Thickness Effect on Microstructure, Strength, and Toughness of a Quenched and Tempered 178 mm Thickness Steel Plate

Abstract

:1. Introduction

2. Materials and Methods

3. Results

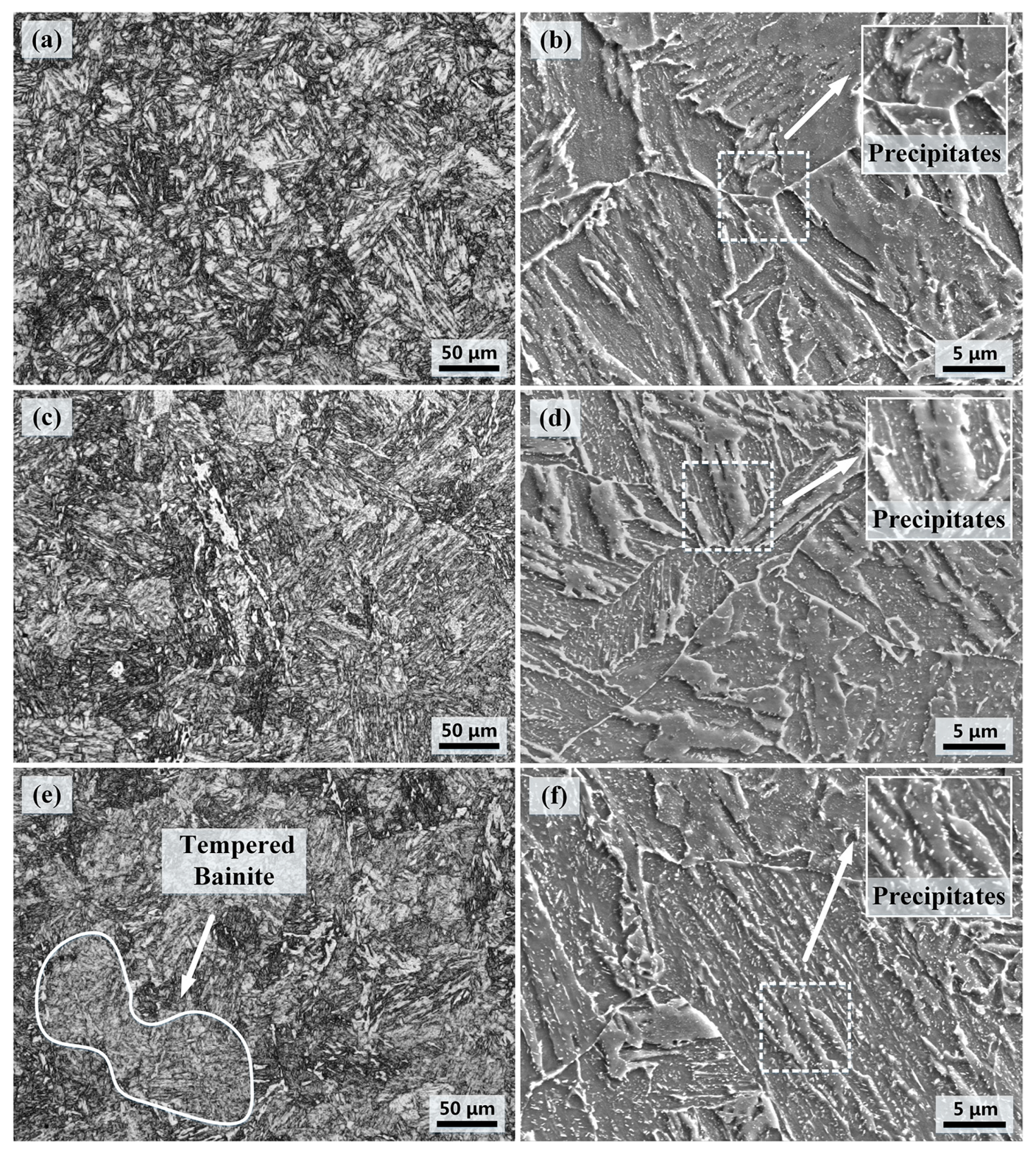

3.1. Microstructural Characterization

3.1.1. OM and SEM

3.1.2. EBSD

3.1.3. XRD

3.1.4. TEM

3.2. Mechanical Properties

3.2.1. Tensile Properties

3.2.2. Hardness Across the Thickness

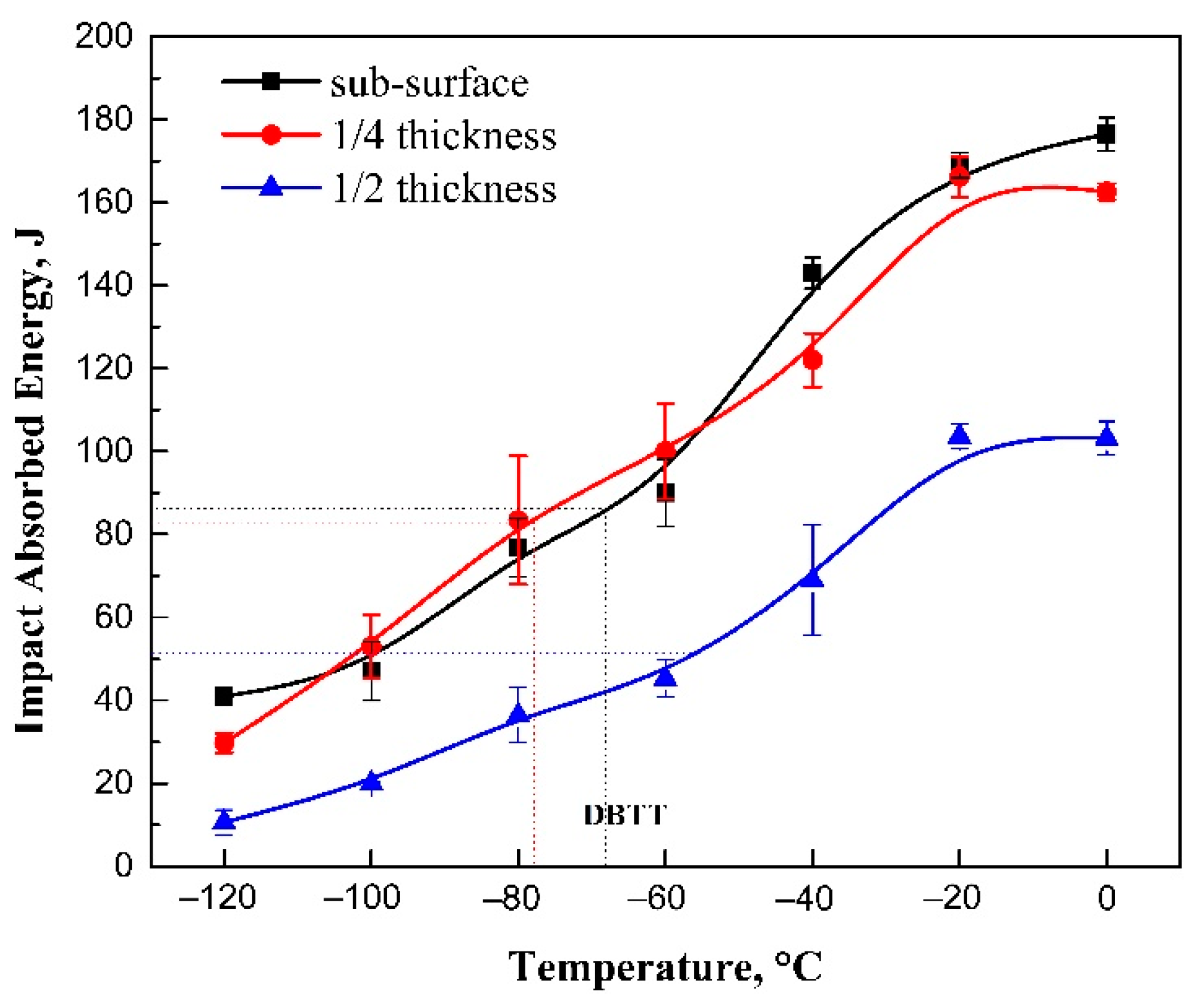

3.2.3. Impact Toughness as A Function of Temperature

3.2.4. Impact Fracture Behavior at −60 °C

3.3. Segregation at t/2

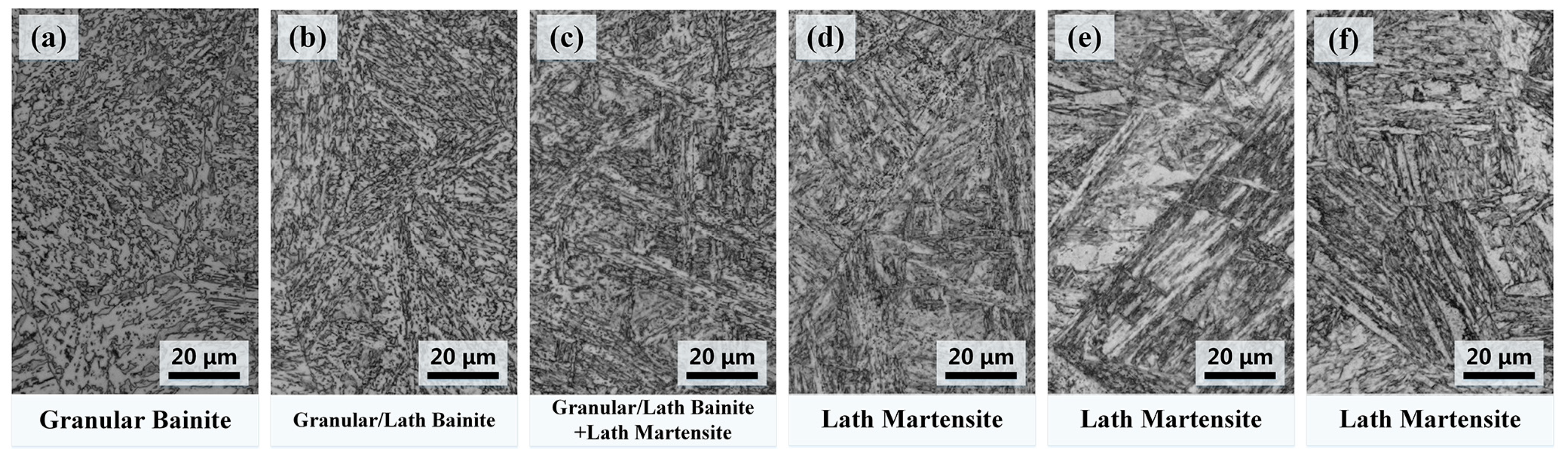

3.4. Continuous Cooling Transformation (CCT) Behavior

4. Discussion

4.1. Thickness Effect on Microstructure Variation

4.2. Thickness Effect on Strength Variation

4.3. Thickness Effect on Toughness Variation

5. Conclusions

- (1)

- The microstructure at t/2 consists of tempered martensite and a large amount of tempered bainite with coarse size and a low fraction of HAGB, as well as high-density coarse carbides along interlath boundaries, which is significantly differs from that at the sub-surface and t/4. The microstructural variation results from the dramatic drop of the cooling rate from 6.8 °C/s at the sub-surface to 0.6 °C/s at t/2 where only partially martensitic transformation occurred.

- (2)

- The lowest strength of 750 MPa at t/2 is from the weaker strengthening contributions from coarse block size and precipitation of coarser carbides. Based on the variation in strengthening components, it could be promising for designing the strength required at the middle thickness for ultra-heavy steel by considering the quenching capability measured.

- (3)

- The lowest impact toughness at t/2 is caused by the complete loss of crack propagation energy and significantly lower crack initiation energy, which could have arisen from the coarse bainitic or martensitic structure and high-density large carbides at the interlath boundaries.

- (4)

- With a dramatic decrease of quenching intensity and severe segregation at t/2 of the ultra-heavy steel plate, further study is needed to understand the complexity in partially martensitic transformation and carbide precipitation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, T.; Yu, H.; Wang, S. Effect of microstructural types on toughness and microstructural optimization of ultra-heavy steel plate: EBSD analysis and microscopic fracture mechanism. Mater. Sci. Eng. A 2016, 658, 150–158. [Google Scholar] [CrossRef]

- Liu, D.; Cheng, B.; Chen, Y. Strengthening and toughening of a heavy plate steel for shipbuilding with yield strength of approximately 690 MPa. Metall. Mater. Trans. A 2013, 44, 440–455. [Google Scholar] [CrossRef]

- Yu, W.; Li, G.; Cai, Q. Effect of a novel gradient temperature rolling process on deformation, microstructure and mechanical properties of ultra-heavy plate. J. Mater. Process. Technol. 2015, 217, 317–326. [Google Scholar]

- Gottlieb, J.; Kern, A.; Schriever, U.; Steinbeck, G. High-performance steels for pressure vessels. Steel Constr. 2010, 3, 49–55. [Google Scholar] [CrossRef]

- Xie, B.-S.; Cai, Q.-W.; Yun, Y.; Li, G.-S.; Ning, Z. Development of high strength ultra-heavy plate processed with gradient temperature rolling, intercritical quenching and tempering. Mater. Sci. Eng. A 2017, 680, 454–468. [Google Scholar] [CrossRef]

- Lesoult, G. Macrosegregation in steel strands and ingots: Characterisation, formation and consequences. Mater. Sci. Eng. A 2005, 413–414, 19–29. [Google Scholar] [CrossRef]

- Pickering, E.J.; Bhadeshia, H.K.D.H. Macrosegregation and microstructural evolution in a pressure-vessel steel. Metall. Mater. Trans. A 2014, 45, 2983–2997. [Google Scholar] [CrossRef]

- Wang, X.Y.; Su, H.; Pan, T.; Liang, F.R.; Li, X.Y. Effect of surface cooling rate on section temperature field of ultra-heavy plate steel by ANSYS. Mater. Sci. Technol. 2013, 21, 49–54. [Google Scholar]

- Sun, X.J.; Yuan, S.F.; Xie, Z.J.; Dong, L.L.; Shang, C.J.; Misra, R.D.K. Microstructure-property relationship in a high strength-high toughness combination ultra-heavy gauge offshore plate steel: The significance of multiphase microstructure. Mater. Sci. Eng. A 2017, 689, 212–219. [Google Scholar] [CrossRef]

- Winning, M.; Rollett, A.D. Transition between low and high angle grain boundaries. Acta Mater. 2005, 53, 2901–2907. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, M.; Guo, Z.; Chen, N.; Rong, Y. A new effect of retained austenite on ductility enhancement in high-strength quenching–partitioning–tempering martensitic steel. Mater. Sci. Eng. A 2011, 528, 8486–8491. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef] [Green Version]

- Ungár, T.; Ott, S.; Sanders, P.G.; Borbély, A.; Weertman, J.R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 1998, 46, 3693–3699. [Google Scholar] [CrossRef]

- Shintani, T.; Murata, Y. Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 2011, 59, 4314–4322. [Google Scholar] [CrossRef]

- Renzetti, R.A.; Sandim, H.R.Z.; Bolmaro, R.E.; Suzuki, P.A.; Möslang, A. X-ray evaluation of dislocation density in ODS-Eurofer steel. Mater. Sci. Eng. A 2012, 534, 142–146. [Google Scholar] [CrossRef]

- Chen, J.; Li, C.; Ren, J.; Tu, X.; Chen, L. Strength and toughness of Fe-1.2Mn-0.3Cr-1.4Ni-0.4Mo-C tempered steel plate in three cooling processes. Mater. Sci. Eng. A 2019, 754, 178–189. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, W.; Wang, X.; Kang, J.; Yuan, G.; Di, H.; Misra, R.D.K. Effect of microstructure on the crack propagation behavior of microalloyed 560MPa (X80) strip during ultra-fast cooling. Mater. Sci. Eng. A 2016, 666, 214–224. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, D.; Qin, X.; Du, L.; Gao, X.; Wang, G. Simulation of central crack closing behavior during ultra-heavy plate rolling. Comput. Mater. Sci. 2009, 47, 439–447. [Google Scholar] [CrossRef]

- Hashemi, S.H. Apportion of Charpy energy in API 5L grade X70 pipeline steel. Int. J. Press. Vessels Pip. 2008, 85, 879–884. [Google Scholar] [CrossRef]

- Morito, S.; Igarashi, R.; Kamiya, K.; Ohba, T.; Maki, T. Effect of cooling rate on morphology and crystallography of lath martensite in Fe-Ni alloys. Mater. Sci. Forum 2010, 638–642, 1459–1463. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, Y.; Di, X.; Yu, L.; Yan, Z. Martensite transformation in the modified high Cr ferritic heat-resistant steel during continuous cooling. J. Mater. Res. 2012, 27, 2779–2789. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, F.; Li, C.; Lin, Y.; Cao, R. Effect of martensite structure and carbide precipitates on mechanical properties of Cr-Mo alloy steel with different cooling rate. High Temp. Mater. Process. 2019, 38, 113–124. [Google Scholar] [CrossRef]

- Yen, H.-W.; Chen, P.-Y.; Huang, C.-Y.; Yang, J.-R. Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. A 2006, 438–440, 237–240. [Google Scholar] [CrossRef]

- Kim, B.; Boucard, E.; Sourmail, T.; San Martín, D.; Gey, N.; Rivera-Díaz-del-Castillo, P.E.J. The influence of silicon in tempered martensite: Understanding the microstructure–properties relationship in 0.5–0.6wt.% C steels. Acta Mater. 2014, 68, 169–178. [Google Scholar] [CrossRef]

- Chauhan, A.; Bergner, F.; Etienne, A.; Aktaa, J.; de Carlan, Y.; Heintze, C.; Litvinov, D.; Hernandez-Mayoral, M.; Oñorbe, E.; Radiguet, B.; et al. Microstructure characterization and strengthening mechanisms of oxide dispersion strengthened (ODS) Fe-9%Cr and Fe-14%Cr extruded bars. J. Nucl. Mater. 2017, 495, 6–19. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Zhang, H.X.; Li, H.; Shen, H.P. Effect of tempering temperature on the microstructure and mechanical properties in mooring chain steel. Mater. Sci. Eng. A 2015, 636, 164–171. [Google Scholar] [CrossRef]

- Shibata, A.; Nagoshi, T.; Sone, M.; Morito, S.; Higo, Y. Evaluation of the block boundary and sub-block boundary strengths of ferrous lath martensite using a micro-bending test. Mater. Sci. Eng. A 2010, 527, 7538–7544. [Google Scholar] [CrossRef]

- HajyAkbary, F.; Sietsma, J.; Böttger, A.J.; Santofimia, M.J. An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures. Mater. Sci. Eng. A 2015, 639, 208–218. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.; Suikkanen, P.; Yang, J.-R.; Tsai, Y.-T. The effect of finish rolling temperature and tempering on the microstructure, mechanical properties and dislocation density of direct-quenched steel. Mater. Charact. 2018, 139, 1–10. [Google Scholar] [CrossRef]

- Wu, Y.X.; Sun, W.W.; Styles, M.J.; Arlazarov, A.; Hutchinson, C.R. Cementite coarsening during the tempering of Fe-C-Mn martensite. Acta Mater. 2018, 159, 209–224. [Google Scholar] [CrossRef]

- Wu, Y.X.; Sun, W.W.; Gao, X.; Styles, M.J.; Arlazarov, A.; Hutchinson, C.R. The effect of alloying elements on cementite coarsening during martensite tempering. Acta Mater. 2020, 183, 418–437. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | Cr | Mo | Cu | Nb | V | Al | B | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.12 | 0.23 | 1.06 | 2.50 | 0.50 | 0.50 | 0.26 | 0.02 | 0.03 | 0.05 | 0.0015 | Balance |

| Position | Rp0.2 (MPa) | Rm (MPa) | A (%) | Z (%) |

|---|---|---|---|---|

| Sub-surface | 782 | 852 | 20.0 | 75 |

| t/4 | 757 | 841 | 20.5 | 74 |

| t/2 | 750 | 830 | 18.0 | 70 |

| Position | Pm (kN) | Pf (kN) | Pa (kN) | Ecf | E3 (J) | E4 (J) | E5 (J) | |

|---|---|---|---|---|---|---|---|---|

| E1 (J) | E2 (J) | |||||||

| surface | 26.1 | 25.0 | 2.3 | 15.8 | 28.2 | 28.4 | 10.2 | 6.6 |

| t/4 | 25.0 | 24.0 | 9.2 | 14.3 | 25.9 | 29.1 | 17.5 | 13.2 |

| t/2 | 27.4 | 27.4 | 3.0 | 16.7 | 16.8 | 0 | 15.7 | 5.0 |

| Position | C | Si | Mn | Ni | Mo | Cu |

|---|---|---|---|---|---|---|

| sub-surface | 0.13 | 0.22 | 1.06 | 2.40 | 0.50 | 0.26 |

| t/4 | 0.14 | 0.23 | 1.08 | 2.40 | 0.51 | 0.26 |

| t/2 | 0.15 | 0.24 | 1.12 | 2.50 | 0.52 | 0.27 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Ye, Q.; Wang, Z.; Kan, L.; Wang, H. Thickness Effect on Microstructure, Strength, and Toughness of a Quenched and Tempered 178 mm Thickness Steel Plate. Metals 2020, 10, 572. https://doi.org/10.3390/met10050572

Wang Q, Ye Q, Wang Z, Kan L, Wang H. Thickness Effect on Microstructure, Strength, and Toughness of a Quenched and Tempered 178 mm Thickness Steel Plate. Metals. 2020; 10(5):572. https://doi.org/10.3390/met10050572

Chicago/Turabian StyleWang, Qinghai, Qibin Ye, Zhaodong Wang, Liye Kan, and Hongtao Wang. 2020. "Thickness Effect on Microstructure, Strength, and Toughness of a Quenched and Tempered 178 mm Thickness Steel Plate" Metals 10, no. 5: 572. https://doi.org/10.3390/met10050572