Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Microstructure and Shape Change of Water-Quenched Equiatomic TiPd Alloys

3.2. Microstructure and Shape Change of Equiatomic TiPd Alloy during the Isobaric Test

4. Conclusions

- (1)

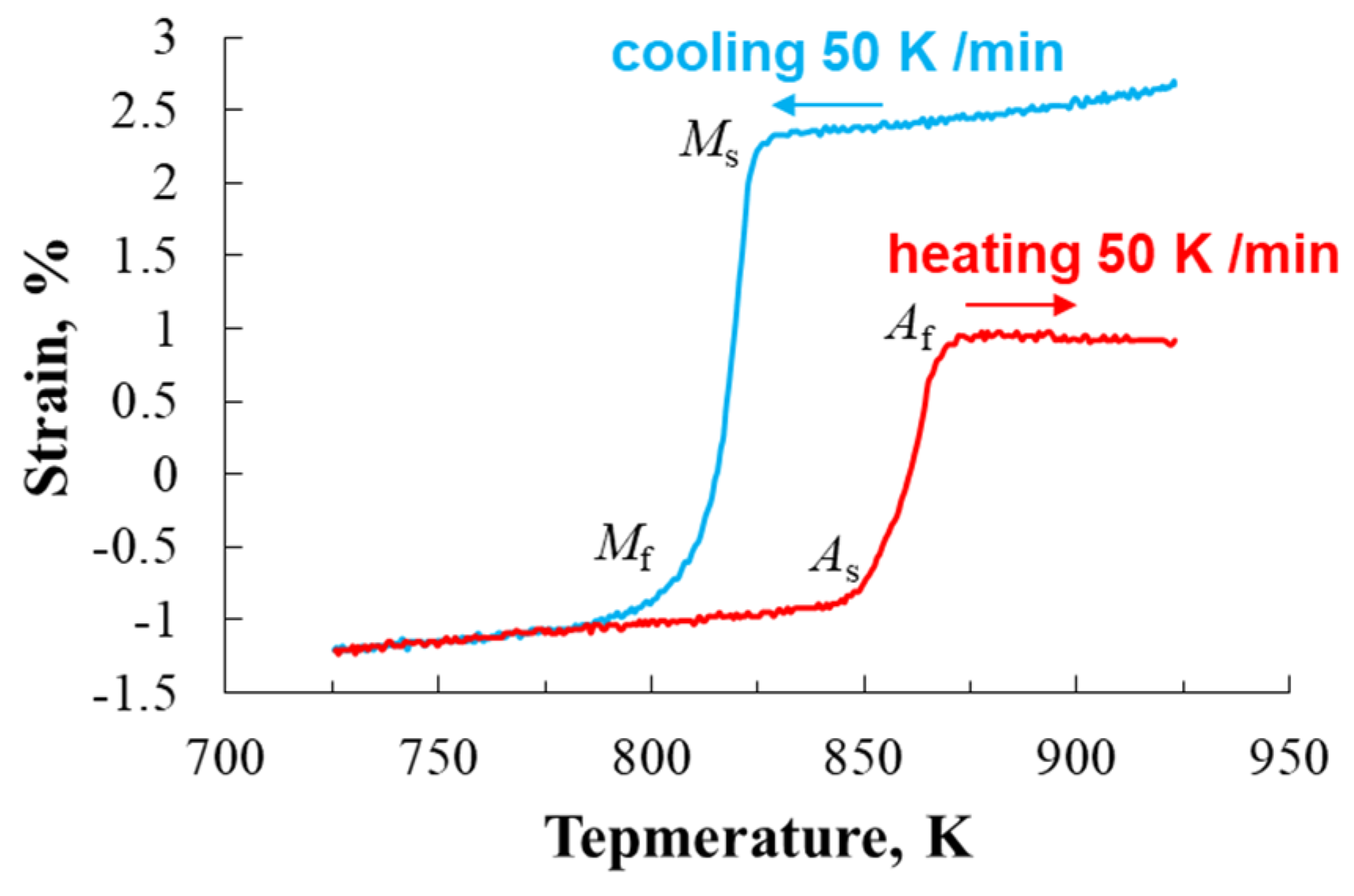

- TMA tests indicate that the direction of the shape change was different between the 0° and 90° samples cutting out parallel and perpendicular to the hearth side of button ingot, respectively. In the 0° sample, shrinking and expansion were, respectively, observed during the reverse and forward martensitic transformations, whereas the opposite tendency was confirmed in the 90° sample compared to the 0° sample.

- (2)

- During the isobaric test, the martensitic variants arranged and oriented to a (010) plane with compressive loading, and the B2 parent phase crystals also became coarse. There was a close relationship between the shape change due to the crystal orientation by the isobaric test and the shear-shuffling direction due to martensitic transformation. The sample shrank along the compression direction, which is perpendicular to the shear-shuffling orientation. In the vertical direction for the compressive loading, the sample expands in a direction parallel to the shear-shuffling orientation.

Author Contributions

Funding

Conflicts of Interest

References

- Otsuka, K.; Sawamura, T.; Shimizu, K. Crystal Structure and Internal Defects of Equiatomie TiNi Martensite. Physica Status Solidi 1971, 5, 457–470. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Donkersloot, H.C.; Van Vucht, J.H.N. Martensitic transformations in gold-titanium, palladium-titanium and platinum-titanium alloys near the equiatomic composition. J. Less Common Metals 1970, 20, 83–91. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y. Development of High-Temperature Shape Memory Alloys Above 673 K. Mater. Sci. Forum 2016, 879, 107–112. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Arockiakumar, R.; Wadood, A.; Suresh, K.S.; Kitashima, T.; Hara, T.; Shimojo, M.; Tasaki, W.; Takahashi, M.; Takahashi, S.; et al. Ti(Pt, Pd, Au) based high temperature shape memory alloys. Mater. Today Proc. 2015, 2S, 517–522. [Google Scholar] [CrossRef]

- Sato, H.; Kim, H.Y.; Shimojo, M.; Yamabe-Mitarai, Y. Training effect on microstructure and shape recovery in Ti-Pd-Zr alloys. Mater. Trans. 2017, 58, 1479–1486. [Google Scholar] [CrossRef]

- Wayman, C.M.; Duerig, T.W. Engineering Aspects of Shape Memory Alloys; Butterworth-Heinemann: Oxford, UK, 1990; p. 10. [Google Scholar]

- Bigelow, G.S.; Padula, S.A., II; Garg, A.; Noebe, R.D. Correlation between mechanical behavior and actuator-type performance of Ni-Ti-Pd high-temperature shape memory alloys. In Proceedings of the 14th International Symposium on: Smart Structures and Materials & Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 18–22 March 2007. [Google Scholar]

- Hisada, S.; Matsuda, M.; Takashima, K.; Yamabe-Mitarai, Y. Structural analysis and martensitic transformation in equiatomic HfPd alloy. J. Solid State Chem. 2018, 258, 712–717. [Google Scholar] [CrossRef]

- Mohapatra, G.; Sommer, F.; Mittemeijer, E.J. Calibration of a quenching and deformation differential dilatometer upon heating and cooling: Thermal expansion of Fe and Fe-Ni alloys. Thermochimica Acta 2007, 453, 31–41. [Google Scholar] [CrossRef]

- Wang, J.J.; Omori, T.; Sutou, Y.; Kainuma, R.; Ishida, K. Two-way shape memory effect induced by cold-rolling in Ti-Ni and Ti-Ni-Fe alloys. Scr. Mater. 2005, 52, 311–316. [Google Scholar] [CrossRef]

- Inoue, H.; Miwa, N.; Inakazu, N. Texture and shape memory strain in TiNi alloy sheets. Acta Mater. 1996, 44, 4825–4834. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.L.; Van Humbeeck, J.; Delaey, L. Effect on texture orientation on the martensite deformation of NiTi shape memory alloy sheet. Acta Mater. 1999, 47, 645–660. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Shu, Y.C.; Bhattacharya, K. The influence of texture on the shape memory effect in polycrystals. Acta Mater. 1998, 46, 5457–5473. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Kim, H.Y.; Sasaki, T.; Okutsu, K.; Kim, J.I.; Inamura, T.; Hosoda, H.; Miyazaki, S. Texture and shape memory behavior of Ti-22Nb-6Ta alloy. Acta Mater. 2006, 54, 423–433. [Google Scholar] [CrossRef]

- Pawley, G.S. Unit-cell refinement from powder diffraction scans. J. Appl. Cryst. 1981, 14, 357–361. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

| (a) | (b) | ||||||

|---|---|---|---|---|---|---|---|

| Area | ε(%) | Area | ε(%) | Area | ε(%) | Area | ε(%) |

| 1 | −0.807 | 1 | −0.314 | 19 | 0.003 | 37 | −0.003 |

| 2 | −0.805 | 2 | −0.313 | 20 | −0.147 | 38 | −0.014 |

| 3 | −0.751 | 3 | −0.073 | 21 | −0.043 | 39 | 0.013 |

| 4 | 0.268 | 4 | −0.107 | 22 | −0.019 | 40 | 0.005 |

| 5 | 0.773 | 5 | 0.039 | 23 | 0.218 | 41 | 0.099 |

| Total | −0.649 | 6 | −0.171 | 24 | −0.033 | 42 | 0.037 |

| 7 | −0.031 | 25 | 0.101 | 43 | 0.007 | ||

| 8 | −0.014 | 26 | −0.084 | 44 | −0.013 | ||

| 9 | −0.075 | 27 | 0.026 | 45 | 0.001 | ||

| 10 | −0.050 | 28 | −0.058 | 46 | 0.026 | ||

| 11 | 0.020 | 29 | 0.003 | 47 | 0.018 | ||

| 12 | −0.123 | 30 | 0.041 | 48 | 0.020 | ||

| 13 | 0.071 | 31 | −0.025 | 49 | −0.018 | ||

| 14 | −0.061 | 32 | −0.019 | 50 | 0.011 | ||

| 15 | −0.040 | 33 | 0.031 | 51 | −0.007 | ||

| 16 | 0.048 | 34 | 0.029 | 52 | 0.041 | ||

| 17 | −0.047 | 35 | 0.019 | Total | −1.091 | ||

| 18 | −0.002 | 36 | −0.110 | ||||

| (a) | (b) | ||

|---|---|---|---|

| Area | ε (%) | Area | ε (%) |

| 1 | 0.660 | 1 | −1.165 |

| 2 | 0.828 | 2 | 0.159 |

| 3 | −0.051 | 3 | −3.059 |

| 4 | 0.285 | 4 | −2.906 |

| 5 | 0.010 | 5 | −0.535 |

| 6 | −0.012 | 6 | −0.288 |

| 7 | −0.029 | 7 | −3.993 |

| Total | 1.690 | 8 | −3.950 |

| 9 | −3.982 | ||

| Total | −2.863 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hisada, S.; Matsuda, M.; Yamabe-Mitarai, Y. Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test. Metals 2020, 10, 375. https://doi.org/10.3390/met10030375

Hisada S, Matsuda M, Yamabe-Mitarai Y. Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test. Metals. 2020; 10(3):375. https://doi.org/10.3390/met10030375

Chicago/Turabian StyleHisada, Shota, Mitsuhiro Matsuda, and Yoko Yamabe-Mitarai. 2020. "Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test" Metals 10, no. 3: 375. https://doi.org/10.3390/met10030375

APA StyleHisada, S., Matsuda, M., & Yamabe-Mitarai, Y. (2020). Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test. Metals, 10(3), 375. https://doi.org/10.3390/met10030375