Society, Materials, and the Environment: The Case of Steel

Abstract

:1. Introduction

- The geosphere because raw materials and energy resources stem from there and much of the waste generated by mining, industry, and end-of-life returns there;

- The biosphere because emissions to air, water, and soil leak into the atmosphere, the hydrosphere, and the top of the geosphere. This should also include Greenhouse gas (GHG) emissions. Steelmaking activities pollute and affect ecosystems and biodiversity;

- The anthroposphere itself, because steel-related elements and compounds influence the health of people (toxicological effects) while steel-related activities create economic and social benefits, directly through the use of steel in the anthroposphere, or indirectly, through its eco-socio-systemic services [3]—two sides of the balance sheet with the pros and cons of steel in the economy and society.

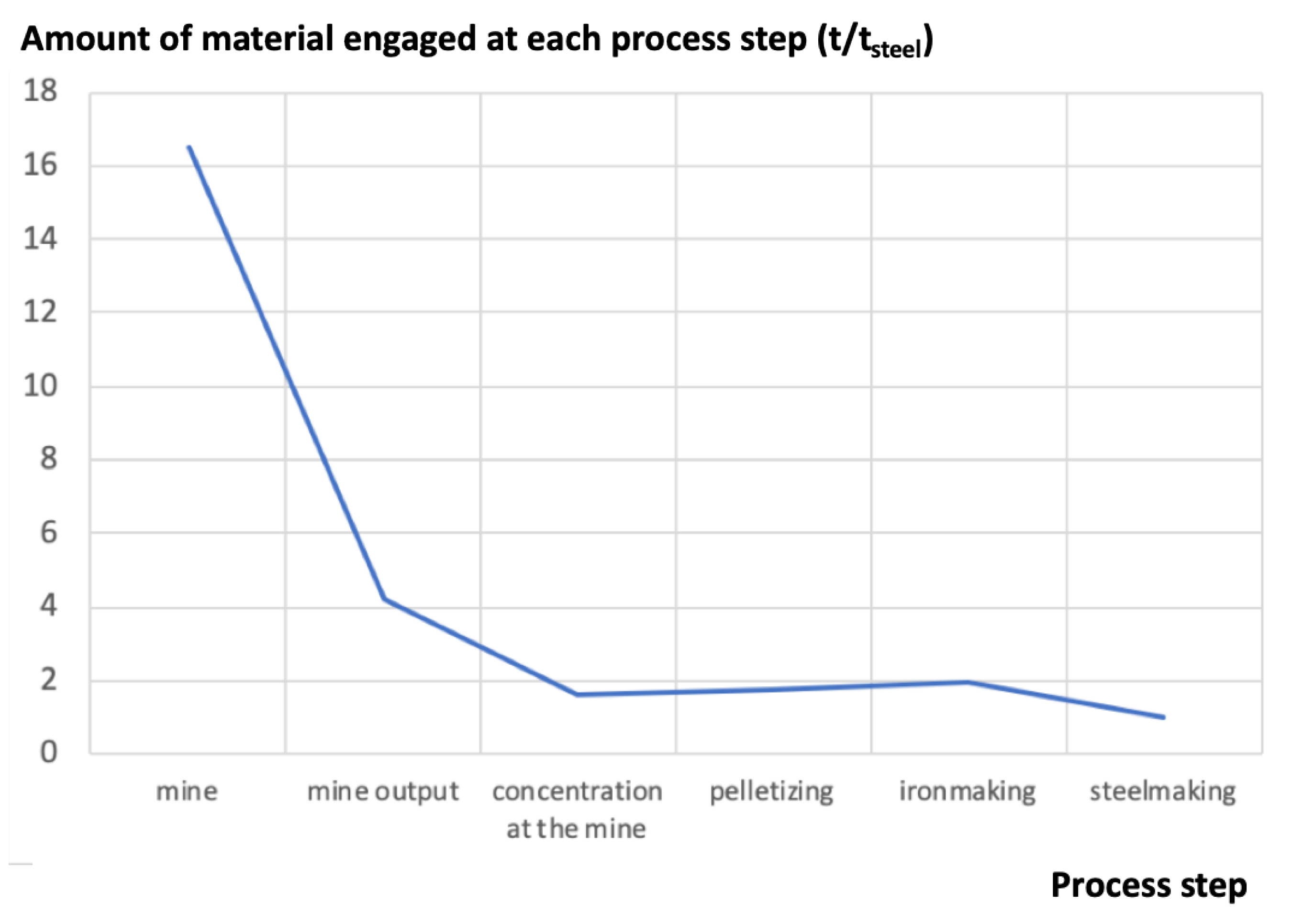

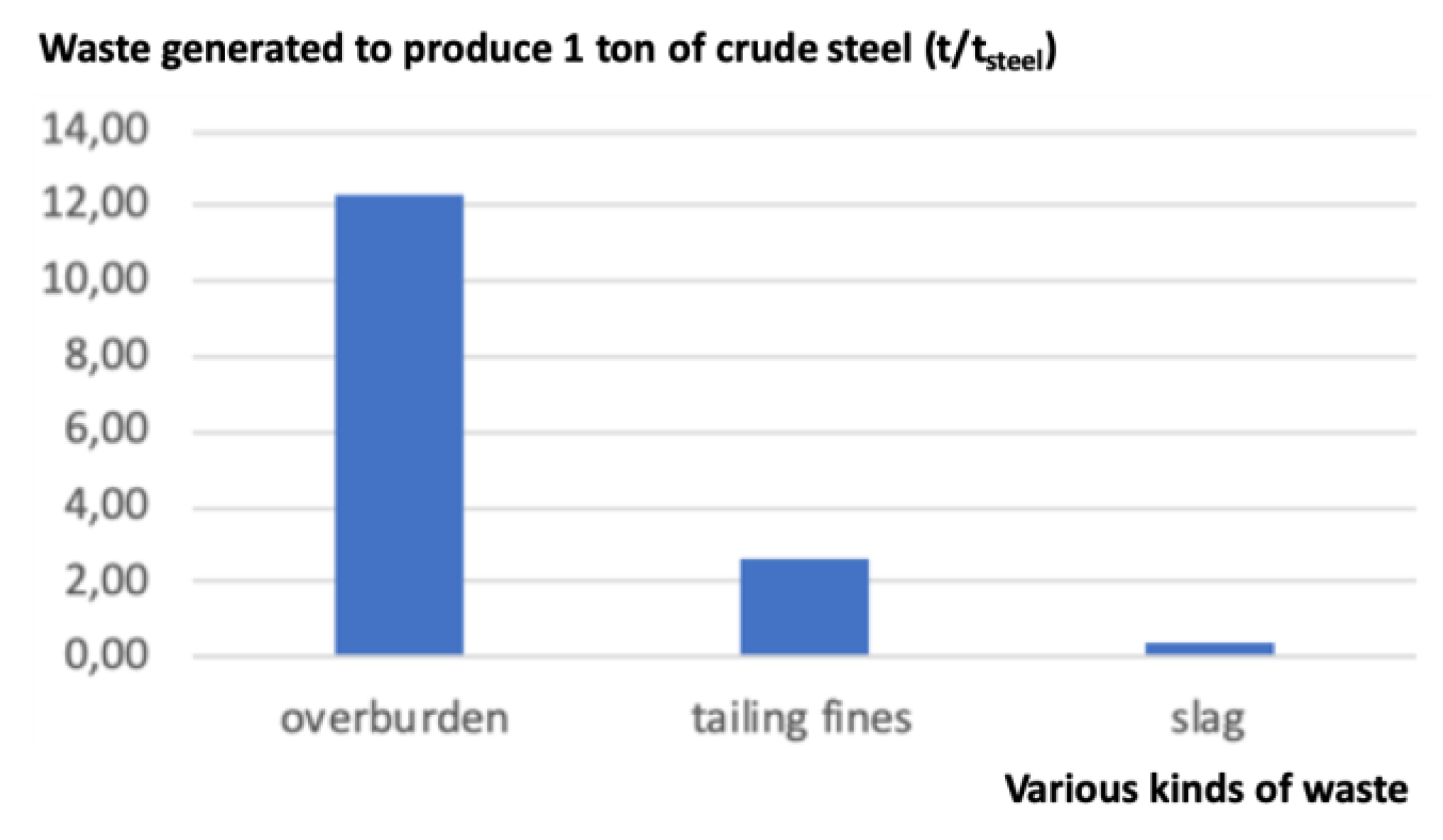

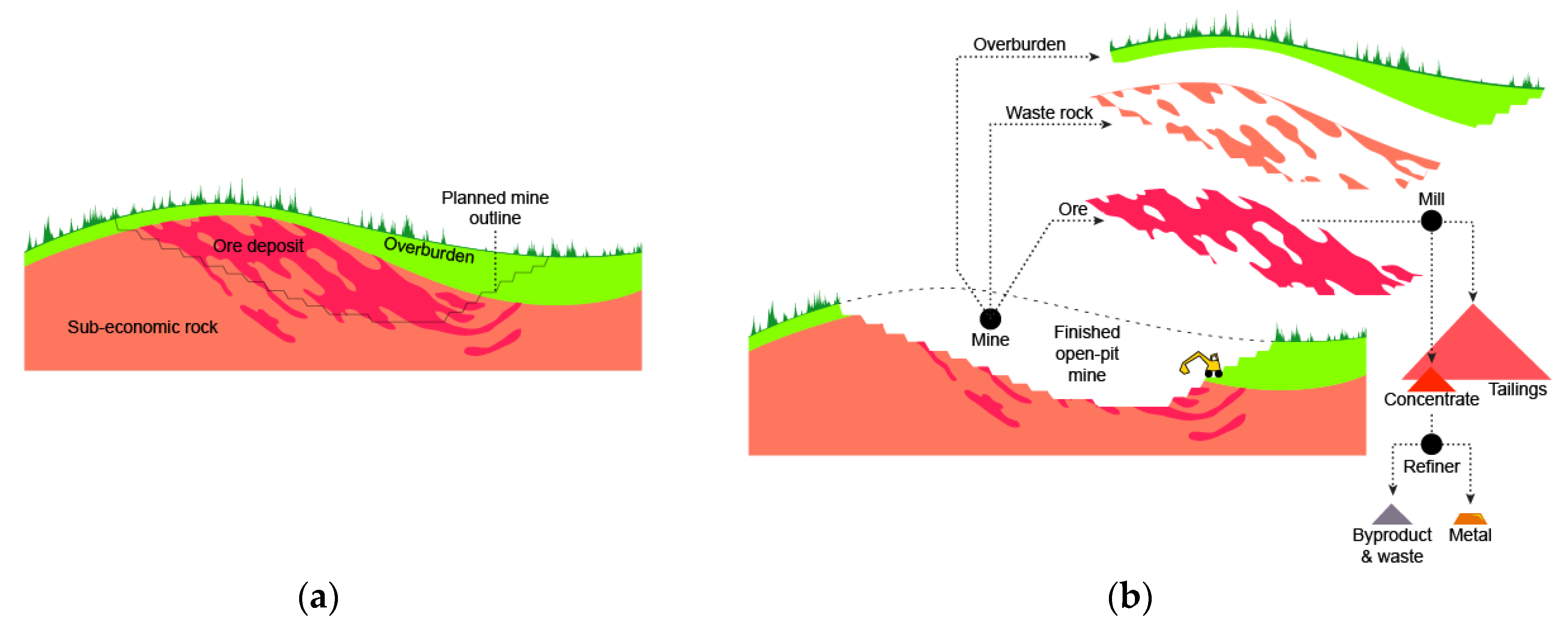

2. Steel and Raw Materials

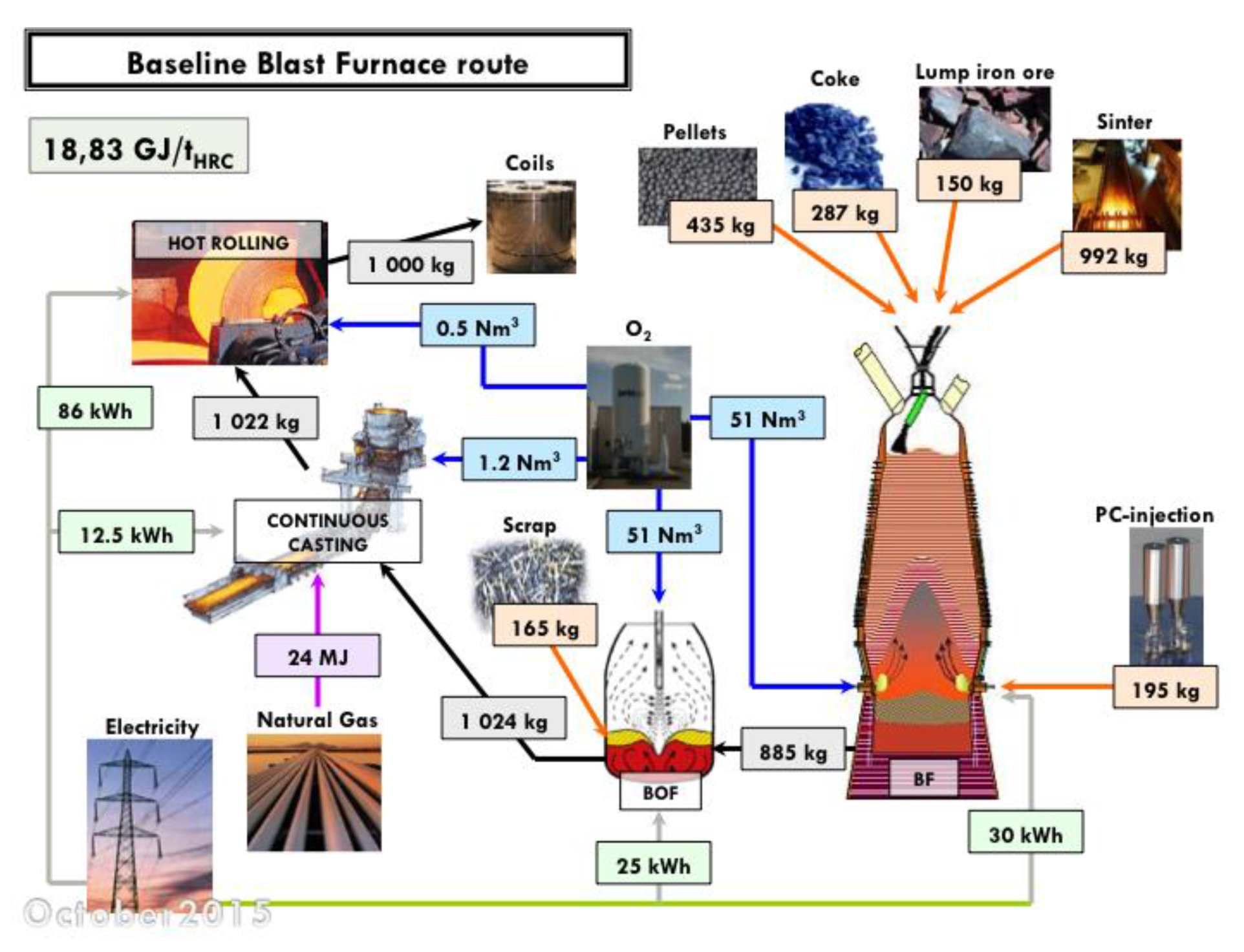

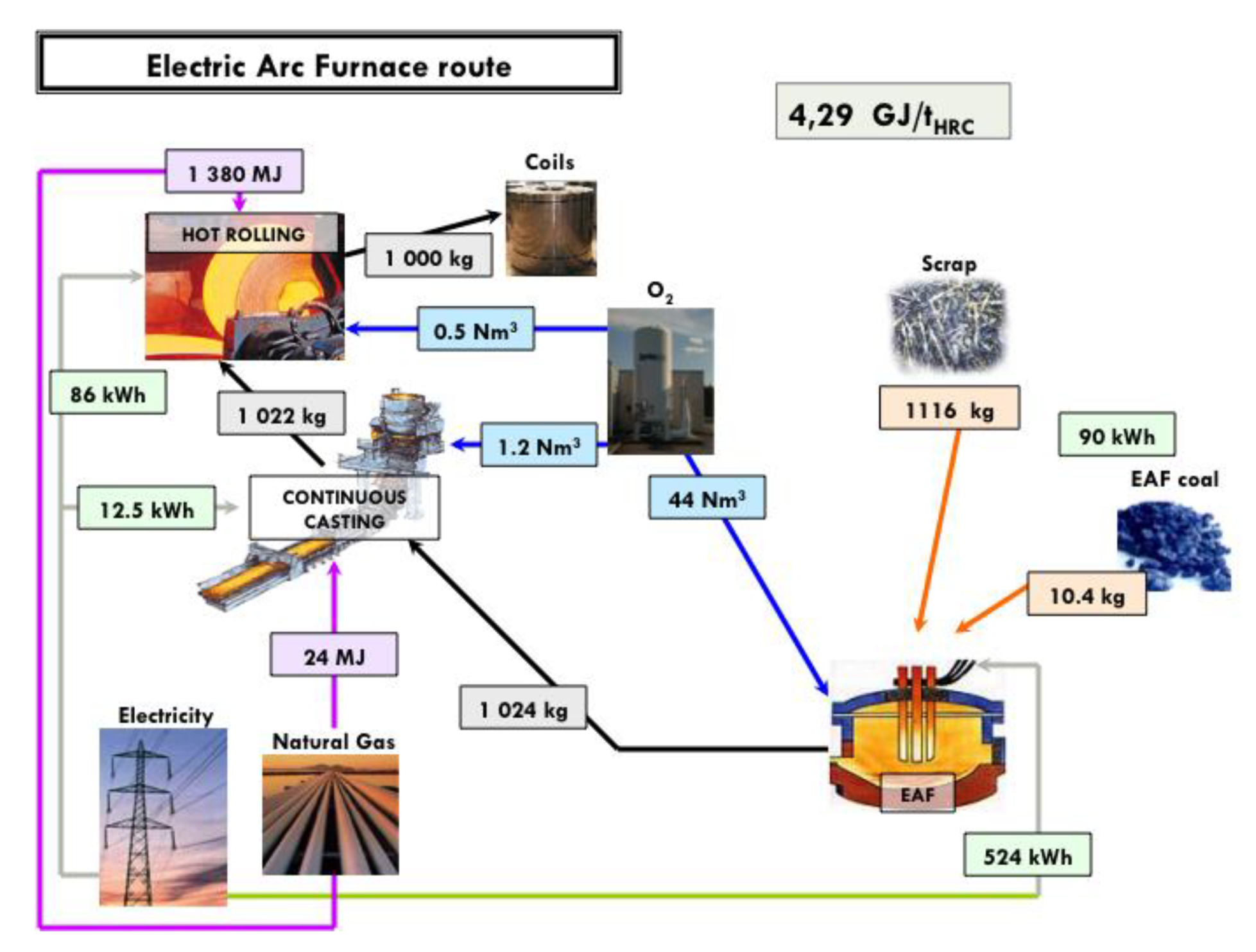

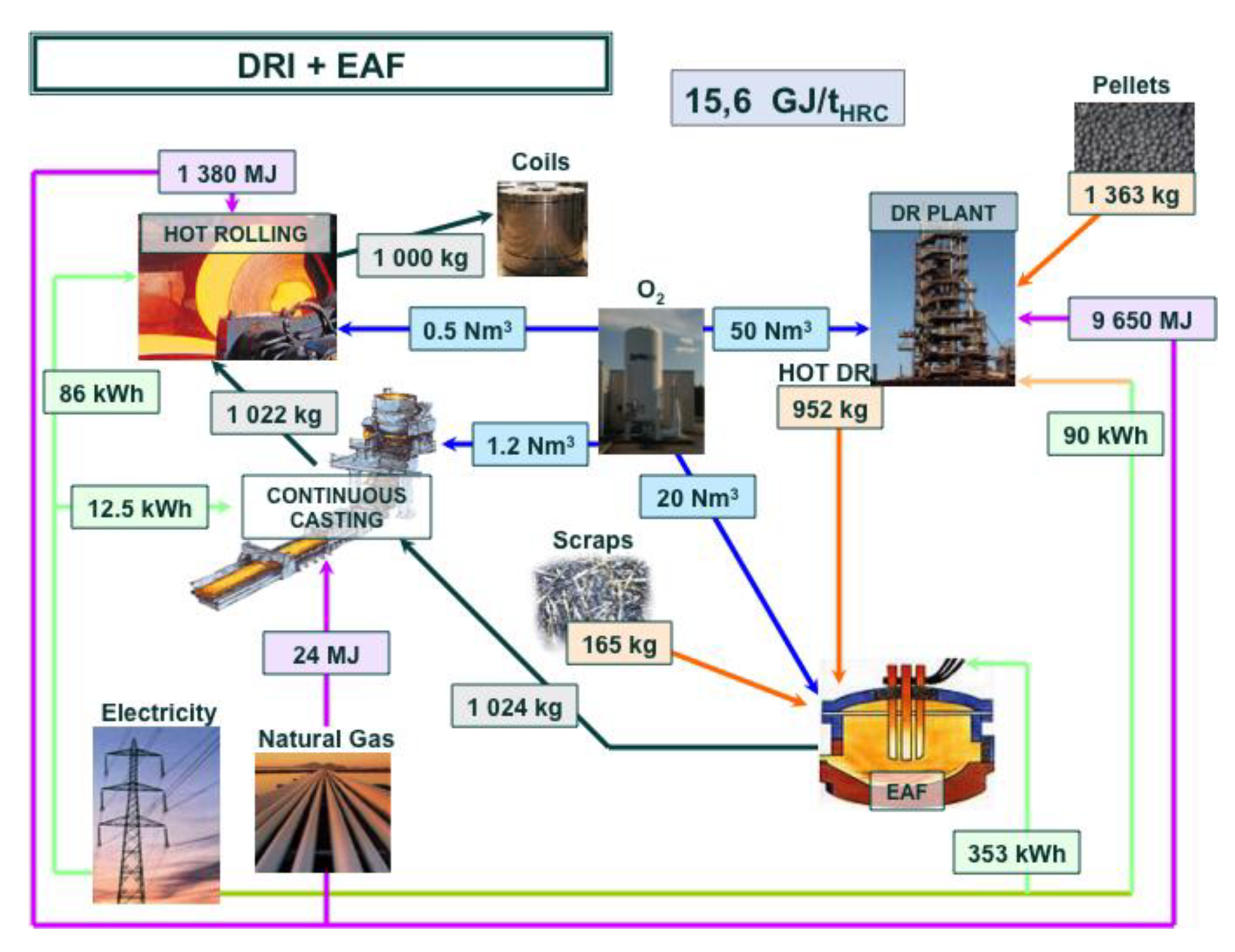

3. Steel and Energy

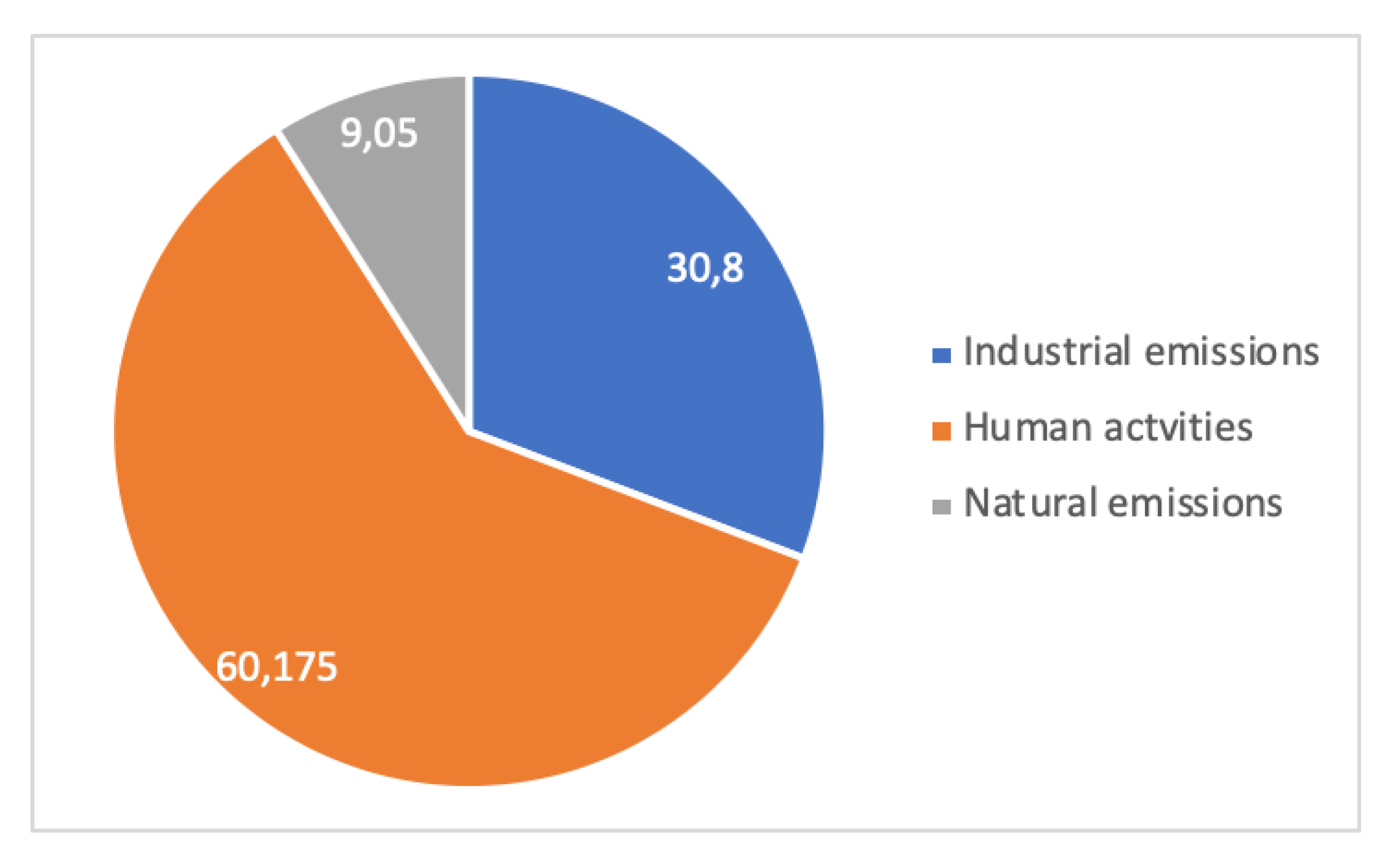

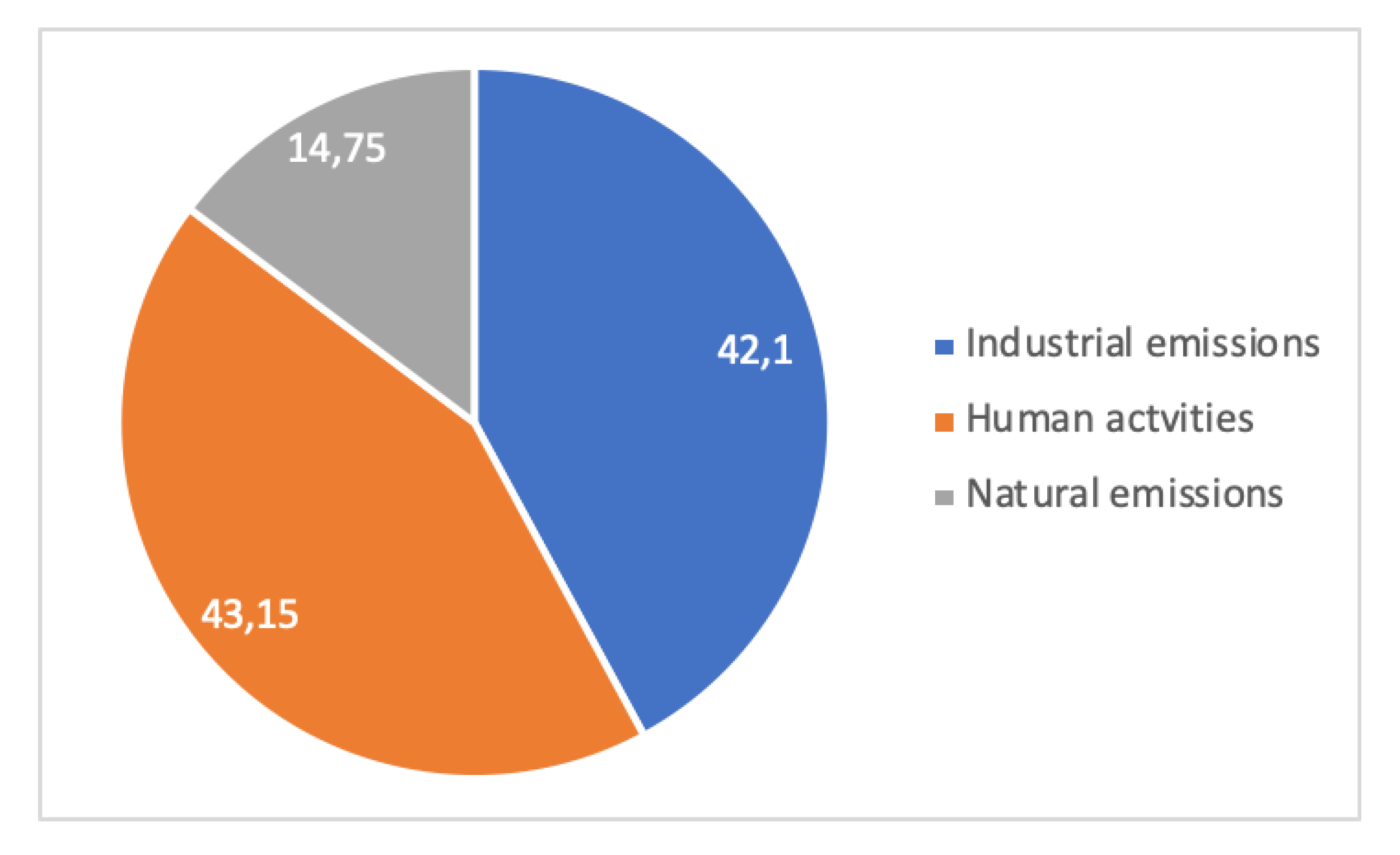

4. Air Emissions and Pollution Related to Steel

4.1. Air Emissions and Pollution Related to Steel

4.2. Dust Generation

- Saltation, the basic mechanism for transporting powder from piles by the action of wind or of gas convection. It is the basic mechanism responsible for the airborne dust originating from sand deserts and transported thousands of kilometers away and for the displacement of sand dunes as well [22]. It is also effective in eroding piles of raw material, like ore, for example, and projecting dust in the atmosphere.

- Erosion can also generate dust, a common phenomenon in the biosphere/geosphere.

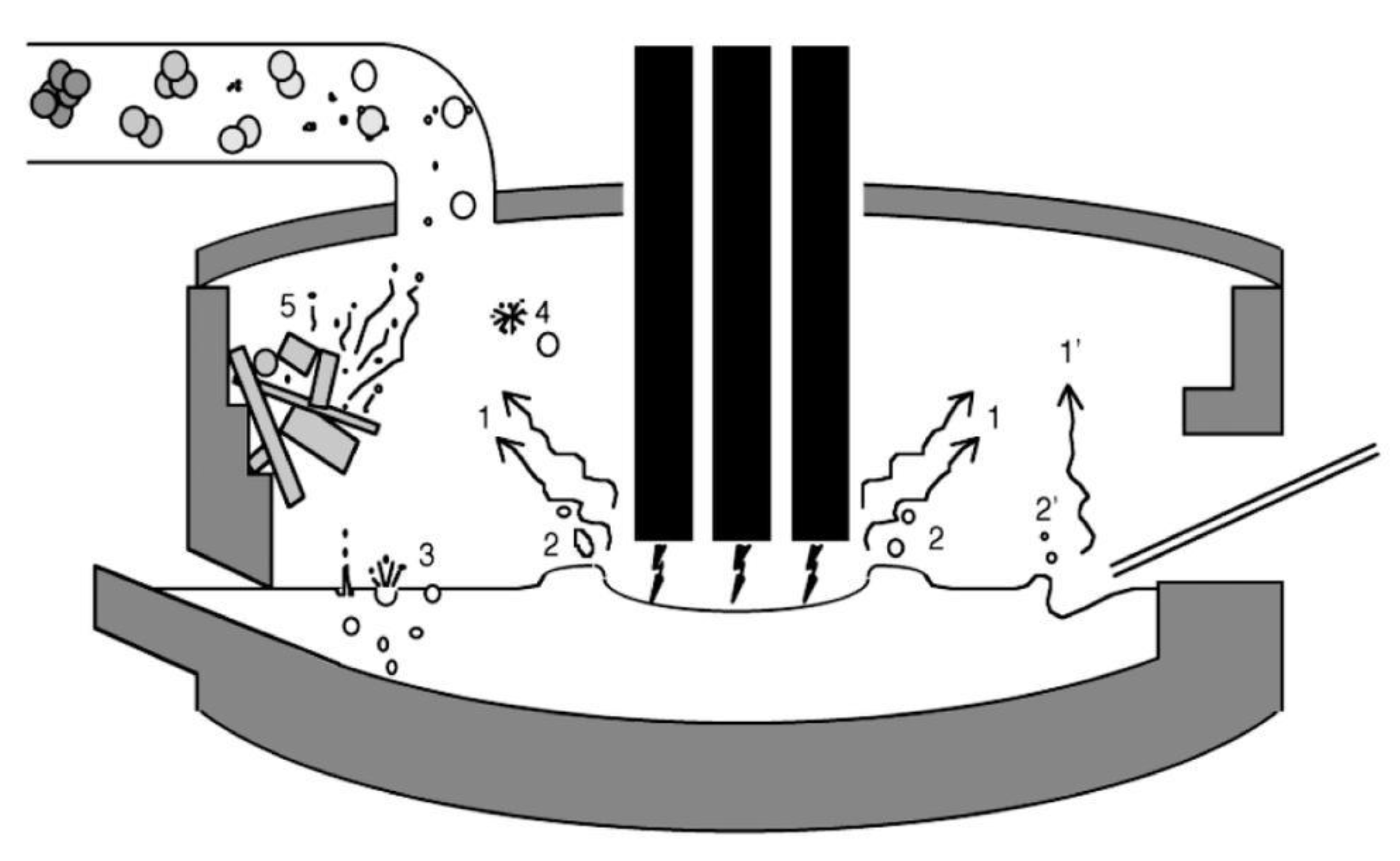

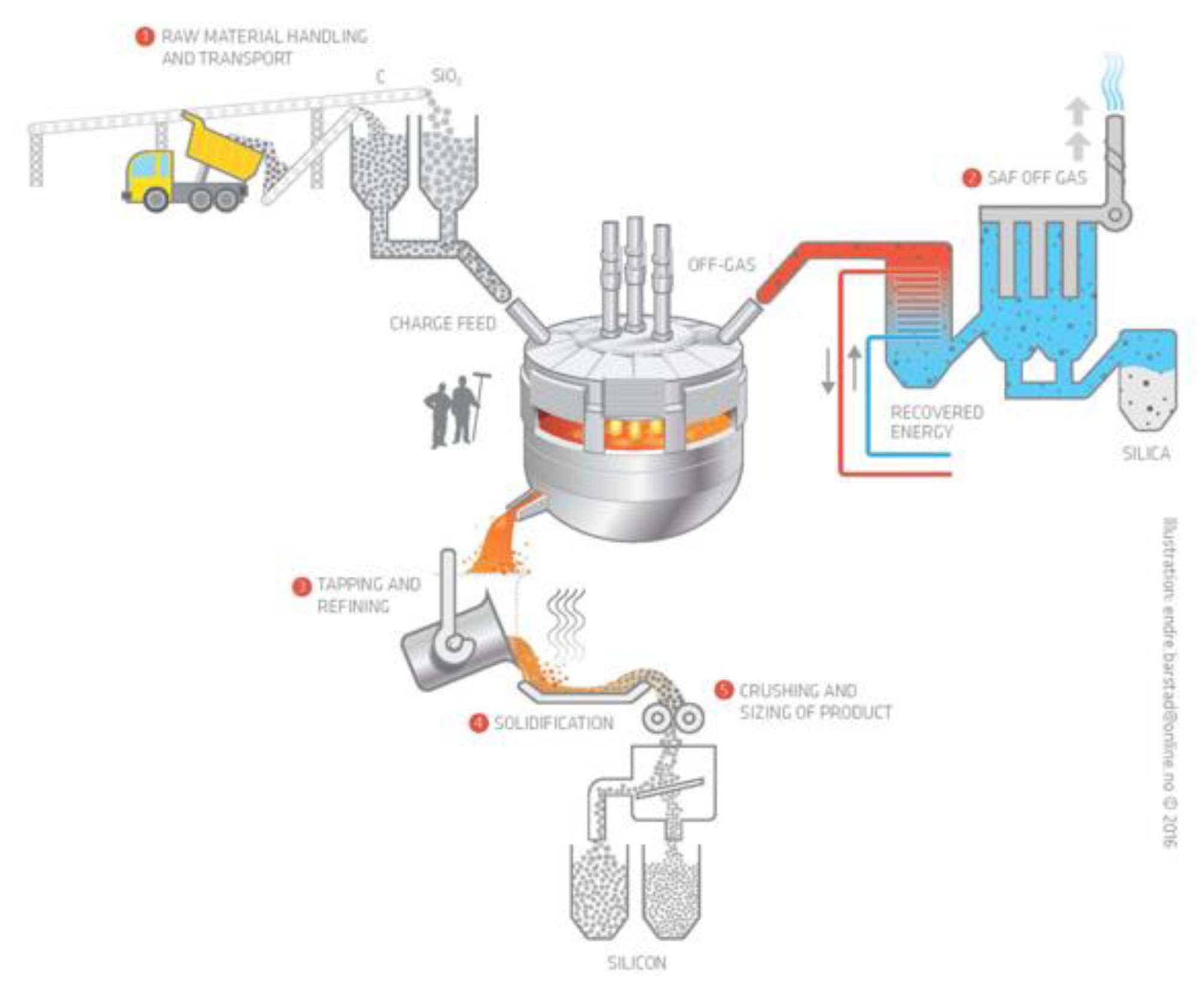

- Volatilization (evaporation) of volatile species (arrow 1 in the figure), such as some metals (e.g., zinc, lead, silicon—even though it is not a metal). This happens in the EAF and is the major mechanism in ferro-silicon furnaces (see further).

- Projection by gas, electric arc, or powder injection (arrows 2 and 2′), as in an EAF where coal or lime is transported with gas into the liquid steel bath through immerged lances while oxygen is injected in the same manner.

- Bubble burst (arrow 3 and 4) is active when large amounts of gas are generated in a liquid bath reactor, either by injection or as a result of a chemical reaction, like the decarburizing of the bath by “burning” dissolved carbon by injected oxygen.

- Probably more, like the reemission of incoming dust (arrow 5) or the precipitation of graphite when tapping a hot metal (pig iron) ladle or just letting it just sit while waiting for the converter.

- Note a variant of the bubble burst, called droplet burst [23], a phenomenon due to the oxidation of the droplet, its encapsulation as liquid metal inside a rigid shell, and then the explosion of that shell due to the buildup of inside pressure by evaporation, followed by the explosion of the droplet itself. Evidence of this mechanism was reported by Nedar Lotta in a steel BOF, but not by Huber et al. in the EAF. It is also reported in a different context, that of the explosion of fuel droplets during combustion.

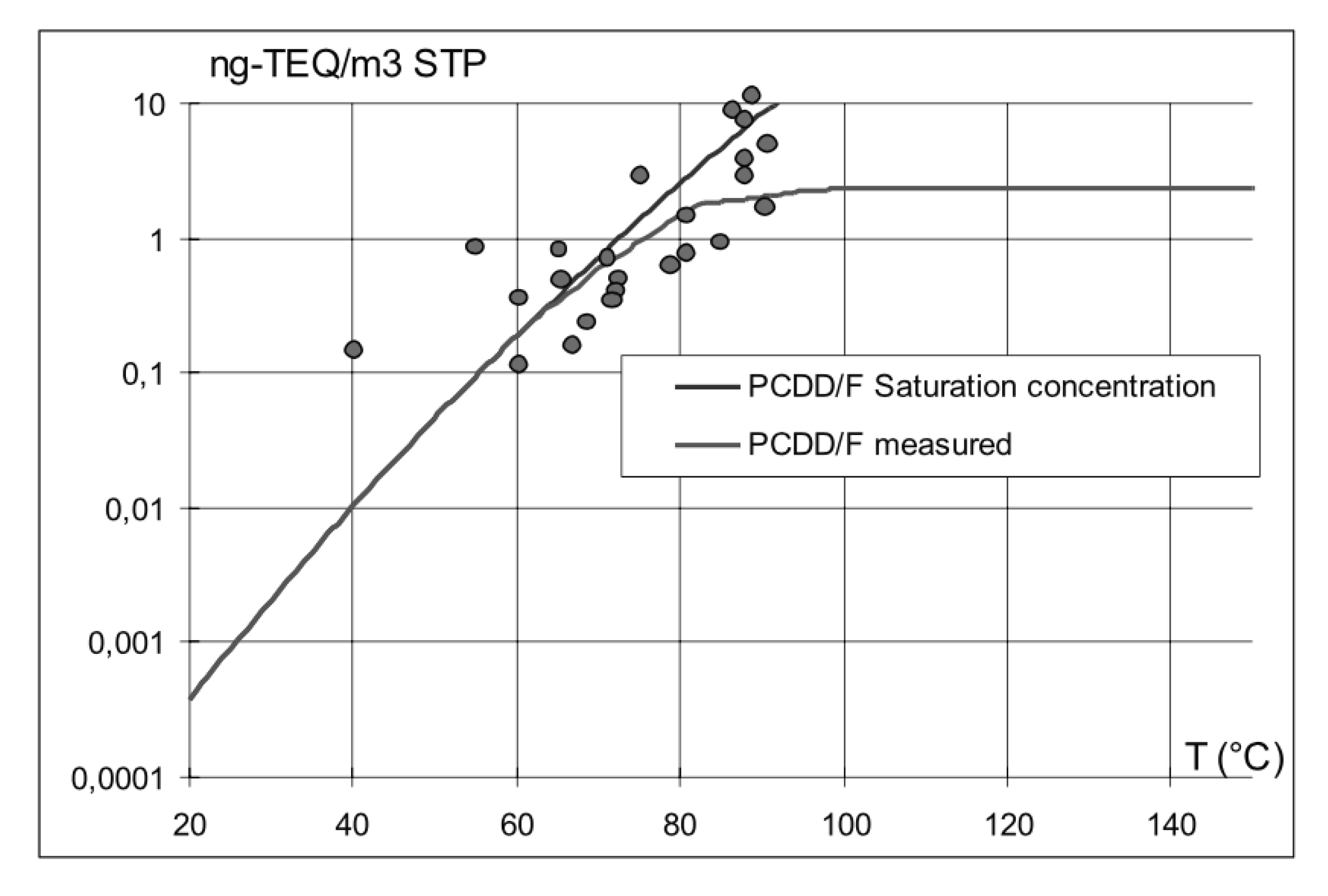

4.3. Organic Compounds Genesis and Emissions

4.4. Emissions and Pollution

4.5. Lifecycle Emissions

5. Greenhouse Gas Emissions Related to Steel

5.1. Anthropogenic vs. Geologic Iron

- Metallic iron, constituting the stock of steel in the anthroposphere, which comprises steel-in-use engaged in various artifacts and discarded steel, known as scrap or as the anthropogenic mine.

- Iron compounds, mainly oxides, which constitute iron ores and are found in ore deposits (≈resources) and in geological mines (≈reserves).

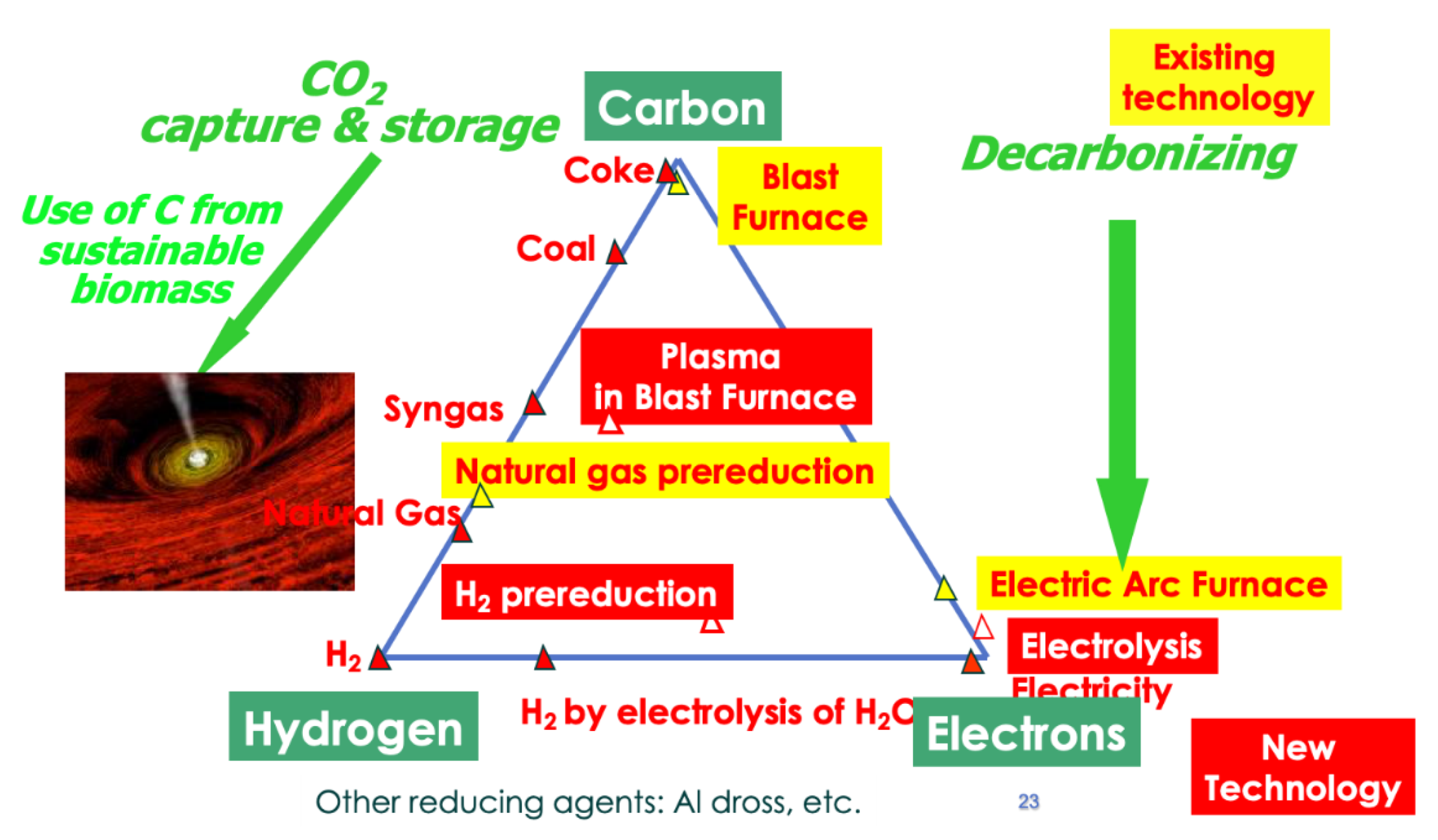

5.2. Reduction of Iron Ore

- Historically, carbon has been used first, as charcoal initially and then as earth coal converted into coke (metallurgical coke). The blast furnace-based, integrated steel mill is the current state-of-the-art technological avatar of this solution.

- Hydrogen is the other option, although it requires the production of hydrogen first, whereas carbon stems directly from mining. Hydrogen reduction has been investigated at the laboratory extensively and some limited industrial operation took places at various scales years ago. See Section 5.9 for the revival of the concept in many on-going research projects.

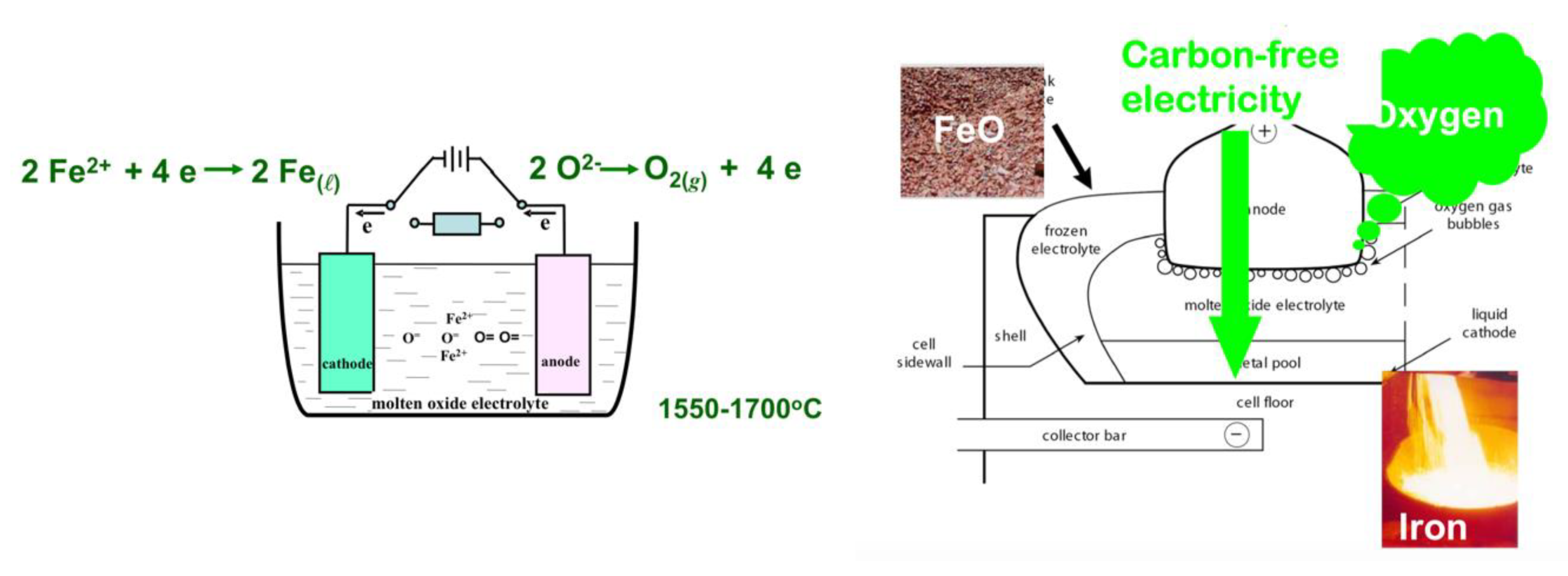

- Electrons (e−) can also behave as reducing agents, in the technological framework of electrolysis. The method is used extensively in non-ferrous metallurgy, most especially for the production of aluminum. However, several pieces of laboratory work have shown that the concept does work for iron as well (see further details in Section 5.4 and Section 5.5).

- In addition to these “mainstream” solutions, there are more, like using metals as reducing agents or powerful reductants like hydrazine (N2H4). Due to the price of metals, especially non-ferrous metals that would have to be used in the case of steel, such as aluminum, this is not a practical solution, although it is used at the margin, e.g., aluminum is sometimes used in the steel shop to raise steel temperature in the ladle.

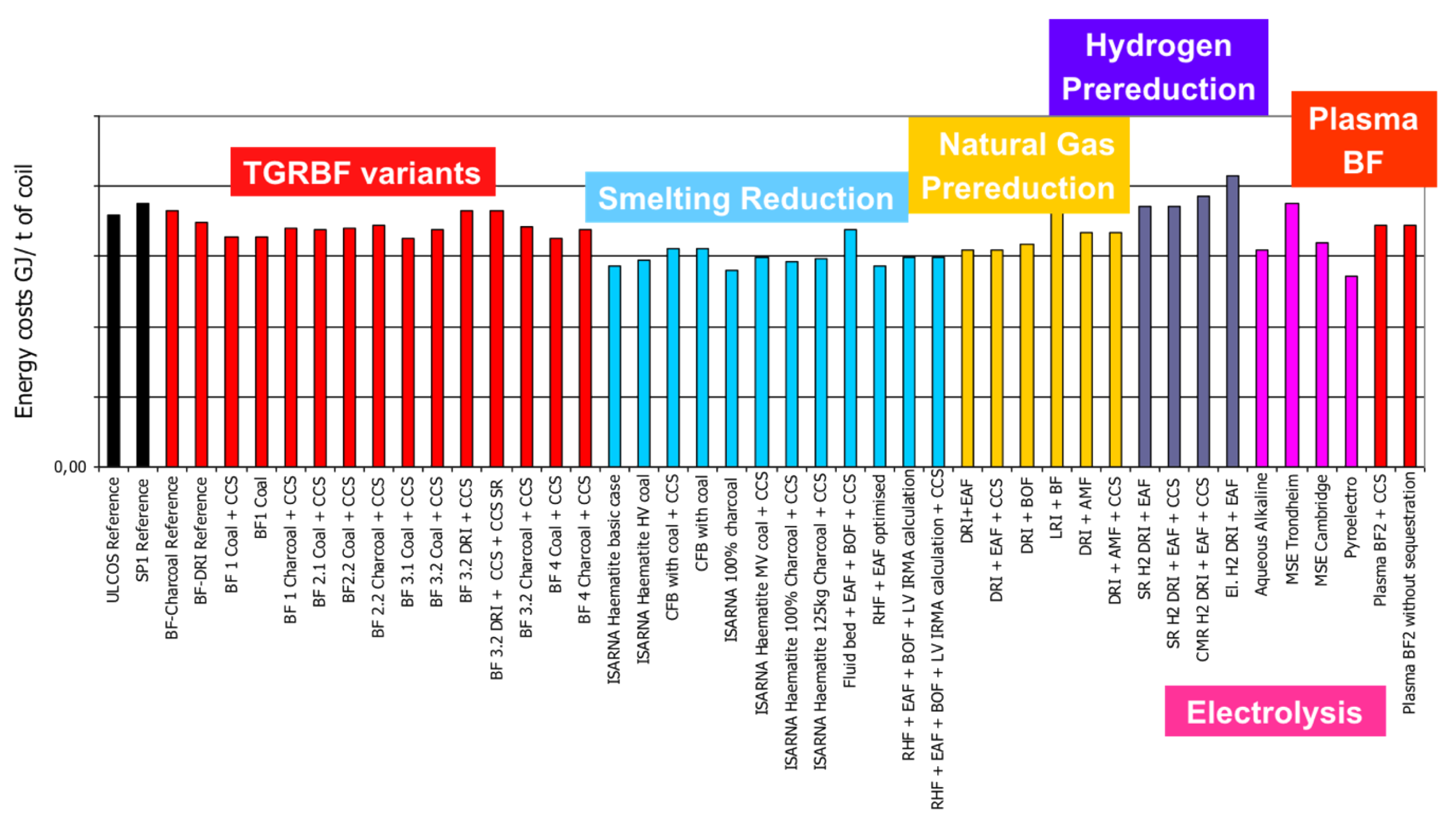

5.3. Benchmarking of Various Iron Reduction Routes

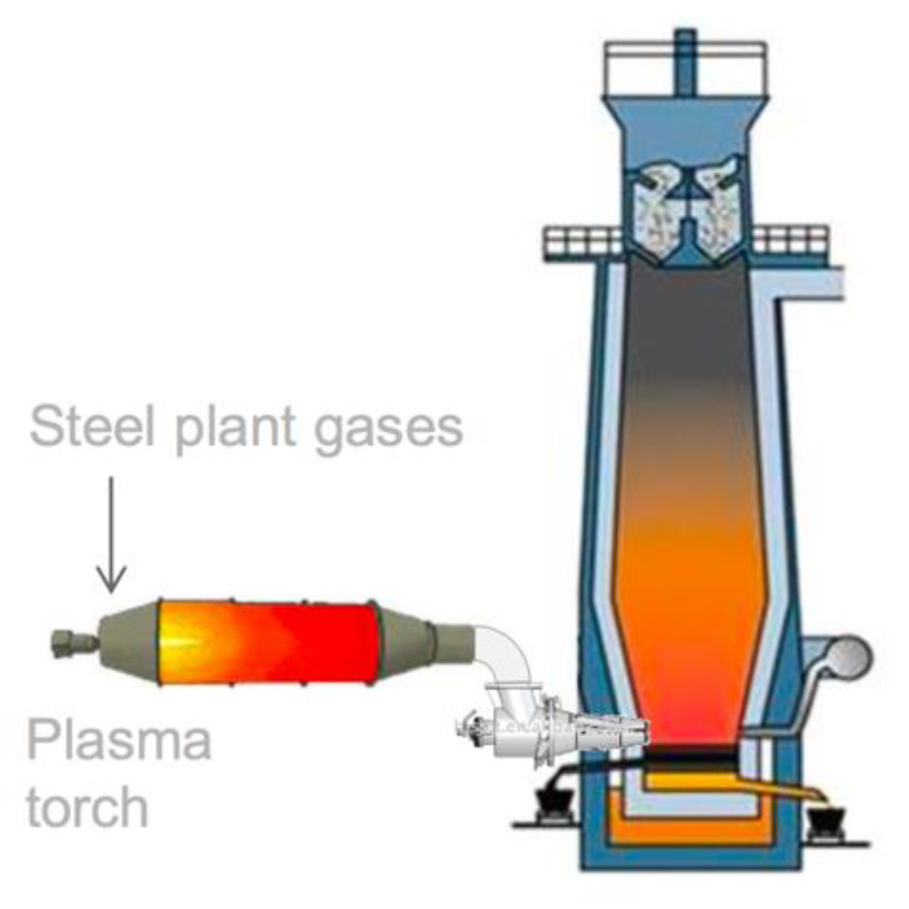

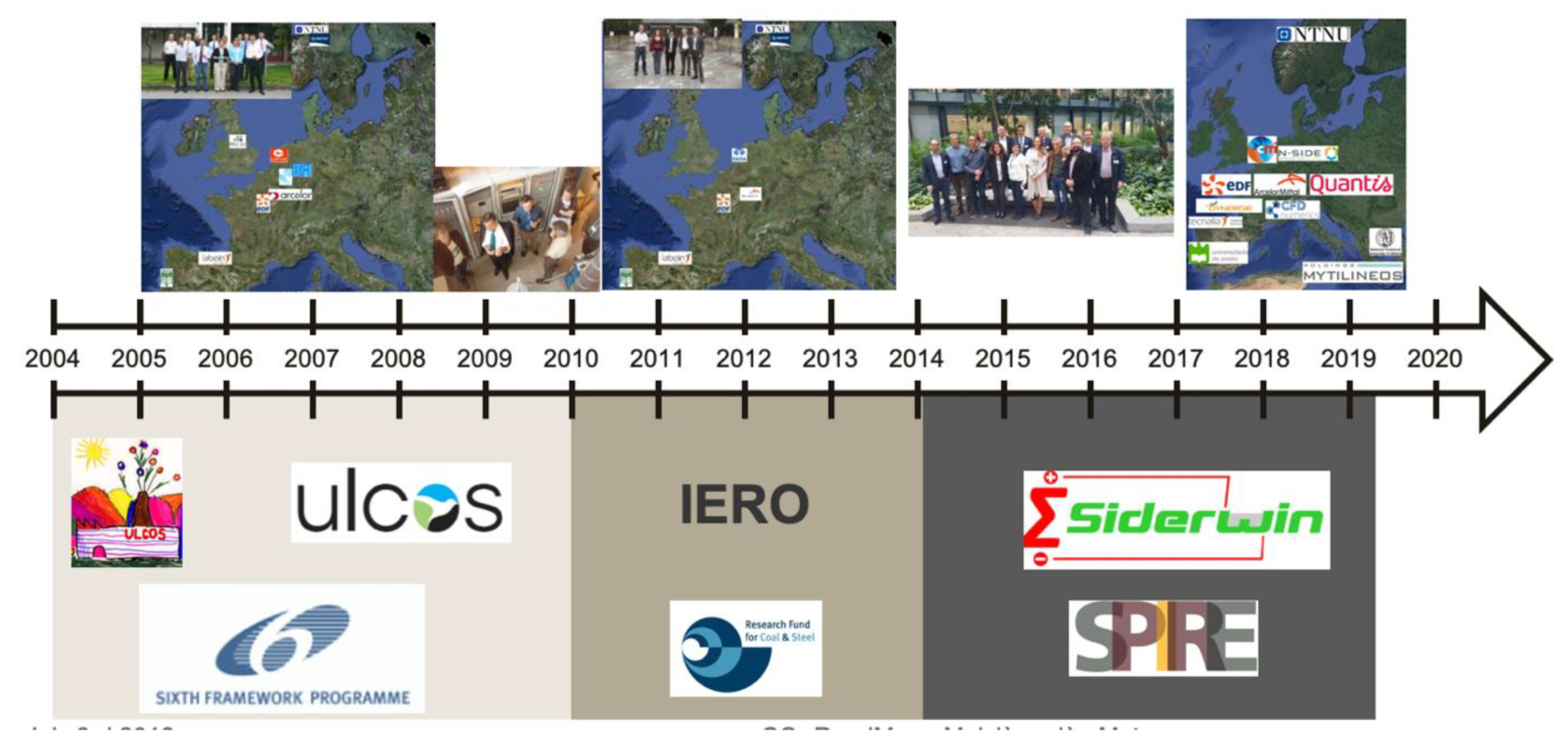

5.4. ULCOS Solutions and Their Present Evolutions

5.5. Low-Carbon Steelmaking Solutions in the US

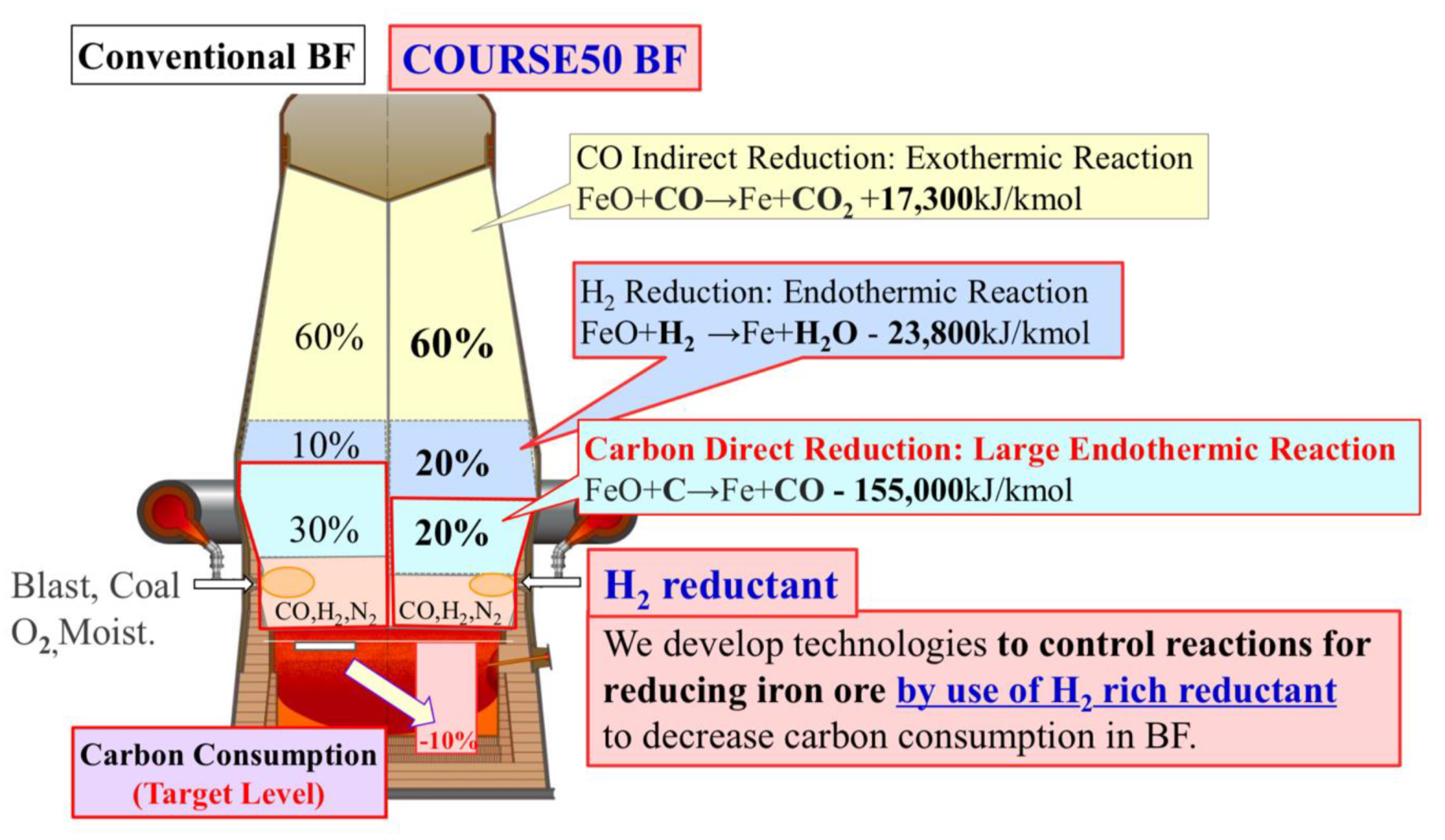

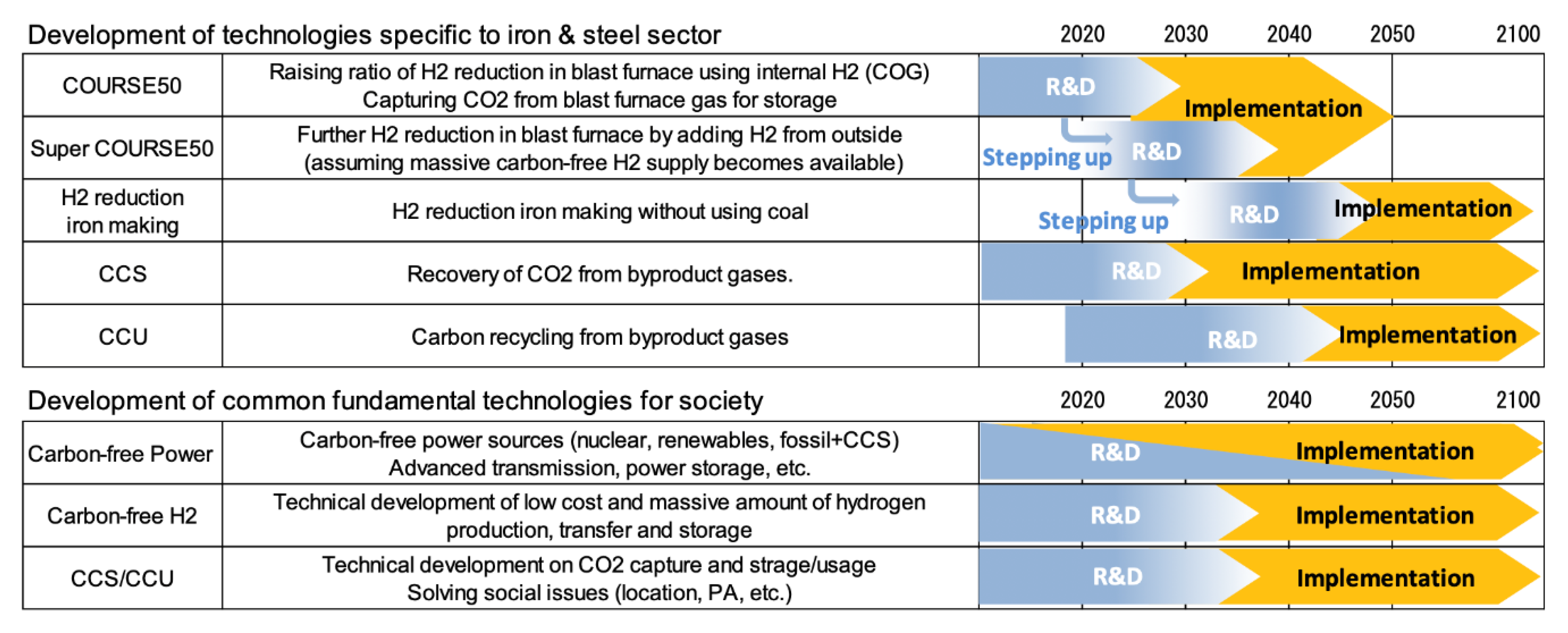

5.6. Low-Carbon Steelmaking Solutions in Japan

5.7. Low-Carbon Steelmaking Solutions in China and Other Parts of the World

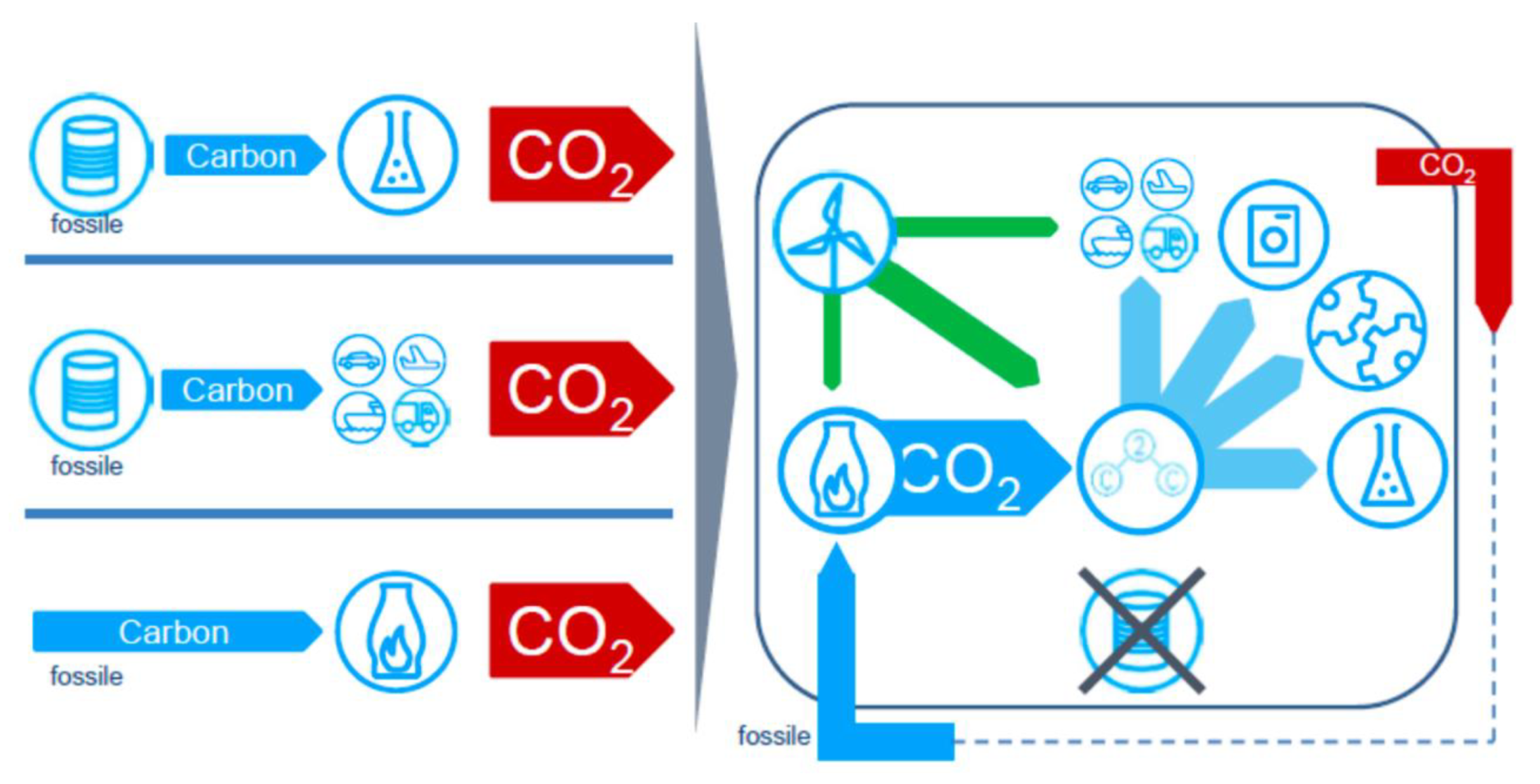

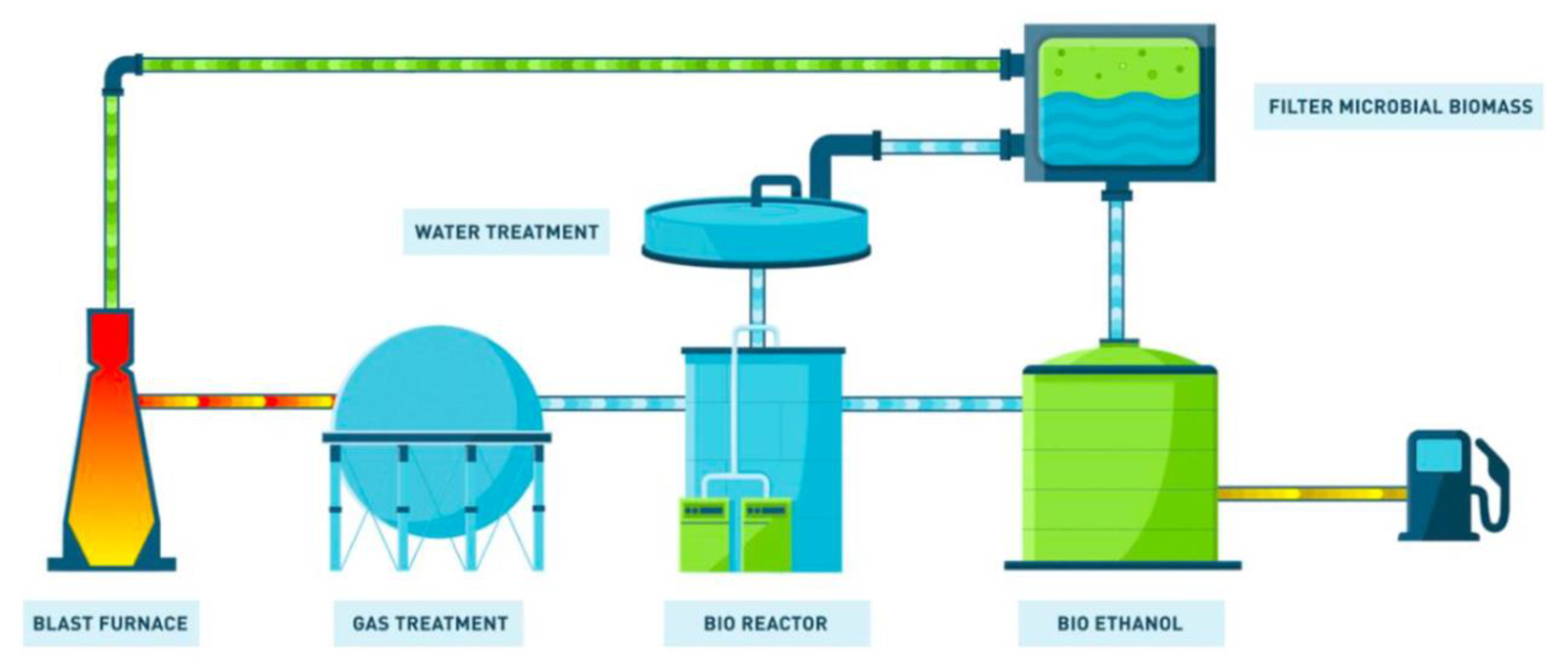

5.8. Carbon Capture and Usage (CCU)

- Carbon2Chem, proposed by ThyssenKrupp steel, Germany [69]. The concept is to make various chemicals, including ammonia, from steel mill gases (44% nitrogen, 23% carbon monoxide, 21% carbon dioxide, 10% hydrogen, and 2% methane) and with the application of renewable energy, which has the reputation of being carbon neutral. The project has support from the Federal Ministry of Education and Research, Germany. Cf. Figure 30.

- Other European projects focusing on CCU are FReSMe, ICO2CHEM, MefCO2, and RECO2DE [72].

5.9. Institutional Support to Low-Carbon Steelmaking Technologies

5.10. Production of Hydrogen

5.11. Conclusions on Zero-Carbon Steelmaking

6. Steel, Biodiversity, and Ecosystem Damages

7. Steel, Health of People, Animals and Ecosystems

- Plant toxicity: Al, As, Cd, Cr, Cu, Pb, Mn, Hg, Ni, Pt, Se, Ag, Th, W, U, V, Zn.Animal toxicity: Al, As, Cd, Cr, Cu, Pb, Li, Mn, Hg, Se, Th, Sn, W, U, V, Zn.

- Essential to plants: Cu, Fe, Mg, Mn, V.

- Essential to animals: Cr, Co, Cu, Fe, Mg, Mn, Ni, Se, Sn, V, Zn.

- Particulate matter or dust: TPM, PM10, and now PM2.5 are routinely measured nowadays [85], but critics point out the fact that smaller particles than 2.5 µm (or 1 for PM 1) and particularly nanoparticles are still unaccounted for, even though they are very likely to penetrate deeply into the body of living organisms and, thus, to be raising the most serious health risks;

- PAHs;

- PCBs;

- PCDDs and PCDFs;

- HCB;

- More generally, VOCs;

- POPs; and

- Inorganic pollutants (SO2, H2S, NH3, HCl, HCN, HNO3, O3, CO, CO2, black carbon, etc.) and products of incomplete combustion (NOx). Note that inorganic and organic pollutants can combine, such as dust particles made of a core of black carbon and a coating of PAHs.

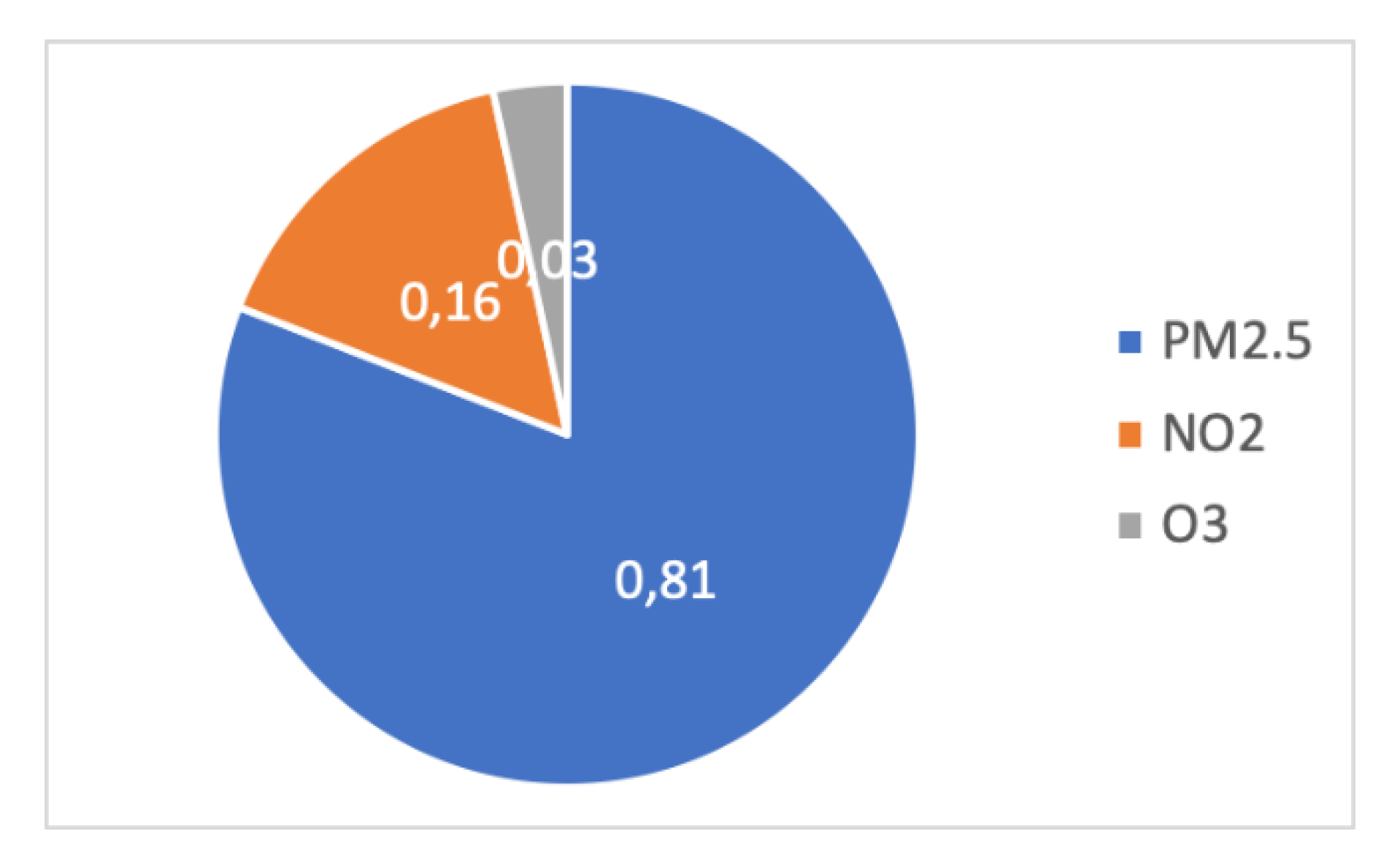

- WHO reports 4.2 million premature deaths (“death that occurs before the average age of death in a certain population”, according to the NIH) due to outdoor pollution (worldwide ambient air pollution accounts for 29% of all deaths and disease from lung cancer, 17% from acute lower respiratory infection, 24% from stroke, 25% from ischemic heart disease, 43% from chronic obstructive pulmonary disease. Pollutants with the strongest evidence for public health concern, include particulate matter (PM), ozone (O3), nitrogen dioxide (NO2), and sulphur dioxide (SO2)).

8. Conclusions

- Iron resources are abundant, both primary and secondary raw materials: indeed, iron ore resources and reserves are plentiful, and steel is fully active in the circular economy, being the most recycled material.

- Energy consumption is already lean, an evolution driven by the high energy intensity of the sector and the high prices of energy. Change will take place by incorporating more renewables in the sector’s energy mix, implementing the energy transition in an original way (electrification, CCUS, and/or use of green hydrogen), and codeveloping lean, frugal, and more durable product solutions with steel users, as well as switching to PSSs.

- Emissions to air, water, and soil have been curbed and most of them have started to decrease, at least in countries with advanced state-of-the-art steel mills. Among all air emissions, rogue emissions of particulate matter (coarse PM10, fine PM2.5, and ultrafine nanoparticles) probably still need to be better measured and better captured than it is yet the case today.

- We did not linger on the looming major biodiversity extinction, because the connection of this phenomenon with a particular metal like steel is only indirect, through its contribution to climate change and to urbanization of the anthroposphere.

- Steel is responsible for a sizeable chunk of greenhouse gas emissions, generating roughly twice as much CO2 as the quantity of steel produced. However, the sector started to explore radical solutions for cutting emissions early, and a large number of them have been identified and tested at some intermediary scale, laboratory, pilot, or demonstrator.

- Regarding raw materials, mine tailings are still mostly out of control, with too many dams failing regularly across the world, thus creating major industrial disasters. All metals bear a similar responsibility.

- Emissions, particularly air emissions, still constitute a major problem in and around steel mills. The main remaining issue is particulate matter, which is generated by most human activities but also and significantly by steel: out of the 10 largest polluters in Europe, 7 are steel mills! The key reason for worrying about PM is the number of premature deaths that it causes.

- The third major task is to arrive at practical solutions to reach carbon neutrality by 2050, a commitment that all stakeholders in Europe have made and that they have to materialize.

Funding

Conflicts of Interest

Glossary

| AP | acidification potential |

| BC | Black Carbon |

| CCS | Carbon capture and storage |

| CCU | Carbon capture and usage |

| CCUS | Carbon capture, usage and storage |

| COURSE 50 | CO2 Ultimate Reduction in Steelmaking process by innovative technology for cool Earth 50 (Japan) |

| EAF | Electric Arc Furnace |

| EEA | European Environment Agency (EU) |

| EP | eutrophication potential |

| GHG | Greenhouse gases |

| GWP | Global Warming potential |

| HCB | Hexachlorobenzene |

| HM | Heavy Metal |

| HRC | Hot-rolled coil |

| IRSID | Institut de recherches de la sidérurgie française (France) |

| IPBES | Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services (UN) |

| ISF | Imperial Smelting Furnace (zinc blast furnace) |

| LCA | Life Cycle Assessment or Life Cycle Analysis |

| MIT | Massachusetts Institute of Technology (US) |

| Mg | megagram = ton |

| NEDO | New Energy and Industrial Technology Development Organization (Japan) |

| NIH | National Cancer Institute (US) |

| NMVOC | Non-methane volatile organic compound |

| PAHs | Poly-Aromatic Hydrocarbon |

| PIA | Programme d’investissements d’avenir (France) |

| PCB | Polychlorinated biphenyl |

| PCDD | polychlorodibenzodioxin |

| PCDF | polychlorodibenzofuran |

| PCDF | polychlorodibenzofuran |

| PED | Primary energy demand |

| PM | Particulate Matter |

| PM10 | Particulate Matter with dimensions less than 10 µm |

| PM2.5 | Particulate Matter with dimensions less than 2.5 µm |

| POCP | photochemical ozone creation |

| POP | persistent organic pollutant |

| PSS | Product Service System |

| PUR | polyurethane |

| SGPI | Secrétariat général pour l’investissement (France) |

| TSP | Total Suspended Particles (<100 µm) |

| ULCOS | Ultra-LOw CO2 Steelmaking |

| USGS | United States Geological Survey |

| VOC | Volatile Organic Compound |

| WHO | World Health Organization, a specialized agency of the UN (OMS in French) |

References

- Birat, J.-P.; Declich, A.; Belboom, S.; Fick, G.; Thomas, J.-S.; Chiappini, M. Society and Materials, a series of regular seminars based on a dialogue between soft and hard sciences. Metall. Res. Technol. 2015, 112, 501. [Google Scholar]

- Birat, J.-P. Musica Universalis or the Music of the Spheres, 2018. Matériaux Tech. 2017, 105, 509. [Google Scholar] [CrossRef]

- Birat, J.-P. Product innovations of key economic importance for the steel industry. Metall. Res. Technol. 2018, 115, 420. [Google Scholar] [CrossRef] [Green Version]

- Mineral Commodity Summaries 2019; National Minerals Information Center, USGS, February 2019; p. 89. Available online: https://prd-wret.s3-us-west-2.amazonaws.com/assets/palladium/production/atoms/files/mcs2019_all.pdf (accessed on 29 February 2020).

- Birat, J.-P.; Thomas, J.-S.; Brimacombe, L.; Colla, V.; Schmidt, D.; Verniory, F.; Linsley, K.; Oliver, S.; Lopes, E.M.D.; Pistelli, I.; et al. The Sustainable Use of Resources in the European Steel Industry: A Roadmap PrePared by WP4/Planet of ESTEP; ESTEP: Brussels, Belgium, 2008. [Google Scholar]

- Birat, J.-P. Resources, materials and primary raw materials, chapter 7. In Sustainable Materials Science; Environmental Metallurgy, Origins, Basics, Resources & Energy Needs; EDP Sciences: Les Ulis, France, 2020; Volume 1, p. 459. [Google Scholar]

- Source: Worldsteel, WORLD STEEL IN FIGURES 2019. Available online: https://www.worldsteel.org/en/dam/jcr:96d7a585-e6b2-4d63-b943-4cd9ab621a91/World%2520Steel%2520in%2520Figures%25202019.pdf (accessed on 29 February 2020).

- CRM, Critical Raw Materials. Available online: http://criticalrawmaterials.org/coking-coal/ (accessed on 29 February 2020).

- Mancini, L.; de Camillis, C.; Pennington, D. Security of Supply and Scarcity of Raw Materials—Towards a Methodological Framework for Sustainability Assessment; EU publication, JRC81762, EUR 26086 EN; Publications Office of the European Union: Luxembourg, 2013.

- Rundman, K. Material Flow in Industry, 42 Pages, 2004. Available online: https://www.academia.edu/5976780/Steel (accessed on 29 February 2020).

- Paulina Concha Larrauri, ID and Upmanu, Chronology of major tailings dam failures, from 1960. Environments 2018, 5, 28. [CrossRef] [Green Version]

- World Mine Tailings Failures—from 1915, Supporting Global Research in Tailings Failure Root Cause, Loss Prevention and Trend Analysis. Available online: https://worldminetailingsfailures.org/ (accessed on 29 February 2020).

- Benjamin, K.; Saleem, S.; Ali, H.; Bazilian, M.; Radley, B.; Nemery, B.; Okatz, J.; Mulvaney, D. Sustainable minerals and metals for a low-carbon future. Science 2020, 367, 30–33. [Google Scholar]

- Birat, J.-P.; Lorrain, J.-P.; de Lassat, Y. The “CO2 Tool”: CO2 emissions & energy consumption of existing & breakthrough steelmaking routes. Rev. Métall. Int. J. Metall. 2009, 106, 325–336. [Google Scholar]

- Iles, L. The Role of Metallurgy in Transforming Global Forests. J. Archaeol. Method Theory 2016, 23, 1219–1241. [Google Scholar] [CrossRef]

- Birat, J.-P.; Lavelaine, H. The Eco-Techno-Systemic Services that Steel Plays in the Energy System; SCANMET V 12–15 June 2016; Swerea MEFOS: Luleå, Sweden, 2016. [Google Scholar]

- Birat, J.-P. The special roles that metals and copper play in the energy system, chapter 1. In Sustainable Materials Science; Environmental Metallurgy, Origins, Basics, Resources & Energy Needs; EDP Sciences: Les Ulis, France, 2020; Volume 2, p. 459. [Google Scholar]

- Kuenen, J.; Berdowski, J.; van der Most, P.; Slager, J.M.; Mulder, W.; Hlawiczka, S.; Fudala, J.; Bloos, J.P.; Verhoeve, P.; Quass, U.; et al. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2016; European Environment Agency, Publication Office of the European Union: Luxembourg, 2016.

- Remus, R.; Miguel; Monsonet, A.A.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT). Reference Document for Iron and Steel Production Industrial Emissions Directive 2010/75/EU Integrated Pollution Prevention and Control; EUR 25521EN; Publication Office of the European Union: Luxembourg, 2013.

- Plickert, S. BAT in the Iron and Steel Industry. In Proceedings of the BAT Workshop, Berlin, Germany, 21 April 2015. [Google Scholar]

- Huber, J.C.; Rocabois, P.; Faral, M.; Birat, J.P.; Patisson, F.; Ablitzer, D. La formation des poussières dans un réacteur sidérurgique. Rev. Métall. 2001, 98, 399–410. [Google Scholar] [CrossRef]

- De Wever, P.; Duranthon, F. Histoire d’un Grain De Sable, EDP Sciences—Collection: Terre à Portée De Main; EDP Sciences: Paris, France, 2015. [Google Scholar]

- Nedar, L. Dust Formation in a BOF Converter; Steel Research: Weinheim, Germany, 1996; Volume 67, pp. 320–327. [Google Scholar] [CrossRef]

- Huber, J.C.; Patisson, F.; Rocabois, P.; Birat, J.P.; Ablitzer, D. Some means to reduce emissions and improve the recovery of electric arc furnace dust by controlling the formation mechanisms. In Proceedings of the REWAS’99 Global Symposium on Recycling, Waste Treatment and Clean Technologies Proceedings, San Sebastian, Spain, 5–9 September 1999; pp. 1483–1492. [Google Scholar]

- Huber, J.C.; Patisson, F.; Rocabois, P.; Faral, M.; Ablitzer, D. Formation of electric arc furnace dust and influence of the process on the recoverable part. In Proceedings of the ECCE’2, 2nd European Conference on Chemical Engineering Proceedings, Montpellier, France, 5–7 October 1999. [Google Scholar]

- Huber, J.C.; Rocabois, P.; Faral, M.; Birat, J.P.; Patisson, F.; Ablitzer, D. The formation of EAF dust. In Proceedings of the 58th Electric Furnace Conference Proceedings, Orlando, FL, USA, 12–15 November 2000; pp. 171–181. [Google Scholar]

- Arion, A.; Baronnet, F.; Birat, J.-P.; Faral, M.; Gonthier, S.; Huber, J.-C.; Marquaire, P.-M. Dust and organic compounds in the flue gas of a steelmaking furnace. In Proceedings of the (新製鋼プロセスフォーラムSSE研究成果-18), ISIJ Autumn Meeting, Nagoya, Japan, 1–3 October 2000; Research of SSE program in Shinseiko Process Forum-18, CAMP-ISIJ. Volume 13, p. 789. [Google Scholar]

- Patisson, F.; Huber, J.C.; Faral, M.; Birat, J.P.; Sessiecq, P.; Ablitzer, D. Emission de Poussières Par éclatement de Bulles de Gaz Dans un Four électrique d’aciérie. In Proceedings of the 8ème Congrès de Génie des Procédés, Nancy, France, 17–19 October 2001; Lavoisier Technique et Documentation: Paris, France, 2001. Société française de Génie des Procédés n°88. Volume 15, pp. 43–50. [Google Scholar]

- Guézennec, A.G.; Huber, J.C.; Patisson, F.; Sessiecq, P.; Birat, J.P.; Ablitzer, D. Etude Expérimentale de L’éclatement de Bulles de Gaz à la Surface D’un Bain D’acier Liquid; Matériaux: Tours, France, 2002. [Google Scholar]

- Guezennec, A.G.; Huber, J.C.; Patisson, F.; Sessiecq, P.; Birat, J.P.; Ablitzer, D. Experimental Study of the Bubble Burst Phenomenon at the Surface of a Liquid Steel Bath. In Proceedings of the TMS Annual Meeting, San Diego, CA, USA, 2–6 March 2003; Schlesinger, M., Ed.; EPD Congress: Warrendale, PA, USA, 2003. [Google Scholar]

- Guézennec, A.G.; Huber, J.C.; Patisson, F.; Sessiecq, P.; Birat, J.P.; Ablitzer, D. Etude de la formation de poussières dans les réacteurs sidérurgiques. In Proceedings of the Journées d’Automne de la SF2M, Paris, France, 28–29 October 2003. [Google Scholar]

- Huber, J.C.; Patisson, F.; Sessiecq, P.; Birat, J.P.; Ablitzer, D. Dust Formation by Bubble-Burst Phenomenon at the Surface of a Liquid steel Bath. ISIJ Int. 2004, 44, 1328–1333. [Google Scholar]

- Guézennec, A.G. La formation des Poussières de Four Électrique d’aciérie: De la Genèse des Particules à Leur Évolution Morphologique. Génie des Procédés. Ph.D. Thesis, Institut National Polytechnique de Lorraine—INPL, Nancy, France, 2004. Available online: https://tel.archives-ouvertes.fr/file/index/docid/370527/filename/Th_AGG.pdf (accessed on 29 February 2020).

- Guézennec, A.; Huber, J.; Patisson, F.; Sessiecq, P.; Birat, J.; Ablitzer, D. Dust formation in electric arc furnace: Birth of the particles. Powder Technol. 2005, 157, 2–11. [Google Scholar] [CrossRef] [Green Version]

- Guézennec, A.G.; Patisson, F.; Sessiecq, P.; Huber, J.C.; Ablitzer, D. Modelling Dust Emissions in Electric Arc Furnace (EAF) Fume Extraction System Process. In Proceedings of the 2006 Sohn Int’l Symposium, San Diego, CA, USA, 27–31 August 2006. [Google Scholar]

- Kero, I.; Gradahl, S.; Tranell, G. Airborne Emissions from Si/FeSi Production. JOM 2017, 69. [Google Scholar] [CrossRef] [Green Version]

- Birat, J.P.; Schneider, M.; Gros, B. Recycling of steel and recycling of zinc: A steel producer’s viewpoint. Rev. Met. Paris. 1998, 95, 721–730. [Google Scholar] [CrossRef]

- Jackson, K.; Aries, E.; Fisher, R.; Anderson, D.R.; Parris, A. Assessment of exposure to PCDD/F, PCB, and PAH at a basic oxygen steelmaking (BOS) and an iron ore sintering plant in the UK. Ann. Occup. Hyg. 2012, 56, 12. [Google Scholar]

- Oberlé, C. Etude de la Dégradation de Matériaux Organiques Associés Aux Ferrailles Automobiles. Ph.D. Thesis, Université de Haute Alsace, Mulhouse, France, 1 December 1995. [Google Scholar]

- Arion, A. Etude de la Dégradation Thermique des Comatériaux Organiques Associés aux Ferrailles Automobiles. Ph.D. Thesis, INPL, Nancy, France, 11 December 1998. [Google Scholar]

- Birat, J.-P.; Arion, A.; Faral, M.; Baronnet, F.; Marquaire, P.-M.; Rambaud, P. Maîtrise des émissions de Produits Organiques Dans Les Fumées du Four électrique à arc. La Revue de Métallurgie-CIT 2001, 98, 839–854. [Google Scholar] [CrossRef]

- Arion, A.; Baronnet, F.; Lartiges, S.; Birat, J.P. Characterization of emissions during the heating of tyre-contamined scrap. Chemosphere 2001, 42, 853–859. [Google Scholar] [CrossRef]

- Arion, A.; Birat, J.P.; Marquaire, P.-M.; Baronnet, F. Abatement of dioxin emissions in electric arc furnace exhaust flue gas. Organohalogen Compd. 2002, 56, 345–348. [Google Scholar]

- Dioxin Facts, a Website Representing Chlorine Producers in the US. Available online: http://www.dioxinfacts.org/sources_trends/the_way.html (accessed on 31 July 2017).

- De Souza, P.A.; de Quieroz, R.S.; Morimoto, T.; Guimarães, A.F.; Garg, V.K. Air pollution investigation in Vitória Metropolitan Region, ES, Brazil. J. Radioanal. Nucl. Chem. 2000, 246, 85–90. [Google Scholar] [CrossRef]

- Birat, J.P. Life Cycle Assessment (LCA) and related methodologies, part of chapter XII. In Treatise on Process Metallurgy; Elsevier: Amsterdam, The Netherlands, 2013; p. 25. [Google Scholar]

- Birat, J.-P. Materials, Secondary Raw Materials and the Circular Economy, chapter 8. In Sustainable Materials Science; Environmental Metallurgy; EDP Science: Les Ulis, France, 2020; Volume 1, p. 459. [Google Scholar]

- Birat, J.-P.; Antoine, M.; Dubs, A.; Gaye, H.; de Lassat, Y.; Nicolle, R.; Roth, J.L. Vers une sidérurgie sans carbone? Rev. Métall. 1993, 90, 411–421. [Google Scholar] [CrossRef]

- Birat J, P. Selected papers from 4th ULCOS SEMINAR (Part 1 and 2). Metall. Res. Technol. 2009, 106, 317. [Google Scholar]

- Birat, J.-P.; Lorrain, J.-P. The “Cost Tool”: Operating and capital costs of existing and breakthrough routes in a future studies framework. La Rev. Métall. 2009, 106, 337–349. [Google Scholar] [CrossRef]

- Available online: https://ec.europa.eu/clima/policies/lowcarbon/ner300_en (accessed on 29 February 2020).

- Available online: https://www.ademe.fr/sites/default/files/assets/documents/valorco.pdf (accessed on 29 February 2020).

- Available online: https://www.usinenouvelle.com/article/europlasma-aide-arcelormittal-a-arreter-de-fumer.N665359 (accessed on 29 February 2020).

- Development of New MethodologieS for InDustrial CO2-FreE Steel PRoduction by ElectroWINning, H2020 SPIRE Project. Available online: https://www.siderwin-spire.eu (accessed on 29 February 2020).

- Lavelaine, H.; ΣIDERWIN partners. ΣIDERWIN Project: Electrification of Primary Steel Production for Direct CO2 Emission Avoidance. In Proceedings of the METEC & 4th ESTAD, Düsseldorf, Germany, 24–28 June 2019. [Google Scholar]

- H2020, “Advanced CO2 capture technologies”—Call ID: LC-SC3-NZE-1-2018. Available online: https://ec.europa.eu/info/funding-tenders/opportunities/portal/screen/opportunities/topic-details/lc-sc3-nze-1-2018 (accessed on 28 February 2020).

- Broutin, P.; Carlier, V.; Grancher, F.; Bertucci, S.; Allemand, J.P.; Coulombet, D.; Valette, P.; Baron, H.; Laborie, G.; Normand, L. Pilot Plant in Dunkirk for Demonstrating the DMXTM Process. In Proceedings of the 14th International Conference on Greenhouse Gas Control Technologies, GHGT-14, Melbourne, Australia, 21–25 October 2018. [Google Scholar]

- Broutin, P.; Petetin, B.; Courtial, X.; Lacroix, M. 3D: A H2020 Project for the Demonstration of the DMX Process. In Proceedings of the 5th Post Combustion Capture Conference PCCC-5, Kyoto, Japan, 17–19 September 2019. organized by IEA-GHG and hosted by RITE. [Google Scholar]

- Available online: https://northernlightsccs.eu (accessed on 28 February 2020).

- Available online: https://hamburg.arcelormittal.com/icc/arcelor-hamburg-de/broker.jsp?uMen=f0e10ffc-365a-0e51-a18f-7ff407d7b2f2&uCon=3a860d3f-5001-3d61-ca98-3d0632940ec7&uTem=aaaaaaaa-aaaa-aaaa-aaaa-000000000042 (accessed on 28 February 2020).

- Duarte, J. Trends in Hydrogen Steelmaking; Steel Times International: Surrey, UK, 2020; Volume 44, No 1; pp. 35–39. [Google Scholar]

- The European Green Deal. Communication from the Commission; EUROPEAN COMMISSION: Brussels, Belgium, 2019; COM (2019) 640 Final.

- Available online: https://mrl.mit.edu/index.php/156-doe-awards-2-15-million-to-boston-metal (accessed on 28 February 2020).

- Sohn, H.Y.; Mohassab, Y.; Elzohiery, M.; Fan, D.Q.; Abdelghany, A. Status of the Development of Flash Ironmaking Technology. In Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies; Wang, S., Free, M., Alam, S., Zhang, M., Taylor, P., Eds.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Course50, Breaking the CO2 Reduction Deadlock; Highlight Japan, 12–13 September 2016. Available online: http://dwl.gov-online.go.jp/video/cao/dl/public_html/gov/pdf/hlj/20160901/12-13.pdf (accessed on 28 February 2020).

- JISF Long-Term Vision for Climate Change Mitigation A Challenge Towards Zero-Carbon Steel; JISF Press Release, September 2019. Available online: https://www.jisf.or.jp/en/activity/climate/documents/JISFLong-termvisionforclimatechangemitigation_text.pdf (accessed on 28 February 2020).

- Available online: http://www.gdccus.org/en/ (accessed on 28 February 2020).

- Jahanshahi, S.; Mathieson, J.G.; Somerville, M.A.; Haque, N.; Norgate, T.E.; Deev, A.; Pan, Y.; Xie, D.; Ridgeway, P.; Zulli, P. Development of Low-Emission Integrated Steelmaking Process. J. Sustain. Metall. 2015, 1, 94–114. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.thyssenkrupp.com/en/carbon2chem/ (accessed on 28 February 2019).

- Available online: https://www.carbon4pur.eu (accessed on 28 February 2020).

- Available online: http://www.steelanol.eu/en (accessed on 28 February 2020).

- Available online: https://www.carbon4pur.eu/news-and-events/spire-projects-on-the-utilisation-of-co2-and-co/ (accessed on 28 February 2020).

- Available online: http://ner400.com (accessed on 28 February 2020).

- Kick-off Workshop for the IEA Global Iron & Steel Technology Roadmap. 20 November 2017. Available online: https://www.iea.org/workshops/kick-off-workshop-for-the-iea-global-iron--steel-technology-roadmap-.html (accessed on 28 February 2020).

- Rifkin, J. The Hydrogen Economy: The Creation of the Worldwide Energy Web and the Redistribution of Power on Earth; Penguin Publishing Group: Oxford, UK, 2002; Volume 304. [Google Scholar]

- Bongaarts, J. IPBES (2019): Summary for policymakers of the global assessment report on biodiversity and ecosystem services of the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services; Díaz, S., Settele, J., Brondízio, E.S., Ngo, H.T., Guèze, M., Agard, J., Arneth, A., Balvanera, P., Brauman, K.A., Butchart, S.H.M., et al., Eds.; IPBES Secretariat: Bonn, Germany, 2019. [Google Scholar]

- Peters, K.; Colla, V.; Moonen, A.C.; Branca, T.A.; del Moretto, D.; Ragaglini, G.; Delmiro, V.M.M.; Romaniello, L.; Carler, S.; Hodges, J.; et al. Steel and Biodiversity: A Promising Alliance. Matériaux Tech. 2017, 105, 5–6. [Google Scholar] [CrossRef]

- Emsley, J. Nature’s Building Blocks, an A-Z Guide to the Elements; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- See for Example the Journal Environmental Health; Springer Nature: London, UK. Available online: https://ehjournal.biomedcentral.com (accessed on 28 February 2020).

- Birat, J.-P.; Zaoui, A. Le Cycle du Fer ou le recyclage durable de l’acier. Rev. Métall. Cah. Inf. Tech. 2002, 99, 795–807. [Google Scholar] [CrossRef]

- Merian, E.; Anke, M.; Ihnat, M.; Stoeppler, M. Elements and their Ccompounds in the Environment: Occurrence, Analysis and Biological Relevance, 2nd ed.; Wiley-VCH: Berlin, Germany, 2008. [Google Scholar]

- Air Pollutant Emissions Data Viewer (Gothenburg Protocol, LRTAP Convention) 1990–2017; European Environment Agency, EEA, Publications Office of the European Union: Luxembourg. Available online: https://www.eea.europa.eu/data-and-maps/dashboards/air-pollutant-emissions-data-viewer-2#tab-based-on-data (accessed on 28 February 2020).

- Gunnar, F.; Bruce, N.; Fowler, A.; Nordberg, M. Handbook on the Toxicology of Metals, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2015; Volumes 1–2. [Google Scholar]

- The ILO Encyclopaedia of Occupational Health and Safety, Workplace Health and Safety Information. Available online: http://www.ilocis.org/en/contilo.html (accessed on 28 February 2020).

- Klimont, Z.; Kupiainen, K.; Heyes, C.; Purohit, P.; Cofala, J.; Rafaj, P.; Borken-Kleefeld, J.; Schöpp, W. Contributions to cities’ ambient particulate matter (PM): A systematic review of local source contributions at global level. Atmos. Chem. Phys. Discuss. 2016. [Google Scholar] [CrossRef] [Green Version]

- Air Quality in Europe—2018 Report; European Environment Agency, EEA, Publications Office of the European Union: Luxembourg, 2018; ISSN 1977–8449.

- Air Quality in Europe—2017 Report; European Environment Agency, EEA, Publications Office of the European Union: Luxembourg, 2017; p. 22.

- Releases of Pollutants to the Environment from Europe’s Industrial Sector—2015; Briefing Published; EEA: Luxembourg, 2017; Last modified 10 August 2018.

- World Health Organization. Ambient Air Pollution: A Global Assessment of Exposure and Burden of Disease; World Health Organization (WHO), Publications of WHO: Geneva, Switzerland, 2016; ISBN 978-92-4-151-135-3. [Google Scholar]

- Mortalité prématurée imputable à l’exposition aux particules fines (PM2.5), à l’ozone (O3) et au dioxyde d’azote (NO2) en 2012 dans 40 pays européens et dans l’ensemble de l’UE, 21/04/2016, European Environnement Agency, Publications Office of the European Union, Luxembourg. Available online: https://www.eea.europa.eu/fr/pressroom/newsreleases/de-nombreux-europeens-restent-exposes/mortalite-prematuree-imputable-a-la (accessed on 28 February 2020).

- Peek, B.; Sadykova, D.; Urbaniak, D.; Jan Haverkamp; Jan Šrytr; Gallop, P.; Dubey, S. ArcelorMittal: Going Nowhere Slowly, A Review of the Global Steel Giant’s Environmental and Social Impacts in 2008–2009, May 2009. Friends of the Earth Europe, CEE Bankwatch Network and Global Action on ArcelorMittal; Available online: https://bankwatch.org/publication/arcelormittal-going-nowhere-slowly-a-review-of-the-global-steel-giants-environmental-and-social-impacts-in-2008-2009 (accessed on 28 February 2020).

- Integrated Annual Review 2018, Smarter, Circular, Lower-Emissions. This is how We are Inventing the Steels of the Future. Pamphlet, ArcelorMittal, 2019. Available online: https://annualreview2018.arcelormittal.com/~/media/Files/A/Arcelormittal-AR-2018/AM_IntegratedAnnualReview_2018.pdf (accessed on 28 February 2020).

- Tonelli, F.; Short, S.W.; Taticchi, P. Case study of ILVA, Italy: The impact of failing to consider sustainability as a driver of business model evolution. In Proceedings of the 11th Global Conference on Sustainable Manufacturing—Innovative Solutions, Berlin, Germany, 23–25 September 2013; Seliger, G., Ed.; Univ.-Verl. der Technische Universität: Berlin, Germany, 2013. [Google Scholar]

- Vagliasindi, G.M.; Gerstetter, C. ILVA Industrial Site in Taranto, in-Depth Analysis; European Parliament, October 2015; IP/A/ENVI/2015-13 PE 563.471; European Parliament: Brussels, Belgium, 2015; Available online: https://www.europarl.europa.eu/RegData/etudes/IDAN/2015/563471/IPOL_IDA(2015)563471_EN.pdf (accessed on 28 February 2020).

- Allen, B.L.; Lees, J.; Jeanjean, M.; Ferrier, Y.; Lecour, M.; Cohen, A.K. Synthèse du rapport FOS EPSEAL—Étude participative en santé environnement ancrée localement sur le front industriel de Fos-sur-Mer et Port-Saint-Louis-du-Rhône (volet 1)—La commune de Saint-Martin-de-Crau (volet 2), juin. 2019. Available online: https://reporterre.net/IMG/pdf/synthe_se_finale_volet_2.pdf (accessed on 28 February 2020).

- Goix, S.; Periot, M.; Douib, K. INDEX—Rapport d’étude. Etude d’imprégnation de la population aux polluants atmosphériques de la zone industrialo-portuaire de Fos-sur-Mer. 2018. Available online: https://www.researchgate.net/publication/325545879_INDEX_-_Rapport_d%27etude_Etude_d%27impregnation_de_la_population_aux_polluants_atmospheriques_de_la_zone_industrialo-portuaire_de_Fos-sur-Mer (accessed on 28 February 2020). [CrossRef]

- Yang, H.; Liu, J.; Jiang, K.; Meng, J.; Guan, D.; Xu, Y.; Tao, S. Multi-objective analysis of the co-mitigation of CO2 and PM2.5 pollution by China’s iron and steel industry. J. Clean. Prod. 2018, 185, 331–341. [Google Scholar] [CrossRef] [Green Version]

| Pollutant | Value | Unit | 95% Confidence Interval | |

|---|---|---|---|---|

| Lower | Upper | |||

| NMVOC | 150 | g/Mgsteel | 55 | 440 |

| TSP | 300 | g/Mgsteel | 90 | 1300 |

| PM10 | 180 | g/Mgsteel | 60 | 700 |

| PM2.5 | 140 | % of PM2.5 | 40 | 500 |

| BC | 0.36 | g/Mgsteel | 0.18 | 0.72 |

| Pb | 4.6 | g/Mgsteel | 0.5 | 46 |

| Cd | 0.02 | g/Mgsteel | 0.003 | 0.1 |

| Hg | 0.1 | g/Mgsteel | 0.02 | 0.5 |

| As | 0.4 | g/Mgsteel | 0.08 | 2.0 |

| Cr | 4.5 | g/Mgsteel | 0.5 | 45.0 |

| Cu | 0.07 | g/Mgsteel | 0.01 | 0.3 |

| Ni | 0.14 | g/Mgsteel | 0.1 | 1.1 |

| Se | 0.02 | g/Mgsteel | 0.002 | 0.2 |

| Zn | 4 | g/Mgsteel | 0.4 | 43 |

| PCB | 2.5 | mg/Mgsteel | 0.01 | 5.0 |

| PCDD/F | 3 | µg I-TEQ/Mgsteel | 0.04 | 6.0 |

| Total 4 PAHs | 0.48 | g/Mgsteel | 0.009 | 0.97 |

| HCB | 0.03 | mg/Mgsteel | 0.003 | 0.3 |

| Pollutant | Process | Limit Values (mg/Nm3) | ||||

|---|---|---|---|---|---|---|

| HM Protocol 1998 | Gothenburg Protocol 1999/2005 | Gothenburg Protocol 2012 | HM Protocol 2012 | POP Protocol 2012 | ||

| SOx | combustion of coke oven gas | new: 400 existing: 800 | 400 | - | - | |

| combustion of blast furnace gas | - | new: 200 existing: 800 | 200 | - | - | |

| NOx | combustion of other gaseous fuel | - | new: 200 existing: 350 | new: 200 existing: 300 | - | - |

| sinter plant | - | 400 | 400 | - | - | |

| Particulate matter | sinter plant | 50 | - | 50 | - | |

| pelletizing plant | 25 40 g/tpellets | - | crushing, grinding & drying: 20 all other process steps: 15 | - | ||

| blast furnace | 50 | - | hot stoves: 10 | - | ||

| basic oxygen steelmaking | - | - | 30 | - | ||

| electric steelmaking | 20 | - | new: 5 - existing: 15 | - | ||

| hot & cold rolling | - | - | 20 bag filters not applicable: 50 | - | ||

| PCDD/F | sinter plant | - | - | - | 0.5 ng/m3 | |

| electric arc furnace plant | - | - | - | 0.5 ng/m3 | ||

| Impact Category | Main Input/Output | Main Phase | Main Processes |

|---|---|---|---|

| Primary energy demand | Hard coal (75–95%) Natural gas (0–15%) | Upstream (~100%) | Upstream energy: electricity and fuels Gate-to-gate: steel production processes up to slab production |

| Global warming potential (100 years) | Carbon dioxide (90–95%) Methane (~6%) | Gate-to-gate (>60%) Upstream (20–30%) | |

| Acidification potential | Sulphur dioxide (50–60%) Nitrogen oxides (30–40%) Hydrogen sulfide (<10%) | Gate-to-gate (40–60%) Upstream (40–60%) | |

| Eutrophication potential | Nitrogen oxides (>90%) Nitrous oxide (~2%) Ammonia (~2%) COD (~2%) | Gate-to-gate (>60%) Upstream (50–80%) | |

| Photochemical ozone creation potential | Carbon monoxide (60–70%) Sulphur dioxide (10–20%) NMVOCs (<10%) Nitrogen oxides (<10%) | Gate-to-gate (>80%) Upstream (~20%) |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birat, J.-P. Society, Materials, and the Environment: The Case of Steel. Metals 2020, 10, 331. https://doi.org/10.3390/met10030331

Birat J-P. Society, Materials, and the Environment: The Case of Steel. Metals. 2020; 10(3):331. https://doi.org/10.3390/met10030331

Chicago/Turabian StyleBirat, Jean-Pierre. 2020. "Society, Materials, and the Environment: The Case of Steel" Metals 10, no. 3: 331. https://doi.org/10.3390/met10030331

APA StyleBirat, J.-P. (2020). Society, Materials, and the Environment: The Case of Steel. Metals, 10(3), 331. https://doi.org/10.3390/met10030331