Synthesis and Characterization of Thermoelectric Co2XSn (X = Zr, Hf) Heusler Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Structural and Microstructural Characterization

3.2. Mechanical Properties

3.3. Temperature Dependence of Electrical Conductivity, Seebeck Coefficient, and Power Factor

3.4. Effect of Composition on Electrical Conductivity, Seebeck Coefficient, and Power Factor

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Poon, S.J. Recent advances in thermoelectric performance of half-heusler compounds. Metals 2018, 8, 989. [Google Scholar] [CrossRef] [Green Version]

- Sakurada, S.; Shutoh, N. Effect of Ti substitution on the thermoelectric properties of (Zr, Hf) NiSn half-Heusler compounds. Appl. Phys. Lett. 2005, 86, 82105. [Google Scholar] [CrossRef]

- Fu, C.; Bai, S.; Liu, Y.; Tang, Y.; Chen, L.; Zhao, X.; Zhu, T. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun. 2015, 6, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Gürth, M.; Rogl, G.; Romaka, V.V.; Grytsiv, A.; Bauer, E.; Rogl, P. Thermoelectric high ZT half-Heusler alloys Ti1- x- yZrxHfyNiSn (0 ≤ x ≤ 1; 0 ≤ y ≤ 1). Acta Mater. 2016, 104, 210–222. [Google Scholar] [CrossRef]

- Rogl, G.; Yubuta, K.; Romaka, V.V.; Michor, H.; Schafler, E.; Grytsiv, A.; Bauer, E.; Rogl, P. High-ZT half-Heusler thermoelectrics, Ti0. 5Zr0. 5NiSn and Ti0.5Zr0.5NiSn0.98Sb0.02: Physical properties at low temperatures. Acta Mater. 2019, 166, 466–483. [Google Scholar] [CrossRef]

- Hirohata, A.; Kikuchi, M.; Tezuka, N.; Inomata, K.; Claydon, J.S.; Xu, Y.B.; van der Laan, G. Heusler alloy/semiconductor hybrid structures. Curr. Opin. Solid State Mater. Sci. 2006, 10, 93–107. [Google Scholar] [CrossRef]

- Felser, C.; Fecher, G.H. Spintronics: From Materials to Devices; Springer Science & Business Media: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Graf, T.; Felser, C.; Parkin, S.S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Lee, S.C.; Lee, T.D.; Blaha, P.; Schwarz, K. Magnetic and half-metallic properties of the full-Heusler alloys Co 2TiX (X = Al, Ga; Si, Ge, Sn; Sb). J. Appl. Phys. 2005, 97, 14–17. [Google Scholar] [CrossRef]

- Boona, S.R.; Myers, R.C.; Heremans, J.P. Spin caloritronics. Energy Environ. Sci. 2014, 7, 885–910. [Google Scholar] [CrossRef]

- Beretta, D.; Neophytou, N.; Hodges, J.M.; Kanatzidis, M.G.; Narducci, D.; Martin-Gonzalez, M.; Beekman, M.; Balke, B.; Cerretti, G.; Tremel, W.; et al. Thermoelectrics: From history, a window to the future. Mater. Sci. Eng. R Rep. 2019, 138, 100501. [Google Scholar] [CrossRef]

- Ziebeck, K.R.A.; Webster, P.J. A neutron diffraction and magnetization study of Heusler alloys containing Co and Zr, Hf, V or Nb. J. Phys. Chem. Solids 1974, 35, 1–7. [Google Scholar] [CrossRef]

- De Souza, S.D.; Saxena, R.N.; Shreiner, W.; Zawislak, F.C. Magnetic hyperfine fields in Heusler alloys Co YZ (Y = Ti, Zr; Z = Al, Ga, Sn). Hyperfine Interact. 1987, 34, 431–434. [Google Scholar] [CrossRef]

- Barth, J.; Fecher, G.H.; Balke, B.; Graf, T.; Shkabko, A.; Weidenkaff, A.; Klaer, P.; Kallmayer, M.; Elmers, H.J.; Yoshikawa, H.; et al. Anomalous transport properties of the half-metallic ferromagnets Co2TiSi, Co2TiGe and Co2TiSn. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2011, 369, 3588–3601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Babiker, A.S.; Gao, G.; Yao, K. Half-metallicity and magnetism of Heusler alloys Co2HfZ (Z = Al, Ga, Ge, Sn). J. Magn. Magn. Mater. 2017, 441, 356–360. [Google Scholar] [CrossRef]

- Bekenov, L.V.; Antonov, V.N.; Shpak, A.P.; Yaresko, A.N. Electronic structure and excited-state properties of Co2TiSn and Co2ZrSn from ab initio calculations. Condens. Matter Phys. 2005, 8, 565–577. [Google Scholar] [CrossRef] [Green Version]

- Curtarolo, S.; Setyawan, W.; Hart, G.L.W.; Jahnatek, M.; Chepulskii, R.V.; Taylor, R.H.; Wang, S.; Xue, J.; Yang, K.; Levy, O.; et al. AFLOW: An automatic framework for high-throughput materials discovery. Comput. Mater. Sci. 2012, 58, 218–226. [Google Scholar] [CrossRef] [Green Version]

- Lutterotti, L.; Matthies, S.; Wenk, H.-R. MAUD (material analysis using diffraction): A user friendly Java program for Rietveld texture analysis and more. In Proceedings of the Twelfth International Conference on Textures of Materials (ICOTOM-12), Montréal, QC, Canada, 9–13 August 1999; Volume 1, p. 1599. [Google Scholar]

- Boldrini, S.; Famengo, A.; Montagner, F.; Battiston, S.; Fiameni, S.; Fabrizio, M.; Barison, S. Test rig for high-temperature thermopower and electrical conductivity measurements. J. Electron. Mater. 2013, 42, 1319–1323. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data, Powder Diffraction File; ICDD: Newton Square, PA, USA, 1997.

- Villars, P.; Prince, A.; Okamoto, H. Handbook of Ternary Alloy Phase Diagrams; ASM International, Materials Park: Novelty, OH, USA, 1995; Volume 5. [Google Scholar]

- Ponton, C.B.; Rawlings, R.D. Vickers indentation fracture toughness test Part 1 Review of literature and formulation of standardised indentation toughness equations. Mater. Sci. Technol. 1989, 5, 865–872. [Google Scholar] [CrossRef]

- Roebuck, B.; Bennett, E.G.; Lay, L.A.; Morrell, R. The Measurement of Palmqvist Toughness for Hard and Brittle Materials; National Physical Laboratory: Teddington, UK, 2008. [Google Scholar]

- Madeiros, E.E.; Dias, A.M.S. Experimental and numerical analysis of Vickers hardness testing. Int. J. Res. Rev. Appl. Sci. 2013, 17, 9–18. [Google Scholar]

- Faisal, N.H.; Ahmed, R.; Prathuru, A.K.; Spence, S.; Hossain, M.; Steel, J.A. An improved Vickers indentation fracture toughness model to assess the quality of thermally sprayed coatings. Eng. Fract. Mech. 2014, 128, 189–204. [Google Scholar] [CrossRef]

- Sktani, Z.D.I.; Rejab, N.A.; Ratnam, M.M.; Ahmad, Z.A. Fabrication of tougher ZTA ceramics with sustainable high hardness through (RSM) optimisation. Int. J. Refract. Met. Hard Mater. 2018, 74, 78–86. [Google Scholar] [CrossRef]

- Liang, K.M.; Orange, G.; Fantozzi, G. Evaluation by indentation of fracture toughness of ceramic materials. J. Mater. Sci. 1990, 25, 207–214. [Google Scholar] [CrossRef]

- Bradt, R.C. Fracture Mechanics on Ceramics: 3rd International Symposium Held July 15–17, 1983, at the Pennsylvania State University in University Park, Pennsylvania; Plenum Press: New York, NY, USA, 1983. [Google Scholar]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Elsevier: Kidlington, UK, 2011. [Google Scholar]

- Rogl, G.; Grytsiv, A.; Gürth, M.; Tavassoli, A.; Ebner, C.; Wünschek, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Bauer, E.; et al. Mechanical properties of half-Heusler alloys. Acta Mater. 2016, 107, 178–195. [Google Scholar] [CrossRef]

- Ikeda, K. Electrical resistivity of Laves phase compounds containing transition elements II. Co2A (A = Ti, Y, Zr, and Nb). J. Phys. Soc. Jap. 1977, 42, 1541–1546. [Google Scholar] [CrossRef]

- Li, S.X.; Yu, K.M.; Wu, J.; Jones, R.E.; Walukiewicz, W.; Ager, J.W.; Shan, W.; Haller, E.E.; Lu, H.; Schaff, W.J. Fermi-level stabilization energy in group III nitrides. Phys. Rev. B Condens. Matter Mater. Phys. 2005, 71, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Dashevsky, Z.; Shusterman, S.; Dariel, M.P.; Drabkin, I. Thermoelectric efficiency in graded indium-doped PbTe crystals. J. Appl. Phys. 2002, 92, 1425–1430. [Google Scholar] [CrossRef]

- Mehdizadeh Dehkordi, A.; Zebarjadi, M.; He, J.; Tritt, T.M. Thermoelectric power factor: Enhancement mechanisms and strategies for higher performance thermoelectric materials. Mater. Sci. Eng. R Reports 2015, 97, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Alleno, E. Review of the thermoelectric properties in nanostructured Fe2VAl. Metals 2018, 8, 864. [Google Scholar] [CrossRef] [Green Version]

- Kurosaki, K.; Muta, H.; Endo, Y.; Charoenphakdee, A.; Uno, M.; Yamanaka, S. Effect of Nb substitution for V on the thermoelectric properties of Fe2VAl. J. Alloys Compd. 2009, 486, 507–510. [Google Scholar] [CrossRef]

- Al-Yamani, H.; Hamad, B. Thermoelectric Properties of Fe2VAl and Fe2V0.75M0.25Al (M = Mo, Nb, Ta) Alloys: First-Principles Calculations. J. Electron. Mater. 2016, 45, 1101–1114. [Google Scholar] [CrossRef]

- Hinterleitner, B.; Knapp, I.; Poneder, M.; Shi, Y.; Müller, H.; Eguchi, G.; Eisenmenger-Sittner, C.; Stöger-Pollach, M.; Kakefuda, Y.; Kawamoto, N.; et al. Thermoelectric performance of a metastable thin-film Heusler alloy. Nature 2019, 576, 85–90. [Google Scholar] [CrossRef]

- Kimura, Y.; Chai, Y.W. Ordered Structures and Thermoelectric Properties of MNiSn (M = Ti, Zr, Hf)-Based Half-Heusler Compounds Affected by Close Relationship with Heusler Compounds. JOM 2015, 67, 233–245. [Google Scholar] [CrossRef]

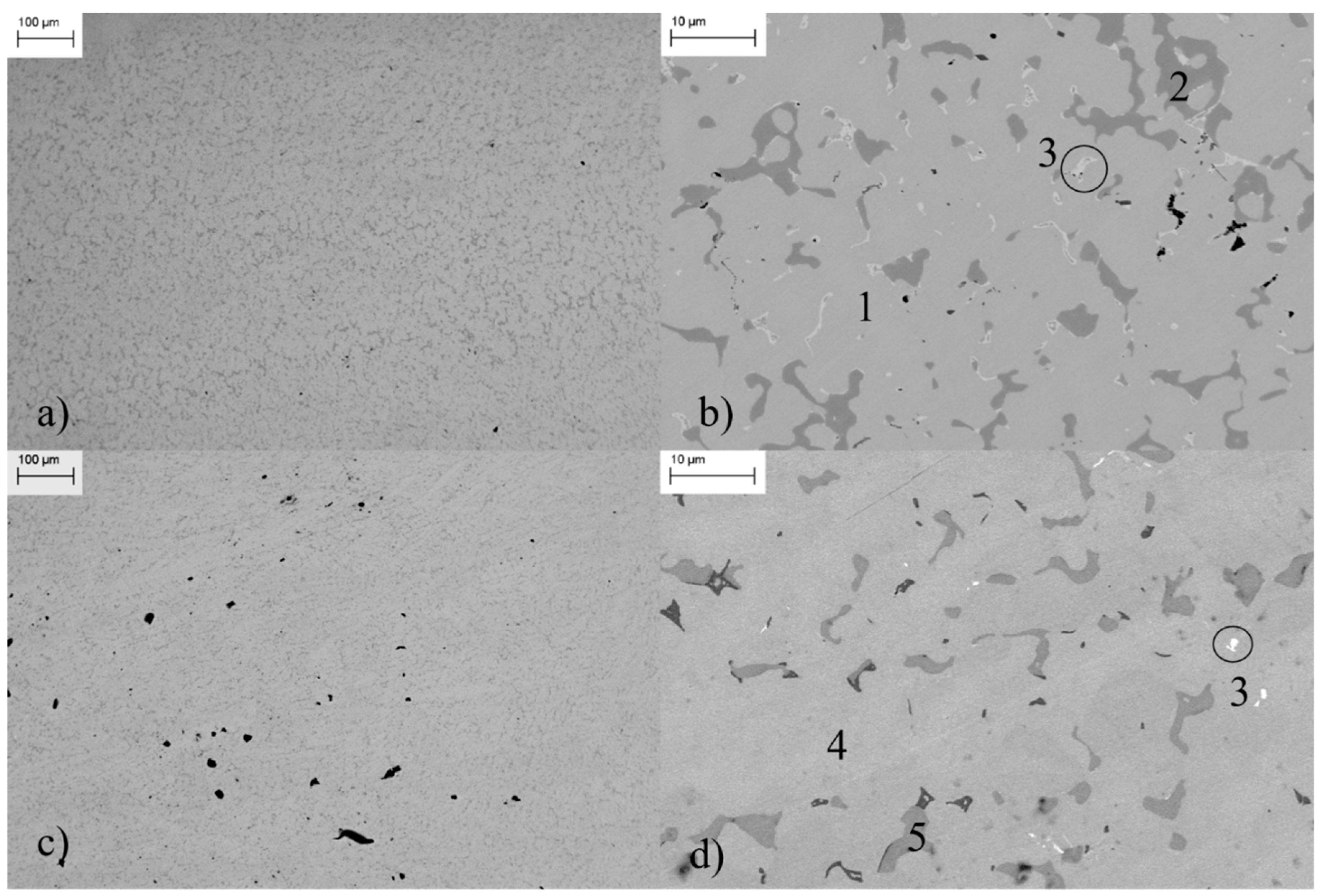

| Co2ZrSn As-Cast | |||||||

| Elemental composition (at %) | Label | Phase | Structure | a (Å) | Abundance (wt %) | ||

| Co | Zr | Sn | |||||

| 45 | 28 | 27 | 1 | Co2ZrSn | L21 | 6.2338 | 88% |

| 65 | 21 | 13 | 2 | Co2ZrxSny | C15 | 6.9174 | 12% |

| 58 | - | 42 | 3 | CoSn | B35 | - | - |

| Co2ZrSn Annealed | |||||||

| Elemental composition (at %) | Label | Phase | Structure | a (Å) | Abundance (wt %) | ||

| Co | Zr | Sn | |||||

| 46 | 27 | 27 | 1 | Co2ZrSn | L21 | 6.2458 | 88% |

| 66 | 19 | 15 | 2 | Co2ZrxSny | C15 | 6.9212 | 12% |

| 58 | - | 42 | 3 | CoSn | B35 | - | - |

| Co2HfSn As-Cast | |||||||

| Elemental composition (at %) | Label | Phase | Structure | a (Å) | Abundance (wt %) | ||

| Co | Hf | Sn | |||||

| 45 | 27 | 28 | 4 | Co2HfSn | L21 | 6.2101 | 93% |

| 65 | 26 | 9 | 5 | Co2HfxSny | C15 | 6.9024 | 7% |

| 56 | - | 44 | 3 | CoSn | B35 | - | - |

| Co2HfSn Annealed | |||||||

| Elemental composition (at %) | Label | Phase | Structure | a (Å) | Abundance (wt %) | ||

| Co | Hf | Sn | |||||

| 47 | 26 | 27 | 4 | Co2HfSn | L21 | 6.2157 | 93% |

| 66 | 25 | 9 | 5 | Co2HfxSny | C15 | 6.8915 | 7% |

| 55 | - | 44 | 3 | CoSn | B35 | - | - |

| Alloy | Hardness (HV) | l/a | KIC (MPa·m1/2) |

|---|---|---|---|

| Co2ZrSn | 903 ± 31 | 1.42 | 2.07 ± 0.23 |

| Co2HfSn | 899 ± 26 | 1.41 | 2.06 ± 0.14 |

| Alloy | TC (K) | S (µV/K) | σ (S/cm) | PF (mW·m−1·K−2) |

|---|---|---|---|---|

| Co2TiSn [14] | 360 | −50 | 2851 | 0.71 |

| Co2ZrSn | 465 | −34 | 3157 | 0.38 |

| Co2HfSn | 426 | −38 | 3214 | 0.47 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Difalco, A.; Aversano, F.; Boldrini, S.; Ferrario, A.; Baricco, M.; Castellero, A. Synthesis and Characterization of Thermoelectric Co2XSn (X = Zr, Hf) Heusler Alloys. Metals 2020, 10, 624. https://doi.org/10.3390/met10050624

Difalco A, Aversano F, Boldrini S, Ferrario A, Baricco M, Castellero A. Synthesis and Characterization of Thermoelectric Co2XSn (X = Zr, Hf) Heusler Alloys. Metals. 2020; 10(5):624. https://doi.org/10.3390/met10050624

Chicago/Turabian StyleDifalco, Alessandro, Francesco Aversano, Stefano Boldrini, Alberto Ferrario, Marcello Baricco, and Alberto Castellero. 2020. "Synthesis and Characterization of Thermoelectric Co2XSn (X = Zr, Hf) Heusler Alloys" Metals 10, no. 5: 624. https://doi.org/10.3390/met10050624