Effect of TiN Spray Coating on Cracking Susceptibility and Energy Absorption in Laser Welding of Aluminum Alloys

Abstract

1. Introduction

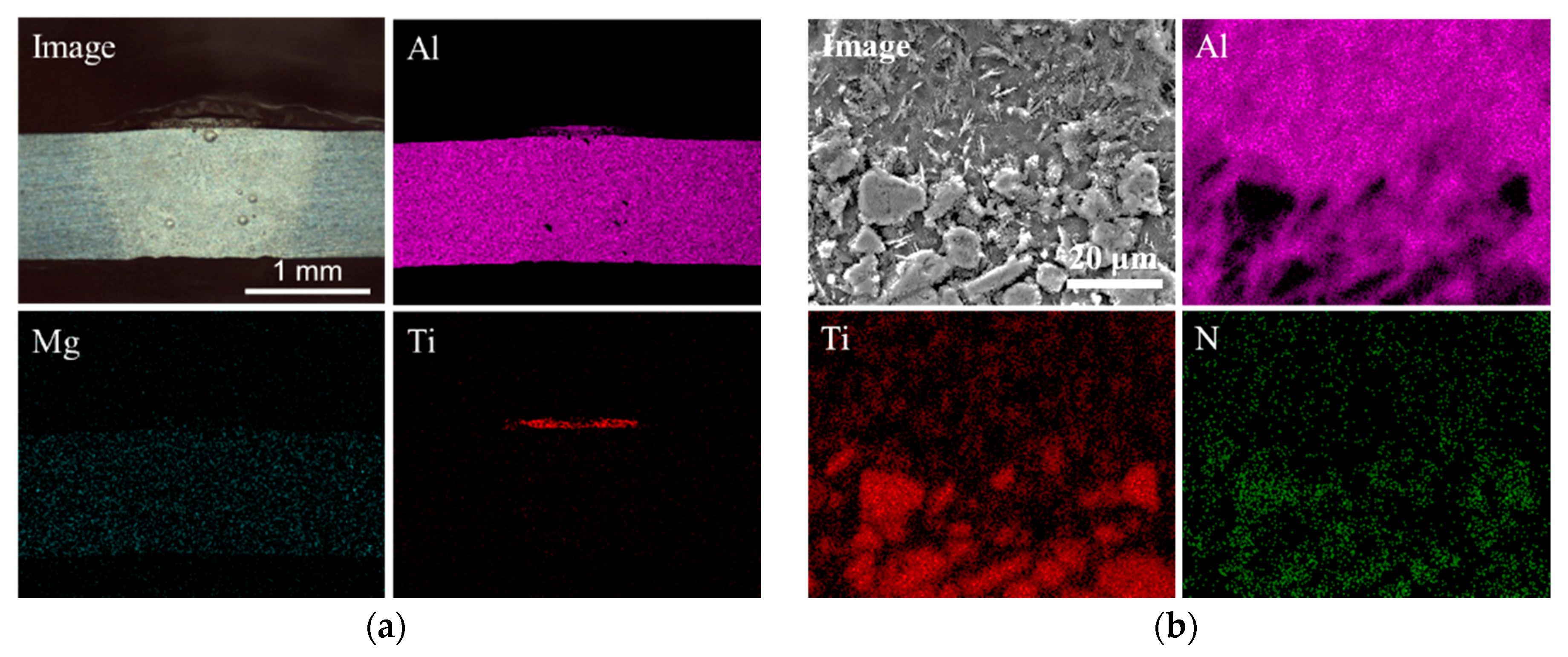

2. Materials and Methods

3. Results

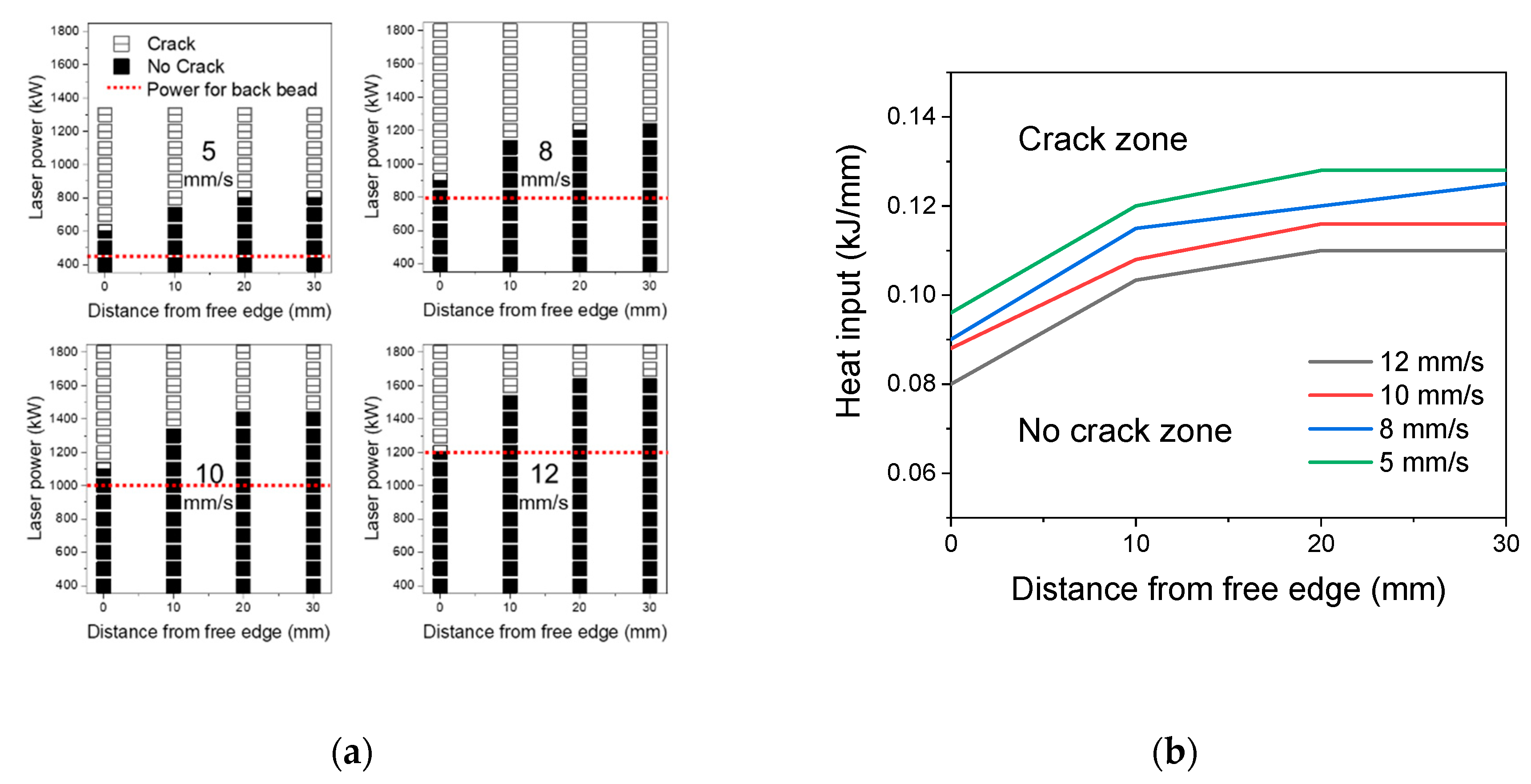

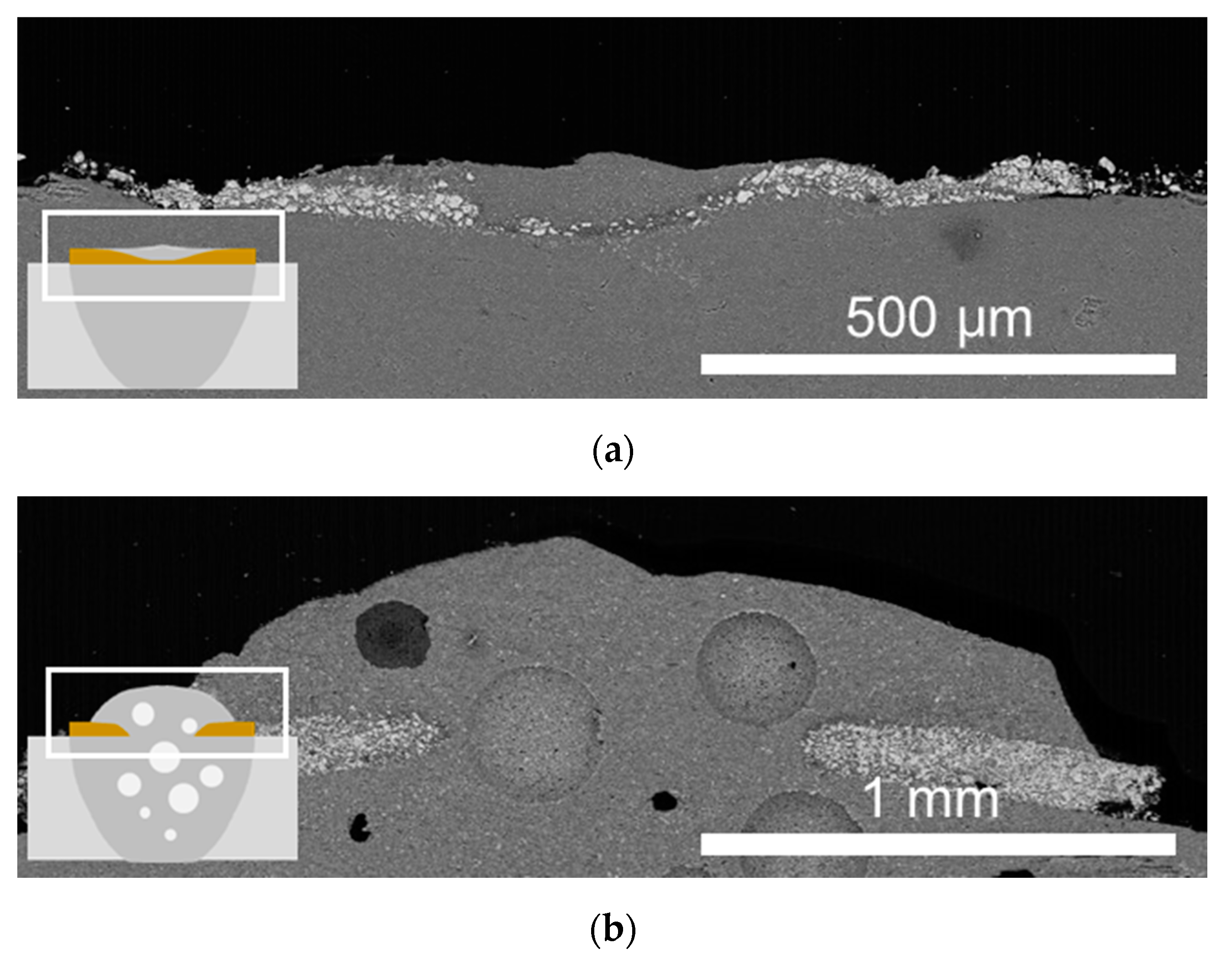

3.1. Cracking Susceptibility of Base Material by Free-Edge Test

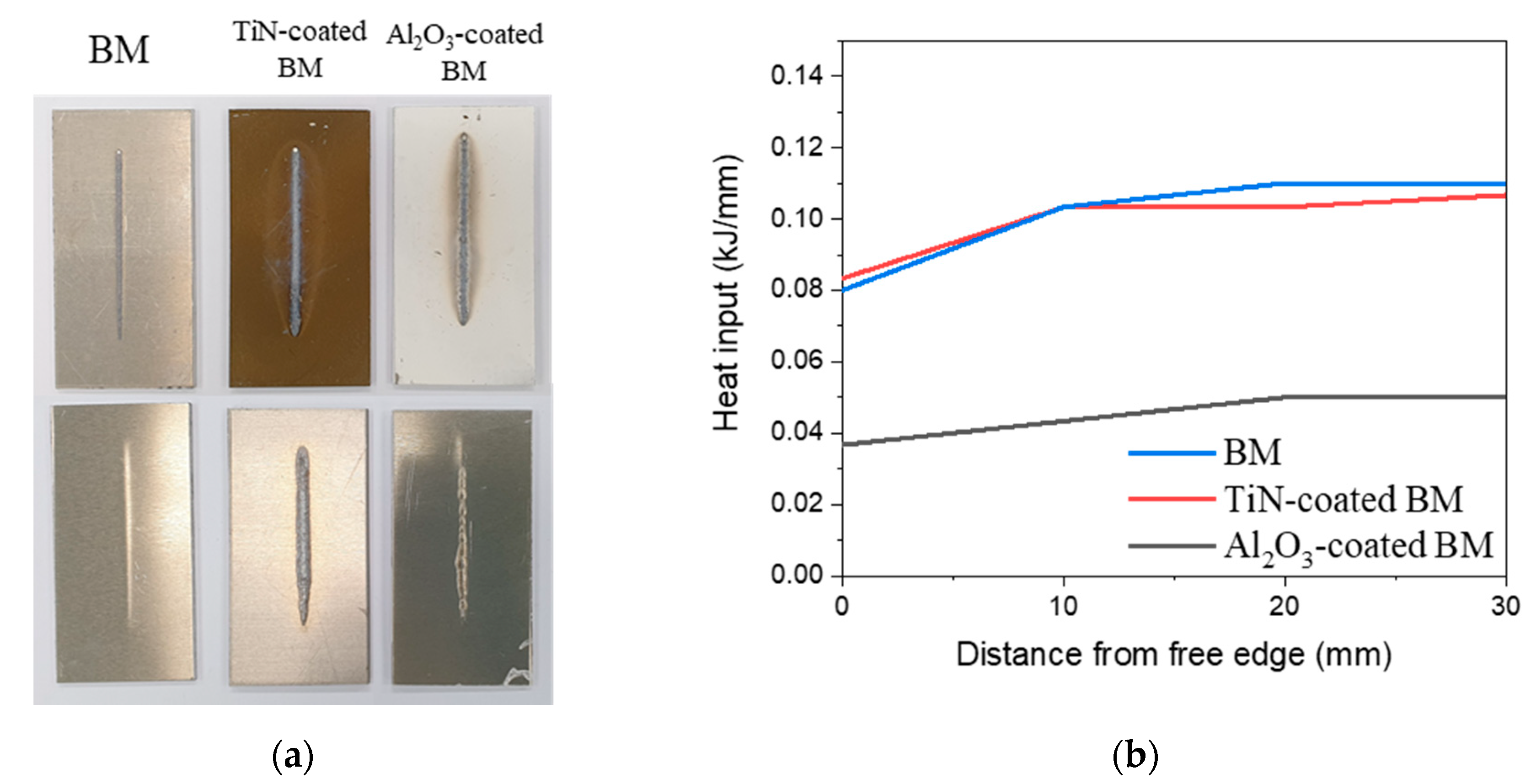

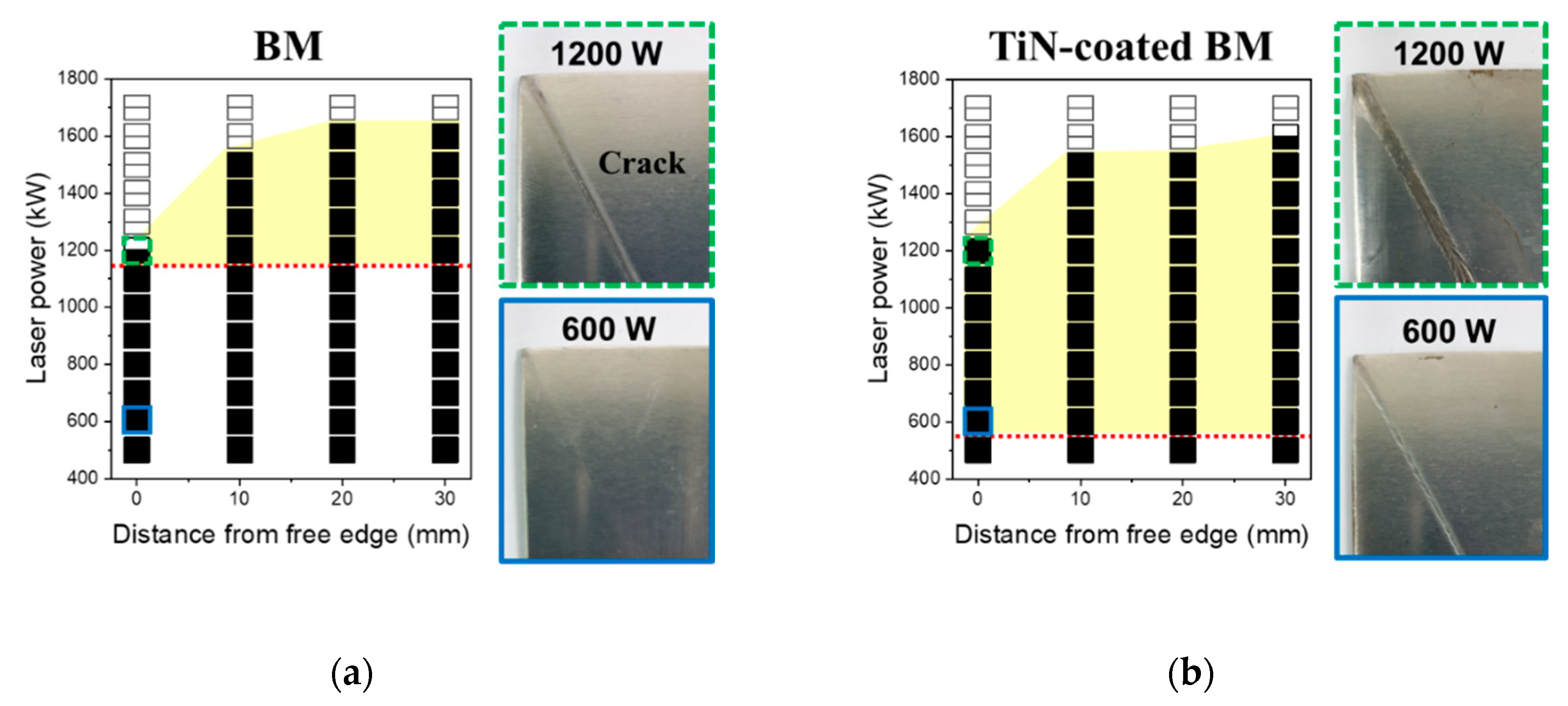

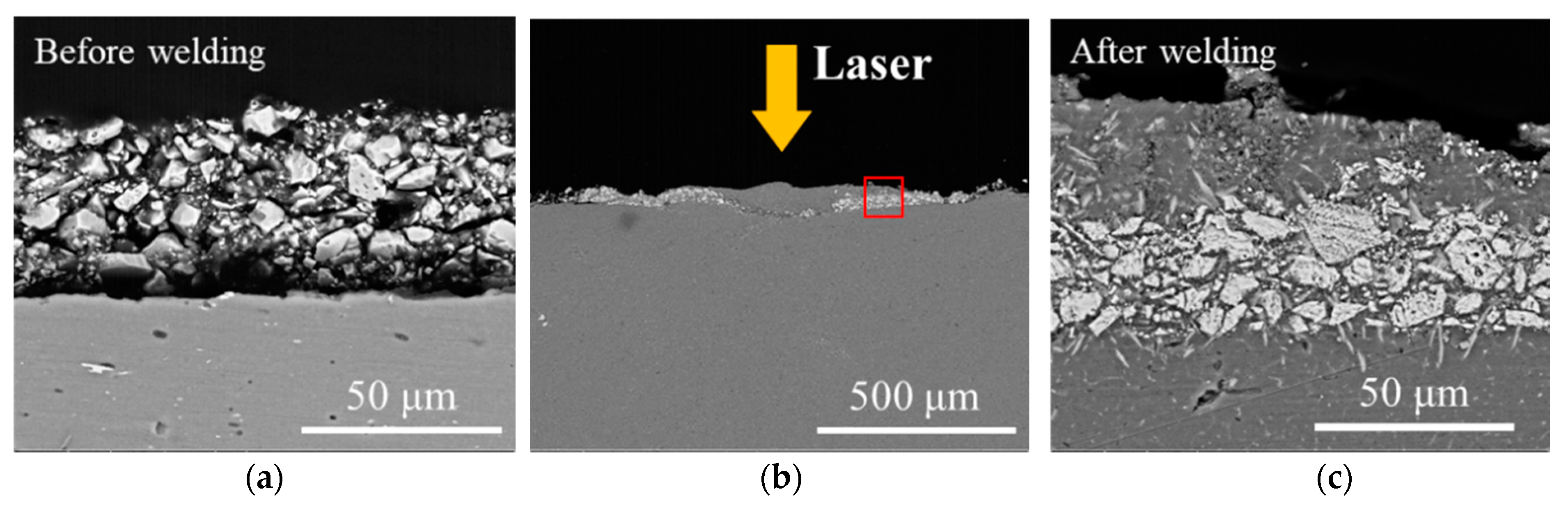

3.2. Effect of Tin Coating on Laser Weldability (Cracking Susceptibility, Laser Absorption)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. Laser-based Surface Modifications of Aluminum and its Alloys. Crit. Rev. Solid State Mater. Sci. 2015, 41, 106–131. [Google Scholar] [CrossRef]

- Hong, K.-M.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Li, L. The advances and characteristics of high-power diode laser materials processing. Opt. Lasers Eng. 2000, 34, 231–253. [Google Scholar] [CrossRef]

- Martukanitz, R.P.; Altshuller, B. Laser beam welding of aluminum alloy 5754-O using a 3 kW Nd:YAG laser and fiber optic beam delivery. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 2–5 November 2009; pp. 39–44. [Google Scholar] [CrossRef]

- Kannengiesser, T.; Boellinghaus, T. Hot cracking tests—An overview of present technologies and applications. Weld. World 2014, 58, 397–421. [Google Scholar] [CrossRef]

- Goodwin, G. Test methods for Evaluating Hot Cracking: Review and Perspective; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1990. [Google Scholar]

- Wang, W.; Xiong, L.; Wang, D.; Ma, Q.; Hu, Y.; Hu, G.; Lei, Y. A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding. Materials 2020, 13, 3178. [Google Scholar] [CrossRef]

- Gao, H.; Agarwal, G.; Amirthalingam, M.; Hermans, M.J.M.; Richardson, I.M. Investigation on hot cracking during laser welding by means of experimental and numerical methods. Weld. World 2017, 62, 71–78. [Google Scholar] [CrossRef]

- Matsuda, F.; Nakata, K. A New Test Specimen for Self-Restraint Solidification Crack Susceptibility Test of Electron-Beam Welding Bead: Fan-Shaped Cracking Test (Materials, Metallurgy & Weldability). Trans. JWRI 1982, 11, 87–94. [Google Scholar]

- Agarwal, G.; Gao, H.; Amirthalingam, M.; Hermans, M. Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel. Metals 2018, 8, 673. [Google Scholar] [CrossRef]

- Wang, X.; Lu, F.; Wang, H.-P.; Cui, H.; Tang, X.; Wu, Y. Mechanical constraint intensity effects on solidification cracking during laser welding of aluminum alloys. J. Mater. Process. Technol. 2015, 218, 62–70. [Google Scholar] [CrossRef]

- Kek, T.; Grum, J. Influence of the Graphite Absorber During Laser Surface Hardening. Stroj. Vestn. J. Mech. Eng. 2010, 56, 150–157. [Google Scholar]

- Chen, J.; Zhang, Q.; Yao, J. The effect of external applied electric field on the laser absorption of metal materials. Laser Technol. 2009, 33, 121–123. [Google Scholar]

- Qin, G.-L.; Wang, G.-G.; Zou, Z.-D. Effects of activating flux on CO2 laser welding process of 6013 Al alloy. Trans. Nonferr. Metal Soc. China 2012, 22, 23–29. [Google Scholar] [CrossRef]

- Yusof, F.; Yukio, M.; Yoshiharu, M.; Shukor, M.H.A. Effect of anodizing on pulsed Nd: YAG laser joining of polyethylene terephthalate (PET) and aluminium alloy (A5052). Mater. Des. 2012, 37, 410–415. [Google Scholar] [CrossRef]

- Punkari, A.; Weckman, D.C.; Kerr, H.W. Effects of magnesium content on dual beam Nd: YAG laser welding of Al—Mg alloys. Sci. Technol. Weld. Join. 2013, 8, 269–281. [Google Scholar] [CrossRef]

- Kang, M.; Han, H.N.; Kim, C. Microstructure and solidification crack susceptibility of Al 6014 molten alloy subjected to a spatially oscillated laser beam. Materials 2018, 11, 648. [Google Scholar] [CrossRef]

- Kang, M.; Kim, C. Evaluation of hot cracking susceptibility on laser welded aluminum alloy using coaxially arranged multiple-beam laser. J. Laser Appl. 2020, 32, 022072. [Google Scholar] [CrossRef]

- von Witzendorff, P.; Kaierle, S.; Suttmann, O.; Overmeyer, L. Using pulse shaping to control temporal strain development and solidification cracking in pulsed laser welding of 6082 aluminum alloys. J. Mater. Process. Technol. 2015, 225, 162–169. [Google Scholar] [CrossRef]

- Wang, M.; Li, Y.; Wang, Z.; Bao, E. Effect of rare earth elements on the thermal cracking resistance of high speed steel rolls. J. Rare Earths 2011, 29, 489–493. [Google Scholar] [CrossRef]

- D’Amato, C.; Buhagiar, J.; Betts, J.C. Tribological characteristics of an A356 aluminium alloy laser surface alloyed with nickel and Ni–Ti–C. Appl. Surf. Sci. 2014, 313, 720–729. [Google Scholar] [CrossRef]

- Zheng, P.; Zhao, G.; Zhang, T.; Wu, L.; Wang, J.; Han, G. Study of titanium nitride for low-e coating application. Chin. Sci. Bull. 2007, 52, 1860–1863. [Google Scholar] [CrossRef]

- Kurtoğlu, S.F.; Yağcı, M.B.; Uzun, A.; Ünal, U.; Canadinc, D. Enhancing biocompatibility of NiTi shape memory alloys by simple NH3 treatments. Appl. Surf. Sci. 2020, 146547. [Google Scholar] [CrossRef]

| Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | others |

|---|---|---|---|---|---|---|---|---|---|

| Bal. | 0.66 | 0.4 | 0.24 | 0.13 | 0.9 | 0.18 | 0.07 | 0.05 | 0.02 |

| Parameter | Value |

|---|---|

| Distance from the free edge (X) | 0, 10, 20, 30 mm |

| Laser power | 400–1800 W (Interval: 100 W) |

| Laser speed | 5, 8, 10, 12 mm/s |

| Coating materials | None, TiN, Al2O3 |

| Welding angle (θ) | 26.6 (tanθ = 0.5) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nam, S.; Jung, I.-H.; Kim, Y.-M. Effect of TiN Spray Coating on Cracking Susceptibility and Energy Absorption in Laser Welding of Aluminum Alloys. Metals 2020, 10, 1657. https://doi.org/10.3390/met10121657

Nam S, Jung I-H, Kim Y-M. Effect of TiN Spray Coating on Cracking Susceptibility and Energy Absorption in Laser Welding of Aluminum Alloys. Metals. 2020; 10(12):1657. https://doi.org/10.3390/met10121657

Chicago/Turabian StyleNam, Sangwoo, In-Ho Jung, and Young-Min Kim. 2020. "Effect of TiN Spray Coating on Cracking Susceptibility and Energy Absorption in Laser Welding of Aluminum Alloys" Metals 10, no. 12: 1657. https://doi.org/10.3390/met10121657

APA StyleNam, S., Jung, I.-H., & Kim, Y.-M. (2020). Effect of TiN Spray Coating on Cracking Susceptibility and Energy Absorption in Laser Welding of Aluminum Alloys. Metals, 10(12), 1657. https://doi.org/10.3390/met10121657