Early Stages of Plastic Deformation in Low and High SFE Pure Metals

Abstract

:1. Introduction

2. Experimental Procedures and Method

2.1. The Pure Metals

2.2. High-Pressure Torsion (HPT) Details

2.3. TEM Sample Preparation and Method

2.4. Nanoindentation Measurement Details

3. Experimental Results

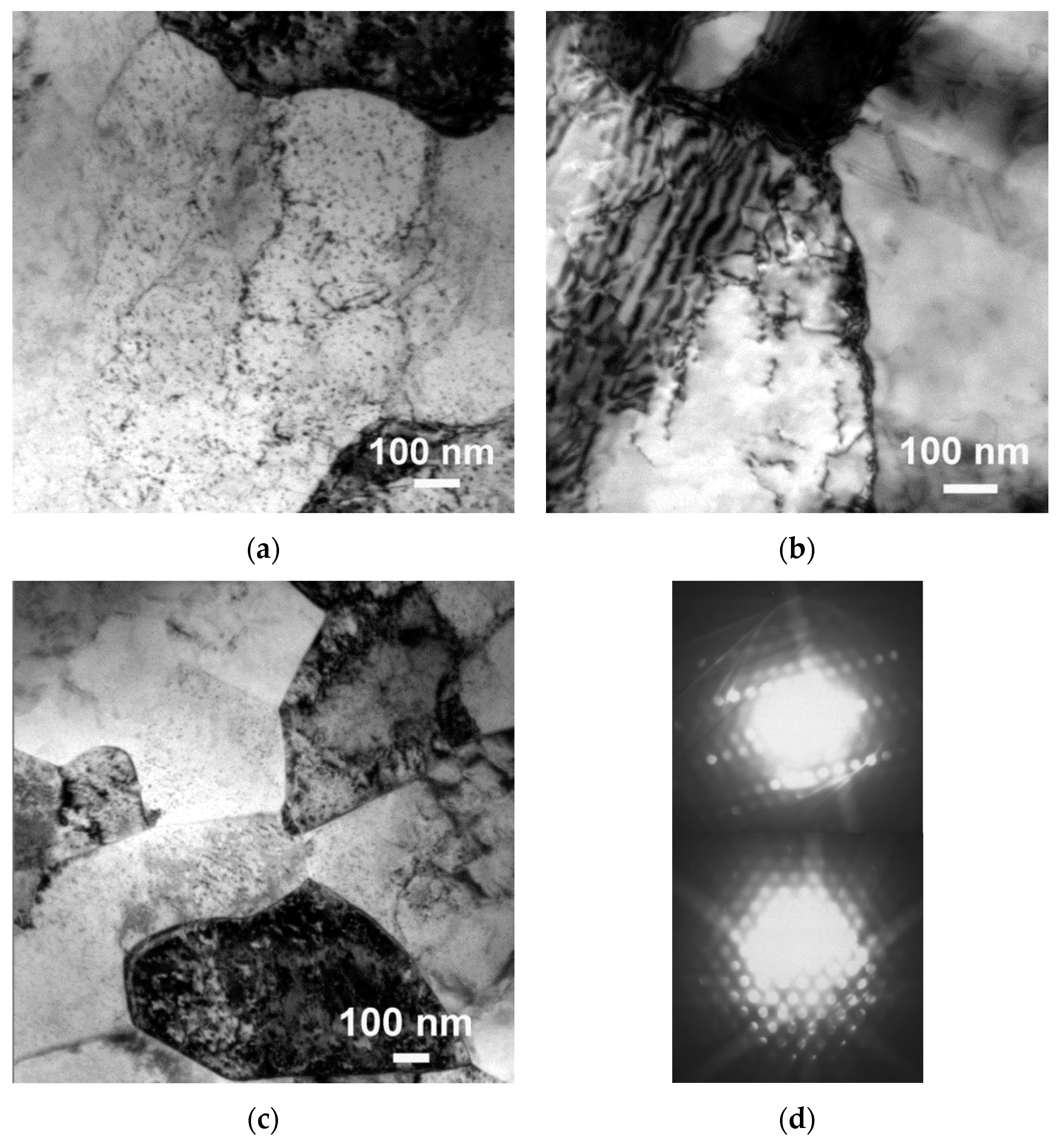

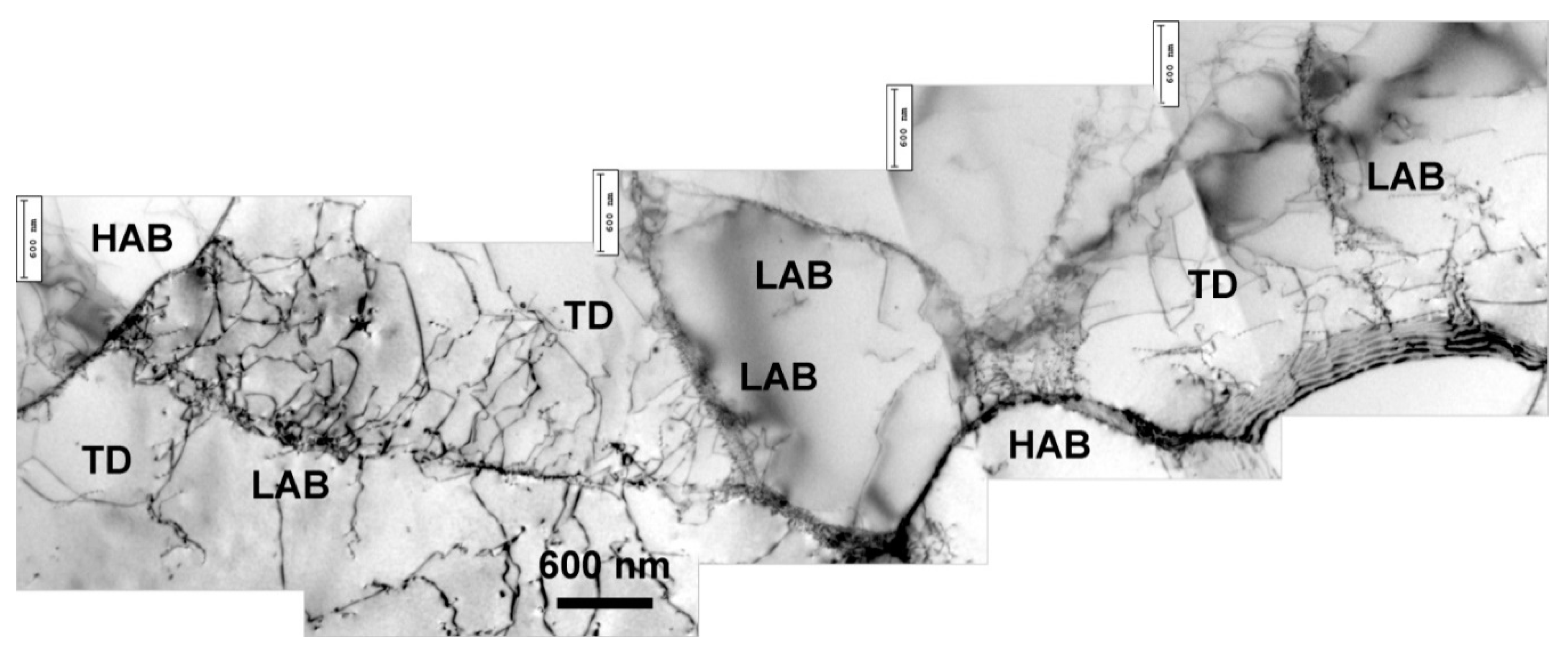

3.1. Microstructure

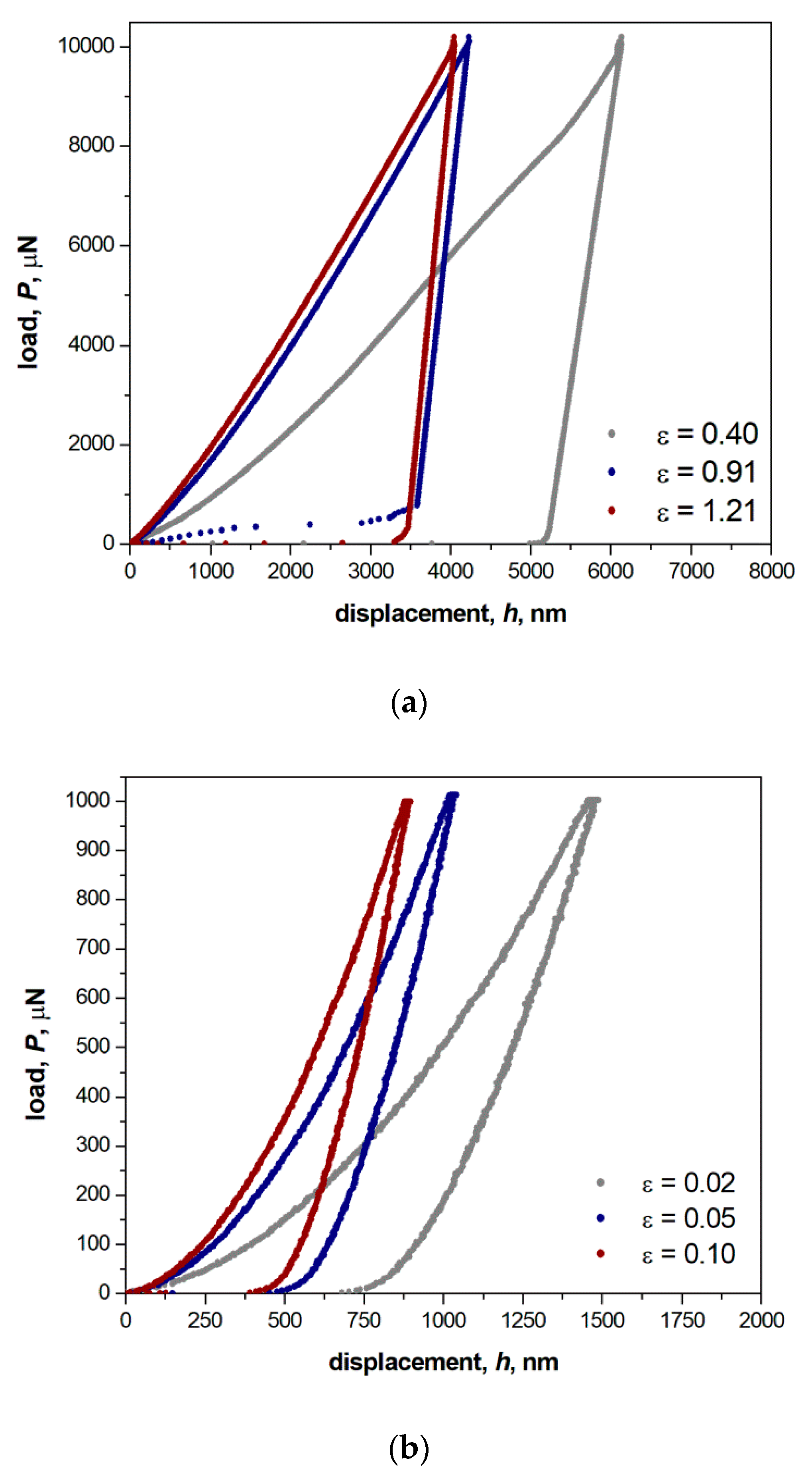

3.2. Nanoindentation Hardness, H

4. Discussion

4.1. Case of OFHC 99.99% Pure Copper

4.2. Case of 6N-Al

5. Conclusions

- A minimum necessary strain level to induce the formation of LABs and eventually HABs was identified for both copper and aluminum, and it was found to be εeq = 0.05 for the 6N-Al, and εeq < 0.40 for the OFHC Cu.

- In OFHC Cu a low cut-off strain level of εeq = 0.91 was identified as the minimum necessary strain to induce twin formation within the grains.

- A microstructure based strengthening model was proposed and applied for both the pure metals. In the case of aluminum, the strengthening contribution came from the tangled dislocations (TDs) which were promoted to form LABs and eventually HABs with cumulative HPT straining. In the case of copper, being a low SFE metal, statistically stored dislocations (SSDs), geometrically necessary dislocations (GNDs), dislocation walls (DWs), and grain boundaries contributed to the metal strengthening before the occurrence of twin that was promoted by the cumulative straining from εeq = 0.91. Beyond this strain, twin boundaries started to act as further strengthening contribution for the HPT OFHC Cu.

- Both microstructure-based models were directly compared to the metal stress obtained by the nanoindentation hardness measurements at the different experimental conditions here tested. Quite a good agreement was found by setting the multiplicative factor between the measured hardness and the resulting metal yield stress, HV/σy, χ = 3.5.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, X.X.; Hansen, N.; Tsuji, N. Hardening by Annealing and Softening by Deformation in Nanostructured Metals. Science 2006, 312, 249–251. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Xun, Y.; Mohamed, F.A. Refining efficiency and capability of top-down synthesis of nanocrystalline materials. Mater. Sci. Eng. A 2011, 528, 5446–5452. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Vinogradov, A.; Estrin, Y. Analytical and numerical approaches to modelling severe plastic deformation. Prog. Mater. Sci. 2018, 95, 172–242. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Li, B.L.; Tsuji, N.; Kamikawa, N. Microstructure homogeneity in various metallic materials heavily deformed by accumulative roll-bonding. Mater. Sci. Eng. A 2006, 423, 331–342. [Google Scholar] [CrossRef]

- Ito, Y.; Edalati, K.; Horita, Z. High-pressure torsion of aluminum with ultrahigh purity (99.9999%) and occurrence of inverse Hall-Petch relationship. Mater. Sci. Eng. A 2017, 679, 428–434. [Google Scholar] [CrossRef]

- Cabibbo, M. Microstructure strengthening mechanisms in different equal channel angular pressed aluminum alloys. Mater. Sci. Eng. A 2013, 560, 413–432. [Google Scholar] [CrossRef]

- Ovid’Ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Cabibbo, M. Nanostructured Cobalt Obtained by Combining Bottom-Up and Top-Down Approach. Metals 2018, 8, 962. [Google Scholar] [CrossRef] [Green Version]

- Venables, J. The electron microscopy of deformation twinning. J. Phys. Chem. Solids 1964, 2, 59. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Zhu, Y.T.; Horita, Z.; Langdon, T.G. Influence of stacking fault energy on nanostructure formation under high pressure torsion. Mater. Sci. Eng. A 2005, 410, 188–193. [Google Scholar] [CrossRef]

- Murr, L.E. Interfacial Phenomena in Metals and Alloys; Addison-Wesley Pub. Co.: Boston, MA, USA, 1975. [Google Scholar]

- Hansen, N.; Huang, X.; Winther, G. Grain orientation, deformation microstructure and flow stress. Mater. Sci. Eng. A 2008, 494, 61–67. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Starink, M.J.; Qiao, X.G.; Zhang, J.; Gao, N. Predicting grain refinement by cold severe plastic deformation in alloys using volume averaged dislocation generation. Acta Mater. 2009, 57, 5796–5811. [Google Scholar] [CrossRef] [Green Version]

- Polakowski, N.H.; Ripling, E.J. Strength and Structure of Engineering Materials; Prentice-Hall: Upper Saddle River, NJ, USA, 1966. [Google Scholar]

- Russ, J.C.; Dehoff, R.T. Practical Stereology; Springer Science and Business Media LLC: Berlin, Germany, 2000. [Google Scholar]

- Cabibbo, M. A TEM Kikuchi pattern study of ECAP AA1200 via routes A, C, BC. Mater. Charact. 2010, 61, 613–625. [Google Scholar] [CrossRef]

- Cabibbo, M.; Blum, W.; Evangelista, E.; Kassner, M.E.; Meyers, M.A. Transmission electron microscopy study of strain induced low- and high-angle boundary development in equal-channel angular-pressed commercially pure aluminium. Metall. Mater. Trans. A 2008, 39, 181–192. [Google Scholar] [CrossRef]

- Cabibbo, M.; Ricci, P.; Cecchini, R.; Rymuza, Z.; Sullivan, J.; Dub, S.; Cohen, S.R. An international round-robin calibration protocol for nanoindentation measurements. Micron 2012, 43, 215–222. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Gong, J.; Miao, H.; Peng, Z. Analysis of the nanoindentation data measured with a Berkovich indenter for brittle materials: Effect of the residual contact stress. Acta Mater. 2004, 52, 785–793. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Han, W.Z.; Zhang, Z.; Wu, S.; Li, S. Combined effects of crystallographic orientation, stacking fault energy and grain size on deformation twinning in fcc crystals. Philos. Mag. 2008, 88, 3011–3029. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; Liao, X.; Kawasaki, M.; Ringer, S.; Langdon, T.G.; Zhu, Y. Applied stress controls the production of nano-twins in coarse-grained metals. Appl. Phys. Lett. 2012, 101, 231903. [Google Scholar] [CrossRef] [Green Version]

- Laplanche, G.; Kostka, A.; Horst, O.; Eggeler, G.; George, E. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef] [Green Version]

- Müllner, P.; Romanov, A. Internal twinning in deformation twinning. Acta Mater. 2000, 48, 2323–2337. [Google Scholar] [CrossRef]

- Christian, J.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Han, W.; Wu, S.; Huang, C.; Li, S.; Zhang, Z. Orientation Design for Enhancing Deformation Twinning in Cu Single Crystal Subjected to Equal Channel Angular Pressing. Adv. Eng. Mater. 2008, 10, 1110–1113. [Google Scholar] [CrossRef]

- Antolovich, S.D.; Armstrong, R.W. Plastic strain localization in metals: Origins and consequences. Prog. Mater. Sci. 2014, 59, 1–160. [Google Scholar] [CrossRef]

- Lapovok, R.; Dallatorre, F.; Sandlin, J.; Davies, C.H.J.; Pereloma, E.; Thomson, P.; Estrin, Y. Gradient plasticity constitutive model reflecting the ultrafine micro-structure scale: The case of severely deformed copper. J. Mech. Phys. Solids 2005, 53, 729–747. [Google Scholar] [CrossRef]

- Dalla Torre, F.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Mughrabi, H. Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall. 1983, 31, 1367–1379. [Google Scholar] [CrossRef]

- Ungár, T.; Toth, L.S.; Illy, J.; Kovacs, I. Dislocation structure and work hardening in polycrystalline ofhc copper rods deformed by torsion and tension. Acta Metall. 1986, 34, 1257–1267. [Google Scholar] [CrossRef]

- Argon, A.; Haasen, P. A new mechanism of work hardening in the late stages of large strain plastic flow in F.C.C. and diamond cubic crystals. Acta Metall. Mater. 1993, 41, 3289–3306. [Google Scholar] [CrossRef]

- Estrin, Y.; Toth, L.S.; Molinari, A.; Bréchet, Y. A dislocation-based model for all hardening stages in large strain deformation. Acta Mater. 1998, 46, 5509–5522. [Google Scholar] [CrossRef]

- Feaugas, X.; Pilvin, P. A Polycrystalline Approach to the Cyclic Behaviour of f.c.c. Alloys-Intra-Granular Heterogeneity. Adv. Eng. Mater. 2009, 11, 703–709. [Google Scholar] [CrossRef]

- Cabibbo, M. Nanoindentation twin-sensitive measurements and strengthening model of HPT OFHC 99.99% purity copper. Mater. Sci. Eng. A 2020, 785, 139348. [Google Scholar] [CrossRef]

- An, X.; Lin, Q.; Qu, S.; Yang, G.; Wu, S.; Zhang, Z. Influence of stacking-fault energy on the accommodation of severe shear strain in Cu-Al alloys during equal-channel angular pressing. J. Mater. Res. 2009, 24, 3636–3646. [Google Scholar] [CrossRef] [Green Version]

- Hedman, E.; Groza, I.; Karlsson, S. Subgrain growth in Al and Al-1% Mn during annealing. J. Mater. Sci. 1978, 13, 1229–1242. [Google Scholar] [CrossRef]

- Cabibbo, M.; Spigarelli, S. A TEM quantitative evaluation of strengthening in an Mg–RE alloy reinforced with SiC. Mater. Charact. 2011, 62, 959–969. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X. Microstructure and flow stress of polycrystals and single crystals. Acta Mater. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Qiao, X.; Starink, M.J.; Gao, N. Hardness inhomogeneity and local strengthening mechanisms of an Al1050 aluminium alloy after one pass of equal channel angular pressing. Mater. Sci. Eng. A 2009, 513, 52–58. [Google Scholar] [CrossRef] [Green Version]

- Toth, L.S.; Estrin, Y.; Lapovok, R.; Gu, C. A model of grain fragmentation based on lattice curvature. Acta Mater. 2010, 58, 1782–1794. [Google Scholar] [CrossRef]

| OFHC Cu | εeq = 0.40 20; 1/18; 2; | εeq = 0.91 45; 1/8; 2; | εeq = 1.21 60; 1/6; 2; |

| 6N-Al | εeq = 0.02 5; 1/120; 0.3; | εeq = 0.05 15; 1/45; 0.3; | εeq = 0.10 15; 1/45; 0.6; |

| OFHC Cu | εeq ρTD, 1014 m−2 | 0.40 3.50 ± 0.30 | 0.91 1.30 ± 0.20 | 1.21 0.90 ± 0.20 |

| 6N-Al | εeq ρTD, 1014 m−2 | 0.02 0.03 ± 0.01 | 0.05 1.80 ± 0.20 | 0.10 0.60 ± 0.10 |

| OFHC Cu | εeq | 0.40 | 0.91 | 1.21 |

| H, MPa | 780 ± 60 | 980 ± 60 | 1060 ± 60 | |

| dg, µm | 19 ± 1 | 14.5 ± 0.5 | 10.6 ± 0.5 | |

| dcell, nm | 1100 ± 100 | 760 ± 50 | 540 ± 50 | |

| 6N-Al | εeq | 0.02 | 0.05 | 0.10 |

| H, MPa | 75 ± 5 | 170 ± 10 | 210 ± 10 |

| Material | Dislocation Data Measured by TEM | εeq = 0.40 | εeq = 0.91 | εeq = 1.21 |

|---|---|---|---|---|

| OFHC Cu | ρwall, 1012 m−2 | 105 ± 10 | 130 ± 20 | 165 ± 20 |

| f (wall), 10−2 | 4 | 6 | 7 | |

| ρTD, 1012 m−2 | 25 ± 5 | 35 ± 5 | 40 ± 5 | |

| ρGND, 1012 m−2 | 95 ± 5 | 110 ± 5 | 120 ± 10 | |

| - | εeq = 0.02 | εeq = 0.05 | εeq = 0.10 | |

| 6N-Al | ρTD, 1012 m−2 | 3 ± 1 | 180 ± 20 | 60 ± 10 |

| Material | Yield Stress, MPa | εeq = 0.40 | εeq = 0.91 | εeq = 1.21 |

| OFHC Cu | σymodel, MPa | 217 | 237 | 256 |

| σynanoind, MPa | 223 | 280 | 303 | |

| εeq = 0.02 | εeq = 0.05 | εeq = 0.10 | ||

| 6N-Al | σTD, MPa | 9 | 22 | 15 |

| σVLAB+LAB, MPa | - | 5 | 14 | |

| σHAB, MPa | - | - | 11 | |

| σymodel, MPa | 19 | 37 | 50 | |

| σynanoind, MPa | 21 | 49 | 60 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabibbo, M.; Santecchia, E. Early Stages of Plastic Deformation in Low and High SFE Pure Metals. Metals 2020, 10, 751. https://doi.org/10.3390/met10060751

Cabibbo M, Santecchia E. Early Stages of Plastic Deformation in Low and High SFE Pure Metals. Metals. 2020; 10(6):751. https://doi.org/10.3390/met10060751

Chicago/Turabian StyleCabibbo, Marcello, and Eleonora Santecchia. 2020. "Early Stages of Plastic Deformation in Low and High SFE Pure Metals" Metals 10, no. 6: 751. https://doi.org/10.3390/met10060751

APA StyleCabibbo, M., & Santecchia, E. (2020). Early Stages of Plastic Deformation in Low and High SFE Pure Metals. Metals, 10(6), 751. https://doi.org/10.3390/met10060751