Effect of Current Input Method on A356 Microstructure in Electromagnetically Stirred Process

Abstract

:1. Introduction

2. Experiment

2.1. Preparation of Tool and Material

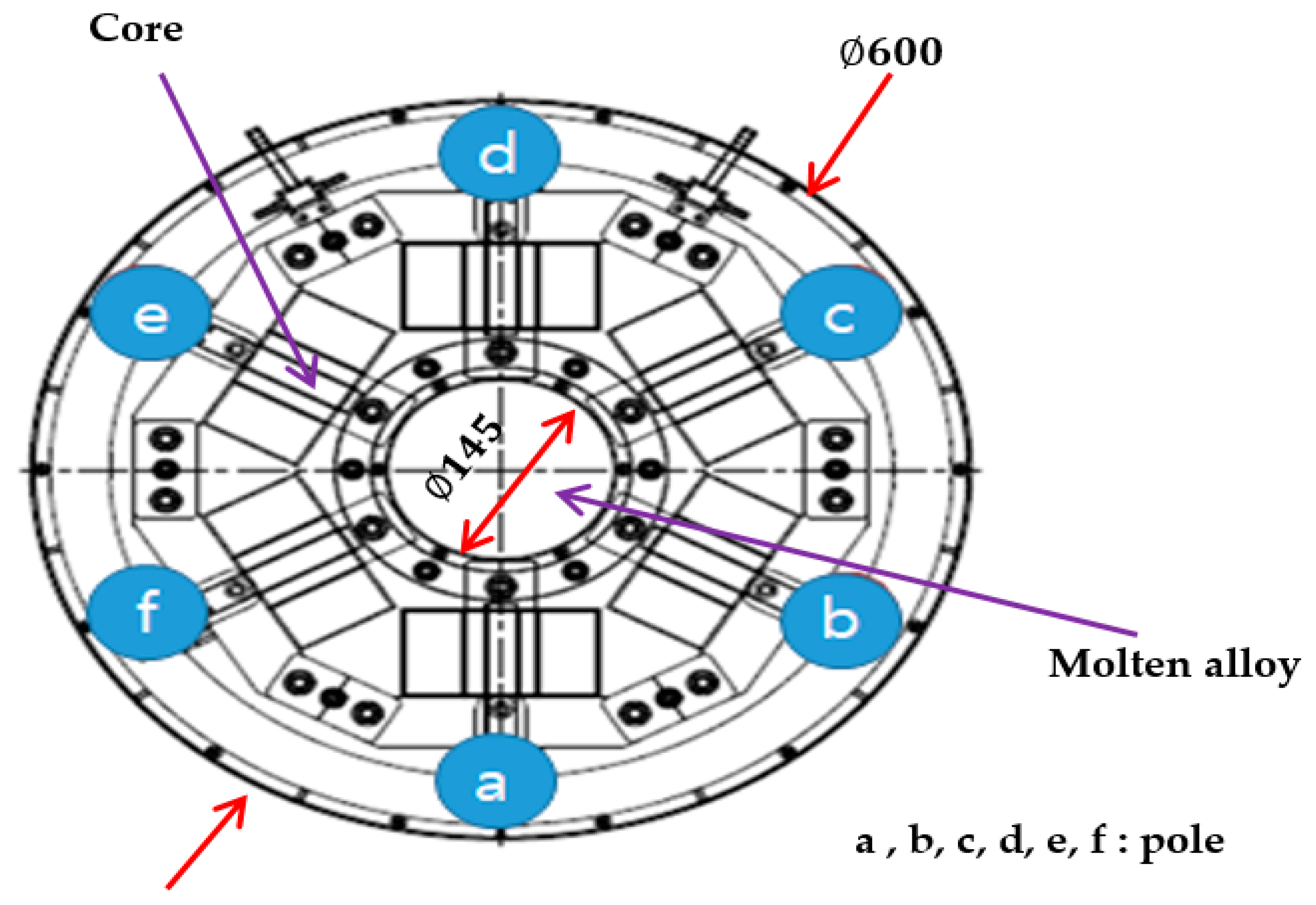

2.1.1. Electromagnetic Stirrer

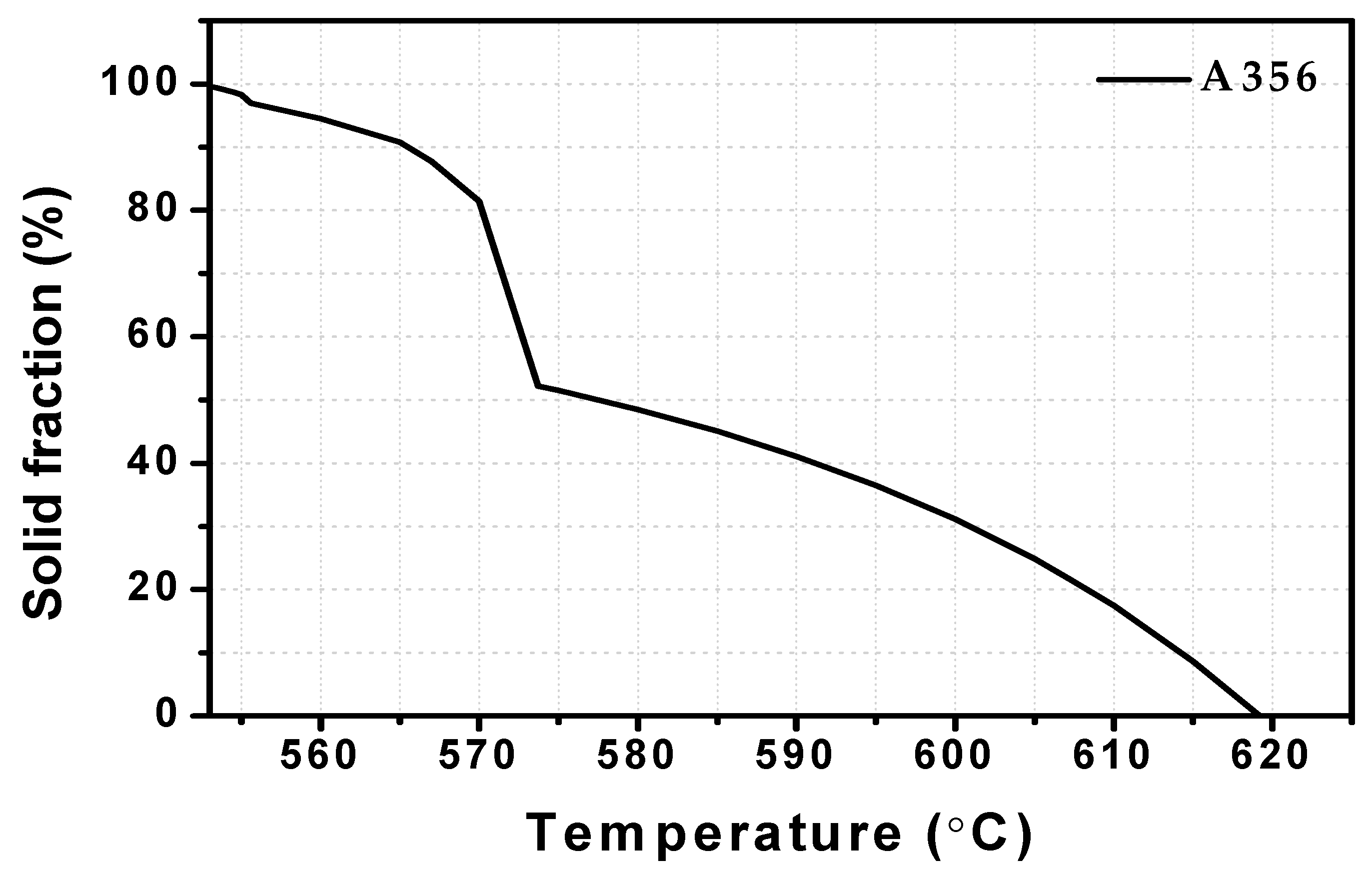

2.1.2. Material for Semi-Solid Surry

2.2. Experimental Method

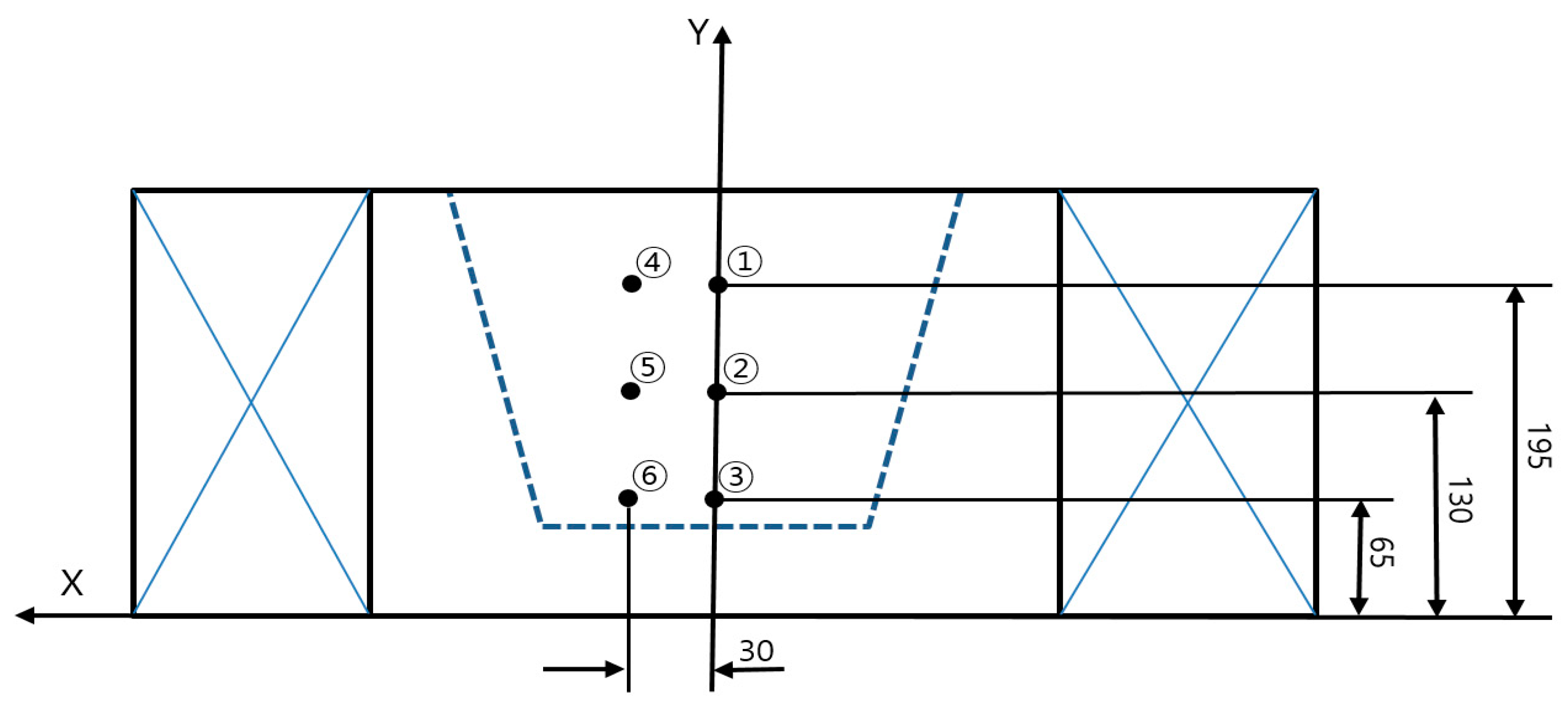

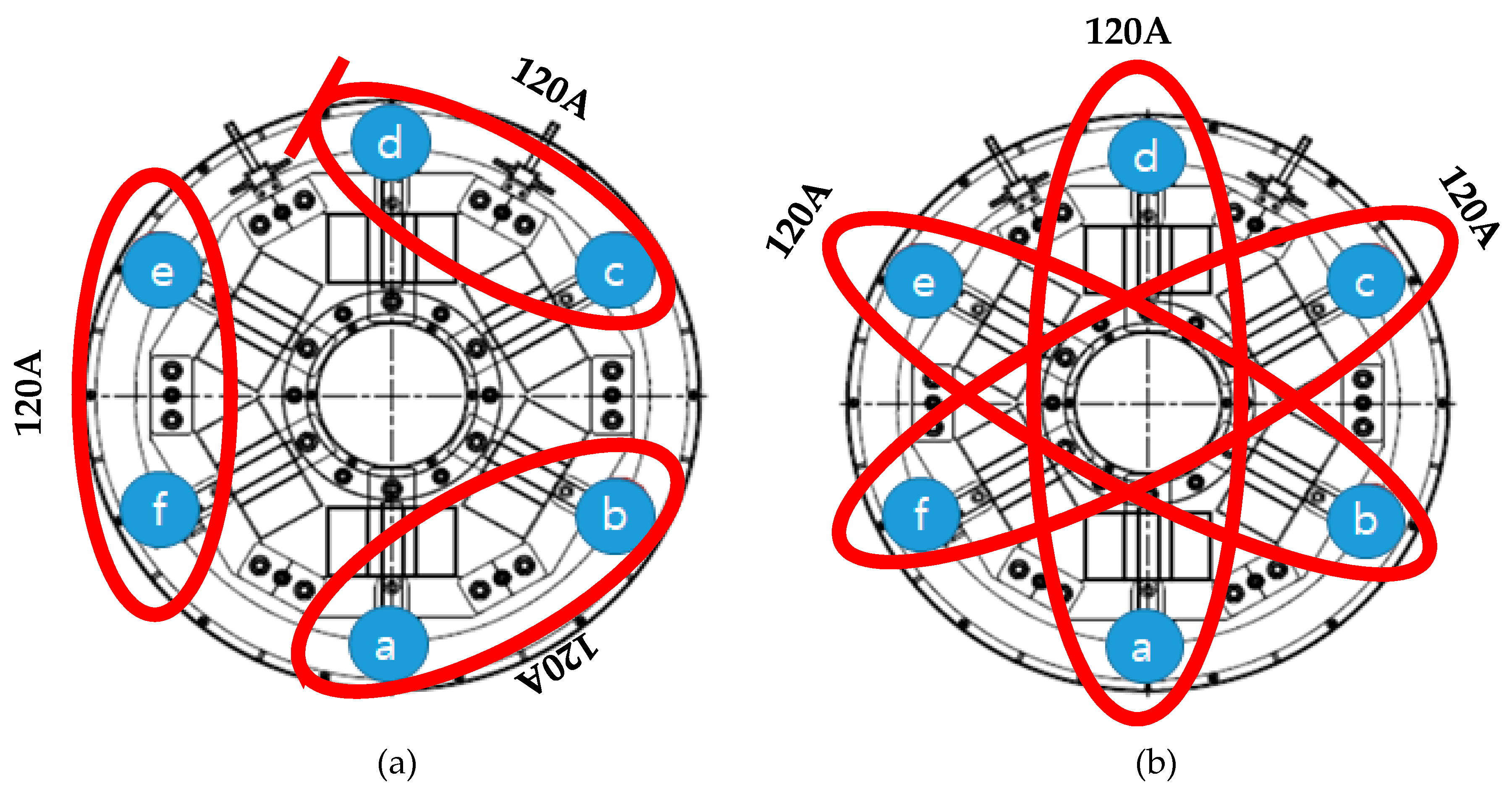

2.2.1. Method of Setting Current Input

2.2.2. Manufacturing Method of Semi-Solid Material

3. Experimental Results

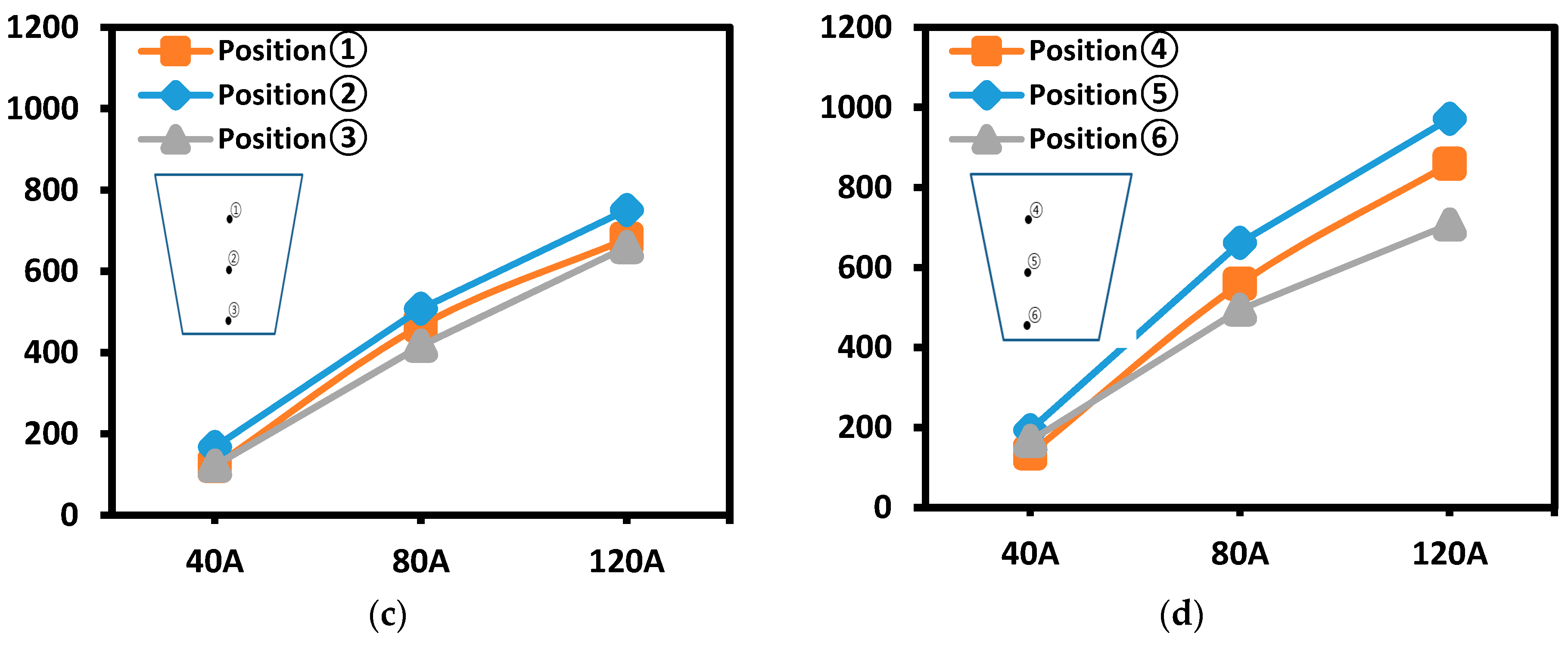

3.1. Comparison of Magnetic Flux Density

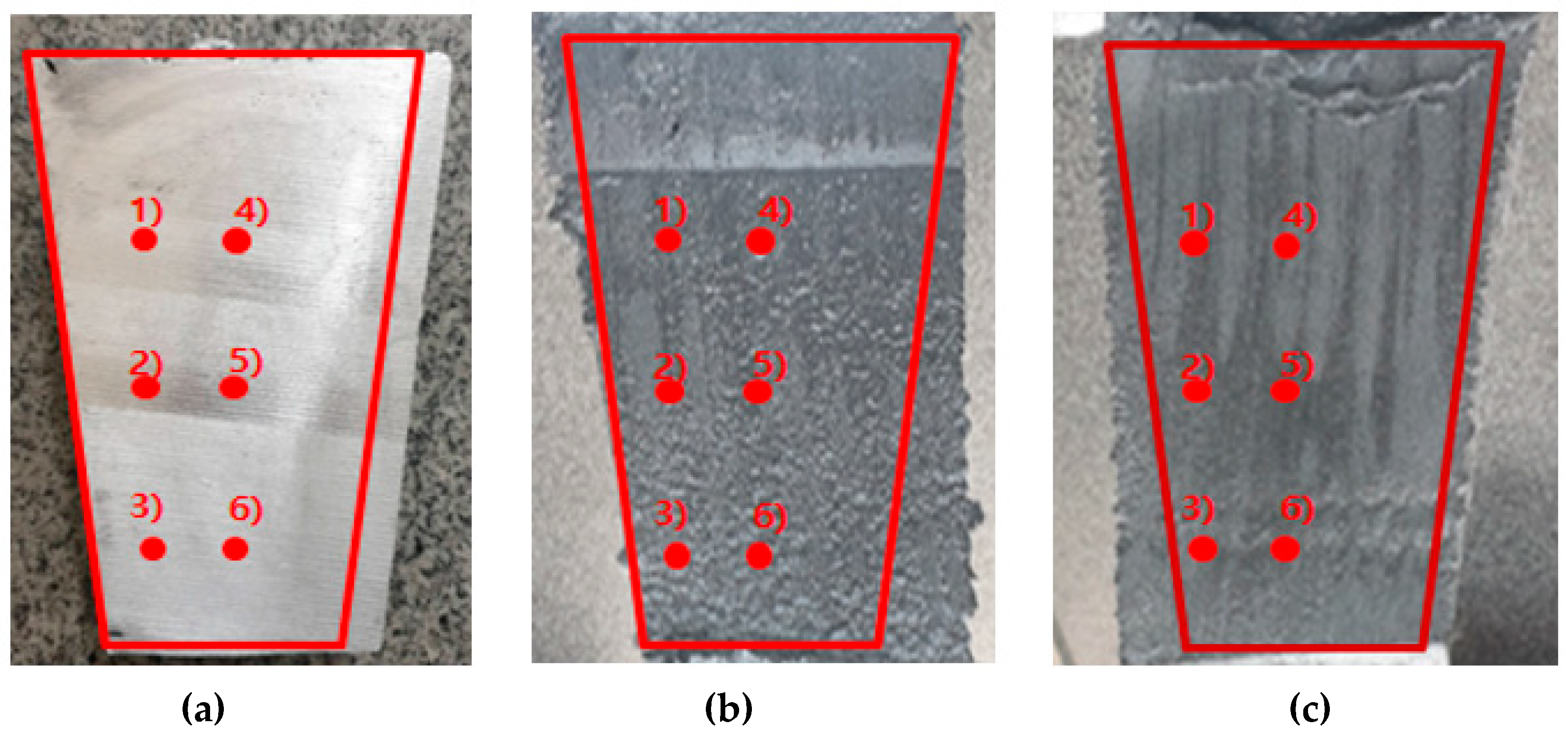

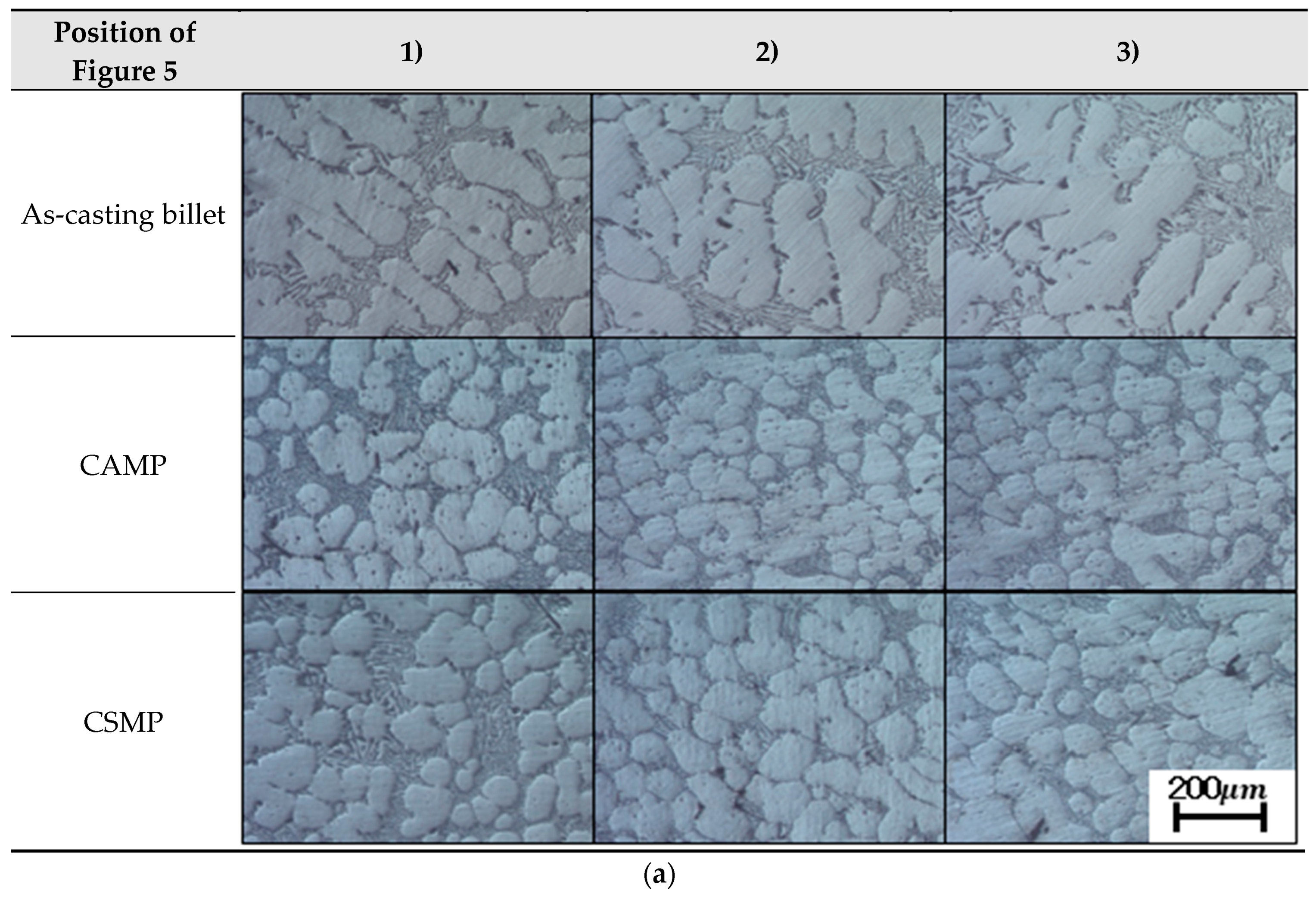

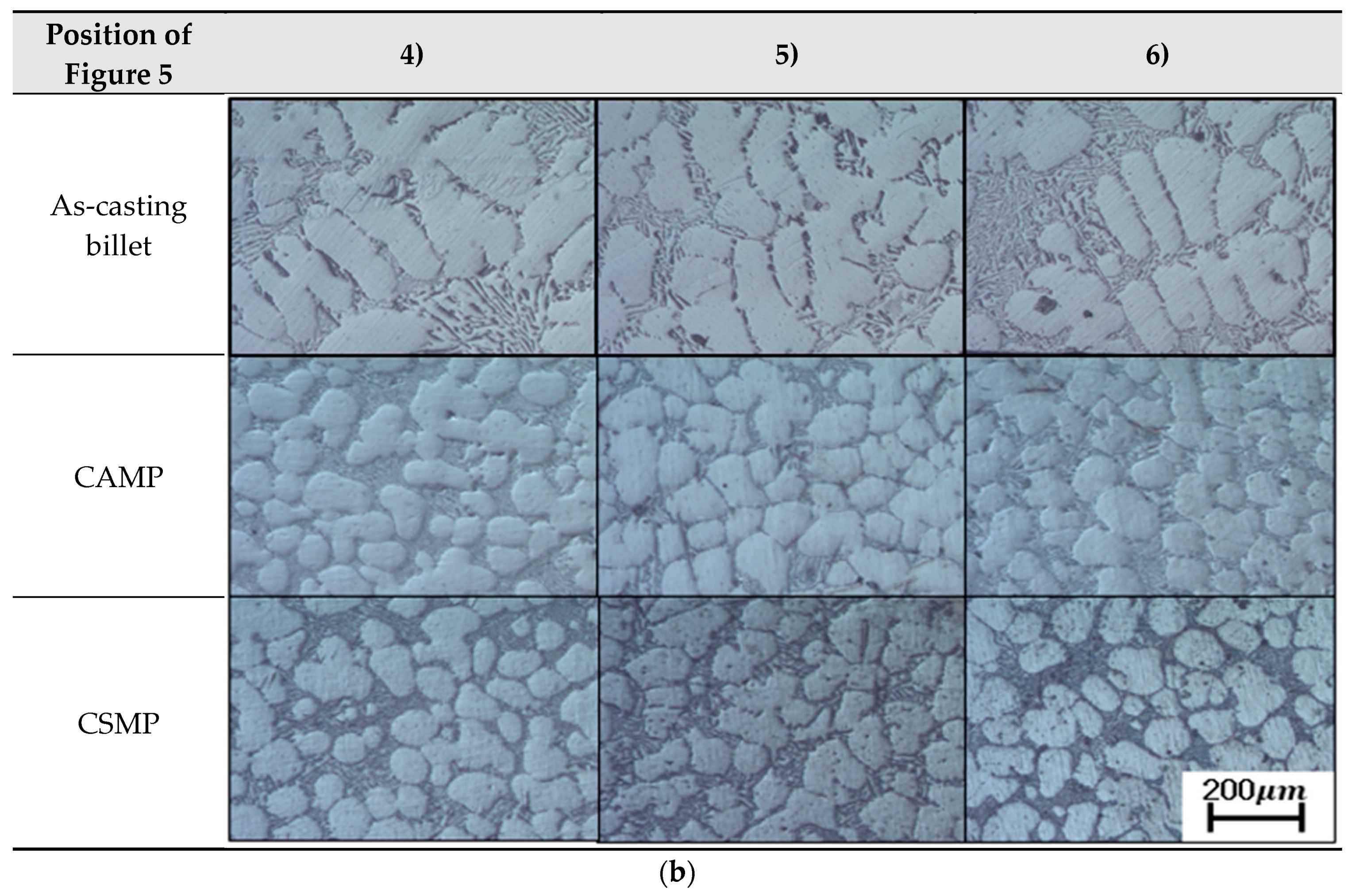

3.2. Analysis of Microstructure

4. Conclusions

- 1)

- In the axial direction of the large electronic stirrer, the magnetic flux densities of the up per part and the lower part were almost similar, but the middle position had a higher magnetic flux density than the upper part and the lower part.

- 2)

- The maximum magnetic flux density of 972 Gauss was obtained with the CSMP whereas the maximum magnetic flux density from the CAMP was 665 Gauss, indicating that the CSMP was the most effective in obta10ing the roundness of aluminum slurry.

- 3)

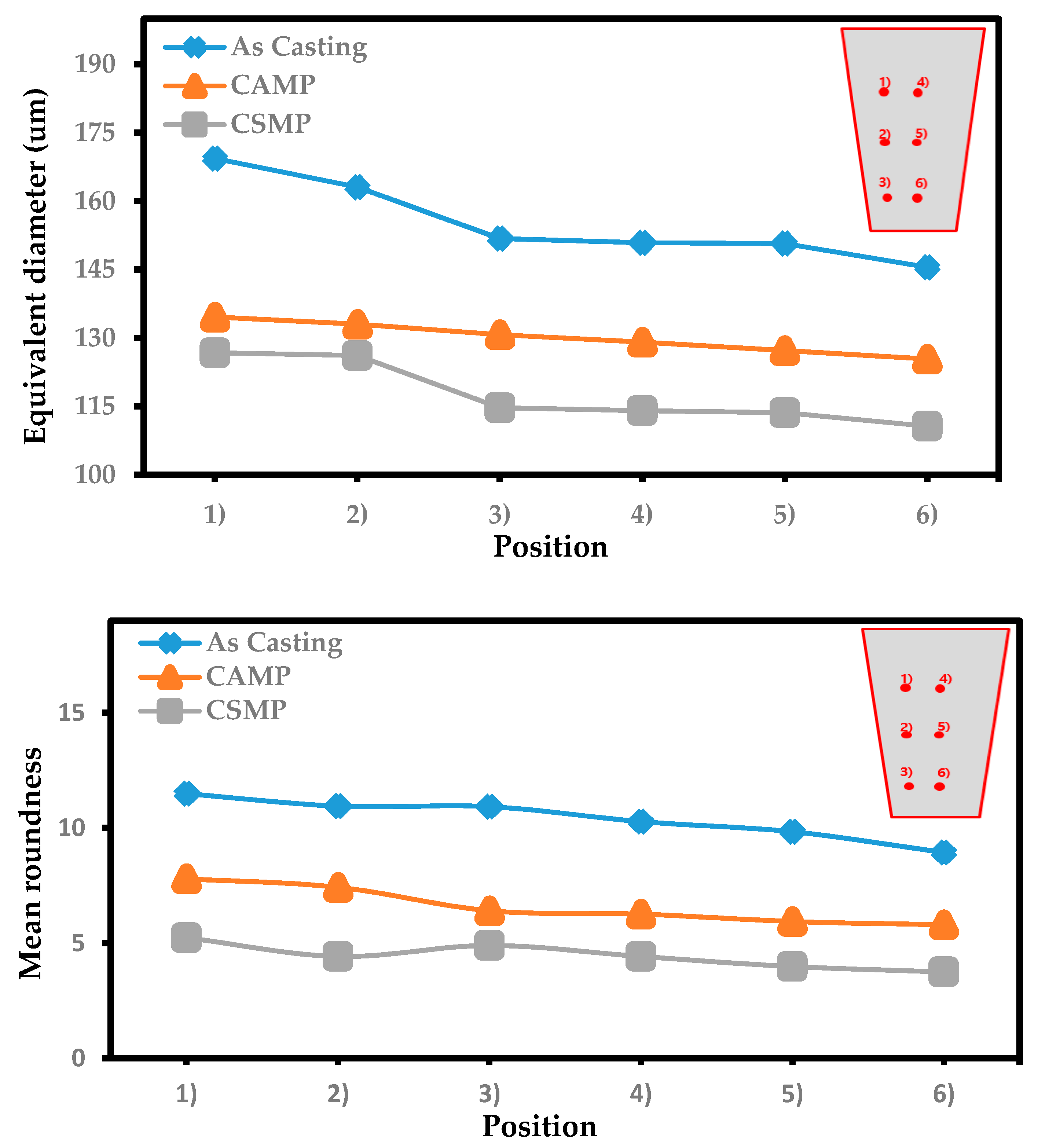

- CSMP showed more spherical particles in the slurry than the CAMP, while the microstructure of the edges was somewhat irregular and relatively larger than those in the center of the slurry.

- 4)

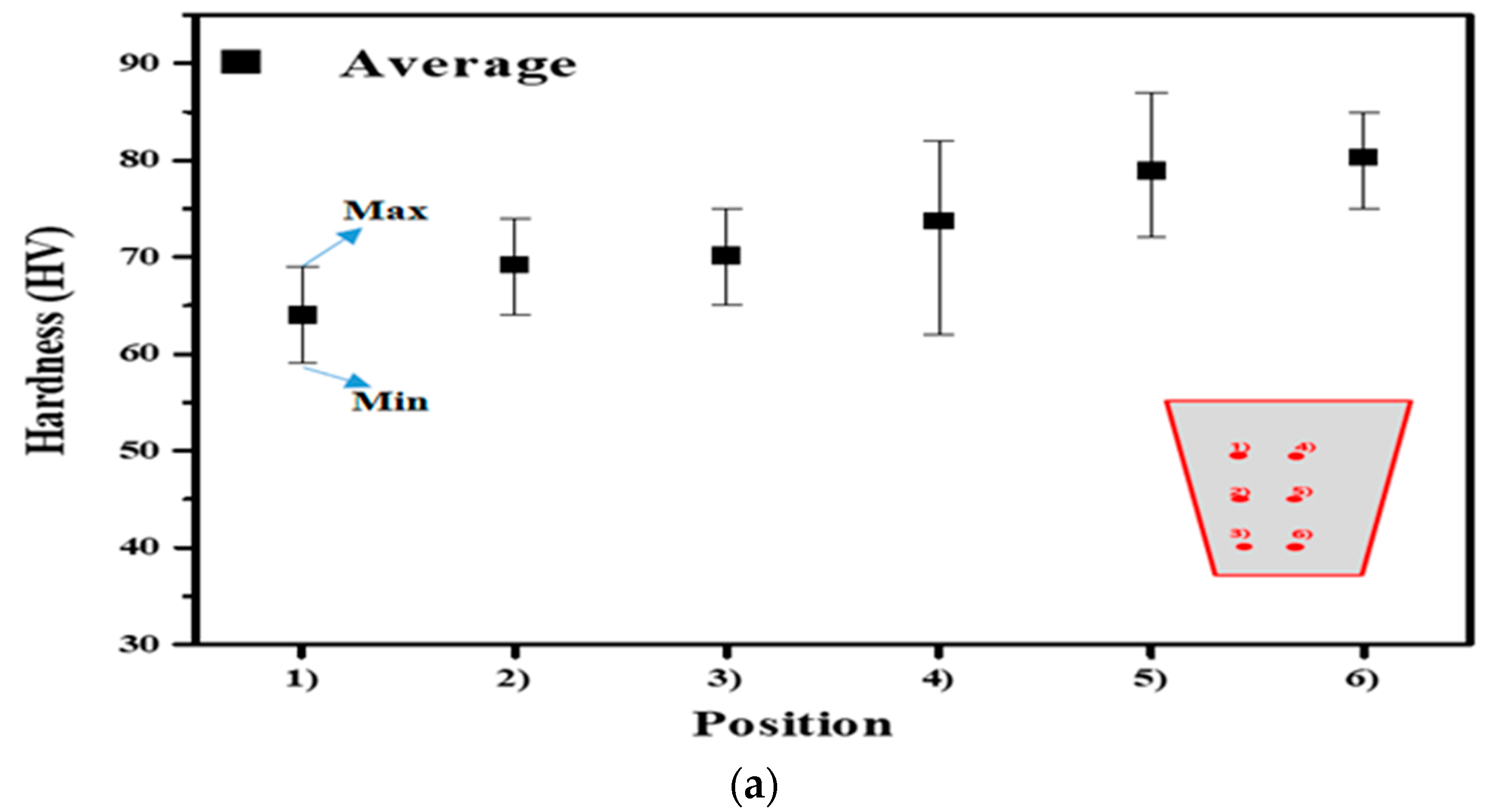

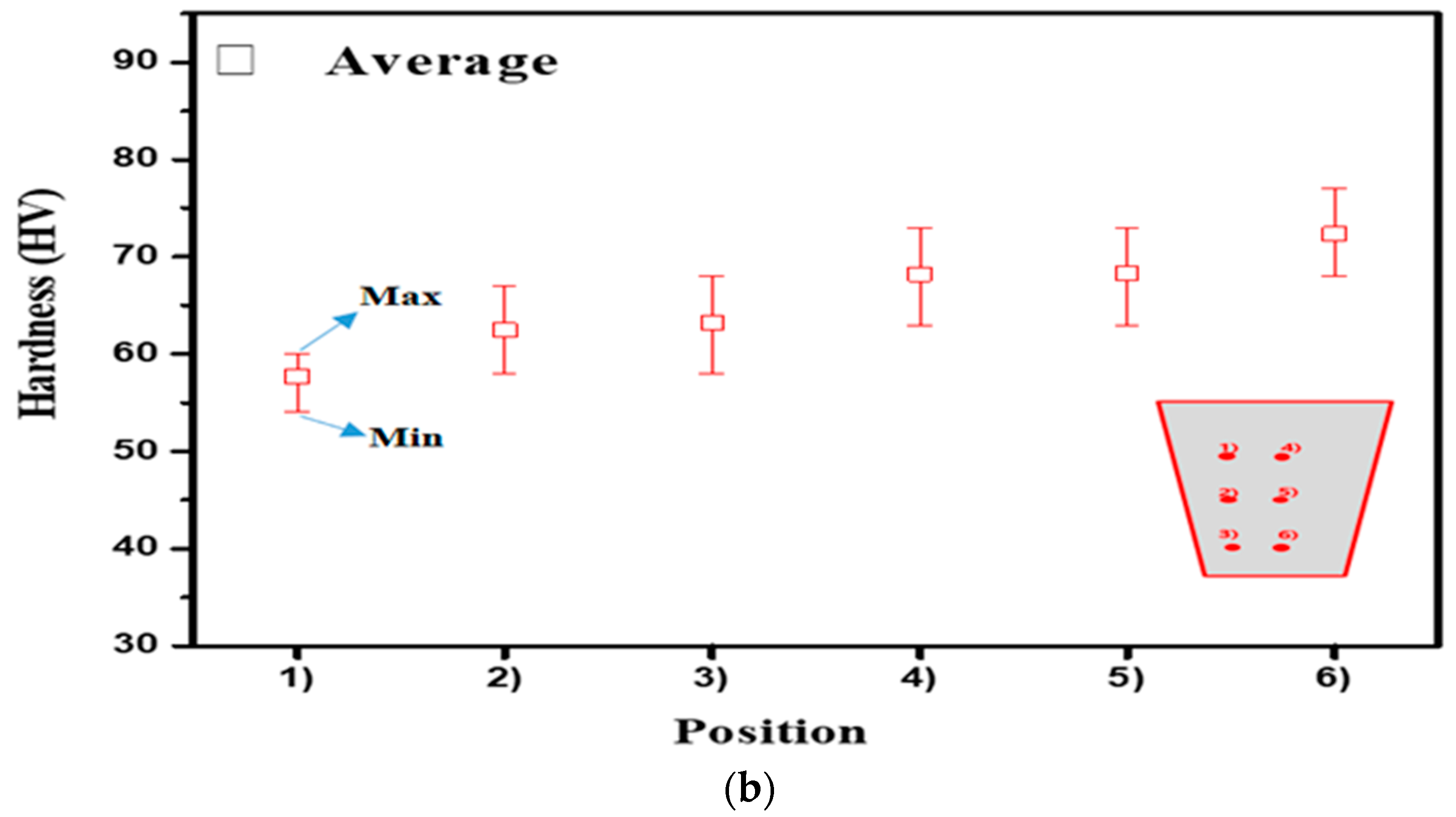

- CSMP, which has the best stirring effect, measured 80 HV to 64 HV, and CAMP 72.1 HV to 59.1 HV.

Author Contributions

Funding

Conflicts of Interest

References

- Park, C.; Kim, S.S.Y.; Kwon, Y.N.; Lee, Y.S.; Lee, J.H. Mechanical and corrosion properties of rheocast and low-pressure cast A356-T6 alloy. Mater. Sci. Eng. A 2005, 391, 86–94. [Google Scholar] [CrossRef]

- Tsai, Y.C.; Chou, C.Y.; Lee, S.L.; Lin, C.K.; Lin, J.C.; Lim, S.S. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al–7Si–0.35Mg) aluminum alloys. J. Alloys Compd. 2009, 487, 157–162. [Google Scholar] [CrossRef]

- Kim, E.S.; Lee, K.H. Product Design for High Technology of DieCasting. J. Korean Foundrymen Soc. 2004, 24, 251–264. [Google Scholar]

- Ebisawa, M. The Latest News of Die Casting Technology. J. Korean Foundrymen Soc. 2004, 2, 71–78. [Google Scholar]

- Kang, C.G.; Choi, J.C.; Bae, W.B. Semi-Solid Forming, Casting and Forging Technologies of Lightweight Materials. J. Korean Soc. Precis. Eng. 2000, 7, 7–21. [Google Scholar]

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological Behavior of Sn-15% Pb in the Crystallization Range. Metall. Mater. Trans. A 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouazara, M.; Bouaicha, A.; Allooui, O. Microstructural and mechanical features of aluminium semi-solid alloys made by rheocasting technique. J. Mater. Sci. Technol. 2016, 33, 646–655. [Google Scholar] [CrossRef]

- Sivabalan, R.; Thangadurai, K.R. Rheocasting of Aluminum Alloy A356 based on Various Parameters: A Review. Int. J. Eng. Res. Technol. 2018, 7, 250–254. [Google Scholar]

- Kumar, S.D.; Ghose, J.; Mandal, A. Thixoforming of light-weight alloys and composites: An approach toward sustainable manufacturing. In Sustainable Engineering Products and Manufacturing Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 25–43. [Google Scholar]

- Afandi, Y.; Zulfia, A. Fabrication of Aluminium Matrix Composite Using Thixoforming Process for High Strength Material Components. J. Mater. Sci. Eng. A 2019, 9, 149–152. [Google Scholar]

- Pola, A.; Tocci, M.; Kapranos, P. Microstructure and Properties of Semi-Solid Aluminum Alloys: A Literature Review. Metals 2018, 8, 181. [Google Scholar] [CrossRef] [Green Version]

- Kapranos, P. Current State of Semi-Solid Net-Shape Die Casting. Metals 2019, 9, 1301. [Google Scholar]

- Irani, S.B.; Hanzaki, A.Z.; Bazaz, B.; Roosraei, A.A. Microstructure evolution and semi-solid deformation behavior of an A356 aluminum alloy processed by strain induced melt activated method. Mater. Des. 2013, 46, 579–587. [Google Scholar]

- Jaberi, F.S.; Cockcroft, S.L.; Maijer, D.M.; Philion, A.B. Comparison of the semi-solid constitutive behaviour of A356 and B206 aluminum foundry alloys. J. Mater. Process. Technol. 2019, 266, 37–45. [Google Scholar]

- Liu, Z.; Mao, W.; Zhao, Z. Research on Semi-Solid Slurry of a Hypoeutectic Al-Si Alloy Prepared by Low Superheat Pouring and Weak Electromagnetic Stirring. Rare Met. 2006, 252, 177–183. [Google Scholar]

- Bae, J.W.; Kim, T.W.; Kang, C.G. Experimental investigation for rheology forming process of Al–7% Si aluminum alloy with electromagnetic system. J. Mater. Process. Technol. 2007, 191, 165–169. [Google Scholar]

- Jin, C.K.; Jang, C.H.; Kang, C.G. Effect of the process parameters on the formability, microstructure and mechanical properties of thin plates fabricated by rheology forging process with electromagnetic stirring method. Metall. Mater. Trans. B 2014, 45, 193–211. [Google Scholar]

- Mingjun, L.; Yuichiro, M.; Isao, M.; Naoki, O.; Shuji, T. Imposition Time Dependent Microstructure Formation in 7150 Aluminum Alloy Solidified by an Electromagnetic Stirring Technique. Mat. Trans. 2018, 59, 1603–1609. [Google Scholar]

- An, G.; Junwen, Z.; Chao, X.; Hu, L.; Jing, H.; Xu, Z. Effects of Pouring Temperature and Electromagnetic Stirring on Porosity and Mechanical Properties of A357 Aluminum Alloy Rheo-Diecasting terials. J. Mater. Eng. Perform. 2018, 27, 2373–2380. [Google Scholar]

- Qiu, Y.; Zhang, Z.; Luo, Y.; Gao, M.; Li, B.; Chen, C. Effect of coupled annular electromagnetic stirring and intercooling on the microstructures, macrosegregation and properties of large-sized 2219 aluminum alloy billets. Int. J. Mater. Res. 2018, 109, 469–475. [Google Scholar]

- Jun, W.Z.; An, G.; Hu, L.; Xu, Z.; Jing, H.; Shu, S.W. Semisolid slurry of 7A04 aluminum alloy prepared by electromagnetic stirring and Sc, Zr additions. China Foundry 2017, 14, 188–193. [Google Scholar]

- Luo, Y.; Zhang, Z. Numerical modeling of annular electromagnetic stirring with intercooling in direct chill casting of 7005 aluminum alloy billet. Prog. Nat. Sci. Mater. Int. 2019, 29, 81–87. [Google Scholar] [CrossRef]

- Kang, C.G.; Bae, J.W.; Kim, B.M. The grain size control of A356 aluminum alloy by horizontal electromagnetic stirring for rheology forging. J. Mater. Process. Technol. 2007, 187, 344–348. [Google Scholar] [CrossRef]

- Zoqui, E.J.; Paes, M.; Sadipi, E.E. Macro- and microstructure analysis of SSM A356 produced by electromagnetic stirring. J. Mater. Process. Technol. 2002, 120, 365–373. [Google Scholar] [CrossRef]

| Inside diameter | 145 mm |

| Outside diameter | 600 mm |

| Height | 260 mm |

| Cu | Si | Fe | Mg | Mn | Zn | Ni |

|---|---|---|---|---|---|---|

| 0.008 | 6.65 | 0.08 | 0.35 | 0.008 | 0.02 | 0.01 |

| Ti | Sn | Pb | Cr | Ca | Sr | Al |

| 0.12 | 0.007 | 0.016 | 0.001 | 0.0008 | 0.022 | Bal |

| Current Input Method Number | Current Input Method | Current Input Procedure | Polarity |

|---|---|---|---|

| (1) | Counterclockwise of adjacent magnetic pole (CAMP) | ⓐⓑ→ⓒⓓ→ⓔⓕ | (+) polarity: ⓐ,ⓒ,ⓔ (−) polarity: ⓑ,ⓓ,ⓕ |

| (2) | Counterclockwise of symmetry magnetic pole (CSMP) | ⓐⓓ→ⓑⓔ→ⓒⓕ | (+) polarity: ⓐ,ⓑ,ⓒ (−) polarity: ⓓ,ⓔ,ⓕ |

| Stirring Current, A | Electromagnetic Force, Gauss | Stirring Temperature, °C | Pouring Temperature, °C | |

|---|---|---|---|---|

| As-casting | 700 | |||

| CSMP, CAMP | 120 | 665, 972 | 585 | 700 |

| Eyepiece (X) | Objectives (X) | Halogen Lamp | Stage |

|---|---|---|---|

| 10 | 50, 100, 200, 500, 1000 | 12V 100W | X-Y |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roh, J.S.; Heo, M.; Jin, C.K.; Park, J.H.; Kang, C.G. Effect of Current Input Method on A356 Microstructure in Electromagnetically Stirred Process. Metals 2020, 10, 460. https://doi.org/10.3390/met10040460

Roh JS, Heo M, Jin CK, Park JH, Kang CG. Effect of Current Input Method on A356 Microstructure in Electromagnetically Stirred Process. Metals. 2020; 10(4):460. https://doi.org/10.3390/met10040460

Chicago/Turabian StyleRoh, Joong Suk, Min Heo, Chul Kyu Jin, Jin Ha Park, and Chung Gill Kang. 2020. "Effect of Current Input Method on A356 Microstructure in Electromagnetically Stirred Process" Metals 10, no. 4: 460. https://doi.org/10.3390/met10040460

APA StyleRoh, J. S., Heo, M., Jin, C. K., Park, J. H., & Kang, C. G. (2020). Effect of Current Input Method on A356 Microstructure in Electromagnetically Stirred Process. Metals, 10(4), 460. https://doi.org/10.3390/met10040460