Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate

Abstract

1. Introduction

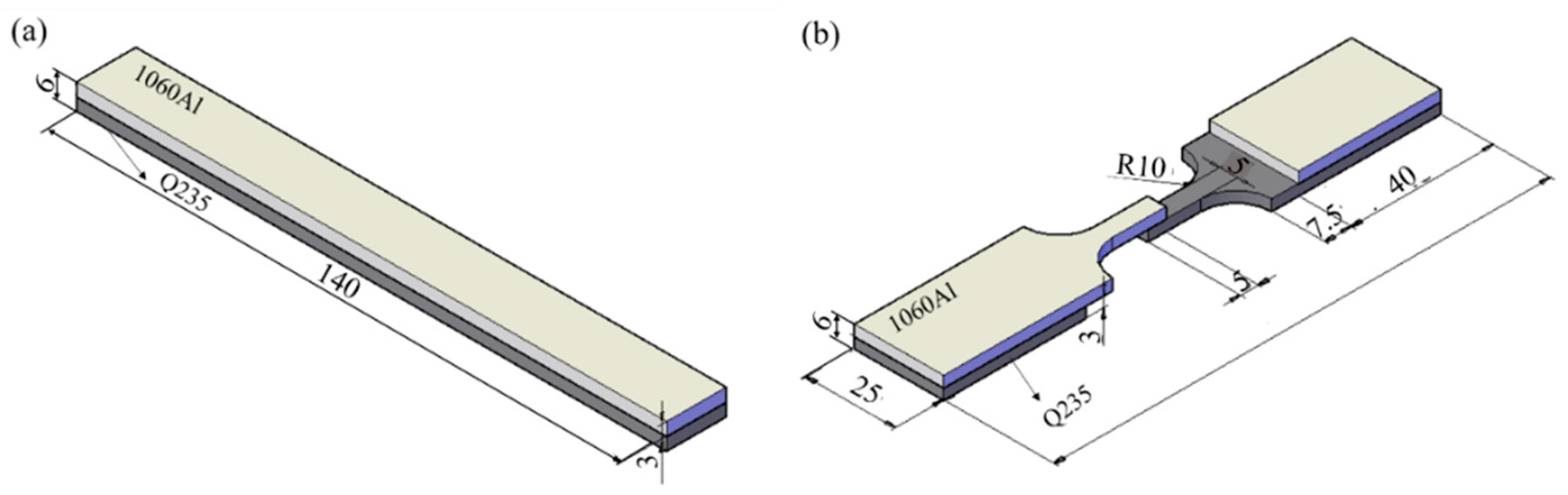

2. Experimental Materials and Methods

3. Results and Discussion

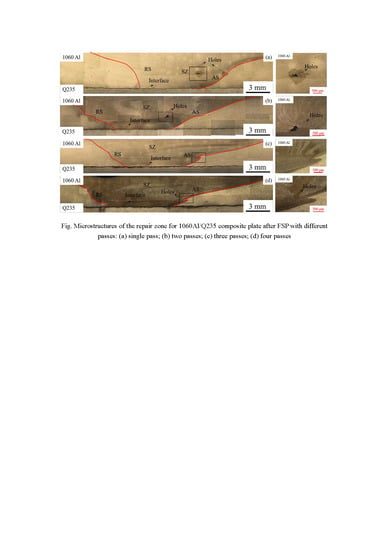

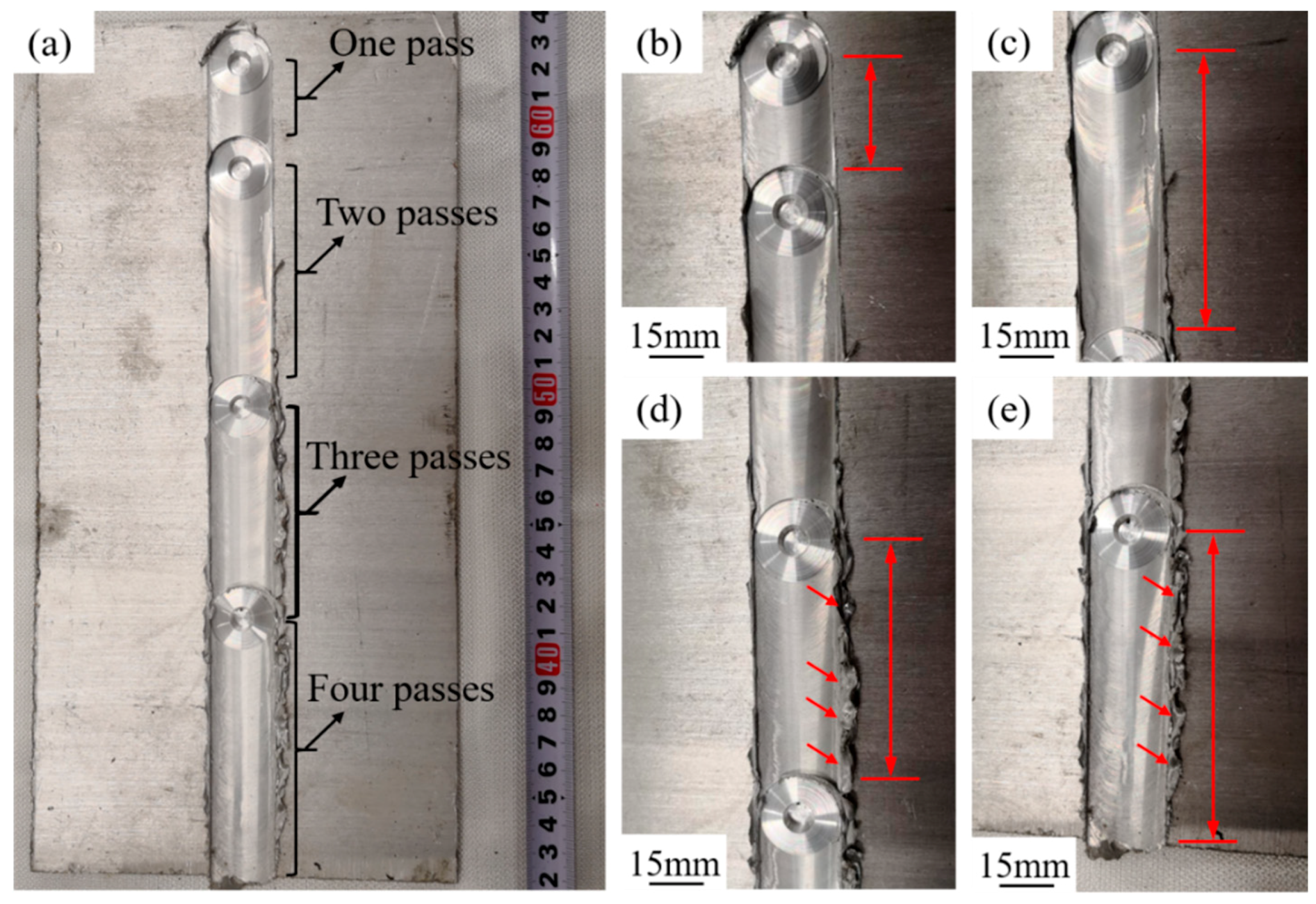

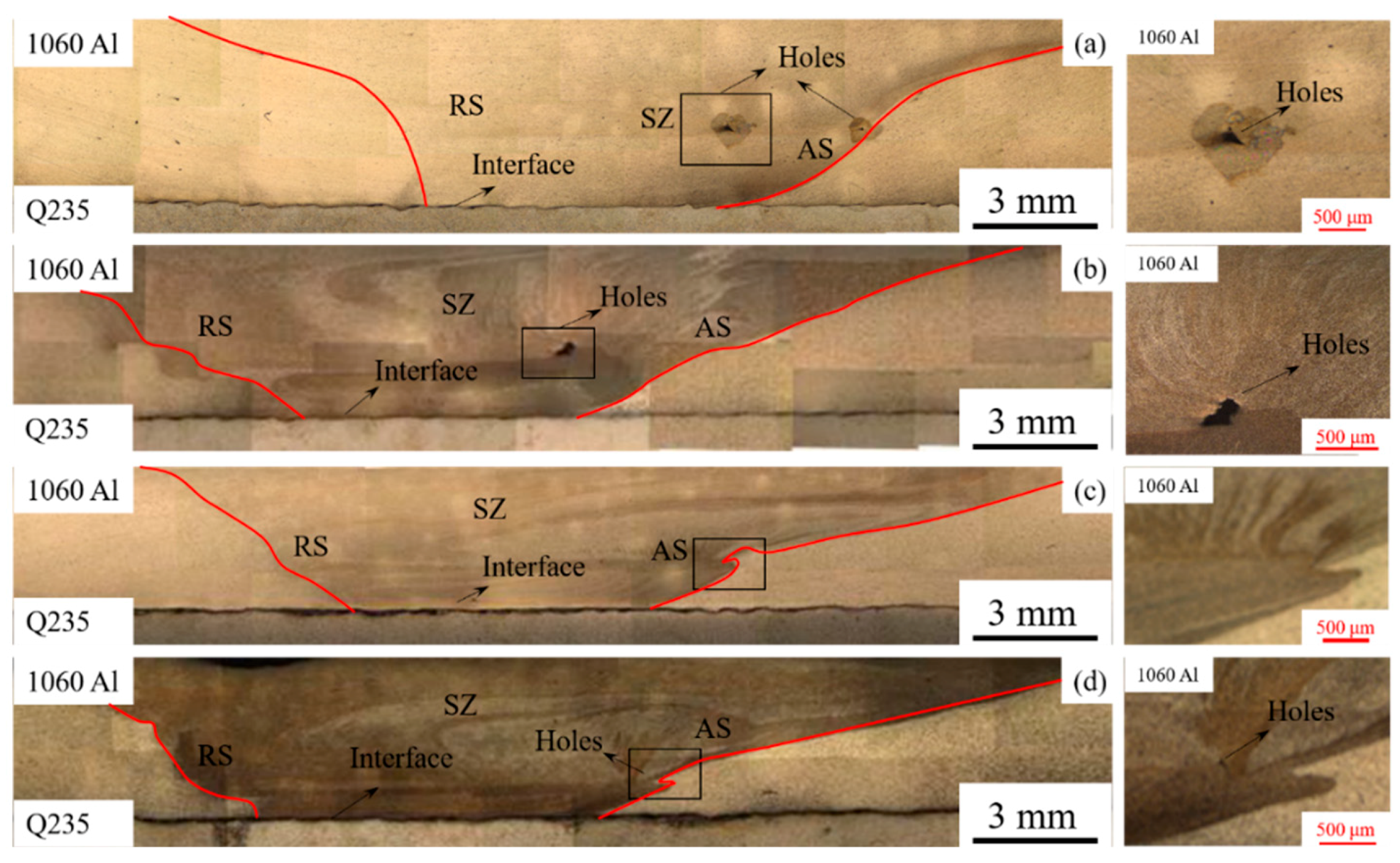

3.1. Macro- & Micro- Structures

3.2. Interface Characterization

3.3. Mechanical Properties

4. Discussion

5. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Kaya, Y.; Kahraman, N. An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel. Mater. Des. 2013, 52, 367–372. [Google Scholar] [CrossRef]

- Feistauer, E.E.; Bergmann, L.A.; Barreto, L.S.; dos Santos, J.F. Mechanical behaviour of dissimilar friction stir welded tailor welded blanks in Al–Mg alloys for Marine applications. Mater. Des. 2014, 59, 323–332. [Google Scholar] [CrossRef]

- Acarer, M.; Demir, B. An investigation of mechanical and metallurgical properties of explosive welded aluminium–dual phase steel. Mater. Lett. 2008, 62, 4158–4160. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Acarer, M.; Gülenç, B.; Findik, F. Investigation of explosive welding parameters and their effects on microhardness and shear strength. Mater. Des. 2003, 24, 659–664. [Google Scholar] [CrossRef]

- Li, X.; Ma, H.; Shen, Z. Research on explosive welding of aluminium alloy to steel with dovetail grooves. Mater. Des. 2015, 87, 815–824. [Google Scholar] [CrossRef]

- Szecket, A. A wavy versus straight interface in the explosive welding of aluminium to steel. J. Vac. Sci. Technol. A Vac. Surf. Film. 1985, 3, 2588–2593. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent International Patent Application Number PCT/GB92/02203 and GB Patent Application 9125978.8. 6 December 1991. [Google Scholar]

- Ma, Z.Y.; Mishra, R.S.; Mahoney, M.W.; Grimes, R. High strain rate superplasticity in friction stir processed Al–Mg–Zr alloy. Mater. Sci. Eng. A 2003, 351, 148–153. [Google Scholar] [CrossRef]

- Hao, H.L.; Ni, D.R.; Huang, H.; Wang, D.; Xiao, B.L.; Nie, Z.; Ma, Z.Y. Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al–Mg–Er alloy. Mater. Sci. Eng. A 2013, 559, 889–896. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, P.; Gulati, P.; Shukla, D.K. Effect of Tool rotation speed and feed rate on the formation of tunnel defect in Friction Stir Processing of AZ31 Magnesium alloy. Mater. Today Proc. 2015, 2, 3463–3470. [Google Scholar] [CrossRef]

- Barmouz, M.; Givi, M.K.B. Fabrication of in situ Cu/SiC composites using multi-pass friction stir processing: Evaluation of microstructural, porosity, mechanical and electrical behavior. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1445–1453. [Google Scholar] [CrossRef]

- Nakata, K.; Kim, Y.G.; Fujii, H.; Tsumura, T.; Komazaki, T. Improvement of mechanical properties of aluminum die casting alloy by multi-pass friction stir processing. Mater. Sci. Eng. A 2006, 437, 274–280. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-Zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminium friction stir welds. J. Alloy Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

- Kim, Y.G.; Fujii, H.; Tsumura, T.; Komazaki, T.; Nakata, K. Three defect types in friction stir welding of aluminum die casting alloy. Mater. Sci. Eng. A 2006, 415, 250–254. [Google Scholar] [CrossRef]

- Fereiduni, E.; Movahedi, M.; Kokabi, A.H. Dissimilar Al/steel friction stir spot welding: To penetrate into the lower steel sheet or not? Sci. Technol. Weld. Join. 2016, 21, 466–472. [Google Scholar] [CrossRef]

- Coelho, R.; Kostka, A.; Santos, J.F.D.; Kaysser-Pyzallaa, A. Friction-stir dissimilar welding of aluminium alloy to high strength steels: Mechanical properties and their relation to microstructure. Mater. Sci. Eng. A 2012, 556, 175–183. [Google Scholar] [CrossRef]

- Ogura, T.; Saito, Y.; Nishida, T.; Nishida, H.; Yoshida, T.; Omichi, N.; Fujimoto, M.; Hirose, A. Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminium alloy/stainless steel lap joint. Scr. Mater. 2012, 66, 531–534. [Google Scholar] [CrossRef]

- Sun, Y.F.; Fujii, H.; Takaki, N.; Okitsu, Y. Microstructure and mechanical properties of dissimilar Al alloy/steel joints prepared by a flat spot friction stir welding technique. Mater. Des. 2013, 47, 350–357. [Google Scholar] [CrossRef]

- Haghshenas, M.; Abdel-Gwad, A.; Omran, A.M.; Gökçe, B.; Sahraeinejad, S.; Gerlich, A.P. Friction stir weld assisted diffusion bonding of 5754 aluminium alloy to coated high strength steels. Mater. Des. 2014, 55, 442–449. [Google Scholar] [CrossRef]

- Ramachandran, K.K.; Murugan, N.; Shashi Kumar, S. Effect of tool axis offset and geometry of tool pin profile on the characteristics of friction stir welded dissimilar joints of aluminium alloy AA5052 and HSLA steel. Mater. Sci. Eng. A 2015, 639, 219–233. [Google Scholar] [CrossRef]

- Chen, Z.W.; Yazdanian, S.; Littlefair, G. Effects of tool positioning on joint interface microstructure and fracture strength of friction stir lap Al-to-steel welds. J. Mater. Sci. 2013, 48, 2624–2634. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.M.S.; Najafi, H.; Farzadfar, S.A.; Cheng, W.J.; Wang, C.J. Growth kinetics of Al–Fe intermetallic compounds during annealing treatment of friction stir lap welds. Mater. Charact. 2014, 90, 121–126. [Google Scholar] [CrossRef]

- Coelho, R.S.; Kostka, A.; Sheikhi, S.; dos Santos, J.; Pyzalla, A.R. Microstructure and Mechanical Properties of an AA6181-T4 Aluminium Alloy to HC340LA High Strength Steel Friction Stir Overlap Weld. Adv. Eng. Mater. 2008, 10, 961–972. [Google Scholar] [CrossRef]

- Bozzi, S.; Helbert-Etter, A.L.; Baudin, T.; Criqui, B.; Kerbiguet, J.G. Intermetallic compounds in Al 6016/IF-steel friction stir spot welds. Mater. Sci. Eng. A 2010, 527, 4505–4509. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.M.S.; Najafi, H. Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminium steel lap joints made by friction stir welding. Sci. Technol. Weld. Join. 2012, 17, 162–167. [Google Scholar] [CrossRef]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminium alloys. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Wang, J.; Lu, X.F.; Chen, C.; Li, B.; Ma, Z.Y. Improve the quality of 1060Al/Q235 explosive composite plate by friction stir processing. J. Mater. Res. Technol. 2020, 9, 42–51. [Google Scholar] [CrossRef]

- Rasti, J. Study of the welding parameters effect on the tunnel void area during friction stir welding of 1060 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 2221–2230. [Google Scholar] [CrossRef]

- Pal, S.; Phaniraj, M.P. Determination of heat partition between tool and workpiece during FSW of SS304 using 3D CFD modeling. J. Mater. Process. Technol. 2015, 222, 280–286. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Heason, C.P.; Colligan, K.J. Grain structures in Al-alloy friction stir welds observed by stop-action technique. Int. J. Offshore Polar Eng. 2004, 14, 289–295. [Google Scholar]

- Hasan, A.F.; Bennett, C.J.; Shipway, P.H. A numerical comparison of the flow behaviour in Friction Stir Welding (FSW) using unworn and worn tool geometries. Mater. Des. 2015, 87, 1037–1046. [Google Scholar] [CrossRef]

- Colligan, K. Material flow behavior during friction stir welding of aluminium. Weld. J. 1999, 172, 220. [Google Scholar]

| Ele. | Fe | Al | Si | Mn | Ti | Zn | C | S | P |

|---|---|---|---|---|---|---|---|---|---|

| 1060Al | 0.19 | Bal. | 0.15 | 0.03 | 0.017 | 0.012 | - | - | - |

| Q235 | Bal. | 0.029 | 0.12 | 0.32 | - | - | 0.13 | 0.009 | 0.022 |

| Pass | Quantities of Holes | Total Area/μm2 |

|---|---|---|

| 1 | 2 | 13.2 × 103 |

| 2 | 1 | 12 × 103 |

| 3 | 0 | 0 |

| 4 | 1 | 1.1 × 103 |

| Pass | S (mm2) | Force (N) | τ (MPa) |

|---|---|---|---|

| 1 | 25.10 | 793.6 | 31.62 |

| 2 | 25.05 | 723.4 | 28.87 |

| 3 | 24.90 | 829.5 | 33.31 |

| 4 | 25.13 | 838.6 | 33.37 |

| Pass | Crack in Steel (Tensile Face) | Crack in Aluminum (Compressed Face) | Crack in Steel (Compressed Face) | Crack in Aluminum (Tensile Face) |

|---|---|---|---|---|

| 0 | No | No | No | No |

| 1 | No | No | No | No |

| 2 | No | No | No | No |

| 3 | No | No | No | No |

| 4 | No | No | No | Yes |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Cheng, Y.; Li, B.; Chen, C. Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate. Metals 2020, 10, 298. https://doi.org/10.3390/met10030298

Wang J, Cheng Y, Li B, Chen C. Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate. Metals. 2020; 10(3):298. https://doi.org/10.3390/met10030298

Chicago/Turabian StyleWang, Jian, Yun Cheng, Bo Li, and Cheng Chen. 2020. "Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate" Metals 10, no. 3: 298. https://doi.org/10.3390/met10030298

APA StyleWang, J., Cheng, Y., Li, B., & Chen, C. (2020). Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate. Metals, 10(3), 298. https://doi.org/10.3390/met10030298