Study of Wire Deformation Characterization and Size Effects during the Micro-Flat-Rolling Process

Abstract

:1. Introduction

2. Experimental and Simulation

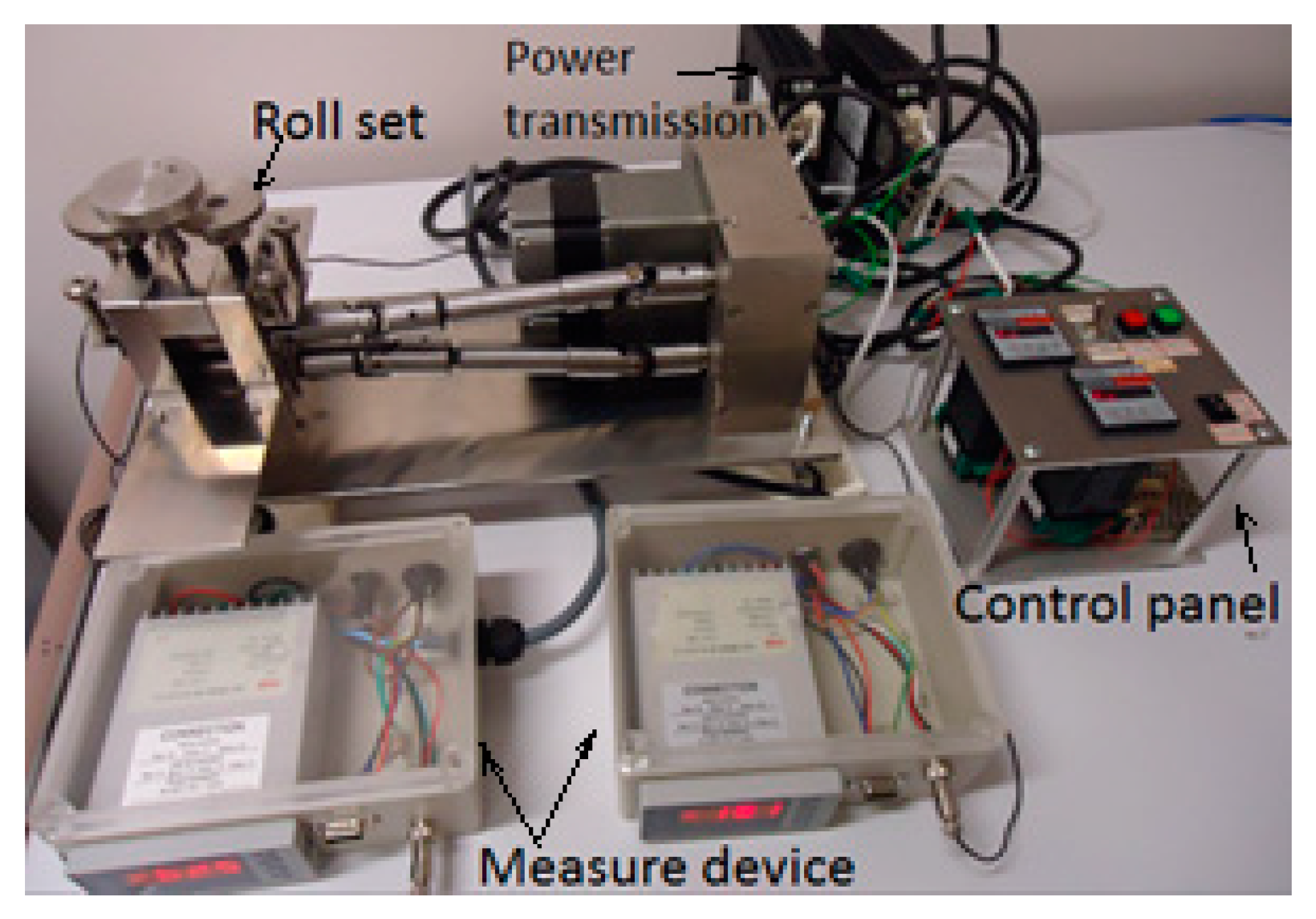

2.1. Micro-Rolling Mill and Materials Used

2.2. Numerical Simulation

2.3. Micro-Compression Test

3. Results and Discussion

3.1. Theoretical Analysis

3.2. Microstructure Evolution and Surface Layer Modeling

3.3. Rolling Parameter Analysis

3.3.1. Forming Resistance

3.3.2. Lateral Spread and Barreling Radius

3.3.3. Contact Width

3.3.4. Surface Roughness Evolution

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kazeminezhad, M.; Taheri, A.K. A theoretical and experimental investigation on wire flat rolling process using deformation pattern. Mater. Design. 2005, 26, 99–103. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Hartley, P. Pilinger. J. Manuf. Sci. Eng. 2001, 123, 397–404. [Google Scholar] [CrossRef]

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Ann. Manuf. Technol. 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Xie, H.B.; Manabe, K.; Furushima, T.; Tada, K.; Jiang, Z.Y. Deformation characterization of micro rolling for stainless steel foil. Procedia Eng. 2014, 81, 179–184. [Google Scholar] [CrossRef] [Green Version]

- Kazeminezhad, M.; Taheri, A.K. Calculation of the rolling pressure distribution and force in wire flat rollingprocess. J. Mater. Process. Technol. 2006, 171, 253–258. [Google Scholar] [CrossRef]

- Vallellano, C.; Cabanillas, P.A.; Garcia-Lomas, F.J. Analysis of deformations and stresses in flat rolling of wire. J. Mater. Process. Technol. 2008, 195, 63–71.14. [Google Scholar] [CrossRef]

- Kazeminezhad, M.; Taheri, A.K. An experimental investigation on the deformation behavior during wire flat rolling process. J. Mater. Process. Technol. 2005, 160, 313–320. [Google Scholar] [CrossRef]

- Kim, N.; Lee, S.M.; Shin, W.; Shivpuri, R. Simulation of square to oval single pass rolling using a computationally effective finite and slab element method. J. Eng. Ind. 1992, 114, 329–335. [Google Scholar] [CrossRef]

- Kobayashi, M. Influence of rolling conditions on spreadingin flat rolling of round wire. J. Jpn. Soc. Technol. Plast. 1978, 19, 630–637. (In Japanese) [Google Scholar]

- Francesco, L.; Antoniomaria, D.I. A parametric study on residual stresses and loads in drawing process with idle rolls. Mater. Des. 2011, 32, 4832–4838. [Google Scholar]

- Bjorn, C. The contact pressure distribution in flat rolling of wire. J. Mater. Process. Technol. 1998, 73, 1–6. [Google Scholar]

- Massé, T.; Chastel, Y.; Montmitonnet, P.; Bobadilla, C.; Persem, N.; Foissey, S. Impact of mechanical anisotropy on the geometry of flat-rolled fully pearlitic steel wires. J. Mater. Process. Technol. 2011, 211, 103–112. [Google Scholar] [CrossRef]

- Helmi, A.; Alexander, J.M. Geometric factors affecting spread in hot flat rolling of steel. J. Iron Steel Inst. 1968, 206, 1110–1117. [Google Scholar]

- Saito, Y.; Takahashi, Y.; Kato, K. Calculation of spread, elongation, effective roll radius, roll force and torque when rolling in the square-diamond, square-oval, and round-oval passes. J. Iron Steel Inst. Jpn. 1983, 2, 1070–1077. [Google Scholar]

- Chitkara, N.R.; Johnson, W. Some experimental results concerning spread in the rolling of lead. ASME J. Basic Eng. 1966, 489–499. [Google Scholar] [CrossRef]

- van Putten, K.; Hirt, G. Size effects on miniaturised rolling processes. Ironmak. Steelmak. 2010, 37, 283–289. [Google Scholar] [CrossRef]

- Lu, H.N.; Wei, D.B.; Jiang, Z.Y.; Liu, X.H.; Manabe, K. Modelling of size effects in microforming process with consideration of grained heterogeneity. Comput. Mater. Sci. 2013, 77, 44–52. [Google Scholar] [CrossRef] [Green Version]

- Xie, H.B.; Manabe, K.; Furushima, T.; Tada, K.; Jiang, Z.Y. An experimental and numerical investigation on micro rolling for ultra-thin strip. Int. J. Mater. Form. 2016, 9, 405–412. [Google Scholar] [CrossRef] [Green Version]

- Hum, K.M.; Zhang, W.M.; Zhong, Z.Y.; Peng, Z.K.; Meng, G. Effect of surface layer thickness on buckling and vibration of nonlocal nanowires. Phys. Lett. A 2014, 378, 650–654. [Google Scholar]

- Zhu, T.T.; Bushby, A.J.; Dunstan, D.J. Materials Mechanical size effects: A review. Mater. Technol. 2008, 23, 196–209. [Google Scholar] [CrossRef]

- Liu, J.G.; Fu, M.W.; Chan, W.L. A constitutive model for modeling of the deformation behaviour in microforming with a consideration of grain boundary strengthening. Comput. Mater. Sci. 2012, 55, 85–94. [Google Scholar] [CrossRef]

- Corrado, M.; Paggi, M.; Carpinteri, A. A multi-scale numerical method for the study of size-scale effects in ductile fracture. Metals 2014, 4, 428–444. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.J.; Wang, S.; Wang, S.T.; Chen, G.; Zhang, P. Investigation on springback behavior of Cu/Ni clad foils during flexible die micro V-bending process. Metals 2019, 9, 892. [Google Scholar] [CrossRef] [Green Version]

- Lu, H. A Study on the Micro Cross Wedge Rolling of Metals. Ph.D. Thesis, School of Mechanical, Materials and Mechatronic Engineering, University of Wollongong, Wollongong, Australia, 2013. [Google Scholar]

| Bi | Te | As | Fe | Ni |

| 0.001 | 0.002 | 0.002 | 0.005 | 0.002 |

| Sn | S | Zn | O | Cu |

| 0.002 | 0.002 | 0.005 | 0.06 | balance |

| Annealing | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Holding time, min | 10 | 20 | 30 | 90 | 120 |

| Grain size, µm | 32 | 42 | 82 | 160 | 240 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Manabe, K.-i.; Jiang, Z. Study of Wire Deformation Characterization and Size Effects during the Micro-Flat-Rolling Process. Metals 2020, 10, 405. https://doi.org/10.3390/met10030405

Xie H, Manabe K-i, Jiang Z. Study of Wire Deformation Characterization and Size Effects during the Micro-Flat-Rolling Process. Metals. 2020; 10(3):405. https://doi.org/10.3390/met10030405

Chicago/Turabian StyleXie, Haibo, Ken-ichi Manabe, and Zhengyi Jiang. 2020. "Study of Wire Deformation Characterization and Size Effects during the Micro-Flat-Rolling Process" Metals 10, no. 3: 405. https://doi.org/10.3390/met10030405

APA StyleXie, H., Manabe, K.-i., & Jiang, Z. (2020). Study of Wire Deformation Characterization and Size Effects during the Micro-Flat-Rolling Process. Metals, 10(3), 405. https://doi.org/10.3390/met10030405