Characterization of High-Strength Packaging Steels: Obtaining Material Data for Precise Finite Element Process Modelling

Abstract

:1. Introduction

2. State of the Art

3. Materials and Methods

3.1. Materials and Condition Prior to Forming

3.2. Experimental Procedure

3.3. Extrapolation of High-Strength Packaging Steel Flow Curves

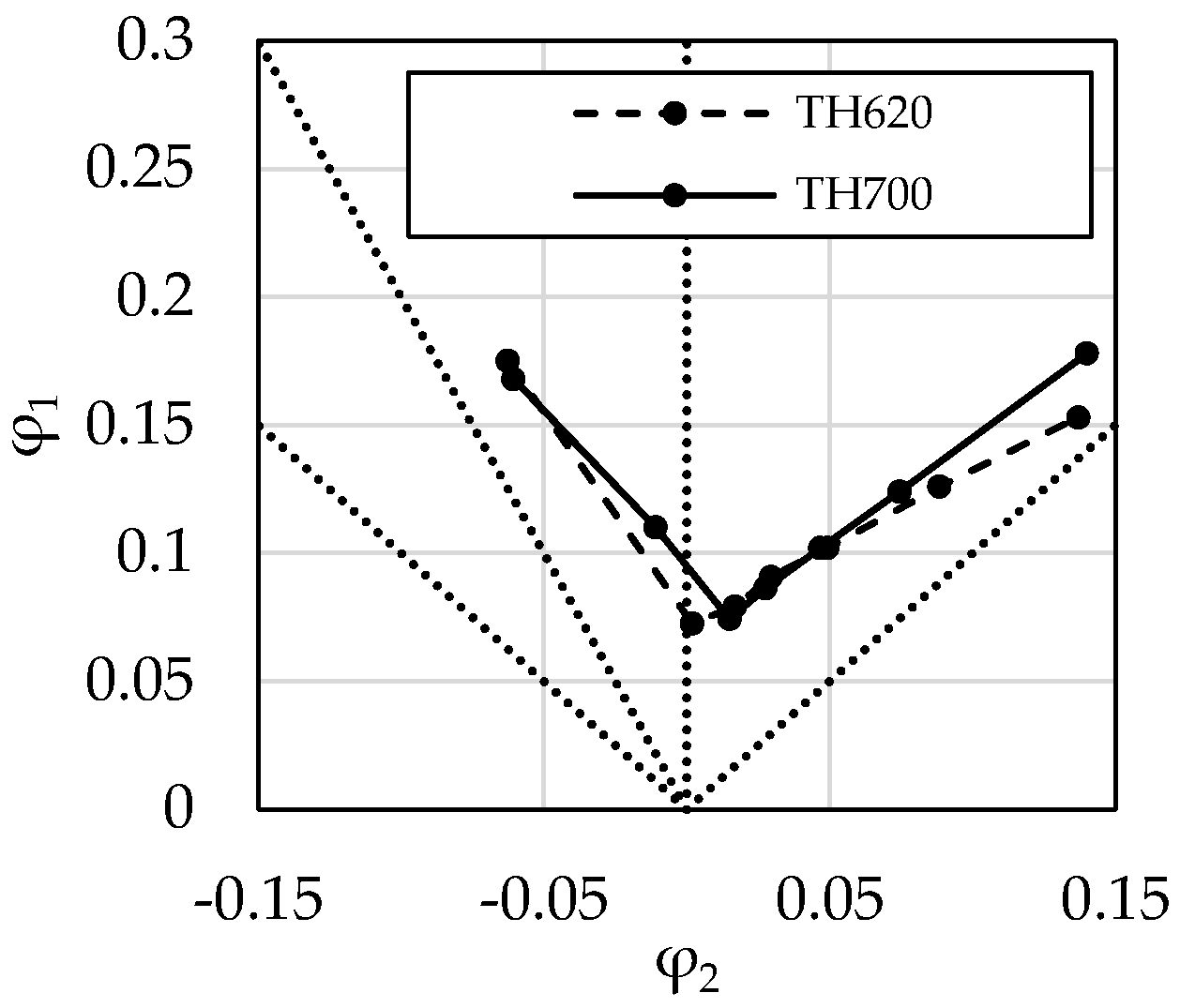

3.4. Yield Locus Parametrisation

3.5. Forming Limit Curve

4. Validation

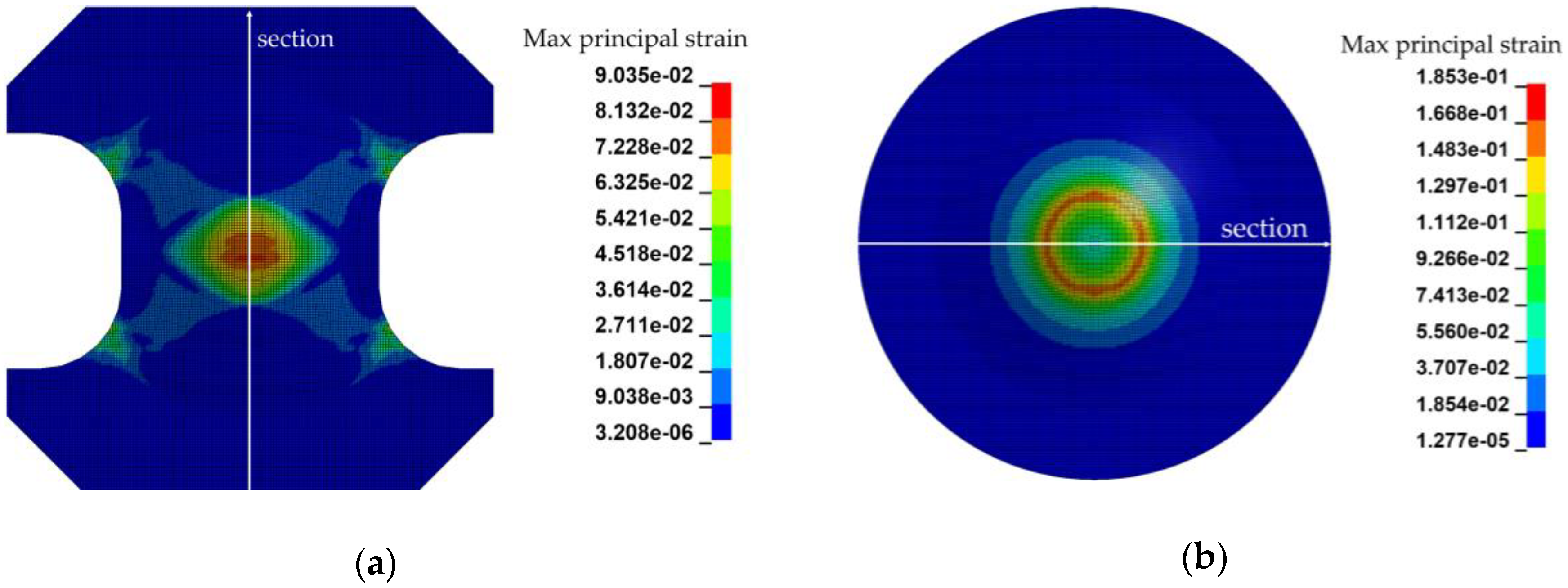

4.1. Strain Distribution Based Validation of the Used Models

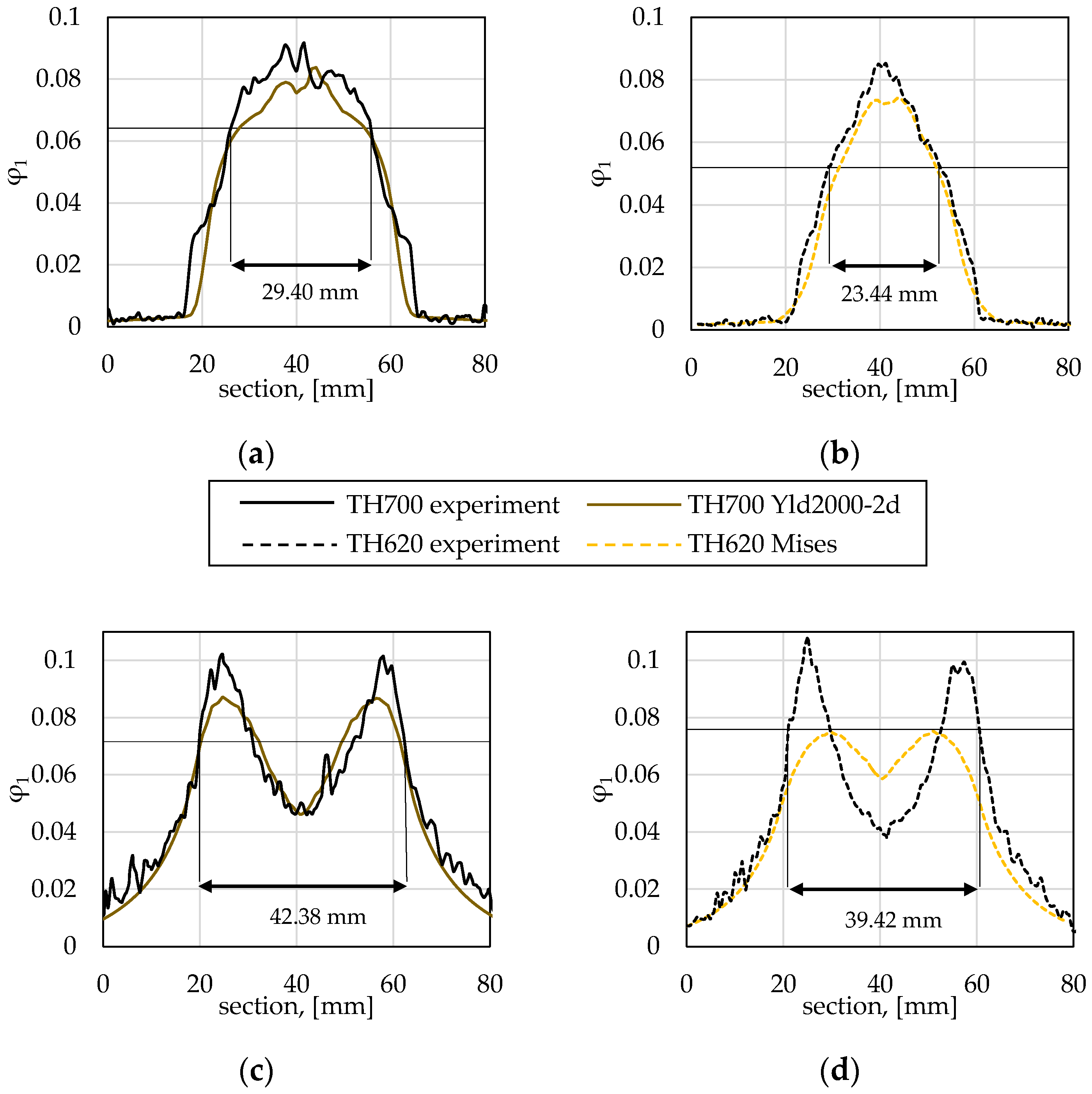

4.2. Prediction of the Strain Localization in a Selected Section of the Validation Specimen

5. Conclusions and Outlook

- A new extrapolation approach was introduced to fulfil specific requirements in HSPS forming, i.e., to capture the high degree of deformation occurring during HSPS processing. The extrapolation method was validated using a set of industrially relevant experiments.

- The need for anisotropic yield functions to simulate industrially relevant HSPS forming processes, i.e., having plane strain to biaxial tension stress states, was pointed out. Therefore, it is indispensable to determine Lankford coefficients and yield strength for all relevant directions with respect to rolling direction.

- Localization behaviour during forming was quantified by considering the section width of the middle section in the investigated validation experiments, and a difference of up to 20% was observed between the two HSPS grades. Simulations based on the tailored characterisation can capture these differences and highlight the associated potential with regards to an efficient material selection of HSPS grades.

Author Contributions

Funding

Conflicts of Interest

References

- Considère, A. Mémoire sur L’emploi du fer et de L’acier Dans les Constructions, Annales des Ponts et Chaussées; Ch. Chunod: Paris, France, 1885; Volume 9, pp. 574–605. [Google Scholar]

- Mises, R.V. Mechanik der festen Körper im plastisch-deformablen Zustand. Nachr. Von Der Ges. Der Wiss. Zu Göttingen Math. Phys. Kl. 1913, 1913, 582–592. [Google Scholar]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A 1948, 193, 281–297. [Google Scholar]

- Barlat, F.; Brem, J.C.; Yoon, J.W.; Chung, K.; Dick, R.E.; Lege, D.J.; Pourboghrat, F.; Choi, S.-H.; Chu, E. Plane stress yield function for aluminum alloy sheets—part 1: Theory. Int. J. Plast. 2003, 19, 1297–1319. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Voce, E. The Relationship between Stress and Strain for Homogeneous Deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Kuwabara, T. Advances in experiments on metal sheets and tubes in support of constitutive modeling and forming simulations. Int. J. Plast. 2007, 23, 385–419. [Google Scholar]

- Suttner, S.; Merklein, M. Experimental and numerical investigation of a strain rate controlled hydraulic bulge test of sheet metal. J. Mater. Process. Technol. 2016, 235, 121–133. [Google Scholar] [CrossRef]

- Gutscher, G.; Wu, H.-C.; Ngaile, G.; Altan, T. Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test. J. Mater. Process. Technol. 2004, 146, 1–7. [Google Scholar] [CrossRef]

- Nam, J.; Han, K.S. Finite element analysis of deep drawing and ironing process in the steel D&I canmaking. ISIJ Int. 2000, 40, 1223–1229. [Google Scholar]

- Pepelnjak, T.; Barisic, B. Analysis and elimination of the stretcher strains on TH415 tinplate rings in the stamping process. J. Mater. Process. Technol. 2007, 186, 111–119. [Google Scholar] [CrossRef]

- Barisic, B.; Pepelnjak, T.; Kuzman, K. Numerical-stochastic modeling and simulation of deep drawing tinplate rings. Adv. Mater. Res. 2005, 6–8, 329–336. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile deformation. Aime Trans. 1945, 12, 1–22. [Google Scholar]

- Moreira, L.P.; Ferron, G. Finite element implementation of an orthotropic plasticity model for sheet metal forming simulations. Lat. Am. J. Solids Strutcuresfor Sheet Metal Form. Simul. 2007, 4, 149–176. [Google Scholar]

- Horta, R.S.; Moreira, L.P.; Oliveira, H.W.d.; Ouverney, T.M.W.; Souza Silva, A.D.; Francisco, A.S. Finite element simulation of the deep-drawing process of a two-piece tinplate can. In Proceedings of the XXXVIII Iberian Latin American Congress on Computational Methods in Engineering; ABMEC Brazilian Association of Computational Methods in Engineering, Santa Catarina, Brazil, 5–8 November 2017. [Google Scholar]

- Slota, J.; Šiser, M.; Gajdoš, I. Failure prediction of axi-symmetric cup in deep drawing and expansion processes. Open Eng. 2018, 8, 354–362. [Google Scholar] [CrossRef]

- Illera, M.; Lostado, R.; Martinez, R.F.; Mac Donald, B.J. Characterization of electrolytic tinplate materials via combined finite element and regression models. J. Strain Anal. Eng. Des. 2014, 49, 467–480. [Google Scholar] [CrossRef]

- Fernández-Martínez, R.; Lostado-Lorza, R.; Illera-Cueva, M.; Escribano-García, R.; Donald, B.J.M. Comparison Analysis of Regression Models Based on Experimental and FEM Simulation Datasets Used to Characterize Electrolytic Tinplate Materials. In International Joint Conference SOCO’14-CISIS’14-ICEUTE’14. Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2014; pp. 279–288. [Google Scholar]

- Linnemann, M.; Lieber, T.; Scheffler, C.; Psyk, V.; Müller, R.; Landgrebe, D. Influence of different strain rates on the flow curve and the formability of thin aluminium and tinplate sheets. In Proceedings of the 7th International Conference on High Speed Forming, Dortmund, Germany, 27–28 April 2016; pp. 245–255. [Google Scholar]

- Moldovan, I.; Linnepe, M.; Keßler, L.; Köhl, M. Virtual modelling of forming processes in metal packaging industry. In Proceedings of the 12th European LS-DYNA Conference, Koblenz, Germany, 14–16 May 2019; pp. 101–103. [Google Scholar]

- Beier, T.; Gerlach, J.; Roettger, R.; Kuhn, P. Possibilities for specific utilization of material properties for an optimal part design. J. Phys. Conf. Ser. 2017, 896, 12014. [Google Scholar] [CrossRef] [Green Version]

- DIN. Kaltgewalzte Verpackungsblecherzeugnisse–Elektrolytisch Verzinnter und Spezialverchromter Stahl Deutsche Fassung EN 10202:2001; Beuth Verlag GmbH: Berlin, Germany, 2001. [Google Scholar]

- Sylwestrowicz, W.; Hall, E.O. The deformation and ageing of mild steel. Proc. Phys. Soc. Sect. B 1951, 64, 495–502. [Google Scholar] [CrossRef]

- Vollertsen, F. Categories of size effects. Prod. Eng. Res. Dev. 2008, 2, 377–383. [Google Scholar]

- Raulea, L.V.; Goijaerts, A.M.; Govaert, L.E.; Baaijens, F.P.T. Size effects in the processing of thin metal sheets. J. Mater. Process. Technol. 2001, 115, 44–48. [Google Scholar] [CrossRef]

- DIN. Metallische Werkstoffe–Zugversuch—Teil 1: Prüfverfahren bei Raumtemperatur (ISO 6892-1:2019); Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- DIN. Metallische Werkstoffe–Blech und Band–Bestimmung der biaxialen Spannung/Dehnung-Kurve durch einen hydraulischen Tiefungsversuch mit Optischen Messsystemen (ISO 16808:2014); Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- ISO. Metallic Materials—Sheet and Strip—Determination of Forming-Limit Curves Part. 2: Determination of Forming-Limit Curves in the Laboratory 12004-2; ISO Copyright Office: Geneva, Switzerland, 2008. [Google Scholar]

- Kim, S.; Lee, J.; Barlat, F.; Lee, M.-G. Formability prediction of advanced high strength steels using constitutive models characterized by uniaxial and biaxial experiments. J. Mater. Process. Technol. 2013, 213, 1929–1942. [Google Scholar] [CrossRef]

- Banabic, D. Sheet Metal. Forming Processes; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Neale, M.J. The Tribology Handbook, 2nd ed.; Butterworth Heinemann: Oxford, UK, 1995. [Google Scholar]

- Tekkaya, A.E.; Pöhlandt, K.; Lange, K. Determining Stress-Strain Curves of Sheet Metal in the Plane Torsion Test. Cirp Ann. 1982, 31, 171–174. [Google Scholar]

- Graser, M.; Lenzen, M.; Merklein, M. On the inverse identification of Lankford coefficients using geometrical changes under quasi-biaxial loading. Int. J. Mater. Form. 2019, 12, 1053–1061. [Google Scholar] [CrossRef]

| Model | σ0 | σ45 | σ90 | r0 | r45 | r90 | σb |

|---|---|---|---|---|---|---|---|

| von Mises | x | - | - | - | - | - | - |

| Hill48 | x | - | - | x | x | x | - |

| Yld2000-2d | x | x | x | x | x | x | x |

| Temper | Thickness | Yield Strength | Proof Strength | |

|---|---|---|---|---|

| temp | t | ReH | ReL | Rp0.5 |

| TH700 | 0.240 mm | 727 MPa | 687 MPa | 694 MPa |

| TH620 | 0.235 mm | 607 MPa | 571 MPa | 577 MPa |

| temp | σ0 | σ45 | σ90 | r0 | r45 | r90 | σb | Elong. (RD) |

|---|---|---|---|---|---|---|---|---|

| TH700 | 694 MPa | 679 MPa | 710 MPa | 0.80 | 1.09 | 0.85 | 761 MPa | 7.8% |

| TH620 | 577 MPa | 566 MPa | - | 0.59 | 0.88 | - | 609 MPa | 8.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knieps, F.; Liebscher, B.; Moldovan, I.; Köhl, M.; Lohmar, J. Characterization of High-Strength Packaging Steels: Obtaining Material Data for Precise Finite Element Process Modelling. Metals 2020, 10, 1683. https://doi.org/10.3390/met10121683

Knieps F, Liebscher B, Moldovan I, Köhl M, Lohmar J. Characterization of High-Strength Packaging Steels: Obtaining Material Data for Precise Finite Element Process Modelling. Metals. 2020; 10(12):1683. https://doi.org/10.3390/met10121683

Chicago/Turabian StyleKnieps, Fabian, Benjamin Liebscher, Ioana Moldovan, Manuel Köhl, and Johannes Lohmar. 2020. "Characterization of High-Strength Packaging Steels: Obtaining Material Data for Precise Finite Element Process Modelling" Metals 10, no. 12: 1683. https://doi.org/10.3390/met10121683

APA StyleKnieps, F., Liebscher, B., Moldovan, I., Köhl, M., & Lohmar, J. (2020). Characterization of High-Strength Packaging Steels: Obtaining Material Data for Precise Finite Element Process Modelling. Metals, 10(12), 1683. https://doi.org/10.3390/met10121683