Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping

Abstract

1. Introduction

2. Methodology

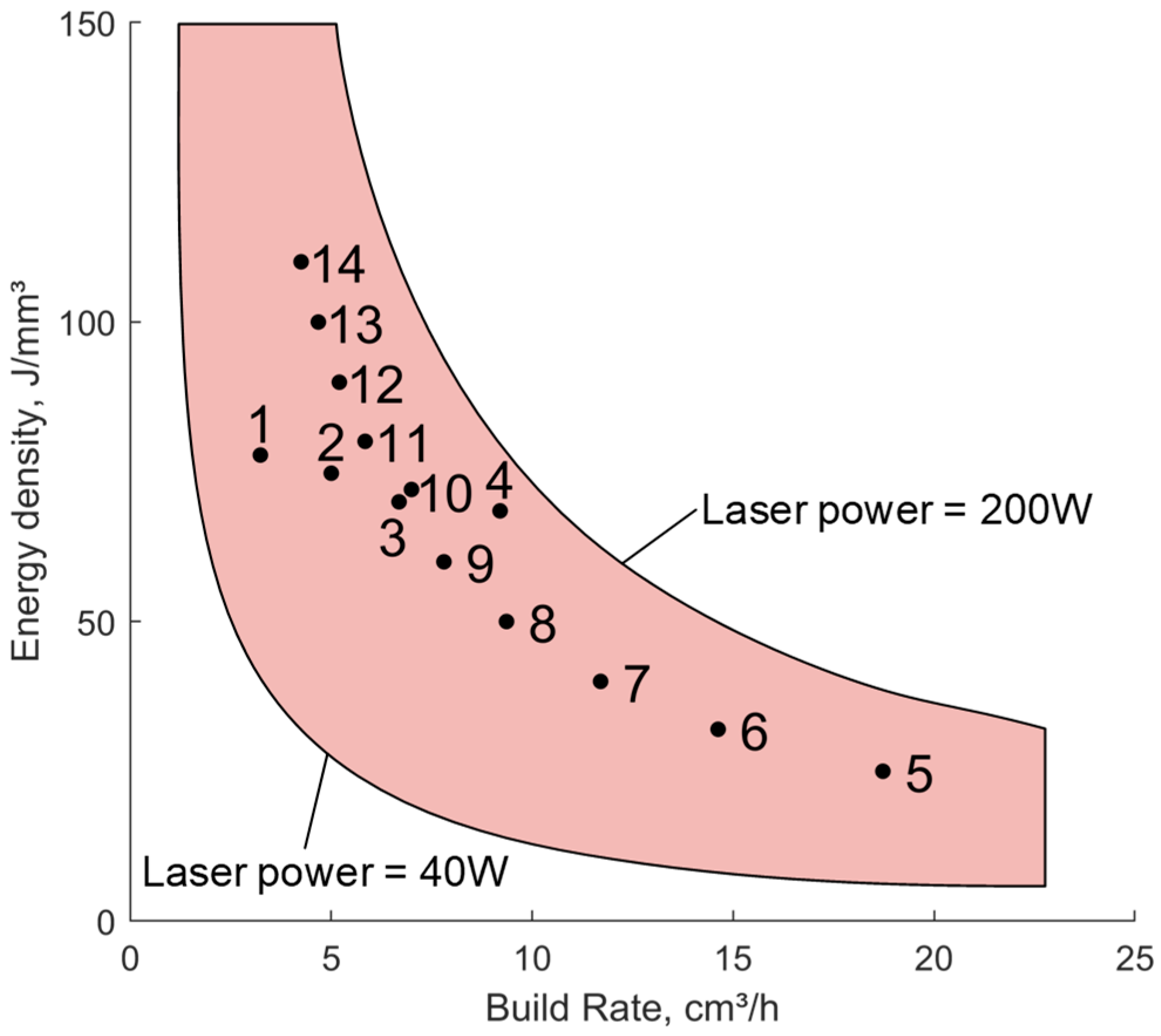

2.1. LPBF Process Calibration Experiment

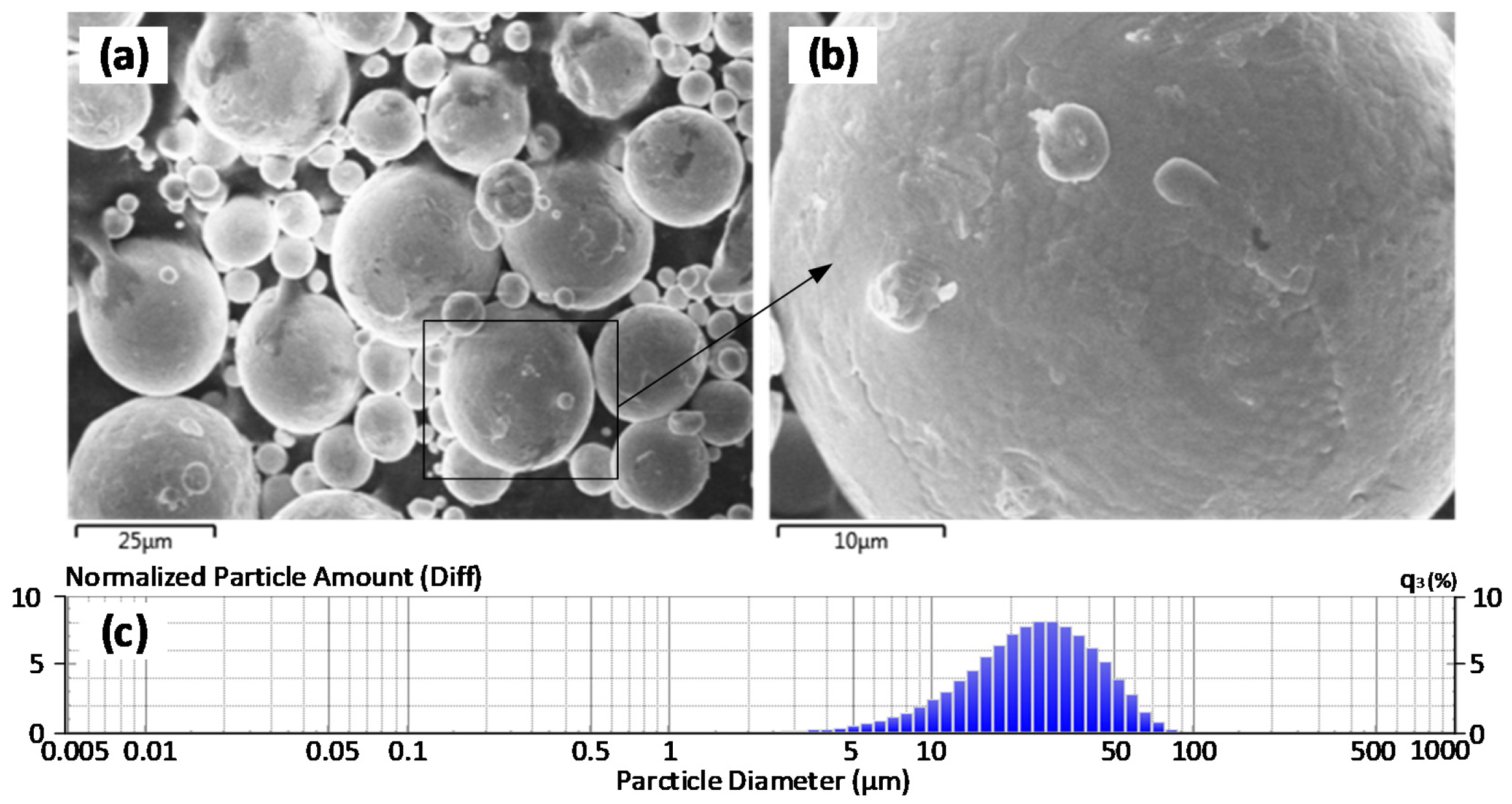

2.2. Powder Production and Analysis

2.3. LPBF Printing and Analyses of Printed Specimens

2.4. Printed Density and Grain Structure Processing Maps

3. Results and Discussion

3.1. Powder Analysis

3.2. Analyses of Printed Specimens

3.2.1. Chemical Composition

3.2.2. Density

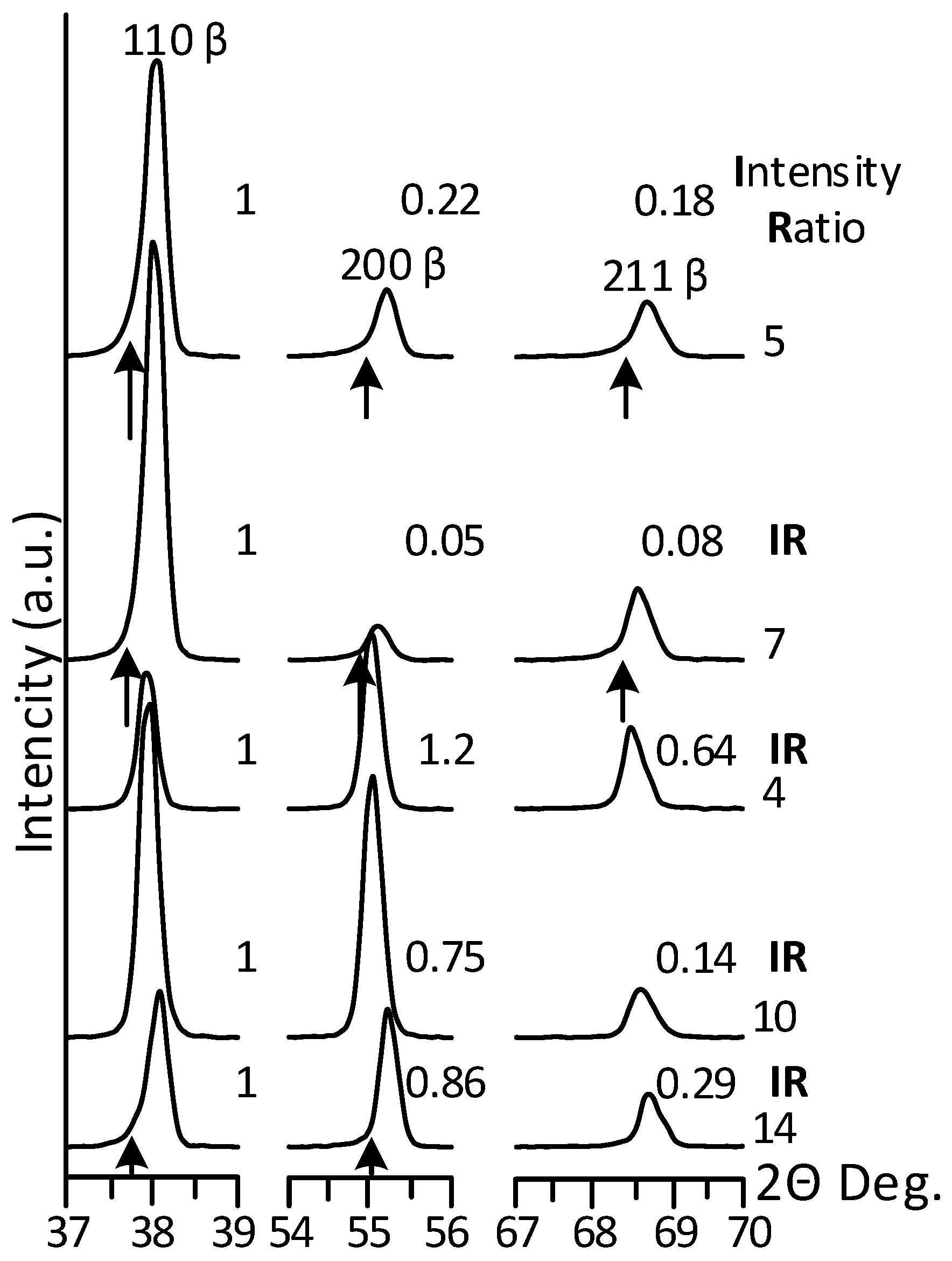

3.2.3. Phases

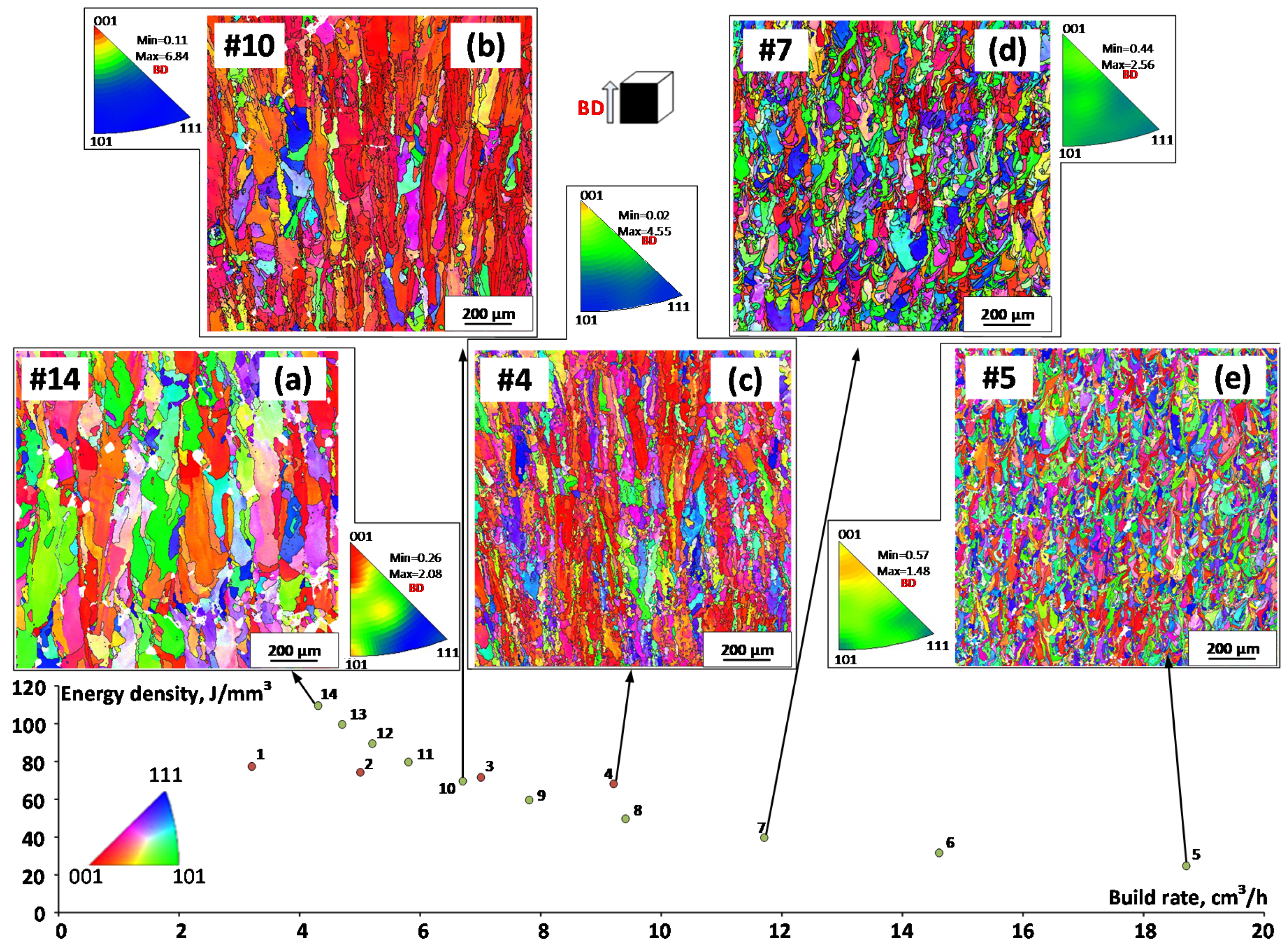

3.2.4. Microstructure and Crystallographic Texture

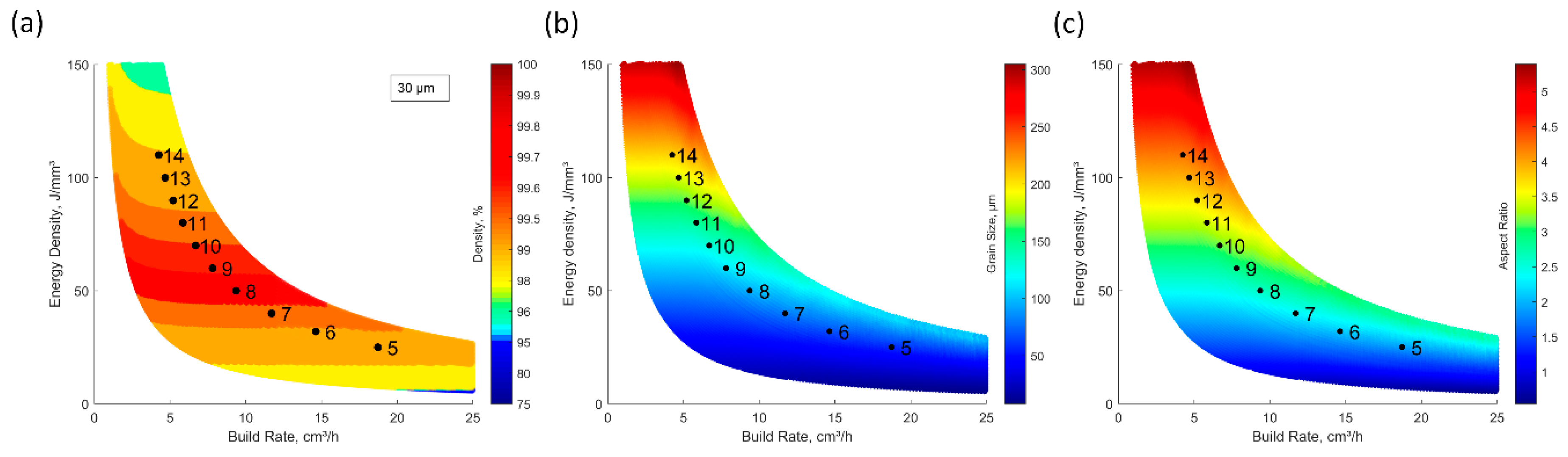

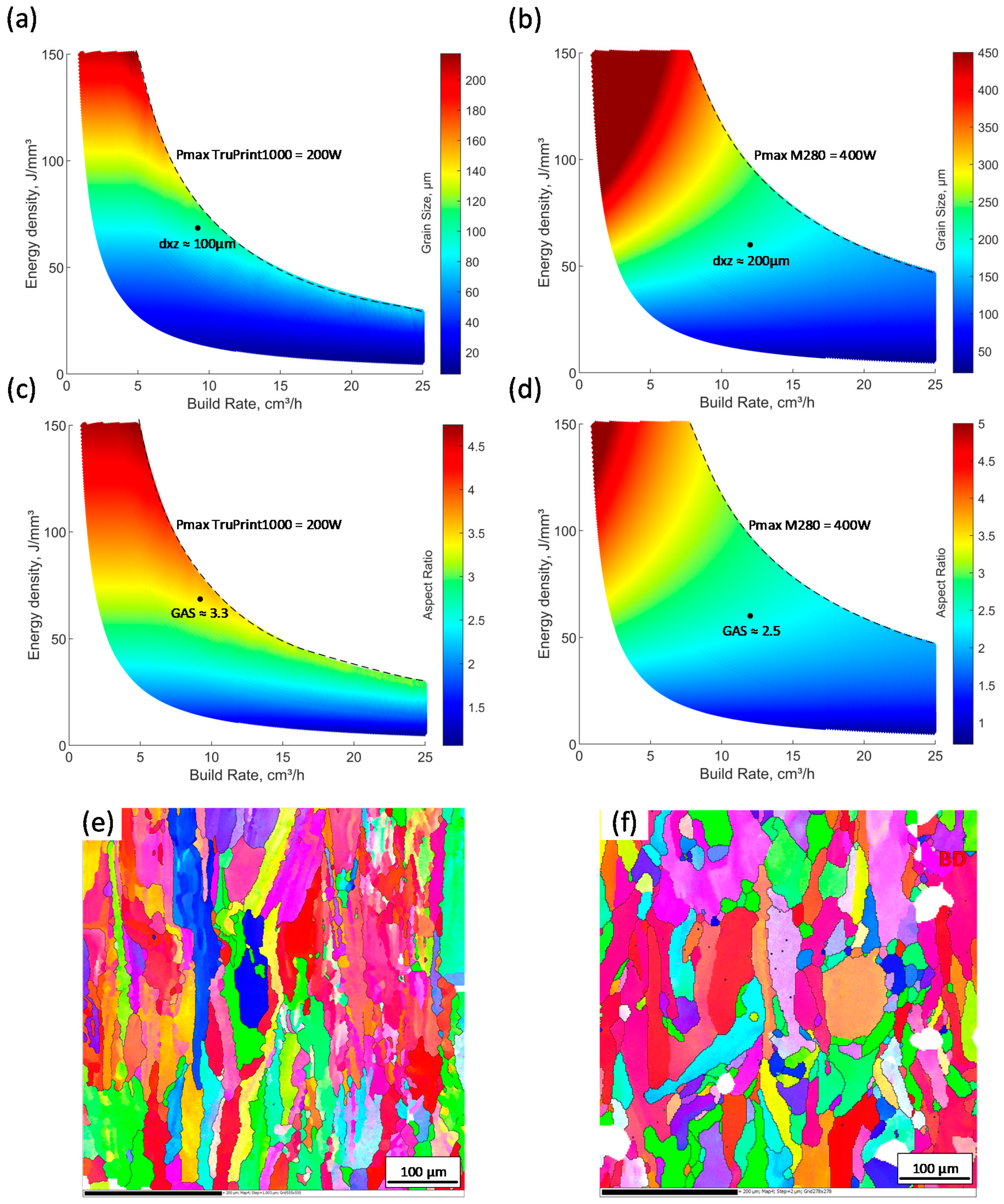

3.2.5. Porosity, Grain Size and Grain Aspect Ratio Processing Maps

4. Discussion

5. Conclusions

- When the laser powder bed fusion parameters of Ti-Zr-Nb alloy powders vary within the operational borders of TruPrint 1000 systems: the laser power from 40 to 200 W, the laser speed from 200 to 4000 mm/s, the hatching space from 60 to 200 μm, while keeping a constant layer thickness of 30 μm; the higher the laser power density, the lower the titanium and the higher the oxygen and nitrogen contents in the alloy: up to 3.0 at. % loss in titanium and 0.025 and 0.012 (wt.%) gains in oxygen and nitrogen, as compared to the precursor powder.

- A printed density greater than 99.5% is obtained for specimens printed within the 25 to 110 J/mm3 laser densities and the 3.2 to 18.7 cm3/h build rates.

- The phase state in all the specimens is parent β-phase, with the lattice parameter slightly larger than that of the conventionally processed alloys; this phenomenon is mainly caused by the enrichment of solid solution in Zr and Nb.

- The lower the laser density energy and the greater the build rate, the finer and the more equiaxed the grain structure of printed specimens, and the less textured the material. In this study, dxz grain size varies from 200 to 50 μm and the grain aspect ratio varies from 4 to 2.

- Using the experimental data obtained and the dedicated processing simulation algorithm, the density and the grain structure processing maps were built. Discrepancies between the experimentally measured and numerically calculated values do not exceed 2% for the printed density, 15% for the grain size and 11% for the grain aspect ratio.

- The Ti-Zr-Nb alloy density, grain size and grain aspect ratio processing maps of this study can be used to control the structure of printed specimens and the process productivity, when using a TruPrint 1000 LPBF systems.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zafar, M.Q.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2019, 26, 564–585. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; et al. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1917, 368, 2000–2032. [Google Scholar] [CrossRef] [PubMed]

- Bobbert, F.S.L.; Lietaert, K.; Eftekhari, A.A.; Pouran, B.; Ahmadi, S.M. Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties. Acta Biomater. 2017, 53, 572–584. [Google Scholar] [CrossRef] [PubMed]

- Metal Foams: Fundamentals and Applications; Dukhan, N., Ed.; DEStech Publications: Lancaster, PA, USA, 2013; 423p. [Google Scholar]

- Sun, S.; Brandt, M.; Easton, M. Powder Bed Fusion Processes: An Overview; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Ma, J.; Franco, B.; Tapia, G.; Karayagiz, K.; Johnson, L.; Liu, J. Spatial Control of Functional Response in 4D-Printed Active Metallic Structures. Sci. Rep. 2017, 7, 46707. [Google Scholar] [CrossRef]

- Yoneyama, T.; Miyazaki, S. SMA for Biomedical Applications; Woodhead: Cambridge, UK, 2008; p. 352. [Google Scholar]

- Miyazaki, S.; Kim, H.; Hosoda, H. Development and characterization of Ni-free Ti-base shape memory and superelastic alloys. Mater. Sci. Eng. A 2006, 438, 18–24. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ikehara, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater. 2006, 54, 2419–2429. [Google Scholar] [CrossRef]

- Li, S.; Cui, T.; Hao, Y.; Yang, R. Fatigue properties of a metastable β-type titanium alloy with reversible phase transformation. Acta Biomater. 2008, 4, 305–317. [Google Scholar] [CrossRef]

- Konopatsky, A.; Dubinskiy, S.; Zhukova, Y.; Sheremetyev, V.; Brailovski, V.; Prokoshkin, S.; Filonov, M. Ternary Ti-Zr-Nb and quaternary Ti-Zr-Nb-Ta shape memory alloys for biomedical applications: Structural features and cyclic mechanical properties. Mater. Sci. Eng. A 2017, 702, 301–311. [Google Scholar] [CrossRef]

- Kudryashova, A.; Sheremetyev, V.; Lukashevich, K.; Cheverikin, V.; Inaekyan, K.; Galkin, S.; Prokoshkin, S.; Brailovski, V. Effect of a combined thermomechanical treatment on the microstructure, texture and superelastic properties of Ti-18Zr-14Nb alloy for orthopedic implants. J. Alloy. Compd. 2020, 843, 156066. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Brailovski, V.; Dubinskiy, S.; Zhukova, Y.; Sheremetyev, V.; Konopatsky, A.; Inaekyan, K. Manufacturing, structure control, and functional testing of Ti–Nb-based SMA for medical application. Shape Mem. Superelast. 2016, 2, 130–144. [Google Scholar] [CrossRef]

- Poulin, J.-R.; Kreitcberg, A.; Terriault, P.; Brailovski, V. Long fatigue crack propagation behavior of laser powder bed-fused inconel 625 with intentionally-seeded porosity. Int. J. Fatigue 2019, 127, 144–156. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, Z.; Li, S.; Liu, Y.-J.; Sercombe, T.; Hou, W.; Zhang, P.; Zhu, Y.; Hao, Y.; Zhang, Z.; et al. Simultaneous improvement in strength and plasticity of Ti-24Nb-4Zr-8Sn manufactured by selective laser melting. Mater. Des. 2018, 157, 52–59. [Google Scholar] [CrossRef]

- Ghosh, S. Predictive modeling of solidification during laser additive manufacturing of nickel superalloys: Recent developments, future directions. Mater. Res. Express 2018, 5, 012001. [Google Scholar] [CrossRef]

- Ahmed, A.; Wahab, M.S.; Raus, A.A.; Kamarudin, K.; Bakhsh, Q.; Ali, D. Effects of Selective Laser Melting Parameters on Relative Density of AlSi10Mg. Int. J. Eng. Technol. 2016, 8, 2552–2557. [Google Scholar] [CrossRef]

- Letenneur, M.; Brailovski, V.; Kreitcberg, A.; Paserin, V.; Bailon-Poujol, I. Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization. J. Manuf. Mater. Process. 2017, 1, 23. [Google Scholar] [CrossRef]

- Letenneur, M.; Kreitcberg, A.; Brailovski, V. Optimization of Laser Powder Bed Fusion Processing Using a Combination of Melt Pool Modeling and Design of Experiment Approaches: Density Control. J. Manuf. Mater. Process. 2019, 3, 21. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Prokoshkin, S. New biocompatible near-beta Ti-Zr-Nb alloy processed by laser powder bed fusion: Process optimization. J. Mater. Process. Technol. 2018, 252, 821–829. [Google Scholar] [CrossRef]

- Letenneur, M.; Kreitcberg, A.; Brailovski, V. The Average Grain Size and Grain Aspect Ratio in Metal Laser Powder Bed Fusion: Modeling and Experiment. J. Manuf. Mater. Process. 2020, 4, 25. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Sheremetyev, V.; Prokoshkin, S. Effect of Laser Powder Bed Fusion Parameters on the Microstructure and Texture Development in Superelastic Ti–18Zr–14Nb Alloy. Shape Mem. Superelast. 2017, 3, 361–372. [Google Scholar] [CrossRef]

- ASTM Standard. ASTM E112-10: Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Schuöcker, D. Handbook of the Eurolaser Academy; Springer Science & Business Media: Berilin, Germany, 1998; Volume 2. [Google Scholar]

- Kundin, J.; Mushongera, L.; Emmerich, H. Phase-field modeling of microstructure formation during rapid solidification in Inconel 718 superalloy. Acta Mater. 2015, 95, 343–356. [Google Scholar] [CrossRef]

- Nelson, J.B.; Riley, D.P. An experimental investigation of extrapolation methods in the derivation of accurate unit-cell dimensions of crystals. Proc. Phys. Soc. 1945, 57, 160–177. [Google Scholar] [CrossRef]

- Kim, H.; Fu, J.; Tobe, H.; Kim, J.; Miyazaki, S. Crystal structure, transformation strain, and superelastic property of Ti–Nb–Zr and Ti–Nb–Ta alloys. Shape Mem. Superelast. 2015, 1, 107–116. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Sheremetyev, V.; Tsaturyants, M.; Prokoshkin, S.; Brailovski, V. Optimization of Post-processing Annealing Conditions of the Laser Powder Bed-Fused Ti–18Zr–14Nb Shape Memory Alloy: Structure and Functional Properties. Shape Mem. Superelast. 2019, 5, 172–181. [Google Scholar] [CrossRef]

- Gockel, J.; Beuth, J.; Taminger, K. Integrated control of solidification microstructure and melt pool dimensions in electron beam wire feed additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2014, 1–4, 119–126. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Yadroitsau, I. Selective laser melting: Direct manufacturing of 3D-objects by selective laser melting of metal powders. Lambert Acad. Publ. 2009, 55, 551–560. [Google Scholar]

- Popovich, V.; Borisov, E.; Sufiiarov, V.; Masaylo, D.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Poulin, J.R.; Letenneur, M.; Terriault, P.; Brailovski, V. Influence of Intentionally Induced Porosity and Postprocessing Conditions on the Mechanical Properties of Laser Powder Bed–Fused Inconel 625. Struct. Integr. Addit. Manuf. Parts 2018, STP1620, 294–312. [Google Scholar]

- Silbernagel, C.; Aremu, A.; Ashcroft, I. Using machine learning to aid in the parameter optimisation process for metal-based additive manufacturing. Rapid Prototyp. J. 2019, 26, 625–637. [Google Scholar] [CrossRef]

| Set | Specimens | Power, W | Speed, m/s | Hatch Distance, mm | E, J/mm3 | BR, cm3/h |

|---|---|---|---|---|---|---|

| 1st set | 1 | 70 | 500 | 0.06 | 77.8 | 3.2 |

| 2 | 104 | 772 | 0.06 | 74.7 | 5.0 | |

| 3 | 140 | 1080 | 0.06 | 72.0 | 7.0 | |

| 4 | 175 | 1420 | 0.06 | 68.5 | 9.2 | |

| 2nd set | 5 | 130 | 1576 | 0.11 | 25.0 | 18.7 |

| 6 | 130 | 1231 | 0.11 | 32.0 | 14.6 | |

| 7 | 130 | 985 | 0.11 | 40.0 | 11.7 | |

| 8 | 130 | 788 | 0.11 | 50.0 | 9.4 | |

| 9 | 130 | 657 | 0.11 | 60.0 | 7.8 | |

| 10 | 130 | 563 | 0.11 | 70.0 | 6.7 | |

| 11 | 130 | 492 | 0.11 | 80.1 | 5.8 | |

| 12 | 130 | 438 | 0.11 | 89.9 | 5.2 | |

| 13 | 130 | 394 | 0.11 | 100.0 | 4.7 | |

| 14 | 130 | 358 | 0.11 | 110.0 | 4.3 |

| Material Characteristics | Bulk | Powder (t = 30 μm; φ = 60%) |

|---|---|---|

| Density, kg/m3 | 5660 | 3396 |

| Thermal conductivity *, W/mK | 7.2 | 3.6 |

| Specific heat *, J/kg.K | 560 | 560 |

| Laser absorptivity ** | 0.46 | 0.91 |

| Melting temperature ***, °C | 1650 | 1650 |

| Printing Conditions | Chemical Composition | |||||

|---|---|---|---|---|---|---|

| Main Elements (at. %) | Interstitial Elements (wt. %) | |||||

| Specimen | Power Density (W/mm3) | Ti | Zr | Nb | O | N |

| 3 | 72 | 65.5 | 18.9 | 15.6 | 0.213 | 0.011 |

| 4 | 68.5 | 65.6 | 18.8 | 15.5 | 0.218 | 0.019 |

| 5 | 25 | 65.6 | 19.0 | 15.4 | 0.200 | 0.010 |

| 14 | 110 | 64.7 | 19.5 | 15.8 | 0.213 | 0.025 |

| Powder | 68.6 | 17.8 | 13.6 | 0.189 | 0.013 | |

| Specimen | E, J/mm3 | BR, cm3/h | a, nm | Peak Intensity Ratio |

|---|---|---|---|---|

| I110:I200:I211 | ||||

| 14 | 110 | 4.3 | 0.3347 ± 0.0003 | 1:0.88:0.42 |

| 10 | 70 | 6.7 | 0.3347 ± 0.0001 | 1:0.88:0.22 |

| 4 | 68.5 | 9.2 | 0.3351 ± 0.0001 | 1:1.32:0.85 |

| 7 | 40 | 11.7 | 0.3349 ± 0.0001 | 1:0.10:0.27 |

| 5 | 25 | 18.7 | 0.3347 ± 0.0003 | 1:0.27:0.26 |

| Specimen | E, J/mm3 | BR, cm3/h | dxz, µm | dxy, µm | GAR | Text Int (Max) |

|---|---|---|---|---|---|---|

| 14 | 110 | 4.3 | 199 ± 6 | 50 ± 6 | 2.88 | 2.08 |

| 10 | 70 | 6.7 | 151 ± 7 | 41 ± 5 | 3.28 | 6.84 |

| 4 | 68.5 | 9.2 | 97 ± 7 | 37 ± 4 | 3.17 | 4.55 |

| 7 | 40 | 11.7 | 66 ± 3 | 30 ± 4 | 2.62 | 2.56 |

| 5 | 25 | 18.7 | 50 ± 3 | 31 ± 4 | 2.34 | 1.48 |

| Specimen | E, J/mm3 | BR, cm3/h | Density, % | Grain Size (XZ), µm | Grain Aspect Ratio | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Meas. | Calc. | Dev. | Meas. | Calc. | Dev., % | Meas. | Calc. | Dev., % | |||

| 1 | 77.8 | 3.2 | 98.29 | 99.64 | 1.35 | - | 75 | - | - | 2.86 | - |

| 2 | 74.7 | 5.0 | 99.07 | 99.64 | 0.57 | - | 76 | - | - | 2.88 | - |

| 3 | 72.0 | 7.0 | 99.69 | 99.64 | 0.05 | - | 85 | - | - | 3.01 | - |

| 4 | 68.5 | 9.2 | 99.61 | 99.64 | 0.03 | 97 ± 7 | 97 | 0 | 3.17 | 3.19 | 0.6 |

| 5 | 25.0 | 18.7 | 98.30 | 98.30 | 0.00 | 50 ± 3 | 54 | 7.4 | 2.34 | 2.28 | 2.6 |

| 6 | 32.0 | 14.6 | 99.31 | 98.93 | 0.39 | - | 65 | - | - | 2.45 | - |

| 7 | 40.0 | 11.7 | 99.48 | 99.41 | 0.07 | 66 ± 3 | 78 | 15.4 | 2.62 | 2.65 | 1.1 |

| 8 | 50.0 | 9.4 | 99.61 | 99.61 | 0.00 | - | 94 | - | - | 2.86 | - |

| 9 | 60.0 | 7.8 | 99.19 | 99.58 | 0.39 | - | 112 | - | - | 3.06 | - |

| 10 | 70.0 | 6.7 | 99.25 | 99.29 | 0.05 | 151 ± 7 | 129 | 14.6 | 3.28 | 3.25 | 2.5 |

| 11 | 80.1 | 5.8 | 99.32 | 99.29 | 0.03 | - | 147 | - | - | 3.43 | - |

| 12 | 89.9 | 5.2 | 98.61 | 98.73 | 0.12 | - | 166 | - | -- | 3.60 | - |

| 13 | 100.0 | 4.7 | 96.93 | 98.73 | 1.83 | - | 186 | - | - | 3.77 | - |

| 14 | 110.0 | 4.3 | 98.11 | 98.03 | 0.08 | 199 ± 6 | X | X | 2.88 | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brailovski, V.; Kalinicheva, V.; Letenneur, M.; Lukashevich, K.; Sheremetyev, V.; Prokoshkin, S. Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping. Metals 2020, 10, 1697. https://doi.org/10.3390/met10121697

Brailovski V, Kalinicheva V, Letenneur M, Lukashevich K, Sheremetyev V, Prokoshkin S. Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping. Metals. 2020; 10(12):1697. https://doi.org/10.3390/met10121697

Chicago/Turabian StyleBrailovski, Vladimir, Victoria Kalinicheva, Morgan Letenneur, Konstantin Lukashevich, Vadim Sheremetyev, and Sergey Prokoshkin. 2020. "Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping" Metals 10, no. 12: 1697. https://doi.org/10.3390/met10121697

APA StyleBrailovski, V., Kalinicheva, V., Letenneur, M., Lukashevich, K., Sheremetyev, V., & Prokoshkin, S. (2020). Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping. Metals, 10(12), 1697. https://doi.org/10.3390/met10121697