Experimental and Simulation Studies on the Compressive Properties of Brazed Aluminum Honeycomb Plates and a Strength Prediction Method

Abstract

:1. Introduction

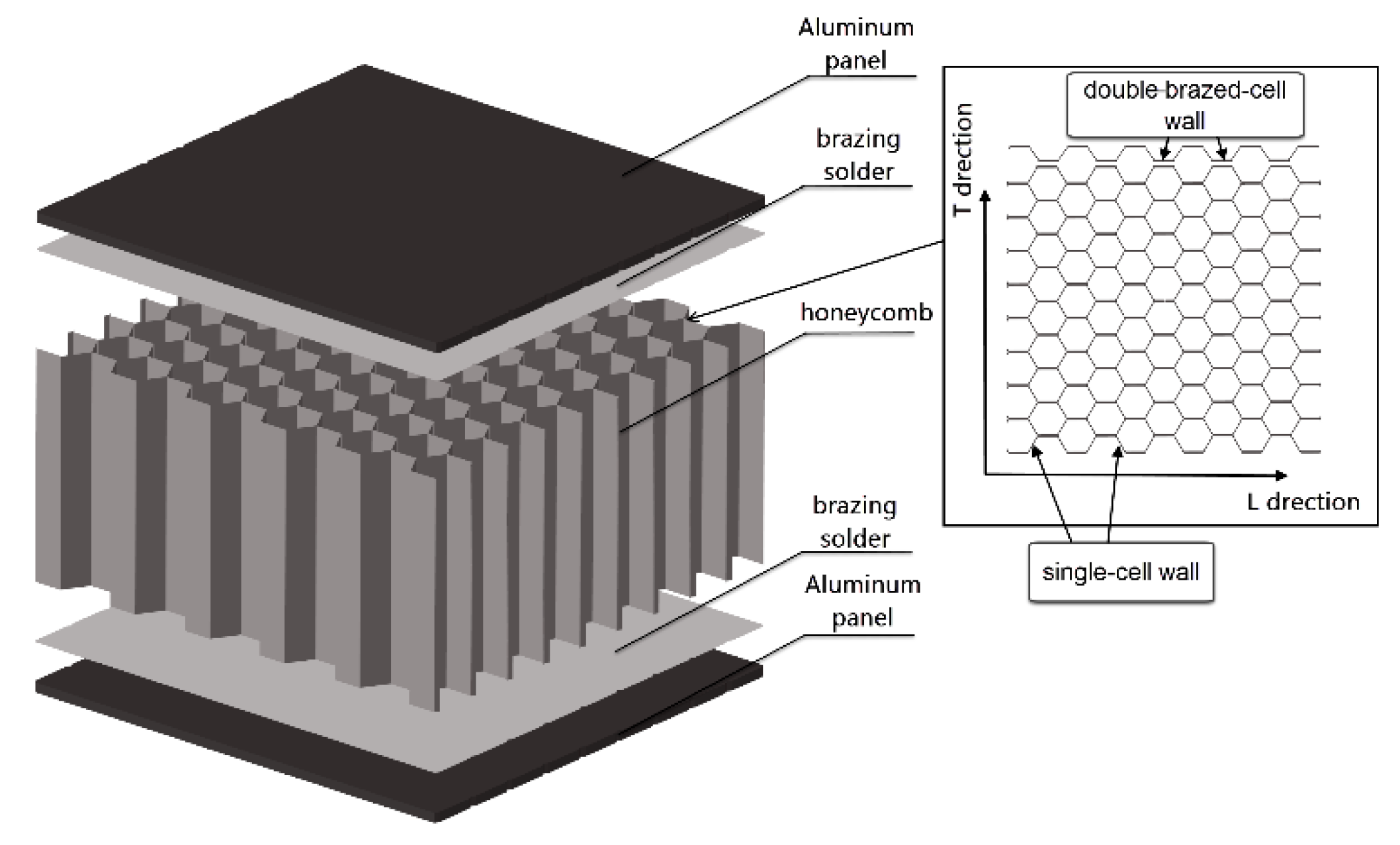

2. Brief Introduction of BAHP and Honeycomb Core Experiment

2.1. Brazed Aluminum Honeycomb Plates (BAHPs)

2.2. Test on Cell Wall in Core

3. Tests on BAHP

3.1. Out-of-Plane Compression Test

3.2. Out-of-Plane Compression Test

4. Theoretical and Simulation Analysis

4.1. Method to Predict Out-of-Plane Compressive Strength

4.2. Finite Element Model

4.3. Simulation Results

4.4. Defects Analysis

5. Conclusions

- (1)

- Tensile tests of the single-cell wall and ten-brazed-cell walls in the honeycomb were conducted, showing that their material properties are completely different. Therefore, their differences should be mainly considered when studying a BAHP.

- (2)

- Considering the out-of-plane compression properties of the BAHP, the brazed area is extremely tight such that there is no debonding. Regarding the in-plane compression properties, two compression directions were designed: transverse and longitudinal. The load–displacement curves, ultimate loads, and failure modes are different in different directions. The interface bonding strength of the BAHP is high and there is no large-scale debonding between the core and the panel.

- (3)

- A theoretical method for the prediction of the strength of the BAHP under out-of-plane compression is proposed. Considering the properties of the BAHP, this method can yield accurate results. The results of the simulation considering two cell walls are more consistent to the test. From the simulation and theoretical analysis, it was seen that the core material parameters have a significant influence during out-of-plane compression, whereas the in-plane compression properties mainly depend on the panel. With the uneven height and debonding defects, the FE models are earlier entered the stage overall instability which are more close to the test.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, Z.H.; Guo, H.R.; Jiang, B.H.; Zhu, F.; Cao, L.B. A study on the mean crushing strength of hexagonal multi-cell thin-walled structures. Thin Wall Struct. 2014, 80, 38–45. [Google Scholar] [CrossRef]

- Bang, S.O.; Cho, J.U. A Study on the Compression Property of Sandwich Composite with Porous Core. Int. J. Precis. Eng. Man. 2015, 16, 1117–1122. [Google Scholar] [CrossRef]

- Wang, D.M.; Bai, Z.Y. Mechanical property of paper honeycomb structure under dynamic compression. Mater. Des. 2015, 77, 59–64. [Google Scholar] [CrossRef]

- Liu, L.Q.; Meng, P.; Wang, H.; Guan, Z.W. The flatwise compressive properties of Nomex honeycomb core with debonding imperfections in the double cell wall. Compos. Part B 2015, 76, 122–132. [Google Scholar] [CrossRef]

- Ogasawara, N.; Chiba, N.; Kobayashi, E.; Kikuchi, Y. Crushing strength of Aluminum Honeycomb with Thinning Cell Wall. J. Solid Mech. Mater. Eng. 2010, 4, 1338–1445. [Google Scholar] [CrossRef] [Green Version]

- Aminanda, Y.; Castanie, B.; Barrau, J.J.; Thevent, P. Experimental Analysis and Modeling of the Crushing of Honeycomb Cores. Appl. Compos. Mater. 2005, 12, 213–227. [Google Scholar] [CrossRef]

- Muhammad, K.K.; Wang, Q.Y. Experimental and Finite Element Based Investigations of In-plane and Out-of-plane Properties of Aluminum Honeycomb. Appl. Mech. Mater. 2013, 275–277, 111–116. [Google Scholar]

- Wang, Z.G.; Li, Z.D.; Zhou, W.; Hui, D. On the influence of structural defects for honeycomb structure. Compos. Part B 2018, 142, 183–192. [Google Scholar] [CrossRef]

- Rajkumar, S.; Arulmurugan, B.; Manikandan, M.; Karthick, R.; Kaviprasath, S. Analysis of Physical and Mechanical Properties of A3003 Aluminum. Appl. Mech. Mater. 2016, 867, 245–253. [Google Scholar] [CrossRef]

- Cai, L.C.; Zhang, D.Y.; Zhou, S.H.; Xu, W. Investigation on Mechanical Properties and Equivalent Model of Aluminum Honeycomb Sandwich Panels. J. Mater. Eng. Perform. 2018, 27, 6585–6596. [Google Scholar] [CrossRef]

- Zakeri, A.A.; Mazraehshahi, H.T. Experimental study on mechanical properties of aircraft honeycomb sandwich structures. EPJ Web Conf. 2010, 6, 24003. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.S.; Hong, S.H. Mechanical behavior and failure process during compressive and shear deformation of honeycomb composite at elevated temperatures. J. Mater. Sci. 2002, 37, 1265–1272. [Google Scholar] [CrossRef]

- Qiu, C.; Guan, Z.D.; Li, Z.S. Edgewise Compression Behavior of Honeycomb Sandwich Structures. In Proceedings of the 8th International Conference on Mechanical and Aerospace Engineering, Prague, Czech Republic, 22–25 July 2017; pp. 85–91. [Google Scholar]

- Paika, J.K.; Thayamballib, A.K.; Kima, G.S. The strength characteristics of aluminum honeycomb andwich panels. Thin Wall Struct. 1999, 35, 205–231. [Google Scholar] [CrossRef]

- Peng, M.J.; Sun, Y.; Yao, J.; Duan, Y.H.; Wang, S.B. Finite Element Simulation on Three-point Bending of Brazed Aluminum Honeycomb Panel. Adv. Mater. Res. 2010, 168–170, 1046–1050. [Google Scholar] [CrossRef]

- Matta, V.; Kumar, J.S.; Venkatara, V.; Reddy, G.B.K. Flexural Behavior of Aluminum Honeycomb Core Sandwich Structure. IOP Conf. Ser. Mater. Sci. Eng. 2017, 27, 1–11. [Google Scholar] [CrossRef]

- Shi, S.S.; Chen, P.Z.; Sun, Z. Three-point bending and in-plane compression properties of carbon-fiber/ aluminum-honeycomb sandwich panels with short-Kevlar-fiber toughening. Acta Mater. Compos. Sin. 2017, 34, 1953–1959. [Google Scholar]

- Gerard, G.; Becker, H. Handbook of Structural Stability Part I: Buckling of Flat Plate. Natl. Advis. Comm. Aeronaut. 1957, 1, 3781. [Google Scholar]

- Zhou, Z.L. Ultimate Strength of Postbuckling for Simply Supported Rectangular Composite Thin Plates under Compression. Appl. Math. Mech. 1998, 19, 365–371. [Google Scholar]

- Zhang, T.L.; Ding, Y.L.; Jin, H.B. Comparative analysis of equivalent models for honeycomb sandwich plates. Chin. J. Appl. Mech. 2011, 28, 275–282. [Google Scholar]

- Shen, G.L.; Hu, G.K. Mechanics of Composite Materials; Tsinghua University Press: Beijing, China, 2006. [Google Scholar]

- Lei, H.S.; Zhu, X.L.; Chen, H.S.; Fan, H.L.; Chen, M.J.; Fang, D.N. Macroscopic response of carbon-fiber pyramidal truss core panel taking account of local defect. Compos. Part B 2015, 79, 311–321. [Google Scholar] [CrossRef]

- Biagi, R.; Smith, H.B. Imperfection sensitivity of pyramidal core sandwich structures. Int. J. Solids Struct. 2007, 44, 4690–4706. [Google Scholar] [CrossRef] [Green Version]

| Construction | Brand | Si | Cu | Mn | Zn | Fe | Al |

|---|---|---|---|---|---|---|---|

| Panel | A602 | 0.5–1.2% | 0.2–0.6% | 0.15–0.35% | 0.2% | 0.5% | the rest |

| Core | 3003 | 0.6% | 0.05–0.2% | 1.0–1.5% | 0.1% | 0.7% | the rest |

| Material | Brand | Elastic Modulus | Poisson’s Ratio | Yield Stress | Ultimate Stress | Density Kg/m3 |

|---|---|---|---|---|---|---|

| Panel | 6A02 | 72,327 MPa | 0.33 | 118 MPa | 180 MPa | 2.7 × 103 |

| Single-cell | 3003 | 58,710 MPa | 0.33 | 154 MPa | 160 MPa | 2.7 × 103 |

| Double-brazed-cell | 3003 | 105,250 MPa | 0.33 | 25 MPa | 134 MPa | 2.7 × 103 |

| Pressure head and fixture | 206,000 MPa | 0.3 | 345 MPa | 600 MPa | 7.8 × 103 |

| Defect Types | Defect Levels |

|---|---|

| Panel unilateral uneven height | dh = 0 mm |

| dh = 1.5 mm | |

| dh = 2.5 mm | |

| Panel bilateral uneven height | dh1 = 1.5 mm, dh2 = 0 mm |

| dh1 = 1.5 mm, dh2 = 0.5 mm | |

| dh1 = 1.5 mm, dh2 = 1 mm | |

| Unilateral debonding between panels and core | One row of unit cell debonding |

| Two row of unit cell debonding | |

| Three row of unit cell debonding | |

| Bilateral debonding between panels and core | One row of unit cell debonding |

| Two row of unit cell debonding | |

| Three row of unit cell debonding |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Xiao, S.; Zhang, J.; Lv, R.; Yang, B.; Dong, D.; Yang, G.; Zhu, T. Experimental and Simulation Studies on the Compressive Properties of Brazed Aluminum Honeycomb Plates and a Strength Prediction Method. Metals 2020, 10, 1544. https://doi.org/10.3390/met10111544

Jiang L, Xiao S, Zhang J, Lv R, Yang B, Dong D, Yang G, Zhu T. Experimental and Simulation Studies on the Compressive Properties of Brazed Aluminum Honeycomb Plates and a Strength Prediction Method. Metals. 2020; 10(11):1544. https://doi.org/10.3390/met10111544

Chicago/Turabian StyleJiang, Lanxin, Shoune Xiao, Jingke Zhang, Ruijuan Lv, Bing Yang, Dawei Dong, Guangwu Yang, and Tao Zhu. 2020. "Experimental and Simulation Studies on the Compressive Properties of Brazed Aluminum Honeycomb Plates and a Strength Prediction Method" Metals 10, no. 11: 1544. https://doi.org/10.3390/met10111544