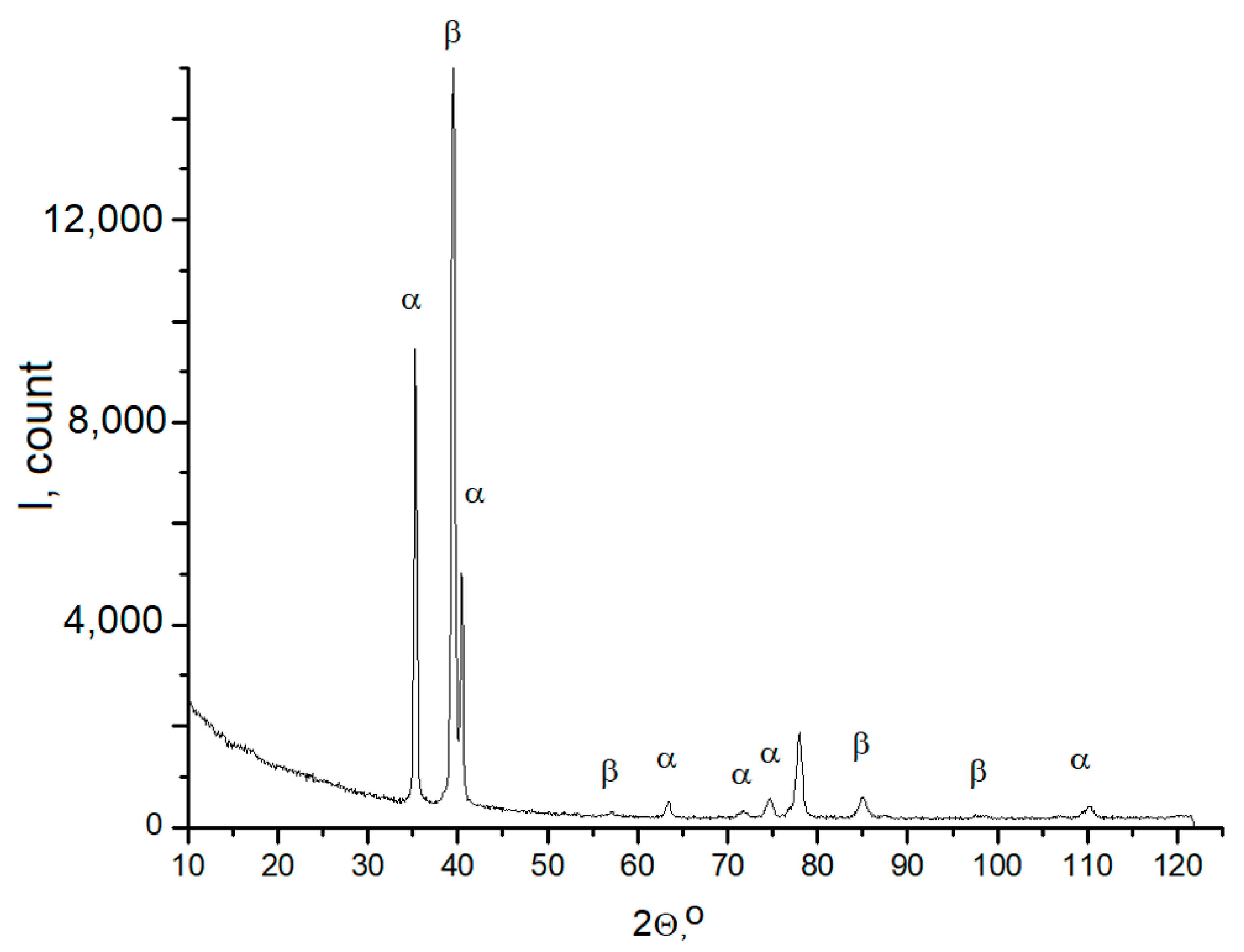

3.3. X-ray Diffraction Analysis of Ti-Al-Mo-V Alloy

4. Discussion

5. Conclusions

- -

- Radial forging of Ti-3.3Al-5Mo-5V alloy workpieces leads to the structural refinement and the changes in grain morphology from predominately lamelar to uniform globular, as well as the variations in phase composition of the alloy and the supression of powder formation.

- -

- The methods of rod deformation and alignment of the RFM working tool, applied in this work, ensure fulfillment of technical requirements to geometrical sizes and surface quality.

- -

- Radial forging is found to allow one to produce semiproducts from titanium-based Ti-Al-Mo-V alloys without using multiple mechanical processing of workpieces and rods.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; John Wiley & Sons: Weinheim, Germany, 2006; pp. 250–302. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 203–250. [Google Scholar]

- Kabra, S.; Ya, K.; Mayer, S.; Schmoelzer, T.; Reid, M.; Dippenaar, R.; Clemens, H.; Liss, K. Phase transition and ordering behavior of ternary Ti–Al–Mo alloys using in-situ neutron diffraction. Int. J. Mater. Res. 2011, 102, 697–702. [Google Scholar] [CrossRef] [Green Version]

- Xiao, D.-H.; Yuan, T.-C.; Ou, X.-Q.; He, Y.-H. Microstructure and mechanical properties of powder metallurgy Ti-Al-Mo-V-Ag alloy. Trans. Nonferrous Met. Soc. China 2011, 21, 1269–1276. [Google Scholar] [CrossRef]

- Prakash, D.G.L.; Honniball, P.; Rugg, D.; Withers, P.J.; da Fonseca, J.Q.; Preuss, M. The effect of beta phase on microstructure and texture evolution during thermo-mechanical processing of alpha plus beta Ti alloy. Acta Mater. 2013, 61, 3200–3213. [Google Scholar] [CrossRef]

- Singh, A.K.; Schwarzer, R.A. Evolution of texture during thermo-mechanical processing of titanium and its alloys. Trans. Ind. Inst. Met. 2008, 61, 371–387. [Google Scholar] [CrossRef]

- Zavodchikov, S.Y.; Zuev, L.B.; Kotrekhov, V.A. On the Use of the Radial Forging Process in Pipe Production. In Physical Metallurgy Aspects of the Production of Zirconium Alloy Components; Glezer, A.M., Ed.; Nauka: Novosibirsk, Russia, 2012; pp. 165–191. [Google Scholar]

- Barannikova, S.; Schlyakhova, G.; Maslova, O.; Li, Y.; Lev, Z. Fine structural characterization of the elements of a Nb-Ti superconducting cable. J. Mater. Res. Technol. 2019, 8, 323–332. [Google Scholar] [CrossRef]

- Barannikova, S.; Shlyakhova, G.; Zuev, L.; Malinovskiy, A. Microstructure of superconducting cable components. Int. J. Geom. 2016, 10, 1906–1911. [Google Scholar] [CrossRef]

- Gloaguen, D.; Girault, B.; Courant, B.; Dubos, P.A.; Moya, M.J.; Edy, F.; Kornmeier, J.R. Study of residual stresses in additively manufactured Ti-6Al-4V by neutron diffraction measurements. Met. Mat. Trans. A 2020, 51, 951–961. [Google Scholar] [CrossRef]

- Wagner, F.; Ouarem, A.; Richeton, T.; Toth, L.S. Improving mechanical properties of cp titanium by heat treatment optimization. Adv. Eng. Mater. 2018, 20, 1700237. [Google Scholar] [CrossRef]

- Lei, X.F.; Dong, L.M.; Zhang, Z.Q.; Liu, Y.J.; Hao, Y.L.; Yang, R.; Zhang, L.C. Microstructure, Texture Evolution and Mechanical Properties of VT3-1 Titanium Alloy Processed by Multi-Pass Drawing and Subsequent Isothermal Annealing. Metals 2017, 7, 131. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Randle, R. An electron backscatter diffraction analysis of misorientation distributions in titanium alloys. Scr. Mater. 2007, 56, 1051–1054. [Google Scholar] [CrossRef]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. Effect of α precipitation on β texture evolution during β-processed forging in a near-β titanium alloy. Mater. Sci. Eng. A 2020, 771, 138640. [Google Scholar] [CrossRef]

- Qin, D.; Lu, Y.; Guo, D.; Zheng, L.; Liu, Q.; Zhou, L. On preparation of bimodal Ti–5Al–5V–5Mo–3Cr–0.4Si (Ti-5553s) alloy: α+β forging and heat treatment. Mater. Sci. Eng. A 2014, 609, 42–52. [Google Scholar] [CrossRef]

- Li, T.R.; Liu, G.H.; Xu, M.; Wang, B.X.; Misra, R.D.K.; Wang, Z.D. High temperature deformation and control of homogeneous microstructure during hot pack rolling of Ti-44Al-5Nb-(Mo, V, B) alloys: The impact on mechanical properties. Mater. Sci. Eng. A 2019, 751, 1–9. [Google Scholar] [CrossRef]

- Li, T.R.; Liu, G.H.; Xu, M.; Wang, B.X.; Fu, T.L.; Wang, Z.D.; Misra, R.D.K. Flow stress prediction and hot deformation mechanisms in Ti-44Al-5Nb-(Mo, V, B) Alloy. Materials 2018, 11, 2044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.; Wang, Z.; Fu, T.; Li, Y.; Liu, H.; Li, T.; Gong, M.; Wang, G. Study on the microstructure, phase transition and hardness for the TiAl–Nb alloy design during directional solidification. J. Alloy. Compd. 2015, 650, 45–52. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhao, Y.B.; Zhang, C.J.; Han, J.C.; Sun, M.J.; Xu, M. The microstructure, mechanical properties, and oxidation behavior of beta-gamma TiAl alloy with excellent hot workability. Mater. Sci. Eng. A 2017, 700, 366–373. [Google Scholar] [CrossRef]

- Nematzadeh, F.; Akbarpour, M.R.; Kokabi, A.H.; Sadrnezhaad, S.K. Structural changes of radial forging die surface during service under thermo-mechanical fatigue. Mater. Sci. Eng. A 2009, 527, 98–102. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, X.; Yu, Q. An upper bound solution of axialmetal flow in cold radial forging process of rods. Int. J. Mech. Sci. 2014, 85, 120–129. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Kudryashova, A.; Cheverikin, V.; Korotitskiy, A.; Galkin, S.; Prokoshkin, S.; Brailovski, V. Hot radial shear rolling and rotary forging of metastable beta Ti-18Zr-14Nb (at. %) alloy for bone implants: Microstructure, texture and functional properties. J. Alloy. Compd. 2019, 800, 320–326. [Google Scholar] [CrossRef]

- Greaves, R.H.; Wrighton, H. Practical Microscopical Metallography; Chapman and Hall: London, UK, 1957; pp. 112–160. [Google Scholar]

- Taylor, A. An Introduction to X-Ray Metallography; Chapman & Hall Ltd.: London, UK, 1945; pp. 170–185. [Google Scholar]

| Ti | Al | Mo | V | C | N | Fe | Si | H2 | O2 |

|---|---|---|---|---|---|---|---|---|---|

| base | 3.3 | 4.6 | 4.5 | 0.05 | 0.01 | <0.01 | ≤0.10 | 0.007 | 0.014 |

| Transition | Number of Beats Per Minute | Feed Rate, mm/s |

|---|---|---|

| Φ20→Φ16 mm | 580 | 5...7 |

| Φ16→Φ10 mm | 580 | 5...7 |

| Sample No. | Workpiece Diameter, μm | Location along the Workpiece | Reduction K, % |

|---|---|---|---|

| 1 | Φ20 | Input (initial state) | 0 |

| 3 | Φ20 | Deformation center (RF) | 17 |

| 5 | Φ16 | output | 20 |

| 7 | Φ16 | Deformation center (RF) | 23 |

| 8 | Φ16 | Deformation center (RF) | 38 |

| 10 | Φ10 | Output (final state) | 50 |

| Ti-Al-Mo-V Sample No. | Pore Density, mm−2 | Maximum Pore Size, μm | Grain Score (in Points) | |||

|---|---|---|---|---|---|---|

| Center of the Workpiece | Surface Layer | Center of the Workpiece | Surface Layer | Center of the Workpiece | Surface Layer | |

| 1 | 771 | 325 | 18 | 3,5 | 6 | 4 |

| 3 | 542 | 274 | 9 | 3 | 5-4 | 3 |

| 5 | 362 | 244 | 2.5 | 3 | 4 | 3-2 |

| 7 | 297 | 202 | 2 | 2 | 3-2 | 2-1 |

| 8 | 183 | 149 | 1.5 | 1 | 2 | 1 |

| 10 | 102 | 98 | <1 | 1 | 2 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuev, L.B.; Shlyakhova, G.V.; Barannikova, S.A. Effect of Radial Forging on the Microstructure and Mechanical Properties of Ti-Based Alloys. Metals 2020, 10, 1488. https://doi.org/10.3390/met10111488

Zuev LB, Shlyakhova GV, Barannikova SA. Effect of Radial Forging on the Microstructure and Mechanical Properties of Ti-Based Alloys. Metals. 2020; 10(11):1488. https://doi.org/10.3390/met10111488

Chicago/Turabian StyleZuev, Lev B., Galina V. Shlyakhova, and Svetlana A. Barannikova. 2020. "Effect of Radial Forging on the Microstructure and Mechanical Properties of Ti-Based Alloys" Metals 10, no. 11: 1488. https://doi.org/10.3390/met10111488

APA StyleZuev, L. B., Shlyakhova, G. V., & Barannikova, S. A. (2020). Effect of Radial Forging on the Microstructure and Mechanical Properties of Ti-Based Alloys. Metals, 10(11), 1488. https://doi.org/10.3390/met10111488