A Study on Work Hardening in the Laser-Assisted Machining of Si3N4 Ceramics under Different Material Removal Modes

Abstract

:1. Introduction

2. LAM Experiment

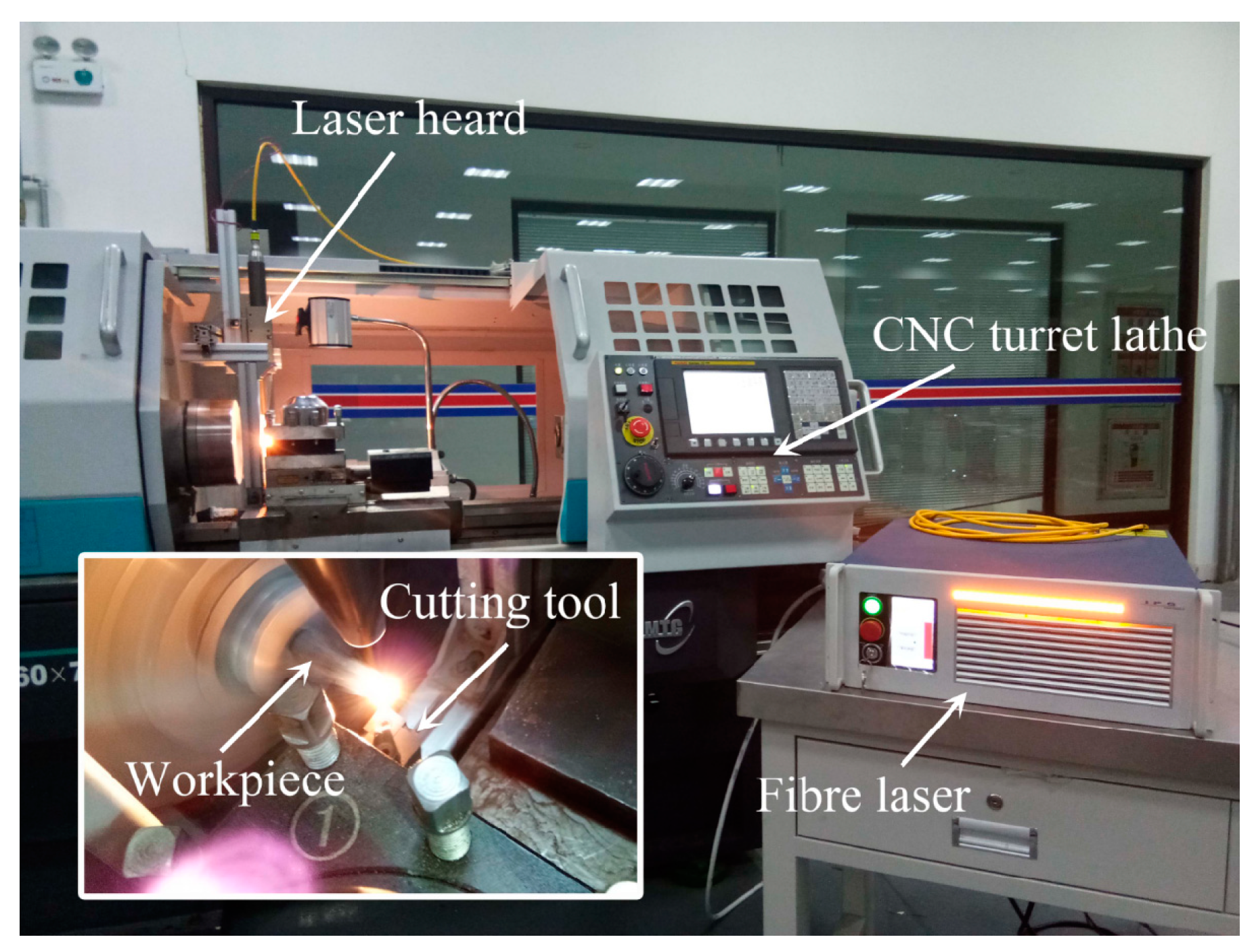

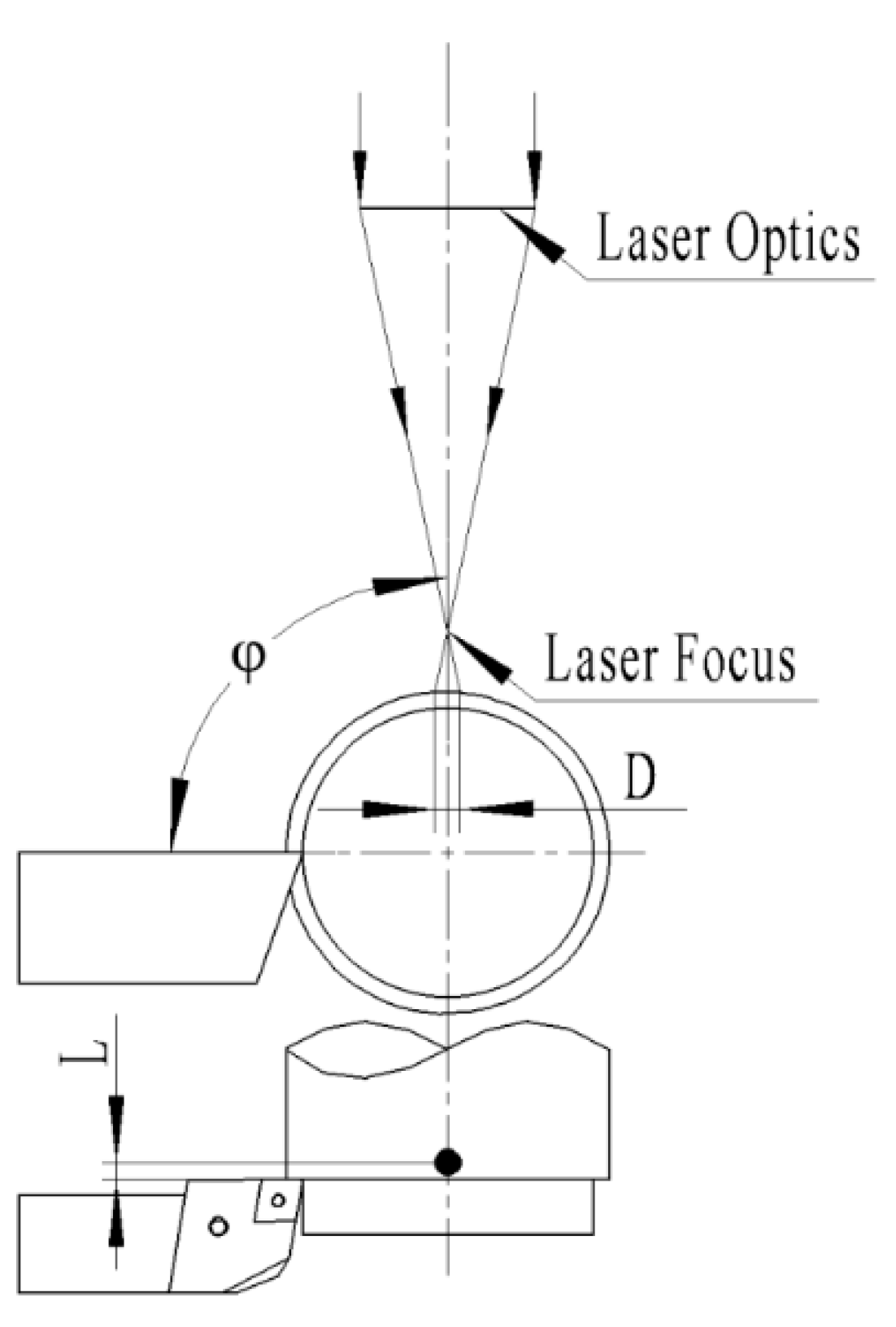

2.1. Experimental System

2.2. Experimental Material

2.3. Test Matrix and Operating Parameters

3. Results and Discussion

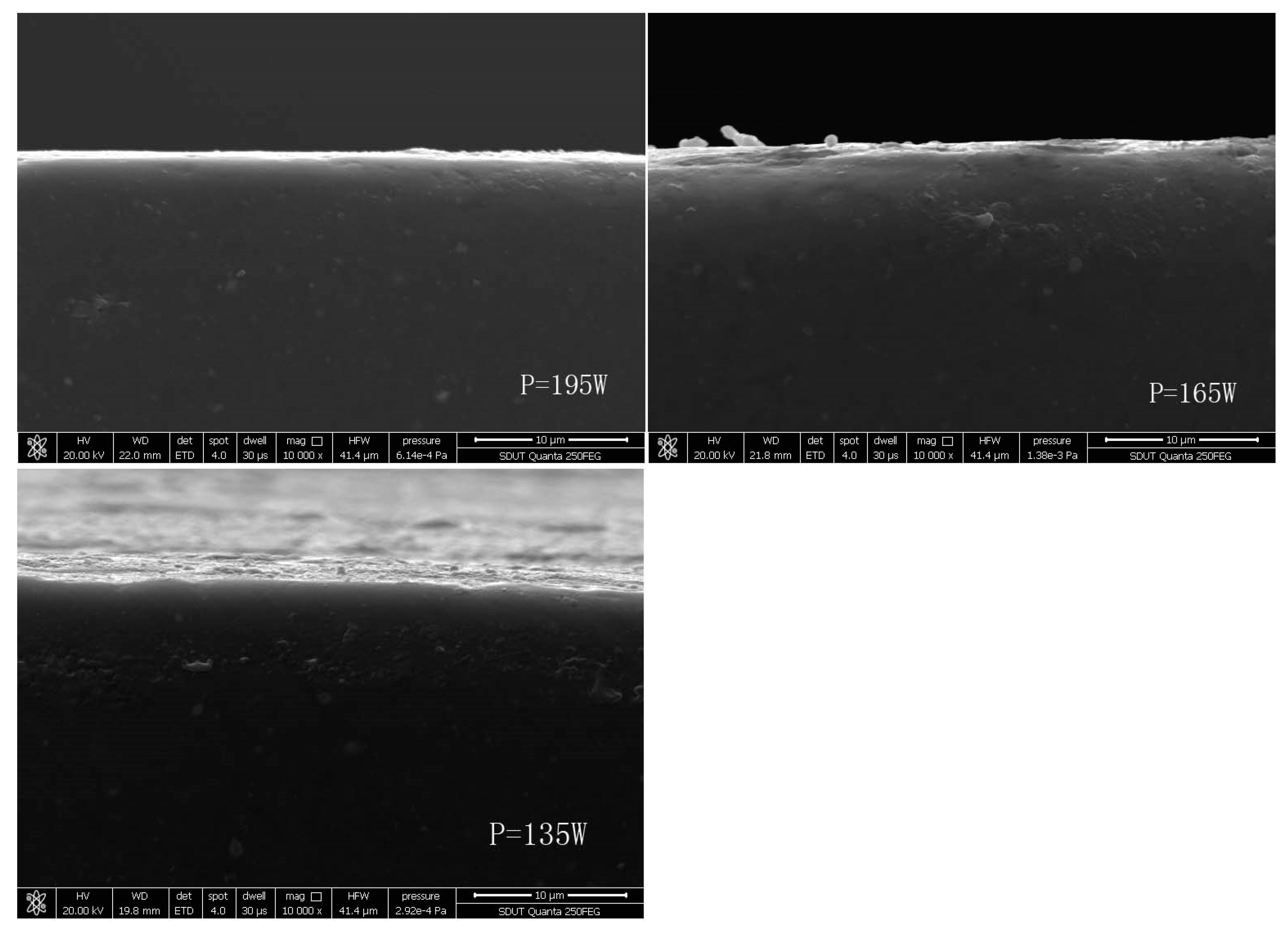

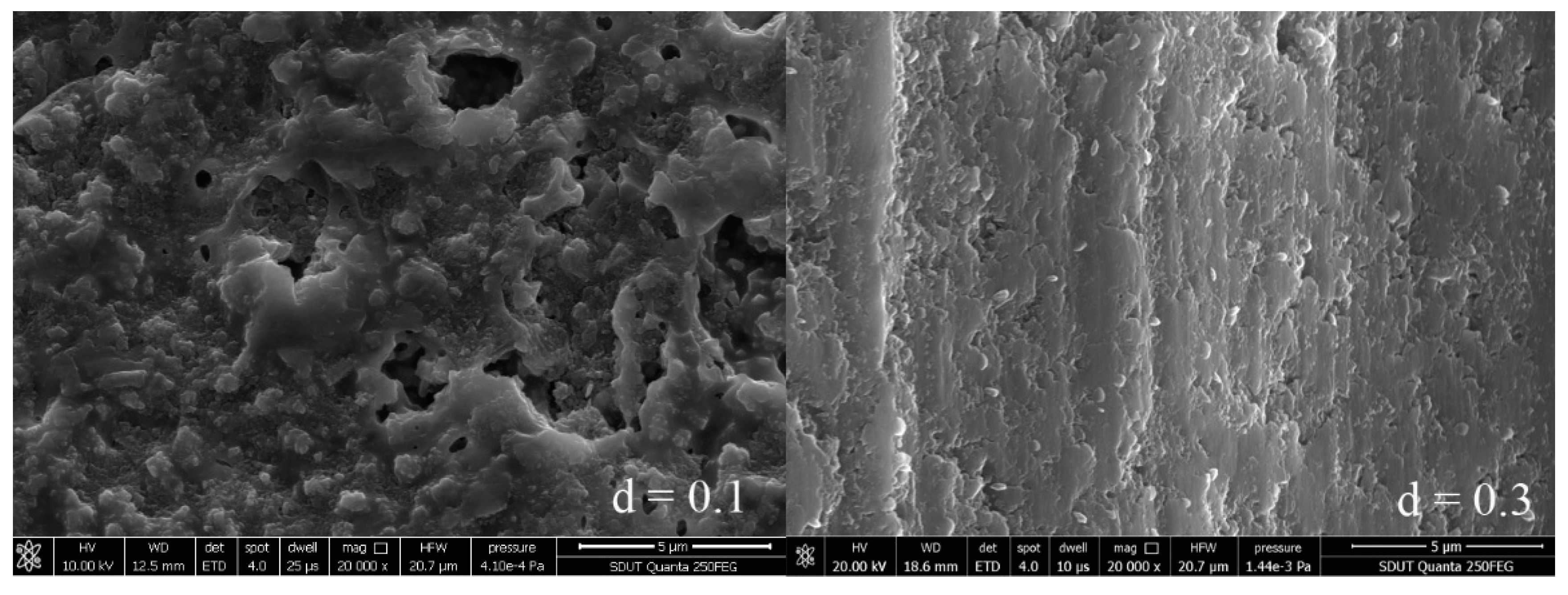

3.1. Microstructural Observations and EDS Analysis

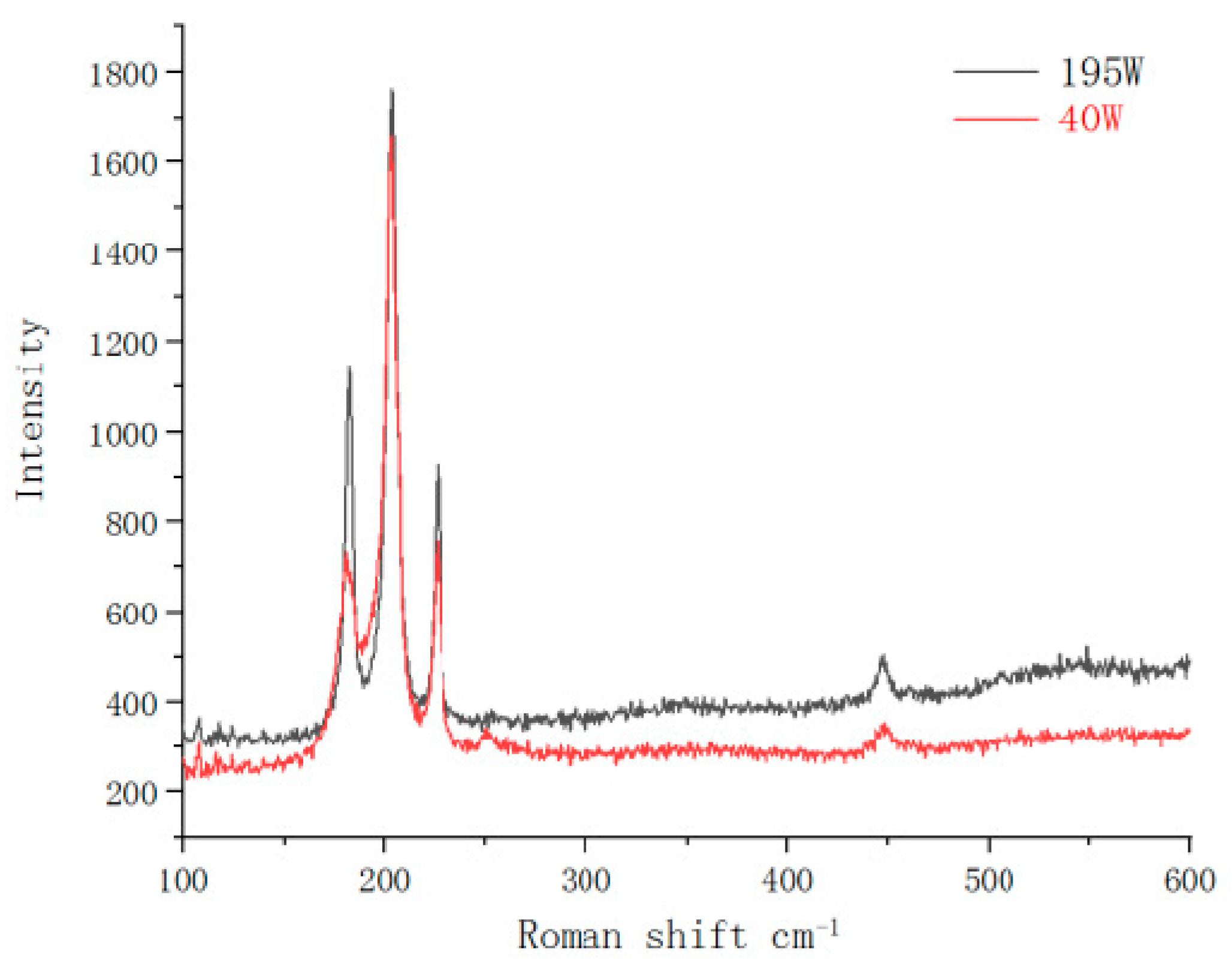

3.2. XRD Analysis and Raman Analysis

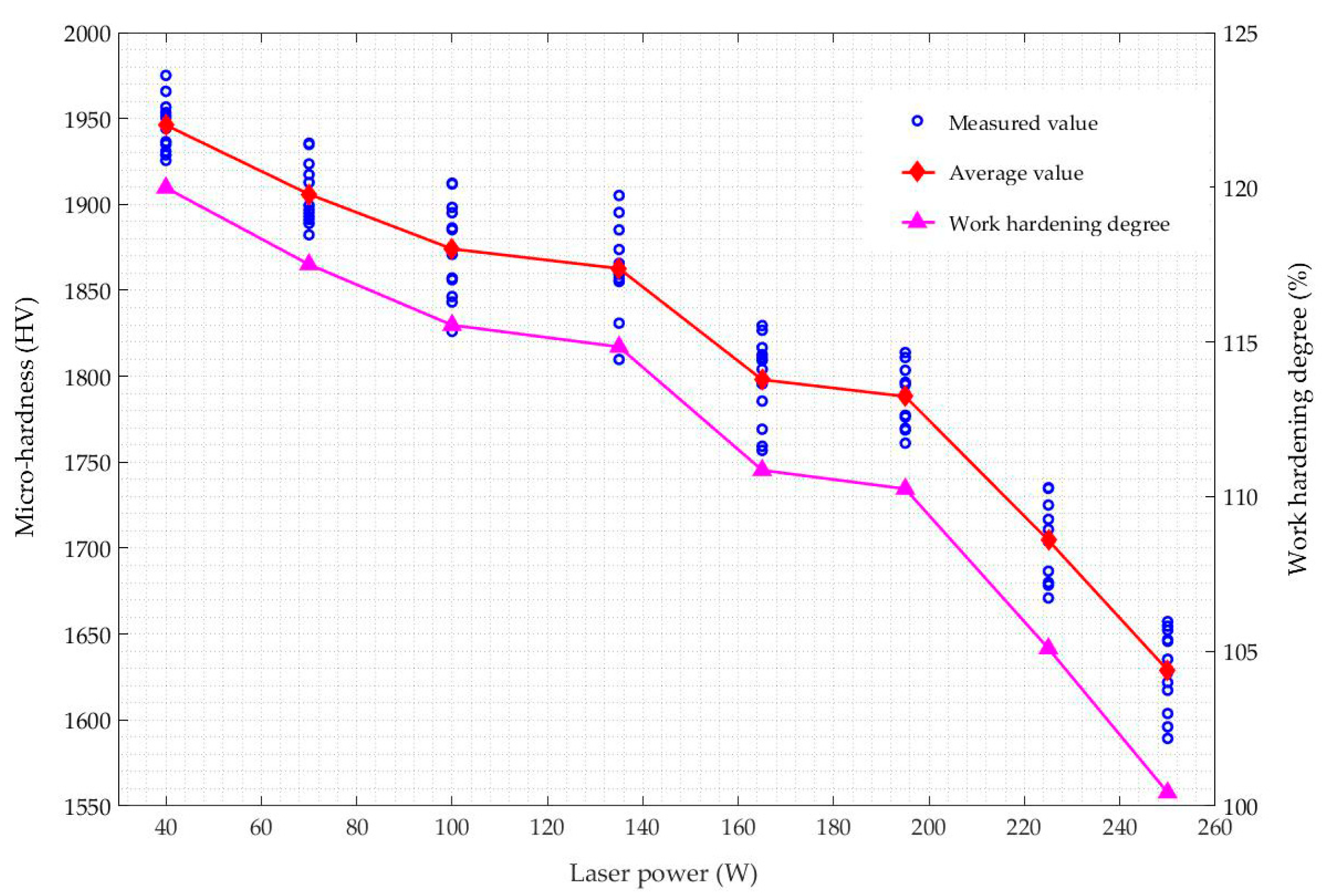

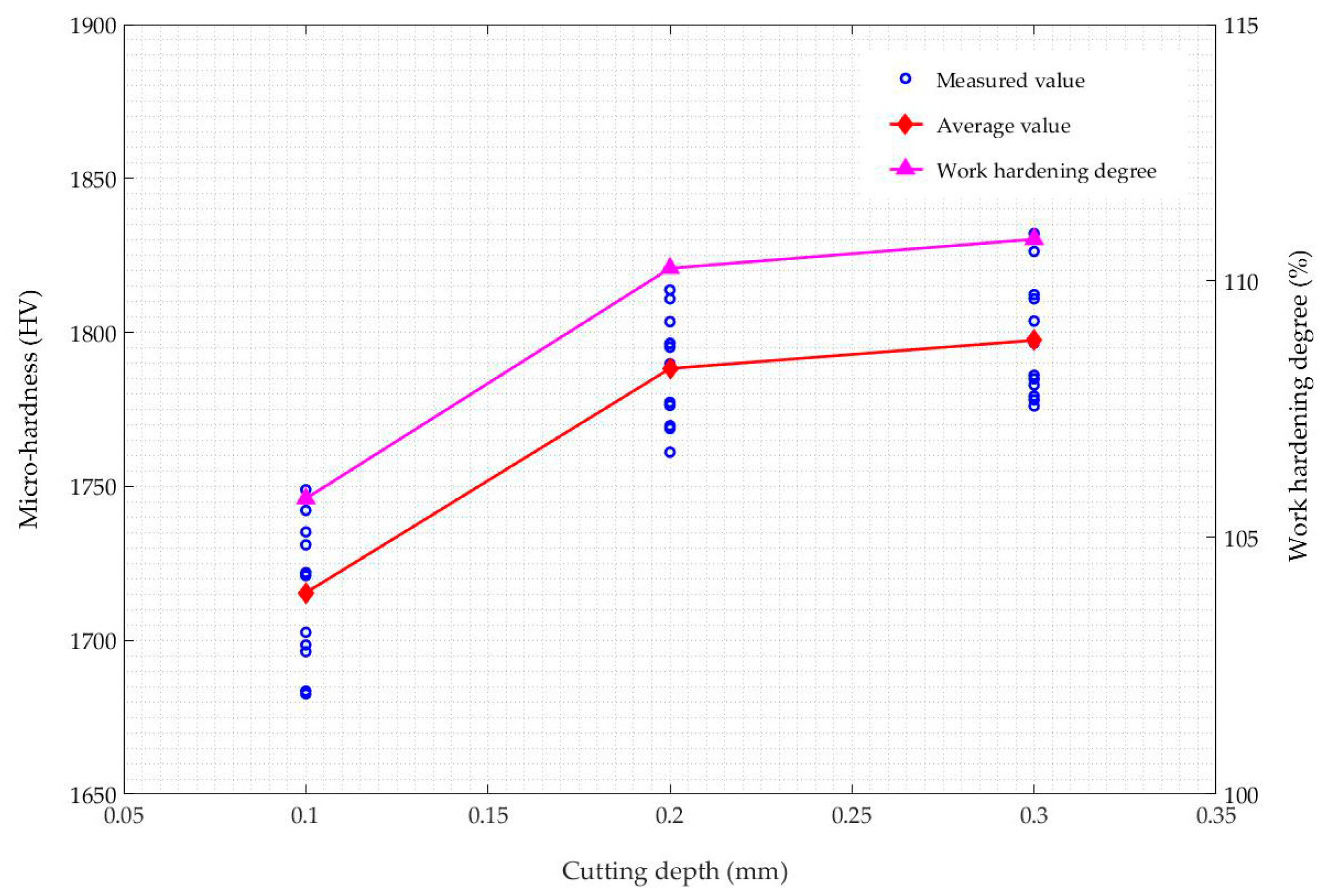

3.3. Work Hardening Degree

3.4. Mechanism

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ferraris, E.; Vleugels, J.; Guo, Y.B.; Bourell, D.; Kruth, J.P.; Lauwers, B. Shaping of engineering ceramics by electro, chemical and physical processes. CIRP Ann. 2016, 65, 761–784. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser machining of structural ceramics—A review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Lei, S.; Shin, Y.C.; Incropera, F.P. Deformation mechanisms and constitutive modeling for silicon nitride undergoing laser-assisted machining. Int. J. Mach. Tools Manuf. 2000, 40, 2213–2233. [Google Scholar] [CrossRef]

- Tian, Y.; Shin, Y.C. Laser-Assisted Machining of Damage-Free Silicon Nitride Parts with Complex Geometric Features via In-Process Control of Laser Power. J. Am. Ceram. Soc. 2006, 89, 3397–3405. [Google Scholar] [CrossRef]

- Lei, S.; Shin, Y.C.; Incropera, F.P. Incropera, Experimental Investigation of ThermoMechanical Characteristics in Laser-Assisted Machining of Silicon Nitride Ceramics. J. Manuf. Sci. Eng. 2000, 123, 639–646. [Google Scholar] [CrossRef]

- Kang, D.W.; Lee, C.M. A study on the development of the laser-assisted milling process and a related constitutive equation for silicon nitride. CIRP Ann. 2014, 63, 109–112. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, J.D.; Suh, J. Microstructural variations and machining characteristics of silicon nitride ceramics from increasing the temperature in laser assisted machining. Int. J. Precis. Eng. Manuf. 2014, 15, 1269–1274. [Google Scholar] [CrossRef]

- Wu, X.F. Basic Research on Laser Assisted Machining of Silicon Nitride Ceramics; Harbin Institute of Technology: Harbin, China, 2011. [Google Scholar]

- Pu, Y.Z.; Zhao, Y.G.; Zhang, H.Y.; Zhao, G.Y.; Meng, J.B.; Song, P.P. Study on the three-dimensional topography of the machined surface in laser assisted machining of Si3N4 ceramics under different material removal modes. Ceram. Int. 2020, 46, 5695–5705. [Google Scholar] [CrossRef]

- Chang, C.-W.; Kuo, C.-P. Evaluation of surface roughness in laser-assisted machining of aluminum oxide ceramics with Taguchi method. Int. J. Mach. Tools Manuf. 2007, 47, 141–147. [Google Scholar] [CrossRef]

- Chang, C.-W.; Kuo, C.-P. An investigation of laser-assisted machining of Al2O3 ceramics planing. Int. J. Mach. Tools Manuf. 2007, 47, 452–461. [Google Scholar] [CrossRef]

- Kizaki, T.; Ito, Y.; Tanabe, S.; Kim, Y.; Sugita, N.; Mitsuishi, M. Laser-assisted Machining of Zirconia Ceramics using a Diamond Bur. Procedia CIRP 2016, 42, 497–502. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Lu, Y.; Luo, X.; Ding, F.; Li, C. Analysis of diamond wheel wear and surface integrity in laser-assisted grinding of RB-SiC ceramics. Ceram. Int. 2019, 45, 24355–24364. [Google Scholar] [CrossRef]

- Dong, X.; Shin, Y. Improved machinability of SiC/SiC ceramic matrix composite via laser-assisted micromachining. Int. J. Adv. Manuf. Technol. 2016, 90, 731–739. [Google Scholar] [CrossRef]

- Rebro, P.A.; Shin, Y.C.; Incropera, F.P. Design of operating conditions for crackfree laser-assisted machining of mullite. Int. J. Mach. Tools Manuf. 2004, 44, 677–694. [Google Scholar] [CrossRef]

- Li, Z.P.; Zhang, F.H.; Luo, X.C.; Chang, W.L.; Cai, Y.K.; Zhong, W.B.; Ding, F. Material removal mechanism of laser-assisted grinding of RB-SiC ceramics and process optimization. J. Eur. Ceram. Soc. 2019, 39, 705–717. [Google Scholar] [CrossRef]

- Song, H.W.; Dan, J.Q.; Li, J.L.; Du, J.; Xiao, J.F.; Xu, J.F. Experimental study on the cutting force during laser-assisted machining of fused silica based on the Taguchi method and response surface methodology. J. Manuf. Process. 2019, 38, 9–20. [Google Scholar] [CrossRef]

- Wang, S.Y. MACHINED Surface Quality for High-Speed Milling; Shandong University: Jinan, China, 2006. [Google Scholar]

- Wada, N.; Solin, S.A.; Wong, J.; Prochazka, S. Raman and IR absorption spectroscopic studies on α, β, and amorphous Si3N4. J. Manuf. Process. 2019, 38, 9–20. [Google Scholar] [CrossRef]

- Chen, X.S.; Zhuang, H.R.; Li, W.L. Studied on the Raman spectroscopy of silicon nitride ceramics with addition of Y2O3 and Al2O3. Shanghai Guisuanyan 1993, 3, 177–183. [Google Scholar]

- Wang, X.D. Study on the Structure and Properties of Silicon Nitride Ceramics by Gas Pressure Sintering; China Academy of Engineering Physics: Mianyang, China, 2017. [Google Scholar]

| Content | Values |

|---|---|

| Density (g/cm3) | 3.2 ± 0.05 |

| Hardness (HV) | ≥1420 |

| Fracture toughness (MPa·m1/2) | 6.0–7.0 |

| Flexural strength (MPa) | 700–800 |

| Elastic modulus (GPa) | 310 |

| Thermal expansion (room temperature ~500°C) 10−6/°C | 3.0–3.2 |

| Breakdown voltage (KV) | >10 |

| Compressive strength (MPa) | ≥1500 |

| Thermal conductivity (W/mK) | 15–20 |

| Text | P (W) | V (rev/min) | f (mm/rev) | d (mm) | l (mm) | t (s) | D (mm) | L (mm) | φ (°) |

|---|---|---|---|---|---|---|---|---|---|

| Case1 | 250 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case2 | 225 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case3 | 195 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case4 | 165 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case5 | 135 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case6 | 100 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case7 | 70 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case8 | 40 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Case9 | 0 | 900 | 0.01 | 0.2 | 15 | 8 | 0.8 | 0.5 | 90 |

| Element | 225 W | 195 W | 165 W | 135 W | 100 W | 70 W | 40 W | The Raw Material |

|---|---|---|---|---|---|---|---|---|

| N | 9.3 | 30.1 | 29.9 | 30.7 | 31.7 | 29.2 | 28.4 | 25.3 |

| O | 37.8 | 21.5 | 17.7 | 14.2 | 18.1 | 17.6 | 13.0 | 13.4 |

| Si | 44.0 | 41.6 | 45.3 | 50.4 | 43.3 | 47.8 | 50.6 | 52.8 |

| Y | 4.0 | 2.3 | 1.7 | 0.9 | 2.2 | 1.4 | 2.6 | 0.7 |

| Mg | 0.1 | 0.4 | 0.2 | 0.0 | 0.3 | 0.3 | 0.2 | 0.1 |

| Al | 4.2 | 3.4 | 3.6 | 2.5 | 3.5 | 3.1 | 4.0 | 2.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, Y.; Zhao, Y.; Zhao, G.; Meng, J.; Zhang, H.; Liu, Q.; Song, P. A Study on Work Hardening in the Laser-Assisted Machining of Si3N4 Ceramics under Different Material Removal Modes. Metals 2020, 10, 432. https://doi.org/10.3390/met10040432

Pu Y, Zhao Y, Zhao G, Meng J, Zhang H, Liu Q, Song P. A Study on Work Hardening in the Laser-Assisted Machining of Si3N4 Ceramics under Different Material Removal Modes. Metals. 2020; 10(4):432. https://doi.org/10.3390/met10040432

Chicago/Turabian StylePu, Yezhuang, Yugang Zhao, Guoyong Zhao, Jianbing Meng, Haiyun Zhang, Qian Liu, and Panpan Song. 2020. "A Study on Work Hardening in the Laser-Assisted Machining of Si3N4 Ceramics under Different Material Removal Modes" Metals 10, no. 4: 432. https://doi.org/10.3390/met10040432

APA StylePu, Y., Zhao, Y., Zhao, G., Meng, J., Zhang, H., Liu, Q., & Song, P. (2020). A Study on Work Hardening in the Laser-Assisted Machining of Si3N4 Ceramics under Different Material Removal Modes. Metals, 10(4), 432. https://doi.org/10.3390/met10040432