Microstructure Evolution of 5052 Aluminum Sheet in Electromagnetic High-Speed Impact

Abstract

:1. Introduction

2. Experimental Conditions

2.1. Material

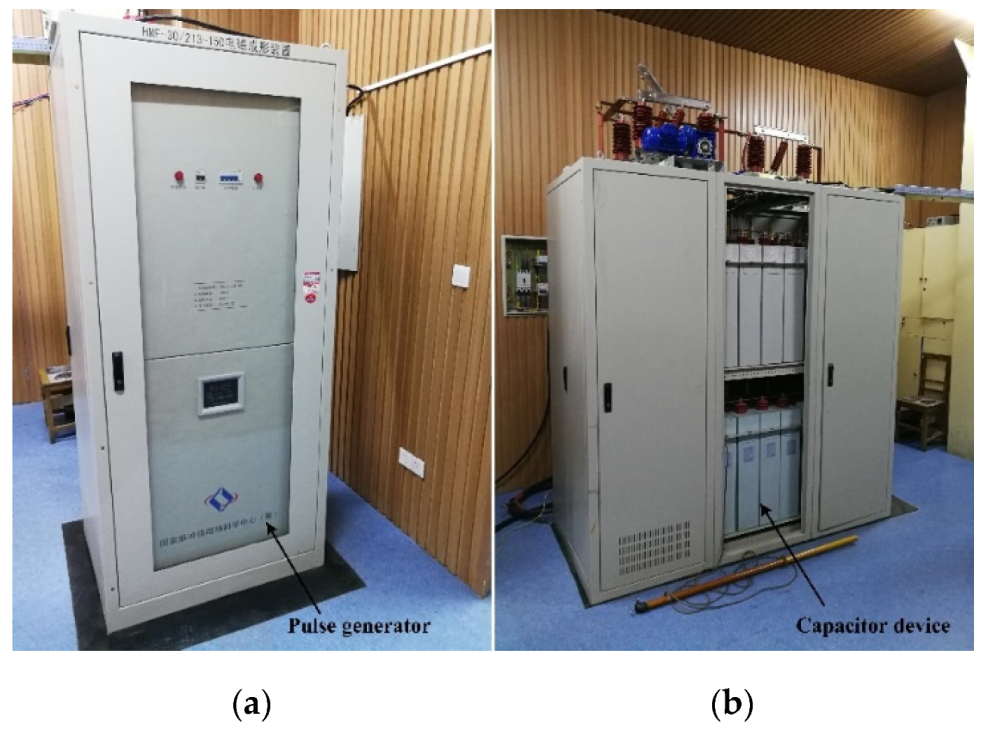

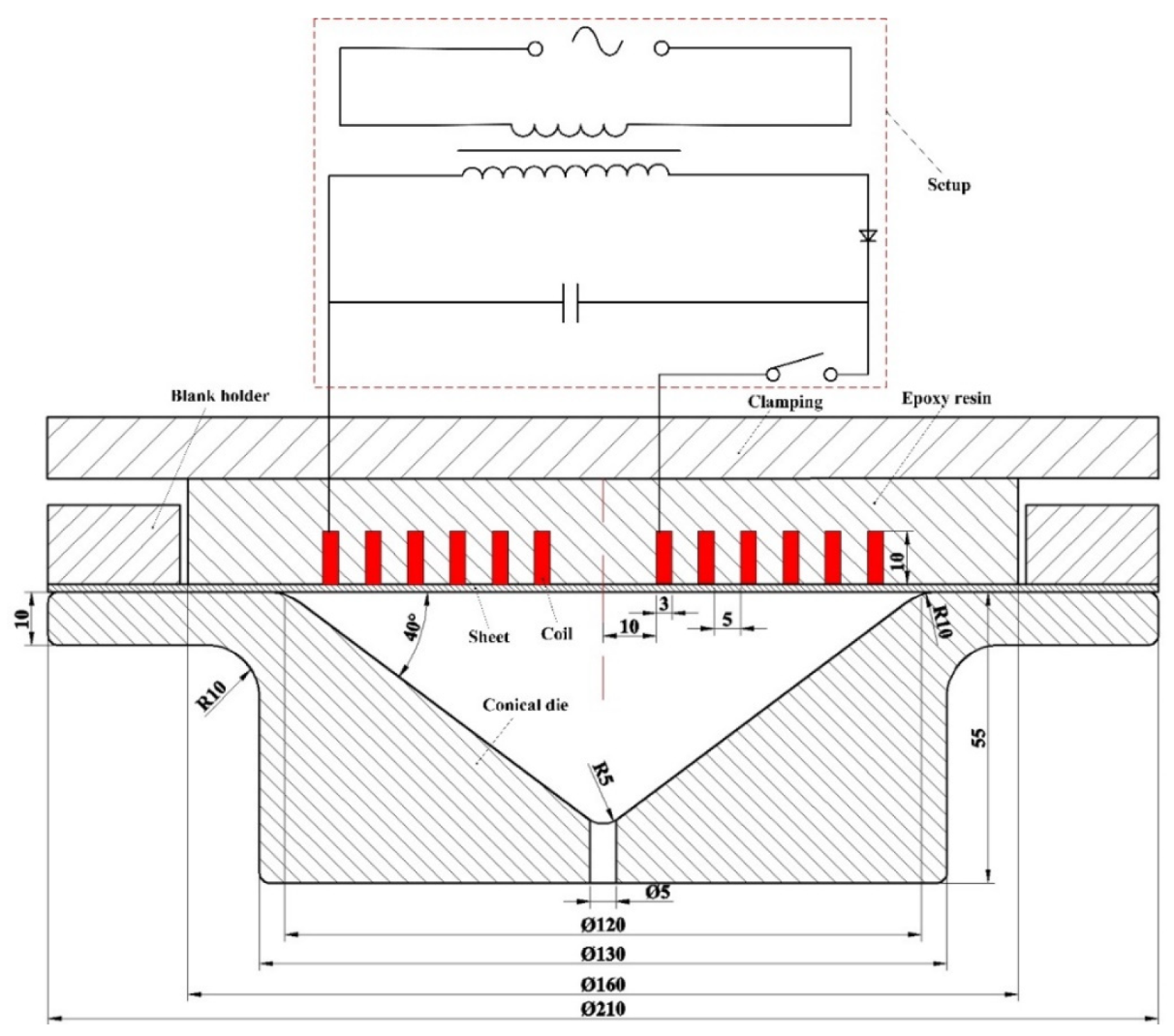

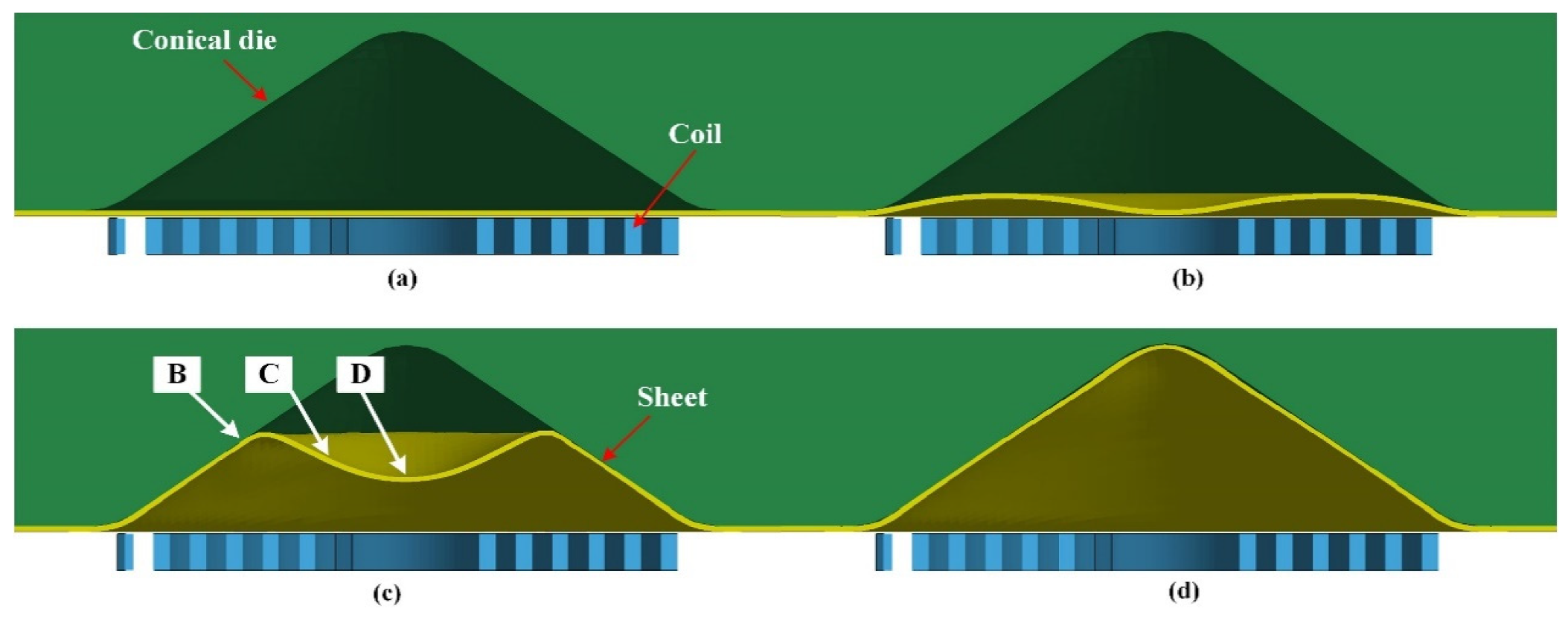

2.2. Electromagnetic High-Speed Impact Experiment

2.3. Micro Hardness Test

2.4. Electron Back Scattering Diffraction Test

2.5. Transmission Electron Microscopy Test

3. Results and Discussions

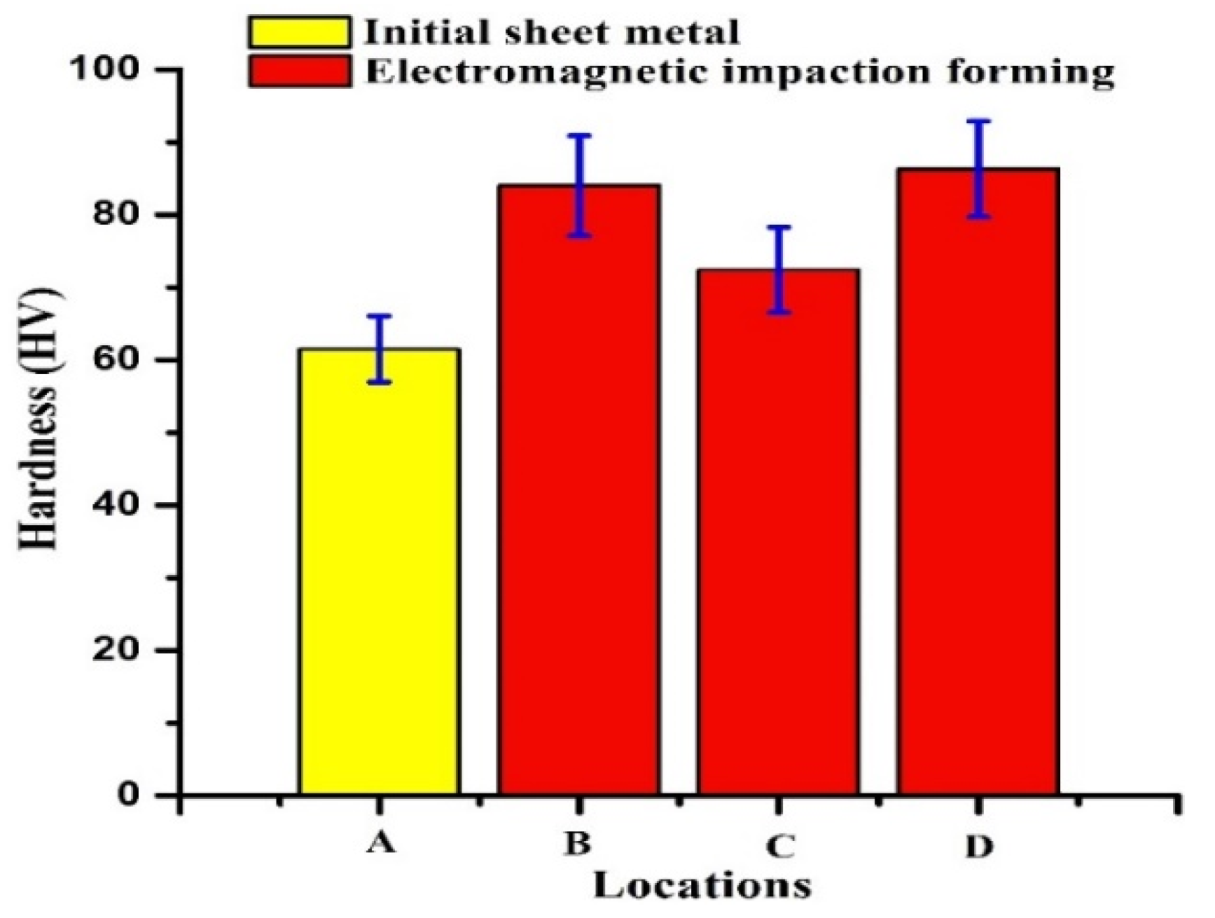

3.1. Micro Hardness

3.2. Discussion of the EBSD Results

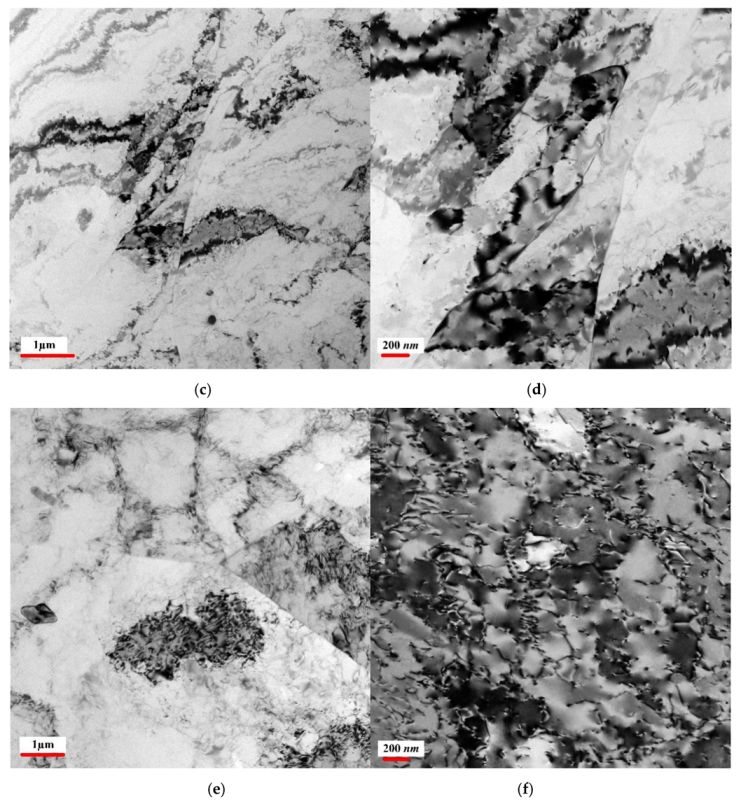

3.3. Discussion of the TEM Results

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Cui, X.; Mo, J.; Li, J.; Xiao, X.; Zhou, B.; Fang, J. Large-scale sheet deformation process by electromagnetic incremental forming combined with stretch forming. J. Mater. Process. Technol. 2016, 237, 139–154. [Google Scholar] [CrossRef]

- Psyk, V.; Risch, D.; Kinsey, B.L.; Tekkaya, A.E.; Kleiner, M. Electromagnetic forming—A review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Li, C.; Liu, D.; Yu, H.; Ji, Z. Research on formability of 5052 aluminum alloy sheet in a quasi-static–dynamic tensile process. Int. J. Mach. Tools Manuf. 2009, 49, 117–124. [Google Scholar] [CrossRef]

- Tamhane, A.A.; Altynova, M.M.; Daehn, G.S. Effect of sample size on ductility in electromagnetic ring expansion. Scr. Mater. 1996, 34, 1345–1350. [Google Scholar] [CrossRef]

- Li, F.-Q.; Mo, J.-H.; Li, J.-J.; Huang, L.; Zhou, H.-Y. Formability of Ti–6Al–4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 2013, 52, 337–344. [Google Scholar] [CrossRef]

- Vohnout, V.J. A Hybrid Quasi-Static/Dynamic Process for Forming Large Sheet Metal Parts from Aluminum Alloys. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 1998; p. 437. [Google Scholar]

- Liu, D.; Yu, H.; Li, C. Experimental observations of quasi-static-dynamic formability in biaxially strained AA5052-O. J. Mater. Eng. Perform. 2011, 20, 223–230. [Google Scholar] [CrossRef]

- Dehra, M.S. High Velocity Formability and Factors Affecting it. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2006. [Google Scholar]

- Golovashchenko, S.F. Material Formability and Coil Design in Electromagnetic Forming. J. Mater. Eng. Perform. 2007, 16, 314–320. [Google Scholar] [CrossRef]

- Imbert, J.M.; Winkler, S.L.; Worswick, M.J.; Oliveira, D.A.; Golovashchenko, S. The Effect of Tool–Sheet Interaction on Damage Evolution in Electromagnetic Forming of Aluminum Alloy Sheet. J. Eng. Mater. Technol. 2005, 127, 145–153. [Google Scholar] [CrossRef]

- Liu, D.H.; Yu, H.P.; Li, C.F. Comparative study of the microstructure of 5052 aluminum alloy sheets under quasi-static and high-velocity tension. Mater. Sci. Eng. A 2012, 551, 280–287. [Google Scholar] [CrossRef]

- Fang, J.; Mo, J.; Li, J. Microstructure difference of 5052 aluminum alloys under conventional drawing and electromagnetic pulse assisted incremental drawing. Mater. Charact. 2017, 129, 88–97. [Google Scholar] [CrossRef]

- Feng, F.; Huang, S.; Hu, J.; Meng, Z.; Lei, Y. Analysis of the bulging process of an AZ31B magnesium alloy sheet with a uniform pressure coil. Int. J. Adv. Manuf. Technol. 2013, 69, 1537–1545. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.06 | 0.29 | 0.01 | 0.06 | 2.5 | 0.16 | 0.01 | Balanced |

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Strain-Hardening Exponent (n) | Total Elongation (%) |

|---|---|---|---|

| 89.4 | 268.5 | 0.25 | 0.325 |

| Region | A | B | C | D |

|---|---|---|---|---|

| Values | 62.0 | 85.0 | 73.5 | 87.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, F.; Li, J.; Zhang, Y.; Huang, L.; Su, H.; Cao, S.; Shao, G.; Chen, R. Microstructure Evolution of 5052 Aluminum Sheet in Electromagnetic High-Speed Impact. Metals 2020, 10, 564. https://doi.org/10.3390/met10050564

Feng F, Li J, Zhang Y, Huang L, Su H, Cao S, Shao G, Chen R. Microstructure Evolution of 5052 Aluminum Sheet in Electromagnetic High-Speed Impact. Metals. 2020; 10(5):564. https://doi.org/10.3390/met10050564

Chicago/Turabian StyleFeng, Fei, Jianjun Li, Yunjun Zhang, Liang Huang, Hongliang Su, Shijing Cao, Guangbao Shao, and Rongchuang Chen. 2020. "Microstructure Evolution of 5052 Aluminum Sheet in Electromagnetic High-Speed Impact" Metals 10, no. 5: 564. https://doi.org/10.3390/met10050564

APA StyleFeng, F., Li, J., Zhang, Y., Huang, L., Su, H., Cao, S., Shao, G., & Chen, R. (2020). Microstructure Evolution of 5052 Aluminum Sheet in Electromagnetic High-Speed Impact. Metals, 10(5), 564. https://doi.org/10.3390/met10050564