Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain)

Abstract

:1. Introduction

2. Theoretical Background

3. Methodology

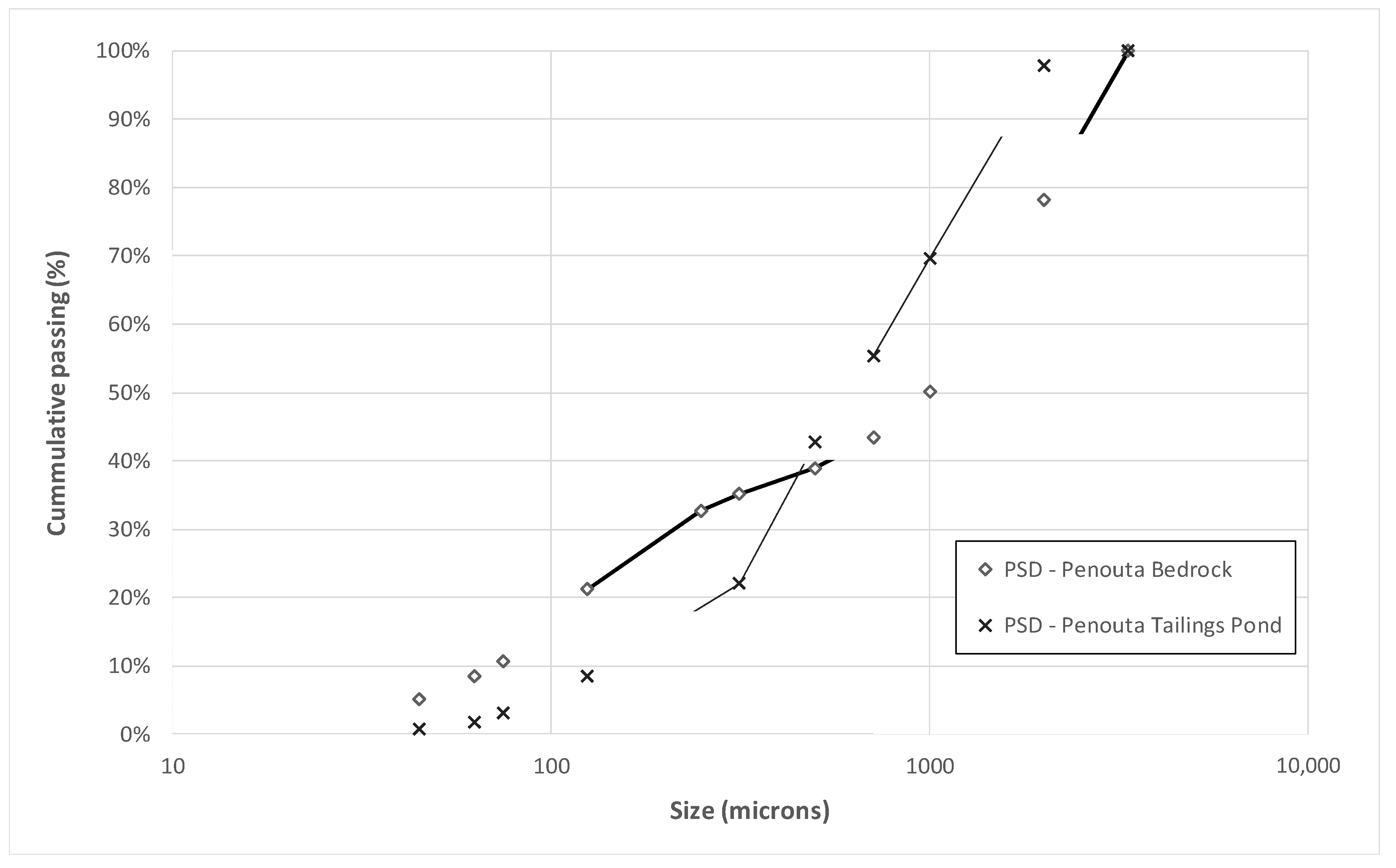

3.1. Sample Characterization

3.2. Calculation of the Critical Speed and Initial Conditions for the Grinding Kinetics Tests

3.3. Determination of the Specific Rate of Breakage (Si) and the Kinetic Parameters (αT, α)

4. Results and Discussion

4.1. Chemical Characterisation of the Feed

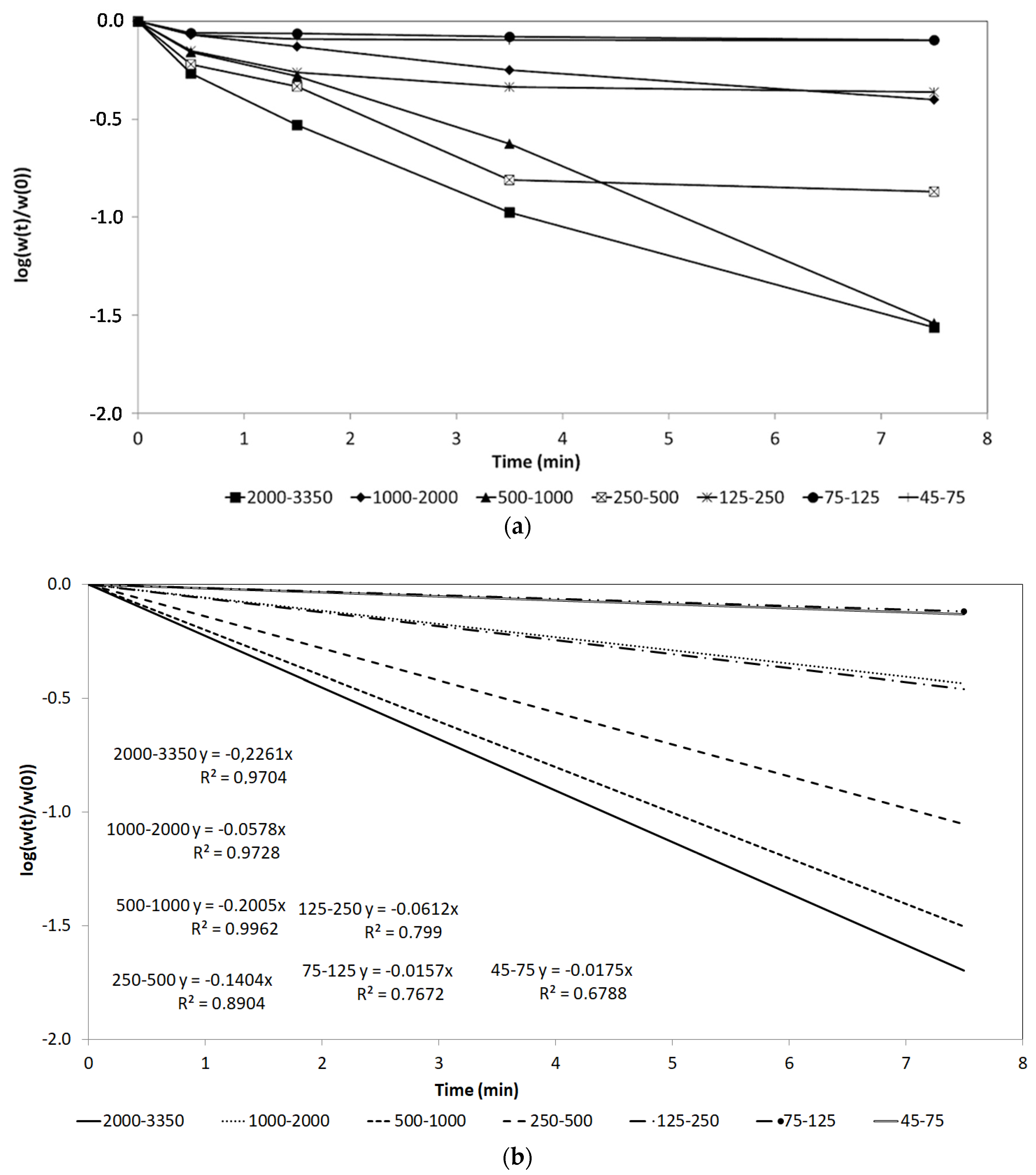

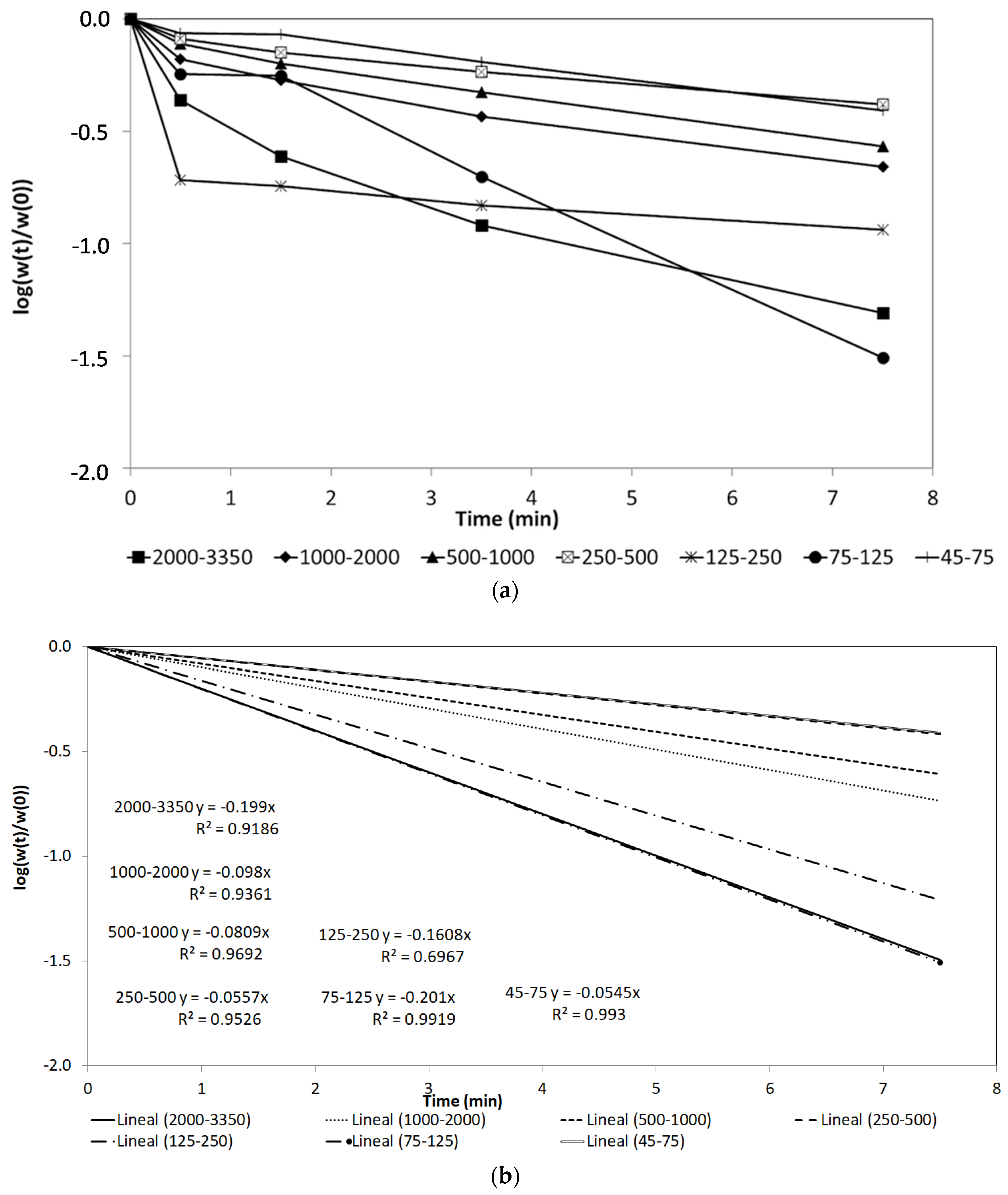

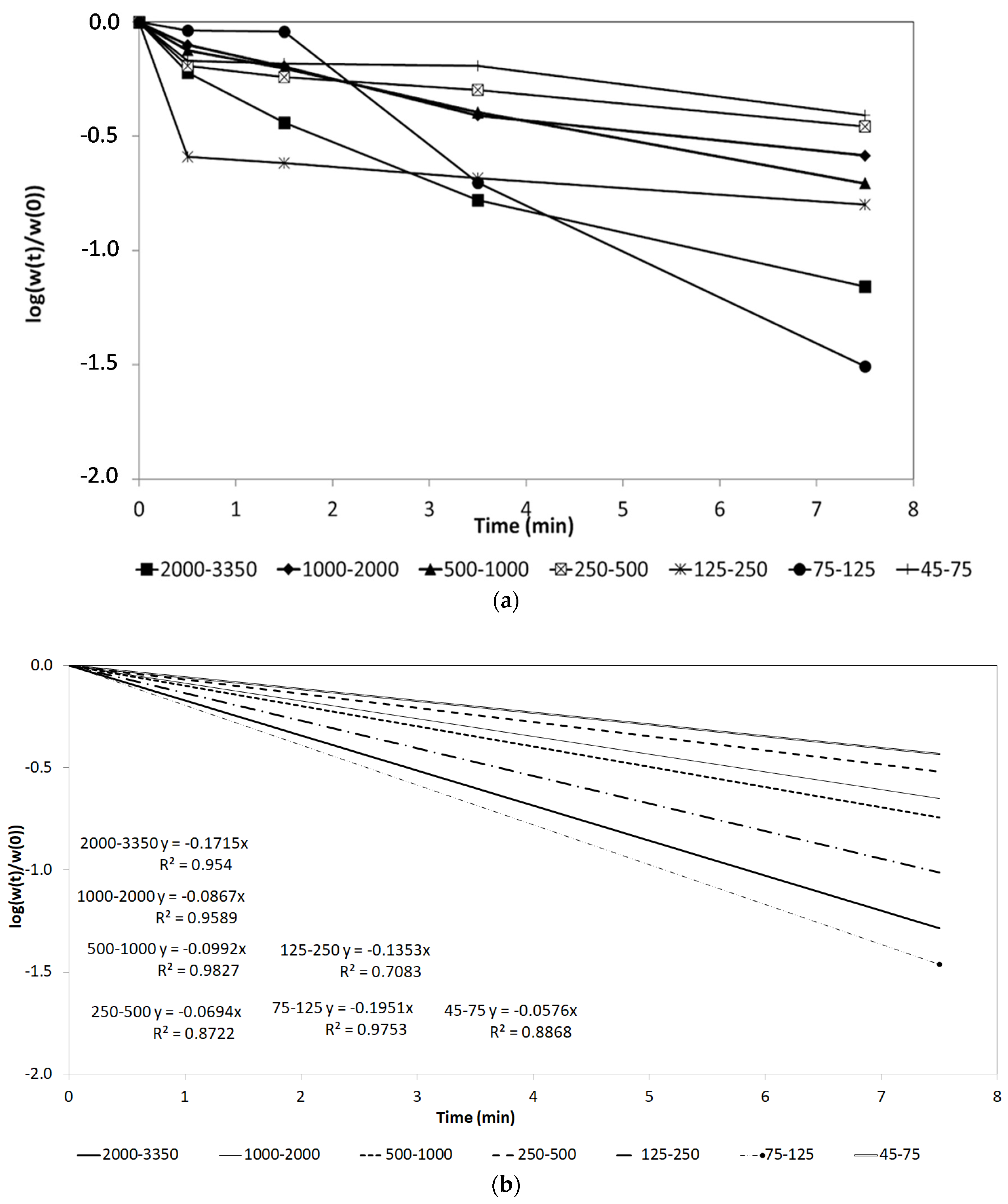

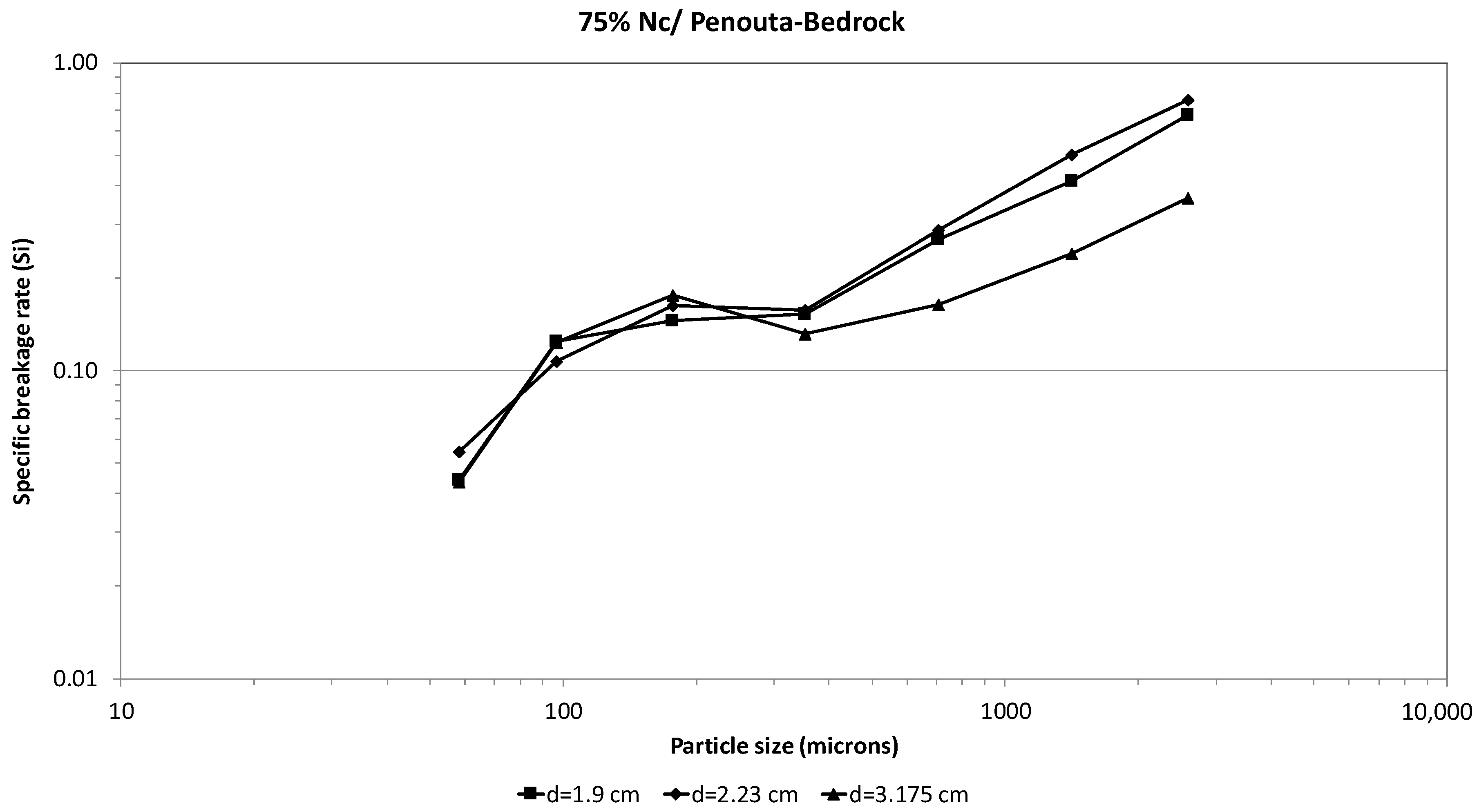

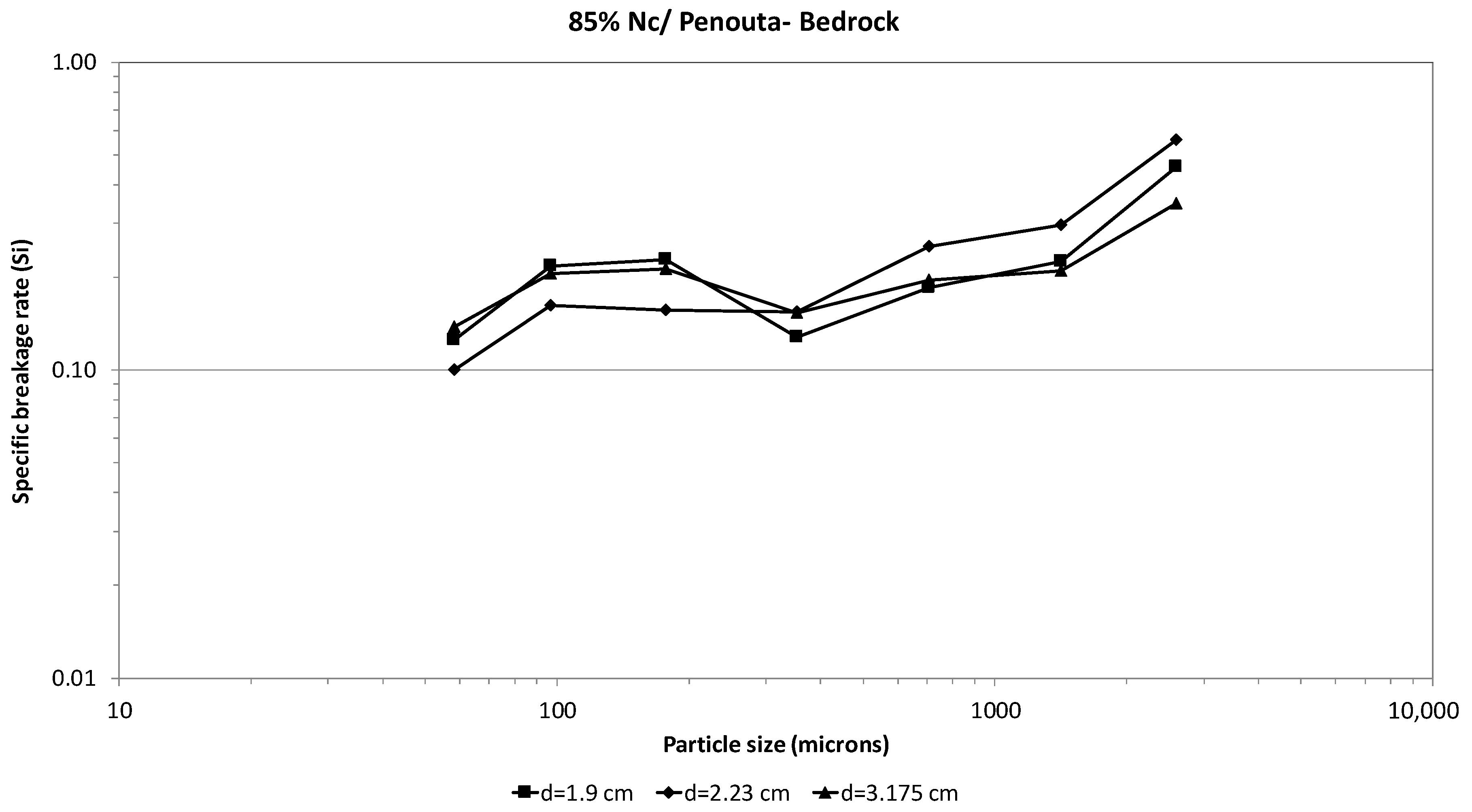

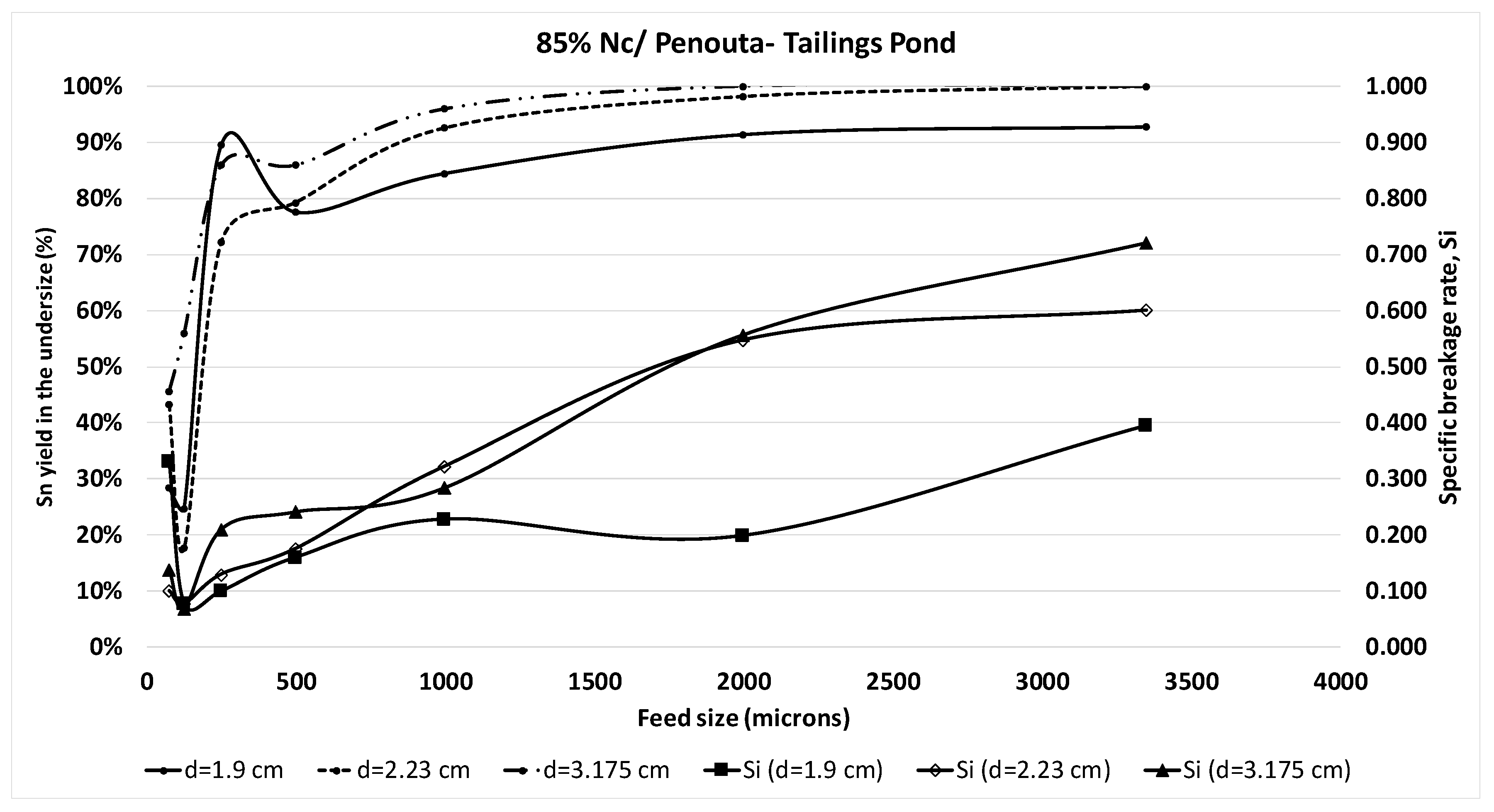

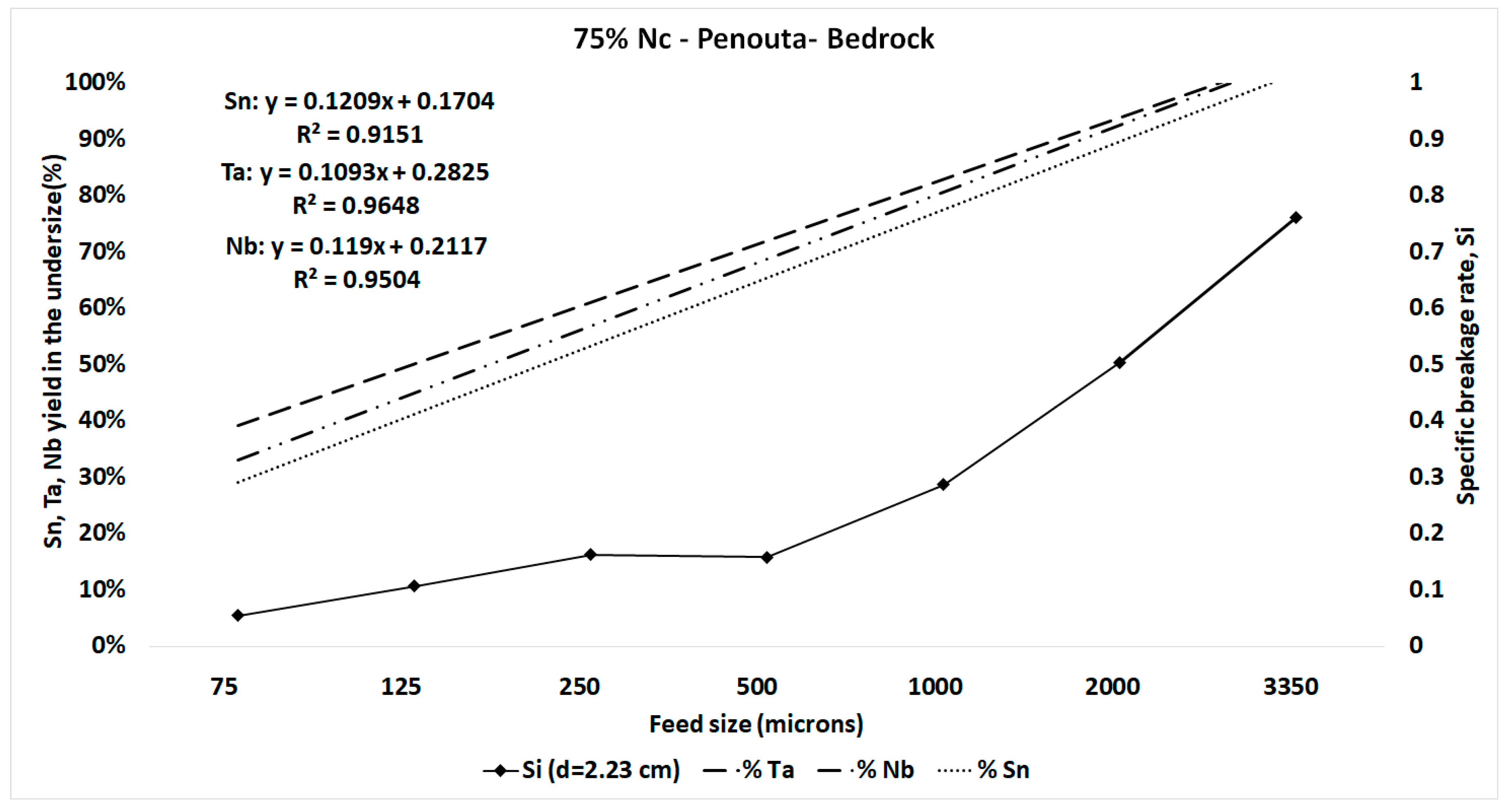

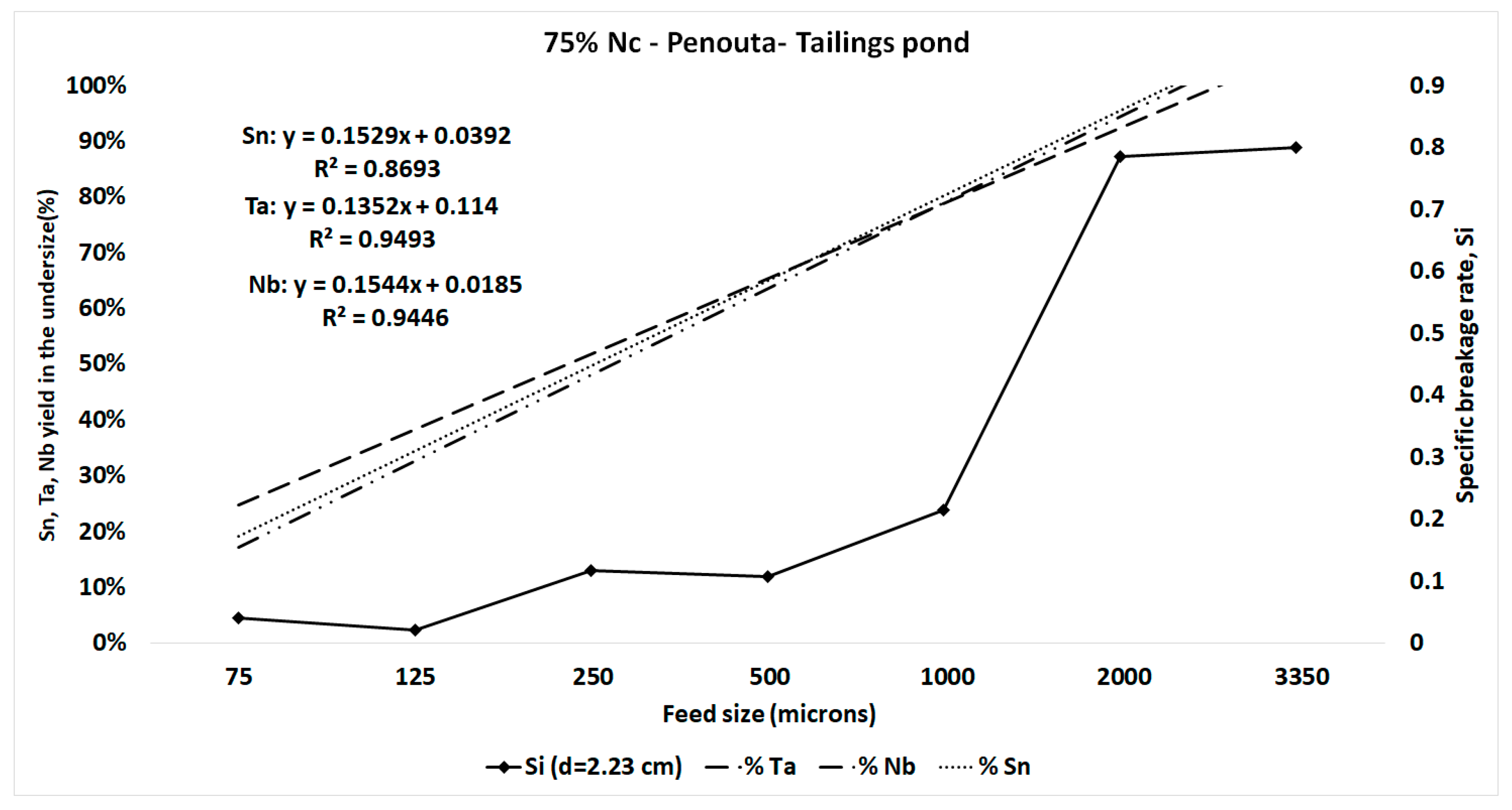

4.2. Obtaining the Specific Rate of Breakage (Si)

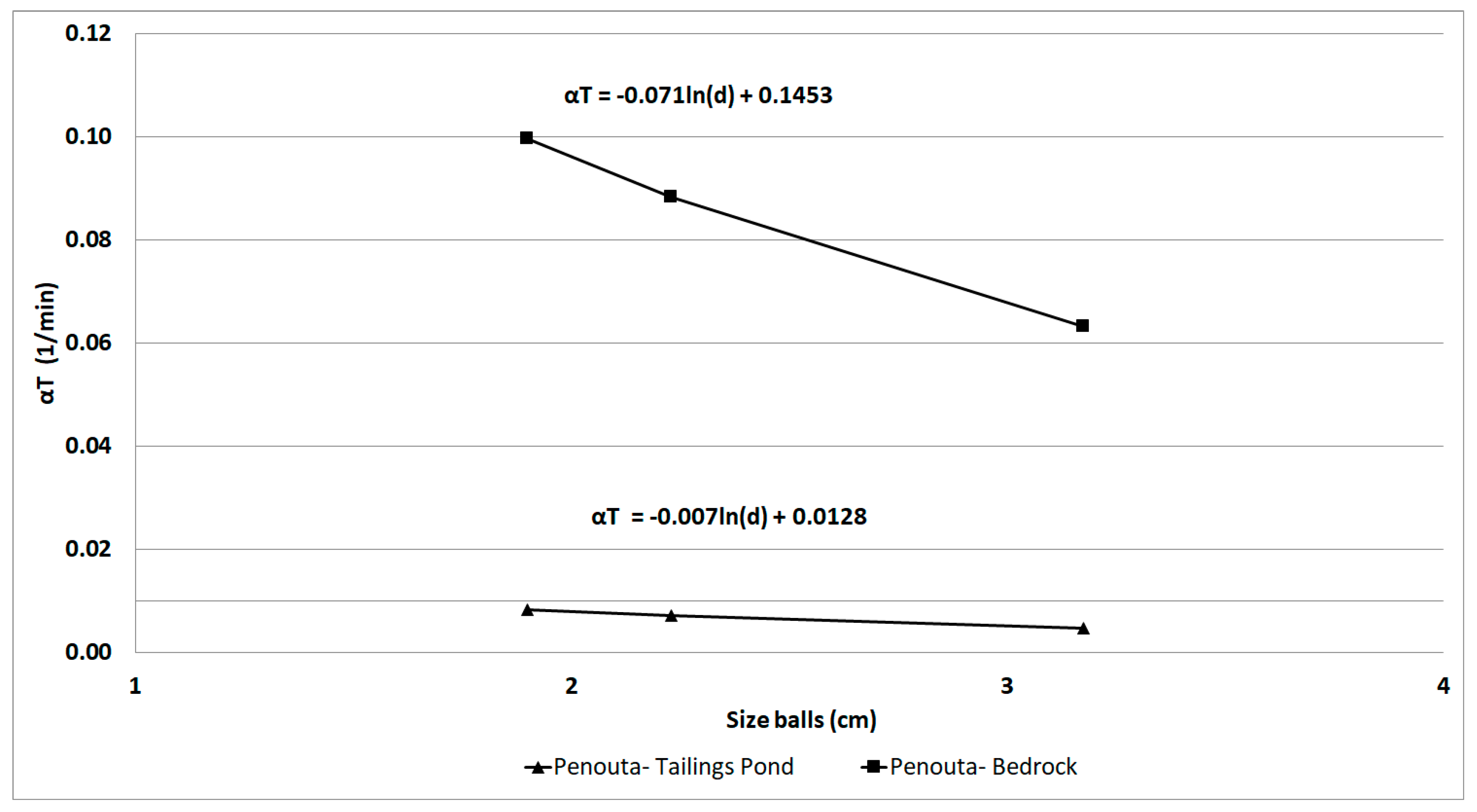

4.3. Kinetic Parameters (α, αT)

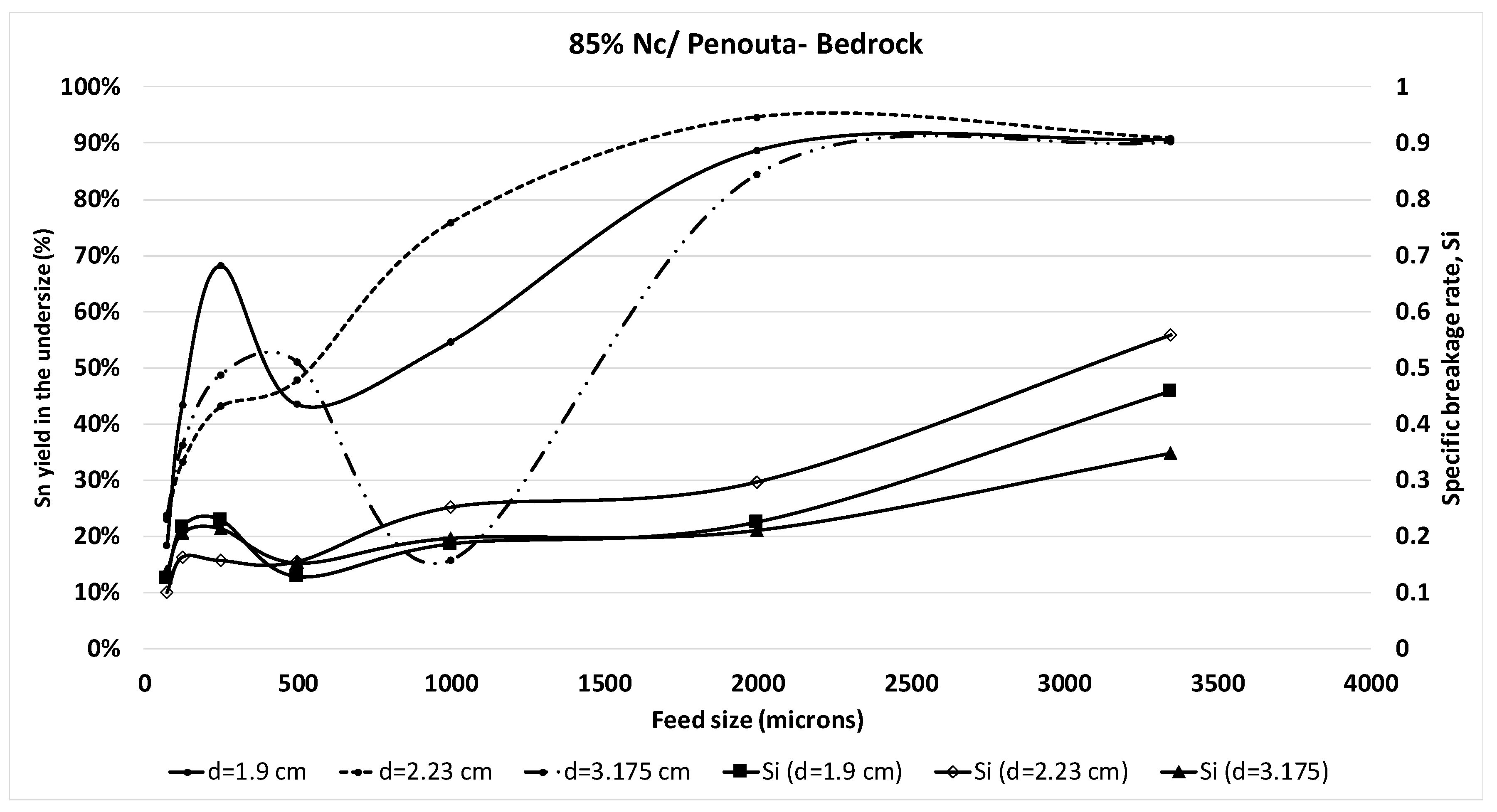

4.4. Chemical Characterisation of the Grinding Products

5. Conclusions

- Austin’s methodology has allowed studying the effects of ball size in the kinetics of dry and batch grinding over a wide range of feed particle size feed for the samples Bedrock and Tailings Pond (Penouta mine). The mineralogical and operational parameters studied in this investigation, mill speed, ball size and feed size, also influenced the grinding kinetics.

- Si decreases as feed particle size decreases and ball size increases. This is due to a reduction of the effective grinding area over most conditions considered, and to the fact that the finer the particle size the higher the fracture strength, owing to the lesser crack and microcrack concentration in the particles.

- A direct relation exists amongst Sn, Ta and Nb yield in the undersize product, the Si and the studied mineralogical and operational variables. Optimal mineralogical and operational conditions will increase the grinding efficiency to obtain the best liberation degree and the highest grade of minerals of interest, such as Sn, Ta and Nb, thus impacting positively the recovery scores of the plant.

- Use of medium-diameter balls is recommended, since they yield a steadier behavior over a wide range of feed particle sizes and studied conditions.

- Using ball size, a selection function, αT, was formulated for the Bedrock and Tailings Pond samples from the Penouta mine. This demonstrated that αΤ values are higher for Bedrock sample than for Tailings Pond sample, resulting in the former being ground more rapidly than the latter, as a consequence of their respective mineralogy and origin.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fuerstenau, D.W.; Lutch, J.J.; De, A. The effect of ball size on the energy efficiency of hybrid high-pressure roll mill/ball mill grinding. Powder Technol. 1999, 105, 199–204. [Google Scholar] [CrossRef]

- Coello Velázquez, A.L.; Menéndez-Aguado, J.M.; Brown, R.L. Grindability of lateritic nickel ores in Cuba. Powder Technol. 2008, 182, 113–115. [Google Scholar] [CrossRef]

- Pedrayes, F.; Norniella, J.G.; Melero, M.G.; Menéndez-Aguado, J.M.; del Coz-Díaz, J.J. Frequency domain characterization of torque in tumbling ball mills using DEM modelling: Application to filling level monitoring. Powder Technol. 2018, 323, 433–444. [Google Scholar] [CrossRef]

- Osorio, A.M.; Menéndez-Aguado, J.M.; Bustamante, O.; Restrepo, G.M. Fine grinding size distribution analysis using the Swebrec function. Powder Technol. 2014, 258, 206–208. [Google Scholar] [CrossRef]

- Rodríguez, B.Á.; García, G.G.; Coello-Velázquez, A.L.; Menéndez-Aguado, J.M. Product size distribution function influence on interpolation calculations in the Bond ball mill grindability test. Int. J. Miner. Process. 2016, 157, 16–20. [Google Scholar] [CrossRef]

- Deniz, V. The effect of mill speed on kinetic breakage parameters of clinker and limestone. Cem. Concr. Res. 2004, 34, 1365–1371. [Google Scholar] [CrossRef]

- Olejnik, T.P. Analysis of the breakage rate function for selected process parameters in quartzite milling. Chem. Process. Eng. Inzynieria Chemiczna i Procesowa 2012, 33, 117–129. [Google Scholar] [CrossRef]

- Gupta, V.K.; Sharma, S. Analysis of ball mill grinding operation using mill power specific kinetic parameters. Adv. Powder Technol. 2014, 25, 625–634. [Google Scholar] [CrossRef]

- Petrakis, E.; Komnitsas, K. Improved modeling of the grinding process through the combined use of matrix and population balance models. Minerals 2017, 7, 67. [Google Scholar] [CrossRef] [Green Version]

- Cayirli, S. Influences of operating parameters on dry ball mill performance. Physicochem. Probl. Mineral Process. 2018, 54, 751–762. [Google Scholar]

- Cho, H.; Kwon, J.; Kim, K.; Mun, M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013, 246, 625–634. [Google Scholar] [CrossRef] [Green Version]

- Hlabangana, N.; Danha, G.; Muzenda, E. Effect of ball and feed particle size distribution on the milling efficiency of a ball mill: An attainable region approach. S. Afr. J. Chem. Eng. 2018, 25, 79–84. [Google Scholar] [CrossRef]

- Bwalya, M.M.; Moys, M.H.; Finnie, G.J.; Mulenga, F.K. Exploring ball size distribution in coal grinding mills. Powder Technol. 2014, 257, 68–73. [Google Scholar] [CrossRef]

- King, R.P. Modeling and Simulation of Mineral Processing Systems; Butterworth-Heinemann Elsevier Ltd.: Oxford, UK, 2001. [Google Scholar]

- Epstein, B. The mathematical description of certain breakage mechanisms leading to the logarithmic-normal distribution. J. Frankl. Inst. 1947, 244, 471–477. [Google Scholar] [CrossRef]

- Kelsall, D.F. A study of the breakage in a small continuous open circuit wet mill. Can. Min. J. 1965, 86, 89–94. [Google Scholar]

- Herbst, J.A.; Fuerstenau, D.W. The zero-order production of fine sizes in comminution and its implications in simulation. Trans. AIME 1968, 241, 538–549. [Google Scholar]

- Austin, L.G.; Luckie, P.T. Methods for the determination of breakage distribution parameters. Powder Technol. 1971, 5, 267–271. [Google Scholar] [CrossRef]

- Austin, L. A Review–Introduction to the mathematical description of grinding as a rate process. Powder Technol. 1972, 5, 1–17. [Google Scholar] [CrossRef]

- Gardner, R.P.; Sukanjnajtee, K. A combined tracer and back-calculation method for determining particulate breakage functions in ball milling: Part I—rationale and description of the proposed method. Powder Technol. 1972, 6, 65–74. [Google Scholar] [CrossRef]

- Kapur, P.C. An improved method for estimating the feed-size breakage distribution functions. Powder Technol. 1982, 33, 269–275. [Google Scholar] [CrossRef]

- Kapur, P.C.; Agrawal, P. Approximate solutions to the discretized batch grinding equation. Chem. Eng. Sci. 1970, 25, 1111–1113. [Google Scholar] [CrossRef]

- Malghan, S.G.; Fuerstenau, D.W. The scale-up of ball mills using population balance models and specific power input. Dechem. Monogr. 1976, 79, 613–630. [Google Scholar]

- Austin, L.G.; Luckie, P.T.; Shoji, K. An analysis of ball-and-race milling part II: The babcock E 1.7 mill. Powder Technol. 1982, 33, 113–125. [Google Scholar] [CrossRef]

- Austin, L.G.; Brame, K. A comparison of the Bond method for sizing wet tumbling ball mills with a size—mass balance simulation model. Powder Technol. 1983, 34, 261–274. [Google Scholar] [CrossRef]

- Austin, L.; Concha, F. Diseño y Simulación de Circuitos de Molienda y Clasificación; CYTED: Valparaiso, Chile, 1994. [Google Scholar]

- Austin, L.G.; Klimpel, R.R.; Luckie, P. Process Engineering of Size Reduction: Ball Milling; Society of Mining Engineers of the AIME: Littleton, CO, USA, 1984. [Google Scholar]

- European Commission. Study on the EU’s List of Critical Raw Materials. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1542 (accessed on 1 January 2020).

- Wang, X.; Gui, W.; Yang, C.; Wang, Y. Wet grindability of an industrial ore and its breakage parameters estimation using population balances. Int. J. Miner. Process. 2011, 98, 113–117. [Google Scholar] [CrossRef]

- Polonio, G.F. El Interés Económico y Estratégico del Aprovechamiento de Metales Raros y Minerales Industriales Asociados, en el Marco Actual de la Minería Sostenible: La Mina de Penouta. Ph.D. Thesis, Universidad Politécnica de Madrid, Orense, España, 2015. [Google Scholar]

- Llorens, G.T.; García, P.F.; López, M.F.J.; Fernández, F.A.; Sanz, C.J.L.; Moro, B.M.C. Tin-tantalum-niobium mineralization in the Penouta deposit (NW Spain): Textural features and mineral chemistry to unravel the genesis and evolution of cassiterite and columbite group minerals in a peraluminous system. Ore Geol. Rev. 2017, 81, 79–95. [Google Scholar] [CrossRef]

- López-Moro, F.J.; García, P.F.; Llorens, G.T.; Sanz, C.J.L.; Fernández, F.A.; Moro, B.M.C. Ta and Sn concentration by muscovite fractionation and degassing in a lens-like granite body: The case study of the Penouta rare-metal albite granite (NW Spain). Ore Geol. Rev. 2017, 82, 10–30. [Google Scholar] [CrossRef]

- Teke, E.; Yekeler, M.; Ulusoy, U.; Canbazoglu, M. Kinetics of dry grinding of industrial minerals: Calcite and barite. Int. Miner. Process. 2002, 67, 29–42. [Google Scholar] [CrossRef]

- Erdem, A.S.; Ergün, S.L. The effect of ball size on breakage rate parameter in a pilot scale ball mill. Miner. Eng. 2009, 22, 660–664. [Google Scholar] [CrossRef]

- Gupta, V.K. Determination of the specific breakage rate parameters using the top-size-fraction method: Preparation of the feed charge and design of experiments. Adv. Powder Technol. 2016, 27, 1710–1718. [Google Scholar] [CrossRef]

- Touil, D.; Belaadi, S.; Frances, C. The specific selection function effect on clinker grinding efficiency in a dry batch ball mill. Int. J. Miner. Process. 2008, 87, 141–145. [Google Scholar] [CrossRef] [Green Version]

- De Carvalho, R.M.; Tavares, L.M. Predicting the effect of operating and design variables on breakage rates using the mechanistic ball mill model. Miner. Eng. 2013, 43–44, 91–101. [Google Scholar] [CrossRef]

- Napier-Munn, T.J.; Morrell, S.; Morrison, R.D.; Kojovic, T. Mineral. Comminution Circuits: Their Operation and Optimization; Napier-Munn, T.J., Ed.; Julius Kruttschnitt Mineral Research Centre, University of Queensland: Indooroopilly, QLD, Australia, 1996. [Google Scholar]

- Wills, B.A.; Napier-Munn, T. Mineral Processing Technology. In An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 7th ed.; Elsevier Science & Technology Books: London, UK, 2006. [Google Scholar]

- Chimwani, N.; Glasser, D.; Hildebrandt, D.; Metzger, M.J.; Mulenga, F.K. Determination of the milling parameters of a platinum group minerals ore to optimize product size distribution for flotation purposes. Miner. Eng. 2013, 43–44, 67–78. [Google Scholar] [CrossRef]

- Mulenga, F. Effect of Ball Size Distribution on Milling Parameters. Ph.D. Thesis, University of Witwatersrand, Johannesburg, South Africa, 2008. [Google Scholar]

- Ucurum, M.; Gulec, Ö.; Cingitas, M. Wet grindability of calcite to ultra-fine sizes in conventional ball mill. Part. Sci. Technol. 2015, 33, 342–348. [Google Scholar] [CrossRef]

- González, G.; Menéndez, A.J.M. Variación del índice de trabajo en molino de bolas según el grado de molienda para varias menas de tungsteno. In Proceedings of the XIII Jornadas Argentinas de Tratamiento de Minerales Octubre de 2016, Mendoza, Argentina, 5–7 October 2016. [Google Scholar]

- Petrakis, E.; Stamboliadis, E.; Komnitsas, K. Identification of Optimal Mill Operating Parameters during Grinding of Quartz with the Use of Population Balance Modeling. KONA Powder Part. J. 2017, 34, 213–223. [Google Scholar] [CrossRef] [Green Version]

| d, Balls Size (mm) | Nc, Mill Critical Speed (rpm) | Work Speed/75% Nc (rpm) | Work Speed/85% Nc (rpm) |

|---|---|---|---|

| 19.1 | 105.9 | 79.4 | 90.0 |

| 22.3 | 106.9 | 80.2 | 90.1 |

| 31.8 | 110.3 | 82.8 | 93.8 |

| Sample | Sn (ppm) | Ta (ppm) | Nb (ppm) |

|---|---|---|---|

| Penouta-Bedrock | 392 ± 5 | 114 ± 10 | 31 ± 2 |

| Penouta-Tailings Pond | 334 ± 5 | 60 ± 10 | 64 ± 2 |

| Kinetic | 75% Nc | 85% Nc | ||||

|---|---|---|---|---|---|---|

| Parameters | d = 1.9 cm | d = 2.23 cm | d = 3.175 cm | d = 1.9 cm | d = 2.23 cm | d = 3.175 cm |

| α (Bedrock) | 0.5531 | 0.6345 | 0.4121 | 0.0885 | 0.3764 | 0.1482 |

| αT (Bedrock) | 0.0083 | 0.0049 | 0.0132 | 0.1451 | 0.0225 | 0.0839 |

| α (Tailings) | 0.7432 | 1.0414 | 0.6280 | 0.4533 | 0.6474 | 0.6320 |

| αT (Tailings) | 0.0024 | 0.0003 | 0.0019 | 0.0100 | 0.0043 | 0.0053 |

| Ball Diameter (cm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 1.9 | 2.23 | 3.175 | |||||||||

| (µm) | Si (min−1) | Sn y.(%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) |

| 75 | 0.044 | 28% | 33% | 27% | 0.055 | 33% | 42% | 36% | 0.043 | 27% | 29% | 28% |

| 125 | 0.125 | 56% | 57% | 52% | 0.107 | 47% | 46% | 41% | 0.124 | 53% | 50% | 50% |

| 250 | 0.145 | 64% | 45% | 70% | 0.163 | 48% | 55% | 49% | 0.176 | 48% | 56% | 51% |

| 500 | 0.153 | 48% | 76% | 63% | 0.158 | 51% | 75% | 78% | 0.131 | 41% | 66% | 66% |

| 1000 | 0.267 | 80% | 89% | 84% | 0.287 | 81% | 88% | 85% | 0.164 | 57% | 72% | 66% |

| 2000 | 0.413 | 98% | 99% | 93% | 0.504 | 99% | 97% | 93% | 0.24 | 94% | 93% | 84% |

| 3350 | 0.677 | 91% | 68% | 92% | 0.761 | 100% | 100% | 100% | 0.365 | 91% | 71% | 90% |

| Pearson c. (r) | 0.83 | 0.51 | 0.80 | 0.92 | 0.87 | 0.84 | 0.89 | 0.68 | 0.89 | |||

| Ball Diameter (cm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 1.9 | 2.23 | 3.175 | |||||||||

| (µm) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) |

| 75 | 0.125 | 18% | 19% | 18% | 0.1 | 23% | 23% | 23% | 0.138 | 24% | 30% | 23% |

| 125 | 0.217 | 43% | 45% | 45% | 0.163 | 33% | 37% | 34% | 0.206 | 36% | 41% | 38% |

| 250 | 0.229 | 68% | 70% | 71% | 0.157 | 43% | 50% | 46% | 0.214 | 49% | 52% | 52% |

| 500 | 0.128 | 43% | 65% | 62% | 0.155 | 48% | 68% | 58% | 0.153 | 51% | 72% | 66% |

| 1000 | 0.186 | 55% | 75% | 67% | 0.252 | 76% | 87% | 81% | 0.197 | 16% | 29% | 23% |

| 2000 | 0.225 | 89% | 89% | 79% | 0.297 | 95% | 93% | 86% | 0.211 | 84% | 83% | 75% |

| 3350 | 0.458 | 91% | 74% | 93% | 0.559 | 91% | 70% | 91% | 0.348 | 90% | 61% | 88% |

| Pearson c. (r) | 0.75 | 0.41 | 0.70 | 0.81 | 0.52 | 081 | 0.68 | 0.25 | 0.64 | |||

| Ball Diameter (cm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 1.9 | 2.23 | 3.175 | |||||||||

| (µm) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) |

| 75 | 0.057 | 23% | 35% | 28% | 0.041 | 15% | 21% | 16% | 0.043 | 11% | 17% | 13% |

| 125 | 0.036 | 23% | 33% | 26% | 0.022 | 21% | 31% | 21% | 0.024 | 15% | 15% | 15% |

| 250 | 0.141 | 73% | 60% | 60% | 0.118 | 73% | 60% | 56% | 0.070 | 87% | 83% | 82% |

| 500 | 0.323 | 82% | 96% | 90% | 0.108 | 58% | 76% | 71% | 0.099 | 44% | 70% | 58% |

| 1000 | 0.461 | 95% | 81% | 90% | 0.216 | 90% | 78% | 84% | 0.101 | 64% | 63% | 64% |

| 2000 | 0.487 | 53% | 70% | 67% | 0.786 | 99% | 93% | 97% | 0.103 | 70% | 58% | 44% |

| 3350 | 0.520 | 93% | 70% | 79% | 0.800 | 100% | 100% | 100% | 0.370 | 90% | 89% | 89% |

| Pearson c. (r) | 0.75 | 0.75 | 0.83 | 0.78 | 0.80 | 0.80 | 0.64 | 0.65 | 0.68 | |||

| Ball Diameter (cm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 1.9 | 2.23 | 3.175 | |||||||||

| (µm) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) | Si (min−1) | Sn y. (%) | Ta y. (%) | Nb y. (%) |

| 75 | 0.331 | 28% | 31% | 30% | 0.100 | 43% | 58% | 48% | 0.138 | 46% | 64% | 51% |

| 125 | 0.077 | 25% | 27% | 23% | 0.078 | 18% | 27% | 20% | 0.069 | 56% | 71% | 62% |

| 250 | 0.100 | 90% | 85% | 83% | 0.130 | 72% | 61% | 56% | 0.210 | 86% | 82% | 78% |

| 500 | 0.160 | 78% | 82% | 75% | 0.176 | 79% | 90% | 67% | 0.241 | 86% | 98% | 90% |

| 1000 | 0.228 | 84% | 81% | 84% | 0.323 | 93% | 92% | 90% | 0.284 | 96% | 92% | 90% |

| 2000 | 0.199 | 91% | 75% | 75% | 0.548 | 98% | 95% | 91% | 0.557 | 100% | 100% | 100% |

| 3350 | 0.395 | 93% | 89% | 89% | 0.601 | 100% | 100% | 100% | 0.721 | 100% | 100% | 100% |

| Pearson c. (r) | 0.13 | 0.13 | 0.19 | 0.80 | 0.79 | 0.88 | 0.76 | 0.77 | 0.81 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nava, J.V.; Llorens, T.; Menéndez-Aguado, J.M. Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain). Metals 2020, 10, 1687. https://doi.org/10.3390/met10121687

Nava JV, Llorens T, Menéndez-Aguado JM. Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain). Metals. 2020; 10(12):1687. https://doi.org/10.3390/met10121687

Chicago/Turabian StyleNava, Jenniree V., Teresa Llorens, and Juan María Menéndez-Aguado. 2020. "Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain)" Metals 10, no. 12: 1687. https://doi.org/10.3390/met10121687

APA StyleNava, J. V., Llorens, T., & Menéndez-Aguado, J. M. (2020). Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain). Metals, 10(12), 1687. https://doi.org/10.3390/met10121687