In Situ Synchrotron X-ray Diffraction Investigations of the Nonlinear Deformation Behavior of a Low Modulus β-Type Ti36Nb5Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure and Macroscopic Mechanical Behavior

3.2. In Situ SXRD Characterization along the LD and SD

4. Discussion

4.1. Variant Selection of Stress-Induced Martensite

4.2. Origin of the Recoverable Strain

4.3. Microscopic Deformation Mechanisms at Different Macroscopic Applied Strains

5. Conclusions

- (1)

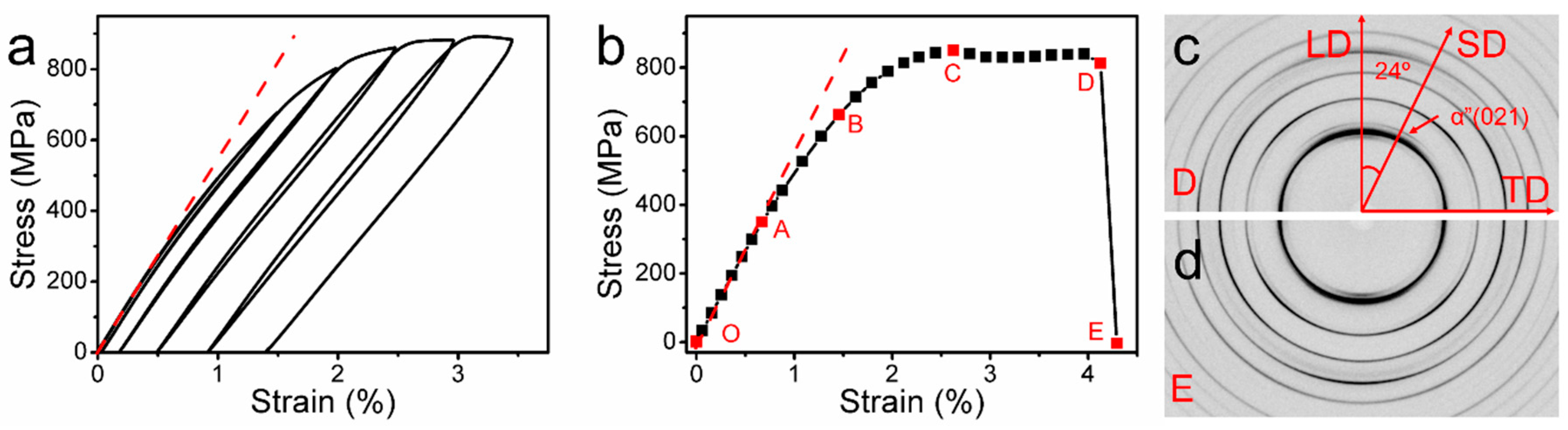

- The cold rolled plus annealed Ti36Nb5Zr alloy consists of dominant β phase and a trace of α phase, and has a {001}<110> texture component. During loading, a nonlinear deformation behavior appeared after the loading strain exceeded the linear range limit of ~0.6%, and large recoverable strains of 2.01% and 2.11% were obtained at applied strains of 2.5% and 3.5%, respectively.

- (2)

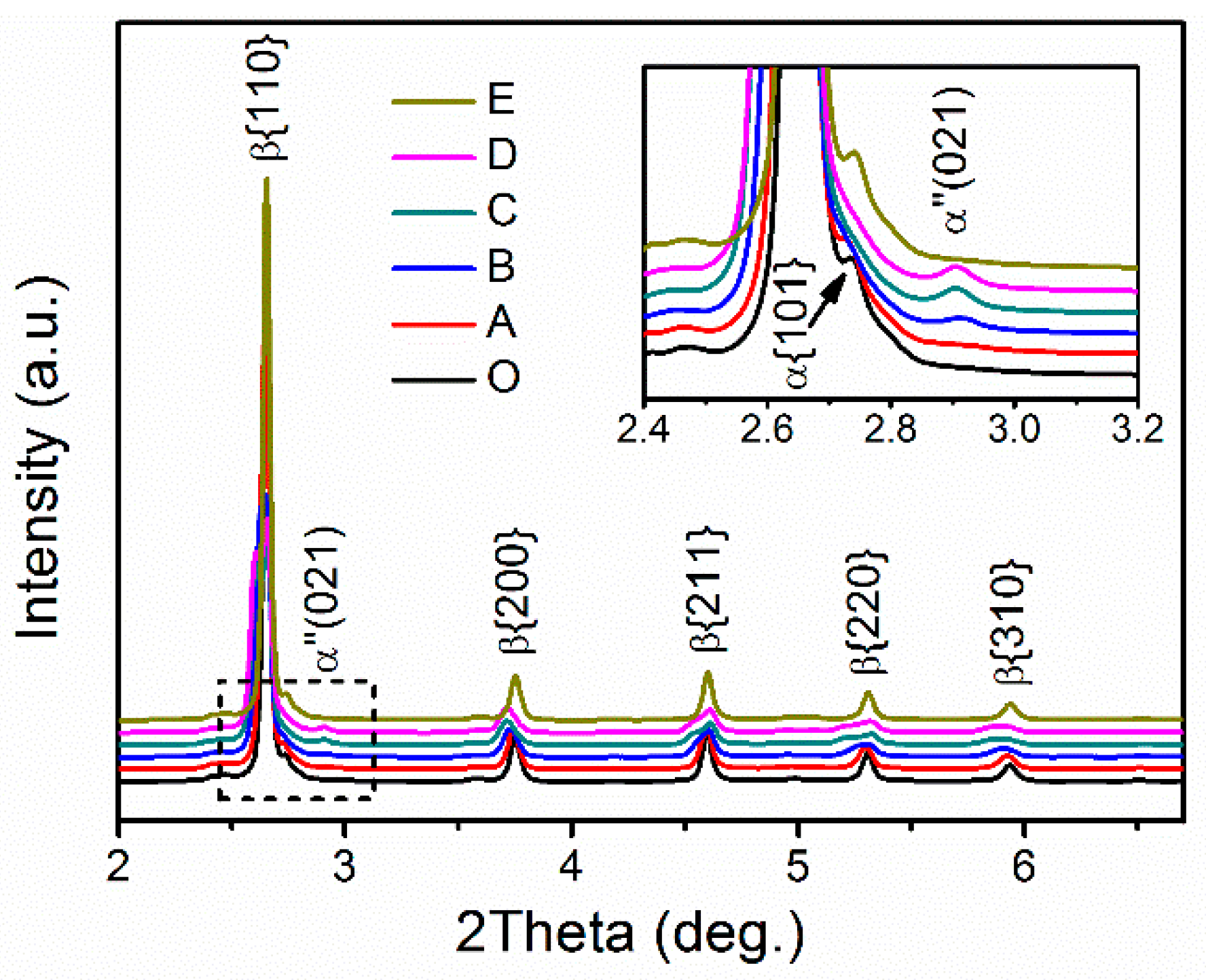

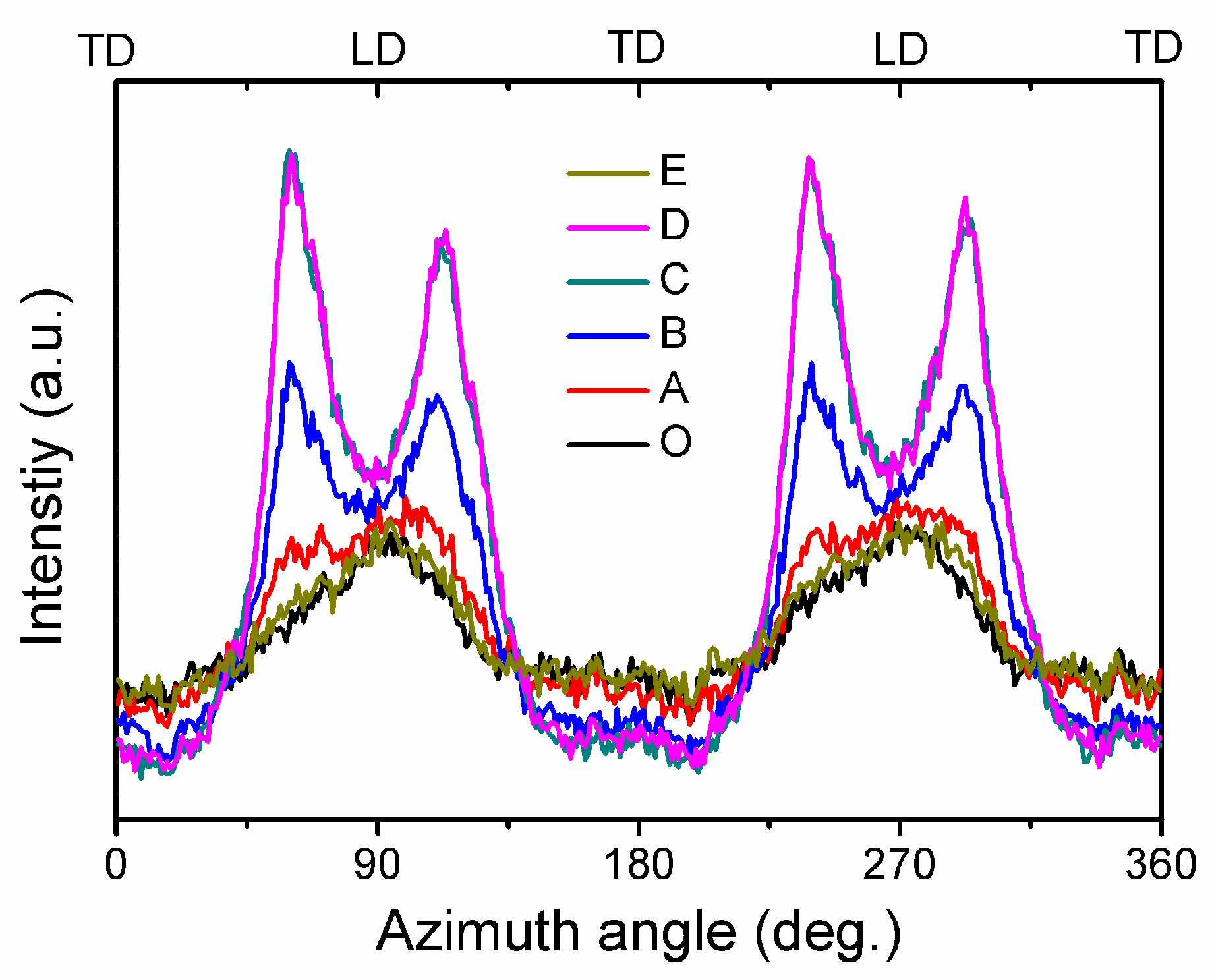

- SIMT occurred at an external strain of 0.67% and continued with an applied strain up to 2.67%. Furthermore, the onset of SIMT corresponds to the beginning of the nonlinearity in macroscopic stress–strain curves, indicating that the nonlinear deformation behavior originates from the SIMT. Besides, the α” diffraction spots only appeared at specific azimuth angles on the 2D SXRD patterns, which was caused by the preferred orientation of the original β grains and the stress-induced selections of martensitic variants.

- (3)

- The large recoverable strain was dominated by the elastic deformation of the β phase, which resulted from the low β phase stability of the Ti36Nb5Zr alloy, whereas the β→α” phase transformation strain contributed little to the recoverable strain due to the low volume fraction of the transformed β phase.

- (4)

- Various deformation mechanisms were activated at different applied strains, including elastic deformation at applied strains of 0–1.46%, SIMT at applied strains of 0.67–2.62%, elastoplastic deformation at applied strains of 1.46–2.62% and plastic deformation at applied strains exceeding 2.62%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-C.; Chen, L.-Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Sumner, D.R.; Turner, T.M.; Igloria, R.; Urban, R.M.; Galante, J.O. Functional adaptation and ingrowth of bone vary as a function of hip implant stiffness. J. Biomech. 1998, 31, 909–917. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Li, P.; Ma, X.; Jia, Y.; Meng, F.; Tang, L.; He, Z. Microstructure and Mechanical Properties of Rapidly Solidified β-Type Ti–Fe–Sn–Mo Alloys with High Specific Strength and Low Elastic Modulus. Metals 2019, 9, 1135. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Ma, X.; Wang, D.; Zhang, H. Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus. Metals 2019, 9, 712. [Google Scholar] [CrossRef] [Green Version]

- Preisler, D.; Janeček, M.; Harcuba, P.; Džugan, J.; Halmešová, K.; Málek, J.; Veverková, A.; Stráský, J. The Effect of Hot Working on the Mechanical Properties of High Strength Biomedical Ti-Nb-Ta-Zr-O Alloy. Materials 2019, 12, 4233. [Google Scholar] [CrossRef] [Green Version]

- Biesiekierski, A.; Wang, J.; Abdel-Hady Gepreel, M.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef]

- Ramezannejad, A.; Xu, W.; Xiao, W.L.; Fox, K.; Liang, D.; Qian, M. New insights into nickel-free superelastic titanium alloys for biomedical applications. Curr. Opin. Solid State Mater. 2019, 23, 100783. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ikehara, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater. 2006, 54, 2419–2429. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Hady, M.; Hinoshita, K.; Morinaga, M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr. Mater. 2006, 55, 477–480. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Liang, Q.; Kloenne, Z.; Zheng, Y.; Wang, D.; Antonov, S.; Gao, Y.; Hao, Y.; Yang, R.; Wang, Y.; Fraser, H.L. The role of nano-scaled structural non-uniformities on deformation twinning and stress-induced transformation in a cold rolled multifunctional β-titanium alloy. Scr. Mater. 2020, 177, 181–185. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.Y.; Marteleur, M.; Gloriant, T.; Vermaut, P.; Laillé, D.; Castany, P.; Curfs, C.; Jacques, P.J.; Prima, F. Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater. 2013, 61, 6406–6417. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.J.; Ma, S.Y.; Wang, S.Q. The Nucleation and the Intrinsic Microstructure Evolution of Martensite from {332}<113>(beta) Twin Boundary in beta Titanium: First-Principles Calculations. Metals 2019, 9, 1202. [Google Scholar] [CrossRef] [Green Version]

- Hanada, S.; Izumi, O. Correlation of tensile properties, deformation modes, and phase stability in commercial β-phase titanium alloys. Met. Mater. Trans. A 1987, 18, 265–271. [Google Scholar] [CrossRef]

- Li, S.; Choi, M.-s.; Nam, T.-h. Effect of thermo-mechanical treatment on microstructural evolution and mechanical properties of a superelastic Ti–Zr-based shape memory alloy. Mater. Sci. Eng. A 2020, 789, 139664. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kim, H.Y.; Hosoda, H. Development and characterization of Ni-free Ti-base shape memory and superelastic alloys. Mater. Sci. Eng. A 2006, 438–440, 18–24. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, F.; Chen, Z.; Yang, Y.; Shen, B.; Li, J.; Prima, F. Strong and ductile beta Ti–18Zr–13Mo alloy with multimodal twinning. Mater. Res. Lett. 2019, 7, 251–257. [Google Scholar] [CrossRef] [Green Version]

- Fu, J.; Yamamoto, A.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Novel Ti-base superelastic alloys with large recovery strain and excellent biocompatibility. Acta Biomater. 2015, 17, 56–67. [Google Scholar] [CrossRef]

- Hao, Y.L.; Li, S.J.; Sun, S.Y.; Zheng, C.Y.; Hu, Q.M.; Yang, R. Super-elastic titanium alloy with unstable plastic deformation. Appl. Phys. Lett. 2005, 87, 091906. [Google Scholar] [CrossRef]

- Saito, T.; Furuta, T.; Hwang, J.-H.; Kuramoto, S.; Nishino, K.; Suzuki, N.; Chen, R.; Yamada, A.; Ito, K.; Seno, Y.; et al. Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 2003, 300, 464–467. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.L.; Li, S.J.; Sun, S.Y.; Zheng, C.Y.; Yang, R. Elastic deformation behaviour of Ti–24Nb–4Zr–7.9Sn for biomedical applications. Acta Biomater. 2007, 3, 277–286. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Li, S.J.; Obbard, E.G.; Wang, H.; Wang, S.C.; Hao, Y.L.; Yang, R. Elastic properties of Ti–24Nb–4Zr–8Sn single crystals with bcc crystal structure. Acta Mater. 2011, 59, 3081–3090. [Google Scholar] [CrossRef]

- Gutkin, M.Y.; Ishizaki, T.; Kuramoto, S.; Ovid’ko, I.A. Nanodisturbances in deformed Gum Metal. Acta Mater. 2006, 54, 2489–2499. [Google Scholar] [CrossRef]

- Cui, J.P.; Hao, Y.L.; Li, S.J.; Sui, M.L.; Li, D.X.; Yang, R. Reversible Movement of Homogenously Nucleated Dislocations in a β-Titanium Alloy. Phys. Rev. Lett. 2009, 102, 045503. [Google Scholar] [CrossRef]

- Liang, Q.; Wang, D.; Zheng, Y.; Zhao, S.; Gao, Y.; Hao, Y.; Yang, R.; Banerjee, D.; Fraser, H.L.; Wang, Y. Shuffle-nanodomain regulated strain glass transition in Ti-24Nb-4Zr-8Sn alloy. Acta Mater. 2020, 186, 415–424. [Google Scholar] [CrossRef]

- Liu, J.P.; Wang, Y.D.; Hao, Y.L.; Wang, H.L.; Wang, Y.; Nie, Z.H.; Su, R.; Wang, D.; Ren, Y.; Lu, Z.P.; et al. High-energy X-ray diffuse scattering studies on deformation-induced spatially confined martensitic transformations in multifunctional Ti–24Nb–4Zr–8Sn alloy. Acta Mater. 2014, 81, 476–486. [Google Scholar] [CrossRef] [Green Version]

- Talling, R.J.; Dashwood, R.J.; Jackson, M.; Dye, D. On the mechanism of superelasticity in Gum metal. Acta Mater. 2009, 57, 1188–1198. [Google Scholar] [CrossRef] [Green Version]

- Al-Zain, Y.; Kim, H.Y.; Koyano, T.; Hosoda, H.; Nam, T.H.; Miyazaki, S. Anomalous temperature dependence of the superelastic behavior of Ti–Nb–Mo alloys. Acta Mater. 2011, 59, 1464–1473. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Cyclic deformation behavior of a Ti–26 at.% Nb alloy. Acta Mater. 2009, 57, 2461–2469. [Google Scholar] [CrossRef]

- Zhao, C.H.; Kisslinger, K.; Huang, X.J.; Lu, M.; Camino, F.; Lin, C.H.; Yan, H.F.; Nazaretski, E.; Chu, Y.; Ravel, B.; et al. Bi-continuous pattern formation in thin films via solid-state interfacial dealloying studied by multimodal characterization. Mater. Horiz. 2019, 6, 1991–2002. [Google Scholar] [CrossRef]

- Zhu, Z.W.; Xiong, C.Y.; Wang, J.; Li, R.G.; Ren, Y.; Wang, Y.D.; Li, Y. In situ synchrotron X-ray diffraction investigations of the physical mechanism of ultra-low strain hardening in Ti-30Zr-10Nb alloy. Acta Mater. 2018, 154, 45–55. [Google Scholar] [CrossRef]

- Warchomicka, F.; Canelo-Yubero, D.; Zehetner, E.; Requena, G.; Stark, A.; Poletti, C. In-Situ Synchrotron X-Ray Diffraction of Ti-6Al-4V During Thermomechanical Treatment in the Beta Field. Metals 2019, 9, 862. [Google Scholar] [CrossRef] [Green Version]

- Castany, P.; Ramarolahy, A.; Prima, F.; Laheurte, P.; Curfs, C.; Gloriant, T. In situ synchrotron X-ray diffraction study of the martensitic transformation in superelastic Ti-24Nb-0.5N and Ti-24Nb-0.5O alloys. Acta Mater. 2015, 88, 102–111. [Google Scholar] [CrossRef]

- Yang, Y.; Castany, P.; Cornen, M.; Prima, F.; Li, S.J.; Hao, Y.L.; Gloriant, T. Characterization of the martensitic transformation in the superelastic Ti–24Nb–4Zr–8Sn alloy by in situ synchrotron X-ray diffraction and dynamic mechanical analysis. Acta Mater. 2015, 88, 25–33. [Google Scholar] [CrossRef]

- Morris, J.W.; Hanlumyuang, Y.; Sherburne, M.; Withey, E.; Chrzan, D.C.; Kuramoto, S.; Hayashi, Y.; Hara, M. Anomalous transformation-induced deformation in 〈110〉 textured Gum Metal. Acta Mater. 2010, 58, 3271–3280. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, S.; Ren, X.; Xu, H.; Zhao, X. Possible contribution of low shear modulus C44 to the low Young’s modulus of Ti-36Nb-5Zr alloy. Appl. Phys. Lett. 2014, 105, 131907. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, J.; Huo, Y.; Sui, Y.; Zhang, J.; Guo, S.; Zhao, X. Design of low modulus β-type titanium alloys by tuning shear modulus C44. J. Alloys Compd. 2018, 745, 579–585. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.; Zhao, X.; Wei, Q.; Xu, H. Design and fabrication of a metastable β-type titanium alloy with ultralow elastic modulus and high strength. Sci. Rep. 2015, 5, 14688. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, Q.; Guo, S.; Zhu, Y.; Zhao, X. Effect of thermo-mechanical treatment on mechanical and elastic properties of Ti–36Nb–5Zr alloy. Prog. Nat. Sci. 2015, 25, 229–235. [Google Scholar] [CrossRef] [Green Version]

- Sander, B.; Raabe, D. Texture inhomogeneity in a Ti–Nb-based β-titanium alloy after warm rolling and recrystallization. Mater. Sci. Eng. A 2008, 479, 236–247. [Google Scholar] [CrossRef]

- Hou, F.Q.; Li, S.J.; Hao, Y.L.; Yang, R. Nonlinear elastic deformation behaviour of Ti–30Nb–12Zr alloys. Scr. Mater. 2010, 63, 54–57. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Inamura, T.; Hosoda, H.; Miyazaki, S. Lattice modulation and superelasticity in oxygen-added β-Ti alloys. Acta Mater. 2011, 59, 6208–6218. [Google Scholar] [CrossRef]

- Sun, B.B.; Sui, M.L.; Wang, Y.M.; He, G.; Eckert, J.; Ma, E. Ultrafine composite microstructure in a bulk Ti alloy for high strength, strain hardening and tensile ductility. Acta Mater. 2006, 54, 1349–1357. [Google Scholar] [CrossRef]

- Chen, X.H.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Jeon, C.; Kim, C.P.; Joo, S.H.; Kim, H.S.; Lee, S. High tensile ductility of Ti-based amorphous matrix composites modified from conventional Ti–6Al–4V titanium alloy. Acta Mater. 2013, 61, 3012–3026. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Yang, H.; Ren, Y.; Cui, L.; Jiang, D.; Wu, Z.; Ma, Z.; Guo, F.; Bakhtiari, S.; et al. Achieving 5.9% elastic strain in kilograms of metallic glasses: Nanoscopic strain engineering goes macro. Mater. Today 2020, 37, 18–26. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, S.; Jiang, D.; Huan, Y.; Cui, L.; Liu, Y.; Ren, Y.; Yang, H. Dual Phase Synergy Enabled Large Elastic Strains of Nanoinclusions in a Dislocation Slip Matrix Composite. Nano Lett. 2018, 18, 2976–2983. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, Y.; Cui, L.; Hao, S.; Jiang, D.; Yu, K.; Mao, S.; Ren, Y.; Yang, H. “Lattice Strain Matching”-Enabled Nanocomposite Design to Harness the Exceptional Mechanical Properties of Nanomaterials in Bulk Forms. Adv. Mater. 2020, 32, 1904387. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Emelianova, E.; Sinyakova, E.; Kazachenok, M. Early prediction of macroscale plastic strain localization in titanium from observation of mesoscale surface roughening. Int. J. Mech. Sci. 2019, 161–162, 105047. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Q.; Li, H.; Wang, K.; Guo, S.; Wei, F.; Qi, J.; Sui, Y.; Shen, B.; Zhao, X. In Situ Synchrotron X-ray Diffraction Investigations of the Nonlinear Deformation Behavior of a Low Modulus β-Type Ti36Nb5Zr Alloy. Metals 2020, 10, 1619. https://doi.org/10.3390/met10121619

Meng Q, Li H, Wang K, Guo S, Wei F, Qi J, Sui Y, Shen B, Zhao X. In Situ Synchrotron X-ray Diffraction Investigations of the Nonlinear Deformation Behavior of a Low Modulus β-Type Ti36Nb5Zr Alloy. Metals. 2020; 10(12):1619. https://doi.org/10.3390/met10121619

Chicago/Turabian StyleMeng, Qingkun, Huan Li, Kai Wang, Shun Guo, Fuxiang Wei, Jiqiu Qi, Yanwei Sui, Baolong Shen, and Xinqing Zhao. 2020. "In Situ Synchrotron X-ray Diffraction Investigations of the Nonlinear Deformation Behavior of a Low Modulus β-Type Ti36Nb5Zr Alloy" Metals 10, no. 12: 1619. https://doi.org/10.3390/met10121619

APA StyleMeng, Q., Li, H., Wang, K., Guo, S., Wei, F., Qi, J., Sui, Y., Shen, B., & Zhao, X. (2020). In Situ Synchrotron X-ray Diffraction Investigations of the Nonlinear Deformation Behavior of a Low Modulus β-Type Ti36Nb5Zr Alloy. Metals, 10(12), 1619. https://doi.org/10.3390/met10121619