Abstract

The metal titanium (Ti) and its alloys have many attributes which are attractive as structural materials, but they also have one major disadvantage, high initial cost. Nevertheless, Ti and Ti alloys are used extensively in airframes, gas turbine engines (GTE), and rocket engines (RE). The high cost is a deterrent, particularly in airframe applications, in that the other alloys it competes with are, for the most part, significantly lower cost. This is less of a concern for GTE and RE where the cost of titanium is closer to and sometimes even lower than some of the materials it competes with for these applications. In spacecraft the weight savings are so important that cost is a lesser concern. Ti and its alloys consist of five families of alloys; α-Ti, near α-alloys, α + β alloys, β-alloys, and Ti-based intermetallic compounds. The intermetallic compounds of primary interest today are those based on the compound TiAl which, at this time, are only used for engine applications because of their higher temperature capability. These TiAl-based compounds are used in a relatively low, but growing, amounts. The first production application was for low pressure turbine blades in the GE engine (GEnx) used on the Boeing 787, followed by the GE LEAP engine used on A-320neo and B-737MAX. These air foils are investment cast and machined. The next application is for the GE90X which will power the Boeing B-777X. These air foils will be made by additive manufacturing (AM). Unalloyed titanium and titanium alloys are typically melted by vacuum arc melting and re-melted either once (2X VAR) or twice (3X VAR); however a new and very different melting method (cold hearth melting) has recently become favored, mainly for high performance applications such as rotors in aircraft engines. This process resulted in higher quality ingots with a significant reduction in melt-related defects. Once melted and cast into ingots, the alloys can be processed using all the standard thermomechanical working and casting processes used for making components of other types of structural alloys. Because of their limited ductility, the TiAl-based intermetallic compounds are quite difficult to process using ordinary wrought methods. Consequently, the low-pressure turbine blades currently in service are investment cast and machined to net shape. The AM air foils will require minimal machining, which is an advantage. This paper describes some relatively recent developments as well as some issues and opportunities associated with the production and use of Ti and its alloys in aerospace components. Included are new Ti alloys, new applications of Ti alloys, and the current status of several manufacturing processes including a discussion of the promise and current reality of additive manufacturing as a potentially revolutionary method of producing Ti alloy components.

1. Introduction

Titanium and its alloys were first fully recognized for their potential for high performance, usually weight critical, applications as early as the late 1950s. However, the reactivity of molten Ti and solid Ti and its alloys at elevated temperatures was a significant barrier to wide-scale commercialization including development of significant production capacity. Today, these barriers have largely been overcome, but the intrinsic reactivity of Ti and it alloys still requires special processing which adds significant cost to the final product, regardless of its intended use. There are several books that contain extensive, detailed information about Ti and Ti alloys [1,2,3,4].

The element titanium (Ti) has two allotropic forms; a low temperature, hexagonal close packed (HCP) α-phase and an elevated temperature, body centered cubic (BCC) β-phase. The α ↔ β transition temperature for unalloyed Ti is 882 °C. The addition of alloying elements to Ti allows the proportions of these two phases at room temperature to be varied in order to manipulate the ease of processing and the resulting properties. As stated in the Abstract, there are five families of Ti alloys, each related to their equilibrium constitution at room temperature. These five are α-alloys, near α-alloys, α + β alloys, β-alloys, and Ti-based intermetallic compounds, mainly those based on the compound TiAl.

The intent of this Introduction is to provide a brief overview of these five families of Ti alloys as a prelude to discussing some examples of processing advances and relatively new applications of these alloys.

α-phase alloys: The α-phase alloys include unalloyed Ti, also called Commercially Pure Ti or just CP Ti. CP Ti predominantly consists of the HCP α-phase with minor amounts (<5 vol. %) of β-phase because of the presence of Fe, either as a residual impurity from the raw material, called sponge, or as a deliberate addition. CP Ti has four grades (1–4), depending on the composition, with corresponding tensile strengths from 240–550 MPa. The higher numbered grades have higher strengths which are primarily due to the presence of increasing concentrations of oxygen, which is present as an interstitial element and a potent solid solution strengthener. CP Ti is used primarily for applications requiring corrosion resistance and weldability, but not requiring the higher strength characteristic of the other classes of Ti alloys [1]. In general, all Ti alloys have superior corrosion resistance compared to that of other alloy systems used for aerospace applications except for some of the Ni-base alloys [1,2,3,4,5]. In aircraft, CP Ti is mainly used for ducts that supply heated air as part of the wing leading edge anti-icing systems, for ducts in the environmental control systems for the passenger cabin, for hydraulic tubing, and for various clips and brackets.

There are other α-alloys that also consist of about 95% α-phase, similar to CP Ti but which, in addition to oxygen, contain the α-stabilizer Al and the neutral alloying element Sn to increase their strength compared to CP Ti. Another of these alloys also contain minor additions of the β-stabilizing elements such as V to improve the ease of processing. This Ti alloy family nomenclature is not strictly correct but also is well-established. Therefore we will adhere to it to avoid creating other, possibly confusing, nomenclature. The most commonly used α-phase alloys are Ti-3Al-2.5V (Ti-3-2.5) and Ti-5Al-2.5Sn (Ti-5-2.5), of which the latter is primarily used at cryogenic temperatures as low as 20 K in rocket engine turbomachinery fuel pumps. In aircraft, Ti-3-2.5 is primarily used by Boeing for hydraulic tubing in all areas of the aircraft except the wheel well where the hydraulic lines that actuate the main landing gear are located. The hydraulic stainless steel tubing in the wheel well is used because it is more resistant to foreign object damage (FOD). Another use for the Ti-3-2.5 alloy is for welded or brazed honeycomb structures. These alloys are stronger than the CP grades yet still are formable and weldable. The α-alloys, except for CP Ti are more difficult to process, i.e., they have predominantly a high alpha content, which is more difficult to work with, though CP is highly workable because of its lower hardness and flow stresses. They also are readily weldable.

Near α-alloys: These alloys primarily contain Al, Sn, and Zr with minor amounts (up to about 2 wt. %) of low diffusivity β-stabilizers such as Mo or Nb, and some Si (up to 0.5 wt. %). The Mo and Nb additions stabilizes small amounts of retained β-phase at room temperature to provide some strengthening, to facilitate microstructure control during processing for improved properties and fabricability. Generally, these alloys are not heat treatable to alter their strength but are used at higher temperatures where creep strength is more important than tensile properties. The two most commonly used near-α alloys are Ti-6Al-2Sn-4Zr-2Mo+Si (Ti-6-2-4-2S), which, depending on loading, can be used up to about 540 °C maximum, and IMI 834 (Ti-5.8Al-4Sn-3.5Zr-0.5Mo-0.7Nb-0.35Si-0.06C) which is used up to about 600 °C. Today, IMI834 is generally considered the highest temperature capability near α-titanium alloy in commercial production. Even though the near α alloys are not heat treatable to promote higher strength, they have excellent creep resistance and a good combination of other properties, including tensile ductility, good weldability, fatigue resistance, and damage tolerant properties. These alloys are seldom used as sheet products because they are more difficult to roll and subsequently form than the α + β and β-alloys. This is due to the lower β-phase content. It also should be noted that, for the most part, the maximum service temperature is not necessarily related to loss of strength or creep resistance at higher temperatures, but due to the surface absorption of oxygen from the atmosphere during elevated temperature service. This results in the formation of an oxygen enriched surface layer of the α-phase referred to as α-case, which is brittle and leads to early fatigue crack initiation [1,2,3,4,5]. These alloys are generally quite weldable but also are more difficult to process because of lower formability due to the high volume fraction of solid solution strengthened α-phase which results in higher strength.

α + β alloys: The α + β alloys are, by far, the most widely used titanium alloys for structural applications. They have higher β-stabilizer contents, with β-stabilizer contents between 4% and 6% (in wt.%). Consequently, they have a higher β-phase content than the near-α alloys and can be processed including heat treatment to attain higher strengths. Retention of some metastable β-phase at room temperature, or the formation of martensite from the prior β-phase on quenching to room temperature are the key strengthening mechanisms. Aging of alloy conditions containing metastable β-phase will form lamellar α in these regions which also will provide higher strength with minimal ductility reduction. By a large measure, the most commonly used α + β titanium alloy is Ti-6Al-4V (Ti-6-4), which has a good combination of properties. Ti-6-4 is usually used in the annealed condition at a minimum tensile strength of 896 MPa (130 ksi). Other α + β alloys include, Ti-6Al-6V-2Sn (Ti-662) and IMI550 (Ti-4Al-2Sn-4Mo-0.5Si). All of the α + β alloys are considered weldable in an inert environment, although special precautions such as pre-heating may be required to weld some of the higher strength alloys [1,2,3,4]. Alloys such as Ti-6-4 are usually used in the mill annealed condition. The post processing annealing is done at relatively low temperatures typically ≈700 °C (or higher) which does not always relieve the residual stresses which remain in mill products after final working. The solution treated and aged (STA) condition is not normally used for Ti-6-4 components as the rapid cooling rate from the ST temperature (usually a water quench) creates residual stresses which cause distortion during subsequent machining. Consequently, Ti-6-4 is most often used in the mill annealed condition for most products, particularly larger ones; even though the STA condition is the highest strength condition for Ti-6-4, there are very few Ti-6-4 STA parts in production. However, for smaller, symmetrical parts, such as fasteners, the residual stresses are lower and more symmetrical because of the cylindrical geometry, so distortion is not an issue. Ti-6-4 fasteners are typically used in the STA condition.

β-alloys: These alloys are the highest strength titanium alloys; they are called β-alloys because 100% metastable β-phase can be retained at room temperature after rapid cooling from the β-phase field. The subsequent aging causes precipitation of the α-phase resulting in the strengthening. For the β-alloys the aging temperature is generally high enough to relieve the residual stresses from the quenching treatment following the solution treatment. Technically, while called β-alloys, these alloys are really metastable β-alloys as they will decompose to form an α + β phase mixture during aging. The α-phase precipitate size and volume fraction in the β-phase matrix of a given alloy can be controlled by different combinations of aging temperature and time. This reaction is responsible for the higher strengths attainable in these alloys compared to α + β alloys. Selection of the appropriate aging temperature and time enable a range of properties to be achieved. Retention of 100% β-phase at room temperature after fast cooling from the β-phase field depends on the alloy composition and the cooling rate. The β-alloys include Ti-6Al-2Sn-4Zr-6Mo (Ti-6-2-4-6), Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti-17), Ti-10V-2Fe-3Al (Ti-10-2-3), Ti-5Al-5Mo-5V-3Cr (Ti-5-5-5-3), Ti-15V-3Cr-3Al-3Sn (Ti-15-3-3-3), and Ti-3Al-8V-6Zr-4Mo-4Zr (Ti-3-8-6-4-4 or Beta-C). Ti-6-2-4-6 and Ti-17 are primarily used as fan disks at higher strength levels in some of the newer, larger aircraft engines. Yield strengths of 1000–1200 MPa (150–170 ksi) are typical. Fan disks are located at the front of the engine where operating temperatures do not exceed about 300 °C even on hot day take-offs, but which is at the limiting capability of Ti-6-4. The strength of these alloys also exceeds that of the near-α alloys so they occupy a niche in the overall application spectrum of Ti alloys.

The alloys containing more solute, such as Ti-5-5-5-3 and Beta-C, are used at tensile strengths up to 1240 MPa, mainly for forgings, fasteners, and springs. Because of their higher strength, they have lower ductility and reduced damage tolerance properties (fracture toughness and fatigue crack growth rates) than the lower strength α + β alloys so are not commonly used for critical load bearing, components. During processing, they have lower flow stresses at a given working temperature and better formability at elevated temperatures due to higher ductility resulting from the presence of higher β contents which enable nearer net shape parts with better buy-to-fly (BTF) ratios. With few exceptions, they are not considered for high temperature applications as the β-alloys in general lose strength more rapidly with increasing temperature than the near α and α + β alloys and are not as creep resistant as the near-α alloys. Welding also is more difficult for these alloys and can be an issue for some applications.

There is only one true (stable) β-alloy with limited commercial status. The alloy is Ti-35V-15 Cr which is used by Pratt and Whitney as part of the exhaust system for military engines because it is considered “fireproof” (not combustible). This is important because other Ti alloys will burn under high mass flow conditions, such as those in the gas stream of a jet engine, following a “rub” that removes the protective surface oxide. This particularly is severe for thin gages. The “fuel” for combustion is Ti itself and Al which nearly all the other Ti alloys contain in greater concentrations. The β-stabilizer alloying content in this alloy is high enough that the β-phase will not normally decompose to α + β at service temperatures. More detailed reviews of the metallurgy of metastable β-alloys can be found elsewhere [2,3,4,5,6].

Ti-based intermetallic compounds: There is another class of Ti base alloys with higher temperature capability than the near-α alloys. These alloys have been under investigation for a number of years but, because of ductility concerns, have only been introduced into actual production engines within the past 8 years. These alloys are called Ti Aluminides because they are based on either of two ordered intermetallic phases, Ti3Al (α2) and TiAl (γ). Presently, the only one of these alloys in use in production engines is a γ alloy because it has acceptable high temperature properties up to about 725 °C, so can be used at higher temperatures than conventional Ti alloys and can supplant some Ni alloys. TiAl also has lower density (about 50% lower) than the Ni-base alloys they are replacing [7].

Initially, the α2 alloys also appeared to be attractive because they had higher temperature strength and better ductility than the TiAl-based alloys up to about 650 °C. It turned out that most of these initially attractive properties were obtained from tensile tests conducted at standard ASTM E-8 strain rates either in vacuum or inert gas. Those tests that were conducted in air showed a modest reduction in ductility but not to an unacceptable extent. Later, slow strain rate tests conducted in air on the same alloy showed the loss in tensile ductility increased with decreasing strain rates and the alloy eventually became brittle. This effect was attributed to oxygen embrittlement by Ward et al. [8]. This issue was judged to be severe enough that further work on the α2 alloys was essentially terminated.

2. Advantages of Titanium: Commercial Aircraft

As noted previously, titanium alloys have some significant advantages over other materials, but also are one of the more expensive metallic materials used in airframes today. However, as the use of carbon fiber-polymer composites (PMCs) increases the cost of Ti alloys has become a lower concern. These advantages of Ti alloys include:

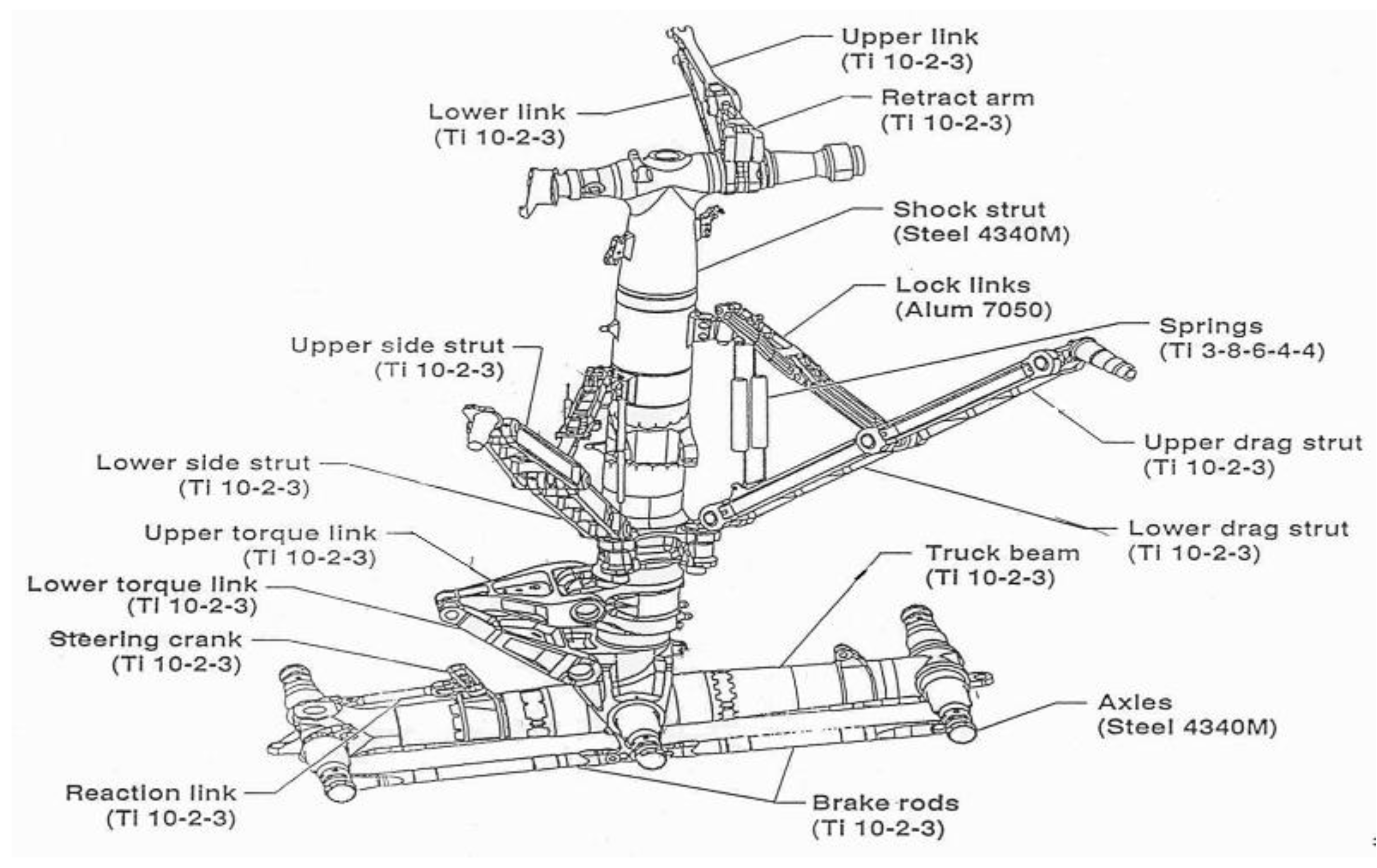

Weight savings: Titanium alloys have a high specific strength (strength-density ratio). The lower density (≈50% lower than that of steel) and the mechanical properties are attractive. For instance, in landing gear structure, replacing steel used at ultimate tensile strength (UTS) of 1930 MPa with Ti-10-2-3 at 1190 MPa (UTS) results in a significant weight savings because of the better strength-density ratio of the Ti alloy. This amounts to about 270 kg (or 600 lbs) for the Boeing 777 main landing gear. Also unlike steel, corrosion is not an issue with Ti alloys which leads to reduced periodic maintenance cost and higher asset availability [9].

Space limitations: There are some structural applications that would normally use Al alloys, but the Al alloy component is too large to fit in the available space. Consequently, Ti alloys are used because of their lower density than steel with equivalent specific strength and excellent corrosion resistance. These characteristics minimize the modest weight impact from using Ti alloys in place of the Al alloys.

Composites compatibility: Titanium is usually used in structures where polymer matrix-carbon fiber composites (PMCs) are used for components which typically operate in the temperature range of about −55 °C, at cruising altitude up to +55 °C for a hot day takeoff in places such as Dubai. The coefficient of thermal expansion of Ti is less than half that of Al alloys and about 75% lower than steel. Even over the small temperature range just described, the higher coefficient of thermal expansion of steel or Al alloys relative to PMCs can result in distorted or even ruptured components. This does not occur with titanium. Unlike Al alloys, Ti alloys also are electrochemically compatible with PMCs which avoids corrosion concerns in a wet or moist environment.

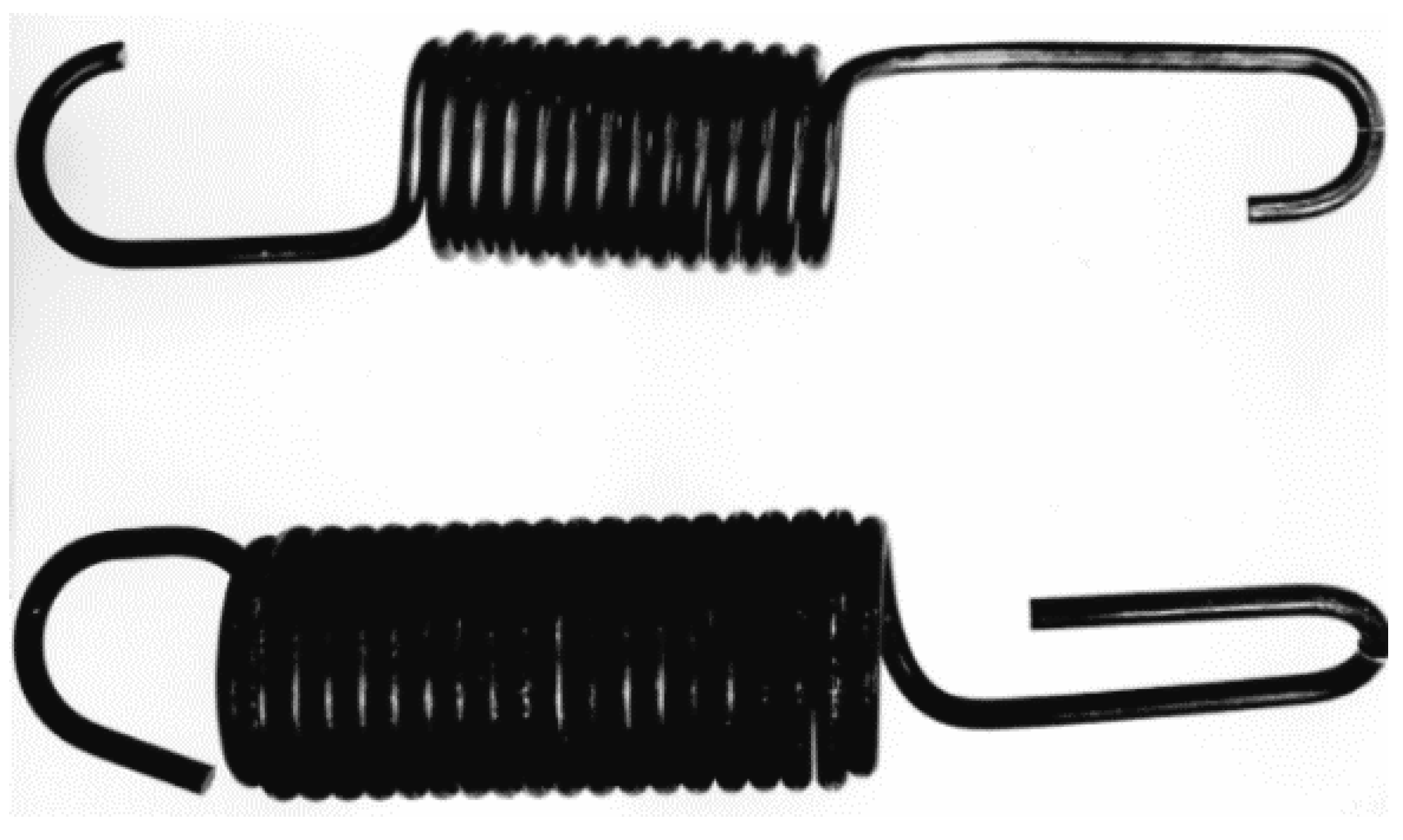

Low modulus: The elastic modulus of titanium is about half that of steel, but β-alloys can be processed to have comparable yield strengths while maintaining a low modulus [8]. This means that only half the coils are required in a spring fabricated from titanium to permit the same elastic extension and load carrying capability. That, in conjunction with the lower density, makes β-alloys excellent spring materials, especially where weight is a concern. Weight savings of 70% have been achieved by substituting β-alloy springs for steel ones. In addition, the pitting corrosion that occurs with steel springs unless they are painted or coated is eliminated. This also reduces maintenance costs and risk of failure if the steel coating (usually paint) is breached. The low modulus and relatively high yield strength of β-alloys is not helpful for cold formability. However, the good ductility and reduced yield stress of these alloys in the annealed and rapid air cooled (also called the ST) condition due to the high β content makes them formable, even at room temperature. If doing more severe forming these alloys will form at lower temperatures than either the α or α + β alloys because of lower flow stresses and good ductility. However, the low modulus and higher yield stress compared to the α-phase alloys leads to greater “spring back” (recovery of elastic strain on unloading) during low or room temperature forming which must be compensated for in the forming operation. For thermomechanically processed shapes, such as forging and extrusions, spring back is not an issue because the lower strength at processing temperatures results in smaller elastic strains and these components are typically machined to net shape. Proper die design is the key for forged products.

3. Advantages of Titanium Alloys: Aircraft and Rocket Engines

The case for using Ti and its alloys for weight savings in aircraft and rocket propulsion systems is similar to that described above for aircraft. However, this case is even more compelling when the elevated and cryogenic temperature capabilities of Ti alloys, which are less pertinent for aircraft, also are included. These advantages include:

Good specific strength: At relatively moderate service temperatures three alloys are used in fan and low pressure compressor sections (up to 300 °C) of essentially all modern, high by-pass ratio, aircraft engines. The alloys used are Ti-6-4, Ti-6-2-4-6, and Ti-17. The superior density corrected strength (specific strength) of Ti alloys has been the sole materials characteristic that has enabled the increased by-pass ratio that are characteristic of the current generation of quieter, more fuel-efficient engines. As the fan by-pass ratio increases, the need for a high strength fan disk becomes critical because of the bigger, and heavier, fan blades that rotate while they are attached to the disk. The latter two higher strength alloys mentioned above satisfy this need.

Elevated temperature capabilities: The near-α alloys are used in the front of the high pressure compressor up to temperatures of about 500 °C for Ti-6-2-4-2S and 600 °C for IMI 834. These alloys are about 50% lighter than steel or Ni-base alloys they replaced in earlier jet engines once Ti alloys were mature. More recently, the Gamma Ti aluminides are used for low pressure turbine blades up to temperatures as high as about 700 °C [7].

Cryogenic temperature capabilities: The turbo-machinery fuel pump in a liquid hydrogen–liquid oxygen rocket engine operates at about −250 °C (20 K). While all metallic alloys have higher strength at lower operating temperatures, it is imperative that they also retain some ductility. In this regard, the α-phase alloy Ti-5-2.5 is the most commonly used alloy for this application [10]. Unlike steel, Ti alloys do not exhibit a ductile to brittle transition at such low temperatures. This, coupled with their high specific strength, make them ideal for such applications.

4. Advances in Processing Ti Alloys and New Applications of Existing Alloys

This section describes some examples of processing advances of Ti alloys that have led to their expanded use in the aerospace industry.

4.1. Cold Hearth Melting of Ti Alloys

As mentioned in the Abstract, production of Ti and Ti alloys in commercial sized ingots has historically been done by initial vacuum arc melting followed by vacuum arc re-melting (VAR), either two or three times, to achieve better ingot quality including chemical homogeneity. This is because the strong reactivity of molten Ti makes the use of more common melting techniques such as vacuum induction melting (VIM) or electro slag melting and re-melting (ESR) used for Ni-base alloys and specialty steels unworkable [2].

One major issue for VAR is the relatively short time that the material remains molten which limits any refining that can occur in the melt pool. Multiple melts are helpful in this regard but are still inadequate as shown by the survival of unwanted defects in the final product. A second limitation is that everything that is part of the melt electrode, by definition, ends up in the ingot. Because of the cost of Ti alloys, mill scrap, turnings and chips from machining are recycled in subsequent heats. The turnings and chips can have broken tool pieces, which are Tungsten Carbide (WC), mixed in with them and, if present, these end up in the VAR ingots. These are called high density inclusions (HDIs). HDIs can cause significant ductility loss or serve as fatigue crack initiation sites, so they are prohibited. They also are difficult to find by ultrasonic inspection so pose a risk for fracture critical components [2,11].

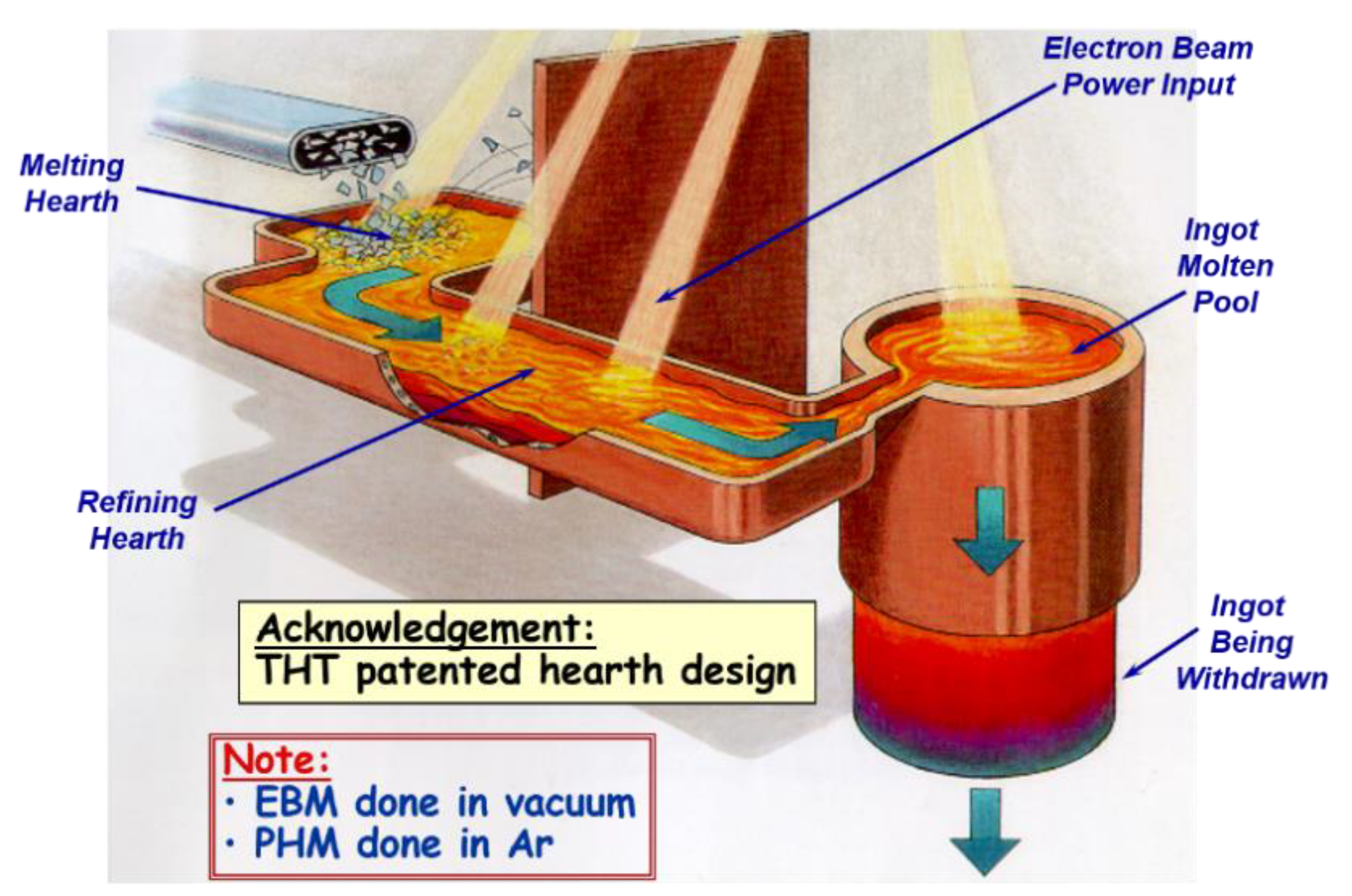

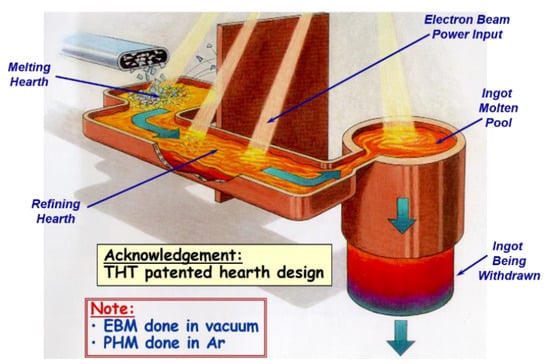

A relatively new approach to melting Ti and its alloys has been developed and commercialized. This method is known as cold hearth melting (CHM) [2]. This process is completely different from VAR and uses a water-cooled Cu hearth to contain the molten metal and several intense heat sources to melt the material and keep it molten. The heat sources can be either electron beams or plasma torches. The heat input is controlled in coordination with the cooling of the Cu hearth so there always is a thin “skull” of solid alloy between the Cu hearth and the molten alloy. A schematic of a CHM unit is shown in Figure 1. From this image, it is clear that the residence time of the molten alloy in the CHM refining hearth can be controlled by the input rate of material to the melting hearth and the heat input from the electron beam guns. The unit illustrated in Figure 1, uses electron guns in the melt chamber which is maintained under a vacuum. In the case of CHM done using plasma torches the melt chamber is held at a partial pressure of Ar. A further advantage of CHM is that unwanted objects such as WC are denser than molten Ti so they sink, are captured in the skull and are not carried over into the ingot. Another advantage of CHM is that the ingot mold can be rectangular instead of cylindrical. In the case of a rectangular ingot, for the production of flat rolled products (sheet and plate), the yield losses during ingot breakdown and conversion are much lower when compared to that of a cylindrical ingot which is the product of VAR melting. Consequently, CHM is now commonly used to melt CP Ti, which is mainly used a sheet, in order to reduce cost by increasing product yields.

Figure 1.

Schematic of a cold hearth melting unit using four electron beam guns as heat sources [2]. Adapted from “Titanium, 2nd edition”, Springer-Verlag, Heidelberg, Germany, 2007.

One issue unique to electron beam CHM is the Al loss due to evaporation from the molten alloy in the vacuum. This is manageable but also results in requiring more frequent cleaning of the melt chamber to avoid Al-rich condensate that cause Al rich “drop ins” during melting. The severity of this issue depends on the Al concentration of the alloy being deposited. Also, the early plasma CHM furnaces operated at a positive Ar pressure to avoid back diffusion of air. This was found to occasionally result in Ar bubbles that ended up as Ar filled voids in the ingot. With improved sealing of these furnaces, the newer ones now operate at a partial atmospheric pressure of Ar, thus solving this issue.

An example of the effects of CHM on the quality of Ti alloys, as of the end of 2018, millions of pounds of material had been produced by CHM and the incidence of rejectable melt-related defects was dramatically lower, e.g., the occurrence of melt-related defects in CHM material was lower than triple melted VAR material by greater than a factor of 104 with no “finds” of WC HDI inclusions. Moreover, this defect reduction data also was achieved during a period when the sensitivity of ultrasonic inspection was also being improved. If these data were collected under conditions of constant ultrasonic capability, the apparent improvement due to CHM would be even greater [11].

4.2. Superplastic Forming (SPF) of Ti Alloys

The ability of Ti alloys to exhibit superplasticity was reported by Lee and Backofen in 1967 [12]. While this was technically interesting, the practical usefulness was not recognized until Ti alloy sheet became readily available, more affordable and interest in components made of formed Ti alloy sheet became greater. Further, because of the relatively high yield strength and low elastic modulus of α + β Ti alloys such as Ti-6-4, it became clear that spring back after conventional forming was a practical limitation in formability. It was then that practical interest in SPF began and grew as the need for sheet components in aircraft and aircraft engines increased. While SPF eliminated the occurrence of spring back, it was performed at elevated temperatures high enough, e.g., 900–950 °C for Ti-6-4, that oxygen pick-up during forming was an issue. The result of this was that the component required chemical milling to remove the α-case and this added cost to the final part. Also, the interaction between the Fe-based tooling and the Ti sheet was an issue both for the part and for the life of the tool. The solution was to find an alloy that was superplastic at lower temperature which minimized both α-case and tooling contamination. Guidance for development of lower temperature SPF alloys was provided by a paper by Ashby and Verrall [13]. This paper showed that superplasticity occurred by diffusion-controlled grain switching.

In response to this need and driven by the economics of the SPF process, Boeing has been investigating lower temperature superplastic forming (SPF) since the early 1990s, starting with the relatively new alloy Ti-4.5 Al-3V-2Fe-2Mo, called SP-700 by its Japanese developer Nippon Kokan (NKK). SP-700 is a more β-rich α + β alloy than Ti-6-4, which was the original alloy used for SPF. SP-700 becomes superplastic at temperatures 250 °C lower than Ti-6-4 [14]. The lower SPF temperature has a very significant impact on SPF processing cost by extending the SPF die life and post-processing costs. SPF of SP-700 also can be done at higher strain rates which enable shorter cycle times for forming. The reduced cycle time also results in less oxidation which reduces the time in the chemical milling bath used to remove the α-case. This also reduces concerns for H2 pickup from the chemical milling bath. Last, but not least, the temperature reduction greatly increases the comfort of the press operators who must put the material into the press and remove the hot formed parts. Boeing has successfully used this alloy in production for forming some non-structural parts [14,15,16].

ATI has recently developed an interesting sheet alloy, ATI425 (nominal composition Ti-4Al-2.5V-1.4Fe), which is cold rollable. Because of this, the final processing step can be done by cold rolling directly to the desired gage with such good gage control that grinding to meet the required gage is not necessary. For example, it can be directly cold rolled to gage with about a ±50 µm tolerance without grinding. Boeing has been using it in production on the leading edge of the composite rotor blades of the Boeing CH-47 helicopter, to protect them from erosion [17]. An important reason why Boeing is using this alloy is the tight gage tolerances on the sheet product as mentioned earlier.

VSMPO developed a process to produce Ti-6-4 sheet with a refined, ≈2 µm α-grain size microstructure, this is compared to a typical 10–15 µm in an ordinary mill product [18]. This fine-grain Ti-6-4 exhibited similar SPF advantages as the SP-700 alloy, but the production process was complex and difficult to adequately control in the mill, making the yields low and the sheet cost too high. It was used in production at Boeing for a while, but its usage was terminated due to the high cost of the sheet [18,19]. This decision prompted further investigation into the development of fine grain Ti-6-4 at Arconic (now Howmet Aerospace) which developed another, lower cost, processing route that was economically more viable. Sheet made by this process has been approved by Boeing because of the lower cost than the VSMPO product. This alloy is capable of SPF at 815 °C and is being used in production by Boeing [20,21,22].

Boeing and VSMPO have also developed another low temperature SPF capable alloy referred to as VST2L with a nominal composition of Ti-5Al-5V-1Fe [23,24] but with a wider chemistry range. This alloy also is attractive because it can utilize revert (scrap) from a range of alloys. Rectangular ingots of this alloy will be produced by hearth melting plus vacuum arc re-melting to enable lower conversion losses, lowering product cost. Another cost saving feature of VST2L is that special processing to achieve a fine grain size is not required. The Al and Mo equivalents must be carefully controlled within certain limits to maintain the ability to achieve the desired microstructure with about 50% α- and 50% β-phase at the SPF temperature, 775 °C.

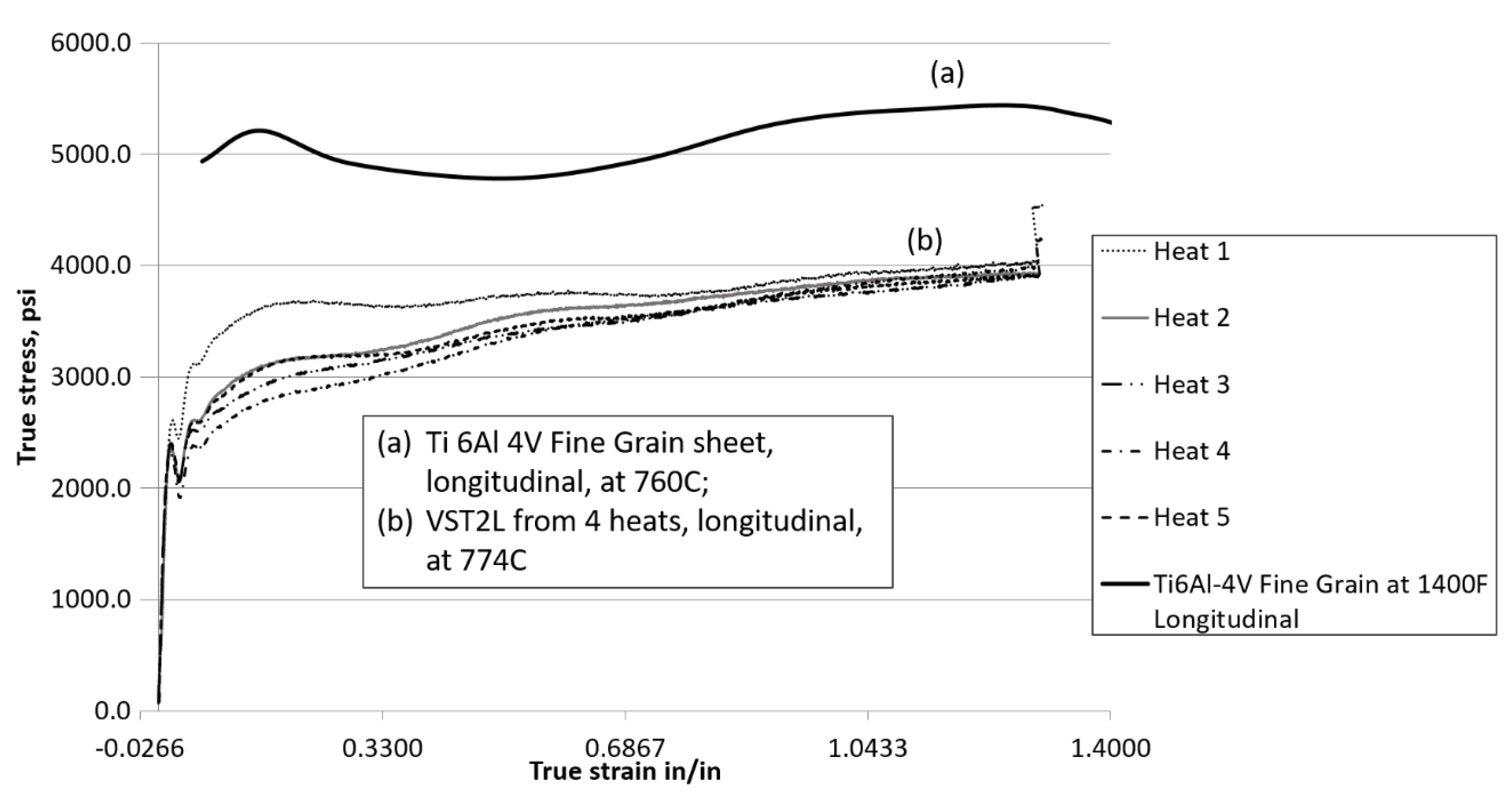

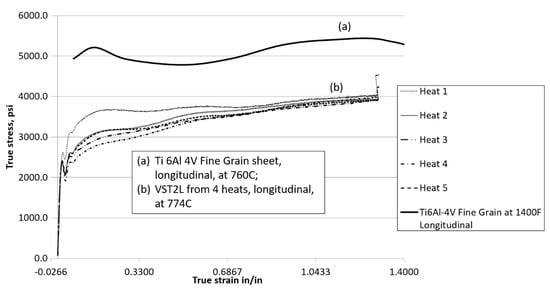

In the annealed condition VST2L has a room temperature tensile strength of ≈1100 MPa. In the as-SPF condition the strength is somewhat lower mainly due to the microstructural coarsening that occurs during SPF. Figure 2 shows test results at 775 °C from three different full-size heats of VST2L and compares these with fine grain Ti-6-4 results.

Figure 2.

The advantage of VST2L is clear because the flow stress at SPF temperatures for this alloy (775 °C) is significantly lower compared to fine grain Ti-6-4 [22].

Two other alloys also are being investigated by Arconic for lower SPF temperatures, but which also can used for higher service temperatures, up to ≈650 °C. The first is Ti-6-2-4-2 made by a modified processing route. The second Arconic alloy is called THOR (Ti-6Al-4Sn-3Nb-0.5Mo-0.3Si) which can be used at service temperatures up to ≈650 °C [25]. THOR also has improved oxidation resistance.

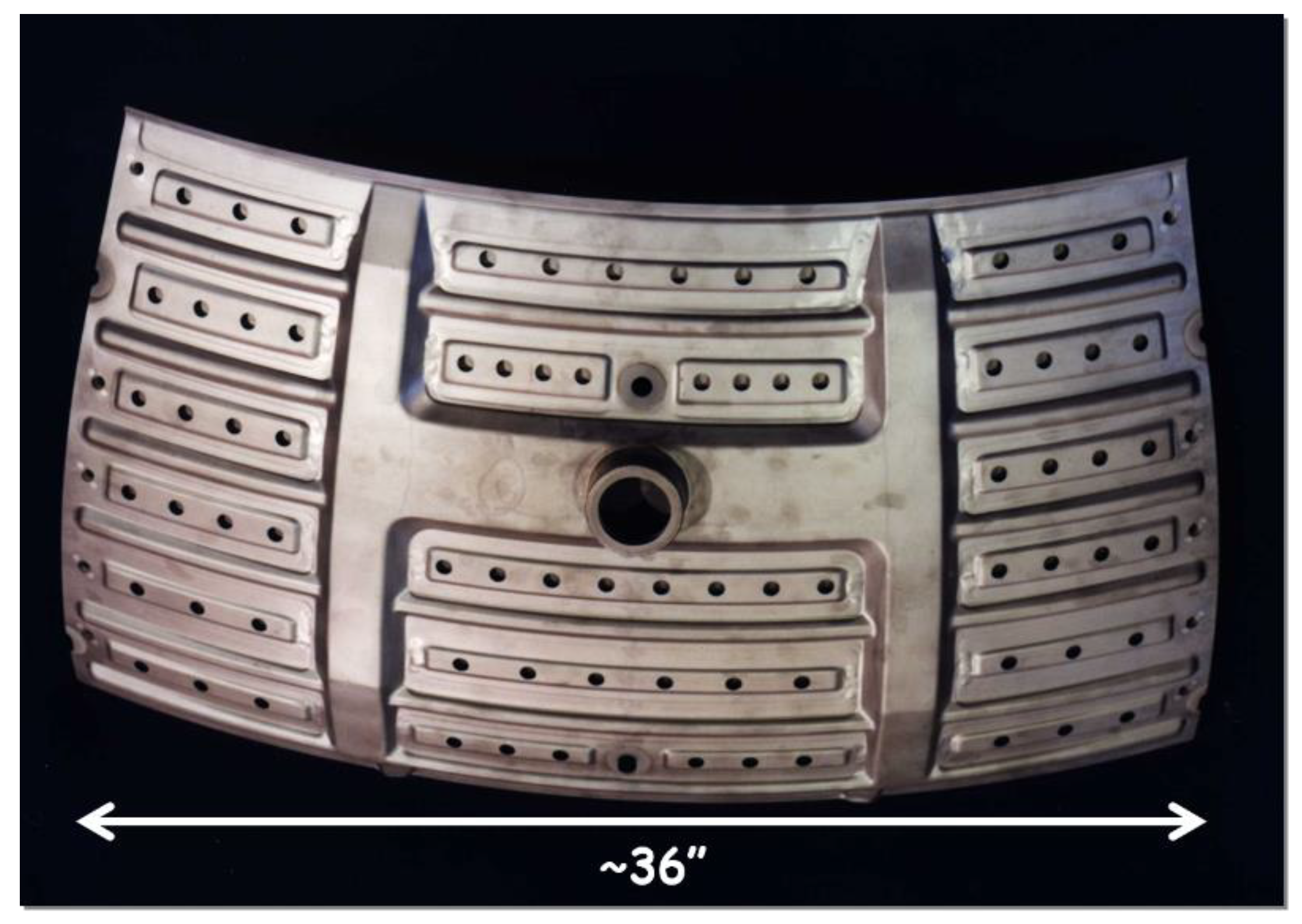

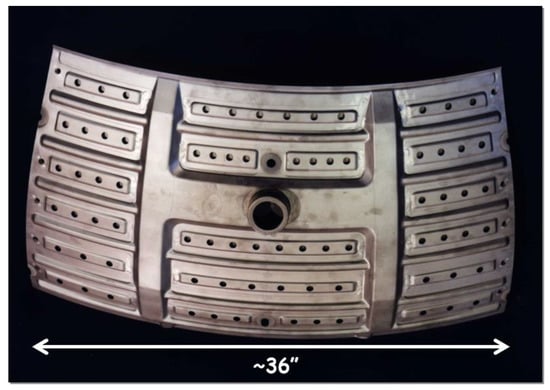

In general, Ti alloys all exhibit good diffusion bonding (DB) capabilities. This is because, when heated above about 500–550 °C in a vacuum or a high quality gas (Ar) environment, they dissolve the surface oxide that acts as a corrosion inhibitor at lower temperatures. This new, pristine, Ti alloy surface that is created in situ readily bonds to another such surface at very low external pressure. This is a characteristic that offers great potential for complex sheet structures in a number of applications. Examples of which include adding gage doublers for reinforcement in desired locations and for making complex, single piece sheet metal parts for gas turbine engines such as variable clearance control manifolds (Figure 3) and noise suppression devices for the exhaust system of engines. Diffusion bonding can be performed at the same time as SPF which also is helpful to cost. When DB and SPF are used together the resulting product is often referred to as a SPF/DB structure.

Figure 3.

Example of a complex sheet metal engine part made by superplastic forming and diffusion bonding (SPFDB) [2].

4.3. Additive Manufacturing (AM) of Ti Alloys

Additive manufacturing (also called 3D printing) has attracted a great deal of interest because of the excellent shape making capability of the process. This capability has the potential to be a game changer in Ti component manufacturing. To a certain extent, this aspect of AM for making structural parts also has been a distraction in the sense that the excitement over the ability to readily create complex shapes has caused important questions and issues regarding the properties of the deposited material and the property repeatability of the same AM shape to be underserved. In this connection, AM of Ti alloys is particularly attractive because of the well-known high cost of making components by conventional manufacturing methods. These methods include forging, casting, and machining from mill products such as plate and bar. To highlight the difference between these methods and AM, the conventional manufacturing methods just mentioned have now appropriately become known as subtractive manufacturing (SM). A general, but a more detailed overview of AM can be found elsewhere [26,27,28].

There are basically three AM processes, two of which use powder as the starting stock and one which uses wire. These processes are called powder bed, blown powder, and wire fed. Further, there are two heat sources for the powder bed process; electron beam and laser. For the wire fed process there are processes either currently available or under active development that use three different heat sources; electron beam, transferred plasma arc, or laser. For blown powder only a laser heat source is available. The electron beam machines must operate in vacuum whereas the laser and plasma arc machines operate in an inert gas (Ar) filled chamber. Currently the part size that can be made using the laser or electron beam processes are limited by the deposition chamber size, but machines with larger chambers are under active development. Consequently, today the larger parts are made today by the plasma torch technique. Once qualified, the wire fed laser process also will have fewer chamber size restrictions.

Because deposition in the electron beam machines occurs in a vacuum, there is some loss of Al due to evaporation from alloys such as Ti-6-4. This can be compensated for by using powder or wire with a higher starting Al composition than is desired if the final part chemistry is to be in the desired specification range. While this is managed routinely, the higher Al makes drawing of wire somewhat more difficult and can reduce the yield of wire. Similarly, creation of higher Al bar to be used in a powder atomizer typically will have somewhat lower yield. Today, these yield losses have not been quantified, at least in the publicly available literature, but these should ultimately be considered in any detailed AM cost model.

Examples of complex shaped parts created with laser powder bed AM are shown in Figure 4. Among these three AM processes, powder bed has the best shape making capability, but also the slowest deposition or build rate. Currently, there also are significant chamber size limitations for the components that can be made by this process. Powder bed machines with larger chambers are available as prototypes and others including ones with two heat sources are under development.

Figure 4.

Examples of parts with complex geometries made by powder bed AM. Figure courtesy of Prof. Xinhua Wu, Monash University, Melbourne, Australia.

Longer term, an intriguing aspect of AM is related to the different intrinsic nature of the processes as compared to the currently practiced SM processes. Take, for example, a complex shaped component created with SM by machining it from plate. It is not unusual for some parts to require much of the starting material to be removed to obtain the required geometry. The starting weight is often as much as 15 to 20 times the final part weight. A BTF of even 30 is not uncommon. This ratio of starting weight to final weight is called buy-to-fly ratio or BTF. Now thinking about AM, in literally all cases, there is material that is not surface connected but also which is not on the load path during service. Because this material cannot be removed, it only adds weight (and cost) with no contribution to functionality. This material has been called “legacy material” [27,28]. If the same component was created by AM it would be built from the inside out and the legacy material could be eliminated simply by not being deposited during the build. The outcome of this can be a significant weight reduction. However, in this connection, it should be noted that the current computer aided design (CAD) software is not capable of supporting design methods that intentionally delete legacy material. Improving these CAD programs to enable such designs will require time and resources but this also will be a key enabling step to realize the full potential of AM.

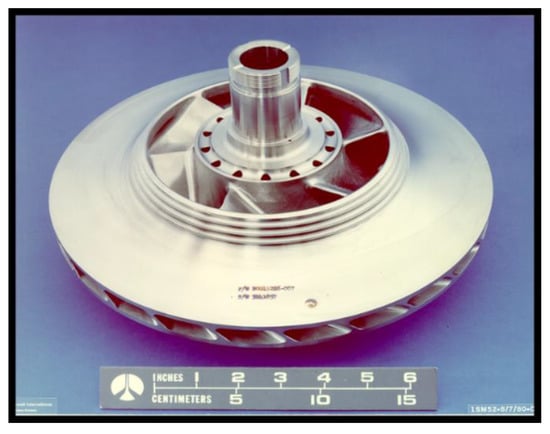

4.4. Applications of Alpha Alloys

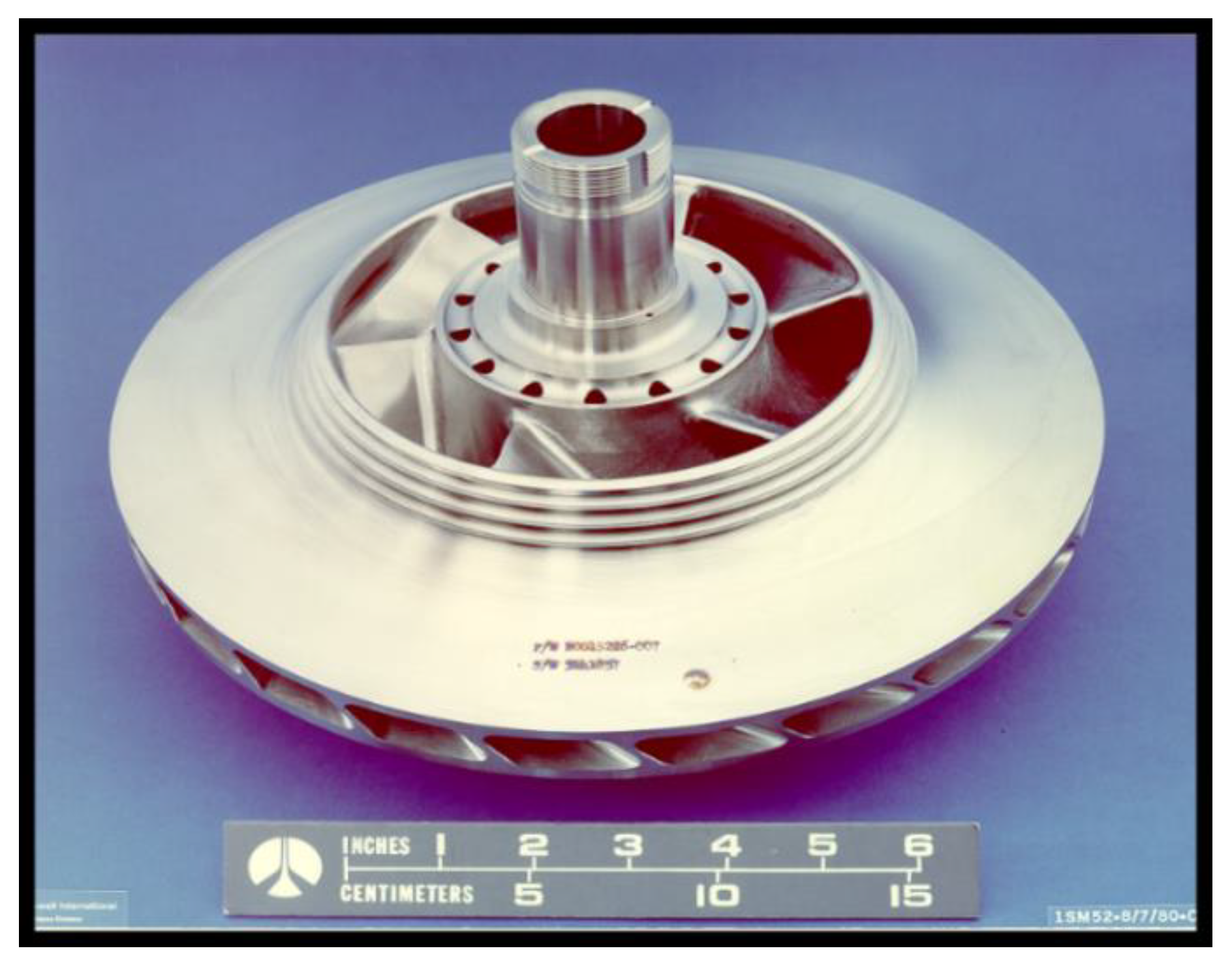

Apart from the use of CP Ti and Ti-3-2.5 for ducts and tubing as described earlier, another major application of α-alloys is in the fuel pump impeller of the turbomachinery of liquid hydrogen fueled rocket engines. These impellers are typically made from Ti-5-2.5 and operate at high stresses at about −250 °C. An example of such an impeller is shown in Figure 5.

Figure 5.

A Ti-5Al-2.5Sn fuel pump impeller used in the space shuttle main engine. John Halchak, Rocketdyne [10].

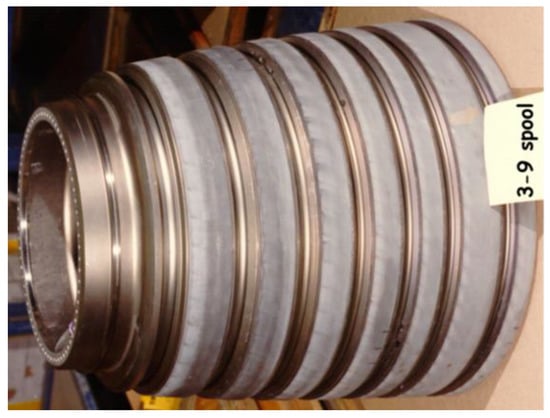

4.5. Applications of Near Alpha Alloys

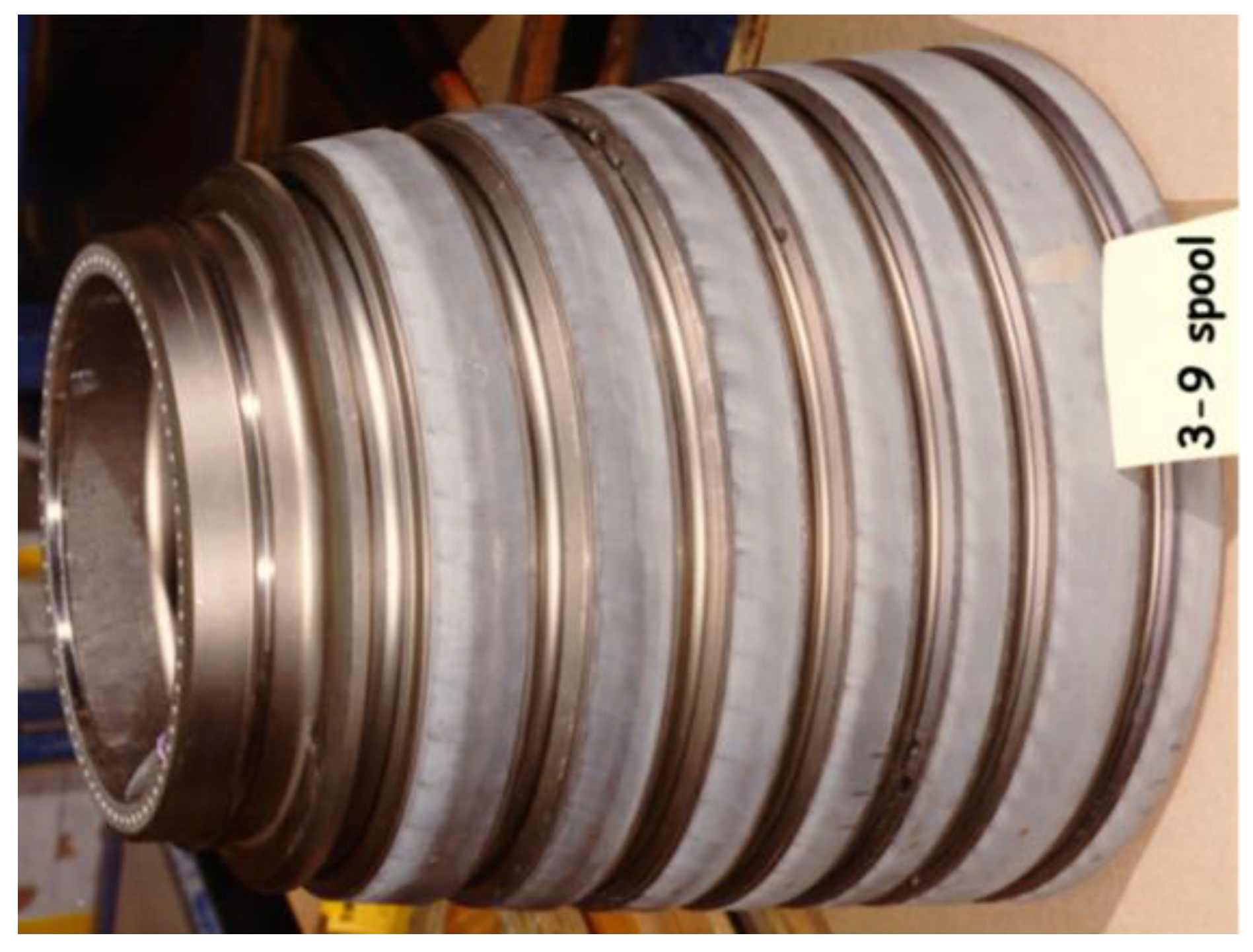

As already mentioned, the near-α alloys are not as strong at or near room temperature as either the α + β or β-alloys, but have superior creep resistance along with the improved strength retention which is important for high temperature applications such as the later stages of the high pressure compressor in an aircraft turbine engine. At the point where the gas temperature exceeds about 500 °C, the remainder of the compressor rotor is made of Ni-base alloys. In current engines it is common for all of the Ti alloy the compressor rotor stages to be a single piece as shown in Figure 6. This single piece is called a “spool” and consists of two alloys; Ti-6-4 at the front stages where the gas temperature is less than about 300 °C and Ti-6242 for the remaining Ti alloy stages. This transition is driven by the creep strength of these two alloys. The multiple stages are produced as individual forgings and are then joined either by fusion welding or by solid state inertia welding. Joining these stages into a spool eliminates bolted flanges between stages which add weight and the bolt holes also can be the source of fatigue crack initiation. An example of a 3–9 stage Ti compressor spool is shown in Figure 6 [2]. The bolted flange on the left hand end is where the remaining Ni alloy stages are connected because welding Ti alloys to Ni alloys is not possible.

Figure 6.

A seven stage one piece compressor spool for a 747 class engine. The front five stages are Ti-6-4 and the last two stages are Ti-6242 [2].

4.6. Applications of α + β Ti Alloys

As the availability and quality of α + β Ti alloy mill products increased, it became clear that Ti alloys had significant advantages over Al alloys or steel for heavily loaded structure. However, in the early days (e.g., the 1960s) there was considerable reluctance on the part of designers and regulators to accept this new class of material (Ti alloys) for such applications with both cost and a lack of experience with them being major factors. The extensive use of Ti in the SR-71 was considered a “special case” because of the extreme operating conditions which were unlike those of sub-sonic transport and transonic military aircraft. An example of this reluctance is illustrated by the TFX military fighter-bomber aircraft competition that occurred in the United States during the late 1950s and early 1960s. The final competitors were Boeing and General Dynamics. The Boeing design used Ti-6-4 for the wing box whereas the General Dynamics design used a high strength steel (D6AC). The contract was eventually awarded to General Dynamics. There were several reasons for this decision but one of the major technical ones was the use of Ti in the Boeing design. Given that the focus of this paper is Ti alloys, it should be noted that the General Dynamics design suffered a major wing box failure during static test which set the program back schedule-wise. There was even an alternate design effort using Ti for the wing box conducted only to discover that the Ti wing box while lighter was too large to fit into the space provided for the steel wing box. The production aircraft eventually entered service as the F-111 and was successfully used by both the US Air Force and the US Navy as well as the Australian Air Force. Far and away, Ti-6-4 is the primary titanium alloy in use today for important structures in airframes. It is a well-established material which available in a wide range of mill products with tolerable costs because of its extensive service experience with outstanding corrosion resistance.

4.7. Applications of β-Titanium Alloys

Much earlier, a β-Ti alloy referred to as VCA120 (Ti-13V-11Cr-3Al) was used on the Lockheed SR71, a high altitude reconnaissance aircraft which could fly at altitudes as high as 26,000 m at speeds in excess of Mach 3.2. For this application, high strength at temperatures in excess of 300 °C was required [3]. Steel or Ni alloys would have been too heavy for the aircraft to meet its performance requirements and VCA120 was the only Ti alloy producible as sheet in large quantities. This alloy was difficult to produce due to solute (Cr) segregation during ingot solidification. Although processing into sheet and extrusions was difficult at the time, there were no other Ti alloys available that had the necessary capabilities. Today, and as mentioned previously, the β-Ti alloys are used primarily where high strength is required [2,4,5,6,29,30,31,32,33,34]. The most significant structural application is in landing gear structure where it has been used on several newer, large commercial aircraft, starting with the Boeing 777 [29,30,31].

One of the principle advantages of the β-alloys is the higher strength capability [29,30,31,32,33,34]. They are routinely used primarily at tensile strengths up to ≈1240 MPa. Strengthening is achieved by precipitation of fine α within the β-phase. They also have processing advantages because the β-phase is softer than the α-phase reducing the flow stress to “form” the material to the desired shape. In addition, the lower strength results in lower rolling forces for flat product which enables lower rolling temperatures and improved material yield. Some of these alloys can even be finished by cold rolling. Most titanium sheet requires extensive grinding to meet the tolerance requirements. A small, final reduction by cold rolling can be done to produce surface quality and gages that easily meet tight tolerance requirements. This eliminates the need for expensive grinding [30].

After the desired configuration is created in the lower strength condition, the material is aged to precipitate fine lamellar or acicular α-phase to achieve the desired higher strength level. This means the flow stress during thermomechanical processing such as rolling (used primarily for sheet and plate), for instance, is low relative to that of the other alloys, providing an advantage. The flow stresses during forging are also lower, so the forgings from these alloys can be produced to shapes nearer to the desired final shape at lower temperatures with lower flow stresses and a lower buy to fly ratio. Then, upon aging to produce a fine α-phase precipitation, the desired high strengths can be achieved.

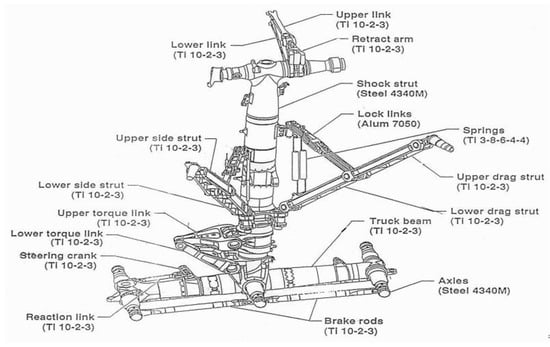

The first commercial application of a β-alloy (other than the Ti-13-11-3 springs used by Douglas) was a bearing housing on the Boeing 757 [30]. This was primarily done to gain production experience with the Ti-10V-2Fe-3Al (Ti-10-2-3) alloy. After this successful experience, a major achievement was approval of Ti-10-2-3 for use on the landing gear structure on the Boeing 777. The most significant application is the landing gear truck beam where each forging weighed about 1800 kg. A weight saving of ≈270 kg was achieved by replacing 4340M and 300M steels with Ti alloys on the landing gear of the 777, even though the tensile strength of the titanium was ≈690 MPa lower than the steels. There also were other Ti alloy landing gear parts (mostly Ti-10-2-3) besides the truck beam as can be seen in Figure 7. Later, Airbus also used Ti-10-2-3 for the landing gear of the A380 aircraft. This alloy, as well as Ti-6-4, has been used for quite some time in rotor components by helicopter manufacturers to replace steel for weight savings.

Figure 7.

Boeing 777 Landing Gear Structure, which is the first commercial aircraft to utilize a Ti-alloy in the landing gear structure [29,30].

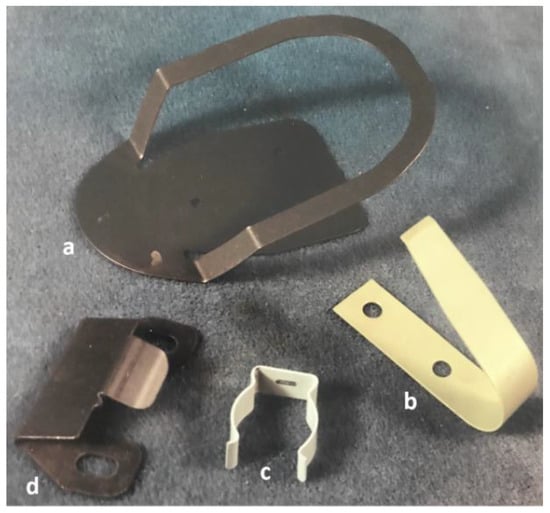

Forged landing gear components for the Boeing 777 are made from Ti-10V-2Fe-3Al (Ti-10-2-3). The newer 787 aircraft utilizes the alloy Ti-5Al-5Mo-5V-3Cr (Ti-5553), initially developed in Russia by VSMPO and jointly reduced to practice for landing gear by Boeing and VSMPO. Ti-5-5-5-3 has slightly higher strength (≈1240 MPa) and has some processing advantages including better hardenability than Ti-10-2-3. [26] This alloy, Ti-5553, is used for most of the landing gear components of the Boeing 787, and Airbus also uses it for landing gear components on the A350-1000 [11]. Other β-alloy applications such as flap tracks, springs, APU struts, fire extinguisher bottles, clips and brackets and the exhaust on the Boeing 777 and 787 have been described elsewhere [34].

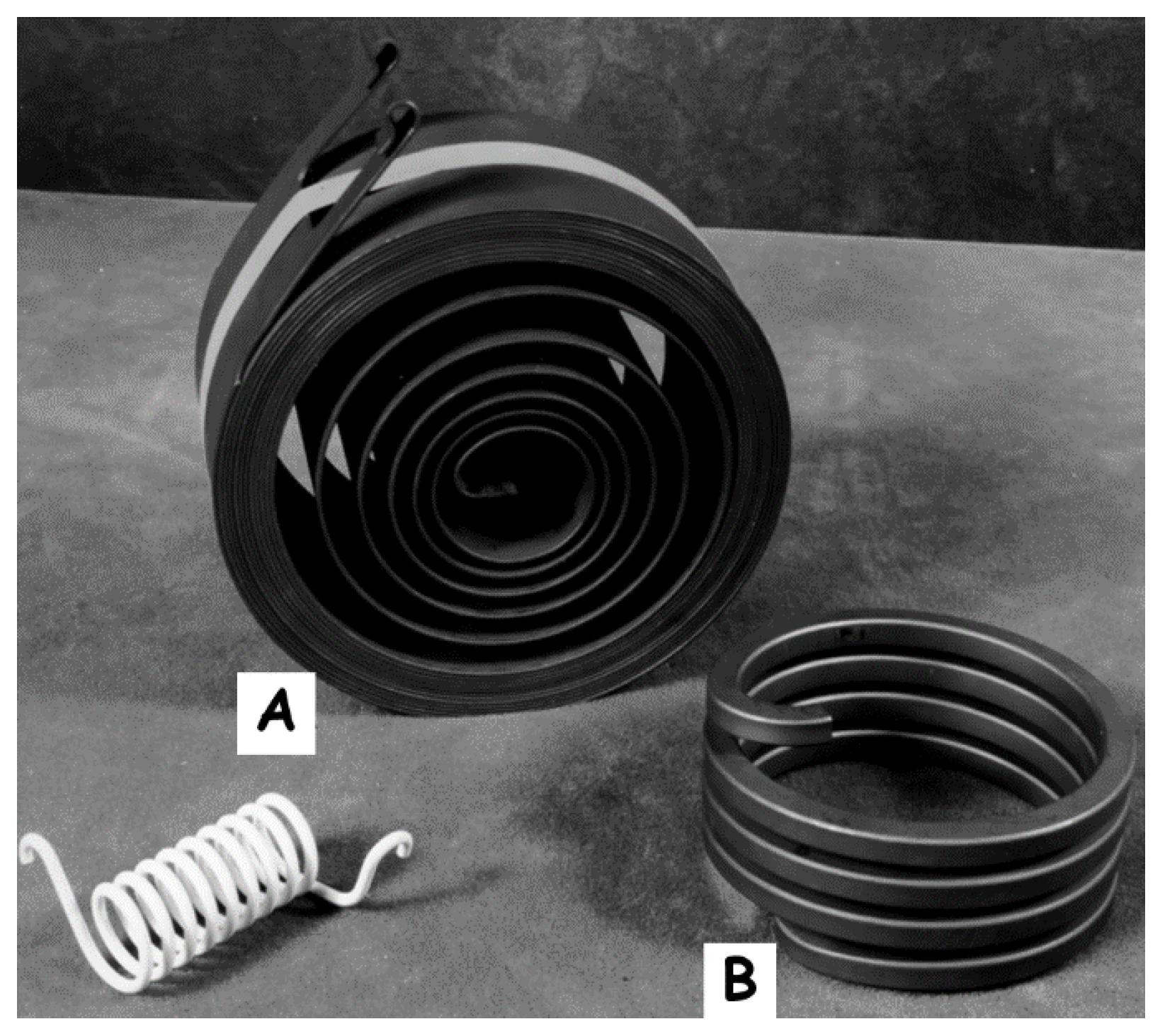

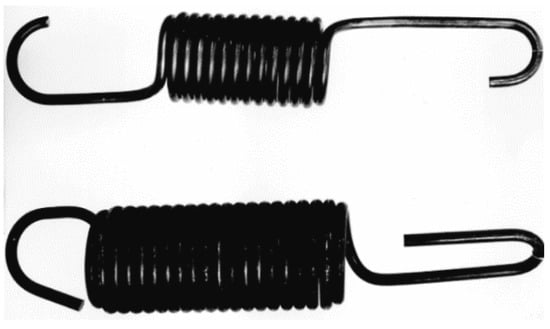

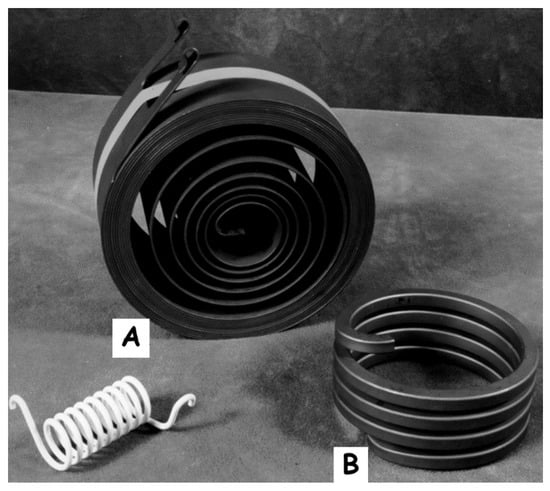

The initial use of β-C titanium coil springs was on the Boeing 757 as passenger door counterbalance springs (Figure 8); Ti-15V-3Cr-3Sn-3Al (Ti-15-3-3-3) was used for clock type springs [31] as shown in Figure 9. Weight savings on the order of 70% can be achieved in replacing steel springs with β-Ti. As mentioned earlier the first use of Ti springs was by McDonnell Douglas in the 1970 time frame for the DC-10. It was an expensive spring material as the processing of this alloy, from melting to final rolling to shape and size was quite difficult, which led to rejected material and related high cost. Ti-15-3-3-3 was first used to create formed sheet metal parts for the B-1 bomber built by North American Rockwell primarily for the nacelle structure (not springs). There were distinct advantages for using a beta alloy for these applications made from sheet. The alloy was producible as strip and readily formable, both of which reduce cost. In addition, it was heat treatable. The B-1 structure was heat treated to ≈1035 MPa ultimate tensile strength. Rockwell used more than 100 Ti-15-3-3-3 formed parts on the B-1.

Figure 8.

The Ti spring (top) carries the same load as the steel spring (bottom) but weighs 1.45 kg compared to 4.35 kg for the steel spring due to the lower density and the fewer coils required [30].

Figure 9.

Titanium aircraft springs. Spring A is a door counterbalance clock spring fabricated from Ti-15-3-3-3 strip. Spring B is a coil spring made from square β-C wire for a launch bar power unit spring for the T-45 Trainer.

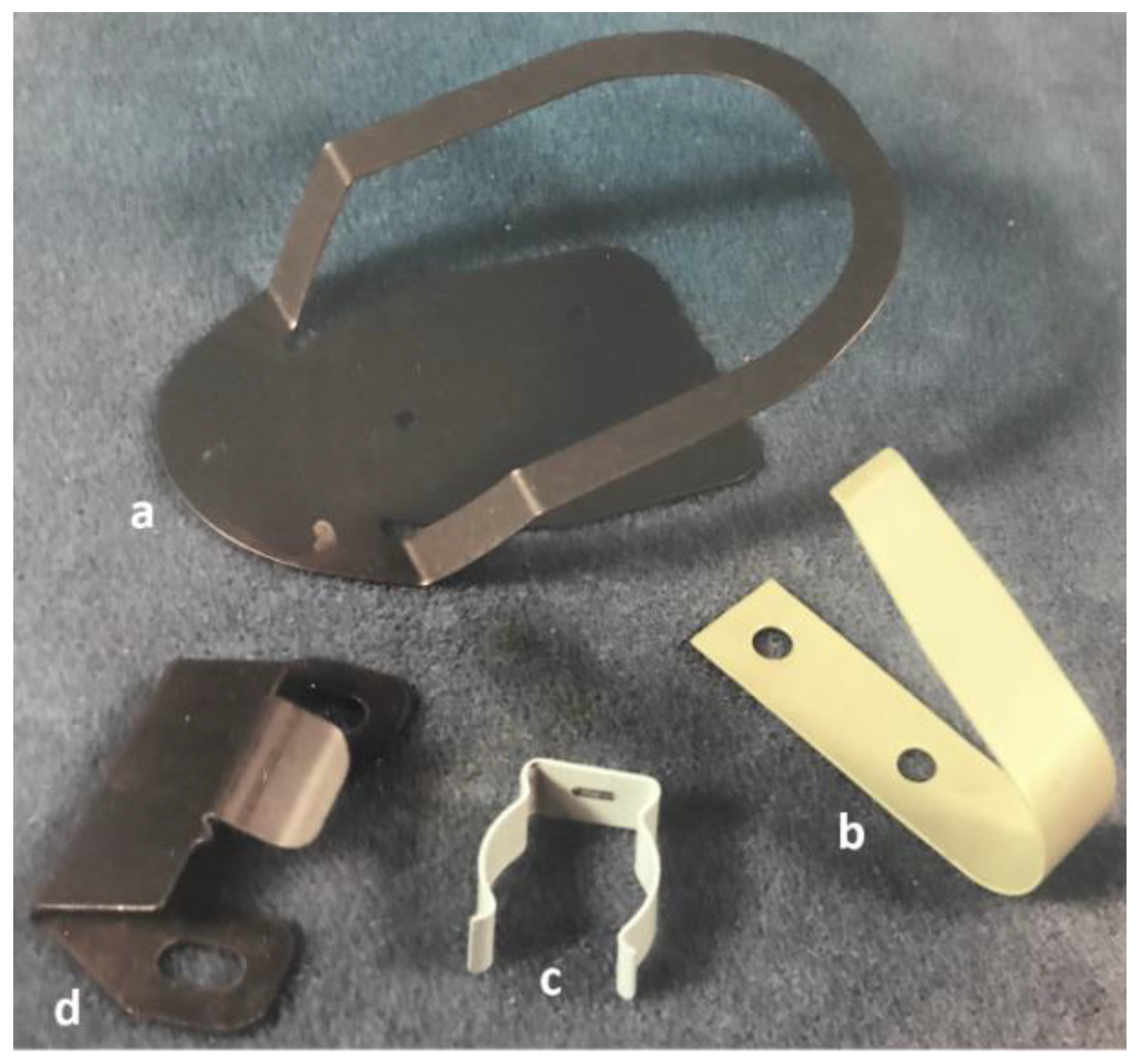

Today Ti-15-3-3-3 is being utilized for clock type springs which also use sheet product and, by now, the processing for this alloy was well established [32]. As mentioned previously β-alloys are capable of higher strengths and lower processing stresses to produce parts, somewhat off-setting the higher initial cost of the material. Typical properties for Ti-10V-2Fe-3Al and Ti-15V-3Cr-3Al-3Sn are discussed in greater detail elsewhere [29,30,31,32,33,34]. These references also contain a lot of information about these alloys e.g., processing, properties, and physical metallurgy. These alloys have many applications starting with different product forms. In addition to sheet metal parts because of higher strength and better formability than Ti-6-4, Ti-15-3-3, was used for clock and leaf spring applications. The clock spring shown as A in Figure 9 resulted in a 20 kg weight savings vs. a steel spring. Other Ti-15-3-3-3 applications include auxiliary power unit (APU) support struts and APU fire extinguisher bottles. [32] Ti-15-3-3-3 sheet also is an economical alloy from which to make small components because it is very producible as sheet and these components can be readily formed at room temperature. There can be as many as hundreds of these small parts in a single airplane (e.g., d in Figure 10) so the collective weight saving can be significant. Examples of such parts are shown in Figure 10.

Figure 10.

Miscellaneous components formed from Ti-15-3-3-3 sheet: (a) crew microphone holder (B-737/757); (b) access door clip; (c) tool clip); (d) interior window clip (B-747-400) [32].

Another important, newer β-alloy is Ti-15Mo-2.7Nb-3Al-0.2Si referred to as Beta-21S. This alloy can be readily rolled into sheet and even foil. It was developed using US Government funding and was intended to be the matrix alloy for SiC fiber metal matrix composites (MMCs) for use on the National Aerospace Plane (NASP). Although NASP was not completed, Beta-21S was a useful legacy. An older alloy, Ti-15-3-3-3 was initially used for this application but it was too susceptible to oxidation during the processing of the MMCs. The NASP program was terminated in the early 90’s. However, since TIMET had already developed β-21S which exhibited a significantly reduced tendency for oxidation during processing, both primary and secondary, and in service (primarily due to removal of the V), it turned out to be of more general interest as a sheet alloy. The β-21S alloy has two additional advantages: it had greater tolerance for higher temperatures than the other β-alloys and it was resistant to hydrogen embrittlement from the hydraulic fluid (Skydrol) used in commercial aircraft in the event of a hydraulic leak in an area where the leaked fluid could come into contact with the hot Ti structure at temperatures over ≈175 °C. The higher temperature tolerance enabled the use of this alloy for the engine tail plug, shown in Figure 11, and nozzle which are exposed to the engine exhaust. The use of β-21S in place of a Ni-base alloy results in a very significant weight savings not only in the Ti alloy nozzle and tail plug, but in the structure that supports the lighter components.

Figure 11.

Fabricating the β-21s tail plug for the B-777 engine.

4.8. Applications of Ti Base Intermetallic Compounds

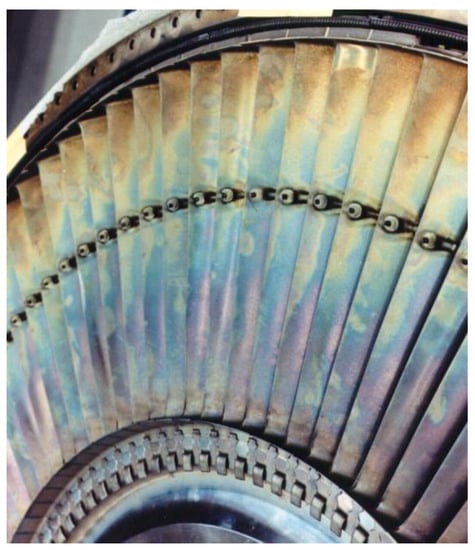

The two Ti rich intermetallic compounds in the Ti-Al alloy system are alpha-2 (α2) based on Ti3Al and gamma (γ) based on TiAl. The gamma-based alloy was described earlier because it is used for low pressure turbine blades in current production commercial aircraft engines. The decision to implement the γ-alloy for LPT air foils was based on extensive testing in a 747 class factory engine. These tests involved, among other things 1500 rejected take-off excursions which are one of the most demanding situations for an engine turbine rotor. Figure 12 shows this rotor after these tests, disassembly and several hundred hours of additional runs. This successful engine test resulted in the decision to introduce the Gamma air foils in the production GEnx engine [35].

Figure 12.

Image of the 747 class engine low-pressure turbine (LPT) rotor with Gamma alloy air foils after the demanding but successful factory test described earlier.

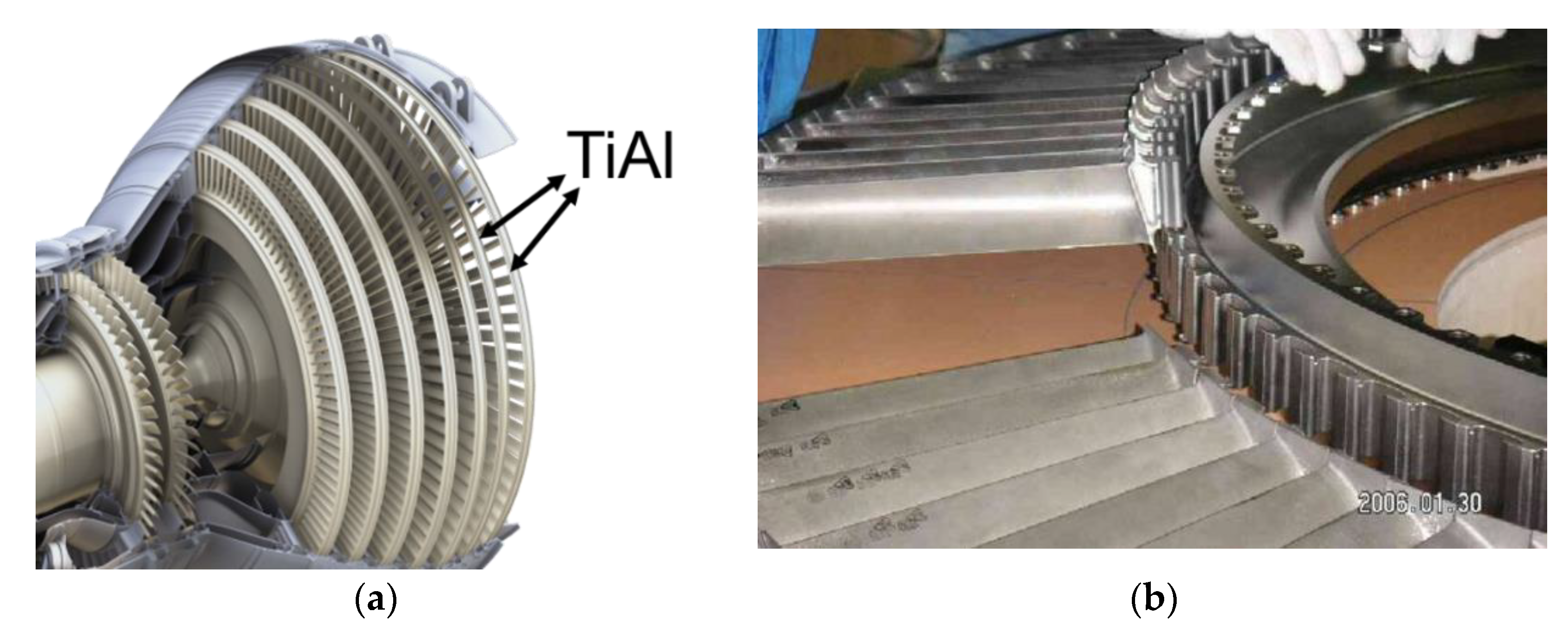

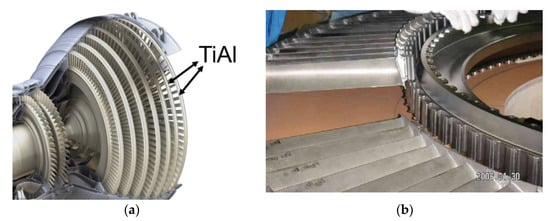

Today, the last two stages of low-pressure turbine (LPT) air foils in the GEnx engine that powers the Boeing 787 and the CFM LEAP engine that powers the A-320NEO and the B-737MAX are made from a Gamma alloy Ti-48Al-2Nb-2Cr (in at %) [9,33]. The GEnx air foils now have accumulated several million flight hours in revenue service without any LPT air foil caused engine removals. Using these air foils allows the weight of each of these stages in the GEnx engine to be reduced by about 90 kg (≈200 pounds), much of which comes from reducing the Ni-base alloy disk weight which is possible due to the lower reaction forces imposed by the lighter Gamma alloy air foils. The GEnx LPT containing the Gamma alloy air foils is shown in Figure 13a, while Figure 13b shows, in more detail, the air foil and disk dove tail connection and the narrower disk bore that is possible because of the lower weight air foils [2].

Figure 13.

(a) The LPT rotor of the GEnx engine which uses 2 stages of Gamma alloy air foils and (b) a close up of the disk.

5. New Alloy Developments

There are several new Ti alloys under development at ATI. One of them is a high strength β-alloy which is presently known as ATI Titan 23™ [36]. The alloy can be heat treated to achieve strengths of 1240–1520 MPa with reasonable ductility and a fracture toughness of >60 MPa √m. This alloy will have the advantages noted earlier of the capability of cold rolling with its gage tolerance advantage previously and low flow stresses enabling forging at lower temperatures with low flow stresses as compared to alloys such as Ti-6-4.

ATI is developing a cold rollable, high-strength alloy with superior properties to Ti-6-4, which resulted in an alloy designated as ATI Titan 27™. The alloy has excellent transverse elongation, higher than in the longitudinal direction. They have found that the alloy had excellent workability and formability whether hot or cold. They determined that the tensile properties were a function of three factors (in declining order of importance), microstructure after final heat treatment, alloy chemistry, and equiaxed primary α-size and volume fraction [36]. The mechanical properties of the conditions investigated ranged from ≈1000 MPa to as high as ≈1300 MPa depending on the precise chemistry, processing route and heat treatment.

ATI is developing a more creep-resistant near-α alloy, ATI Titan 42TM. The alloy is similar in composition to Ti-6Al-2Sn-4Zr-2Mo-0.1Si, with the notable addition of germanium. They have shown that this addition reduces the secondary creep rate from 7.9E-4 to 1.7E-4 at a temperature of 482 °C and with 0.4% germanium [37].

ATI Titan 171TM is a β-rich α + β titanium alloy based on Ti-17 that ATI has developed for aero engine applications that demand high temperature strength. The alloy has notably more Al, Sn, and Zr, as well as less eutectoid β-stabilizer content and intentional addition of Si. Resulting from these changes, the alloy demonstrates 20% higher strength than typical Ti-17 strength at 426 °C, 20% higher HCF runout strength at room temperature, and double the creep life to 0.2% elongation at 426 °C [38].

Titanium Metals Corporation (TIMET) also has several new alloys and processes under development [39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57]. The TIMETAL alloy Ti18 is a new high strength near-β alloy for forged products and fastener stock [39,40,41,42]. During its development attention was paid to balancing the appropriate levels of total Mo equivalent, the ratio of β-isomorphous to β-eutectoid element additions. The Al equivalent also was controlled to provide maximum strengthening capability while avoiding formation of intermetallic compounds that are harmful to ductility. Other important considerations were the ratio of Cr to Fe, which controls the kinetics of precipitation aging, and limiting the Fe to a level that would avoid segregation during melting at commercially interesting rates. Subscale manufacturing and testing of initial sub-scale heats confirmed that the alloying concept was as intended and is capable of providing materials with significantly improved tensile properties.

A particularly interesting aspect of the alloy is the extraordinarily high strength levels that can be achieved. It is the only known alloy capable of a strength level of above 1500 MPa (218 ksi) with a useful level of ductility to enter continuous full-scale production.

The alloy Ti-6-4 offers an attractive combination of ballistic and mechanical properties for armor used on military ground vehicle systems, but the relatively high cost of titanium plate inhibits increased usage on many programs. Although production of the titanium alloy Ti-6-4 by Electron-Beam Single-Melting (Ti-6-4 EBSM) has already enabled the more cost-effective implementation of titanium in many systems [43], further cost reductions will help to continue the expansion of titanium use for armor.

TIMETAL® 108 (Ti108), [44,45] nominal composition Ti-4.8Al-3V-0.6Fe-0.18O, [44] is a lower cost α + β Ti alloy with similar physical and mechanical properties to Ti-6-4. It is intended for use in armor applications as described in MIL-DTL-46077 Class 4 [44] and similar applications at significant cost savings. The cost savings potential is the alloy formulation which uses Ti-6-4 turnings, sponge, iron powder, and aluminum shot; i.e., no costly Al-V master alloy is required but, obviously, could be used if desired. The concept of formulating Ti108 with only revert and sponge (plus small amounts of elemental Fe and Al) offers the potential for significant cost savings. Other formulation options include the substitution of CP Ti revert for sponge and/or the use of high iron sponge.

The Ti108 alloy qualifies as a new Class 4 alloy [46] that satisfies the specification and all other customer requirements. This is the lowest cost composition in this class. It also is expected to be weldable to Ti-6-4 because its composition is so similar.

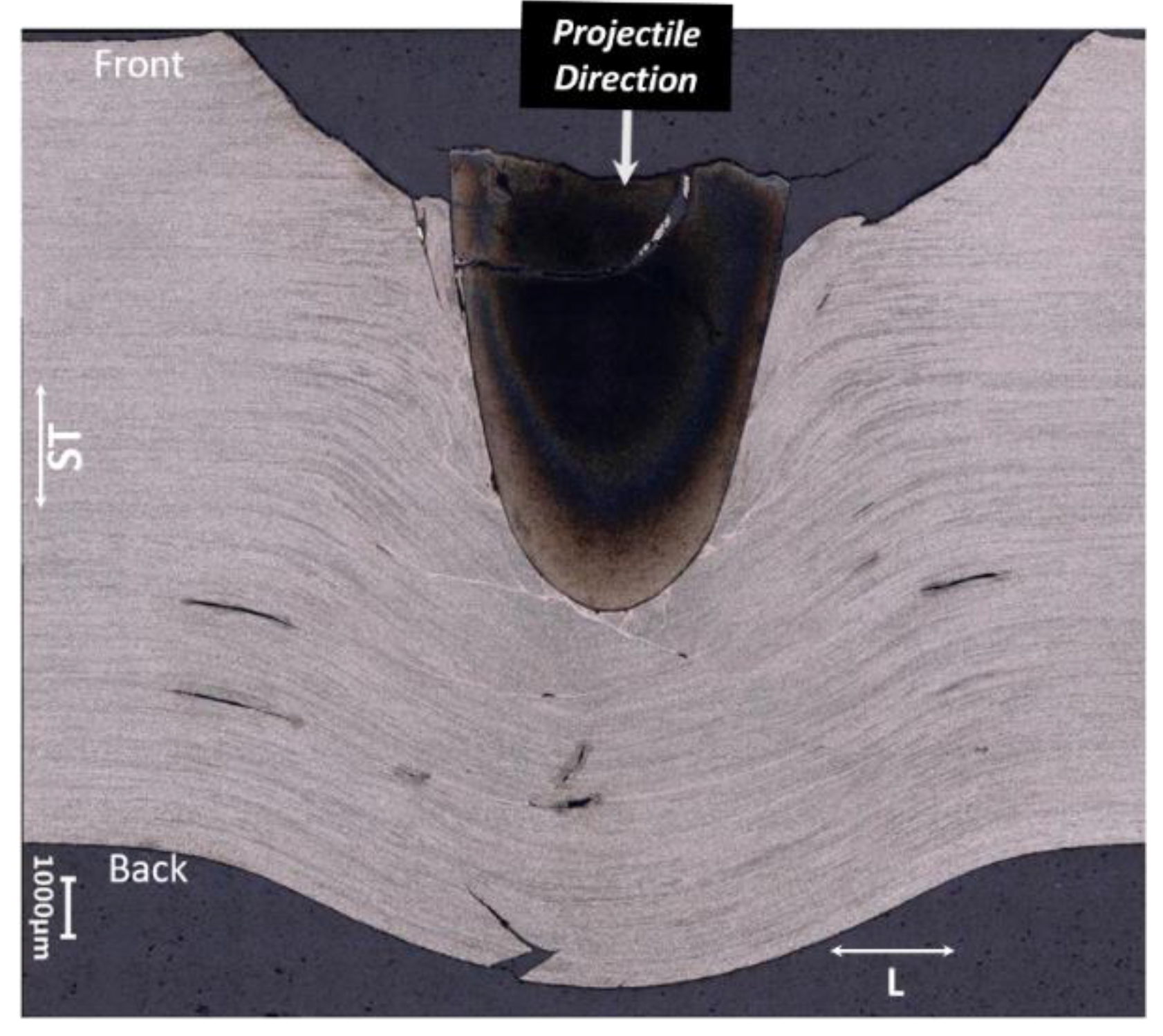

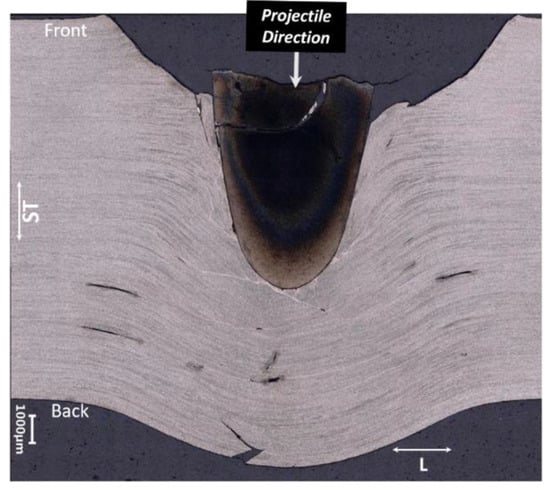

Ti108 has been extensively evaluated for ballistic performance at thicknesses ranging from 5–78 mm (0.2–3.1 inches). When the alloy is forged or rolled below the β-transus, then followed by a sub-transus mill anneal, the ballistic performance against armor penetrating (AP) projectiles is similar to that of Ti-6-4. However, the resistance to ball ammunition and fragment simulating projectiles (FSP) is significantly better than that of Ti-6-4 because of the reduced susceptibility to strain localization by formation of adiabatic shear bands.

Ballistic testing was performed on Ti108 in accordance with standard military test procedures [47]. Figure 14 shows a high partial penetration result from a test with Caliber .30 (7.62mm) 166 grain AP (Armor Piercing) M2 ammunition. The features visible in the figure, particularly the large amount of ductile deformation with minimal formation of localized adiabatic shear bands, are very favorable for high energy absorption. This is especially important for protection against Fragment Simulating (FSP) projectiles. The average tensile properties for this plate sample were: Ultimate Tensile Strength (UTS) = 924 MPa (134 ksi); Tensile Yield Strength (TYS) = 876 MPa (127 ksi); elongation = 14%; and reduction of area = 31%.

Figure 14.

Cross-sectional view of a partial penetration of 13.6 mm (0.536 inches) Ti108 plate by a .30 AP M2 projectile at 679 m s−1 (2227 ft s−1). This impact velocity was slightly below the V50 of 687 m s−1 (2254 ft sec−1) [49].

TIMETAL® 407 (Ti 407) nominal composition Ti-0.85Al-3.9V-0.25Fe-0.25Si, [49,50] is a α + β alloy that exhibits high ductility and excellent energy absorption as well as improved manufacturability compared to Ti-6-4 [48,49,50,51,52]. Production scale billet, bar, wire, and coil sheet have been produced showing moderate strength levels and higher ductility compared to Ti-6-4 [50]. Despite the relatively low UTS compared to Ti-6-4, Ti-407 has been shown to have excellent HCF fatigue strength [53]. An additional benefit of Ti-407 is lower forming temperatures and decreased tool wear life compared to Ti-6-4 [1,2]. The alloy was developed with a lower aluminum content compared to traditional alpha/beta alloys, which allows for cold-rolling of coil product. Cold formed strip product has been produced on the production scale and exhibits improved properties over Ti-3-2.5 [49]. Cost reductions in downstream processing can be realized in Ti-407 through improved machinability and lower processing temperatures compared to the competitive alloys (Ti-6-4 and Ti-3-2.5) [49,50].

TIMETAL® 575 (TIMETAL® 575), nominal composition Ti-5.5Al-7.7V-0.5Si-0.25Fe, [52,53,54,55,56,57] is a high strength alpha-beta forgeable titanium alloy designed for aerospace engine and structural applications. Compared to Ti-6-4, Ti-575 exhibits ~15–20% higher strength at both room and elevated temperatures. [51]. In addition to improved strength, Ti-575 shows superior fatigue properties [1,2,3,4,5]. The alloy has been reported to be immune to dwell fatigue Ti-575 [57] and typical production forging routes do not appear to generate micro texture [55,57]. A second variant with lowered silicon (≈0.3 wt. %) has been developed for applications requiring higher damage tolerance, but exhibits a slightly lower strength by ~100MPa. Ti-575 is formulated such that Ti-6-4 chips can be added as raw material [52].

A recent study of the effect of additions of small amounts of carbon (0.1 wt. %) on the strength and ductility of Beta-C (Ti-3-8-6-4-4) has produced some very promising results. [58] This study has shown that small additions of C to a heavily stabilized alloy such as Beta-C together with some cold deformation prior to aging dramatically accelerates the kinetics of α-phase precipitation during aging with a concurrent reduction of grain boundary α (GB α) formation. It is well-known that GB α causes major reductions in tensile ductility in β-alloys at yield strengths above ≈ 1100–1200 MPa. The exact number depends on the β grain size. The C additions also serve as a grain refiner so provide an additional benefit in this regard. Perhaps even more intriguing is the apparent versatility of such additions to a range of β-alloys that exhibit severe ductility losses because of the presence GB α when processed to high strength levels. Strengths as high as 1500 MPa were achieved with good ductility [58].

6. Summary

This paper has attempted to summarize the nature and uses of Ti and its alloys in aerospace products such as aircraft, aircraft engines, and liquid fueled rocket engines. It is clear that the growth and maturation of the Ti industry has played a significant role in enabling more durable, quieter, and fuel efficient commercial aircraft. The reader who is interested in more detailed descriptions of the physical metallurgy of Ti and its alloys is referred to [1,2,3,4]. For more detailed information about the applications of a specific class of Ti alloys, references are also provided. The paper also has described some selected, relatively new, processing methods but the examples are far from complete. Perhaps one of the more exciting processes is additive manufacturing because of the great but currently unrealized potential this process has. The authors hope that the readers find this paper helpful but we acknowledge that it is not comprehensive. To make it such would be a much greater undertaking than was intended.

Author Contributions

Multiple authored reference were done collaboratively. Individual author contributions. To a particular paper are unknown. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors gratefully acknowledge useful discussions with and the information, especially on new developments, provided by the following individuals: Mike Weimer (GE retired), Peter Wayte (GE, retired), John Foltz (ATI), John Fanning (TIMET), Kayla Calvert (TIMET), Sesh Tamirisakandala (Arconic, now Howmet Aerospace), Ernie Crist (Arconic, now Howmet Aerospace), Dan Sanders (Boeing Seattle), Larry Hefti (Boeing Seattle), and Natalia Mitropolskaya (Boeing Russia).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Boyer, R.; Welsch, G.; Collings, E.W. Materials Properties Handbook Titanium Alloys; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Heidelberg/Berlin, Germany, 2007. [Google Scholar]

- Donachie, M.J. Titanium-A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co: Weinheim, Germany, 2003; ISBN 9783527305346. [Google Scholar]

- Boyer, R.R.; Briggs, R.D. The Use of β Titanium Alloys in the Aerospace Industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandal, S.; Russo, P.; Shchetinokov, N.; Fanning, J.C. State of the Art of Beta Titanium Alloys for Aerospace Applications. JOM 2015, 5, 1281–1303. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Ward, C.H.; Williams, J.C.; Thompson, A.W.; Rosenthal, D.G.; Froes, F.H. Fracture Mechanisms in Titanium Aluminide Intermetallics. In Sixth World Conference on Titanium; Lacombe, P., Tricot, R., Beranger, G., Eds.; Les Éditions de Physique: Ulis, France, 1988; p. 1103. [Google Scholar]

- Boyer, R.R. Aerospace Applications of Beta Alloys. JOM 1994, 46, 20–23. [Google Scholar] [CrossRef]

- Halchak, J.; (Rocketdyne, CA, USA). Private communication, 2015.

- Wayte, P.; (St. Augustine, FL, USA). Private communication, 2019.

- Lee, D.; Backofen, W.A. Superplasticity of Ti Alloys. Trans. Met. Soc. 1967, 239, 1034–1040. [Google Scholar]

- Ashby, M.F.; Verrall, R.A. Diffusion Accommodated Flow and Superplasticity. Acta Met. 1973, 21, 149. [Google Scholar] [CrossRef]

- Boyer, R.R.; Minakawa, K.; Ogawa, A. Strength/Toughness Properties of SP-700. In Titanium’95; Blenkinsop, P.A., Evans, W.J., Flower, H.M., Eds.; Institute of Materials: London, UK, 1996; Volume 2, pp. 933–939. [Google Scholar]

- Comley, P.N. Lowering the Heat-The Development of Reduced Temperature Titanium Alloys for Aircraft Production. In Superplasticity in Advanced Materials ICSAM2003; Todd, R.I., Ed.; Trans Tech Publications: Baech, Switzerland, 2004; pp. 233–238. [Google Scholar]

- Comley, P. Aerospace Part Production Using SP700. Mater. Sci. Forum 2002, 357, 41. [Google Scholar]

- Young, K.W.; Martinez, M.E. The qualification of ATI 425 alloy titanium for boeing CH-47 chinook helicopter rotor blade erosion caps. In Proceedings of the Aeromat 23 Conference and Exposition American Society for Metals, Charlotte, NC, USA, 18–21 June 2012. [Google Scholar]

- Comley, P. Manufacturing Advantages of Superplastically Forming Fine Grain Ti-6Al-4V. Alloy J. Mater. Eng. Perform. 2004, 13, 660. [Google Scholar] [CrossRef]

- Comley, P. Multi-Rate Super Plastic Forming of Fine Grain Ti-6Al-4V Titanium Alloy. Alloy J. Mater. Eng. Perform 2007, 16, 150. [Google Scholar] [CrossRef]

- Hefti, L.D. Elevated Temperature Forming of Titanium Aircraft Hardware. Mat. Sci. Forum 2013, 735, 338–346. [Google Scholar] [CrossRef]

- Hefti, L.D. The Application of Fine Grain Titanium 6Al-4V for Superplastic Forming and Superplastic Forming and Diffusion Bonding of Aerospace Products. JOM 2010, 62, 42–45. [Google Scholar] [CrossRef]

- Hefti, L.D. Elevated Temperature Fabrication of Titanium Aerospace Components. Key Engr. Matls. 2010, 433, 49–55. [Google Scholar]

- Mitropolskaya, N.G.; Berestov, A.V. New lower temperature superplastic titanium sheet alloy. In Proceedings of the AeroMat 2019, Reno, NV, USA, 6–8 May 2019. [Google Scholar]

- Berestov, A.; Mitropolskaya, N.; Puzakov, I.; Michael Leder, N.; Tarenkova, R.D.; Briggs, R.F. Titanium Alloy-Based Sheet Material for Low-Temperature Superplastic Deformation. Patent Number 2691434, 1 November 2018. [Google Scholar]

- Tamirisakandala, S.; Crist, E.; Sun, F.; Dahar, M. Superior Oxidation Resistance Titanium Alloy ARCONIC-THORTM for Aerospace Applications. In Proceedings of the 14th World Conference on Titanium, Nantes, France, 10–14 June 2019. [Google Scholar]

- Froes, F.; Boyer, R. (Eds.) Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 10:0128140623. [Google Scholar]

- Chen, J.; Ma, J.; Williams, J.C. Additive manufacturing of high value Ti components: Opportunities and challenges. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 119–132. [Google Scholar] [CrossRef]

- Williams, J.; Post, B.; Love, L.; Blue, C. Opportunities for Lighter Weight and Lower Total Cost Component Manufacturing. In Light Weighting for Defense, Aerospace, and Transportation; Gokhale, A.A., Prasad, N., Basu, B., Eds.; Springer: Singapore, 2019. [Google Scholar]

- Boyer, R.R. Design Properties of a High-Strength Titanium Alloy, Ti-10V-2Fe-3Al. JOM 1980, 32, 61–65. [Google Scholar]

- Boyer, R.R.; Rosenberg, H.W. (Eds.) Beta Titanium Alloys in the 1980’s; Metallurgical Society of AIME: New York, NY, USA, 1984. [Google Scholar]

- Millet, Y. (Ugine, France). Personal communication, TIMET France. 2019.

- Eylon, D.; Boyer, R.R.; Koss, D.A. (Eds.) Beta Titanium Alloys in the 1990’s; TMS: Warrendale, PA, USA, 1993. [Google Scholar]

- Vassel, A.; Eylon, D.; Combres, Y. (Eds.) Current Issues in the Development in the Development of Beta Titanium Alloys; Société Francais de Métallurgie et de Matériaux: Paris, France, 1994. [Google Scholar]

- Boyer, R.R. Titanium Airframe Applications: Brief History, Present Applications and Future Trends. In Thermec 2003, International Conference on Processing and Manufacturing of Advanced Materials; Chandra, T., Torralba, J.M., Sakai, T., Eds.; Transtech Publications Ltd.: Zurich, Switzerland, 2003; pp. 643–648. [Google Scholar]

- Bewlay, B.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P. The Science, Technology, and Implementation of TiAl Alloys in Commercial Aircraft Engines. MRS Proc. 2013, 1516, 49–58. [Google Scholar] [CrossRef]

- Foltz, J. Microstructure-Property Relationships in Cold Rollable, High-Strength of α/β Alloy. In Proceedings of the World Conference on Titanium, Nantes, France, 10–14 June 2019. (electronic proceedings). [Google Scholar]

- Mantione, J. Properties of a Novel High Strength Titanium Alloy for Aerospace Applications. In Proceedings of the 14th World Conference on Titanium, Nantes, France, 10–14 June 2019. [Google Scholar]

- Mantione, J.; Garcia-Avila, M. ATI Development of High Temperature Titanium Alloys for Aerospace Applications. In Proceedings of the AeroMat 19, Reno, NV, USA, 6–8 May 2019. [Google Scholar]

- Fanning, J. Properties of Ti18-A New High-Strength Near-Beta Alloy for Forged Products and Fastener Stock. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015. [Google Scholar]

- Fanning, J.; Boyer, R. Properties of TIMETAL®18 [Ti18]—A new high-strength near-beta titanium alloy. In Proceedings of the 12th World Conference on Titanium, Beijing, China, 19–24 June 2011. [Google Scholar]

- Fanning, J. Near-Beta Titanium alloy for High Strength Application and Methods for Manufacturing the Same. U.S. Patent 8,454,768, 4 June 2013. [Google Scholar]

- Fanning, J. Near-Beta Titanium alloy for High Strength Application and Methods for Manufacturing the Same. U.S. Patent 8,906,295, 9 December 2014. [Google Scholar]

- Burkins, M.; Wells, M.; Fanning, J.; Roopchand, B. The Mechanical and Ballistic Properties of an Electron Beam Single Melt of Ti-6Al-4V Plate; ARL-MR-515; US Army Research Laboratory: Adelphi, MD, USA, May 2001. [Google Scholar]

- Fanning, J.C. Low-Cost Alpha-Beta Titanium Alloy with Good Ballistic and Mechanical Properties. U.S. Patent 9,631,261 B2, 25 April 2017. [Google Scholar]

- Thomas, R.; Kosaka, Y.; James, S. Titanium Alloys Exhibiting Resistance to Impact or Shock Loading. U.S. Patent 10,000,838, 19 June 2018. [Google Scholar]

- Detail Specification: Armor Plate, Titanium Alloy, Weldable, MIL-DTL-46077F; U.S. Department of Defense, US Army Research Laboratory: Adelphi, MD, USA, 1999.

- Military Standard: V50 Ballistic Test for Armor, MIL-STD-662E; U.S. Department of Defense, US Army Research Laboratory: Adelphi, MD, USA, 1987.

- James, S.; Kosaka, Y.; Thomas, R.; Garratt, P. TIMETAL®407: A Titanium Alloy to Enable Cost Reduction. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2016; pp. 721–726, TMS (electronic proceedings). [Google Scholar]

- Calvert, K.; James, S.; Kosaka, Y. TIMET Alpha-Beta Titanium Alloy Designed for Improved Formability and Machinability. In Proceedings of the 29th Aeromat Conference and Exposition, Orlando, FL, USA, 7–10 May 2018. [Google Scholar]

- Favey, W.; Bache, M.; Davies, H. Fatigue Performance of the Novel Titanium Alloy TIMETAL 407. In Proceedings of the MATEC Web of Conferences 165, Poitiers, France, 27 May–1 June 2018. [Google Scholar]

- James, R.; Thomas, R. TIMETAL ® 407: A New Impact Resistant Titanium Alloy. In Proceedings of the 27th Aeromat, Bellevue, WA, USA, 23–26 May 2016. [Google Scholar]

- Thomas, R.; Garratt, P.; Thomas, M. High-Strength Alpha-Beta Titanium Alloy. U.S. Patent 10,066,282, 4 September 2018. [Google Scholar]

- Thomas, M.; Hewitt, J.; Bache, M. TIMETAL®575: A Novel High Strength Forgeable α/β Titanium Alloy. In Proceedings of the 13th World Conference on Titanium, San Diego, CA USA, 16–20 August 2015; pp. 1537–1547. [Google Scholar]

- Andrieu, A.; von Thungen, I.; Lenain, A. Ti575: A New TIMET Alloy for Structural Parts in Aeronautics. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; p. 1543. [Google Scholar]

- Thomas, M.; Hewitt, J.; Bache, M. Determination and Analysis of the Cyclic and Dwell Fatigue Performance of TIMEAL®575. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; pp. 979–991. [Google Scholar]

- Kosaka, Y.; Thomas, R.; Garratt, P. Properties of High Strength Alpha-Beta Titanium Alloy TIMETAL® 575. In Proceedings of the 27th Aeromat Conference and Exposition, Bellevue, WA, USA, 23–26 May 2016. [Google Scholar]

- Bach, M.; Thomas, M. Alloy Development and Optimisation Informed by an Understanding of Cold Dwell Fatigue Sensitivity. In Proceedings of the 14th World Conference on Titanium, Nantes, France, 10–14 June 2019. [Google Scholar]

- Cao, S.; Zhou, X.; Yang, Y.; Lim, C.V.S.; Boyer, R.R.; Williams, J.C.; Wu, X. A strong and ductile Ti-3Al-8V-6Cr-4Mo-4Zr (Beta-C) alloy achieved by introducing trace carbon addition and cold work. Scripta Mater. 2020, 178, 124–128. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).