Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears

Abstract

:1. Introduction

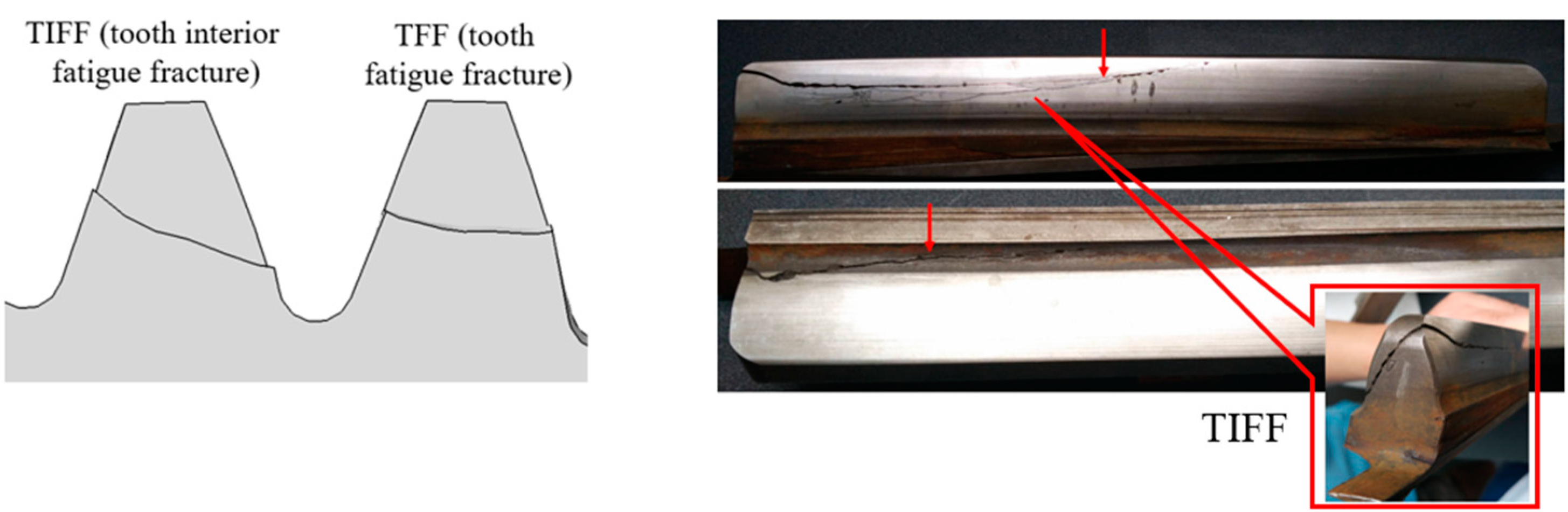

- (1)

- TIFF is commonly reported in heavy-duty carburized gears.

- (2)

- The fracture section is usually observed in the mid-height of the tooth.

- (3)

- The main crack of TIFF is at an angle of 40–50° with the tooth surface.

- (4)

- Most of the failure gears caused by TIFF do not show micropitting or pitting on the tooth surface.

- (5)

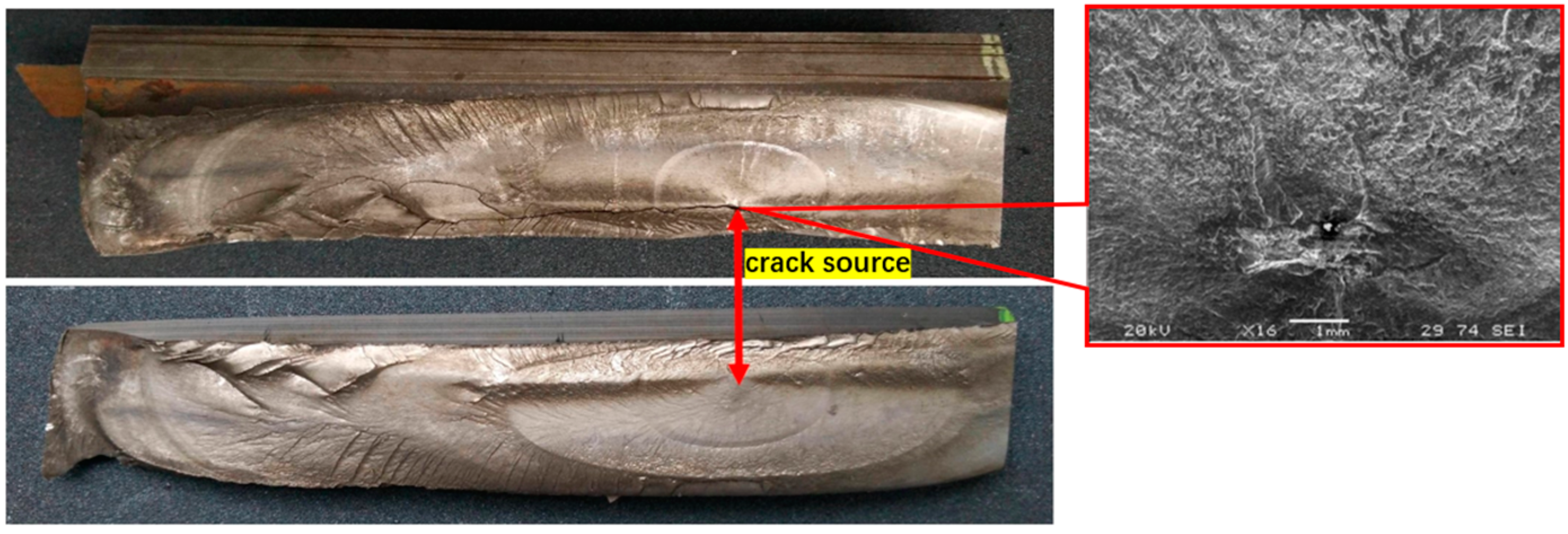

- Crack initiation occurs at the junction between the hardened layer and the core and is often accompanied by non-metallic inclusion, as shown in Figure 2.

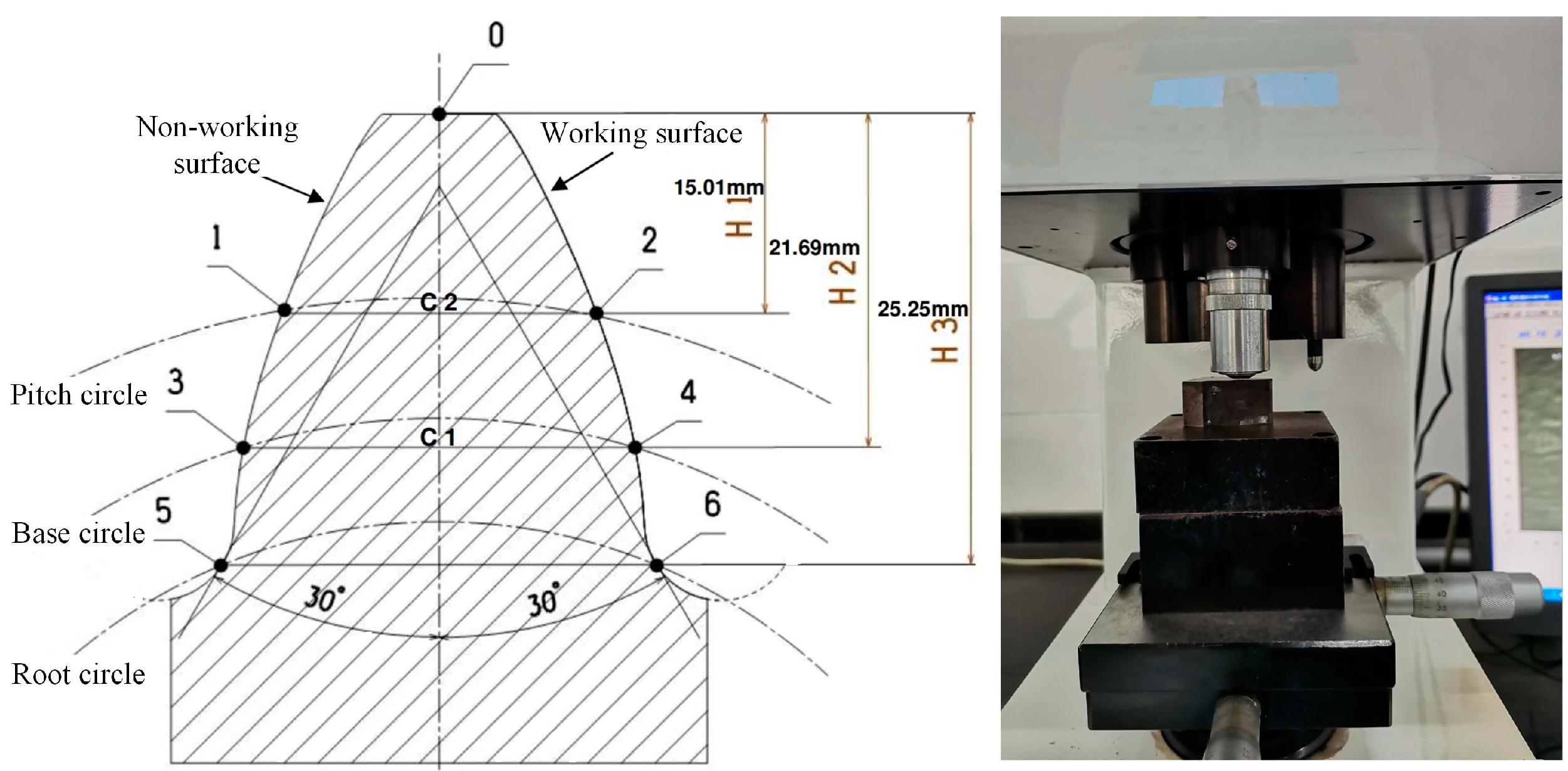

2. Methodology

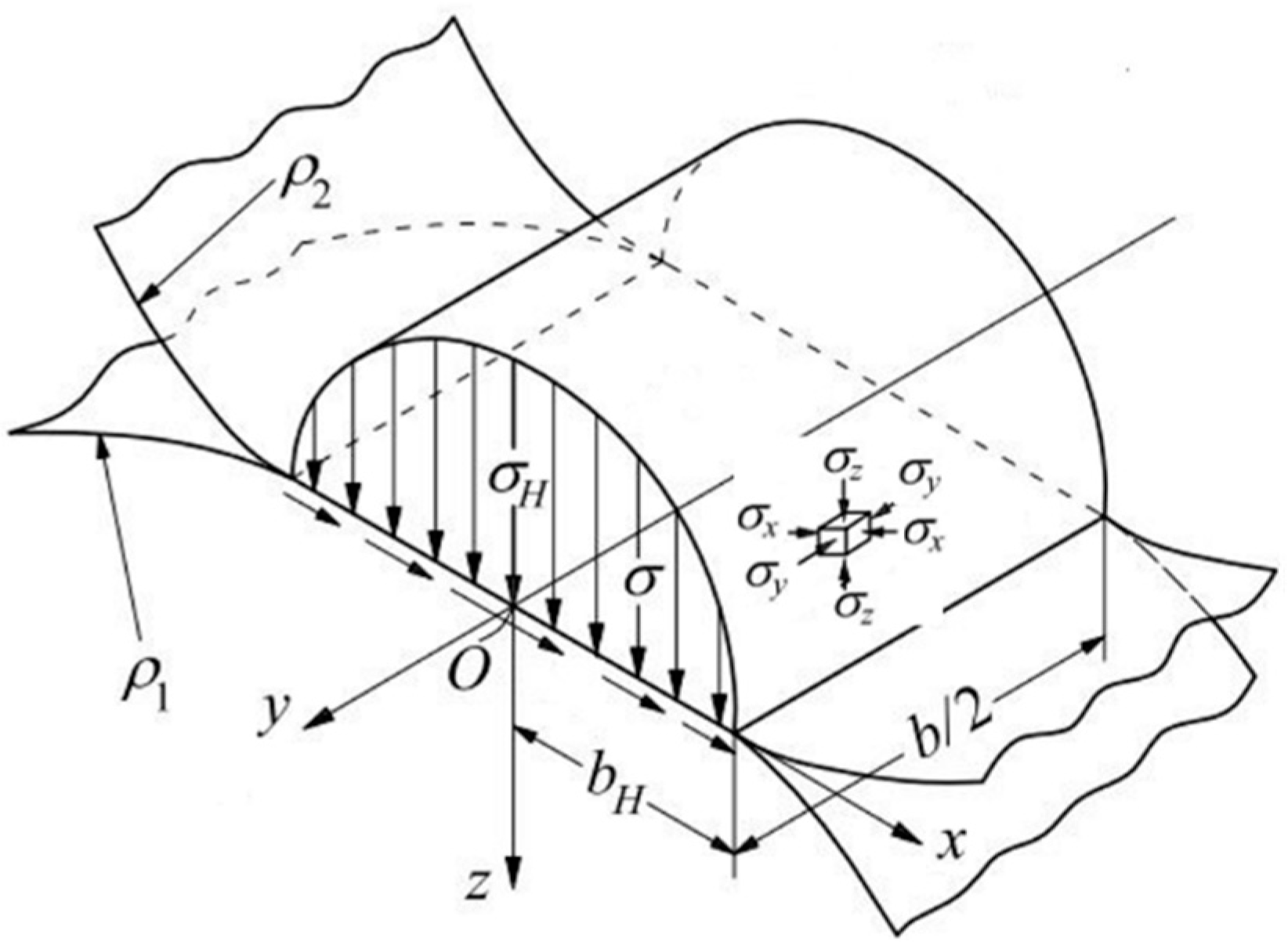

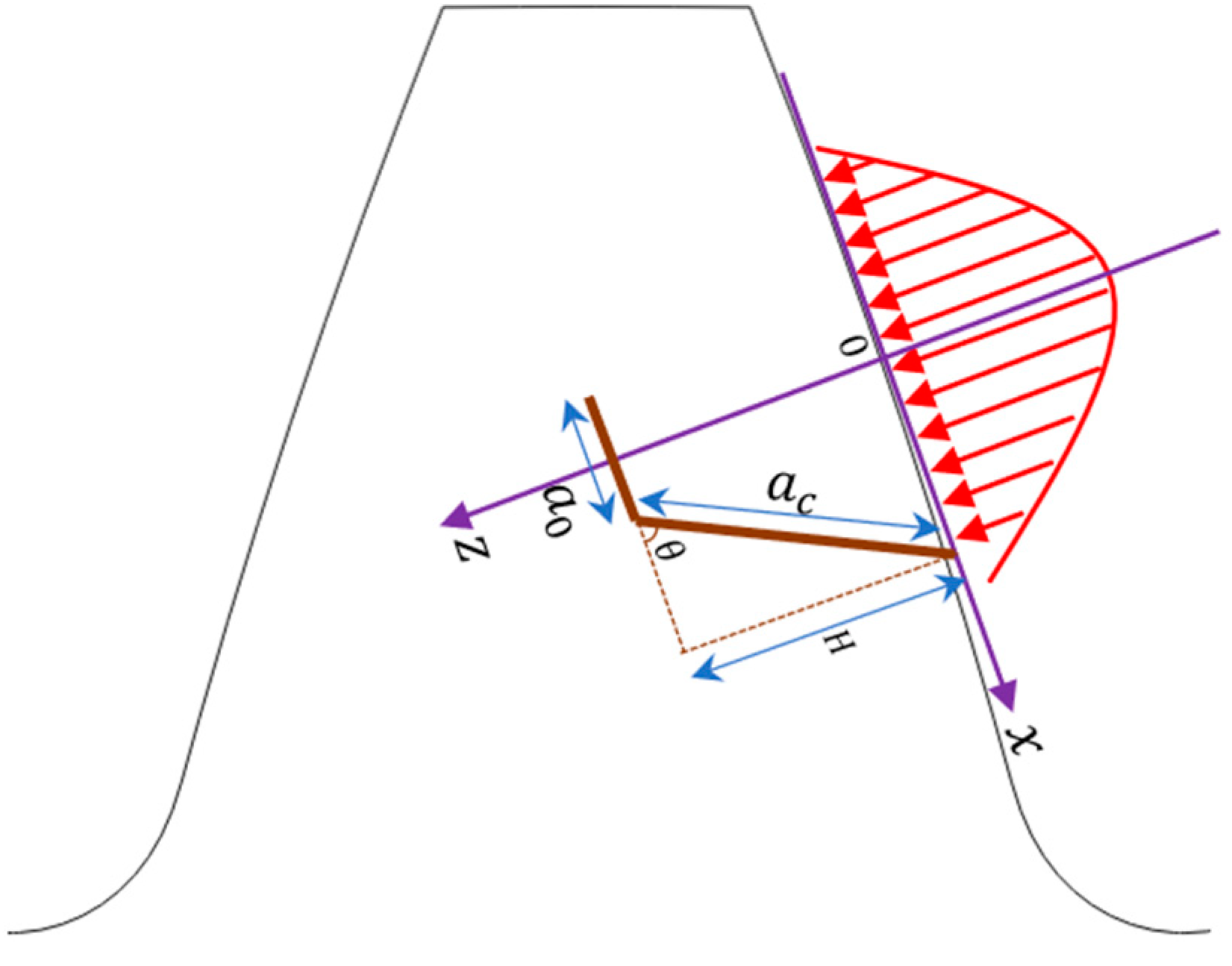

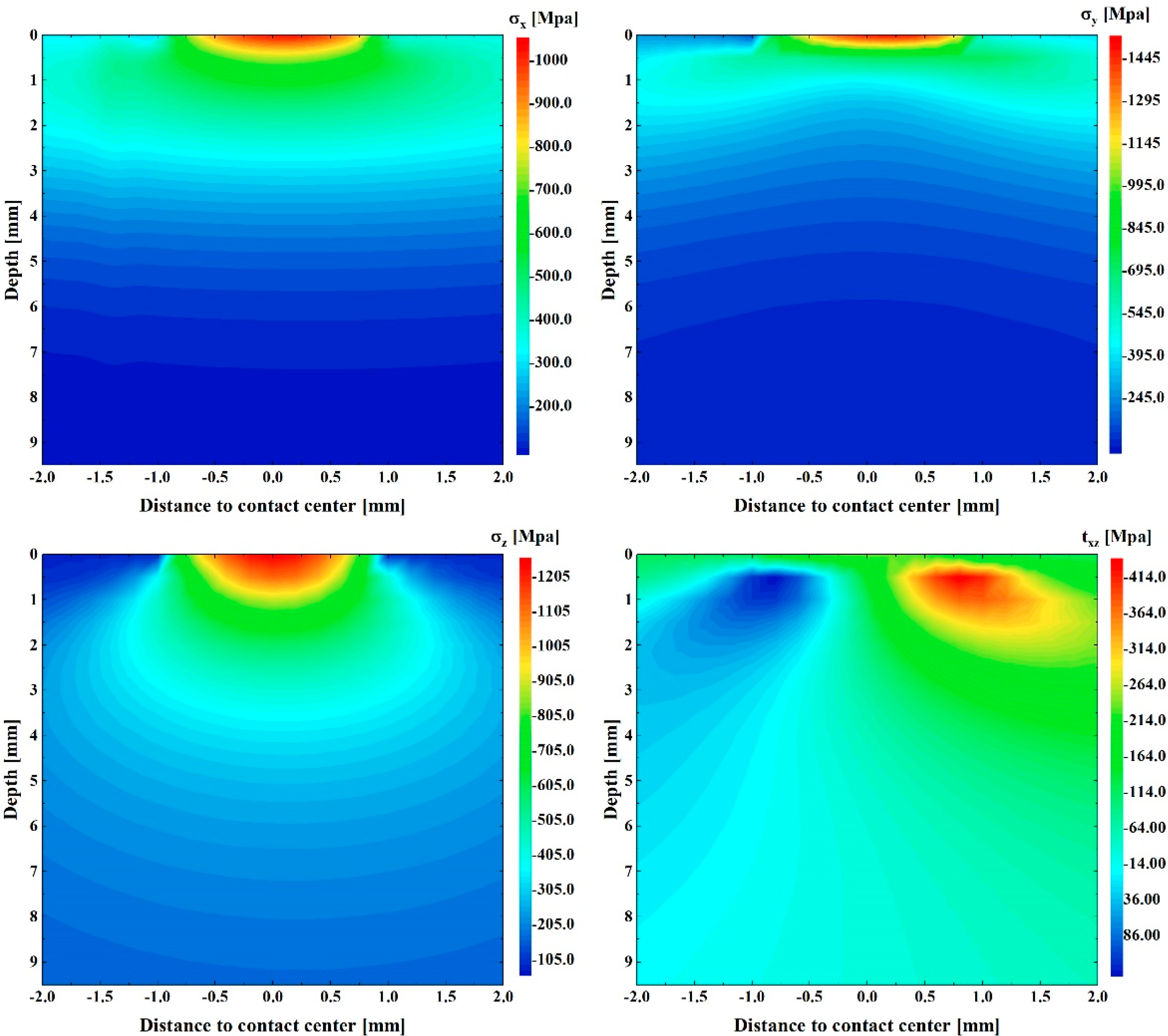

2.1. Sub-Surface Stress Field

2.2. Hardness Gradient

2.3. Multiaxial Fatigue Criterion

2.4. Crack Life Prediction

3. Results and Discussion

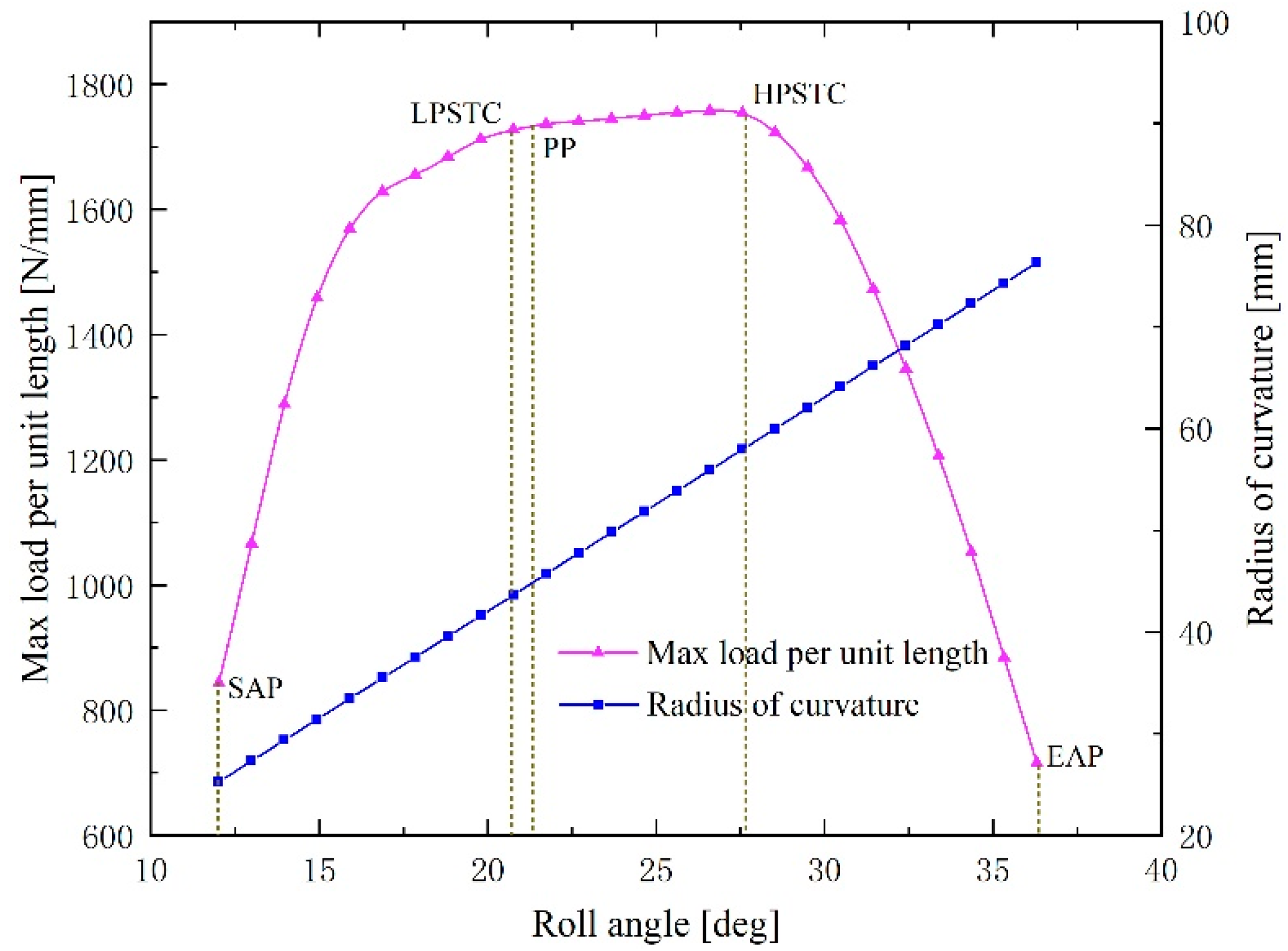

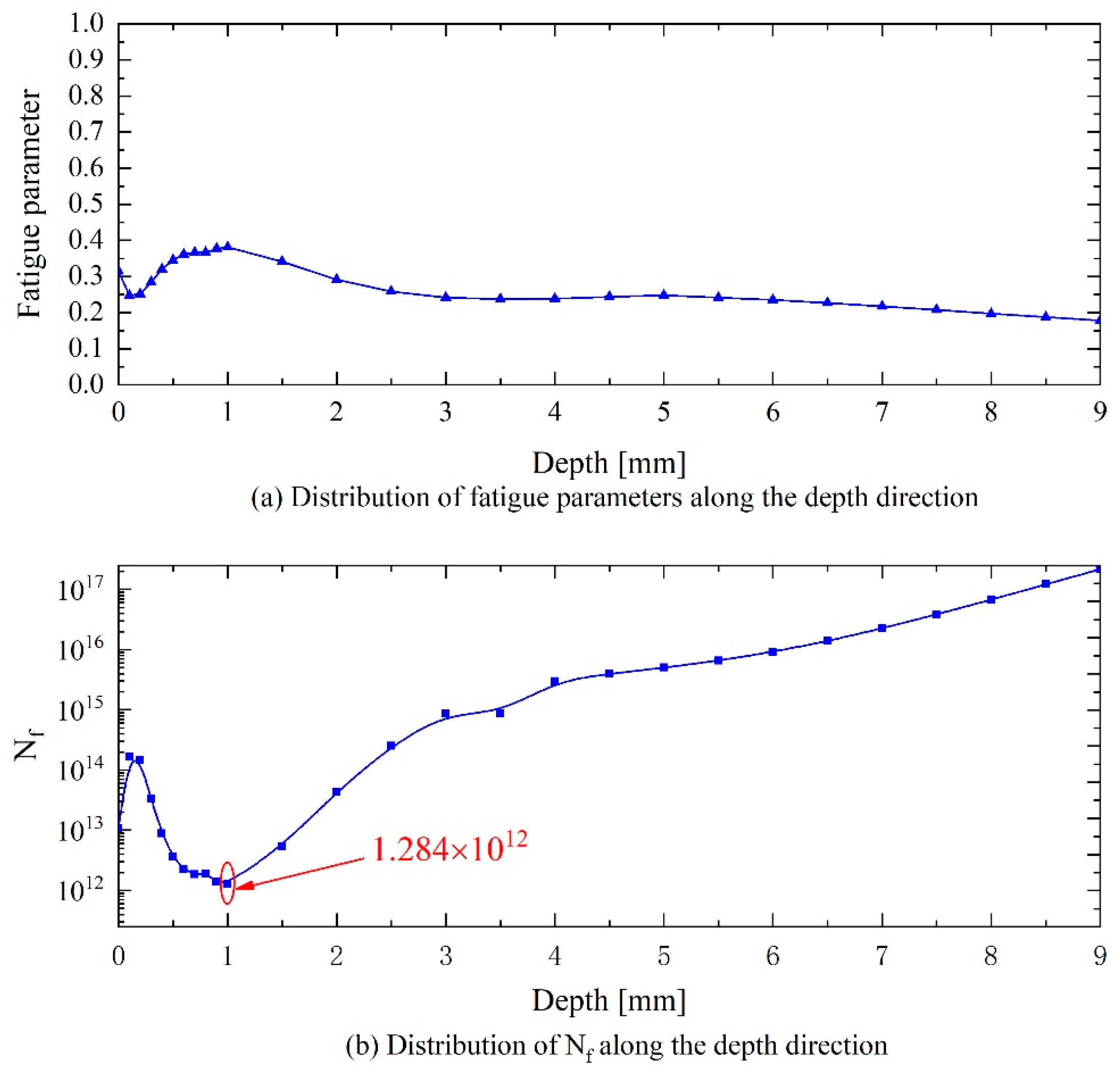

3.1. Calculation of Contact Life

3.2. Analysis of Life Influencing Factors

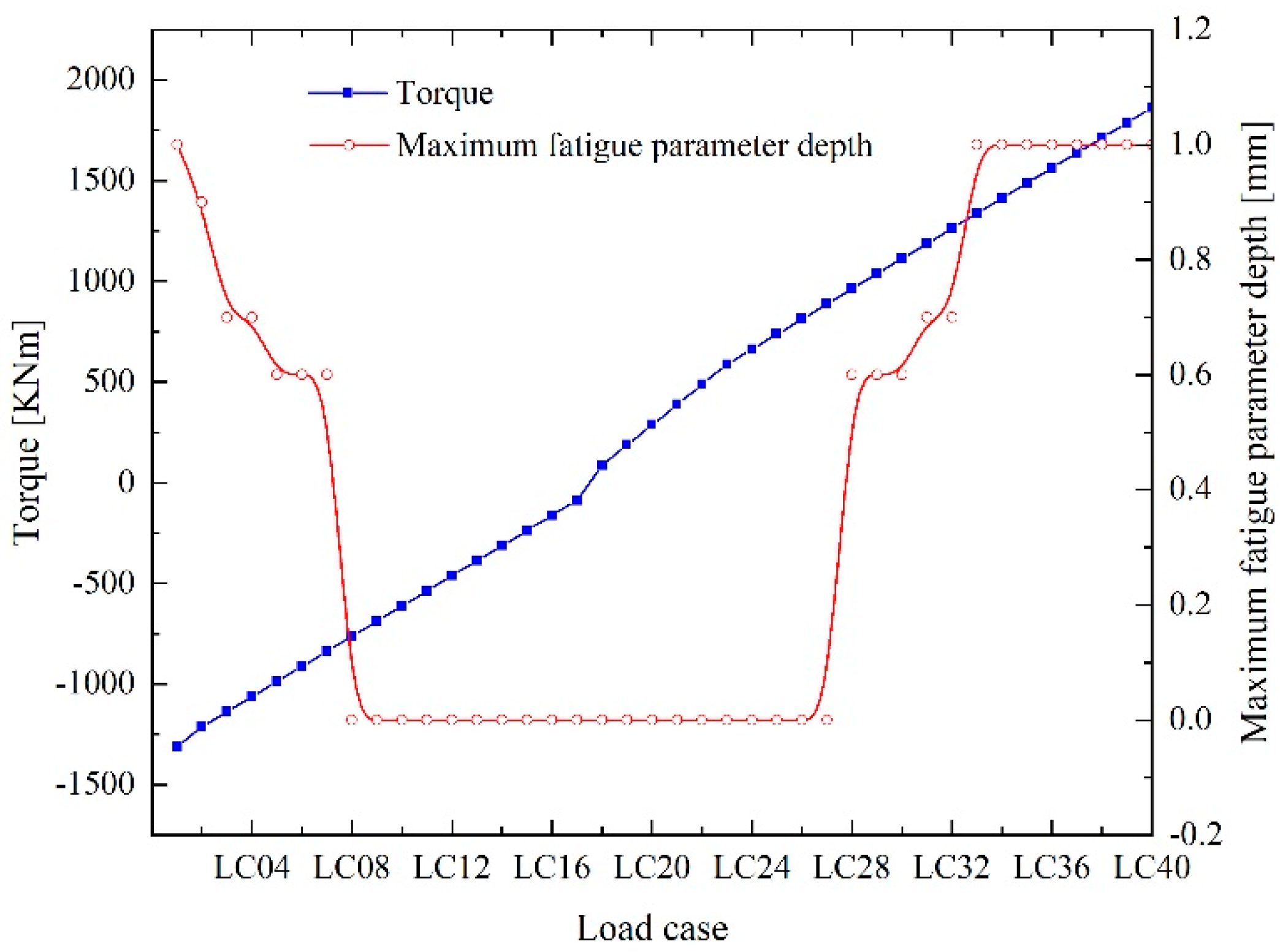

3.2.1. Influence of External Loads

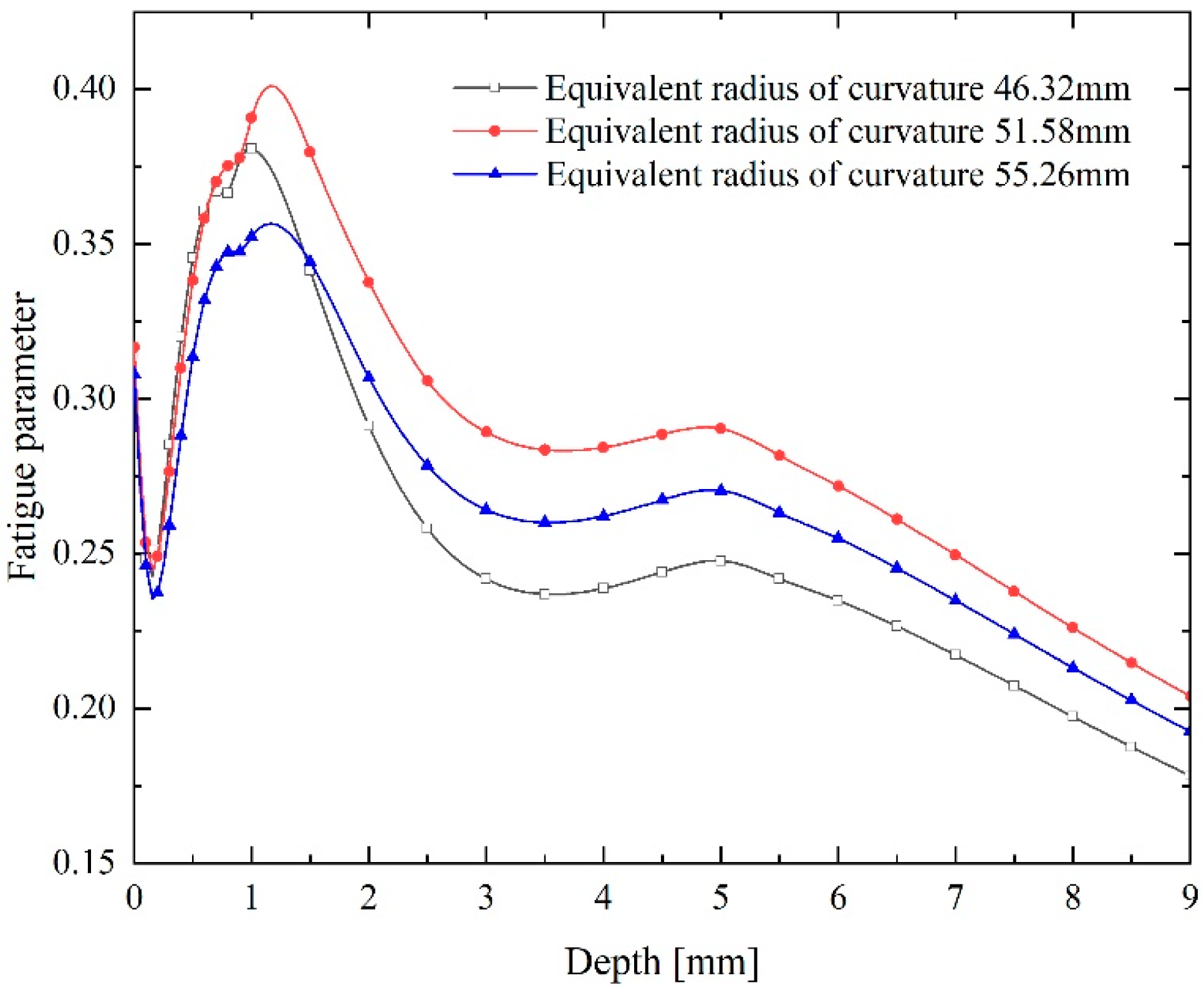

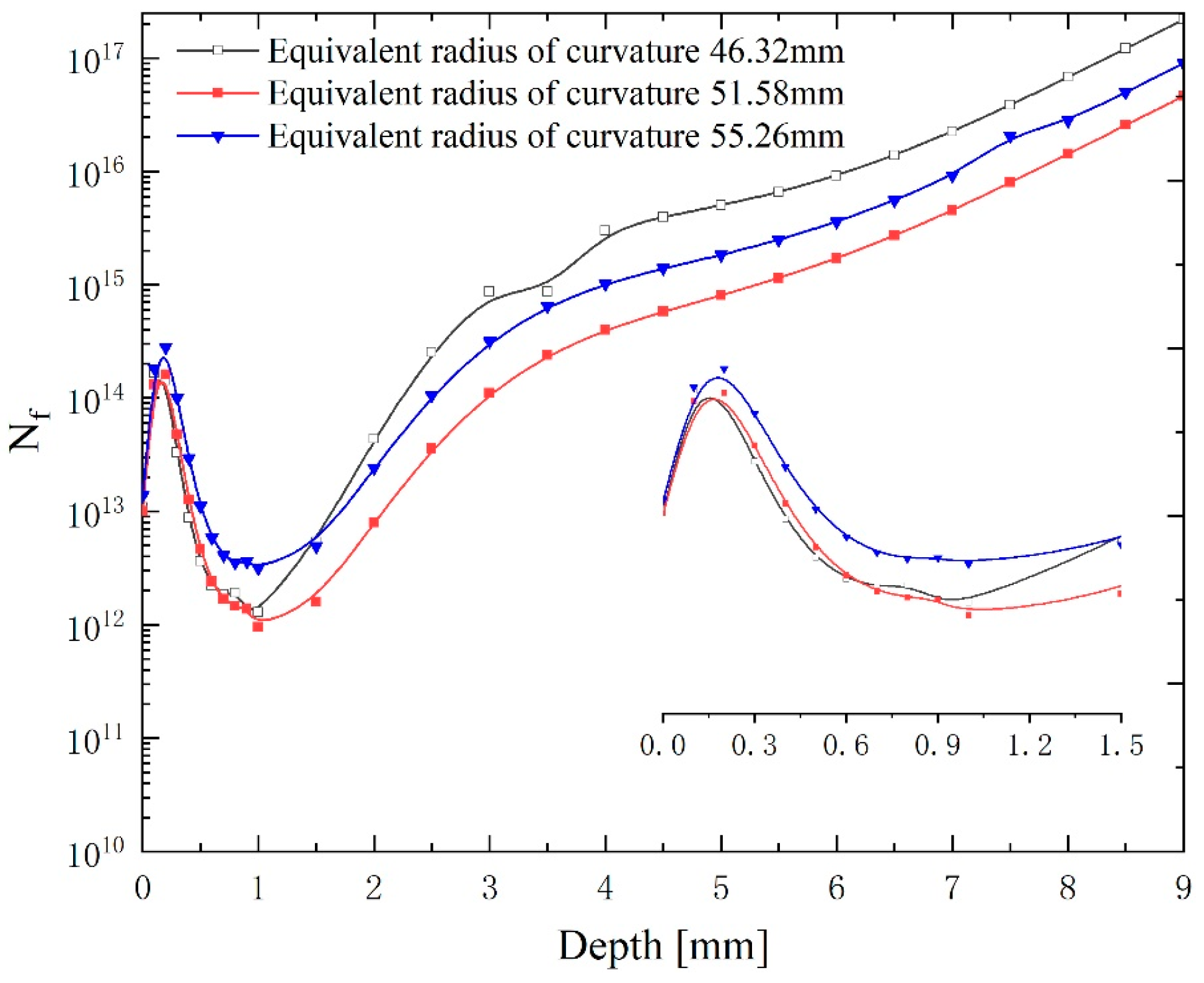

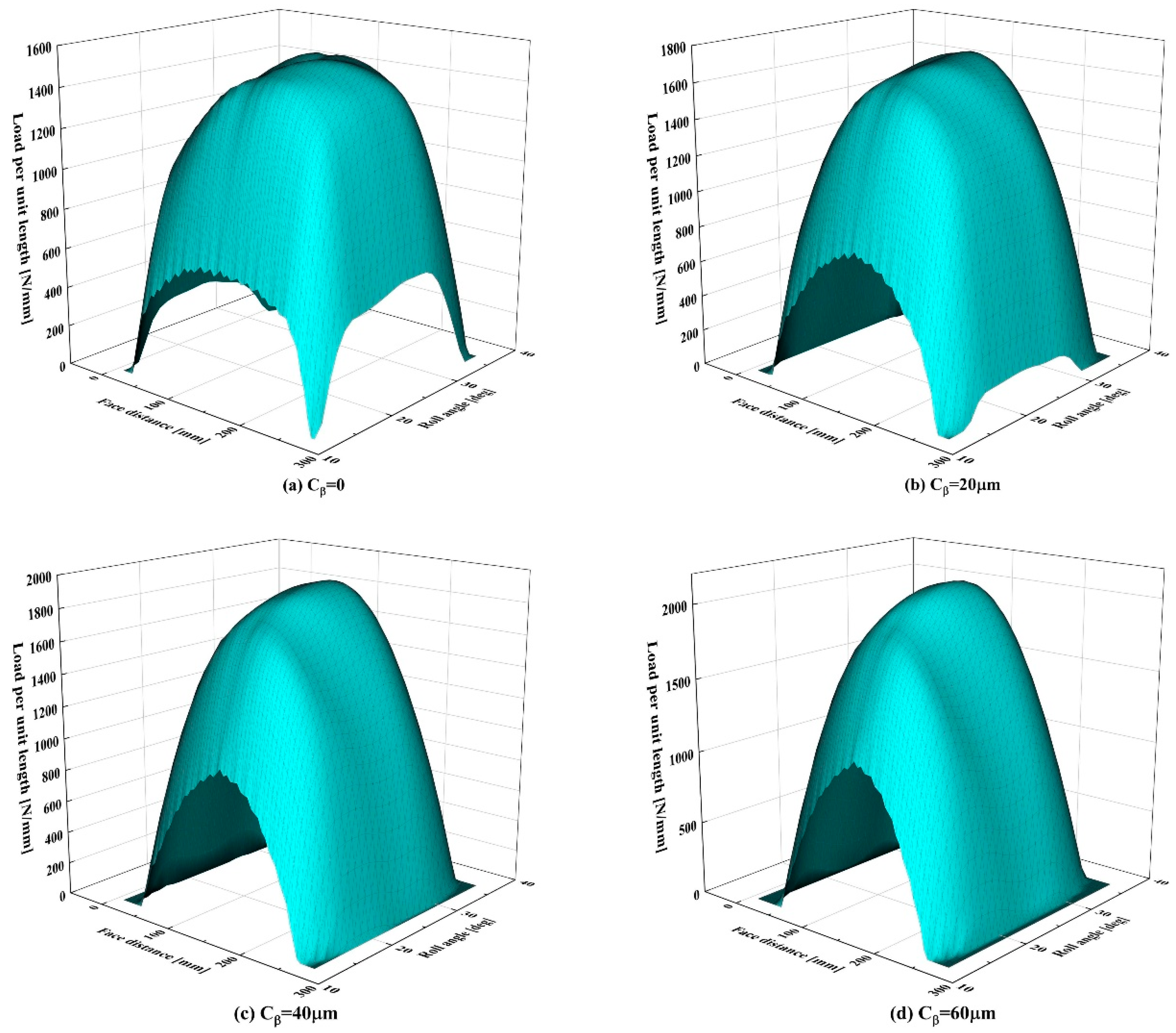

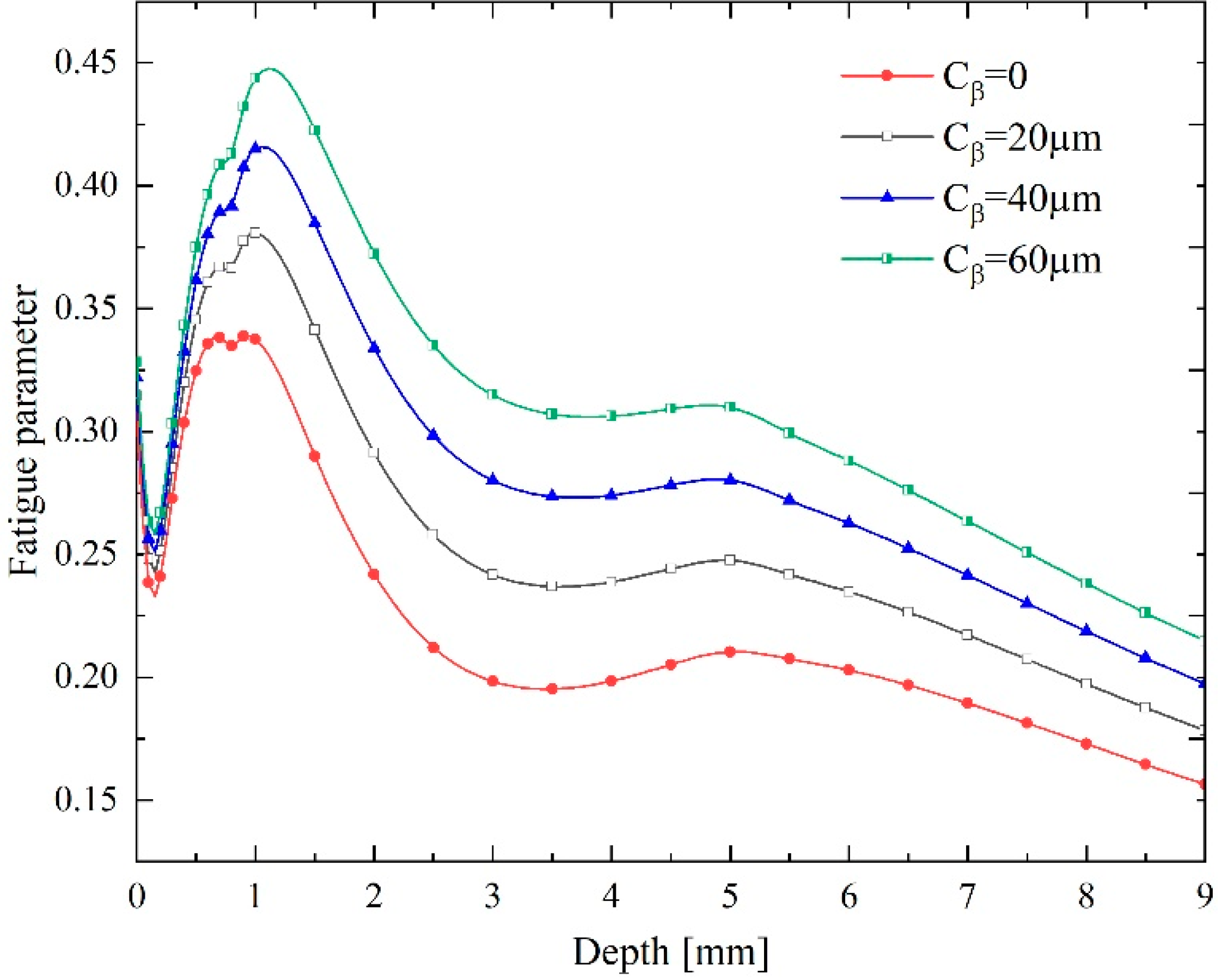

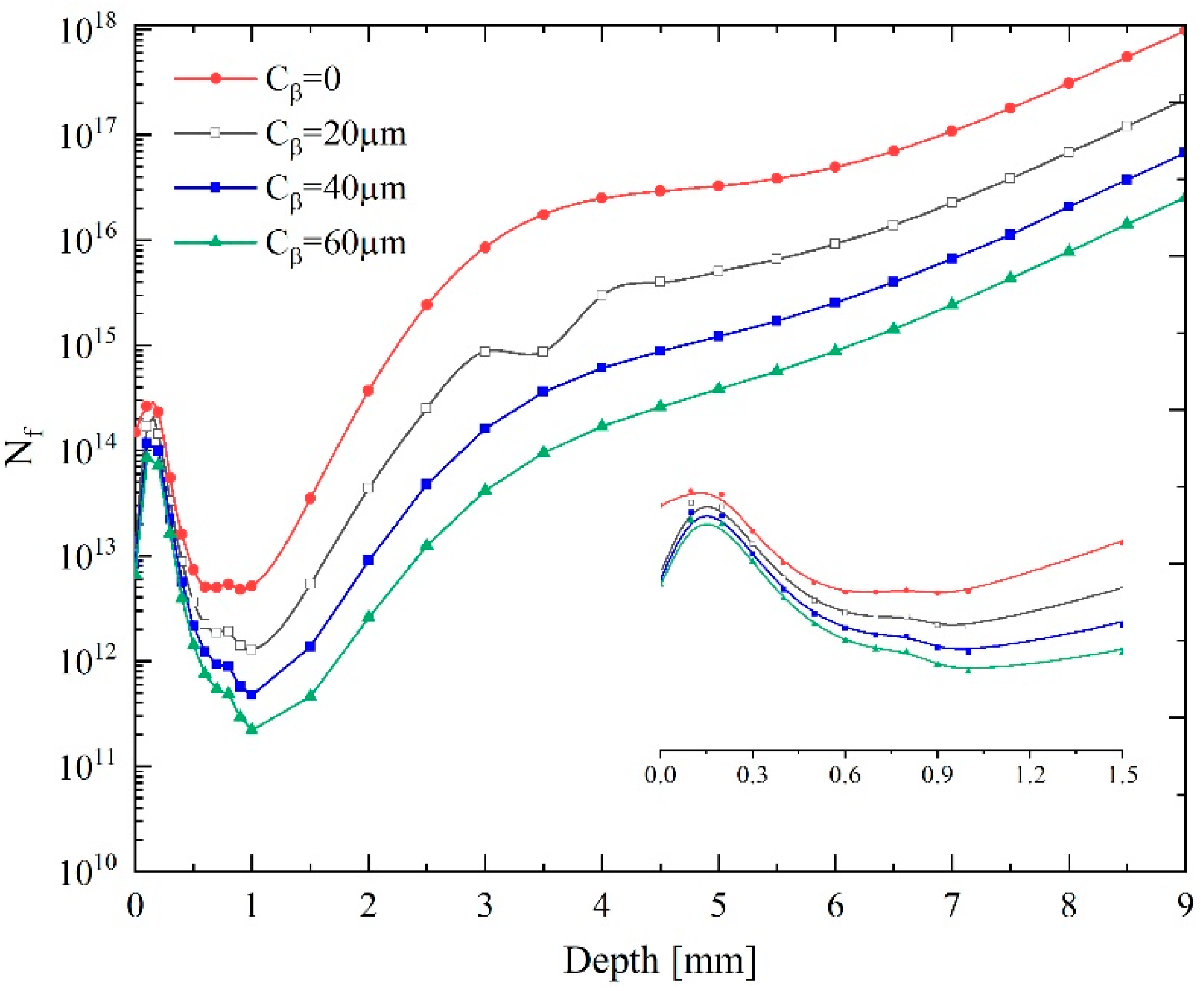

3.2.2. Influence of Gear Geometric Parameters

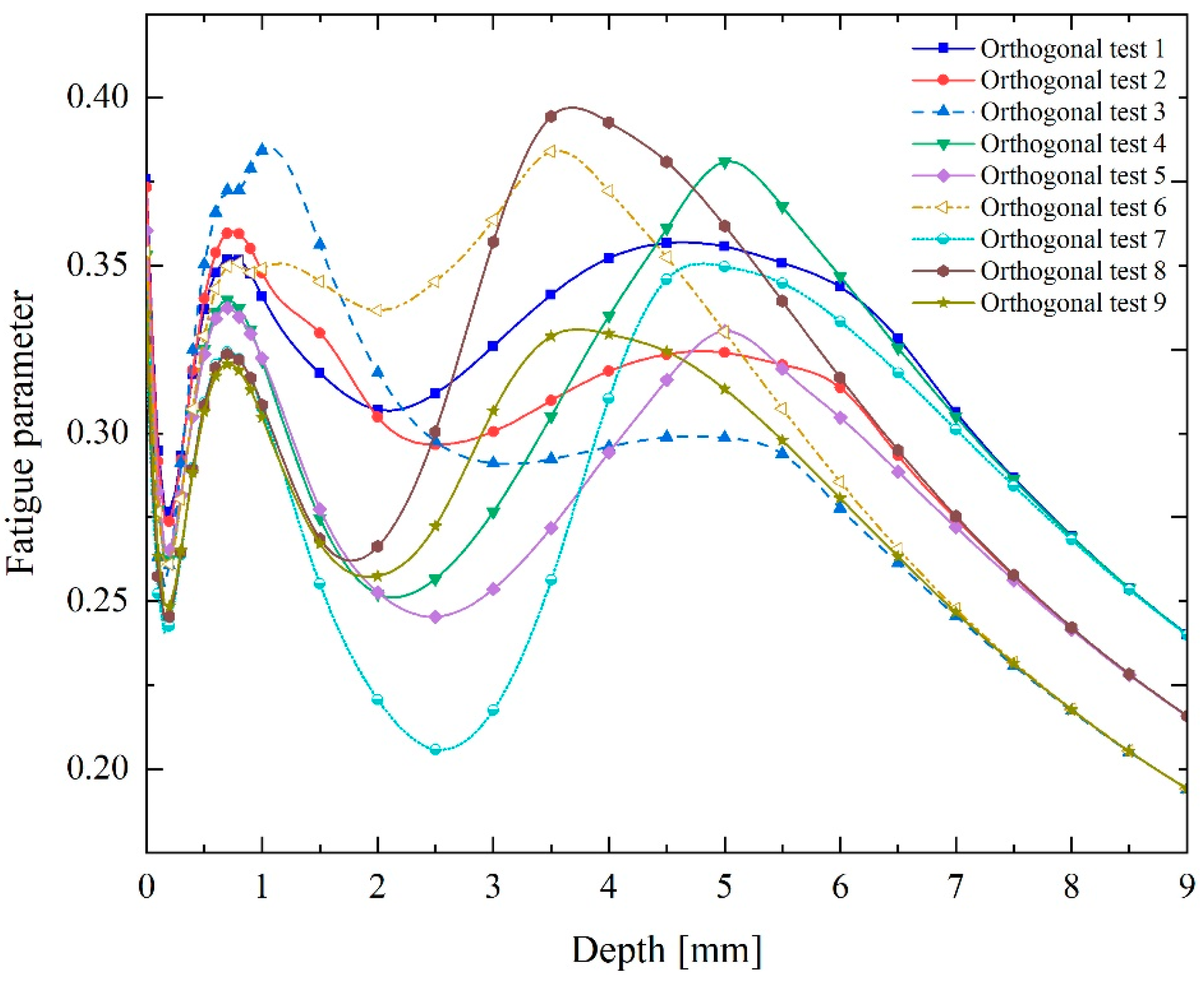

3.3. Influence of Gear Material Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Pressure angle | |

| Helix angle | |

| Normal modulus | |

| Stress component along the axis | |

| Stress component along the z axis | |

| Hardness at any point under the tooth surface | |

| Core hardness | |

| Effective hardness depth | |

| Hardened layer depth | |

| Residual stress at any depth | |

| Component of residual stress along the coordinate axis | |

| Component of residual stress in the direction of shear stress | |

| Hydrostatic stress | |

| Maximum shear stress | |

| Dang Van equivalent stress at any depth | |

| The fatigue limits at N = 107 cycles under fully reversed bending | |

| The fatigue limits at N = 107 cycles under fully reversed torsion | |

| The shear fatigue coefficient | |

| The axial fatigue strength exponent | |

| Crack initiation life | |

| Crack growth rate | |

| Crack growth factor | |

| m | Crack growth index |

| Equivalent stress intensity factor | |

| Critical stress intensity factor | |

| Initial crack length | |

| Initial crack length | |

| Crack growth life | |

| Material tensile strength | |

| Mises stress |

References

- IEC 61400-4. Wind Turbines-Part 4: Design Requirements for Wind Turbine Gearboxes; International Electrotechnical Comission: Geneva, Switzerland, 2012; p. 146. [Google Scholar]

- DNV GL-ST-0361-2016. Machinery for Wind Turbines; DNV GL AS: Oslo, Norway, 2016. [Google Scholar]

- MackAldener, M. Tooth Interior Fatigue Fracture&Robustness of Gears; Maskinkonstruktion: Stockholm, Switzerland, 2001. [Google Scholar]

- Vullo, V. GEARS: Analysis of Load Carrying Capacity and Strength Design; Springer Nature: Berlin, Germany, 2020. [Google Scholar]

- Boiadjiev, I.; Witzig, J.; Tobie, T.; Stahl, K. Tooth flank fracture–basic principles and calculation model for a sub-surface-initiated fatigue failure mode of case-hardened gears. In Proceedings of the International Gear Conference, Lyon, France, 26–28 August 2014; pp. 26–28. [Google Scholar]

- Al, B.; Langlois, P. Analysis of tooth interior fatigue fracture using boundary conditions from an efficient and accurate loaded tooth contact analysis. In Proceedings of the British Gears Association (BGA) Gears 2015 Technical Awareness Seminar, Nottingham, UK, 12 November 2015. [Google Scholar]

- Beermann, S.; Kissling, U. Tooth Flank Fracture—A Critical Failure Mode Influence of Macro and Micro Geometry. In Proceedings of the KISSsoft User Conference, Pune, India, 25–26 November 2015; pp. 25–26. [Google Scholar]

- MackAldener, M.; Olsson, M. Tooth interior fatigue fracture—Computational and material aspects. Int. J. Fatigue 2001, 23, 329–340. [Google Scholar] [CrossRef]

- MackAldener, M.; Olsson, M. Design against tooth interior fatigue fracture. Gear Technol. (USA) 2000, 17, 18–24. [Google Scholar]

- Al, B.C.; Patel, R.; Langlois, P. Comparison of Tooth Interior Fatigue Fracture Load Capacity to Standardized Gear Failure Modes. In Proceedings of the 2016 AGMA Fall Technical Meeting, Pittsburgh, PA, USA, 2–4 October 2016. [Google Scholar]

- ISO/TS 6336-4. Calculation of Load Capacity of Spur and Helical Gears—Part. 4: Calculation of Tooth Flank Fracture Load Capacity; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- Hein, M.; Tobie, T.; Stahl, K. Parameter study on the calculated risk of tooth flank fracture of case hardened gears. J. Adv. Mech. Des. Syst. Manuf. 2017, 11, JAMDSM0074. [Google Scholar] [CrossRef] [Green Version]

- Octrue, M.; Ghribi, D.; Sainsot, P. A contribution to study the tooth flank fracture (TFF) in cylindrical gears. Procedia Eng. 2018, 213, 215–226. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Bocher, P.; Zhu, C.; Sun, Z. Effects of case hardening properties on the contact fatigue of a wind turbine gear pair. Int. J. Mech. Sci. 2018, 141, 520–527. [Google Scholar] [CrossRef]

- He, H.; Liu, H.; Zhu, C.; Yuan, L. Shakedown analysis of a wind turbine gear considering strain-hardening and the initial residual stress. J. Mech. Sci. Technol. 2018, 32, 5241–5250. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, C.; Gould, B.; Demas, N.G.; Liu, H.; Greco, A.C. The effect of contact severity on micropitting: Simulation and experiments. Tribol. Int. 2019, 138, 463–472. [Google Scholar] [CrossRef]

- Boresi, A.P.; Schmidt, R.J.; Sidebottom, O.M. Advanced Mechanics of Materials; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Lang, O. The dimensioning of complex steel members in the range of endurance strength and fatigue life. Z. Fuer Werkst. 1979, 10, 24–29. [Google Scholar] [CrossRef]

- He, H.; Liu, H.; Zhu, C.; Tang, J. Study on the gear fatigue behavior considering the effect of residual stress based on the continuum damage approach. Eng. Fail. Anal. 2019, 104, 531–544. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, C.; Liu, H.; Song, H. Investigation of Contact Performance of Case-Hardened Gears Under Plasto-elastohydrodynamic Lubrication. Tribol. Lett. 2019, 67, 92. [Google Scholar] [CrossRef]

- Thomas, J. Flankentragfähigkeit und Laufverhalten von Hartfeinbearbeiteten Kegelrädern. Ph.D. Thesis, Technische Universität München, München, Germany, 1998. [Google Scholar]

- Dang Van, K.; Griveau, B.; Message, O. On a new multiaxial fatigue limit criterion: Theory and application. In Biaxial and Multiaxial Fatigue, EGF 3; Brown, M., Miller, K., Eds.; University of Sheffield: London, UK, 1989; pp. 459–478. [Google Scholar]

- Snidle, R.W.; Evans, H.P.; Qiao, H. Comparison of fatigue model results for rough surface elastohydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 381–393. [Google Scholar]

- Karolczuk, A.; Macha, E. A Review of Critical Plane Orientations in Multiaxial Fatigue Failure Criteria of Metallic Materials. Int. J. Fract. 2005, 134, 267–304. [Google Scholar] [CrossRef]

- Osman, T.; Velex, P. A model for the simulation of the interactions between dynamic tooth loads and contact fatigue in spur gears. Tribol. Int. 2012, 46, 84–96. [Google Scholar] [CrossRef]

- Kluger, K.; Łagoda, T. Application of the Dang-Van criterion for life determination under uniaxial random tension–compression with different mean values. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 505–512. [Google Scholar] [CrossRef]

- Boller, C.; Seeger, T. Materials Data for Cyclic Loading: Low-Alloy. Steels; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue; Pearson: Boston, MA, USA, 2012. [Google Scholar]

- Kato, M.; Deng, G.; Inoue, K.; Takatsu, N. Evaluation of the strength of carburized spur gear teeth based on fracture mechanics. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1993, 36, 233–240. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; He, H.; Wei, P. Evaluation of contact fatigue life of a wind turbine gear pair considering residual stress. J. Tribol. 2018, 140. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Number of teeth | |

| Normal module | |

| Face width | |

| Pressure angle | |

| Helix angle | |

| Gear shifting coefficients | |

| Rated input torque | |

| Input speed | |

| Gear material | 18CrNiMo7-6 |

| Press Angle (deg) | Working Center Distance (mm) | Profile Shift Coefficient | Radius of Curvature at HPSTC | Equivalent Radius of Curvature (mm) | ||

|---|---|---|---|---|---|---|

| Pinion | Wheel | Pinion | Wheel | |||

| 20 | 777 | 0.33 | 0.27 | 58.15 | 227.60 | 46.316 |

| 22.5 | 777 | 0.28 | 0.22 | 64.62 | 255.61 | 51.58 |

| 25 | 777 | 0.24 | 0.17 | 68.63 | 283.65 | 55.26 |

| Influence Parameter | Parameter Value | ||

|---|---|---|---|

| 633 HV | 675 HV | 745 HV | |

| 303 HV | 343 HV | 390 HV | |

| 2 mm | 2.2 mm | 2.4 mm | |

| Orthogonal Test Number | Fatigue Parameters | |||

|---|---|---|---|---|

| 1 | 633 (I) | 303 (I) | 2 (I) | 0.376 |

| 2 | 633 (I) | 343 (II) | 2.2 (II) | 0.373 |

| 3 | 633 (I) | 390 (III) | 2.4 (III) | 0.384 |

| 4 | 675 (II) | 303 (I) | 2.2 (II) | 0.381 |

| 5 | 675 (II) | 343 (II) | 2.4 (III) | 0.360 |

| 6 | 675 (II) | 390 (III) | 2 (I) | 0.384 |

| 7 | 745 (III) | 303 (I) | 2.4 (III) | 0.350 |

| 8 | 745 (III) | 343 (II) | 2 (I) | 0.394 |

| 9 | 745 (III) | 390 (III) | 2.2 (II) | 0.336 |

| K(I) | 1.133 | 1.107 | 1.154 | |

| K(II) | 1.125 | 1.127 | 1.090 | |

| K(III) | 1.080 | 1.104 | 0.744 | |

| (=K(I)/3) | 0.378 | 0.369 | 0.385 | |

| (=K(II)/3) | 0.375 | 0.376 | 0.363 | |

| (=K(III)/3) | 0.360 | 0.368 | 0.248 | |

| 0.02 | 0.01 | 0.14 | ||

| Optimal parameter combination |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, H.; Zhu, C.; Zhou, Y.; Chen, X.; Feng, H.; Ye, W. Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears. Metals 2020, 10, 1497. https://doi.org/10.3390/met10111497

Bai H, Zhu C, Zhou Y, Chen X, Feng H, Ye W. Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears. Metals. 2020; 10(11):1497. https://doi.org/10.3390/met10111497

Chicago/Turabian StyleBai, Houyi, Caichao Zhu, Ye Zhou, Xiaojin Chen, Houbin Feng, and Wei Ye. 2020. "Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears" Metals 10, no. 11: 1497. https://doi.org/10.3390/met10111497

APA StyleBai, H., Zhu, C., Zhou, Y., Chen, X., Feng, H., & Ye, W. (2020). Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears. Metals, 10(11), 1497. https://doi.org/10.3390/met10111497