A Physics-Based Mean-Field Model for Ferrite Recovery and Recrystallization

Abstract

:1. Introduction

2. Materials and Methods

3. Modeling Approach

3.1. Recovery

3.2. Recrystallization

3.3. Calibration of the Model

4. Results and Discussions

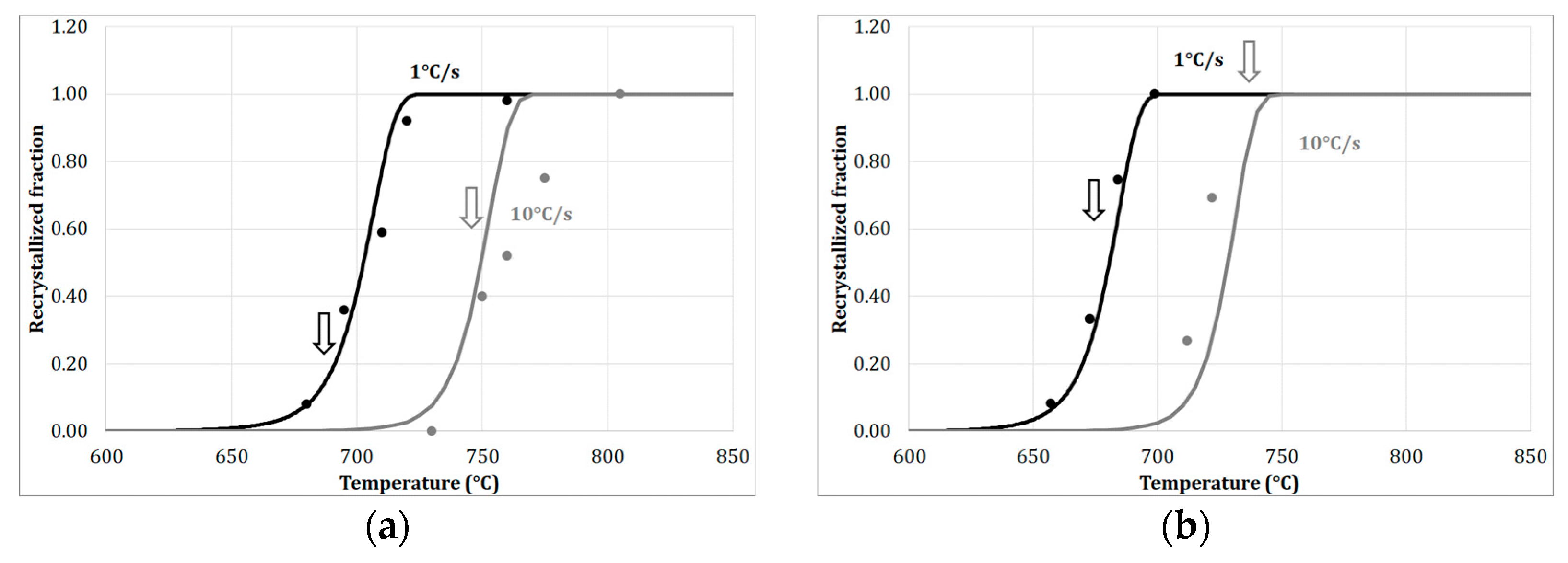

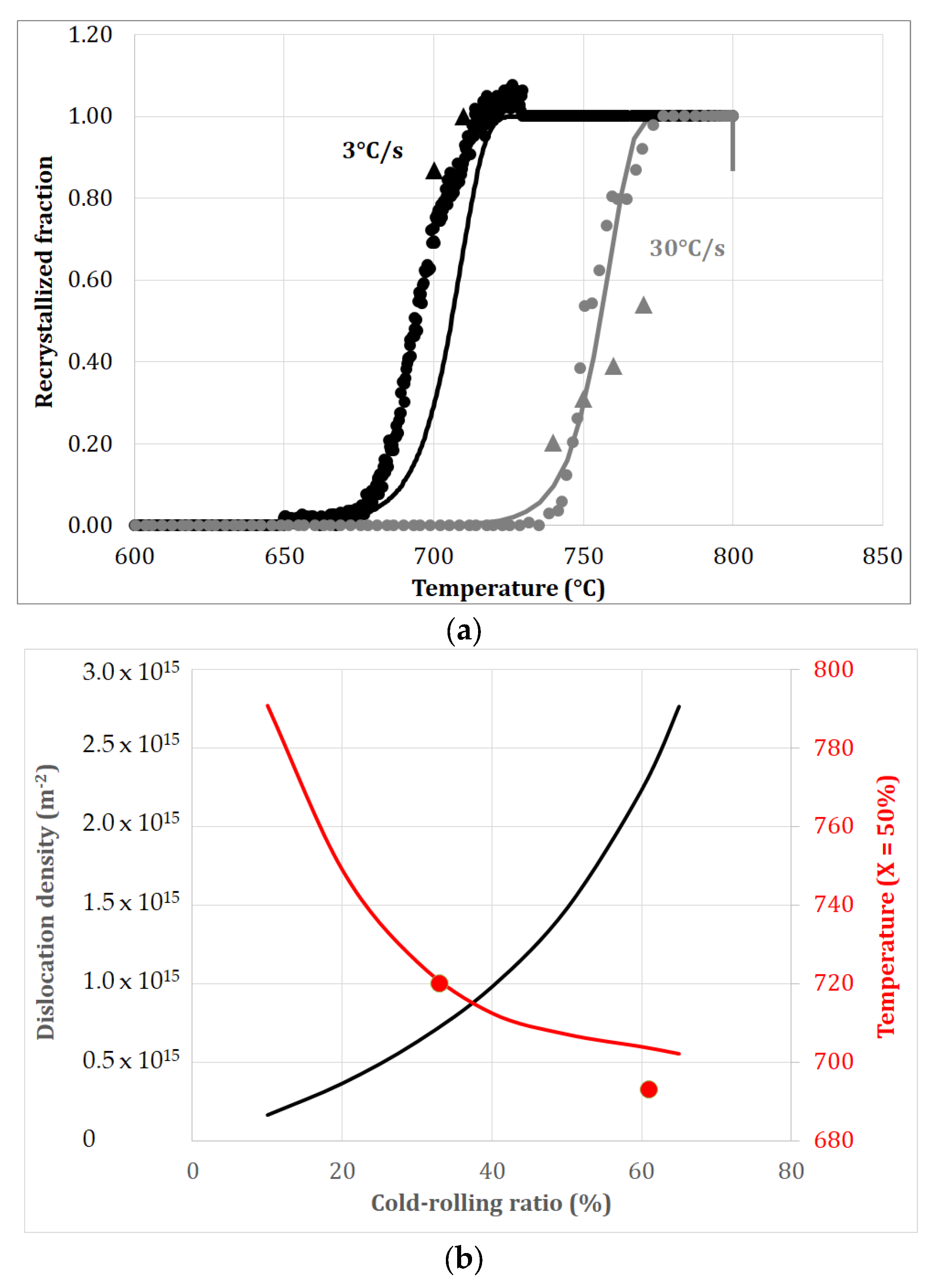

4.1. Results of the Calibration Procedure

4.2. Effect of the Cold-Rolling Ratio

5. Conclusions

- The nucleation process in ferrite. The model inspired from previous works on austenite has been integrally adapted to the case of ferritic steels. It permits efficiently predicting the start of the recrystallization on a physical basis (SIBM theory) and avoiding the use of empirical T* functions.

- The modeling of the mean grain size considering both interface mobility and nucleation rate of small grains at the critical size. In most of recrystallization models, only the growth process is considered.

- The calibration of the mobility of interfaces (subgrains and recrystallized grains) on the results from different sources. This procedure highlights the key role played by the composition of the alloy on the kinetics (Mn content in the considered cases).

- Contrary to empirical models, it permits predicting the recrystallization start temperature, the microstructure state (grain and subgrain size) and the nucleation rate all along any complex temperature schedule.

- It accounts for the two-stage kinetics of recrystallization of ferritic microstructures observed experimentally with a regime controlled by the nucleation and a regime controlled by the growth only, even if not revealed obviously by the global kinetics.

- The model is sensitive to the chemical composition of the steel based on the mobility equation and to its deformed microstructure (initial grain size, cold-rolling ratio). It still needs to be improved to explicitly elucidate the composition dependence of the mobility of the HAB and to account for nucleation sites other than triple junctions and consider flatten deformed grains.

- The model is highly versatile, as it is CPU efficient and it permits conducting easy sensitivity analysis of processing conditions, compositions and microstructural parameters (resulting from the upstream process).

- As this model has been developed via an industrial collaboration, there is also no doubt that it could be useful for the steel industry for their product/process developments

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peranio, N.; Li, Y.J.; Roters, F.; Raabe, D. Microstructure and texture evolution in dual-phase steels: Competition between recovery, recrystallization, and phase transformation. Mater Sci. Eng. A 2010, 527, 4161–4168. [Google Scholar] [CrossRef]

- Zheng, C.; Raabe, D. Interaction between recrystallization and phase transformation during intercritical annealing in a cold-rolled dual-phase steel: A cellular automaton model. Acta Mater. 2013, 61, 5504–5517. [Google Scholar] [CrossRef]

- Chbihi, A.; Barbier, D.; Germain, L.; Hazotte, A.; Gouné, M. Interactions between ferrite recrystallization and austenite formation in high-strength steels. J. Mater. Sci. 2014, 49, 3608–3621. [Google Scholar] [CrossRef]

- Kulakov, M.; Poole, W.J.; Militzer, M. A microstructure evolution model for intercritical annealing of a lowcarbon dualphase steel. ISIJ Int. 2014, 54, 2627–2636. [Google Scholar] [CrossRef] [Green Version]

- Lai, Q.; Gouné, M.; Perlade, A.; Pardoen, T.; Jacques, P.; Bouaziz, O.; Bréchet, Y. Mechanism of austenite formation from spheroidized microstructure in an intermediate Fe-0.1C-3.5Mn steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 3375–3386. [Google Scholar] [CrossRef]

- Ollat, M.; Militzer, M.; Massardier, V.; Fabregue, D.; Buscarlet, E.; Keovilay, F.; Perez, M. Mixed-mode model for ferrite-to-austenite phase transformation in dual-phase steel. Comput. Mater. Sci. 2018, 149, 282–290. [Google Scholar] [CrossRef]

- Moreno, M. Metallurgical Mechanisms and their Interactions during the Annealing of Cold-Rolled Ferrite-Pearlite Steels: Characterization and Modeling; Université de Lorraine: Nancy cedex, France, 2019. [Google Scholar]

- Allain, S.Y.P.; Bouaziz, O.; Pushkareva, I.; Scott, C.P. Towards the microstructure design of DP steels: A generic size-sensitive mean-field mechanical model. Mater. Sci. Eng. A 2015, 637, 222–234. [Google Scholar] [CrossRef]

- Pushkareva, I.; Allain, S.; Scott, C.; Redjaïmia, A.; Moulin, A.; Redjaimia, A.; Moulin, A. Relationship between microstructure, mechanical properties and damage mechanisms in high martensite fraction dual phase steels. ISIJ Int. 2015, 55, 2237–2246. [Google Scholar] [CrossRef] [Green Version]

- Scott, C.P.; Fazeli, F.; Shalchi Amirkhiz, B.; Pushkareva, I.; Allain, S.Y.P. Structure-properties relationship of ultra-fine grained V-microalloyed dual phase steels. Mater. Sci. Eng. A 2017, 703, 293–303. [Google Scholar] [CrossRef]

- Zurob, H.S.; Hutchinson, C.R.; Brechet, Y.; Purdy, G. Modeling recrystallization of microalloyed austenite: Effect of coupling recovery, precipitation and recrystallization. Acta Mater. 2002, 50, 3077–3094. [Google Scholar] [CrossRef]

- Zurob, H.S.; Bréchet, Y.; Dunlop, J. Quantitative criterion for recrystallization nucleation in single-phase alloys: Prediction of critical strains and incubation times. Acta Mater. 2006, 54, 3983–3990. [Google Scholar] [CrossRef]

- Rehman, M.K.; Zurob, H.S. A novel approach to model static recrystallization of austenite during hot rolling of Nb microalloyed steel. Part I: Precipitate-free case. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 1862–1871. [Google Scholar] [CrossRef]

- Li, P.; Li, J.; Meng, Q.; Hu, W.; Xu, D. Effect of heating rate on ferrite recrystallization and austenite formation of cold-roll dual phase steel. J. Alloys Compd. 2013, 578, 320–327. [Google Scholar] [CrossRef]

- Zhu, B.; Militzer, M. 3D phase field modelling of recrystallization in a low-carbon steel. Model. Simul. Mater. Sci. Eng. 2012, 20. [Google Scholar] [CrossRef]

- Huang, J.; Poole, W.J.; Militzer, M. Austenite formation during intercritical annealing. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 3363–3375. [Google Scholar] [CrossRef]

- Stechauner, G.; Kozeschnik, E. Self-Diffusion in Grain Boundaries and Dislocation Pipes in Al, Fe, and Ni and Application to AlN Precipitation in Steel. In Proceedings of the Journal of Materials Engineering and Performance; Springer: New York, NY, USA, 2014; Volume 23, pp. 1576–1579. [Google Scholar]

- Sinclair, C.W.; Hutchinson, C.R.; Bréchet, Y. The Effect of Nb on the Recrystallization and Grain Growth of Ultra-High-Purity α-fe: A combinatorial Approach. In Proceedings of the Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science; Springer: Boston, MA, USA, 2007; Volume 38, pp. 821–830. [Google Scholar]

- Liu, Z.; Olivares, R.O.; Lei, Y.; Garcia, C.I.; Wang, G. Microstructural characterization and recrystallization kinetics modeling of annealing cold-rolled vanadium microalloyed HSLA steels. J. Alloys Compd. 2016, 679, 293–301. [Google Scholar] [CrossRef] [Green Version]

- Zhu, B.; Militzer, M. Phase-field modeling for intercritical annealing of a dual-phase steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 1073–1084. [Google Scholar] [CrossRef]

- Madej, L.; Sieradzki, L.; Sitko, M.; Perzynski, K.; Radwanski, K.; Kuziak, R. Multi scale cellular automata and finite element based model for cold deformation and annealing of a ferritic-pearlitic microstructure. Comput. Mater. Sci. 2013, 77, 172–181. [Google Scholar] [CrossRef]

- Bouaziz, O.; Le Corre, C. Flow stress and microstructure modelling of ferrite-pearlite steels during cold rolling. Mater. Sci. Forum 2003, 426–432, 1399–1404. [Google Scholar] [CrossRef]

- Moreno, M.; Teixeira, J.; Geandier, G.; Hell, J.-C.; Bonnet, F.; Salib, M.; Allain, S.Y.P. Real-time investigation of recovery, recrystallization and austenite transformation during annealing of a cold-rolled steel using high energy X-ray diffraction (HEXRD). Metals (Basel) 2019, 9. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, F.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier Science: Oxford, UK, 1995. [Google Scholar]

- Nishitani, N.; Hiramoto, T.; Takemoto, Y.; Senuma, T. Model for predicting recrystallization behavior of colled rolled extralow carbon steel sheets. Tetsu-To-Hagane/J. Iron Steel Inst. Japan 2011, 97, 238–244. [Google Scholar] [CrossRef] [Green Version]

- Verdier, M.; Brechet, Y.; Guyot, P. Recovery of A1Mg alloys: Flow stress and strain-hardening properties. Acta Mater. 1998, 47, 127–134. [Google Scholar] [CrossRef]

- Friedel, J. Dislocations: International Series of Monographs on Solid State Physics; Pergamon Press: Oxford, UK, 1964; ISBN 1483135926. [Google Scholar]

- Ghosh, G.; Olson, G.B. The isotropic shear modulus of multicomponent Fe-base solid solutions. Acta Mater. 2002, 50, 2655–2675. [Google Scholar] [CrossRef]

- Nes, E. Recovery revisited. Acta Metall. Mater. 1995, 43, 2189–2207. [Google Scholar] [CrossRef]

- Winning, M.; Rollett, A.D.; Gottstein, G.; Srolovitz, D.J.; Lim, A.; Shvindlerman, L.S. Mobility of low-angle grain boundaries in pure metals. Philos. Mag. 2010, 90, 3107–3128. [Google Scholar] [CrossRef]

- Kučera, J.; Stránský, K. Diffusion in iron, iron solid solutions and steels. Mater. Sci. Eng. 1982, 52, 1–38. [Google Scholar] [CrossRef]

- Militzer, M.; Hawbolt, E.B.; Meadowcroft, T.R. Microstructural model for hot strip rolling of high-strength low-alloy steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2000, 31, 1247–1259. [Google Scholar] [CrossRef]

- Senuma, T.; Takemoto, Y. Model for predicting recrystallization behavior of cold rolled extralow carbon steel sheets. Mater. Sci. Forum 2012, 706–709, 2302–2307. [Google Scholar] [CrossRef]

- Lefevre-Schlick, F.; Brechet, Y.; Zurob, H.S.; Purdy, G.; Embury, D. On the activation of recrystallization nucleation sites in Cu and Fe. Mater. Sci. Eng. A 2009, 502, 70–78. [Google Scholar] [CrossRef]

- Senuma, T.; Takemoto, Y. Model for predicting the microstructural evolution of extralow carbon steels. ISIJ Int. 2008, 48, 1635–1639. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. II Transformation-time relations for random distribution of nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Hillert, M. Diffusion and interface control of reactions in alloys. Metall. Trans. A 1975, 6, 5–19. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allain, S.Y.P.; Moreno, M.; Lamari, M.; Zurob, H.; Teixeira, J.; Bonnet, F. A Physics-Based Mean-Field Model for Ferrite Recovery and Recrystallization. Metals 2020, 10, 622. https://doi.org/10.3390/met10050622

Allain SYP, Moreno M, Lamari M, Zurob H, Teixeira J, Bonnet F. A Physics-Based Mean-Field Model for Ferrite Recovery and Recrystallization. Metals. 2020; 10(5):622. https://doi.org/10.3390/met10050622

Chicago/Turabian StyleAllain, Sébastien Y.P., Marc Moreno, Mathias Lamari, Hatem Zurob, Julien Teixeira, and Frédéric Bonnet. 2020. "A Physics-Based Mean-Field Model for Ferrite Recovery and Recrystallization" Metals 10, no. 5: 622. https://doi.org/10.3390/met10050622

APA StyleAllain, S. Y. P., Moreno, M., Lamari, M., Zurob, H., Teixeira, J., & Bonnet, F. (2020). A Physics-Based Mean-Field Model for Ferrite Recovery and Recrystallization. Metals, 10(5), 622. https://doi.org/10.3390/met10050622