Influence of Aging Treatment on Microstructure and Tensile Properties of a Hot Deformed UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy

Abstract

:1. Introduction

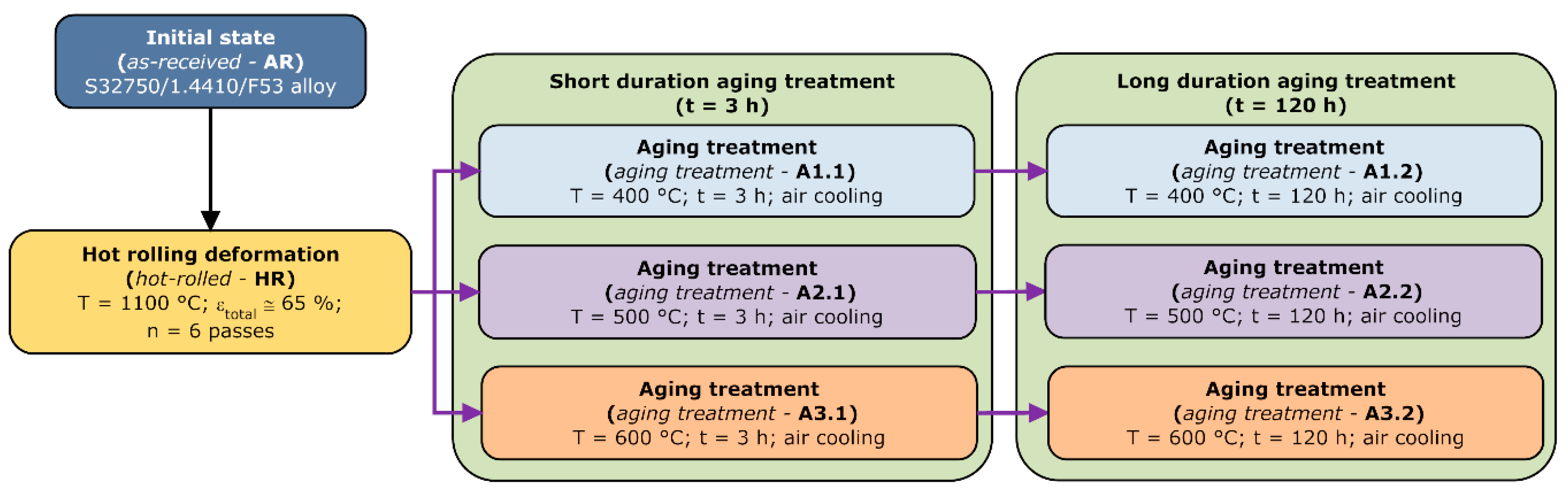

2. Materials and Methods

3. Results

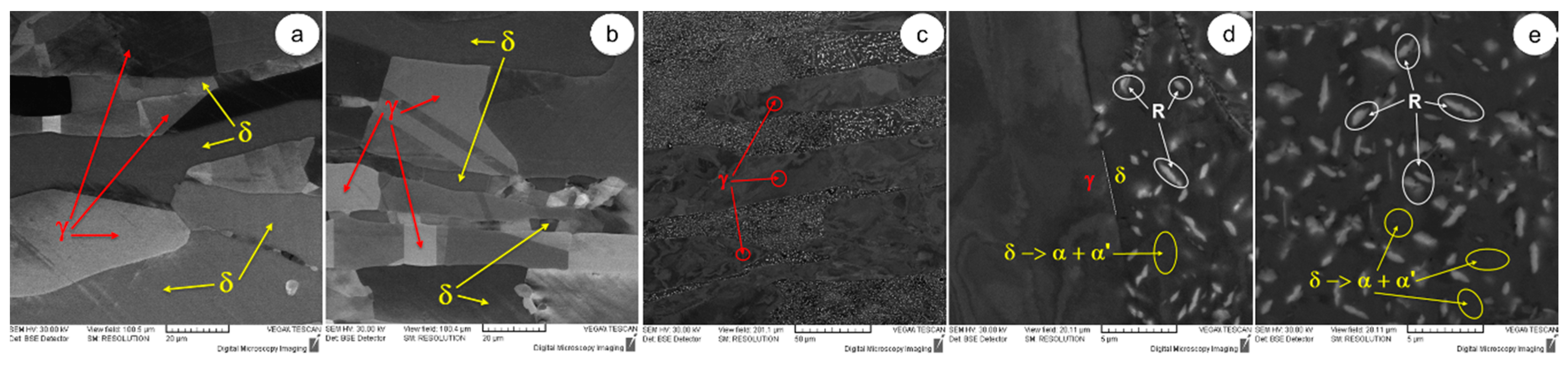

3.1. Microstructural Evolution During TM Processing of UNS S32750 SDSS Alloy

3.2. Mechanical Properties Evolution During TM Processing of the UNS S32750 SDSS Alloy

4. Discussion

5. Conclusions

- the main positive effect of isothermal aging treatment is represented by the possibility to control the exhibited mechanical properties of the TM processed alloy;

- the average grain-size and number of dynamically recrystallized new δ-phase grains can be controlled by varying the isothermal aging treatment temperature and duration;

- during the short-duration aging treatment, at temperatures between 400 °C and 600 °C, the most influential occurring phenomena is represented by the stress relieving;

- during the long-duration aging treatment, at temperatures between 400 °C and 600 °C, the most influential occurring phenomena are represented by the secondary phase precipitation, with a strong influence on material’s embrittlement.

Author Contributions

Funding

Conflicts of Interest

References

- Nilsson, J.O. Super duplex stainless steels. J. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Weisbrodt-Reisch, A.; Brummer, M.; Hadler, B.; Wolbank, B.; Werner, E.A. Influence of temperature, cold deformation and a constant mechanical load on the microstructural stability of a nitrogen alloyed duplex stainless steel. Mater. Sci. Eng. A 2006, 416, 1–10. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R. 12 - Stainless Steel. In Steels - Microstructure and Properties, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2006; pp. 259–286. [Google Scholar]

- Luo, H.; Dong, C.F.; Xiao, K.; Li, X.G. Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution. Appl. Surf. Sci. 2011, 258, 631–639. [Google Scholar] [CrossRef]

- Xiong, J.; Tan, M.Y.; Forsyth, M. The corrosion behaviors of stainless steel weldments in sodium chloride solution observed using a novel electrochemical measurement approach. Desalination 2013, 327, 39–45. [Google Scholar] [CrossRef]

- Yousefieh, M.; Shamanian, M.; Saatchi, A. Optimization of the pulsed current gas tungsten arc welding (PCGTAW) parameters for corrosion resistance of super duplex stainless steel (UNS S32760) welds using the Taguchi method. J. Alloys Compd. 2011, 509, 782–788. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Silva, V.G.; Pardal, J.M.; Corte, J.S. Investigation of stress corrosion cracks in a UNS S32750 superduplex stainless steel. Eng. Fail. Anal. 2013, 35, 88–94. [Google Scholar] [CrossRef]

- Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Zucchi, F. Stress corrosion cracking of LDX 2101 duplex stainless steel in chloride solutions in the presence of thiosulphate. Corros. Sci. 2014, 80, 205–212. [Google Scholar] [CrossRef]

- Hattestrand, M.; Larsson, P.; Chai, G.; Nilsson, J.O.; Odqvist, J. Study of decomposition of ferrite in a duplex stainless steel cold worked and aged at 450–500 °C. Mater. Sci. Eng. A 2009, 499, 489–492. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Li, S.; Zhang, H.; Xue, F.; Wang, X. Microstructures and mechanical properties of cast austenite stainless steels after long-term thermal aging at low temperature. Mater. Des. 2013, 50, 886–892. [Google Scholar] [CrossRef]

- Argandona, G.; Palacio, J.F.; Berlanga, C.; Biezma, M.V.; Rivero, P.J.; Pena, J.; Rodriguez, R. Effect of the temperature in the mechanical properties of austenite, ferrite and sigma phases of duplex stainless steels using hardness, microhardness and nanoindentation techniques. Metals 2017, 7, 219. [Google Scholar] [CrossRef] [Green Version]

- Southwick, P.D.; Honeycombe, R.W.K. Precipitation of M23C6 at austenite/ferrite interfaces in duplex stainless steel. Met. Sci. 1982, 16, 475–482. [Google Scholar] [CrossRef]

- Unnikrishnan, K.; Mallik, A.K. Aging behaviour of a duplex stainless steel. Mater. Sci. Eng. A 1987, 95, 259–265. [Google Scholar] [CrossRef]

- Duprez, L.; Cooman, B.D.; Akdut, N. Microstructure evolution during isothermal annealing of a standard duplex stainless steel type 1.4462. Steel Res. 2000, 71, 417–422. [Google Scholar] [CrossRef]

- Nowacki, J.; Lukojc, A. Microstructural transformations of heat affected zones in duplex steel welded joints. Mater. Charact. 2006, 56, 436–441. [Google Scholar] [CrossRef]

- Pohl, M.; Storz, O.; Glogowski, T. Effect of intermetallic precipitations on the properties of duplex stainless steel. Mater. Charact. 2007, 58, 65–71. [Google Scholar] [CrossRef]

- Maetz, J.Y.; Cazottes, S.; Verdu, C.; Kleber, X. Precipitation and phase transformations in 2101 lean duplex stainless steel during isothermal aging. Metall. Mater. Trans. A 2016, 47, 239–253. [Google Scholar] [CrossRef]

- Armas, A.F.; Herenu, S.; Alvarez-Armas, I.; Degallaix, S.; Condo, A.; Lovey, F. The influence of temperature on the cyclic behavior of aged and unaged super duplex stainless steels. Mater. Sci. Eng. A 2008, 491, 434–439. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Serban, N.; Angelescu, M.L.; Cotrut, M.C.; Cojocaru, E.M.; Vintila, A.N. Influence of solution treatment temperature on microstructural properties of an industrially forged UNS S32750/1.4410/F53 super duplex stainless steel (SDSS) alloy. Metals 2017, 7, 210. [Google Scholar] [CrossRef] [Green Version]

- Angelescu, M.L.; Cojocaru, V.D.; Serban, N.; Cojocaru, E.M. Evaluation of optimal forging temperature range for an industrial UNS S32750 SDSS alloy using SEM-EBSD analysis. Metals 2018, 8, 496. [Google Scholar] [CrossRef] [Green Version]

- Cojocaru, V.D.; Raducanu, D.; Angelescu, M.L.; Vintila, A.N.; Serban, N.; Dan, I.; Cojocaru, E.M.; Cinca, I. Influence of solution treatment duration on microstructural features of an industrial forged UNS S32750/1.4410/F53 super duplex stainless steel (SDSS) alloy. JOM 2017, 69, 1439–1445. [Google Scholar] [CrossRef]

- Grube, W.L.; Rouze, S.R. The origin, growth and annihilation of annealing twins in austenite. Can. Metall. Q. 1963, 2, 31–52. [Google Scholar] [CrossRef]

- Gleiter, H. The formation of annealing twins (Formation des macles de recuit/Die bildung von anaβzwillingen). Acta Metall. 1969, 17, 1421–1428. [Google Scholar]

- Mahajan, S.; Pande, C.S.; Imam, M.A.; Rath, B.B. Formation of annealing twins in f.c.c. crystals. Acta Mater. 1997, 45, 2633–2638. [Google Scholar] [CrossRef]

- Schayes, C.; Bouquerel, J.; Vogt, J.B.; Palleschi, F.; Zaefferer, S. A comparison of EBSD based strain indicators for the study of Fe-3Si steel subjected to cyclic loading. Mater. Charact. 2016, 115, 61–70. [Google Scholar] [CrossRef]

- Kamaya, M. Characterization of microstructural damage due to low-cycle-fatigue by EBSD observation. Mater. Charact. 2009, 160, 1454–1462. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Kamaya, M. Assessment of local deformation using EBSD: Quantification of local damage at grain boundaries. Mater. Charact. 2012, 66, 56–67. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Huang, M.X. Deformation twinning in small-sized face-centred cubic single crystals: Experiments and modelling. J. Mech. Phys. Solids 2015, 85, 128–142. [Google Scholar] [CrossRef]

- Chen, Z.; Cai, H.; Li, S.; Zhang, X.; Wang, F.; Tan, C. Analysis of crystallographic twinning and slip in fcc crystals under plane strain compression. Mater. Sci. Eng. A 2007, 464, 101–109. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Misra, A.; Zhang, X.; Huang, J.Y.; Hirth, J.P. Twinning dislocation multiplication at a coherent twin boundary. Acta Mater. 2011, 59, 5989–5996. [Google Scholar] [CrossRef]

- Marinelli, M.C.; El-Bartali, A.; Signorelli, J.W.; Evrard, P.; Aubin, V.; Alvarez-Armas, I.; Degallaix-Moreuil, S. Activated slip systems and microcrack path in LCF of a duplex stainless steel. Mater. Sci. Eng. A 2009, 509, 81–88. [Google Scholar] [CrossRef]

- Smida, T.; Bosansky, J. Deformation twinning and its possible influence on the ductile brittle transition temperature of ferritic steels. Mater. Sci. Eng. A 2000, 287, 107–115. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Sun, X.; Wang, Y.D.; Hu, X.H.; Zbib, H.M. A mechanism-based model for deformation twinning in polycrystalline FCC steel. Mater. Sci. Eng. A 2014, 607, 206–218. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Yang, W.Y.; Qi, J.J.; Hu, A.M. Deformation enhanced transformation and dynamic recrystallization of ferrite in a low carbon steel during multipass hot deformation. Mater. Sci. Eng. A 2002, 334, 201–206. [Google Scholar] [CrossRef]

- Rys, J.; Cempura, G. Microstructure and deformation behavior of metastable duplex stainless steel at high rolling reductions. Mater. Sci. Eng. A 2017, 700, 656–666. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.H.; Wang, Z.P.; Jin, Y.H.; Zhang, X.L.; Liu, J.N. Thermal ageing on the deformation and fracture mechanisms of a duplex stainless steel by quasi in-situ tensile test under OM and SEM. Mater. Sci. Eng. A 2016, 666, 184–190. [Google Scholar] [CrossRef]

- Williams, R.O. Further studies of the iron-chromium system. Trans. TMS-AIME. 1958, 212, 497–502. [Google Scholar]

- Vintaikin, E.Z.; Loshmanov, A.A. Brittlness of 475 C. Iron-chromium alloys. Fiz. Metallov Metalloved. 1966, 22, 473–476. [Google Scholar]

- Pettersson, N.; Wessman, S.; Thuvander, M.; Hedstrom, P.; Odqvist, J.; Pettersson, R.F.A.; Hertzman, S. Nanostructure evolution and mechanical property changes during aging of a super duplex stainless steel at 300 °C. Mater. Sci. Eng. A 2015, 647, 241–248. [Google Scholar] [CrossRef]

- Sahu, J.K.; Krupp, U.; Ghosh, R.N.; Christ, H.J. Effect of 475 °C embrittlement on the mechanical properties of duplex stainless steel. Mater. Sci. Eng. A 2009, 508, 1–14. [Google Scholar] [CrossRef]

- Auger, P.; Danoix, F.; Menand, A.; Bonnet, S.; Bourgoin, J.; Guttmann, M. Atom probe and transmission electron microscopy study of aging of cast duplex stainless steels. Mater. Sci. Technol. 1990, 6, 301–313. [Google Scholar] [CrossRef]

- Johansson, J.; Odeon, M. Load sharing between austenite and ferrite in a duplex stainless steel during cyclic loading. Metall. Mater. Trans. A 2000, 36, 1557–1570. [Google Scholar] [CrossRef]

| Structural State | Mechanical Properties | |||

|---|---|---|---|---|

| Ultimate Tensile Strength, σUTS [MPa] | 0.2 Yield Strength, σ0.2 [MPa] | Elongation to Fracture, εf [%] | Absorbed Energy, E [J] | |

| As-received (AR) | 720 ± 10 | 473 ± 14 | 55.5 ± 4.0 | 103 ± 4 |

| Hot-rolled (HR): T = 1100 °C; ε = 65% | 775 ± 14 | 601 ± 11 | 36.5 ± 2.5 | 90 ± 3 |

| Aged (A1.1): T = 400 °C; t = 3 h | 769 ± 12 | 595 ± 13 | 33.0 ± 5.5 | 103 ± 4 |

| Aged (A1.2): T = 400 °C; t = 120 h | 863 ± 14 | 641 ± 13 | 42.0 ± 2.5 | 39 ± 3 |

| Aged (A2.1): T = 500 °C; t = 3 h | 833 ± 12 | 610 ± 11 | 44.5 ± 4.5 | 96 ± 3 |

| Aged (A2.2): T = 500 °C; t = 120 h | 814 ± 11 | 624 ± 11 | 32.5 ± 3.0 | 38 ± 3 |

| Aged (A3.1): T = 600 °C; t = 3 h | 813 ± 14 | 598 ± 15 | 47.0 ± 3.5 | 51 ± 2 |

| Aged (A3.2): T = 600 °C; t = 120 h | 877 ± 13 | 599 ± 14 | 39.0 ± 3.5 | 9 ± 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cojocaru, E.M.; Raducanu, D.; Nocivin, A.; Cinca, I.; Vintila, A.N.; Serban, N.; Angelescu, M.L.; Cojocaru, V.D. Influence of Aging Treatment on Microstructure and Tensile Properties of a Hot Deformed UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals 2020, 10, 353. https://doi.org/10.3390/met10030353

Cojocaru EM, Raducanu D, Nocivin A, Cinca I, Vintila AN, Serban N, Angelescu ML, Cojocaru VD. Influence of Aging Treatment on Microstructure and Tensile Properties of a Hot Deformed UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals. 2020; 10(3):353. https://doi.org/10.3390/met10030353

Chicago/Turabian StyleCojocaru, Elisabeta Mirela, Doina Raducanu, Anna Nocivin, Ion Cinca, Adrian Nicolae Vintila, Nicolae Serban, Mariana Lucia Angelescu, and Vasile Danut Cojocaru. 2020. "Influence of Aging Treatment on Microstructure and Tensile Properties of a Hot Deformed UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy" Metals 10, no. 3: 353. https://doi.org/10.3390/met10030353

APA StyleCojocaru, E. M., Raducanu, D., Nocivin, A., Cinca, I., Vintila, A. N., Serban, N., Angelescu, M. L., & Cojocaru, V. D. (2020). Influence of Aging Treatment on Microstructure and Tensile Properties of a Hot Deformed UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals, 10(3), 353. https://doi.org/10.3390/met10030353