Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints

Abstract

:1. Introduction

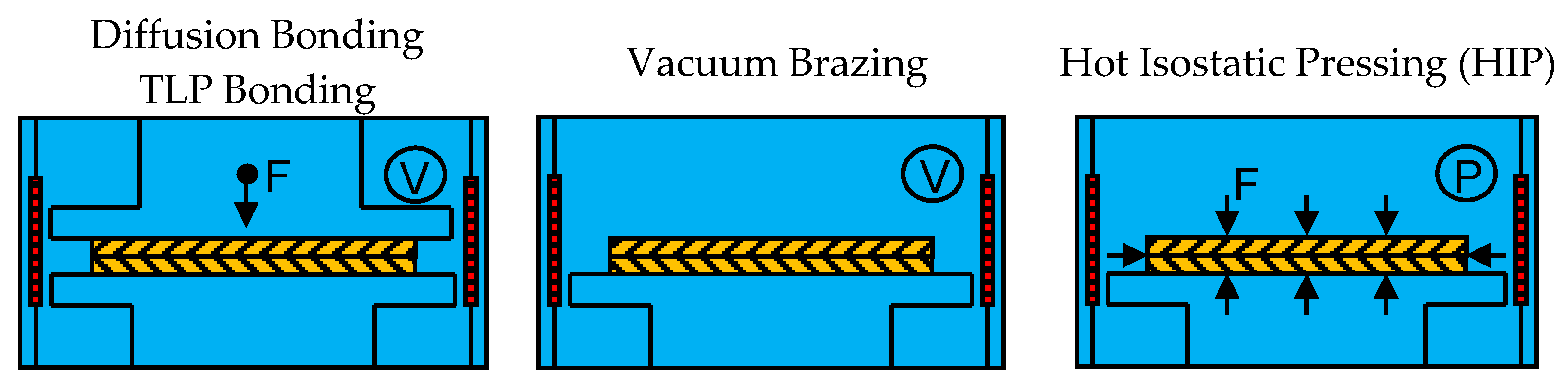

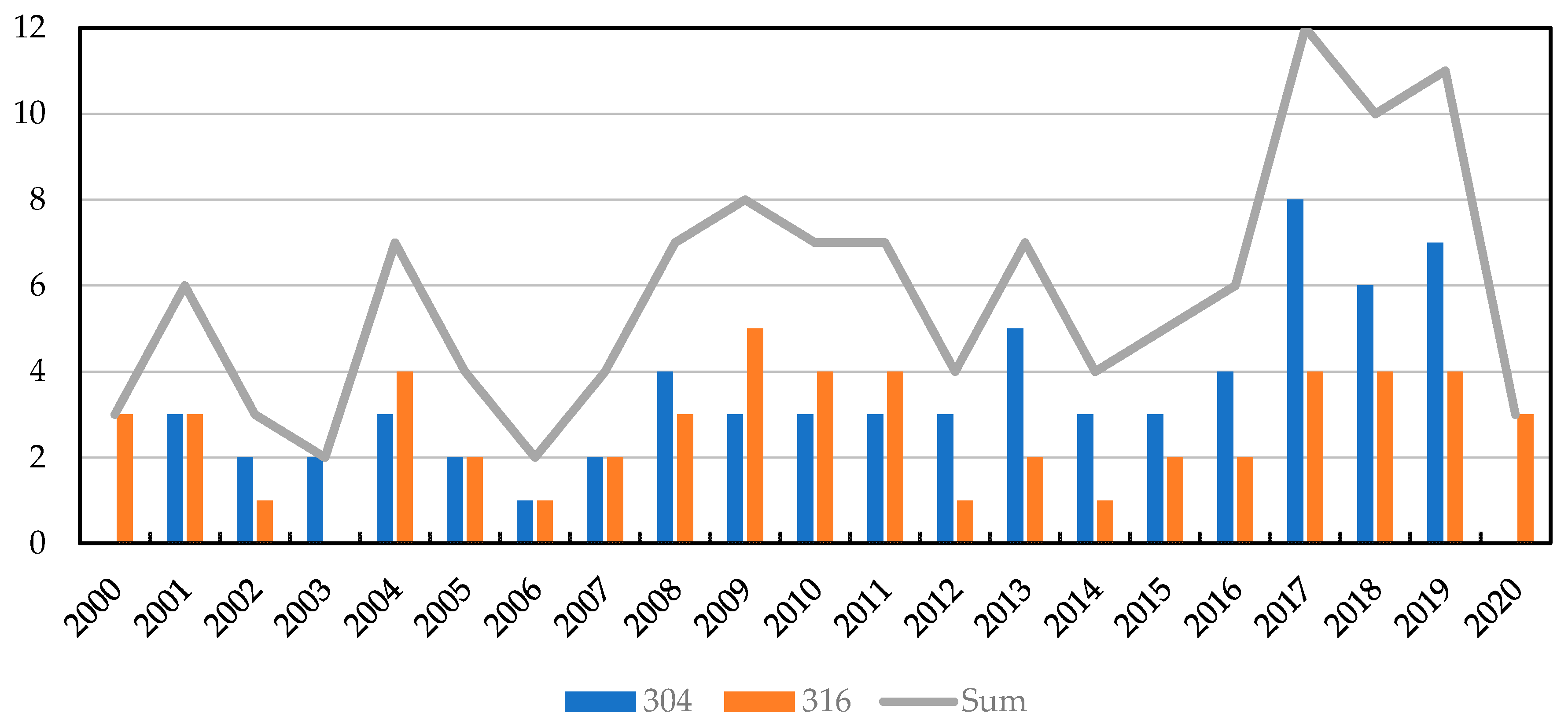

2. Materials and Methods

3. Results and Discussion

3.1. Diffusion Bonding and TLP Bonding of 304 (Similar Joints)

3.2. Diffusion Bonding and TLP Bonding of 316 (Similar Joints)

3.3. Diffusion Bonding and TLP Bonding of 304 and 316 to Commercially Pure Titanium (cpTi)

3.4. Diffusion Bonding and TLP Bonding of 304 and 316 to Ti-6Al-4V

3.5. Diffusion Bonding and TLP Bonding of 304 and 316 to Cu and CuZrCr

3.6. Diffusion Bonding and TLP Bonding of 304 and 316 to Zircaloy and Zr-Sn-Nb

3.7. Diffusion Bonding and TLP Bonding of 304 and 316 to Other Materials

3.8. Hot Isostatic Pressing (HIP) of 304 and 316 (Similar and Dissimilar Joints)

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Kazakov, N.F. Diffusion Bonding of Materials; Elsevier: Oxford, UK, 1985; ISBN 978-1483118130. [Google Scholar]

- Carlone, P.; Astarita, A. Dissimilar Metal Welding. Metals 2019, 9, 1206. [Google Scholar] [CrossRef] [Green Version]

- Kah, P.; Shrestha, M.; Martikainen, J. Trends in Joining Dissimilar Metals by Welding. Appl. Mech. Mater. 2014, 440, 269–276. [Google Scholar] [CrossRef]

- Song, G.; Li, T.; Yu, J.; Liu, L. A Review of Bonding Immiscible Mg/Steel. Materials 2018, 11, 2515. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gietzelt, T.; Toth, V.; Huell, A. Challenges of Diffusion Bonding of Different Classes of Stainless Steels. Adv. Eng. Mater. 2017, 20, 1700367. [Google Scholar] [CrossRef] [Green Version]

- Gietzelt, T.; Toth, V.; Huell, A.; Dittmeyer, R. Determining the Dependence of Deformation during Diffusion Welding on the Aspect Ratio Using Samples Made of SS 304 (1.4301). Adv. Eng. Mater. 2017, 19, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Cook, G.O.; Sorensen, C.D. Overview of transient liquid phase and partial transient liquid phase bonding. J. Mater. Sci. 2011, 46, 5305–5323. [Google Scholar] [CrossRef] [Green Version]

- Gale, W.; Butts, D. Transient liquid phase bonding. Sci. Technol. Weld. Join. 2004, 9, 283–300. [Google Scholar] [CrossRef]

- Shirzadi, A.A.; Assadi, H.; Wallach, E.R. Interface evolution and bond strength when diffusion bonding materials with stable oxide films. Surf. Interface Anal. 2001, 31, 609–618. [Google Scholar] [CrossRef]

- MacDonald, W.; Eagar, T. Transient liquid phase bonding. Annu. Rev. Mater. Sci. 1992, 22, 23–46. [Google Scholar] [CrossRef]

- Was, G.S.; Ukai, S. Austenitic Stainless Steels; Elsevier Inc: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-397046-6. [Google Scholar]

- Michler, T. Austenitic Stainless Steels. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 1–6. [Google Scholar] [CrossRef]

- Cobb, H.M. The History of Stainless Steel; ASM International: Cleveland, OH, USA, 2010; ISBN 9781615030118. [Google Scholar]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Cleveland, OH, USA, 2008; ISBN 978-0-87170-717-8. [Google Scholar]

- Campbell, F. Manufacturing Technology for Aerospance Structural Materials; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Lee, H.; Yoon, J.; Yoo, J. Manufacturing of Aerospace Parts with Diffusion Bonding Technology. Appl. Mech. Mater. 2011, 87, 182–185. [Google Scholar] [CrossRef]

- Simões, S. Diffusion Bonding and Brazing of Advanced Materials. Metals 2018, 8, 959. [Google Scholar] [CrossRef] [Green Version]

- Shin, J.; Yoon, S.H. Thermal and hydraulic performance of a printed circuit heat exchanger using two-phase nitrogen. Appl. Therm. Eng. 2020, 168, 114802. [Google Scholar] [CrossRef]

- Li, Q.; Flamant, G.; Yuan, X.; Neveu, P.; Luo, L. Compact heat exchangers: A review and future applications for a new generation of high temperature solar receivers. Renew. Sustain. Energy Rev. 2011, 15, 4855–4875. [Google Scholar] [CrossRef]

- Pra, F.; Tochon, P.; Mauget, C.; Fokkens, J.; Willemsen, S. Promising designs of compact heat exchangers for modular HTRs using the Brayton cycle. Nucl. Eng. Des. 2008, 238, 3160–3173. [Google Scholar] [CrossRef]

- Wilden, J.; Jahn, S.; Beck, W. Some examples of current diffusion bonding applications. Mater. Sci. Eng. Technol. 2008, 39, 349–352. [Google Scholar] [CrossRef]

- Mylavarapu, S.K.; Sun, X.; Christensen, R.N.; Unocic, R.R.; Glosup, R.E.; Patterson, M.W. Fabrication and design aspects of high-temperature compact diffusion bonded heat exchangers. Nucl. Eng. Des. 2012, 249, 49–56. [Google Scholar] [CrossRef]

- Chai, L.; Tassou, S.A. A review of printed circuit heat exchangers for helium and supercritical CO2 Brayton cycles. Therm. Sci. Eng. Prog. 2020, 18, 100543. [Google Scholar] [CrossRef]

- Brandner, J.J.; Anurjew, E.; Bohn, L.; Hansjosten, E.; Henning, T.; Schygulla, U.; Wenka, A.; Schubert, K. Concepts and realization of microstructure heat exchangers for enhanced heat transfer. Exp. Therm. Fluid Sci. 2006, 30, 801–809. [Google Scholar] [CrossRef]

- Sabharwall, P.; Clark, D.; Glazoff, M.; Zheng, G.; Sridharan, K.; Anderson, M. Advanced heat exchanger development for molten salts. Nucl. Eng. Des. 2014, 280, 42–56. [Google Scholar] [CrossRef]

- Rowcliff, A.; Zinkle, S.; Stubbins, J.; Edwards, D.; Alexander, D. Austenitic stainless steels and high strength copper alloys for fusion components. J. Nucl. Mater. 2008, 263, 183–192. [Google Scholar] [CrossRef]

- Ivanov, A.D.; Sato, S.; Marois, G. Le Evaluation of hot isostatic pressing for joining of fusion reactor structural components. J. Nucl. Mater. 2000, 287, 35–42. [Google Scholar] [CrossRef]

- Suri, A.; Krishnamurthy, N.; Batra, I. Materials issues in fusion reactors. J. Phys. Conf. Ser. 2010, 208, 012001. [Google Scholar] [CrossRef]

- Montemor, M.; Ferreira, M.; Hakiki, N.; Da Cunha Belo, M. Chemical composition and electronic structure of the oxide films formed on 316L stainless steel and nickel based alloys in high temperature aqueous environments. Corros. Sci. 2000, 42, 1635–1650. [Google Scholar] [CrossRef]

- Fang, Y.; Jiang, X.; Mo, D.; Zhu, D.; Luo, Z. A review on dissimilar metals’ welding methods and mechanisms with interlayer. Int. J. Adv. Manuf. Technol. 2019, 102, 2845–2863. [Google Scholar] [CrossRef]

- Cai, W.; Daehn, G.; Vivek, A.; Li, J.; Khan, H.; Mishra, R.; Komarasamy, M. A state-of-the-art review on solid-state metal joining. J. Manuf. Sci. Eng. 2018, 141, 031012. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P. Metallurgical Strategies for the Joining of Titanium Alloys with Steels. Adv. Eng. Mater. 2018, 20, 1700764. [Google Scholar] [CrossRef]

- Mo, D.; Song, T.; Fang, Y.; Jiang, X.; Luo, C.Q.; Simpson, M.D.; Luo, Z. A Review on Diffusion Bonding between Titanium Alloys and Stainless Steels. Adv. Mater. Sci. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- Gietzelt, T.; Toth, V.; Huell, A.; Messerschmidt, F.; Dittmeyer, R. Systematic investigation of the diffusion welding behavior of the austenitic stainless steel 304 (1.4301). Adv. Eng. Mater. 2014, 16, 1381–1390. [Google Scholar] [CrossRef]

- Lee, M.K.; Lee, J.G.; Choi, Y.H.; Kim, D.W.; Rhee, C.K.; Lee, Y.B.; Hong, S.J. Interlayer engineering for dissimilar bonding of titanium to stainless steel. Mater. Lett. 2010, 64, 1105–1108. [Google Scholar] [CrossRef]

- Moravec, J.; Novakova, I.; Kik, T. Possibilities of using interlayers during diffusion welding of Ti Gr2 and AISI 316L. MATEC Web Conf. 2018, 244, 1–8. [Google Scholar] [CrossRef]

- Shirzadi, A.A.; Zhu, Y.; Bhadeshia, H.K.D.H. Joining ceramics to metals using metallic foam. Mater. Sci. Eng. A 2008, 496, 501–506. [Google Scholar] [CrossRef] [Green Version]

- Özdemir, N.; Aksoy, M.; Orhan, N. Effect of graphite shape in vacuum-free diffusion bonding of nodular cast iron with gray cast iron. J. Mater. Process. Technol. 2003, 141, 228–233. [Google Scholar] [CrossRef]

- Kato, H.; Shibata, M.; Yoshikawa, K. Diffusion vvelding of Ti/Ti and Ti/stainless steel rods under phase transformation in air. Mater. Sci. Technol. 1986, 2, 405–409. [Google Scholar] [CrossRef]

- Calderon, P.; Walmsley, D.; Munir, Z. An Investigation of Diffusion Welding of Pure and Alloyed Aluminum to Type 316 Stainless Steel. Weld. J. 1985, 64, 104–114. [Google Scholar]

- Cox, M.J.; Kim, M.J.; Carpenter, R.W. Interface Nanochemistry Effects on Stainless Steel Diffusion Bonding. Metall. Mater. Trans. A 2002, 33, 437–442. [Google Scholar] [CrossRef]

- Song, T.F.; Jiang, X.S.; Shao, Z.Y.; Fang, Y.J.; Mo, D.F.; Zhu, D.G.; Zhu, M.H. Microstructure and mechanical properties of vacuum diffusion bonded joints between Ti-6Al-4V titanium alloy and AISI316L stainless steel using Cu/Nb multi-interlayer. Vacuum 2017, 145, 68–76. [Google Scholar] [CrossRef]

- Shirzadi, A.A.; Wallach, E.R. Analytical Modeling of transient liquid phase (TLP) diffusion bonding when a temperature gradient is imposed. Acta Metall. 1999, 47, 3551–3560. [Google Scholar]

- Shirzadi, A.A.; Wallach, E.R. Metal Bonding. US Patent 6,257,481 B1, 10 July 2001. [Google Scholar]

- Shirzadi, A.A.; Wallach, E.R. Temperature gradient transient liquid phase diffusion bonding: A new method for joining advanced materials. Sci. Technol. Weld. Join. 1997, 2, 89–94. [Google Scholar] [CrossRef]

- Sheng, G.M. An experimental investigation of phase transformation superplastic diffusion bonding of titanium alloy to stainless steel. J. Mater. Sci. 2005, 40, 6385–6390. [Google Scholar] [CrossRef]

- Sharma, G.; Tiwari, L.; Kumar, D. Impulse Pressure Assisted Diffusion Bonding of Low Carbon Steel Using Silver Interlayer. Trans. Indian Inst. Met. 2018, 71, 11–21. [Google Scholar] [CrossRef]

- Sharma, G.; Dwivedi, D.K. Impulse pressure-assisted diffusion bonding of ferritic stainless steel. Int. J. Adv. Manuf. Technol. 2018, 95, 4293–4305. [Google Scholar] [CrossRef]

- Wang, F.; Sheng, G.; Deng, Y.-Q. Impulse pressuring diffusion bonding of titanium to 304 stainless steel using pure Ni interlayer. Rare Met. 2014, 35, 331–336. [Google Scholar] [CrossRef]

- Yuan, X.; Tang, K.; Deng, Y.; Luo, J.; Sheng, G. Impulse pressuring diffusion bonding of a copper alloy to a stainless steel with/without a pure nickel interlayer. Mater. Des. 2013, 52, 359–366. [Google Scholar] [CrossRef]

- Yuan, X.J.; Sheng, G.M.; Qin, B.; Huang, W.Z.; Zhou, B. Impulse pressuring diffusion bonding of titanium alloy to stainless steel. Mater. Charact. 2008, 59, 930–936. [Google Scholar] [CrossRef]

- Han, J.; Sheng, G.M.; Zhou, X.L.; Sun, J.X. Pulse Pressuring Diffusion Bonding of Ti Alloy/Austenite Stainless Steel Processed by Surface Self-nanocrystallization. ISIJ Int. 2009, 49, 86–91. [Google Scholar] [CrossRef]

- Huang, L.; Sheng, G.; Li, J.; Huang, G.; Yuan, X. Partial transient-liquid-phase bonding of TiC cermet to stainless steel using impulse pressuring with Ti/Cu/Nb interlayer. J. Cent. South Univ. 2018, 25, 1025–1032. [Google Scholar] [CrossRef]

- Jia, L.; Guangmin, S. Diffusion Bonding of TiC Cermet to Stainless Steel Using Impulse Pressuring with Ti-Nb Interlayer. Rare Met. Mater. Eng. 2017, 46, 882–887. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Sheng, G.; Tang, K. Effect of interlayer type on microstructure and mechanical property of impulse pressuring diffusion bonded joints in austenitic stainless steel to α titanium alloy. Mater. Res. Innov. 2013, 17, 186–189. [Google Scholar] [CrossRef]

- Yuan, X.; Sheng, G.; Luo, J.; Li, J. Microstructural characteristics of joint region during diffusion-brazing of magnesium alloy and stainless steel using pure copper interlayer. Trans. Nonferrous Met. Soc. China 2013, 23, 599–604. [Google Scholar] [CrossRef]

- Akhter, J.I.; Ahmad, M.; Iqbal, M.; Akhtar, M.; Shaikh, M.A. Formation of dendritic structure in the diffusion zone of the bonded Zircaloy-4 and stainless steel 316L in the presence of Ti interlayer. J. Alloys Compd. 2005, 399, 96–100. [Google Scholar] [CrossRef]

- Akhter, J.I.; Ahmad, M.; Ali, G. Diffusion bonding of Ti coated Zircaloy-4 and 316-L stainless steel. Mater. Charact. 2009, 60, 193–196. [Google Scholar] [CrossRef]

- Munis, A.; Zheng, M.; Akhter, J.; Ahmad, M. Characterization of Bonded Zone and Evaluation of Cracking in Vacuum Brazed Zircaloy-4 and Stainless Steel 316L Joint. Arch. Met. Mater. 2019, 64, 707–713. [Google Scholar]

- Mukherjee, A.B.; Laik, A.; Kain, V.; Chakravartty, J.K. Shrinkage-Stress Assisted Diffusion Bonds Between Titanium and Stainless Steel: A Novel Technique. J. Mater. Eng. Perform. 2016, 25, 4425–4436. [Google Scholar] [CrossRef]

- Kang, S.; Chen, Y.; Liu, H. Brazing diffusion bonding of micro-nickel cylinders and SUS-316 stainless steel. J. Mater. Process. Technol. 2005, 168, 286–290. [Google Scholar] [CrossRef]

- Kale, G.B.; Patil, R.V.; Gawade, P.S. Interdiffusion studies in titanium-304 stainless steel system. J. Nucl. Mater. 1998, 257, 44–50. [Google Scholar] [CrossRef]

- Salmaliyan, M.; Shamanian, M. Formation mechanism of intermetallic components during dissimilar diffusion bonding of IN718/BNi-2/AISI 316L by TLP process. Heat Mass Transf. 2019, 55, 2083–2093. [Google Scholar] [CrossRef]

- Ganesan, V.; Seetharaman, V.; Raghunathan, V.S. Interdiffusion in the type 316 austenitic stainless steel/iron. J. Nucl. Mater. 1983, 118, 313–319. [Google Scholar] [CrossRef]

- Deqing, W.; Ziyuan, S.; Ruobin, Q. Cladding of stainless steel on aluminum and carbon steel by interlayer diffusion bonding. Scr. Mater. 2007, 56, 369–372. [Google Scholar] [CrossRef]

- Harumoto, T.; Ohashi, O.; Tsushima, H.; Narui, M.; Aihara, K.; Ishiguro, T. Thermal Stress-Based Diffusion Bonding Method: The Case of Oxygen Free Copper to 316L Stainless Steel. Mater. Trans. 2015, 56, 1683–1687. [Google Scholar] [CrossRef] [Green Version]

- Ghaderi, S.; Karimzadeh, F.; Ashra, A. Evaluation of microstructure and mechanical properties of transient liquid phase bonding of Inconel 718 and nano/ultrafine-grained 304L stainless steel. J. Manuf. Process. 2020, 49, 162–174. [Google Scholar] [CrossRef]

- Reuven, R.; Bolind, A.; Haneklaus, N.; Andreades, C.; Cionea, C.; Buster, G.; Hosemann, P.; Peterson, P. Ni Interlayer to Improve Low-Pressure Diffusion Bonding of 316L SS Press Fit Tube-to-Tubesheet Joints for Coiled Tube Gas Heaters. J. Nucl. Eng. Radiat. Sci. 2017, 3, 1–6. [Google Scholar] [CrossRef]

- Haneklaus, N.; Reuven, R.; Cionea, C.; Hosemann, P.; Peterson, P.F. Tube expansion and diffusion bonding of 316L stainless steel tube-to-tube sheet joints using a commercial roller tube expander. J. Mater. Process. Tech. 2016, 234, 27–32. [Google Scholar] [CrossRef] [Green Version]

- Haneklaus, N.; Reuven, R.; Cionea, C.; Hosemann, P.; Peterson, P.F. Development of engineering parameters for low pressure diffusion bonds of 316 SS tube-to-tube sheet joints for fhr heat exchangers. In TMS 2016 145th Annual Meeting & Exhibition; Springer: Cham, Switzerland, 2016; pp. 583–588. [Google Scholar]

- Shiue, R.; Chen, C.; Wu, S. Memory Alloy and 316L Stainless Steel with Two Sliver-Based Fillers. Metall. Mater. Trans. A 2015, 46, 2364–2371. [Google Scholar] [CrossRef]

- Dong, H.; Yang, Z.; Wang, Z.; Deng, D.; Dong, C. Vacuum Brazing TC4 Titanium Alloy to 304 Stainless Steel with Cu-Ti-Ni-Zr-V Amorphous Alloy Foil. J. Mater. Eng. Perform. 2014, 23, 3770–3777. [Google Scholar] [CrossRef]

- Shafiei, A.; Abachi, P.; Dehghani, K.; Pourazarang, K. On the Formation of Intermetallics during the Furnace Brazing of Pure Titanium to 304 Stainless Steel Using Ag ( 30–50%)–Cu Filler Metals. Mater. Manuf. Process. 2010, 25, 37–41. [Google Scholar] [CrossRef]

- Hdz-Garcia, H.; Martinez, A.; Munoz-Arroyo, R.; Acevedo-Davila, J.; Garcia-Vazquez, F.; Reyes-Valdes, F. Effects of Silicon Nanoparticles on the Transient Liquid Phase Bonding of 304 Stainless Steel. J. Mater. Sci. Technol. 2014, 30, 259–262. [Google Scholar] [CrossRef]

- Eluri, R.; Paul, B. Hermetic joining of 316L stainless steel using a patterned nickel nanoparticle interlayer. J. Manuf. Process. 2012, 14, 471–477. [Google Scholar] [CrossRef]

- Chung, T.; Kim, J.; Bang, J.; Rhee, B.; Nam, D. Microstructures of brazing zone between titanium alloy and stainless steel using various filler metals. Trans. Nonferrous Met. Soc. China 2012, 22, S639–S644. [Google Scholar] [CrossRef]

- Abed, A.; Jalham, I.S.; Hendry, A. Wetting and reaction between sialon, stainless steel and Cu-Ag brazing alloys containing Ti. J. Eur. Ceram. Soc. 2001, 21, 283–290. [Google Scholar] [CrossRef]

- González-Sánchez, J.; Verduzco, J.; Lemus-Ruiz, J.; Téllez, M.; Torres, A.; Torres, R. Corrosion resistance of stainless steel joints bonded with a Ni-based amorphous interlayer. Anti Corros. Methods Mater. 2007, 54, 68–73. [Google Scholar] [CrossRef]

- Verduzco, J.A.; González-sánchez, J.; Verduzco, V.H.; Solís, J.; Lemus-ruiz, J. Journal of Materials Processing Technology Microstructure and electrochemical properties of the bonding zone of AISI 316L steel joined with a Fe-based amorphous foil. J. Mater. Process. Technol. 2010, 210, 1051–1060. [Google Scholar] [CrossRef]

- Tashi, R.S.; Mousavi, S.A.A.A.; Atabaki, M.M. Diffusion brazing of Ti–6Al–4V and austenitic stainless steel using silver-based interlayer. Mater. Des. 2014, 54, 161–167. [Google Scholar] [CrossRef]

- Bajgholi, M.E.; Tashi, R.S.; Mousavi, A.A.A.; Dehkordi, E.H. An Investigation on Metallurgical and Mechanical Properties of Vacuum Brazed Ti-6Al-4V to 316L Stainless Steel Using Zr-Based Filler Metal. J. Adv. Mater. Process. 2013, 1, 47–54. [Google Scholar]

- Lee, S.; Kang, K.-H.; Hong, H.S.; Yun, Y. Microstructure and Interfacial Morphologies of Brazed NiO-YSZ/316 stainless steel using B-Ni2 brazing alloy. Mater. Test. Join. Technol. 2010, 52, 257–262. [Google Scholar] [CrossRef]

- Paiva, O.C.; Barbosa, M.A. Microstructure, mechanical properties and chemical degradation of brazed AISI 316 stainless steel/alumina systems. Mater. Sci. Eng. A 2008, 480, 306–315. [Google Scholar] [CrossRef] [Green Version]

- Kale, G.B.; Bhanumurthy, K.; Ratnakala, K.C.; Khera, S.K. Solid State Bonding of Zircaloy-2 with Stainless Steel. J. Nucl. Mater. 1986, 138, 73–80. [Google Scholar] [CrossRef]

- Lugscheider, E.; Partz, K.D.; Lison, R. Thermal and Metallurgical Influences on AISI 316 and Inconel 625 by High Temperature Brazing with Nickel Base Filler Metals. Weld. Res. Suppl. 1982, 61, 329–333. [Google Scholar]

- Kumar, A.; Ganesh, P.; Kaul, R.; Bhatnagar, V.K.; Yedle, K.; Sankar, P.R.; Sindal, B.K.; Kumar, K.; Singh, M.K.; Rai, S.K.; et al. A New Vacuum Brazing Route for Niobium-316L Stainless Steel Transition Joints for Superconducting RF Cavities. J. Mater. Eng. Perform. 2015, 24, 952–963. [Google Scholar] [CrossRef]

- Yue, X.; He, P.; Feng, J.C.; Zhang, J.H.; Zhu, F.Q. Microstructure and interfacial reactions of vacuum brazing titanium alloy to stainless steel using an AgCuTi filler metal. Mater. Charact. 2008, 59, 1721–1727. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Hao, X.; Li, P.; Li, S. Vacuum brazing of Ti6Al4V alloy to 316L stainless steel using a Ti-Cu-based amorphous fi ller metal. J. Mater. Process. Tech. 2019, 269, 35–44. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Zhang, R.; Wang, Y.; Hao, X.; Li, P.; Dong, C. Interfacial microstructure and shear strength of Ti6Al4V alloy/316 L stainless steel joint brazed with Ti33.3Zr16.7Cu50−x Nix amorphous filler metals. Mater. Des. 2020, 187, 108380. [Google Scholar] [CrossRef]

- Xia, Y.; Li, P.; Hao, X.; Dong, H. Interfacial microstructure and mechanical property of TC4 titanium alloy/316L stainless steel joint brazed with Ti-Zr-Cu-Ni-V amorphous fi ller metal. J. Manuf. Process. 2018, 35, 382–395. [Google Scholar] [CrossRef]

- Roos, A.; Winkler, M.; Wimmer, G.; Dos Santos, J.F.; Hanke, S. New Approach on Solid State Joining of Stainless Steel Tube to Tube Sheet Joints. In ASME 2017 Pressure Vessels and Piping Conference; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2017; pp. 1–8. [Google Scholar]

- Haneklaus, N.; Cionea, C.; Reuven, R.; Frazer, D.; Hosemann, P.; Peterson, P.F. Hybrid friction diffusion bonding of 316L stainless steel tube-to-tube sheet joints for coil-wound heat exchangers. J. Mech. Sci. Technol. 2016, 30, 4925–4930. [Google Scholar] [CrossRef]

- Esmaeilzadeh, R.; Salimi, M.; Zamani, C.; Hadian, A.M.; Hadian, A. Effects of milling time and temperature on phase evolution of AISI 316 stainless steel powder and subsequent sintering. J. Alloys Compd. 2018, 766, 341–348. [Google Scholar] [CrossRef]

- Safarian, A.; Suba, M.; Karata, Ç. The effect of sintering parameters on diffusion bonding of 316L stainless steel in inserted metal injection molding. Int. J. Adv. Manuf. Technol. 2016, 89, 2165–2173. [Google Scholar] [CrossRef]

- Sahli, M.; Lebied, A.; Gelin, J.; Barrière, T.; Necib, B. Numerical simulation and experimental analysis of solid-state sintering response of 316 L stainless steel micro-parts manufactured by metal injection molding. Int. J. Adv. Manuf. Technol. 2015, 79, 2079–2092. [Google Scholar] [CrossRef] [Green Version]

- Qin, L.; Hu, J.; Cui, C.; Wang, H.; Guo, Z. Reaction sintering and joining nickel aluminide to AISI 316 stainless steel by self-propagating high temperature synthesis. Mater. Sci. Technol. 2009, 25, 1364–1368. [Google Scholar] [CrossRef]

- Gal, C.W.; Han, S.S.; Han, J.S.; Lin, D.; Park, S.J. Investigation on Stainless steel 316L/Zirconia Joint Part fabricated by Powder Injection Molding. Appl. Ceram. Technol. 2019, 16, 315–323. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.; Zhao, J.; Huang, Z.; Chang, L.; Zhou, H.; Jiang, Z. Analysis of sintering and bonding of ultra fine WC powder and stainless steel by hot compaction diffusion bonding. Fusion Eng. Des. 2018, 133, 39–50. [Google Scholar] [CrossRef]

- Verma, D.; Singh, J.; Varma, A.H.; Tomar, V. Evaluation of Incoherent Interface Strength of Solid-State- Bonded Ti64/Stainless Steel Under Dynamic Impact Loading. JOM 2015, 67, 1694–1703. [Google Scholar] [CrossRef]

- Firouzdor, V.; Simchi, A.; Kokabi, A. An investigation of the densification and microstructural evolution of M2/316L stepwise graded composite during co-sintering. J. Mater. Sci. 2008, 43, 55–63. [Google Scholar] [CrossRef]

- Park, D.Y.; Lee, S.W.; Park, S.J.; Kwon, Y. Effects of Particle Sizes on Sintering Behavior of 316L Stainless Steel Powder. Metall. Mater. Trans. A 2013, 44, 1508–1518. [Google Scholar] [CrossRef] [Green Version]

- Jeon, B.; Sohn, S.H.O.; Lee, W.; Han, C.; Kim, Y.D.O.; Choi, H. Double step sintering behavior of 316L nanoparticle dispersed micro-sphere powder. Arch. Metall. Mater. 2015, 60, 11–14. [Google Scholar] [CrossRef] [Green Version]

- Gawde, P.S.; Kishore, R.; Pappachan, A.L.; Kale, G.B.; Dey, G.K. Low temperature diffusion bonding of stainless steel. Trans. Indian Inst. Met. 2010, 63, 853–857. [Google Scholar] [CrossRef]

- Lamjiri, R.J.; Ekrami, A. Transient Liquid Diffusion Bonding of AISI304 Stainless Steel with a Nickel Base Interlayer. Defect Diffus. Forum 2017, 380, 48–54. [Google Scholar] [CrossRef]

- Kazazi, A.; Ekrami, A. Corrosion behavior of TLP bonded stainless steel 304 with Ni-based interlayer. J. Manuf. Process. 2019, 42, 131–138. [Google Scholar] [CrossRef]

- Sadeghian, M.; Ekrami, A.; Jamshidi, R. Transient liquid phase bonding of 304 stainless steel using a Co-based interlayer. Sci. Technol. Weld. Join. 2017, 22, 666–672. [Google Scholar] [CrossRef]

- Atabaki, M.; Wati, J.; Idris, J. Transient liquid phase diffusion bonding of stainless steel 304. Met. Mater. Eng. 2012, 18, 177–186. [Google Scholar]

- Ohashi, O.; Kaieda, Y. Hot isostatic pressing of diffusion bonds in SUS 304 stainless steel. Weld. Int. 1990, 4, 35–41. [Google Scholar] [CrossRef]

- Gietzelt, T.; Toth, V.; Huell, A. Diffusion Bonding: Influence of Process Parameters and Material Microstructure. Join. Technol. 2016. [Google Scholar] [CrossRef] [Green Version]

- Ogawa, K.; Azuma, S. Intergranular corrosion resistance of stainless steel diffusion-bonded joints with B-containing amorphous insert metal. Weld. Int. 1995, 9, 440–445. [Google Scholar] [CrossRef]

- Harumoto, T.; Yamashita, Y.; Ohashi, O.; Ishiguro, T. Influence of Cold Rolling on Diffusion Bondability of SUS316L Stainless Steel Sheets. Mater. Trans. 2014, 55, 633–636. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Xuan, F.; Tu, S. In situ observation of interfacial fatigue crack growth in diffusion bonded joints of austenitic stainless steel. J. Nucl. Mater. 2007, 366, 1–7. [Google Scholar] [CrossRef]

- Yeh, M.S.; Chuang, T.H. Low-pressure diffusion bonding of SAE 316 stainless steel by inserting a superplastic interlayer. Scr. Metall. Mater. 1995, 33, 1277–1281. [Google Scholar] [CrossRef]

- Li, S.; Xuan, F.; Tu, S.; Yu, S. Microstructure evolution and interfacial failure mechanism in 316LSS diffusion-bonded joints. Mater. Sci. Eng. A 2008, 491, 488–491. [Google Scholar] [CrossRef]

- Mateus, L.B.; George, G.; Nuernberg, V.; Henriques, M.; Mantelli, B. 316L Stainless Steel Diffusion Bonding Optimized Parameters. In Proceedings of the COBEM 2017, Curitiba, Brazil, 3–8 December 2017. [Google Scholar]

- Shirzadi, A.A.; Kocak, M.; Wallach, E.R. Joining stainless steel metal foams. Sci. Technol. Weld. Join. 2004, 9, 277–279. [Google Scholar] [CrossRef]

- Martin, P.; Matson, D.; Bennett, W. Microfabrication Methods for Microchannel Reactors and Separations Systems. Chem. Eng. Commun. 1999, 173, 245–254. [Google Scholar] [CrossRef]

- Yusa, N.; Hashizume, H. Fabrication of imitative stress corrosion cracking specimen using lithography and solid state bonding. Int. J. Appl. Electromagn. Mech. 2012, 39, 291–296. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, S.; Paul, B. Application of Nickel Nanoparticles in Diffusion Bonding of Stainless Steel Surfaces. In Proceedings of the MSEC2008, Evanston, IL, USA, 7–10 October 2008; pp. 1–6. [Google Scholar]

- Tiwari, S.; Paul, B. Comparison of Nickel Nanoparticle-Assisted Diffusion Brazing of Stainless Steel to Conventional Diffusion Brazing and Bonding Processes. J. Manuf. Sci. Eng. 2010, 132, 1–5. [Google Scholar] [CrossRef]

- Kim, S.H.; Cha, J.-H.; Jang, C.; Sah, I. Microstructure and Tensile Properties of Diffusion Bonded Austenitic Fe-Base Alloys—Before and After Exposure to High Temperature Supercritical-CO2. Metals 2020, 10, 480. [Google Scholar] [CrossRef] [Green Version]

- An, Z.; Luan, W.; Xuan, F.; Tu, S. High Temperature Performance of 316L-SS Joint Produced by Diffusion Bonding. Key Eng. Mater. 2005, 300, 2795–2799. [Google Scholar] [CrossRef]

- Crockett, M.; Lane, J.W.; Kirchhoff, V.; Josephson, M.E.; Gao, H.P.; Manjunath, B. Method of Diffusion Bonding a fluid flow apparatus. US Patent 7,798,388 B2, 21 September 2010. [Google Scholar]

- Li, S.; Li, L.; Yu, S.; Akid, R.; Xia, H. Investigation of intergranular corrosion of 316L stainless steel diffusion bonded joint by electrochemical potentiokinetic reactivation. Corros. Sci. 2011, 53, 99–104. [Google Scholar] [CrossRef]

- Li, S.; Xuan, F.; Tu, S. Fatigue damage of stainless steel diffusion-bonded joints. Mater. Sci. Eng. A 2008, 480, 125–129. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 14–34. [Google Scholar]

- Kundu, S.; Chatterjee, S. Interface microstructure and strength properties of diffusion bonded joints of titanium-Al interlayer-18Cr-8Ni stainless steel. Mater. Sci. Eng. A 2010, 527, 2714–2719. [Google Scholar] [CrossRef]

- Yang, G.; Ma, D.; Liu, L.; Rong, J.; Yu, X. Thermal Diffusion Bonding of Pure Titanium to 304 Stainless Steel Using Aluminum Interlayer. Chem. Eng. Trans. 2017, 59, 1045–1050. [Google Scholar]

- Bhanumurthy, K.; Kale, G. Reactive diffusion between titanium and stainless steel. J. Mater. Sci. Lett. 1993, 12, 1879–1881. [Google Scholar] [CrossRef]

- Ananthakumar, K.; Kumaran, S. Experimental Investigation and Prediction of Optimum Process Parameter for Plasma Assisted Diffusion Bonding of Commercial Pure Titanium and Austenitic Stainless Steel. Arab. J. Sci. Eng. 2019, 44, 1017–1032. [Google Scholar] [CrossRef]

- Alemán, B.; Gutiérrez, L.; Urcola, J. Interface microstructures in diffusion bonding of titanium alloys to stainless and lovvalloy steels. Mater. Sci. Technol. 1993, 9, 633–641. [Google Scholar] [CrossRef]

- Ghosh, M.; Laik, A.; Bhanumurthy, K.; Kale, G.B.; Krishnan, J.; Chatterjee, S. Evolution of interface microstructure and strength properties in titanium-Stainless steel diffusion bonded transition joints. Mater. Sci. Technol. Dec. 2004, 20, 1578–1584. [Google Scholar] [CrossRef]

- Shirzadi, A.A.; Laik, A.; Tewari, R.; Orsborn, J.; Dey, G.K. Materialia Gallium-assisted diffusion bonding of stainless steel to titanium; microstructural evolution and bond strength. Materialia 2018, 4, 115–126. [Google Scholar] [CrossRef]

- Deng, Y.; Sheng, G.; Xu, C. Evaluation of the microstructure and mechanical properties of diffusion bonded joints of titanium to stainless steel with a pure silver interlayer. Mater. Des. 2013, 46, 84–87. [Google Scholar] [CrossRef]

- Deng, Y.Q.; Sheng, G.M.; Huang, Z.H.; Fan, L.Z. Microstructure and mechanical properties of diffusion bonded titanium/304 stainless steel joint with pure Ag interlayer. Sci. Technol. Weld. Join. 2013, 18, 143–147. [Google Scholar] [CrossRef]

- Jie, W.; Yang, F.; Hao, L.; Jin, Y.; Haotian, Y.; Fuqi, Z. Microstructure and mechanical properties of TC4/0Cr18Ni9 joint prepared by transient liquid phase diffusion bonding. Mater. Res. Express 2019, 6, 1065d6. [Google Scholar] [CrossRef]

- Ghosh, M.; Bhanumurthy, K.; Kale, G.B. Diffusion bonding of titanium to 304 stainless steel. J. Nucl. Mater. 2003, 322, 235–241. [Google Scholar] [CrossRef]

- Li, J.; Huo, L.; Zhang, F.; Xiong, J.; Li, W. Fracture Characteristics of Vacuum Diffusion Bonded TA2 Titanium to 1Cr18Ni9Ti Stainless Steel Joint with Nb + Ni Interlayers. Mater. Sci. Forum 2009, 622, 399–402. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Evolution of Interface Microstructure and Mechanical Properties of Titanium/304 Stainless Steel Diffusion Bonded Joint Using Nb Interlayer. ISIJ Int. 2010, 50, 1460–1465. [Google Scholar] [CrossRef] [Green Version]

- Szwed, B.; Konieczny, M. Structural changes during the formation of diffusion bonded joints between titanium and stainless steel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012082. [Google Scholar] [CrossRef]

- Szwed, B.; Konieczny, M. Microstructure and Mechanical Properties of Joints of Titanium with Stainless Steel Performed using Nickel Filler. Arch. Met. Mater. 2016, 61, 997–1001. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Interfacial microstructure and mechanical properties of diffusion-bonded titanium-stainless steel joints using a nickel interlayer. Mater. Sci. Eng. A 2006, 425, 107–113. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Effect of Reaction Products on Mechanical Properties of Diffusion Bonded of Titanium to 304 Stainless Steel with Cu Interlayer Joints. Trans. Indian Inst. Met. 2008, 61, 457–464. [Google Scholar] [CrossRef]

- Kundu, S.; Ghosh, M.; Laik, A.; Bhanumurthy, K.; Kale, G.B.; Chatterjee, S. Diffusion bonding of commercially pure titanium to 304 stainless steel using copper interlayer. Mater. Sci. Eng. A 2005, 407, 154–160. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Effects of temperature on interface microstructure and strength properties of titanium-Niobium stainless steel diffusion bonded joints. Mater. Sci. Technol. 2011, 27, 1177–1182. [Google Scholar] [CrossRef]

- Akbar, A.; Mahdi, B.; Aluwi, A. Characterization of Diffusion Bonding of Stainless Steel AISI 316 and Pure Titanium sheets Using Copper Interlayer. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 032041. [Google Scholar] [CrossRef]

- Ghosh, M.; Kundu, S.; Chatterjee, S.; Mishra, B. Influence of Interface Microstructure on the Strength of the Transition Joint between Ti-6Al-4V and Stainless Steel. Metall. Mater. Trans. A 2005, 36, 1891–1899. [Google Scholar] [CrossRef]

- Chandrappa, K.; Kumar, A.; Shubham, K. Diffusion bonding of a titanium alloy to a stainless steel with an aluminium alloy interlayer. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012124. [Google Scholar] [CrossRef]

- Alhazaa, A.; Khan, T.I.; Haq, I. Transient liquid phase (TLP) bonding of Al7075 to Ti-6Al-4V alloy. Mater. Charact. 2010, 61, 312–317. [Google Scholar] [CrossRef]

- Alhazaa, A.N.; Khan, T.I. Diffusion bonding of Al7075 to Ti-6Al-4V using Cu coatings and Sn-3. 6Ag-1Cu interlayers. J. Alloys Compd. 2010, 494, 351–358. [Google Scholar] [CrossRef]

- He, P.; Yue, X.; Zhang, J.H. Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater. Sci. Eng. A 2008, 486, 171–176. [Google Scholar] [CrossRef]

- Habisch, S.; Peter, S.; Grund, T.; Mayr, P. The Effect of Interlayer Materials on the Joint Properties of Diffusion-Bonded Aluminium and Magnesium. Metals 2018, 8, 138. [Google Scholar] [CrossRef] [Green Version]

- Thirunavukarasu, G.; Kundu, S.; Mishra, B. Effect of Bonding Temperature on Interfacial Reaction and Mechanical Properties of Diffusion-Bonded Joint Between Ti-6Al-4V and 304 Stainless Steel Using Nickel as an Intermediate Material. Metall. Mater. Trans. A 2014, 45, 2067–2077. [Google Scholar] [CrossRef]

- Balasubramanian, M. Application of Box-Behnken design for fabrication of titanium alloy and 304 stainless steel joints with silver interlayer by diffusion bonding. Mater. Des. 2015, 77, 161–169. [Google Scholar] [CrossRef]

- Balasubramanian, M. Characterization of diffusion-bonded titanium alloy and 304 stainless steel with Ag as an interlayer. Int. J. Adv. Manuf. Technol. 2016, 82, 153–162. [Google Scholar] [CrossRef]

- He, P.; Zhang, J.; Li, X. Diffusion bonding of titanium alloy to stainless steel wire mesh. Mater. Sci. Technol. 2001, 17, 1158–1162. [Google Scholar] [CrossRef]

- Thirunavukarasu, G.; Kundu, S.; Laha, T.; Roy, D.; Chatterjee, S. Exhibition of veiled features in diffusion bonding of titanium alloy and stainless steel via copper. Metall. Res. Technol. 2018, 115, 115. [Google Scholar] [CrossRef]

- Balasubramanian, M. Development of processing windows for diffusion bonding of Ti-6Al-4V titanium alloy and 304 stainless steel with silver as intermediate layer. Trans. Nonferrous Met. Soc. China 2015, 25, 2932–2938. [Google Scholar] [CrossRef]

- Özdemir, N.; Bilgin, B. Interfacial properties of diffusion bonded Ti-6Al-4V to AISI 304 stainless steel by inserting a Cu interlayer. Int. J. Adv. Manuf. Technol. 2009, 41, 519–526. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, X.; Sun, H.; Song, T.; Mo, D.; Li, X.; Luo, Z. Interfacial reaction and microstructure investigation of TC4/V/Cu/Co/316L diffusion-bonded joints. Mater. Lett. 2020, 261, 127140. [Google Scholar] [CrossRef]

- Kurt, B.; Orhan, N.; Kaya, M. Interface characterisation of diffusion bonded Ti-6Al-4V alloy and austenitic stainless steel couple. Mater. Sci. Technol. 2009, 25, 556–560. [Google Scholar] [CrossRef]

- Zakipour, S.; Halvaee, A.; Ali, A.; Samavatian, M.; Khodabandeh, A. An investigation on microstructure evolution and mechanical properties during transient liquid phase bonding of stainless steel 316L to Ti-6Al-4V. J. Alloys Compd. 2015, 626, 269–276. [Google Scholar] [CrossRef]

- Vigraman, T.; Ravindran, D.; Narayanasamy, R. Effect of phase transformation and intermetallic compounds on the microstructure and tensile strength properties of diffusion-bonded joints between Ti-6Al-4V and AISI 304L. Mater. Des. 2012, 36, 714–727. [Google Scholar] [CrossRef]

- Negemiya, A.A.; Rajakumar, S.; Balasubramanian, V. High-temperature diffusion bonding of austenitic stainless steel to titanium dissimilar joints. Mater. Res. Express 2019, 6, 066572. [Google Scholar] [CrossRef]

- Ferrante, M.; Pigoretti, E.V. De Diffusion bonding of TI-6AL-4V to AISI 316L stainless steel: Mechanical resistance and interface microstructure. J. Mater. Sci. 2002, 7, 2825–2833. [Google Scholar] [CrossRef]

- Norouzi, E.; Atapour, M.; Shamanian, M. Effect of bonding time on the joint properties of transient liquid phase bonding between Ti-6Al-4V and AISI 304. J. Alloys Compd. 2017, 701, 335–341. [Google Scholar] [CrossRef]

- Norouzi, E.; Atapour, M.; Shamanian, M.; Allafchian, A. Effect of bonding temperature on the microstructure and mechanical properties of Ti-6Al-4V to AISI 304 transient liquid phase bonded joint. Mater. Des. 2016, 99, 543–551. [Google Scholar] [CrossRef]

- Surendar, A.; Lucas, A.; Abbas, M.; Rahim, R.; Salmani, M. Transient liquid phase bonding of stainless steel 316 L to Ti-6Al-4 V using Cu/Ni multi-interlayer: Microstructure, mechanical properties, and fractography. Weld. World 2019, 63, 1025–1032. [Google Scholar] [CrossRef]

- Zakipour, S.; Samavatian, M.; Halvaee, A.; Amadeh, A.; Khodabandeh, A. The effect of interlayer thickness on liquid state diffusion bonding behavior of dissimilar stainless steel 316/Ti-6Al-4V system. Mater. Lett. 2015, 142, 168–171. [Google Scholar] [CrossRef]

- Akbar, A.; Ajeel, S.; Hassoni, S. Optimization of Diffusion Bonding of Pure Copper (OFHC) with Stainless Steel 304L. Al-Khwarizmi Eng. J. 2018, 14, 30–39. [Google Scholar] [CrossRef]

- Yılmaz, O. Effect of welding parameters on diffusion bonding of type 304 stainless steel-Copper bimetal. Mater. Sci. Technol. 2001, 17, 989–994. [Google Scholar] [CrossRef]

- Kaya, Y.; Kahraman, N.; Durgutlu, A.; Gülenc, B. A novel approach to diffusion bonding of copper to stainless steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 226, 478–484. [Google Scholar] [CrossRef]

- Xiong, J.; Xie, Q.; Li, J.; Zhang, F.; Huang, W. Diffusion Bonding of Stainless Steel to Copper with Tin Bronze and Gold Interlayers. J. Mater. Eng. Perform. 2012, 21, 33–37. [Google Scholar] [CrossRef]

- Sabharwall, P.; Clark, D.E.; Mizia, R.E.; Glazoff, M.V.; Mckellar, M.G. Diffusion-Welded Microchannel Heat Exchanger for Industrial Processes. J. Therm. Sci. Eng. Appl. 2013, 5, 011009. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, M.; Wu, H.; Yang, B. Materials Characterization Study on the dynamic recrystallization model and mechanism of nuclear grade 316LN austenitic stainless steel. Mater. Charact. 2016, 118, 92–101. [Google Scholar] [CrossRef]

- Uhs, U.; Zhang, C.; Bellet, M.; Bobadilla, M.; Shen, H. A Coupled Electrical-Thermal-Mechanical Modeling of Gleeble Tensile Tests for Ultra-High-Strength (UHS) Steel at a High Temperature. Metall. Mater. Trans. A 2010, 41, 2304–2317. [Google Scholar]

- Luo, J.; Chen, B.; Yuan, Q.; Zhang, D.F. Effect of heating-rate on failure temperature of pre-loaded magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, S371–S375. [Google Scholar] [CrossRef]

- Kheder, A.; Akbar, A.; Jubeh, N. Diffusion welding of OFHC copper to austenitic stainless steel 316L. Int. J. Join. Mater. 2004, 16, 97–102. [Google Scholar]

- Nishi, H.; Araki, T.; Eto, M. Diffusion bonding of alumina dispersion-strengthened copper to 316 stainless steel with interlayer metals. Fusion Eng. Des. 1998, 40, 505–511. [Google Scholar] [CrossRef]

- Krishnan, J.; Bhanumurthy, K.; Gawde, P.; Derose, J.; Kale, G.; Srikrushnamurthy, G. Manufacture of a matrix heat exchanger by diffusion bonding. J. Mater. Process. Technol. 1997, 66, 85–89. [Google Scholar] [CrossRef]

- Batra, I.S.; Kale, G.B.; Saha, T.K.; Ray, A.K.; Derose, J.; Krishnan, J. Diffusion bonding of a Cu–Cr–Zr alloy to stainless steel and tungsten using nickel as an interlayer. Mater. Sci. Eng. A 2004, 369, 119–123. [Google Scholar] [CrossRef]

- Nishi, H.; Araki, T. Low cycle fatigue strength of diffusion bonded joints of alumina dispersion-strengthened copper to stainless steel. J. Nucl. Mater. 2000, 287, 1234–1237. [Google Scholar] [CrossRef]

- Nishi, H. Notch toughness evaluation of diffusion-bonded joint of alumina dispersion-strengthened copper to stainless steel. Fusion Eng. Des. 2006, 81, 269–274. [Google Scholar] [CrossRef]

- Singh, K.P.; Patel, A.; Bhope, K.; Khirwadkar, S.S.; Mehta, M. Optimization of the diffusion bonding parameters for SS316L/CuCrZr with and without Nickel interlayer. Fusion Eng. Des. 2016, 112, 274–282. [Google Scholar] [CrossRef]

- Nishi, H.; Muto, Y.; Sato, K. Solid-state diffusion bonding of alumina dispersion-strengthened copper to 316 stainless steel. J. Nucl. Mater. 1994, 5, 1585–1589. [Google Scholar] [CrossRef]

- Banerjee, S.; Banerjee, M. Nuclear Applications: Zirconium Alloys. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 1–15. [Google Scholar] [CrossRef]

- Yagnik, S.; Garde, A. Zirconium Alloys for LWR Fuel Cladding and Core Internals. In Structural Alloys for Nuclear Energy Applications; Elsevier Inc: Amsterdam, The Netherlands, 2019; pp. 247–291. ISBN 9780123970466. [Google Scholar]

- Matweb Zirconium Alloy. Available online: http://www.matweb.com/search/datasheettext.aspx?matguid=eb1dad5ce1ad4a1f9e92f86d5b44740d (accessed on 24 April 2020).

- Bhanumurthy, K.; Krishnan, J.; Kale, G.B.; Banerjee, S. Transition joints between Zircaloy-2 and stainless steel by diffusion bonding. J. Nucl. Mater. 1994, 217, 67–74. [Google Scholar] [CrossRef]

- Pan, H.; Liu, B.; Guo, Y.; Liu, Y.; Quan, G. An investigation on diffusion bonding of Zircaloy-4 and 304L stainless steel with Ti and Ag multiple interlayers. Mater. Lett. 2019, 240, 185–188. [Google Scholar] [CrossRef]

- Srikanth, V.; Laik, A.; Dey, G.K. Materials & Design Joining of stainless steel 304L with Zircaloy-4 by diffusion bonding technique using Ni and Ti interlayers. Mater. Des. 2017, 126, 141–154. [Google Scholar]

- Abdelatif, L.; Taouinet, M.; Soltane, L. Microstructural Aspects of the Zircaloy-4/SS-304L Interface Obtained by Diffusion Bonding Technique. Solid State Phenom. 2019, 297, 17–30. [Google Scholar]

- Taouinet, M.; Lebaili, S.; Souami, N. Characterization of the interface to diffusion bonding of zircaloy-4 and stainless steel. Phys. Procedia 2009, 2, 1231–1239. [Google Scholar] [CrossRef] [Green Version]

- Zaid, B.; Taouinet, M.; Souami, N.; Lebaili, S. Microstructure and Corrosion Aspects of Dissimilar Joints of Zircaloy-4 and 304L Stainless Steel. J. Mater. Eng. Perform. 2013, 22, 854–862. [Google Scholar] [CrossRef]

- Lebaili, A.; Lebaili, S.; Hodaj, F. Interfacial interactions between 304L stainless steel and Zy-4 alloy during isothermal holdings at 1050 C. J. Alloys Compd. 2019, 805, 565–577. [Google Scholar] [CrossRef]

- Taouinet, M.; Kamel, N.E.; Lebaili, S. Diffusion Bonding Between Zircaloy-4 and 304L Stainless Steel in the Presence of a Eutectic. Mater. Manuf. Process. 2013, 28, 1327–1334. [Google Scholar] [CrossRef]

- Lebaili, A.; Taouinet, M.; Nibou, D.; Lebaili, S.; Hodaj, F. Effect of Isothermal Hold on the Microstructural Evolution of the Stainless Steel 304L/Zircaloy-4 Interface. J. Mater. Eng. Perform. 2017, 26, 3112–3120. [Google Scholar] [CrossRef]

- Aboudi, D.; Lebaili, S.; Taouinet, M.; Zollinger, J. Microstructure evolution of diffusion welded 304L/Zircaloy 4 with copper interlayer. Mater. Des. 2017, 116, 386–394. [Google Scholar] [CrossRef]

- Chen, H.; Long, C.; Wei, T.; Gao, W.; Xiao, H.; Chen, L. Effect of Ni interlayer on partial transient liquid phase bonding of Zr–Sn–Nb alloy and 304 stainless steel. J. Mater. Des. 2014, 60, 358–362. [Google Scholar] [CrossRef]

- Lucuta, P.; Patru, I.; Visiliu, F. Microstructural features of hot pressure bonding between stainless steel type AISI-304L and Zircaloy-2. J. Nucl. Mater. 1981, 99, 154–164. [Google Scholar] [CrossRef]

- Ahmad, M.; Akhter, J.I.; Zaman, Q.; Shaikh, M.A.; Akhtar, M.; Iqbal, M.; Ahmed, E. Diffusion bonding of stainless steel to Zircaloy-4 in the presence of a Ta intermediate layer. J. Nucl. Mater. 2003, 317, 212–216. [Google Scholar] [CrossRef]

- YHang, Y.; Feng, D.; He, Z.; Chen, X. Main Joining Methods of Ceramic and Metal. J. Iron Steel Res. 2006, 13, 1–5. [Google Scholar]

- Akselsen, O. Review Diffusion bonding of ceramics. J. Mater. Sci. 1992, 27, 569–579. [Google Scholar] [CrossRef]

- Mehrzad, M.; Sadeghi, A.; Farahani, M. Microstructure and properties of transient liquid phase bonding of AM60 Mg alloy to 304 stainless steel with Zn interlayer. J. Mater. Process. Tech. 2019, 266, 558–568. [Google Scholar] [CrossRef]

- Elthalabawy, W.; Khan, T. Diffusion Bonding of Austenitic Stainless Steel 316L to a Magnesium Alloy. Key Eng. Mater. 2018, 442, 26–33. [Google Scholar] [CrossRef]

- Elthalabawy, W.M.; Khan, T.I. Microstructural development of diffusion-brazed austenitic stainless steel to magnesium alloy using a nickel interlayer. Mater. Charact. 2010, 61, 703–712. [Google Scholar] [CrossRef]

- Elthalabawy, W.; Khan, T. Liquid Phase Bonding of 316L Stainless Steel to AZ31 Magnesium Alloy. J. Mater. Sci. Technol. 2011, 27, 22–28. [Google Scholar] [CrossRef]

- Shushan, S.; Charles, E.; Congleton, J. The Environment Assisted Cracking of Diffusion Bonded Stainless to Carbon Steel Joints in an Aqueous Chloride Solution. Corros. Sci. 1996, 38, 4–9. [Google Scholar] [CrossRef]

- Bhanumurthy, K.; Derose, D.J.; Kale, G.B.; Krishnan, J. Solid state bonding of porous nickel electrode to AISI 304 austenitic stainless steel. Mater. Sci. Technol. 2004, 20, 1059–1063. [Google Scholar] [CrossRef]

- Aleman, B.; Guticrrez, I.; Urcola, J.J. The use of Kirkendall effect for calculating intrinsic diffusion coefficients in a 316L/Ti6242 diffusion bonded couple. Scr. Mater. 1997, 36. [Google Scholar] [CrossRef]

- Abdolvand, R.; Atapour, M.; Shamanian, M.; Allafchian, A. The effect of bonding time on the microstructure and mechanical properties of transient liquid phase bonding between SAF 2507. J. Manuf. Process. 2017, 25, 172–180. [Google Scholar] [CrossRef]

- Moravec, J.; Novakova, I. The Selection of Appropriate Process Parameters of Diffusion Bonding in Heterogeneous Weld of 355J2/AISI 316L Steels. Key Eng. Mater. 2017, 737, 101–106. [Google Scholar] [CrossRef]

- Kurt, B.; Eroglu, M. Diffusion bonding between high chromium white iron and austenitic stainless steel. Sci. Technol. Weld. Join. 2007, 12, 467–472. [Google Scholar] [CrossRef]

- Song, T.; Jiang, X.; Shao, Z.; Mo, D.; Zhu, D.; Zhu, M. The Interfacial Microstructure and Mechanical Properties of Diffusion-Bonded Joints of 316L Stainless Steel and the 4J29 Kovar Alloy Using Nickel as an Interlayer. Metals 2016, 6, 263. [Google Scholar] [CrossRef]

- Fang, Y.J.; Jiang, X.S.; Mo, D.F.; Song, T.F.; Luo, Z.P. Microstructure and mechanical properties of the vacuum di ff usion bonding joints of 4J29 kovar alloy and 316L stainless steel using pure cobalt interlayer. Vacuum 2019, 168, 108847. [Google Scholar] [CrossRef]

- Travessa, D.; Ferrante, M.; den Ouden, G. Diffusion bonding of aluminium oxide to stainless steel using stress relief interlayers. Mater. Sci. Eng. A 2002, 337, 287–296. [Google Scholar] [CrossRef]

- Kliauga, A.M.; Travessa, D.; Ferrante, M. Al2O3/Ti interlayer/AISI 304 diffusion bonded joint Microstructural characterization of the two interfaces. Mater. Charact. 2001, 46, 65–74. [Google Scholar] [CrossRef]

- Torun, O.; Celikyürek, I. Microstructure and strength of diffusion-bonded joint between nickel aluminide Ni75Al25 and AISI 316 L stainless steel using a nickel interlayer. Kov. Mater. 2009, 47, 263–267. [Google Scholar]

- Çalik, A. Interface microstructure of diffusion bonded Ni3Al intermetallic alloy and austenitic stainless steel. Mater. Lett. 2009, 63, 2462–2465. [Google Scholar] [CrossRef]

- Stoop, B.; Den Ouden, G. Diffusion Bonding of Silicon Nitride to Austenitic Stainless Steel with Metallic Interlayers. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1995, 26, 203–208. [Google Scholar] [CrossRef]

- Polanco, R.; Pablos, A.; Miranzo, P.; Osendi, M.I. Metal—Ceramic interfaces: Joining silicon nitride—Stainless steel. Appl. Surf. Sci. 2004, 238, 506–512. [Google Scholar] [CrossRef]

- Hussain, P.; Mamat, O.; Mohammad, M.; Jaafar, W. Formation of Nitrogen-Pearlite in the Diffusion Bonding of Sialon to 316L Stainless. AIP Conf. Proc. 2010, 2007, 129–134. [Google Scholar]

- Hussain, P.; Isnin, A. Joining of austenitic stainless steel and ferritic stainless steel to sialon. J. Mater. Process. Technol. 2001, 113, 222–227. [Google Scholar] [CrossRef]

- Jia, L.; Guangmin, S.; Li, H. Ti-Nb-Cu Stress Buffer Layer for TiC Cermet/304 Stainless Steel Diffusion Bonding. Rare Met. Mater. Eng. 2016, 45, 555–560. [Google Scholar]

- Yönetken, A.; Cakmakkaya, M.; Erol, A.; Talas, S. Diffusion Bonding of Electroless Ni plated WC composite to Cu and AISI 316 Stainless Steel. Mater. Sci. 2011, 29, 15–21. [Google Scholar] [CrossRef]

- Vegter, R.; den Ouden, G. The Influence of Residual Stresses on the Mechanical Behaviour of ZrO2 Ni AISI 316 Diffusion Bonds. Mater. Sci. Forum 2000, 349, 634–639. [Google Scholar] [CrossRef]

- Qin, C.; Derby, B. Diffusion Bonds between a Stainless Steel and Zirconia. J. Am. Ceram. Soc. 1993, 76, 232–234. [Google Scholar] [CrossRef]

- Loh, N.L.; Sia, K.Y. An overview of hot isostatic pressing. J. Mater. Process. Technol. 1992, 30, 45–65. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Davies, S. Fundamental Aspects of Hot Isostatic Pressing: An Overview. Metall. Mater. Trans. A 2000, 31, 2981–3000. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M. Hot Isostatic Pressing (HIP) technology and its applications to metals and ceramics. J. Mater. Sci. 2004, 9, 6399–6420. [Google Scholar] [CrossRef]

- Lipa, M.; Durocher, A.; Tivey, R.; Huber, T.; Schedler, B.; Weigert, J. The use of copper alloy CuCrZr as a structural material for actively cooled plasma facing and in vessel components. Fusion Eng. Des. 2005, 79, 469–473. [Google Scholar] [CrossRef]

- Yamada, T.; Noto, H.; Hishinuma, Y.; Muroga, T.; Nakamura, H. Development of a dispersion strengthened copper alloy using a MA-HIP method. Nucl. Mater. Energy 2016, 9, 455–458. [Google Scholar] [CrossRef] [Green Version]

- Wei, R.; Li, Q.; Wang, W.J.; Wang, J.C.; Wang, X.L.; Xie, C.Y.; Luo, G. Microstructure and properties of W-Cu/CuCrZr/316L joint bonded by one- step HIP technique. Fusion Eng. Des. 2018, 128, 47–52. [Google Scholar] [CrossRef]

- Wikman, S.; Peacock, A.; Zlamal, O.; Öijerholm, J.; Tähtinen, S.; Rödig, M.; Marmy, P.; Gillia, O.; Lorenzetto, P.; Heikkinen, S. Assessment of materials data for blanket materials within the European contribution to ITER. J. Nucl. Mater. 2013, 442, S414–S419. [Google Scholar] [CrossRef]

- Wei, R.; Zhao, S.X.; Dong, H.; Che, H.Y.; Li, Q.; Wang, W.J.; Wang, J.C.; Wang, X.L.; Sun, Z.X.; Luo, G. Enhancing the CuCrZr/316L HIP-joint by Ni electroplating. Fusion Eng. Des. 2017, 117, 58–62. [Google Scholar] [CrossRef]

- Goods, S.H.; Puskar, J.D. Solid state bonding of CuCrZr to 316L stainless steel for ITER applications. Fusion Eng. Des. 2011, 86, 1634–1638. [Google Scholar] [CrossRef]

- Frayssines, P.; Bucci, P.; Vito, E.; Rigal, E.; Lorenzetto, P. Cleaning surface treatments for the fabrication of ITER First Wall panels by HIP. J. Nucl. Mater. 2009, 386, 866–870. [Google Scholar] [CrossRef]

- Sato, S.; Hatano, T.; Kuroda, T.; Furuya, K.; Hara, S.; Enoeda, M.; Takatsu, H. Optimization of HIP bonding conditions for ITER shielding blanket/First wall made from austenitic stainless steel and dispersion strengthened copper alloy. J. Nucl. Mater. 1998, 263, 265–270. [Google Scholar] [CrossRef]

- Sato, S.; Kuroda, T.; Kurasawa, T.; Furuya, K.; Togami, I.; Takatsu, H. Mechanical properties of HIP bonded joints of austenitic stainless steel and Cu-alloy for fusion experimental reactor blanket. J. Nucl. Mater. 1996, 237, 940–944. [Google Scholar] [CrossRef]

- Sato, S.; Kuroda, T.; Hatano, T.; Furuya, K.; Tokami, I.; Takatsu, H. Development of first wall/blanket structure by hot isostatic pressing (HIP) in the JAERI. Fusion Eng. Des. 1998, 40, 609–614. [Google Scholar] [CrossRef]

- Hatano, T.; Saito, M.; Enoeda, M.; Takatsu, H. Fracture strengths of HIPed DS-Cu/SS joints for ITER shielding blanket/First wall. J. Nucl. Mater. 1998, 263, 950–954. [Google Scholar] [CrossRef]

- Marois, G.; Burlet, H.; Solomon, R.; Marini, B.; Gentzbittel, J.M. Structural materials joints for ITER in-vessel components. Fusion Eng. Des. 1998, 40, 253–261. [Google Scholar] [CrossRef]

- Marois Le, G.; Dellis, C.; Gentzbittel, J.M.; Moret, F. HIP’ing of copper alloys to stainless steel. J. Nucl. Mater. 1996, 237, 927–931. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Wei, R.; Wang, X.; Sun, Z.; Xie, C.; Li, Q.; Luo, G. Effect of Ti interlayer on the bonding quality of W and steel HIP joint. J. Nucl. Mater. 2017, 485, 8–14. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, D.; Li, Q.; Jiang, C.; Li, Q. Effect of holding time on the microstructure and strength of tungsten/steel joints by HIP diffusion bonded using a Cu interlayer. Mater. Lett. 2020, 261, 126875. [Google Scholar] [CrossRef]

- JWS, I.G. Material Assessment Report (MAR); G A1 DDD 1 98-05-28 W0.3; TER: Garching, Germany, 1998. [Google Scholar]

| max % | 304 | 304L | 316 | 316L | 316LN | 316H |

|---|---|---|---|---|---|---|

| Fe | balance | balance | balance | balance | balance | Balance |

| Cr | 18–20 | 18–20 | 16–18 | 16–18 | 16–18 | 16–18 |

| Ni | 8.0–10.5 | 8.0–10.5 | 10.0–14.0 | 10.0–14.0 | 10.0–14.0 | 10.0–14.0 |

| Mo | - | - | 2–3 | 2–3 | 2–3 | 2–3 |

| Mn | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

| Si | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| N | 0.10 | 0.10 | 0.10 | 0.10 | 0.10–0.30 | - |

| P | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| C | max. 0.08 | max. 0.03 | max. 0.08 | max. 0.03 | max. 0.03 | 0.04–0.10 |

| S | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304 | 304 | Ni-Cu-Ag (2–3; 5; 2–3 µm) 1 | 500 °C | 120 min | 0.1 MPa | [103] |

| 304 | 304 | Cu (50 µm) | 950 °C | 72 min | 0.5 MPa | [107] |

| 304 | 304 | - | 1000 °C | 60 min | 3.5 MPa | [41] |

| 304 | 304 | - | 1100 °C | 16 min | NR 2 | [108] |

| 304 | 304 | Ni (75 µm) | 1150 °C | 20 min | 0.5 MPa | [104] |

| 304 | 304 | Ni (75 µm) | 1150 °C | 20 min | 0.5 MPa | [105] |

| 304 | 304 | - | 1175 °C | 60 min | 15 MPa | [109] |

| 304 | 304 | Co (40 µm) | 1180 °C | 30 min | 0.2 MPa | [106] |

| 304 | 304 | NiB (25 µm) | 1200 °C | 3 min | 9.8 MPa | [110] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 316 1 | 316 | Cu-Ti (~1; ~1 µm) | 900 °C | 10 min | 0.9 MPa | [116] |

| 316 | 316 | - | 920 °C | 240 min | 27.6 MPa | [117] |

| 316L | 316L | - | 1000 °C | 30 min | 9.8 MPa | [111] |

| 316L | 316L | - | 1000 °C | 120 min | 4 MPa | [118] |

| 316L | 316L | Ni 2 (min. 2 µm) | 1000 °C | 120 min | 6.9 MPa | [119] |

| 316L | 316L | Ni 2 (6 µm) | 1000 °C | 120 min | 10 MPa | [120] |

| 316 | 316 | Dux 65 (1000 µm) | 1027 °C | 30 min | 7 MPa | [113] |

| 316L | 316L | - | 1040 °C | 60 min | 8 MPa | [115] |

| 316H | 316H | - | 1050 °C | 60 min | 8 MPa | [121] |

| 316L | 316L | - | 1050 °C | 60 min | 10 MPa | [122] |

| 316L | 316L | - | 1075 °C | 300 min | 6.4 MPa | [123] |

| 316L | 316L | - | 1100 °C | 180 min | 10 MPa | [112,114,124,125] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304L | cpTi | Al (120 µm) | 650 °C | 90 min | 3 MPa | [127] |

| 304 | cpTi | Al (50–60 µm) | 650 °C | 120 min | 2 MPa | [128] |

| 316L | cpTi | - | 677 °C | 15 min | 5 MPa | [129] |

| 304L | cpTi | - | 738 °C | 8 min | 51 MPa | [130] |

| 316L | cpTi | - | 800 °C | 15 min | 15 MPa | [131] |

| 304 | cpTi | - | 800 °C | 120 min | 3 MPa | [132] |

| 304 | cpTi | - | 820 °C | 60 min | NR | [133] 1 |

| 304 | cpTi | Ni (0.5–1.1 µm) | 850 °C | 60 min | NR | [133] 1 |

| 304 | cpTi | Ag (50 µm) | 850 °C | 20 min | 8 MPa | [134,135] |

| 304 | cpTi | Cu-Zn (100; 100 µm) | 850 °C | 30 min | NR | [136] |

| 304 | cpTi | - | 850 °C | 120 min | 3 MPa | [137] |

| 304 | cpTi | Nb–Ni (10, 10 µm) | 900 °C | 30 min | 1 MPa | [138] |

| 304 | cpTi | Nb (300 µm) | 900 °C | 30 min | 3 MPa | [139] |

| 304 | cpTi | Ni (100 µm) | 900 °C | 60 min | 2 MPa | [140,141] |

| 304 | cpTi | Ni (300 µm) | 900 °C | 60 min | 3 MPa | [142] |

| 304 | cpTi | Cu (300 µm) | 900 °C | 60 min | 3 MPa | [143] |

| 304 | cpTi | Cu (300 µm) | 900 °C | 90 min | 3 MPa | [144] |

| 304 | cpTi | Nb (300 µm) | 900 °C | 120 min | 3 MPa | [145] |

| 316 | cpTi | Cu (40 µm) | 950 °C | 50 min | 3 MPa | [146] |

| Study | 304 | Interlayer | cpTi | UTS of cpTi 1 | UTS of Joint | % UTS of cpTi |

|---|---|---|---|---|---|---|

| Gosh et al. [137] | 304 | - | Gr 1 | 319 MPa | 222 MPa | 70% |

| Gosh et al. [132] | 304 | - | Gr 1 | 319 MPa | 242 MPa | 76% |

| Li et al. [138] | 304 | Nb-Ni (10; 10 µm) | Gr 2 | 490 MPa | 398 MPa | 81% |

| Shirzadi et al. [133] 2 | 304 | Ni (0.5–1.1 µm) | Gr 2 | 340 MPa | 280 MPa | 82% |

| Kundu and Chatterjee [127] | 304L | Al (120 µm) | Gr 1 | 319 MPa | 266 MPa | 83% |

| Deng et al. [134] | 304 | Ag (50 µm) | Gr 2 | 486 MPa | 410 MPa | 84% |

| Deng et al. [135] | 304 | Ag (50 µm) | Gr 2 | 486 MPa | 421 MPa | 87% |

| Kundu and Chatterjee [145] | 304 | Nb (300 µm) | Gr 1 | 319 MPa | 287 MPa | 90% |

| Shirzadi et al. [133] 2 | 304 | - | Gr 2 | 340 MPa | 313 MPa | 92% |

| Kundu and Chatterjee [139] | 304 | Nb (300 µm) | Gr 1 | 319 MPa | 297 MPa | 93% |

| Kundu and Chatterjee [142] | 304 | Ni (300 µm) | Gr 1 | 319 MPa | 302 MPa | 95% |

| Kundu and Chatterjee [144] | 304 | Cu (300 µm) | Gr 1 | 319 MPa | 318 MPa | 100% |

| Kundu and Chatterjee [143] | 304 | Cu (300 µm) | Gr 1 | 319 MPa | 322 MPa | 101% 3 |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304 | Ti-6Al-4V | Al (1,000 µm) | 550 °C | 60 min | 12 MPa | [148] |

| 304 | Ti-6Al-4V | Ni (200 µm) | 750 °C | 60 min | 3 MPa | [153] |

| 304 | Ti-6Al-4V | Au (100 µm) | 800 °C | 60 min | 5 MPa | [154] |

| 304 | Ti-6Al-4V | - | 800 °C | 90 min | 3 MPa | [147] |

| 304 | Ti-6Al-4V | Ag (60 µm) | 800 °C | 90 min | 5 MPa | [155] |

| 304 | Ti-6Al-4V | Ni (30 µm) | 850 °C | 10 min | 10 MPa | [156] |

| 304 | Ti-6Al-4V | Cu (200 µm) | 850 °C | 75 min | 4 MPa | [157] |

| 304 | Ti-6Al-4V | Ag (5000 µm) | 850 °C | 90 min | 5 MPa | [158] |

| 304 | Ti-6Al-4V | Cu (60 µm) | 870 °C | 90 min | 1 MPa | [159] |

| 316L | Ti-6Al-4V | V-Cu-Co (NR) | 880 °C | 90 min | 5 MPa | [160] |

| 316L | Ti-6Al-4V | - | 885 °C | 30 min | 5 MPa | [161] |

| 316 | Ti-6Al-4V | Cu (50 µm) | 900 °C | 60 min | 2 MPa | [162] |

| 304L | Ti-6Al-4V | - | 900 °C | 60 min | 4 MPa | [163] |

| 304 | Ti-6Al-4V | - | 900 °C | 75 min | 14 MPa | [164] |

| 316L | Ti-6Al-4V | Cu-Nb (20; 25 µm) | 900 °C | 90 min | 5 MPa | [42] |

| 316L | Ti-6Al-4V | - | 950 °C | 180 min | 8 MPa | [165] |

| 304 | Ti-6Al-4V | Cu (25 µm) | 960 °C | 60 min | <1 MPa | [166] |

| 304 | Ti-6Al-4V | Cu (25 µm) | 960 °C | 60 min | 1 MPa | [167] |

| 316L | Ti-6Al-4V | Cu-Ni (100; 50 µm) | 1000 °C | 30 min | 2 MPa | [168] |

| 316 | Ti-6Al-4V | Cu (50 µm) | 1100 °C | 60 min | 2 MPa | [169] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304 | Cu | - | 650 °C | 45 min | 30.0 MPa | [170] |

| 316L | Cu 1 | - | 660 °C | 90 min | 20.0 MPa | [178] |

| 316L | Cu 1 | - | 690 °C | 90 min | 20.0 MPa | [178] |

| 304 | Cu | - | 825 °C | 18 min | 5.0 MPa | [171] |

| 304L | Cu | Ni (12.5 µm) | 850 °C | 20 min | 5–20.0 MPa 2 | [50] |

| 304L | Cu | Sn Bronze-Au (100; 5 µm) | 850 °C | 60 min | 3.0 MPa | [173] |

| 316 | Cu 3 | Au (20 µm) | 850 °C | 60 min | 4.8 MPa | [179] |

| 304 | Cu | Ni (10–15 µm) | 850 °C | 60 min | 8.0 MPa | [180] |

| 316 | CuCrZr | - | 850 °C | 60 min | 10.0 MPa | [181] |

| 316 | Cu 3 | Au (20 µm) | 850 °C | 60 min | NR | [182] |

| 316 | Cu 3 | Au (20 µm) | 850 °C | 120 min | 9.8 MPa | [183] |

| 304 | Cu | - | 875 °C | 30 min | 3.0 MPa | [172] |

| 316L | CuCrZr | Ni (25 µm) | 900 °C | 15 min | 5.0 MPa | [184] 4 |

| 316L | CuCrZr | - | 900 °C | 15 min | 7.0 MPa | [184] 4 |

| 316 | Cu 3 | - | 900 °C | 60 min | 4.8 MPa | [185] |

| 304 | Cu | - | 900 °C | 60 min | 10.0 MPa | [180] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304L | Zircaloy-4 | Ti-Ag (50; 50 µm) | 800 °C | 90 min | 12.0 MPa | [190] |

| 304L | Zircaloy-4 | - | 820 °C | 45 min | 7.5 MPa | [192] |

| 304L | Zircaloy-4 | - | 850 °C | 45 min | 11.2 MPa | [193,194,195,196,197] |

| 304L | Zircaloy-4 | Ni-Ti (20;40 µm) | 850 °C | 60 min | 20.0 MPa | [191] |

| 304L | Zircaloy-2 | Ni-Cu-Nb (30-70 µm) | 870 °C | 120 min | 10.0 MPa | [189] |

| 316L | Zircaloy-4 | Fe-Ti (NR) | 927 °C | 15 min | NR | [84] |

| 304L | Zircaloy-4 | Cu (50 µm) | 950 °C | 45 min | 2.0 MPa | [198] |

| 304L | Zircaloy-4 | - | 950 °C | 45 min | 2.0 MPa | [193,194,195,196,197] |

| 304L | Zircaloy-4 | - | 950 °C | 45 min | 2.2 MPa | [192] |

| 304 | Zr-Sn-Nb | Ni (5 µm) | 1000 °C | 30 min | NR | [199] |

| 304L | Zircaloy-2 | - | 1000 °C | 60 min | 0.2 MPa | [200] |

| 316L | Zircaloy-4 | Ti (NR) | 1000 °C | 240 min | NR | [57,58] |

| 304L | Zircaloy-4 | - | 1020 °C | 45 min | 0.8 MPa | [193,194,195,196,197] |

| 304L | Zircaloy-4 | - | 1050 °C | 45 min | 0.2 MPa | [193,194,195,196,197] |

| 316L | Zircaloy-4 | Ti (NR) | 1050 °C | 60 min | NR | [57,58] |

| 304L | Zircaloy-2 | - | 1100 °C | 60 min | 0.3 MPa | [200] |

| 304L | Zircaloy-4 | Ta (NR) | 1150 °C | 180 min | NR | [201] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 304 | AM60 | Zn (1 µm) | 470 °C | 30 min | NR | [204] |

| 316L | AZ 31 | Cu (20 µm) | 530 °C | 60 min | <1 MPa | [205] |

| 316L | AZ 31 | Ni (20 µm) | 510 °C | 60 min | <1 MPa | [205] |

| 316L | AZ 31 | Ni (20 µm) | 510 °C | 20 min | <1 MPa | [206,207] |

| 316L | AZ 31 | Cu (20 µm) | 530 °C | 30 min | <1 MPa | [207] |

| 316 | A533B | Ni (NR) | 900 °C | 120 min | 95 MPa | [208] |

| 316 | A533B | - | 1050 °C | 150 min | 95 MPa | [208] |

| 316 | En3B | Ni (NR) | 900 °C | 120 min | 95 MPa | [208] |

| 316 | En3B | - | 1050 °C | 150 min | 95 MPa | [208] |

| 304 | Ni | Ni (10–15 µm) | 800 °C | 60 min | 10 MPa | [209] |

| 316L | Ti 6242 | - | 900 °C | 15 min | 15 MPa | [131] |

| 316L | Ti 6242 | - | 900 °C | 15 min | 15 MPa | [210] |

| 304 | SAF 2507 | BNi-2 (50 µm) | 1045 °C | 45 min | NR | [211] |

| 316 | 355 | - | 1050 °C | 60 min | 13 MPa | [212] |

| 316L | Cast Iron | - | 1000 °C | 30 min | 10 MPa | [213] |

| 316L | Kovar | Ni (70 µm) | 900 °C | 240 min | 35 MPa | [214] |

| 316L | Kovar | Co (50 µm) | 945 °C | 150 min | 10 MPa | [215] |

| 304 | Al2O3 | Ti (500 µm) | 800 °C | 15 min | 15 MPa | [216] |

| 304 | Al2O3 | Ti (500 µm) | 900 °C | 60 min | 15 MPa | [217] |

| 316L | Ni3Al | Ni (10 µm) | 1000 °C | 240 min | 5 MPa | [218] |

| 316L | Ni3Al | - | 1050 °C | 30 min | 6 MPa | [219] |

| 316 | Si3N4 | Invar (250 µm) | 1000 °C | 90 min | 7 MPa | [220] |

| 316 | Si3N4 | - | 1100 °C | 120 min | 4–5 MPa | [221] |

| 316L | Sialon | - | 1200 °C | 60 min | 15 MPa | [222] |

| 316L | Sialon | - | 1250 °C | 60 min | 15 MPa | [223] |

| 304 | TiC | Ti-Nb-Cu (400 µm) | 925 °C | 20 min | 8 MPa | [224] |

| 316 | WC | Ni (NR) | 1200 °C | 30 min | 1 MPa | [225] |

| 316 | ZrO2 | Ni (300 µm) | 900 °C | 90 min | 20 MPa | [226] |

| 316 | ZrO2 | - | 1200 °C | 60 min | 10 MPa | [227] |

| M1 | M2 | Interlayer | Temperature | Time | Pressure | Ref. |

|---|---|---|---|---|---|---|

| 316L | CuCrZr | Ni (6 µm) | 900 °C | 120 min | 130 MPa | [233] |

| 316LN | CuCrZr | Fe42Ni (NR) | 920 °C | 180 min | 120 MPa | [27] |

| 316LN | CuCrZr | - | 980 °C | 120 min | 140 MPa | [234] |

| 316L | CuCrZr | Ni (6 µm) | 980 °C | 120 min | 140 MPa | [235] |

| 316LN | CuCrZr | Ni (NR) | 1000 °C | 60 min | 130 MPa | [27] |

| 316L | CuCrZr | - | 1040 °C | 120 min | 103 MPa | [236] |

| 316LN | CuCrZr | - | 1040 °C | 120 min | 140 MPa | [234,237] |

| 316L | DS Cu | - | 1050 °C | 120 min | 150 MPa | [238,239,240,241] |

| 316LN | DS Cu | - | 1090 °C | 120 min | 100 MPa | [242] |

| 316LN | DS Cu | Ni (NR) | 1090 °C | 120 min | 100 MPa | [242] |

| 316LN | DS Cu | - | 1125 °C | 240 min | 100 MPa | [243] |

| 316 | W | Ti (100 µm) | 930 °C | 120 min | 100 MPa | [244] |

| 316L | W | Cu (250 µm) | 1050 °C | 120 min | 150 MPa | [245] |

| 304 | 304 | - | 1100 °C | 150 min | 100 MPa | [108] |

| 316LN | 316LN | - | 1100 °C | 120 min | 150 MPa | [246] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

AlHazaa, A.; Haneklaus, N. Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints. Metals 2020, 10, 613. https://doi.org/10.3390/met10050613

AlHazaa A, Haneklaus N. Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints. Metals. 2020; 10(5):613. https://doi.org/10.3390/met10050613

Chicago/Turabian StyleAlHazaa, Abdulaziz, and Nils Haneklaus. 2020. "Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints" Metals 10, no. 5: 613. https://doi.org/10.3390/met10050613

APA StyleAlHazaa, A., & Haneklaus, N. (2020). Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints. Metals, 10(5), 613. https://doi.org/10.3390/met10050613