Recent Developments and Trends in Sheet Metal Forming

Abstract

:1. Introduction

2. Methods

- To fulfil the goal of this study, international databases were explored including (in alphabetical order: Bielefield Academic Search Engine, DOAJ Directory of Open Access Journals, eLibrary;ru, GoogleScholar, INGENTA, ScienceDirect, Springer, Web of Science, WorldCat, WorldWideScience;

- Year restrictions: the databases were explored for the period of the past decade with special attention to the 2015–2020 period;

- The English language is selected as the main source of review;

- Duplicated articles found in different databases were not considered;

- Papers which did not fit the goal of this study were excluded;

- No search engines were used; papers were reviewed manually;

- References available in the articles found were also considered.

3. Conventional Sheet Metal Forming

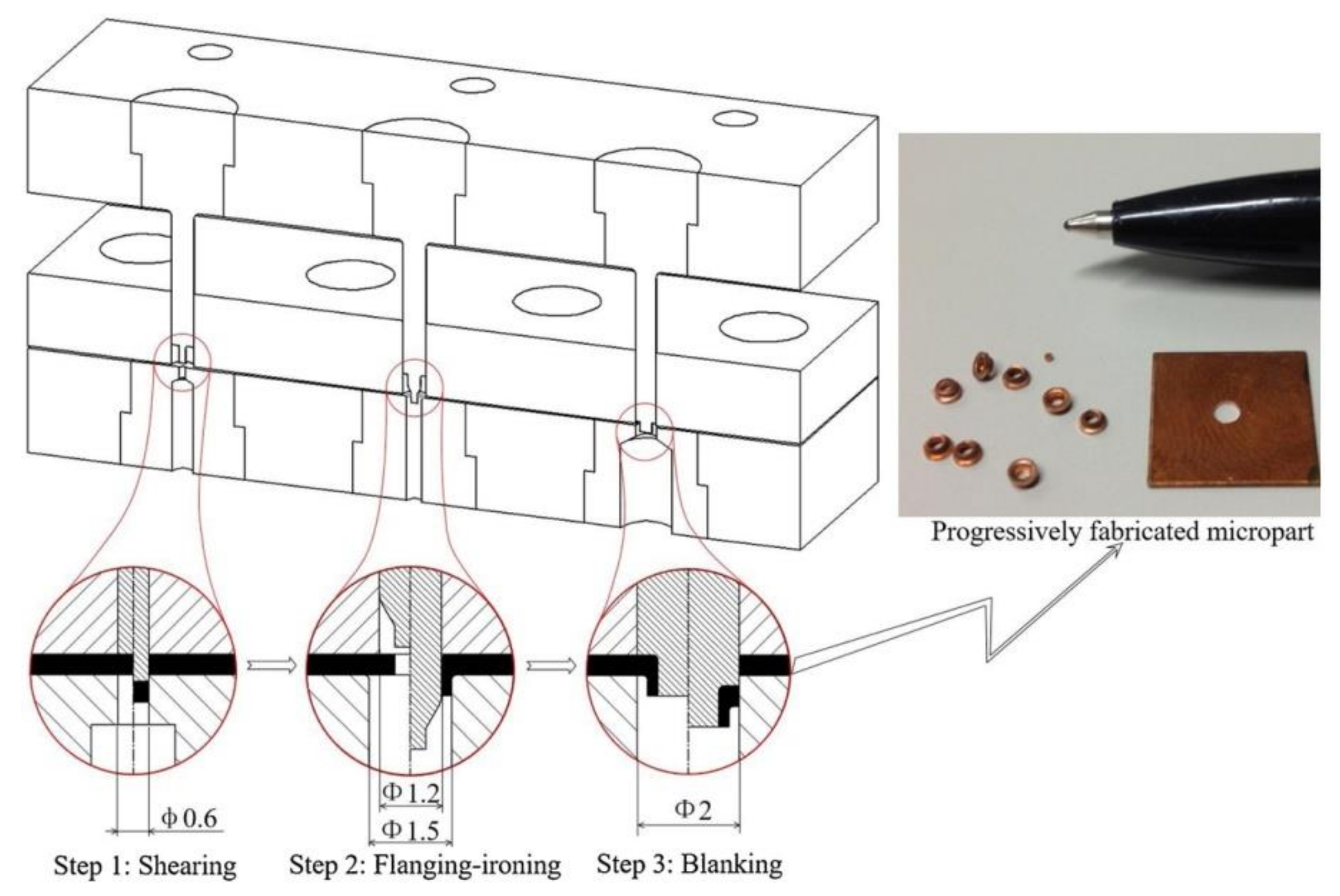

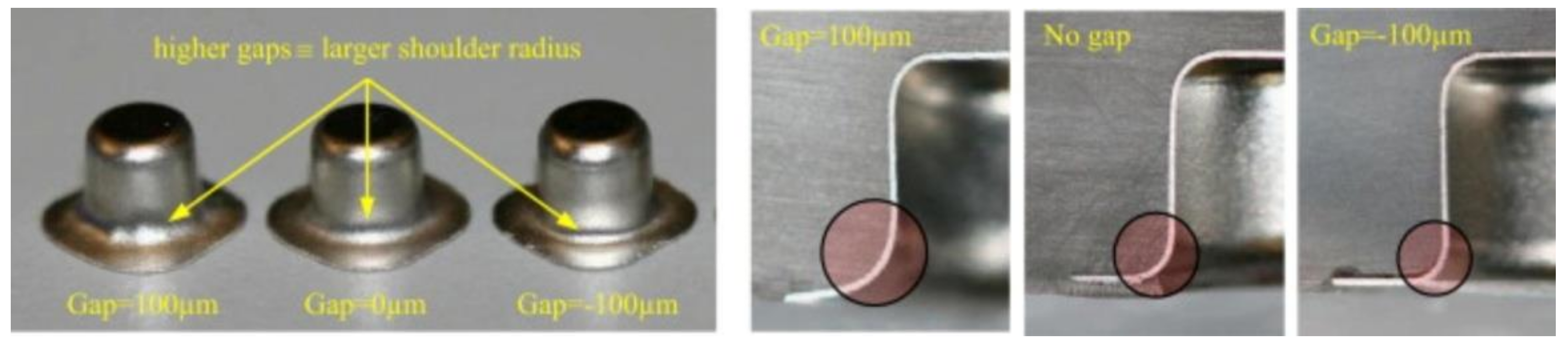

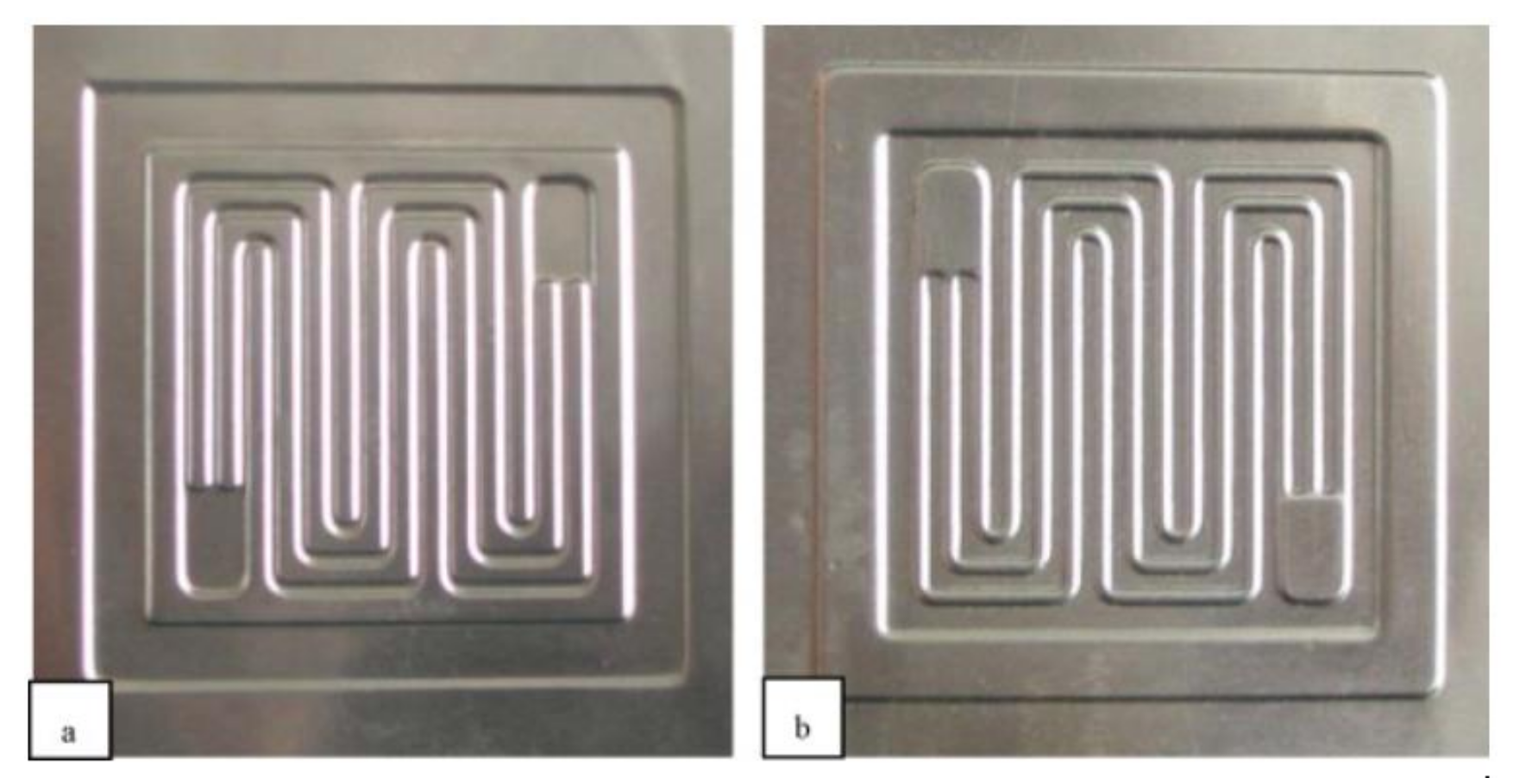

3.1. Sheet Microforming

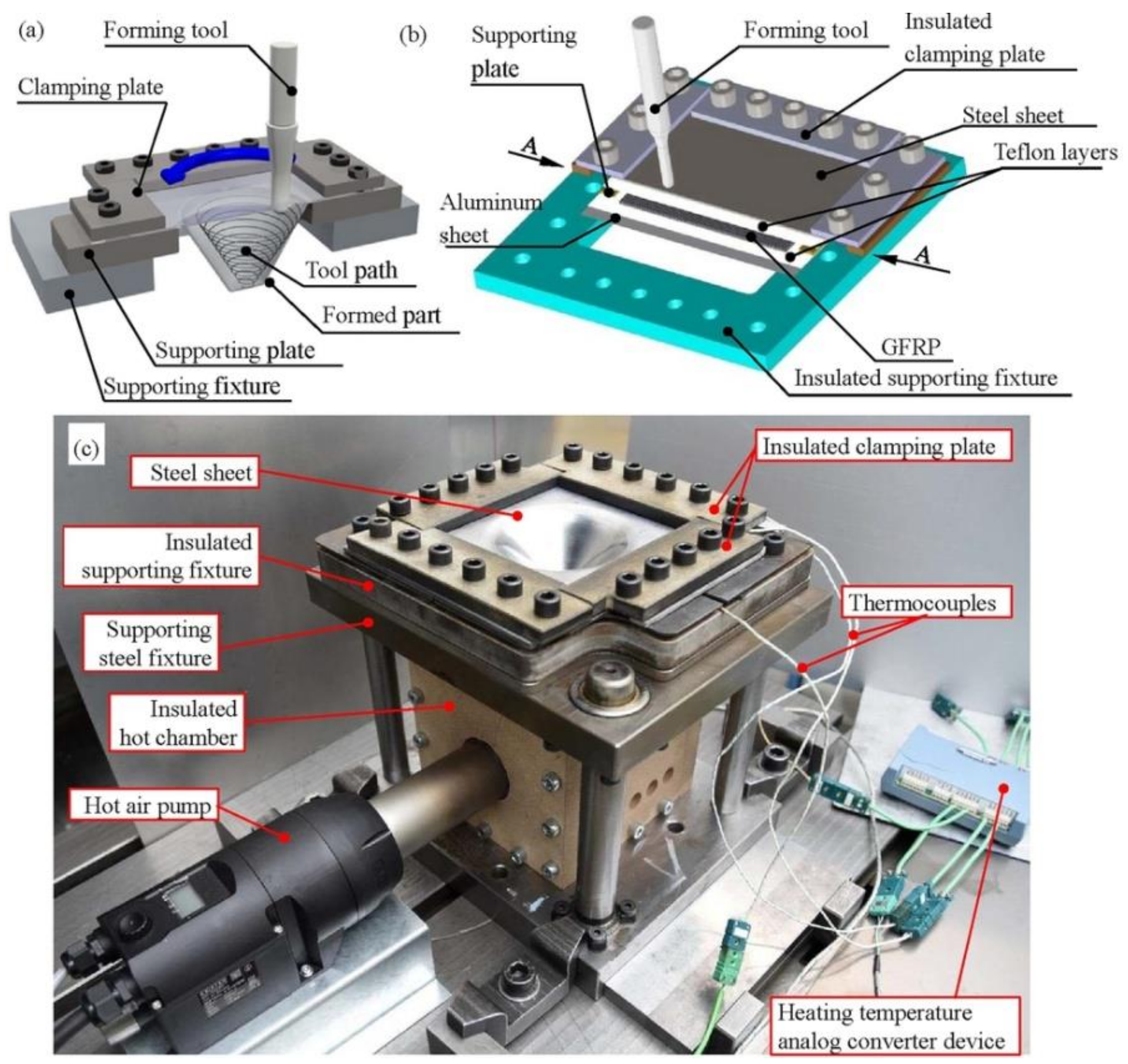

3.2. Warm/Hot Forming

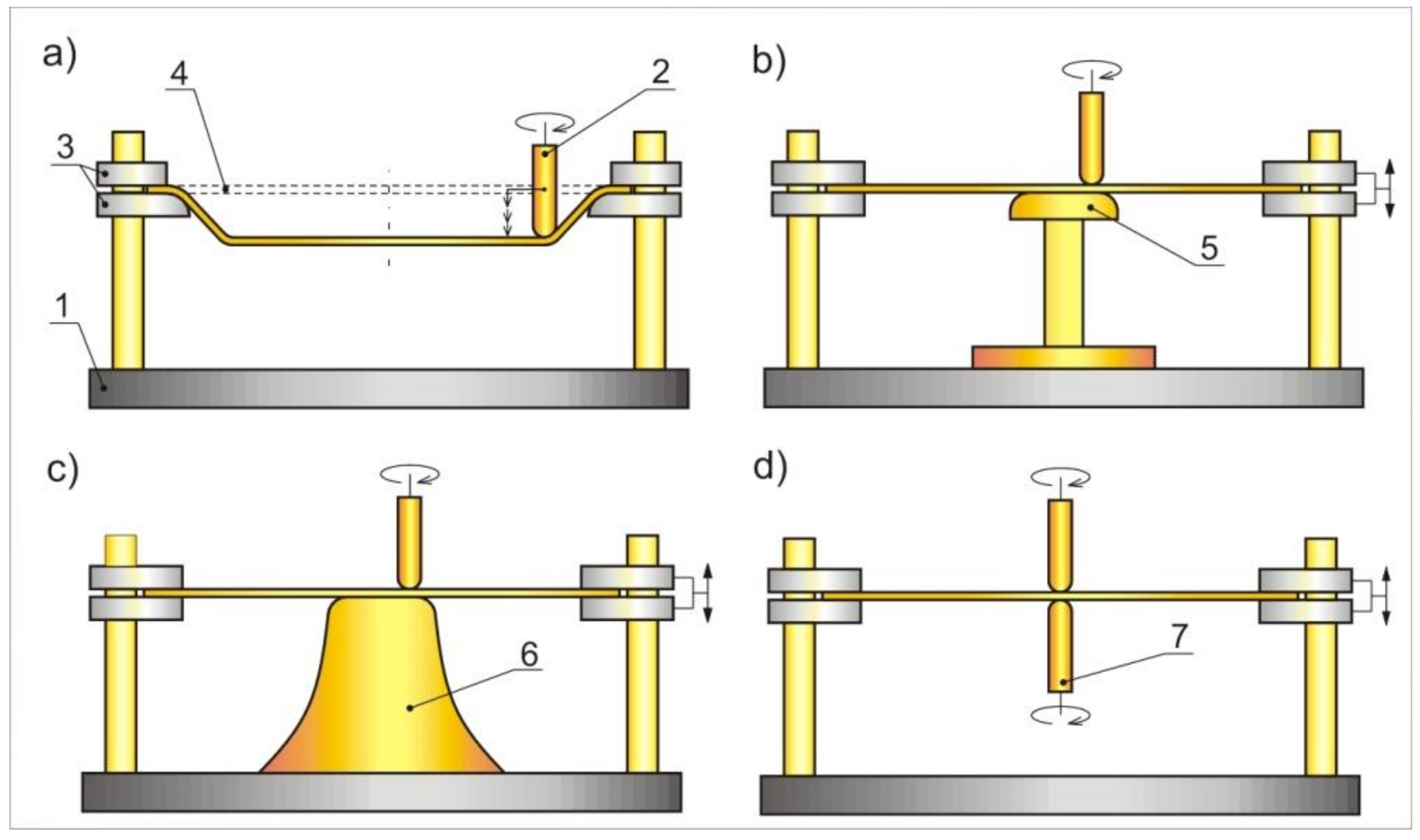

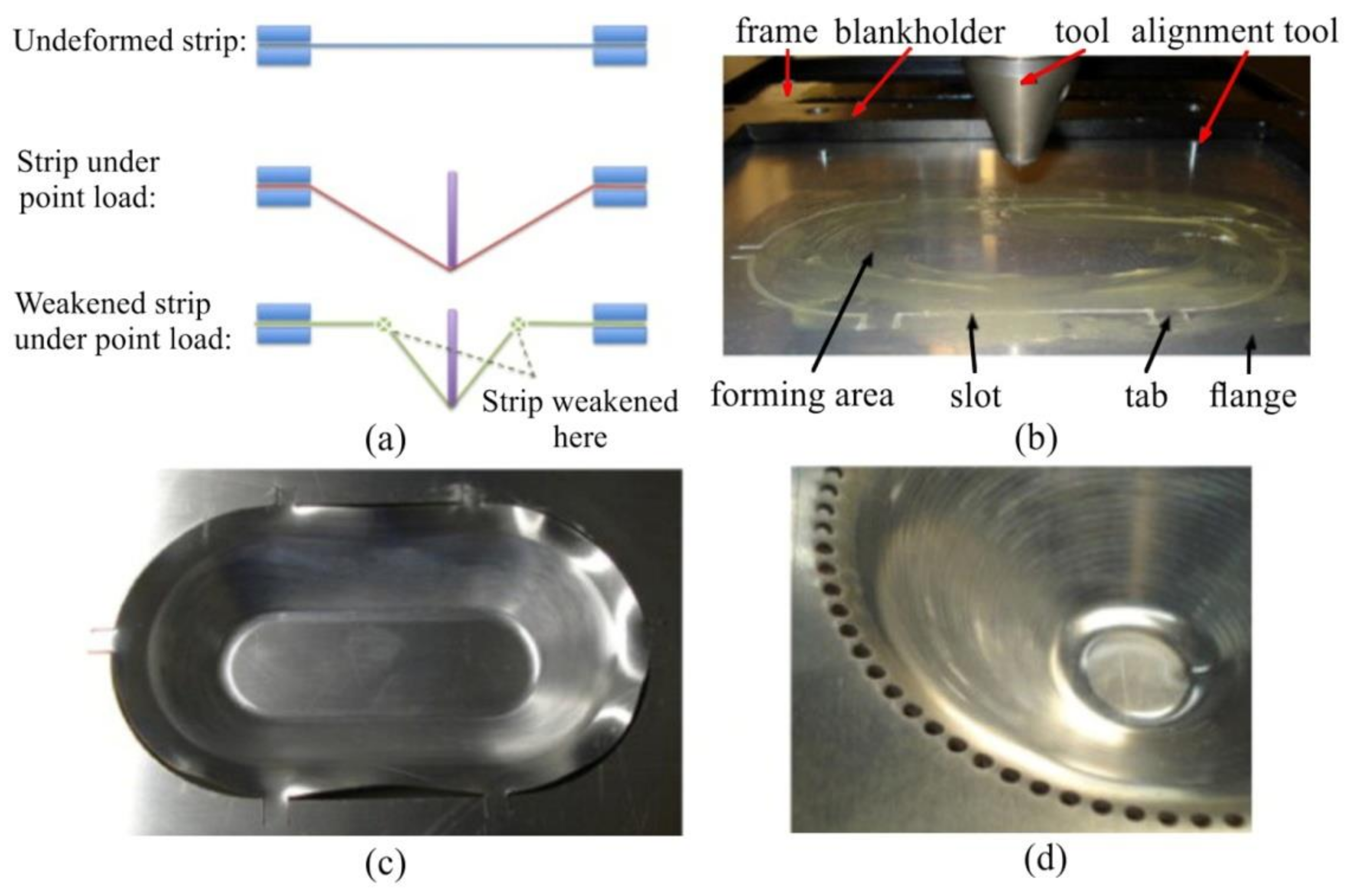

4. Incremental Sheet Forming

4.1. Background

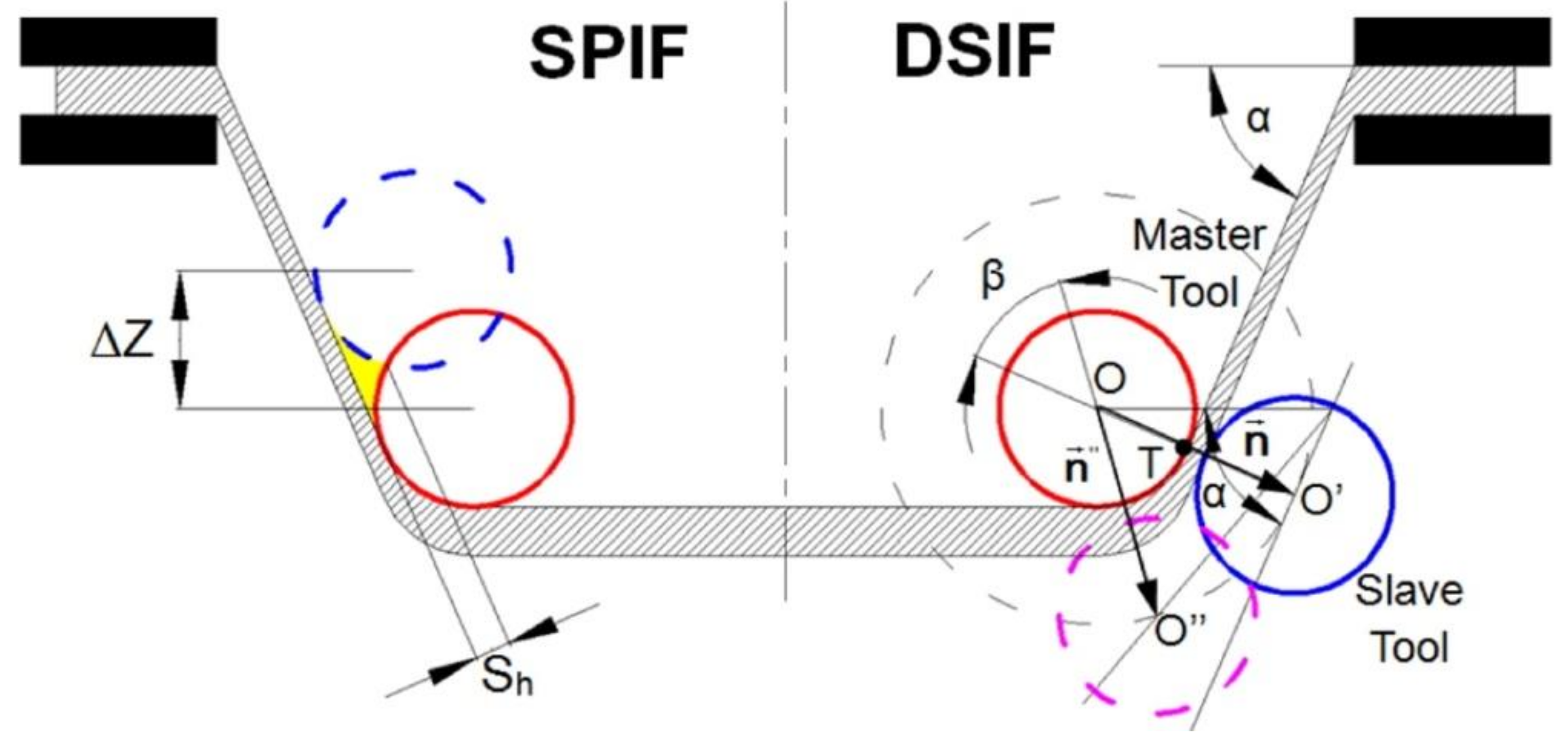

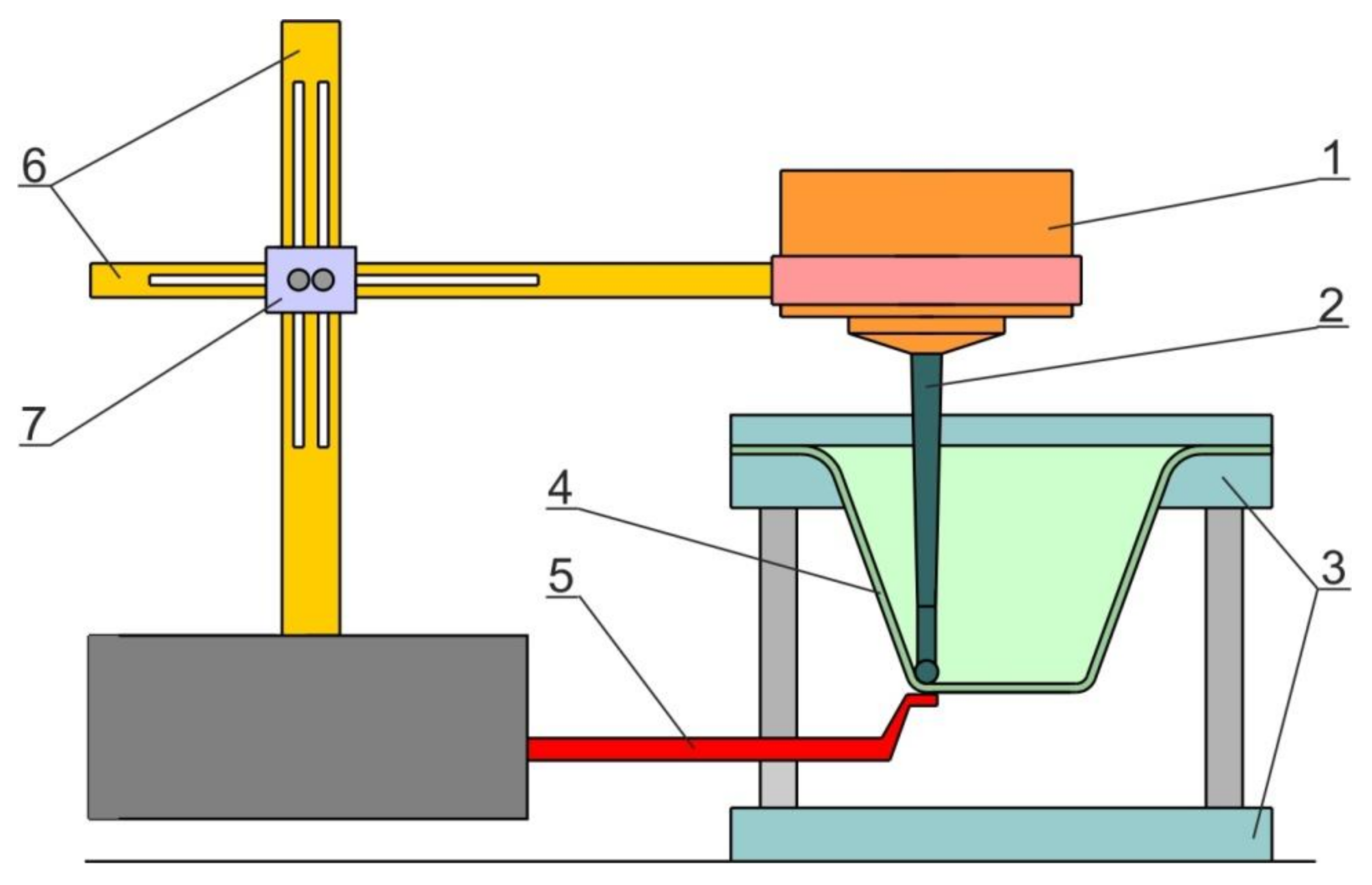

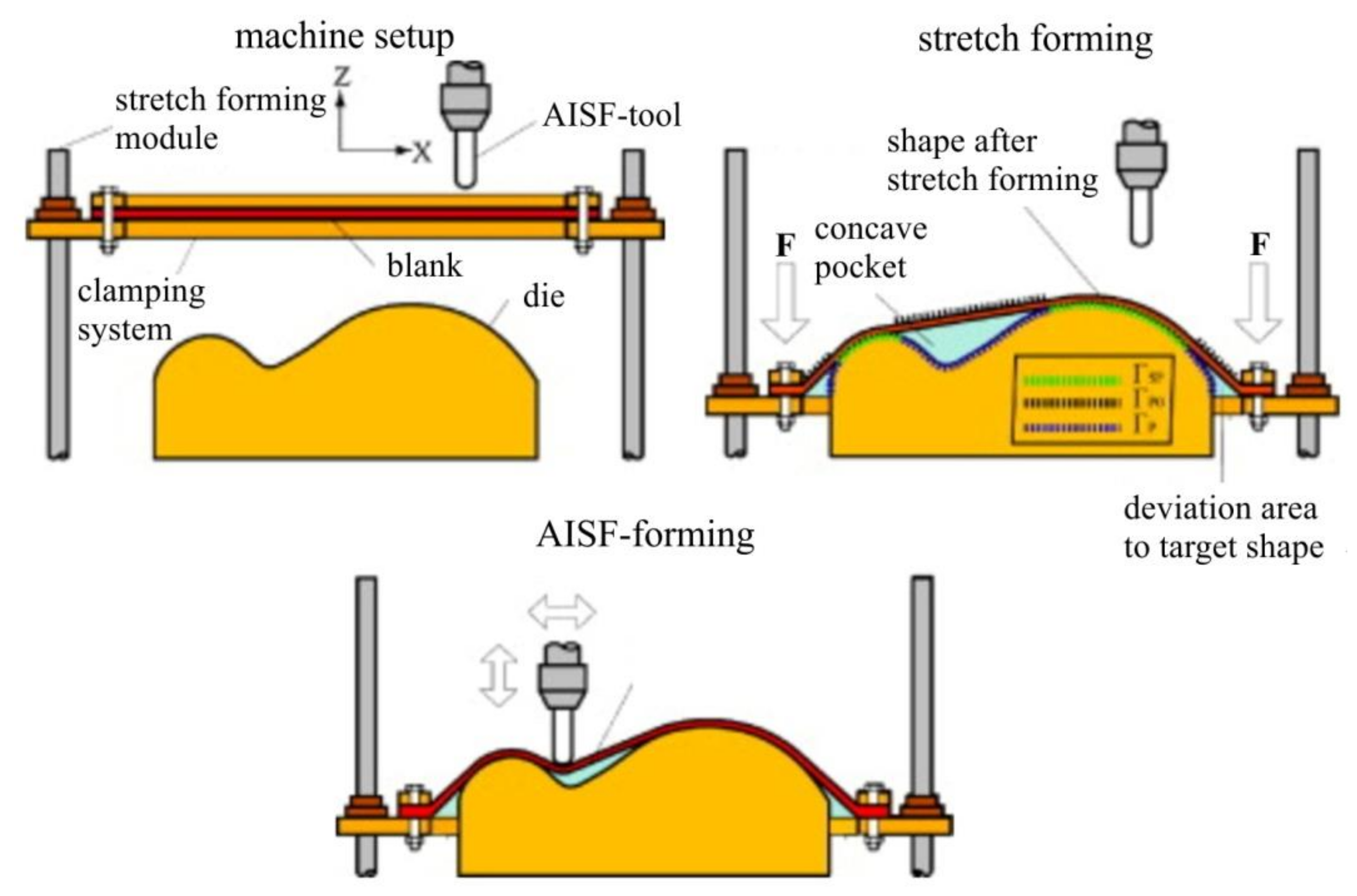

4.2. Incremental Sheet Forming with Metallic Tool

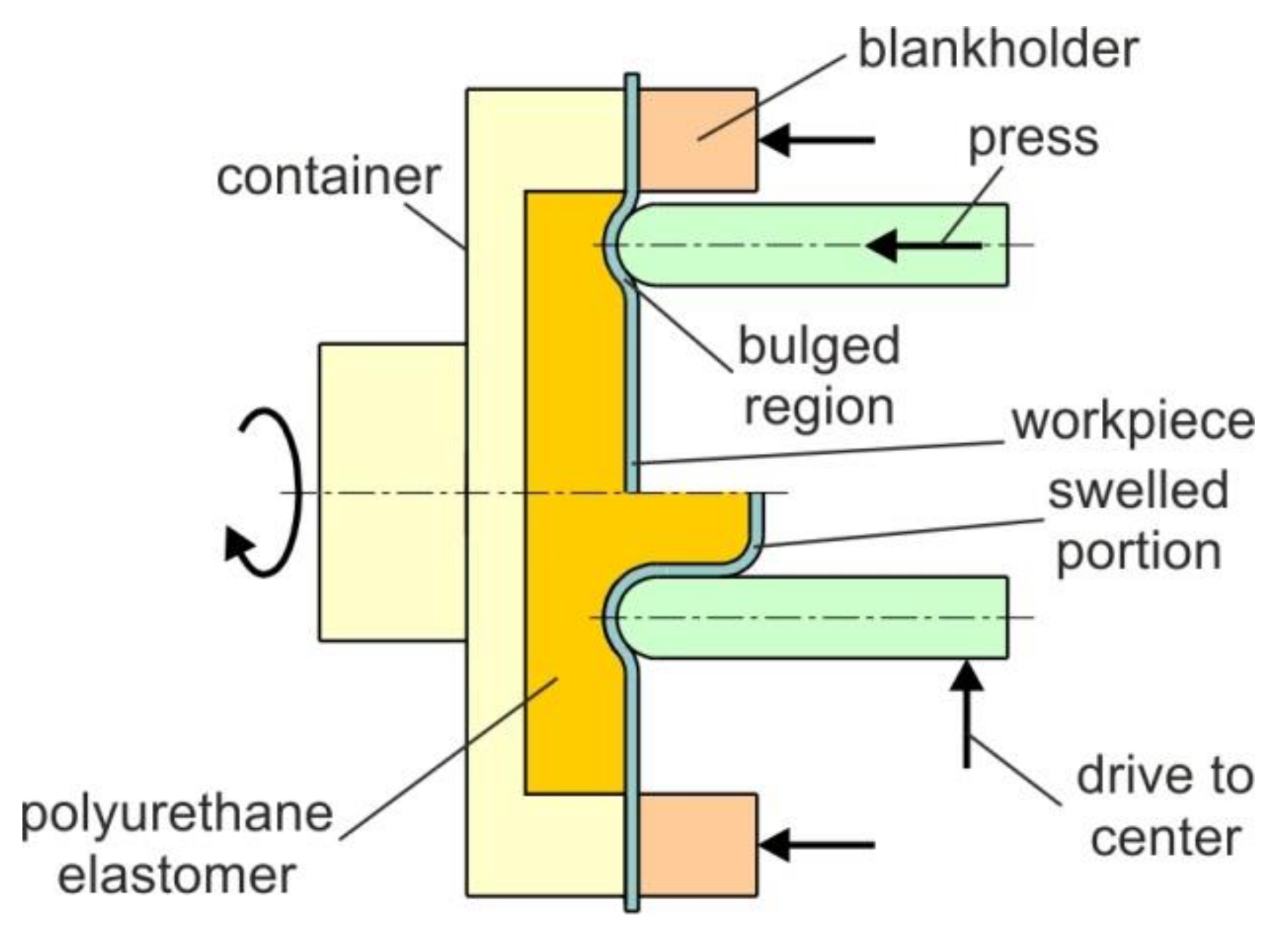

5. Flexible-Die Forming

5.1. Background

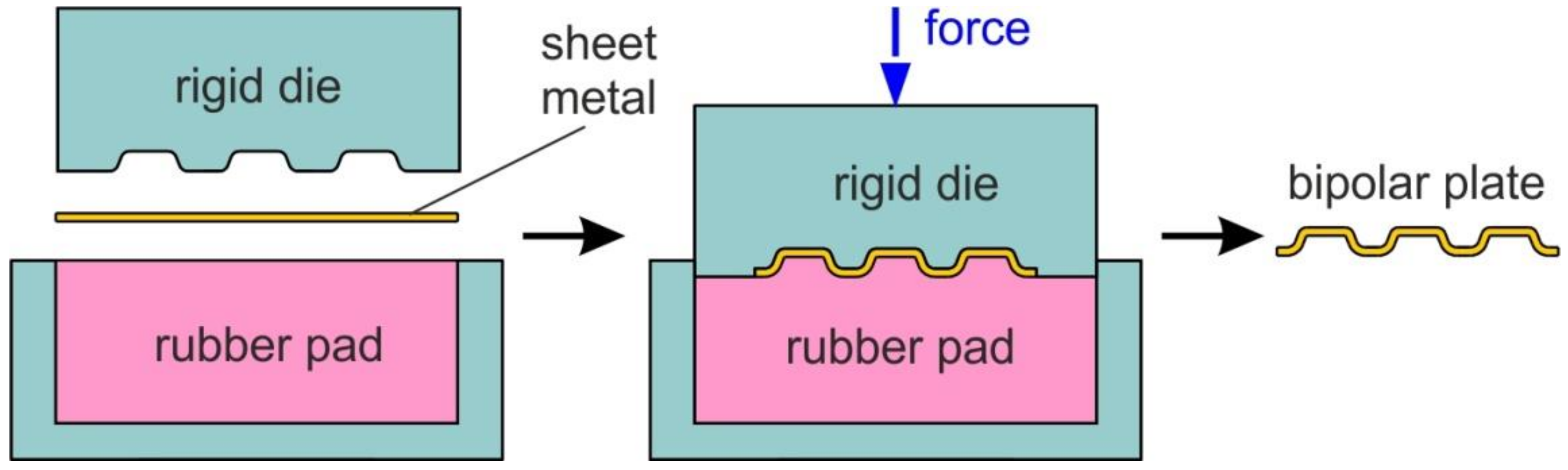

5.2. Rubber-Pad Forming

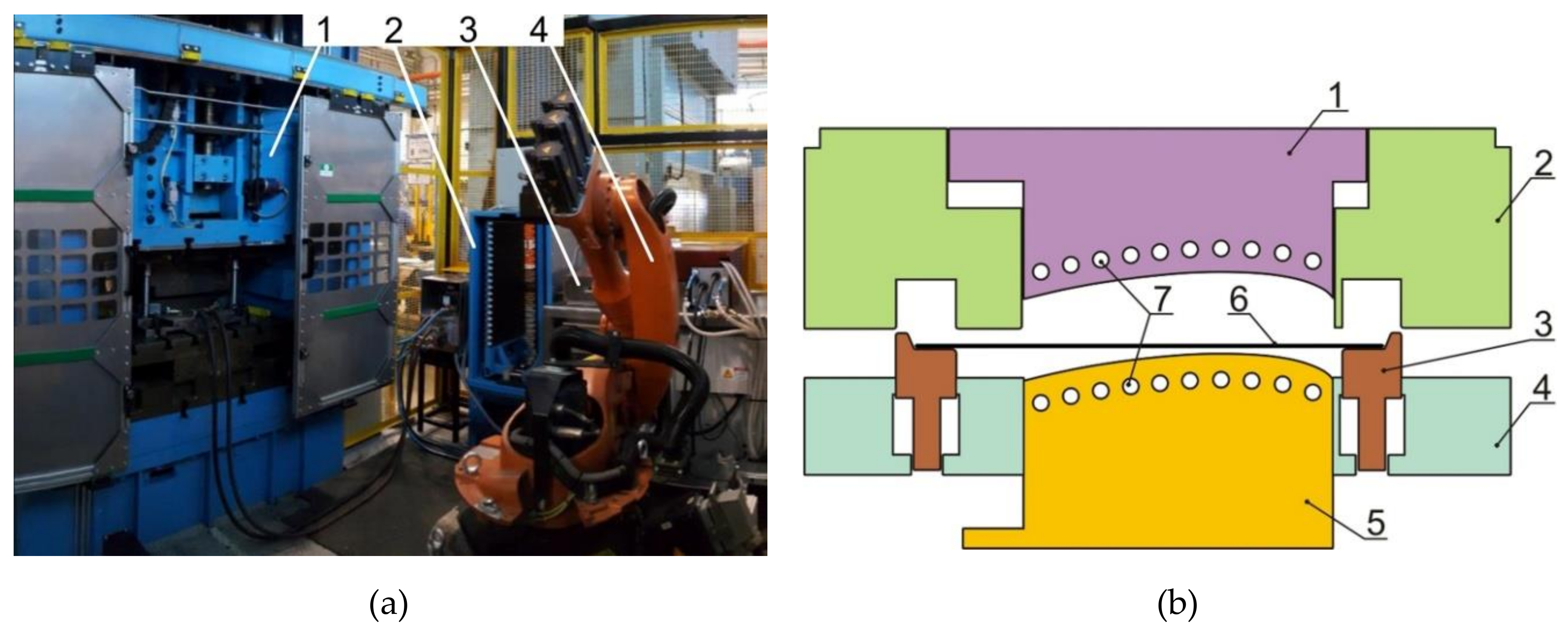

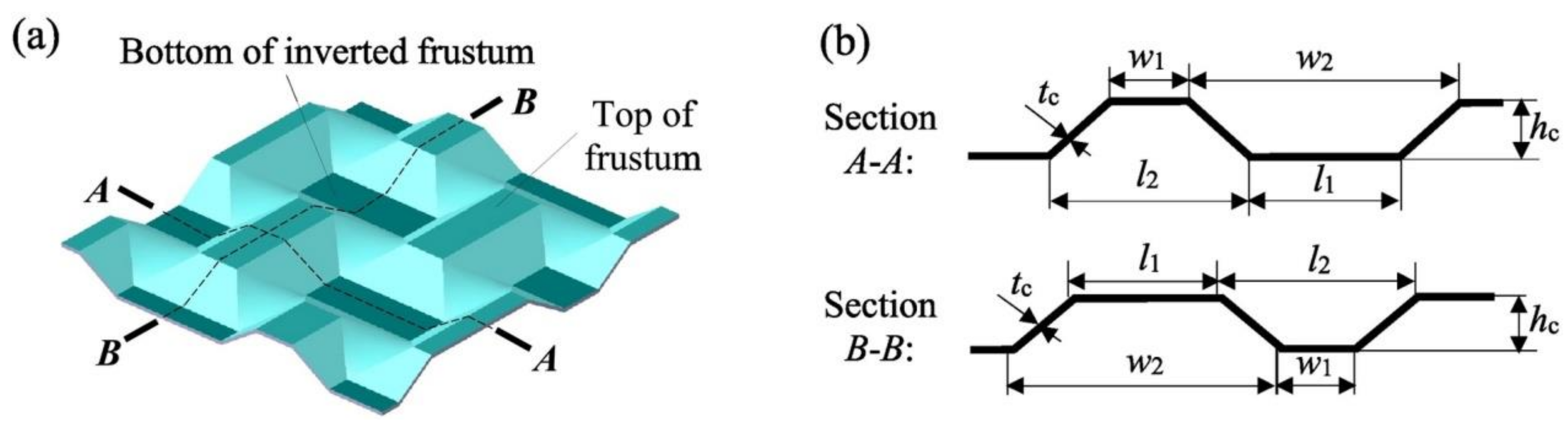

5.3. Multipoint Die Forming

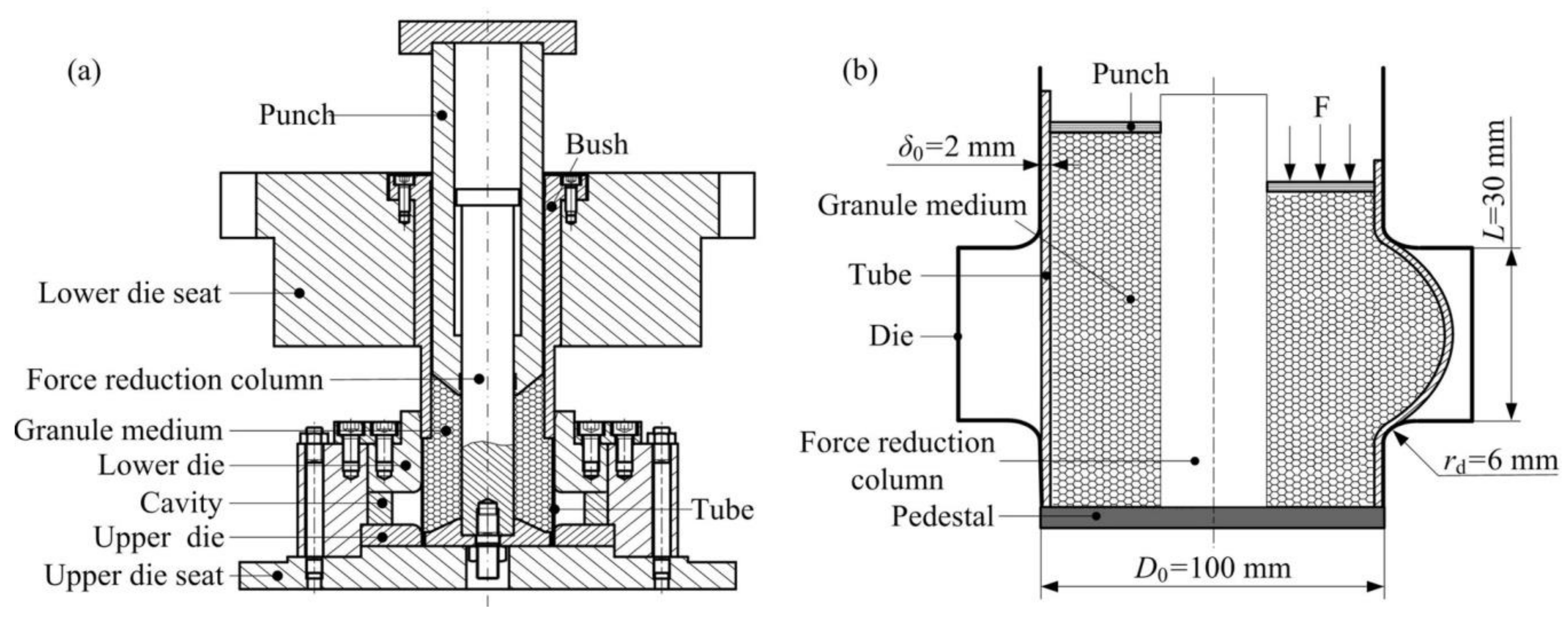

5.4. Solid Granular Medium Forming

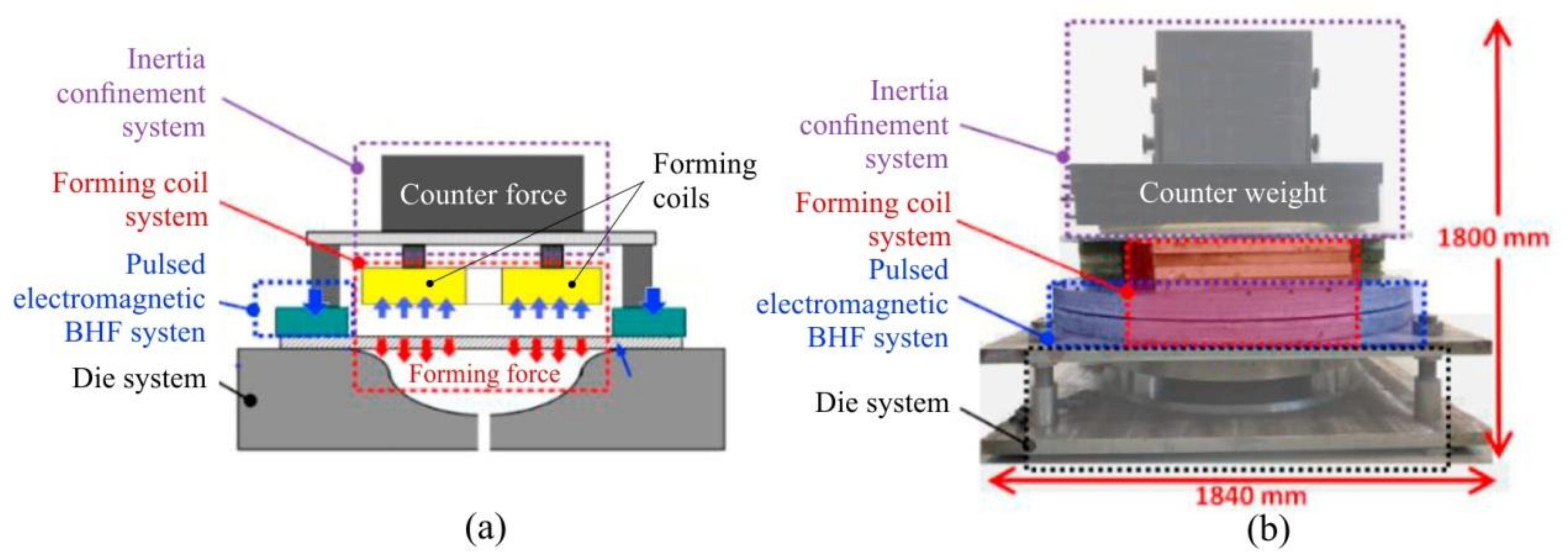

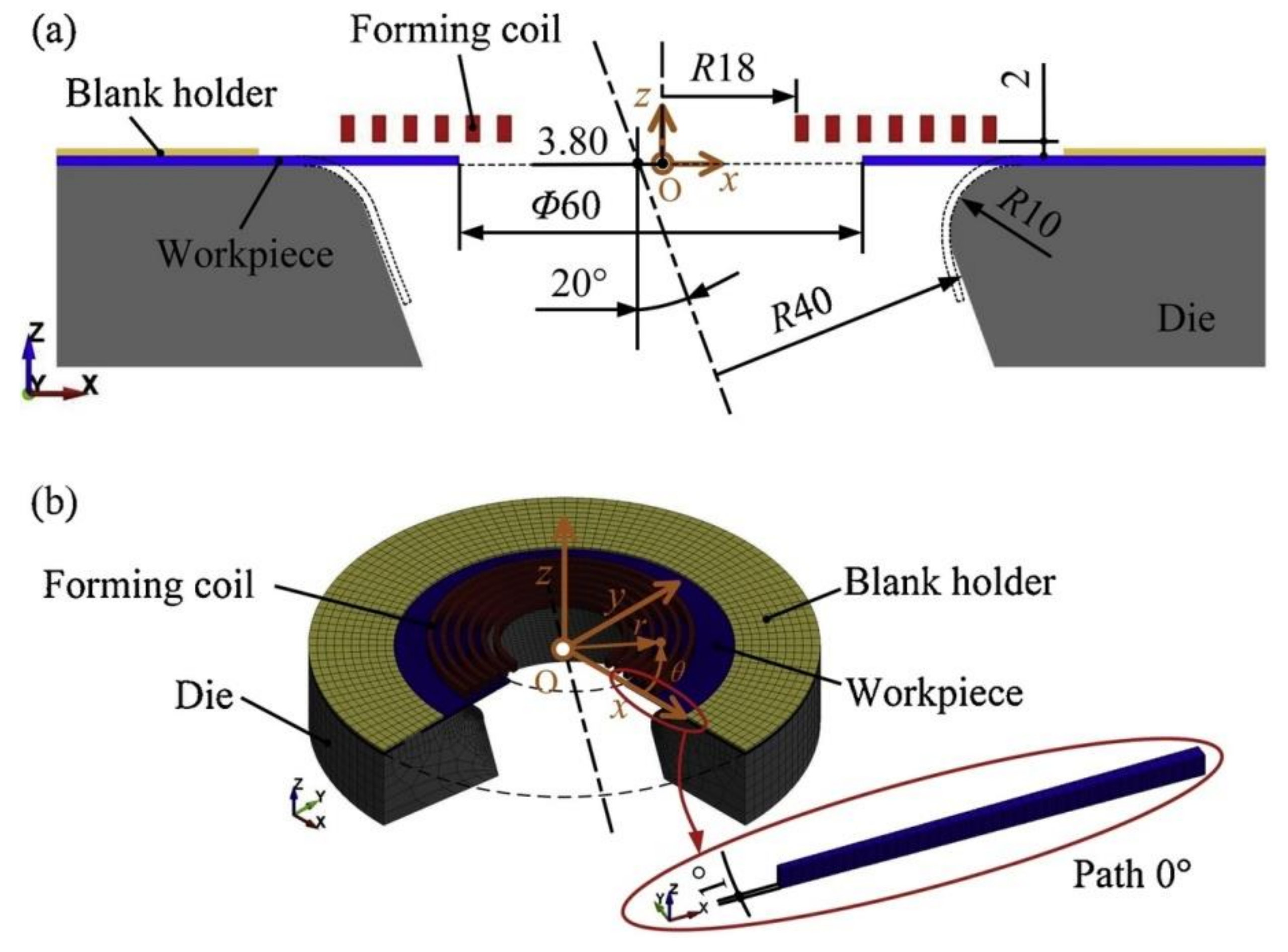

6. Electromagnetic Sheet Forming

- It is an environmentally friendly process; no lubricants are needed;

- There is no mechanical contact with the work piece;

- Controllability and repeatability of the formed parts are ensured;

- The greatest advantage is a significant increase in workpiece ductility over conventional SMF methods;

- Parts formed by EMF possess the merits of low springback [300], uniform strain distribution and good surface quality.

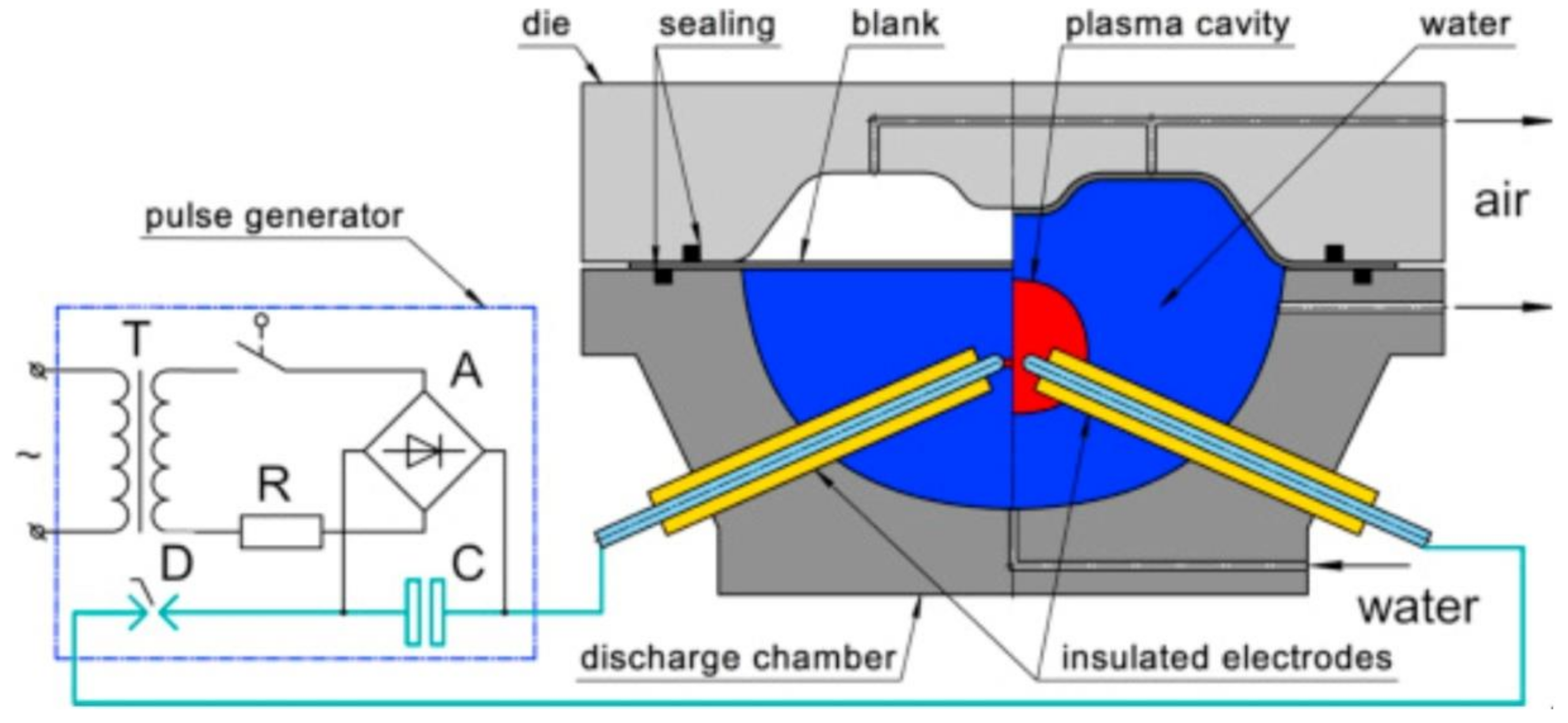

7. Electrohydraulic Forming

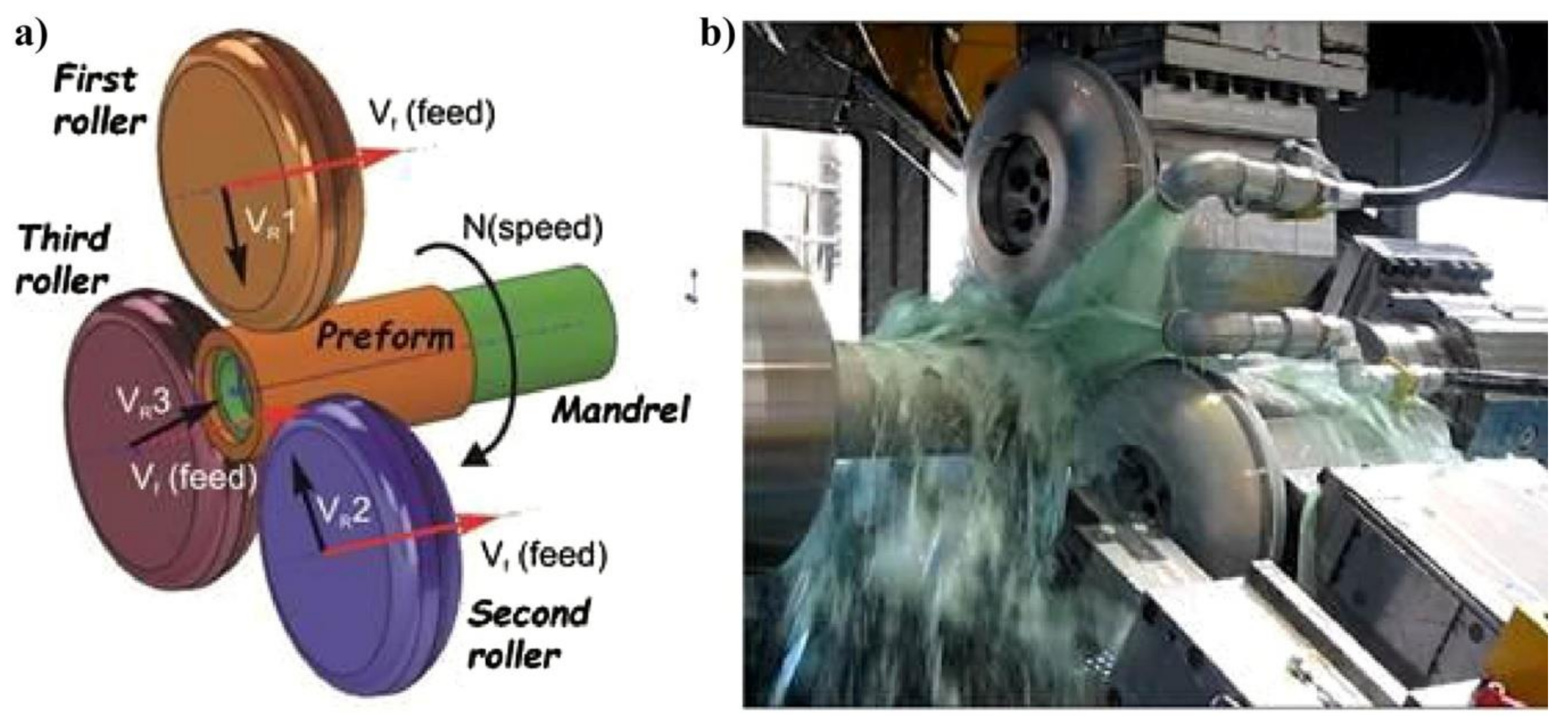

8. Spinning and Shear Spinning

8.1. Background

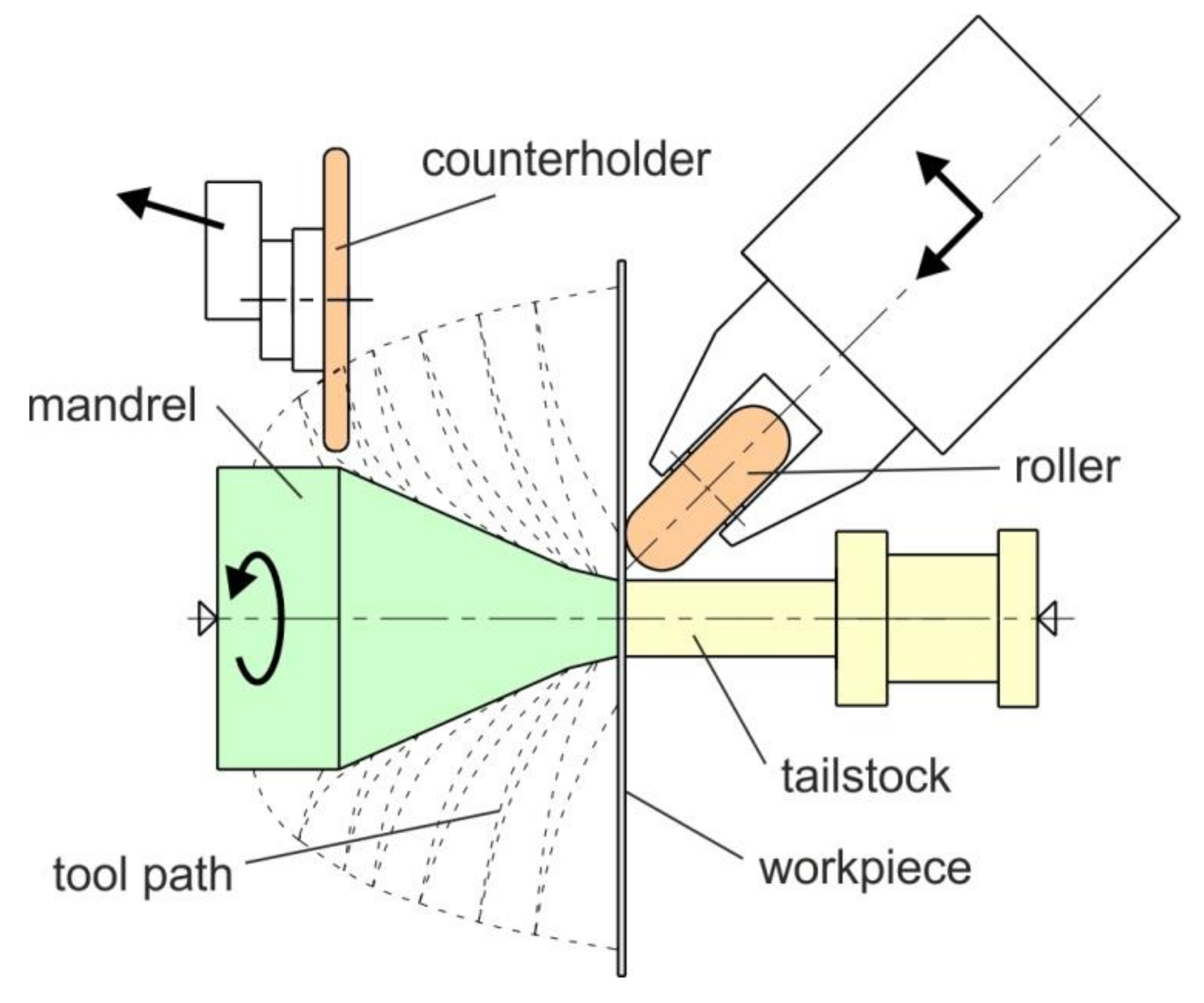

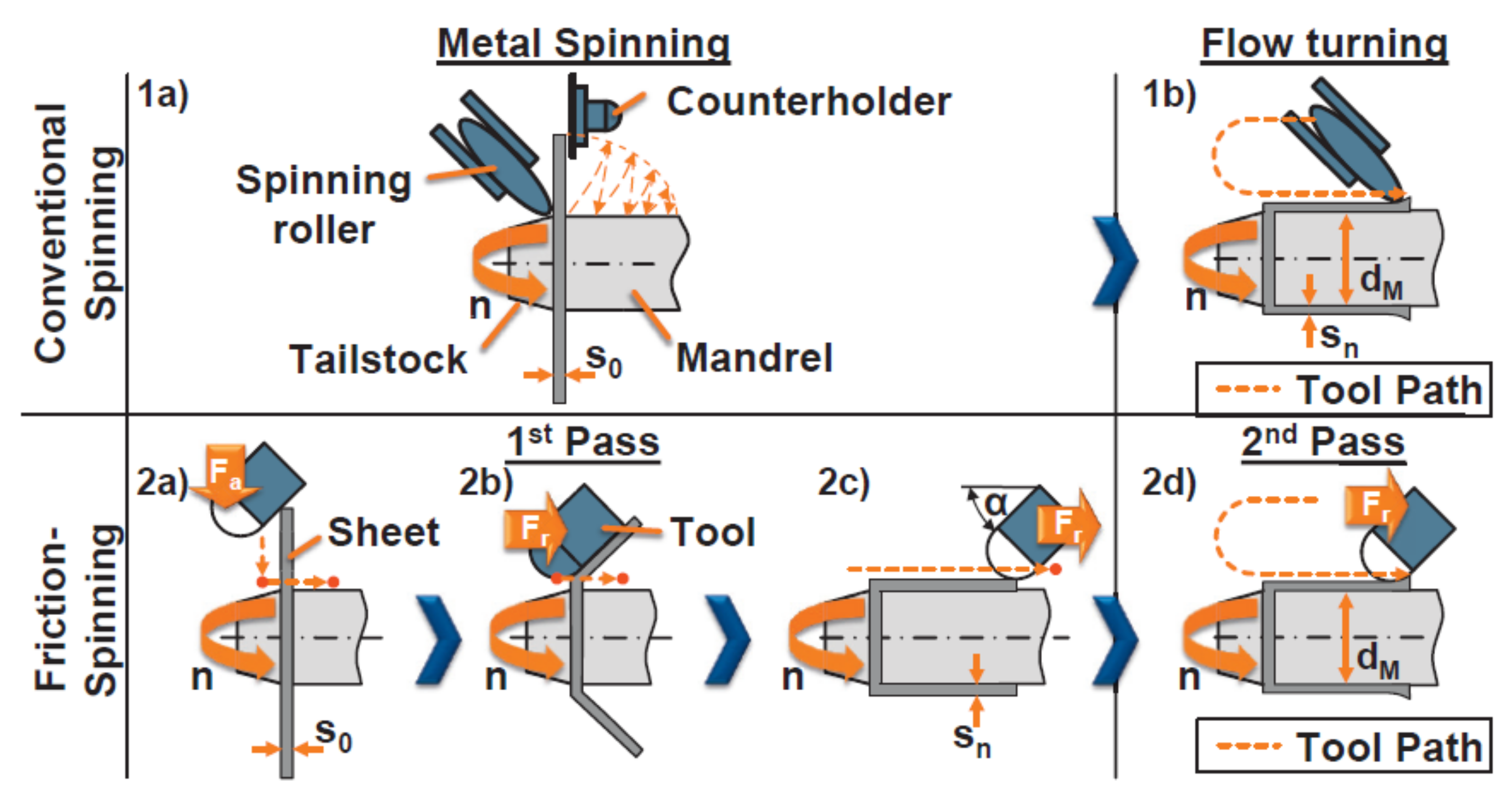

8.2. Conventional Axisymmetrical Spinning

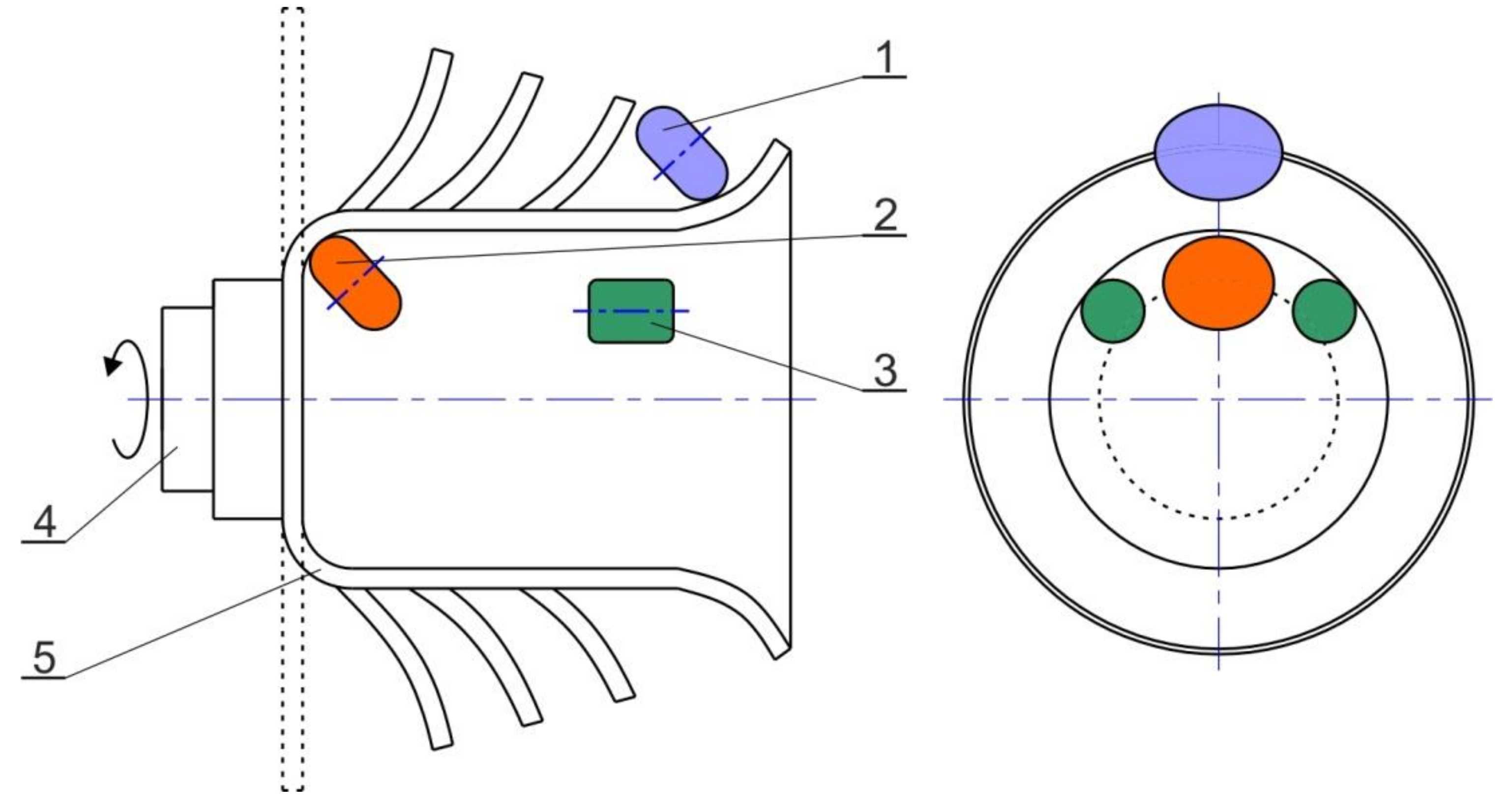

8.3. Asymmetric Spinning

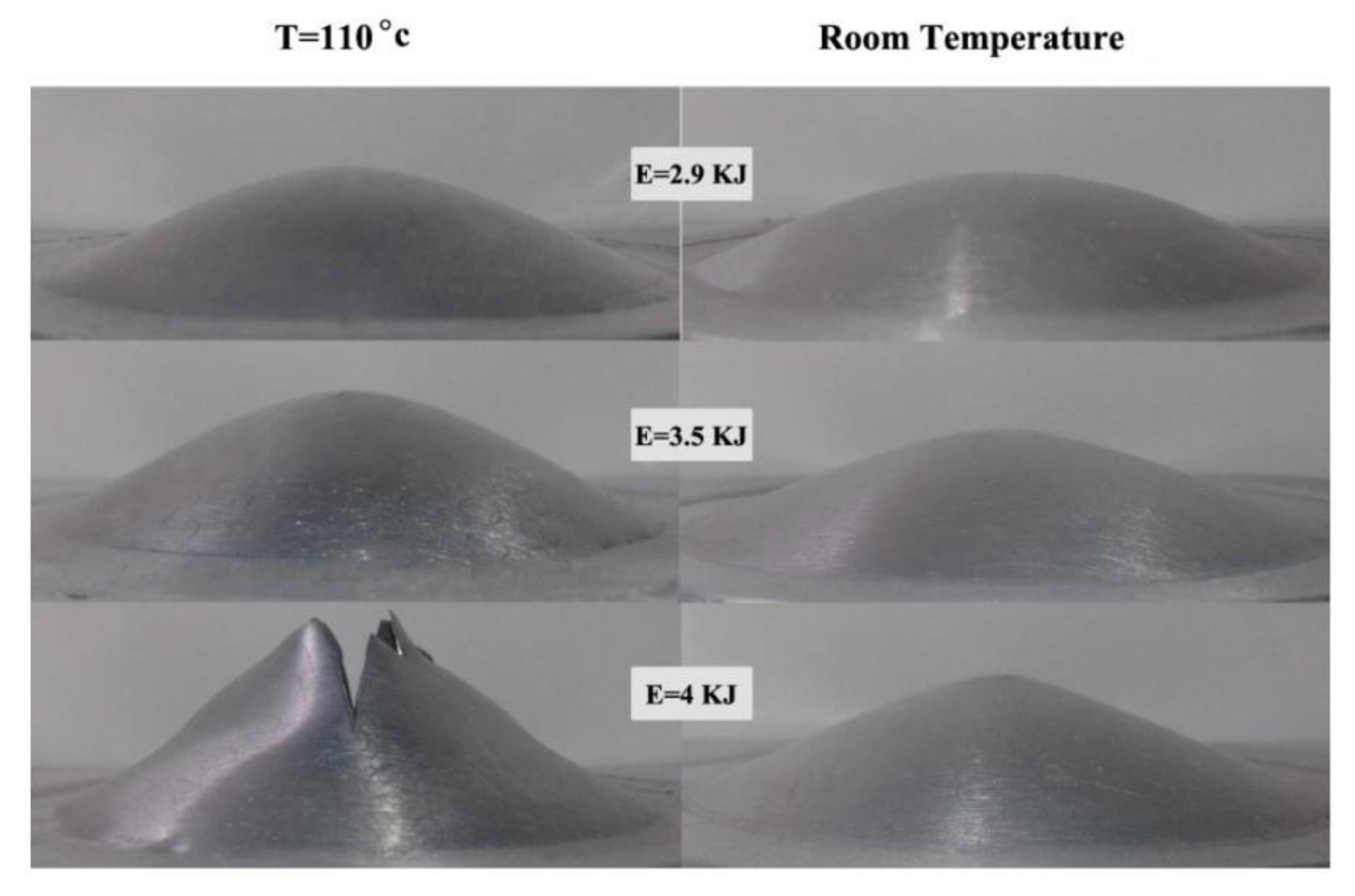

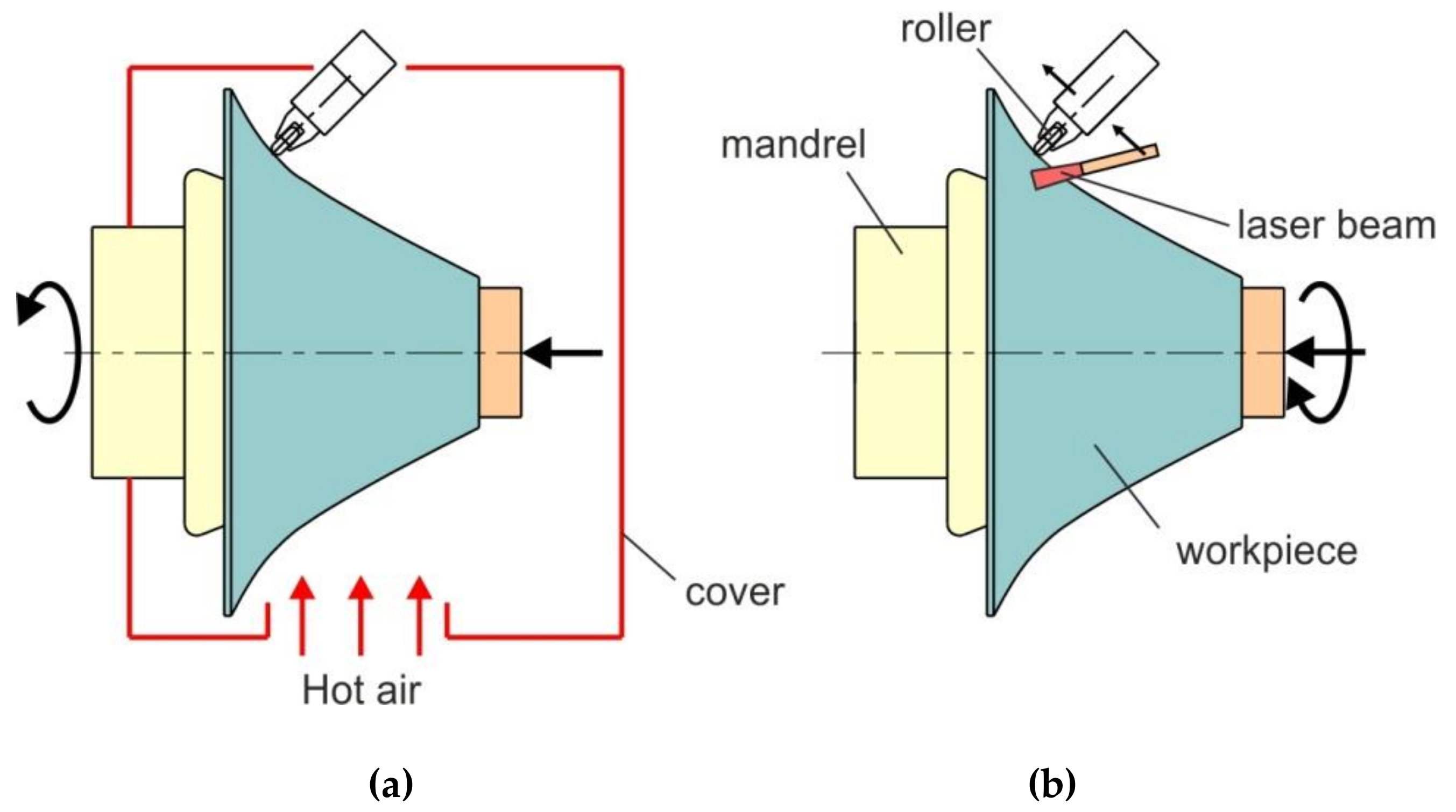

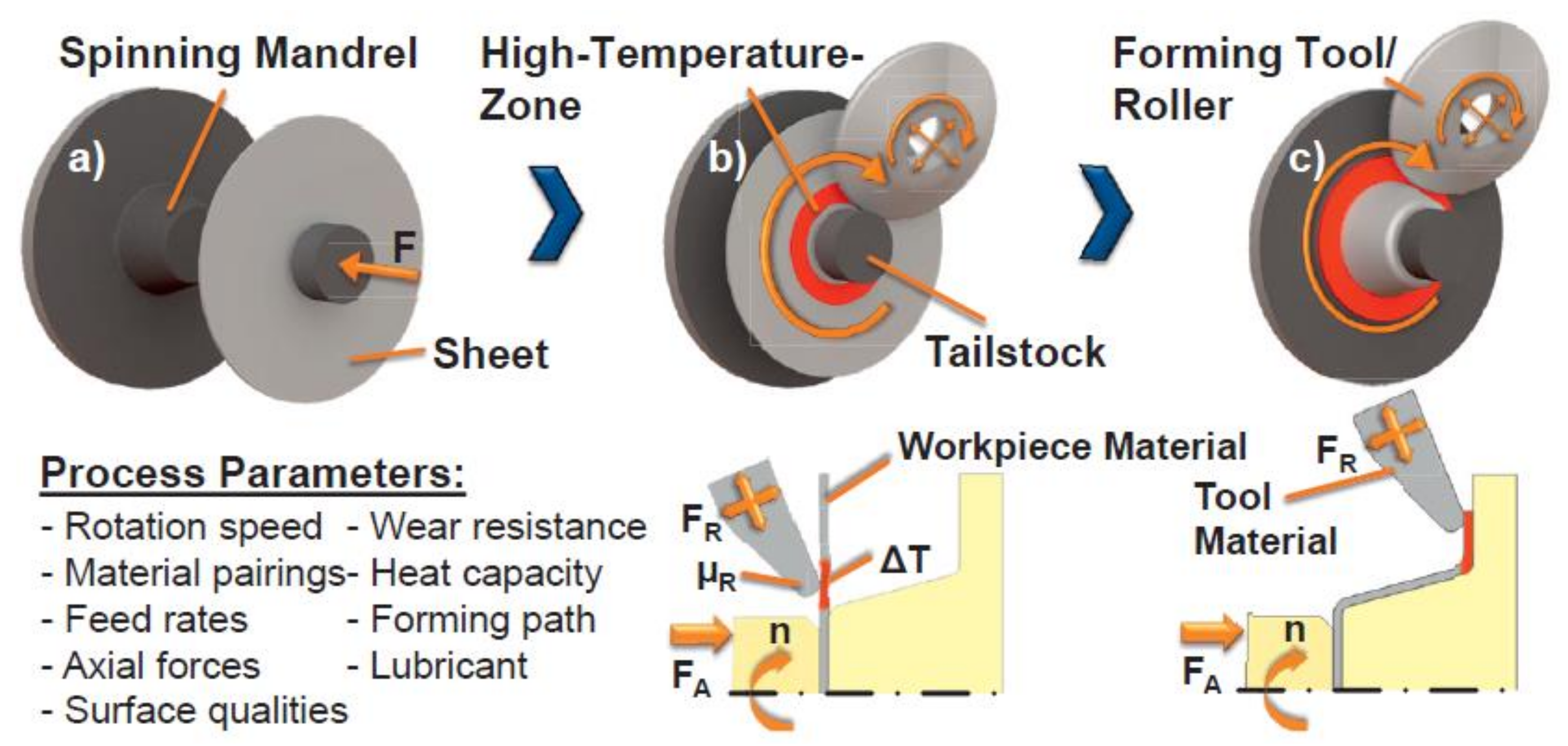

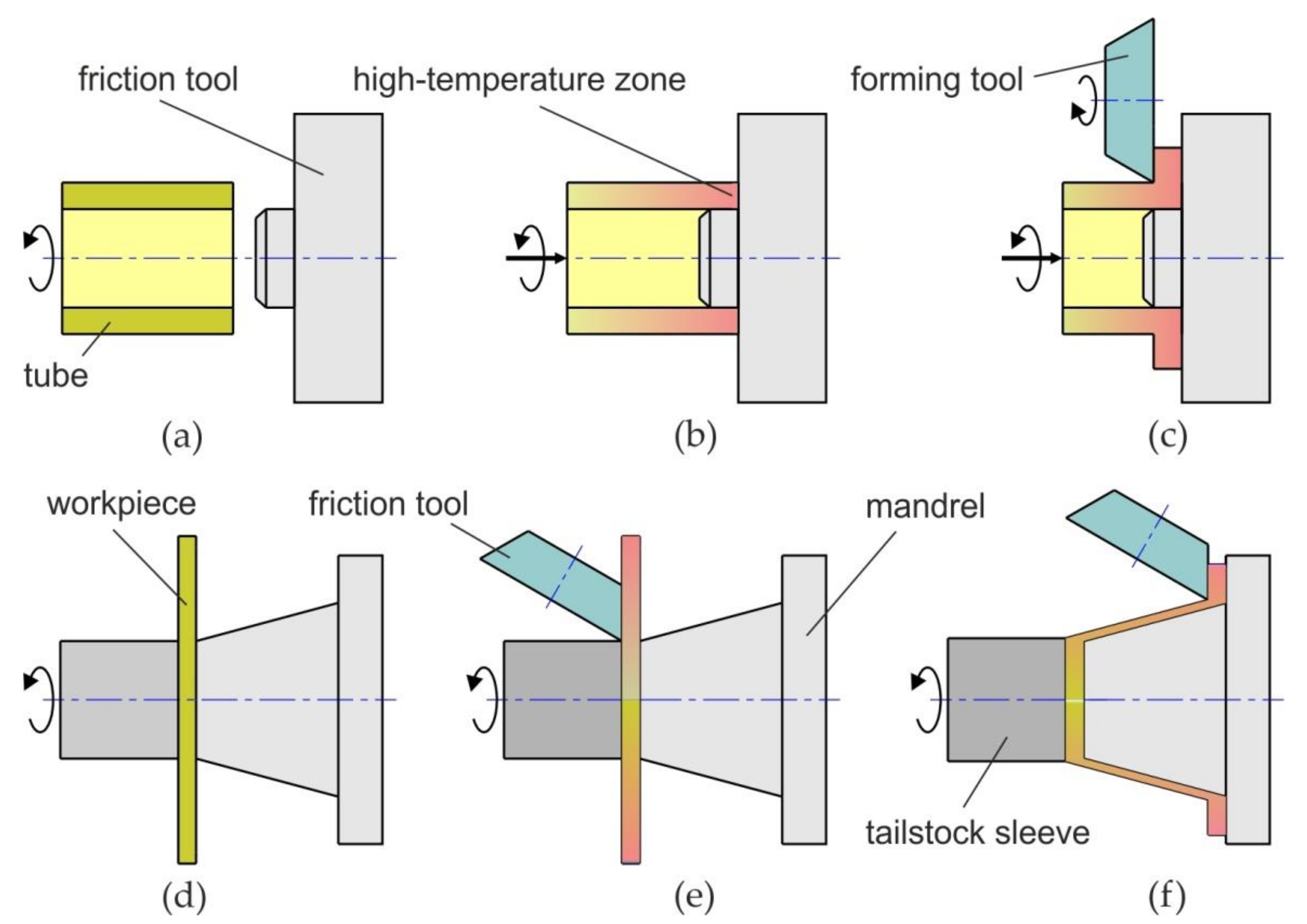

8.4. Heat-Assisted Spinning

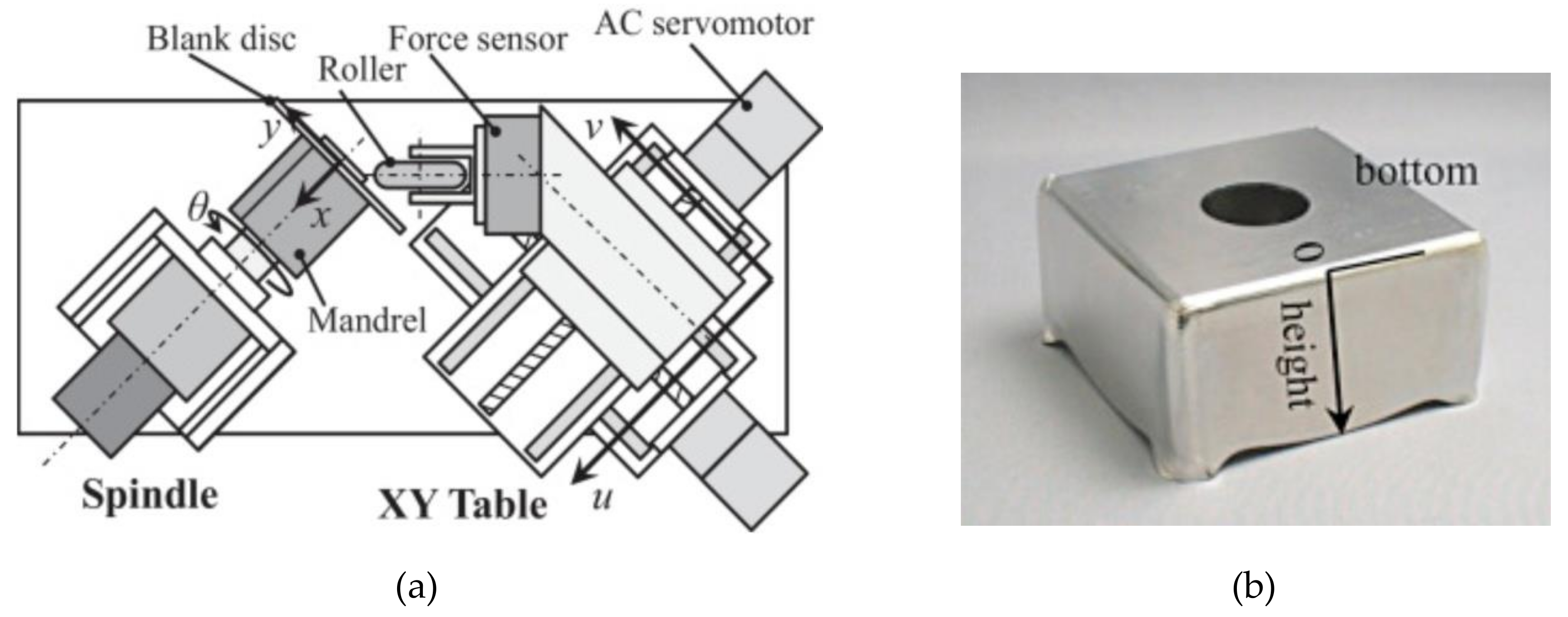

8.5. Shear Spinning and Flow Forming

9. Conclusions

- Friction and lubrication are key factors in sheet metal forming which decide product quality and productivity as well as the environmental performance of manufacturing. The main problems observed in SMF concern processes carried out at elevated temperatures where high levels of friction and wear occur due to high adhesion between the tool surface and the workpiece and surface fatigue is then initiated. National and international regulations have meant that the use of environmentally friendly lubricants has become increasing important. At the same time friction conditions have to be minimized in order to reduce loads. An example of environmentally friendly technology is hydroforming, which eliminates metallic contact of the forming tool with the workpiece. Thus, friction forces and tool wear are eliminated. In evaluating the ecological convenience of SMF processes the tribological aspects will receive great attention in the near future.

- In new vehicle development, weight reduction is one of the most important driving forces. The main trend involved in producing lightweight automotive structures with low cost manufacturing and reduced vehicle weight is the use of advanced high-strength steels and aluminum alloys with very high strength and good formability. However, some manufacturing problems related to residual stresses and springback must be overcome. Nonconventional forming techniques (i.e., electromagnetic or electrohydraulic forming, solid granular medium forming) with high deformation rates cover these requirements. Hot forming utilizing the advantageous effect of higher temperatures on the improvement of formability should be also mentioned. The advantage of hydroforming is that it shapes the product in one operation, which speeds up the production cycle and eliminates the need for interoperational storage.

- The utilization of conventional forming is more time-consuming and costly for processes recently applied in the production of parts in small batch production. Consequently, there is a need to disseminate an alternative process to reduce the manufacturing costs and time while forming individual parts, like medical implants. Processes which show benefits in this respect are methods of incremental sheet forming which do not require the manufacture of dies for operation and have the ability to shape elements on a conventional CNC milling machine. The problems related to material springback may be effectively reduced by rapid change of the forming strategy and tool path.

- The increasing complexity of components formed by SMF techniques as well as the continuous extension of the process window have made it necessary to develop new methods to efficiently analyze the forming strategies. Current numerical analysis software offers the capability of designing the tooling and process parameters in a virtual environment. Application of general purpose FEM, DEM, ALE and CFD codes may be regarded as one of the possible routes in the simulation of sheet metal forming. The use of simulation programs requires a thorough knowledge of continuum mechanics and FE programming to develop a suitable numerical analysis for a forming process. In the future, most experimental and numerical research work must be focused on the development of a macroscopic constitutive model based on a physical mechanism, grain-twinning interactions and a crystal plasticity model considering the grain–grain interaction and new constitutive models to establish the material behavior of new multifunctional materials.

- The goal of the designers of modern machines and instrumentation for SMF is to ensure that the product can be manufactured in one work cycle and on one machine. The development of machine tool design for plastic working is focused on improving the quality of the product and increasing productivity while maintaining the economic aspects of the manufacturing process. Progress in the implementation of automatic control systems and product manipulation during and after machining is clearly visible in the area of plastic forming processes. Despite the constant tendency to reduce the size of the production series related to the short-term launching of new series of vehicles, it should be hoped that the demand of the automotive and aviation industries for innovative technologies will translate into a greater interest in metal forming technologies. In this manufacturing area, all the considerations given in the previous section should be analyzed taking into account the sustainable break-even point. The development of innovative SMF processes will depend upon the improvement of materials and require adaptive control systems and integrated design of the forming process equipment and tooling.

Funding

Conflicts of Interest

References

- Hagenah, H.; Schulte, R.; Vogel, M.; Hermann, J.; Scharrer, H.; Lechner, M.; Merklein, M. 4.0 in metal forming - questions and challenges. Procedia CIRP 2019, 79, 649–654. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Lukaszek-Solek, A.; Luksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent development trends in metal forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Han, S.S. The influence of tool geometry on friction behavior in sheet metal forming. J. Mater. Process. Technol. 1997, 63, 129–133. [Google Scholar] [CrossRef]

- Wang, P.Y.; Wang, Z.J.; Xiang, N.; Li, Z.X. Investigation on changing loading path in sheet metal forming by applying a property-adjustable flexible-die. J. Manuf. Process. 2020, 53, 364–375. [Google Scholar] [CrossRef]

- Shisode, M.P.; Hazrati, J.; Mishra, T.; de Rooij, M.; van den Boogaard, T. Modeling mixed lubrication friction for sheet metal forming applications. Procedia Manuf. 2020, 47, 586–590. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M. Verification of models implemented in the simulation software. Mater. Sci. Forum 2020, 994, 223–231. [Google Scholar] [CrossRef]

- Löfgren, H.B. A first order friction model for lubricated sheet metal forming. Theor. Appl. Mech. Lett. 2018, 8, 57–61. [Google Scholar] [CrossRef]

- Figueiredo, L.; Ramalho, A.; Oliveira, M.C.; Menezes, L.F. Experimental study of friction in sheet metal forming. Wear 2011, 271, 1651–1657. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, Y.; Wang, Z.; Hua, M.; Wei, X. A study on variable friction model in sheet metal forming with advanced high strength steels. Tribol. Int. 2016, 93, 17–28. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, R.; Chen, S.; Wang, W.; Wei, X. Effect of upper-die temperature on the formability of AZ31B magnesium alloy sheet in stamping. J. Mater. Process. Technol. 2018, 257, 180–190. [Google Scholar] [CrossRef]

- Kowalik, M.; Trzepiecinski, T. Examination of the influence of pressing parameters on strength and geometry of joint between aluminum plate and sheet metal. Arch. Civ. Mech. Eng. 2012, 12, 292–298. [Google Scholar] [CrossRef]

- Seshacharyulu, K.; Bandhavi, C.; Naik, B.B.; Rao, S.S.; Singh, S.K. Understanding friction in sheet metal forming-A review. Mater. Today Proc. 2018, 5, 18238–18244. [Google Scholar] [CrossRef]

- Jaworski, J.; Trzepieciński, T. Research on durability of turning tools made of low-alloy high-speed steels. Kov. Mater.-Met. Mater. 2016, 54, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Kirkhorn, L.; Bushlya, V.; Andersson, M.; Ståhl, J.E. The influence of tool steel microstructure on friction in sheet metal forming. Wear 2013, 302, 1268–1278. [Google Scholar] [CrossRef]

- Sulaiman, M.H.; Farahana, R.N.; Bienk, K.; Nielsen, C.V.; Bay, N. Effects of DLC/TiAlN-coated die on friction and wear in sheet-metal forming under dry and oil-lubricated conditions: Experimental and numerical studies. Wear, 2019; 438–439, 203040. [Google Scholar]

- Wang, C.; Ma, R.; Zhao, J.; Zhao, J. Calculation method and experimental study of coulomb friction coefficient in sheet metal forming. J. Manuf. Process. 2017, 27, 126–137. [Google Scholar] [CrossRef]

- Flegler, F.; Neuhäuser, S.; Groche, P. Influence of sheet metal texture on the adhesive wear and friction behaviour of EN AW-5083 aluminum under dry and starved lubrication. Tribol. Int. 2020, 141, 105956. [Google Scholar] [CrossRef]

- Makhkamov, A.; Wagre, D.; Baptista, A.M.; Santos, A.D.; Malheiro, L. Tribology testing to friction determination in sheet metal forming processes. Ciência Tecnol. dos Mater. 2017, 29, e249–e253. [Google Scholar] [CrossRef]

- Sigvant, M.; Pilthammar, J.; Hol, J.; Wiebenga, J.H.; Chezan, T.; Cerleer, B.; van den Boogard, T. Friction in sheet metal forming: Influence of surface roughness and strain rate on sheet metal forming simulaion results. Procedia Manuf. 2019, 29, 512–519. [Google Scholar] [CrossRef]

- Ma, N.; Sugitomo, N. Development and application of non-linear friction models for metal forming simulation. AIP Conf. Proc. 2011, 1383, 382–389. [Google Scholar]

- Ma, N.; Sugimoto, N. Nonlinear friction model for servo press simulation. AIP Conf. Proc. 2013, 1567, 918. [Google Scholar]

- Trzepiecinski, T.; Lemu, H.G. Recent developments and trends in the friction testing for conventional sheet metal forming and incremental sheet forming. Metals 2020, 10, 47. [Google Scholar] [CrossRef] [Green Version]

- Yuan, B.; Wang, Z. A multi-deformable bodies solution method coupling finite element with meshless method in sheet metal flexible-die forming. Procedia Eng. 2017, 207, 1641–1646. [Google Scholar] [CrossRef]

- Jamli, M.R.; Farid, N.M. The sustainability of neural network applications within finite element analysis in sheet metal forming: A review. Measurement 2019, 138, 446–460. [Google Scholar] [CrossRef]

- Ma, N.; Zhu, T.; Ogawa, R.; Liu, Y.; Harada, Y. Development of 3D Thick Shell and its Application to Sheet Metal Forming Simulation. In Proceedings of the 10th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes Numisheet, Bristol, UK, 4–9 September 2016; pp. 5–6. [Google Scholar]

- Topčagić, Z.; Križaj, D.; Bulić, E. Application of a current sheet in BEM analysis for numerical calculation of torque in the magnetostatic field. IEEE Trans. Magn. 2020, 56, 1–9. [Google Scholar] [CrossRef]

- Siddiqui, M.A.; Correia, J.P.M.; Ahzi, S.; Belouettar, S. A numerical model to simulate electromagnetic sheet metal forming process. Int. J. Mater. Form. 2008, 1, 1387–1390. [Google Scholar] [CrossRef]

- Kumar, R.U. Role of CFD in sheet metal forming. Int. J. Tech. Innov. Mod. Eng. Sci. 2018, 4, 458–462. [Google Scholar]

- Zakaria, A.; Ibrahim, M.S.N.; Dezfouli, M.M.S. CFD evaluation of hot stamping die cooling system. Int. J. Eng. Technol. 2018, 7, 68–71. [Google Scholar] [CrossRef] [Green Version]

- Saad, M.; Akhtar, S.; Srivastava, M.; Chaurasia, J. Role of simulation in metal forming processes. Mater. Today Proc. 2018, 5, 19576–19585. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, Y.; Chen, K.; Yu, Y.; He, G.; Wu, P. Multi-scale crystal plasticity finite element method (CPFEM) simulations for shear band development in aluminum alloys. J. Alloy. Compd. 2017, 711, 495–505. [Google Scholar] [CrossRef]

- Mellbin, Y.; Hallberg, H.; Ristinmaa, M. A combined plasticity and graph-based vertex model of dynamic recrystallization at large deformations. Model. Simul. Mater. Sci. Eng. 2015, 23, 045011. [Google Scholar] [CrossRef]

- da Silva, G.S.; Kosteski, L.E.; Iturrioz, I. Analysis of the failure process by using the Lattice Discrete Element Method in the Abaqus environment. Theoret. Appl. Fract. Mech. 2020, 107, 102563. [Google Scholar] [CrossRef]

- Tallinen, T.; Åström, J.A.; Timonen, J. Discrete element simulations of crumpling of thin sheets. Comput. Phys. Commun. 2009, 180, 512–516. [Google Scholar] [CrossRef]

- Xue, F.; Li, F.; Li, J.; He, M.; Yuan, Z.; Wang, R. Numerical modeling crack propagation of sheet metal forming based on stress state parameters using XFEM method. Comput. Mater. Sci. 2013, 69, 311–326. [Google Scholar] [CrossRef]

- Gasiorek, D.; Baranowski, P.; Malachowski, J.; Mazurkiewicz, L.; Wiercigroch, M. Modelling of guillotine cutting of multi-layered aluminum sheets. J. Manuf. Process. 2018, 34, 374–388. [Google Scholar] [CrossRef]

- Crutzen, Y.; Boman, R.; Papeleux, L.; Ponthot, J.P. Lagrangian and arbitrary Lagrangian Eulerian simulations of complex roll-forming processes. Comptes Rendus Mécanique 2016, 344, 251–266. [Google Scholar] [CrossRef]

- Łach, Ł.; Nowak, J.; Svyetlichnyy, D. The evolution of the microstructure in AISI 304L stainless steel during the flat rolling – modeling by frontal cellular automata and verification. J. Mater. Process. Technol. 2018, 255, 488–499. [Google Scholar] [CrossRef]

- Yang, H.; Wu, C.; Li, H.; Fan, X.G. Review on cellular automata simulations of microstructure evolution during metal forming process: Grain coarsening, recrystallization and phase transformation. Sci. China Technol. Sci. 2011, 54, 2107–2118. [Google Scholar] [CrossRef]

- Kochmann, J.; Wulfinghoff, S.; Reese, S.; Mianroodi, J.R.; Svendsen, B. Two-scale FE–FFT- and phase-field-based computational modeling of bulk microstructural evolution and macroscopic material behavior. Comput. Methods Appl. Mech. Eng. 2016, 305, 89–110. [Google Scholar] [CrossRef]

- Hongyu, W.; Fei, T.; Zhen, W.; Pengchao, Z.; Juncai, S.; Shijun, J. Simulation research about rubber pad forming of corner channel with convex or concave mould. J. Manuf. Process. 2019, 40, 94–104. [Google Scholar] [CrossRef]

- Li, T.; Garg, R.; Galvin, J.; Pannala, S. Open-source MFIX-DEM software for gas-solids flows: Part II-Validation studies. Powder Technol. 2012, 220, 138–150. [Google Scholar] [CrossRef]

- Neuwirth, J.; Antonyuk, S.; Heinrich, S.; Jacob, M. CFD-DEM study and direct measurement of the granular flow in a rotor granulator. Chem. Eng. Sci. 2013, 86, 151–163. [Google Scholar] [CrossRef]

- Martínez-Valle, Á.; Martínez-Jiménez, J.M.; Goes, P.; Faes, K.; De Waele, W. Multiphysics fully-coupled modelling of the electromagnetic compression of steel tubes. Adv. Mater. Res. 2011, 214, 31–39. [Google Scholar] [CrossRef]

- Liu, X.; Sun, W.K.; Liew, K.M. Multiscale modeling of crystal plastic deformation of polycrystalline titanium at high temperatures. Comput. Methods Appl. Mech. Eng. 2018, 340, 932–955. [Google Scholar] [CrossRef]

- Tolipov, A.A.; Elghawail, A.; Shushing, S.; Pham, D.; Essa, K. Experimental research and numerical optimisation of multi-point sheet metal forming implementation using a solid elastic cushion system. IOP Conf. Ser. J. Phys. 2017, 896, 012120. [Google Scholar] [CrossRef] [Green Version]

- Ablat, M.A.; Quattawi, A. Numerical simulation of sheet metal forming: A review. Int. J. Adv. Manuf. Technol. 2017, 89, 1235–1250. [Google Scholar] [CrossRef]

- Makinouchi, A.; Teodosiu, C.; Nakagawa, T. Advance in FEM simulation and its related technologies in sheet metal forming. CIRP Ann. -Manuf. Technol. 1998, 47, 641–649. [Google Scholar] [CrossRef]

- Reis, F.J.P.; Pires, F.M.A. An adaptive sub-incremental strategy for the solution of homogenization-based multi-scale problems. Comput. Methods Appl. Mech. Eng. 2013, 257, 164–182. [Google Scholar] [CrossRef]

- Coenen, E.W.C.; Kouznetsova, V.G.; Bosco, E.; Geers, M.G.D. A multi-scale approach to bridge microscale damage and macroscale failure: A nested computational homogenization-localization Framework. Int. J. Fract. 2012, 178, 157–178. [Google Scholar] [CrossRef]

- Dong, G.J.; Bi, J.; Du, B.; Zhao, C.C. Research on AA6061 tubular components prepared by combined technology of heat treatment and internal high pressure forming. J. Mater. Process. Technol. 2017, 242, 126–138. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Lemu, H.G. Effect of computational parameters on springback prediction by numerical simulation. Metals 2017, 7, 380. [Google Scholar] [CrossRef] [Green Version]

- Madej, L. Digital/virtual microstructures in application to metals engineering—A review. Arch. Civ. Mech. Eng. 2017, 17, 839–854. [Google Scholar] [CrossRef]

- Perzyński, K.; Wrożyna, A.; Kuziak, R.; Legwand, A.; Madej, L. Development and validation of multi scale failure model for dual phase steel. Finite Elem. Anal. Des. 2017, 124, 7–21. [Google Scholar] [CrossRef]

- Han, F.; Roters, F.; Raabe, D. Microstructure-based multiscale modeling of large strain plastic deformation by coupling a full-field crystal plasticity-spectral solver with an implicit finite element solver. Int. J. Plast. 2020, 125, 97–117. [Google Scholar] [CrossRef]

- Gerasimov, D.; Gartvig, A. Parallel computing of metal forming simulation in QForm software. Comput. Methods Mater. Sci. 2016, 16, 139–142. [Google Scholar]

- Alfaro, I.; Yvonnet, J.; Cueto, E.; Chinesta, F.; Doblare, M. Meshless methods with application to metal forming. Comput. Methods Appl. Mech. Eng. 2006, 195, 6661–6675. [Google Scholar] [CrossRef] [Green Version]

- Liewald, M.; Riedmüller, K.R. A new one-phase material model for the numerical prediction of critical material flow conditions in thixoforging processes. CIRP Ann. 2019, 68, 293–296. [Google Scholar] [CrossRef]

- Van Houtte, P.; Gawad, J.; Eyckens, P.; Van Bael, B.; Samaey, G.; Roose, D. Multi-scale modelling of the development of heterogeneous distributions of stress, strain, deformation texture and anisotropy in sheet metal forming. Procedia IUTAM 2012, 3, 67–75. [Google Scholar] [CrossRef]

- Barik, S.K.; Narayanan, R.G.; Sahoo, N. Forming response of AA5052–H32 sheet deformed using a shock tube. Trans. Nonferrous Met. Soc. China 2020, 30, 603–618. [Google Scholar] [CrossRef]

- Raju, C.; Haloi, N.; Narayanan, C.S. Strain distribution and failure mode in single point incremental forming (SPIF) of multiple commercially pure aluminum sheets. J. Manuf. Process. 2017, 30, 328–335. [Google Scholar] [CrossRef]

- Nakata, T.; Xu, C.; Ohashi, H.; Yoshida, Y.; Yoshida, K.; Kamado, S. New Mg–Al based alloy sheet with good room-temperature stretch formability and tensile properties. Scr. Mater. 2020, 180, 16–22. [Google Scholar] [CrossRef]

- Badrish, A.; Morchhale, A.; Kotkunde, N.; Singh, S.K. Influence of material modeling on warm forming behavior of nickel based super alloy. Int. J. Mater. Form. 2020. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Zhan, M. A review on the modeling and simulations of solid-state diffusional phase transformations in metals and alloys. Manuf. Rev. 2018, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Martínez, J.A.; Rusinek, A.; Pesci, R.; Zaera, R. Experimental and numerical analysis of the martensitic transformation in AISI 304 steel sheets subjected to perforation by conical and hemispherical projectiles. Int. J. Solids Struct. 2013, 50, 339–351. [Google Scholar] [CrossRef] [Green Version]

- Neto, D.M.; Oliveira, M.C.; Santos, A.D.; Alves, J.L.; Menezes, L.F. Influence of boundary conditions on the prediction of springback and wrinkling in sheet metal forming. Int. J. Mech. Sci. 2017, 122, 244–254. [Google Scholar] [CrossRef] [Green Version]

- Han, F.; Mo, J.H.; Qi, H.W.; Long, R.F.; Cui, X.H.; Li, Z.W. Springback prediction for incremental sheet forming based on FEM-PSONN technology. Trans. Nonferrous Met. Soc. China 2013, 23, 1061–1071. [Google Scholar] [CrossRef]

- Basak, S.; Panda, S.K.; Lee, M.G. Formability and fracture in deep drawing sheet metals: Extended studies for pre-strained anisotropic thin sheets. Int. J. Mech. Sci. 2020, 170, 105346. [Google Scholar] [CrossRef]

- Bansal, A.; Lingam, R.; Yadav, S.K.; Reddy, N.V. Prediction of forming forces in single point incremental forming. J. Manuf. Process. 2017, 28, 486–493. [Google Scholar] [CrossRef]

- Abdelkader, W.B.; Bahloul, R.; Arfa, H. Numerical investigation of the influence of some parameters in SPIF process on the forming forces and thickness distributions of a bimetallic sheet CP-titanium/low-carbon steel compared to an individual layer. Procedia Manuf. 2020, 47, 1319–1327. [Google Scholar] [CrossRef]

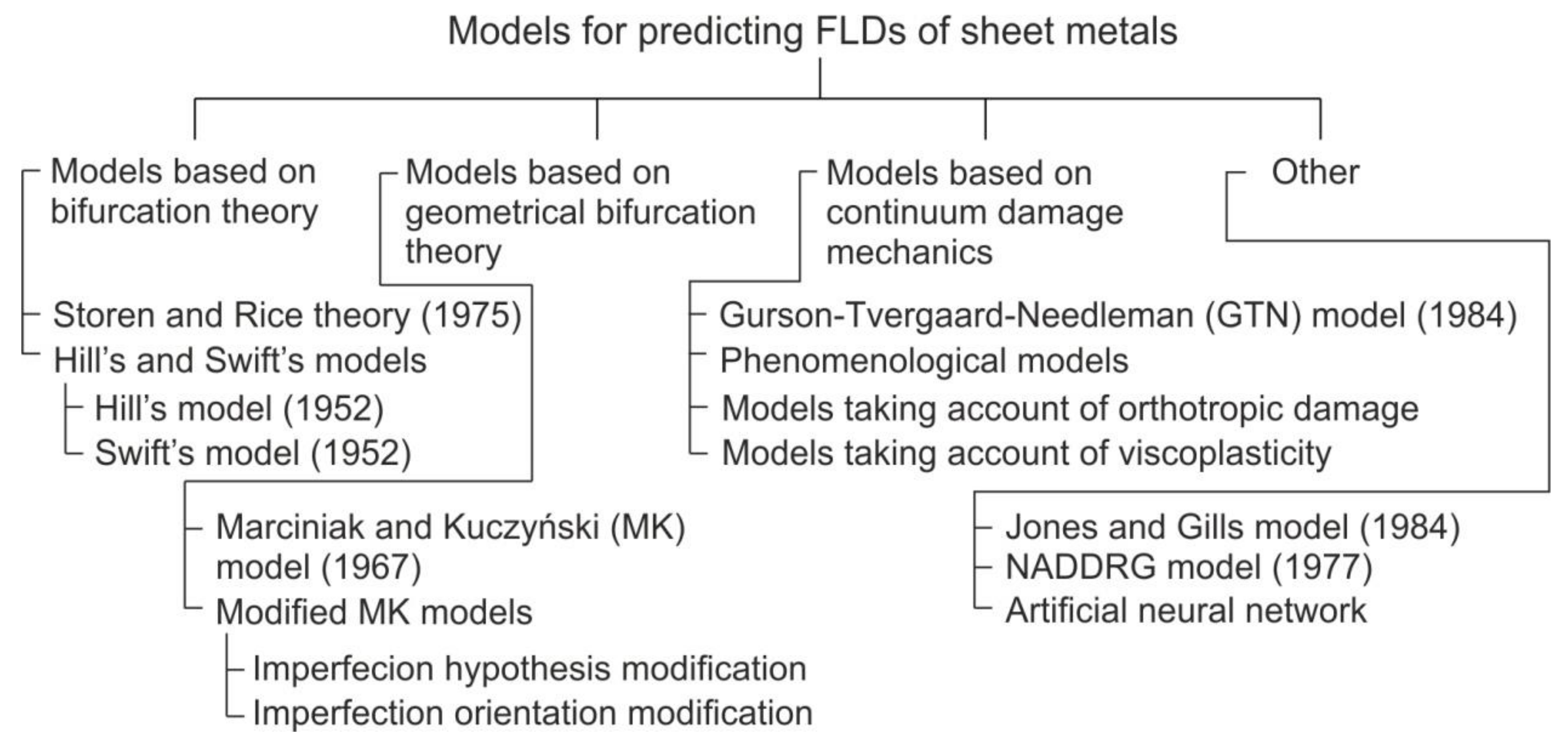

- Hu, Q.; Zhang, F.; Li, X.; Chen, J. Overview on the prediction models for sheet metal forming failure: Necking and ductile fracture. Acta Mech. Solida Sin. 2018, 31, 259–289. [Google Scholar] [CrossRef]

- Amaral, R.; Santos, A.D.; de Sá José, C.; Miranda, S. Formability prediction for AHSS materials using damage models. J. Phys. Conf. Ser. 2017, 843, 012018. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Fernandes, J.V. Modelling and simulation of sheet metal forming processes. Metals 2019, 9, 1356. [Google Scholar] [CrossRef] [Green Version]

- Madej, L.; Ambrozinski, M.; Kwiecien, M.; Gronostajski, Z.; Pietrzyk, M. Digital material representation concept applied to investigation of local inhomogeneities during manufacturing of magnesium components for automotive applications. Int. J. Mater. Res. 2017, 108, 3–11. [Google Scholar] [CrossRef]

- Ma, N.; Takada, K.; Sato, K. Measurement of local strain path and identification of ductile damage limit based on simple tensile test. Procedia Eng. 2014, 81, 1402–1407. [Google Scholar] [CrossRef] [Green Version]

- Takuda, H.; Hama, T.; Nishida, K.; Yoshida, T.; Nitta, J. Prediction of forming limit in stretch flanging by finite element simulation combined with ductile fracture criterion. Comp. Meth. Mater. Sci. 2009, 9, 137–142. [Google Scholar]

- Ma, N.; Sato, K.; Takada, K. Analysis of local fracture strain and damage limit of advanced high strength steels using measured displacement fields and FEM. Comput. Mater. Contin. 2015, 46, 195–219. [Google Scholar]

- Siswanto, W.A.; Anggono, A.D.; Omar, B.; Jusoff, K. An alternate method to springback compensation for sheet metal forming. Sci. World. J. 2014, 2014, 301271. [Google Scholar] [CrossRef] [PubMed]

- Fekete, J.R.; Hall, J.N.; Meuleman, D.J.; Rupp, M. Progress in implementation of advanced high-strength steels into vehicle structures. Iron Steel Technol. 2008, 5, 55–64. [Google Scholar]

- Lingbeek, R.A.; Huetink, H.; Ohnimus, S.; Weiher, J. Iterative Springback Compensation of NUMISHEET Benchmark #1. In Proceedings of the 6th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, NUMISHEET 2005, Detroit, MI, USA, 15–19 August 2005; pp. 1–6. [Google Scholar]

- Ren, H.; Xie, J.; Liao, S.; Leem, D.; Cao, J. In-situ springback compensation in incremental sheet forming. CIRP Ann. 2019, 68, 317–320. [Google Scholar] [CrossRef]

- Li, Y.; Liang, Z.; Zhang, Z.; Zou, T.; Shi, L. An analytical model for rapid prediction and compensation of springback for chain-die forming of an AHSS U-channel. Int. J. Mech. Sci. 2019, 159, 195–212. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex—Shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Alghtani, A.; Brooks, P.C.; Barton, D.C.; Toropov, V.V. Springback Analysis and Optimization in Sheet Metal Forming. In Proceedings of the 9th European LS-DYNA Conference, Menchester, UK, 3–4 June 2013; pp. 1–11. [Google Scholar]

- Ma, N.; Sugitomo, N. Dynamic explicit FEM and simulation on sheet metal forming. J. Jpn. Soc. Technol. Plast. 2006, 47, 29–34. [Google Scholar] [CrossRef]

- Kato, Y.; Umezu, Y.; Watanabe, Y. Recent Developments in JSTAMP/NV for the Best Stamping Simulation Environment. In Proceedings of the 11th International LS-DYNA Users Conference, Dearborn, MI, USA, 6–8 June 2010. [Google Scholar]

- Shindo, T.; Sugimoto, N.; Ma, N. Springback simulation and compensation for high strength parts using JSTAMP. AIP Conf. Proc. 2011, 1383, 1086–1091. [Google Scholar]

- Ma, N.; Zhu, X. Computational stoning method for surface defect detection. AIP Conf. Proc. 2013, 1567, 728–731. [Google Scholar]

- Transparent Reporting of Systematic Reviews and Meta-Analyses. Available online: http://prisma-statement.org/ (accessed on 7 April 2020).

- Engel, U.; Eckstein, R. Microforming - from basic research to its realization. J. Mater. Process. Technol. 2002, 125, 35–44. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. A review on the state-of-the-art microforming technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 2411–2437. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Yang, H.P.; Fu, M.W.; Ng, C. Study on size effect affected progressive microforming of conical flanged parts directly using sheet metals. J. Mater. Process. Technol. 2019, 272, 72–86. [Google Scholar] [CrossRef]

- Furushima, T.; Tsunezaki, H.; Manabe, K.I.; Alexsandrov, S. Ductile fracture and free surface roughening behaviors of pure copper foils for micro/meso-scale forming. Int. J. Mach. Tools Manuf. 2014, 76, 34–48. [Google Scholar] [CrossRef]

- Mao, M.Y.; Peng, L.F.; Fu, M.W.; Lai, X.M. Co-effect of microstructure and surface constraints on plastic deformation in micro- and mesoscaled forming process. Int. J. Adv. Manuf. Technol. 2018, 98, 1861–1886. [Google Scholar] [CrossRef]

- Cheng, C.; Wan, M.; Meng, B.; Zhao, Z.; Han, W.P. Size effect on the yield behavior of metal foil under multiaxial stress states: Experimental investigation and modelling. Int. J. Mech. Sci. 2019, 151, 760–771. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Wang, X.; Cui, R.; Zhang, W. Modeling of surface layer and strain gradient hardening effects on micro-bending of non-oriented silicon steel sheet. Mater. Sci. Eng. A 2018, 711, 498–507. [Google Scholar] [CrossRef]

- Cheng, T.C.; Lee, R.S. The influence of grain size and strain rate effects on formability of aluminium alloy sheet at high-speed forming. J. Mater. Process. Technol. 2018, 253, 134–159. [Google Scholar] [CrossRef]

- Lin, B.T.; Huang, K.M.; Kuo, C.C.; Wang, W.T. Improvement of deep drawability by using punch surfaces with microridges. J. Mater. Process. Technol. 2015, 225, 275–285. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Jiang, Z.; Zhu, W.L.; Shan, D.; Guo, B.; Cao, J. Size effects on flow stress behavior during electrically-assisted micro-tension in a magnesium alloy AZ31. Mater. Sci. Eng. A 2016, 659, 215–224. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Peng, L.; Bao, E. Size effect affected springback in micro/meso scale bending process: Experiments and numerical modeling. J. Mater. Process. Technol. 2018, 252, 407–420. [Google Scholar] [CrossRef]

- Wang, J.L.; Fu, M.W.; Ran, J.Q. Analysis of the size effect on springback behavior in micro-scaled U-bending process of sheet metals. Adv. Eng. Mater. 2014, 16, 421–432. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. Geometry and grain size effects on the fracture behavior of sheet metal in micro-scale plastic deformation. Mater. Des. 2011, 32, 4738–4746. [Google Scholar] [CrossRef]

- Ran, J.Q.; Fu, M.W.; Chan, W.L. The influence of size effect on the ductile fracture in micro-scaled plastic deformation. Int. J. Plast. 2013, 41, 65–81. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental and simulation based study on micro-scaled sheet metal deformation behavior in microembossing process. Mater. Sci. Eng. A 2012, 556, 60–67. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental studies of plastic deformation behaviors in microheading process. J. Mater. Process. Technol. 2012, 212, 1501–1512. [Google Scholar] [CrossRef]

- Rosochowski, A.; Presz, W.; Olejnik, L.; Richert, M. Micro-extrusion of ultra-fine grained aluminium. Int. J. Adv. Manuf. Technol. 2007, 33, 137–146. [Google Scholar] [CrossRef]

- Meng, B.; Fu, M.W.; Shi, S.Q. Deformation characteristic and geometrical size effect in continuous manufacturing of cylindrical and variable-thickness flanged microparts. J. Mater. Process. Technol. 2018, 252, 546–558. [Google Scholar] [CrossRef]

- Sato, H.; Manabe, K.I.; Wei, D.; Jiang, Z.; Alexandrov, S. Tribological behavior in micro–sheet hydroforming. Tribol. Int. 2016, 97, 302–312. [Google Scholar] [CrossRef] [Green Version]

- Mahabunphachai, S.; Cora, O.N.; Koç, M. Effect of manufacturing processes on formability and surface topography of protonexchange membrane fuel cell metallic bipolar plates. J. Power. Sources 2010, 195, 5269–5277. [Google Scholar] [CrossRef]

- Liu, Y.; Hua, L. Fabrication of metallic bipolar plate for protonexchange membrane fuel cells by rubber pad forming. J. Power Sources 2010, 195, 3529–3535. [Google Scholar] [CrossRef]

- Peng, L.; Hu, X.; Mei, D.; Ni, J. Investigation of micro/meso sheet soft punch stamping process – simulation and experiments. Mater. Des. 2009, 30, 783–790. [Google Scholar] [CrossRef]

- Lim, S.S.; Kim, Y.T.; Kang, C.G. Fabrication of aluminum 1050 micro-channel proton exchange membrane fuel cell bipolar plate using rubber-pad-forming process. Int. J. Adv. Manuf. Technol. 2013, 65, 231–238. [Google Scholar] [CrossRef]

- Elyasi, M.; Khatir, F.A.; Hosseinzadeh, M. Manufacturing metallic bipolar plate fuel cells through rubber pad forming process. Int. J. Adv. Manuf. Technol. 2017, 89, 3257–3269. [Google Scholar] [CrossRef]

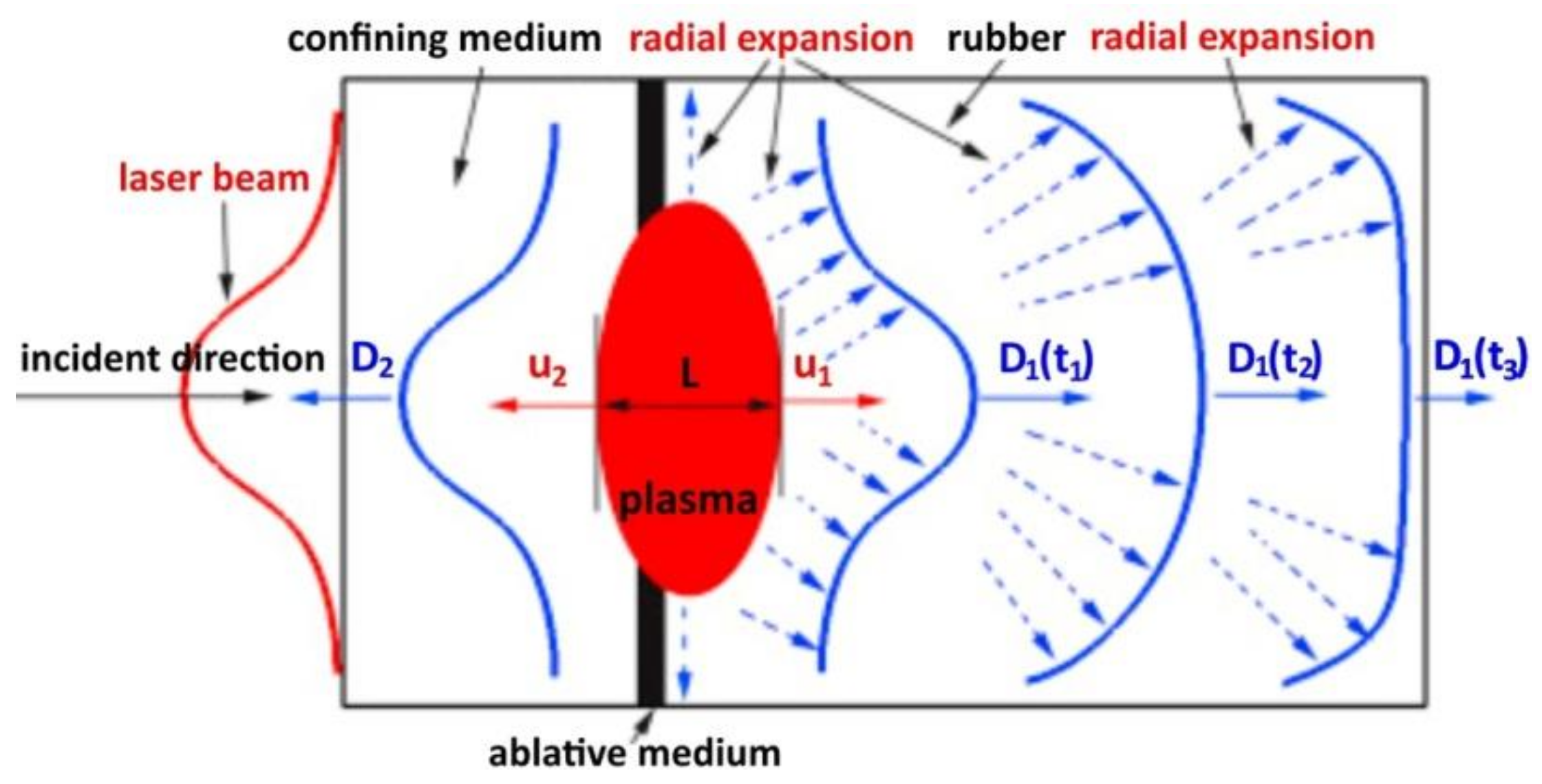

- Morales, M.; Porro, J.A.; García-Ballesteros, J.J.; Molpeceres, C.; Ocaña, J.L. Effect of plasma confinement on laser shock microforming of thin metal sheets. Appl. Surf. Sci. 2011, 257, 5408–5412. [Google Scholar] [CrossRef]

- Ocaña, J.L.; Morales, M.; García-Ballesteros, J.J.; Porro, J.A.; García, O.; Molpeceres, C. Laser shock microforming of thin metal sheets. Appl. Surf. Sci. 2009, 255, 5633–5636. [Google Scholar] [CrossRef]

- Shen, Z.; Gu, C.; Liu, H.; Wang, X. An experimental study of overlapping laser shock micro-adjustment using a pulsed Nd:YAG laser. Opt. Laser Technol. 2013, 54, 110–119. [Google Scholar] [CrossRef]

- Risch, D.; Beerwald, C.; Brosius, A.; Kleiner, M. On the significance of the die design for electromagnetic sheet metal forming. In Proceedings of the 1st International Conference on High Speed Forming, Dortmund, Germany, 31 March–1 April 2004; pp. 191–200. [Google Scholar]

- Shen, Z.; Wang, X.; Liu, H.; Wang, Y.; Wang, C. Rubber-induced uniform laser shock wave pressure for thin metal sheets microforming. Appl. Surf. Sci. 2015, 327, 307–312. [Google Scholar] [CrossRef]

- Kuhfuss, B.; Schattmann, C.; Jahn, M.; Schmidt, A.; Vollertsen, F.; Moumi, E.; Schenck, C.; Herrmann, M.; Ishkina, S.; Rathmann, L.; et al. Micro forming processes. In Cold Micro Metal Forming, 1st ed.; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.W., Eds.; Springer: Cham, Switzerland, 2020; pp. 27–94. [Google Scholar]

- Thomy, C.; Wilhelmi, P.; Onken, A.K.; Schenck, C.; Kuhfuss, B.; Tracht, K.; Rippel, D.; Lütjen, M.; Freitag, M. Process design. In Cold Micro Metal Forming, 1st ed.; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.W., Eds.; Springer: Cham, Switzerland, 2020; pp. 95–132. [Google Scholar]

- Vollertsen, F.; Seven, J.; Messaoudi, H.; Mikulewitsch, M.; Fischer, A.; Goch, G.; Mehrafsun, S.; Riemer, O.; Maaß, P.; Böhmermann, F.; et al. Tooling. In Cold Micro Metal Forming, 1st ed.; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.W., Eds.; Springer: Cham, Switzerland, 2020; pp. 133–251. [Google Scholar]

- Maaß, P.; Piotrowska-Kurczewski, I.; Agour, M.; von Freyberg, A.; Staar, B.; Falldorf, C.; Fischer, A.; Lütjen, M.; Freitag, M.; Goch, G.; et al. Quality control and characterization. In Cold Micro Metal Forming, 1st ed.; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.W., Eds.; Springer: Cham, Switzerland, 2020; pp. 253–310. [Google Scholar]

- Trzepieciński, T.; Pieja, T.; Malinowski, T.; Smusz, R.; Motyka, M. Investigation of 17-4PH steel microstructure and conditions of elevated temperature forming of turbine engine strut. J. Mater. Process. Technol. 2018, 252, 191–200. [Google Scholar] [CrossRef]

- Takuhiro, S.; Suzuki, N.; Takeuchi, O. Culinder forming by die-less shear spinning with sheet thickness controlling of its wall. Procedia Manuf. 2018, 15, 1232–1238. [Google Scholar] [CrossRef]

- Lade, J.; Banoth, B.N.; Gupta, A.K.; Singh, S.K. Metallurgical studies of austenitic stainless steel 304 under warm deep drawing. J. Iron Steel Res. Int. 2014, 21, 1147–1151. [Google Scholar] [CrossRef]

- Afshin, E.; Kadkhodayan, M. An experimental investigation into the warm deep-drawing process on laminated sheets under various grain sizes. Mater. Des. 2015, 87, 25–35. [Google Scholar] [CrossRef]

- Panicker, S.S.; Panda, S.K. Investigations into improvement in formability of AA5754 and AA6082 sheets at elevated temperatures. J. Mater. Eng. Perform. 2019, 28, 2967–2982. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, Y.; Yuan, S. Analysis of thickness variation of reverse deep drawing of preformed 5A06 aluminum alloy cup under different temperatures. Int. J. Adv. Manuf. Technol. 2016, 86, 521–529. [Google Scholar] [CrossRef]

- Liu, S.; Long, M.; Ai, S.; Zhao, Y.; Chen, D.; Feng, Y.; Duan, H.; Ma, M. Evolution of phase transition and mechanical properties of ultra-high strength hot-stamped steel during quenching process. Metals 2020, 10, 138. [Google Scholar] [CrossRef] [Green Version]

- Kayhan, E.; Kaftanoglu, B. Experimental investigation of non-isothermal deep drawing of DP600 steel. Int. J. Adv. Manuf. Technol. 2018, 99, 695–706. [Google Scholar] [CrossRef]

- Singh, K.; Mahesh, K.; Gupta, A.K. Prediction of mechanical properties of extra deep drawn steel in blue brittle region using artificial neural Network. Mater. Des. 2010, 31, 2288–2295. [Google Scholar] [CrossRef]

- Krishna, P.G.; Venugopal, L.; Prabhu, T.R. Experimental investigation of failures in redrawing of Ti-6Al-4V alloy at warm conditions. Mater. Today Proc. 2017, 4, 8478–8485. [Google Scholar] [CrossRef]

- Panicker, S.S.; Prasad, K.S.; Sawale, G.; Hazra, S.; Shollock, B.; Panda, S.K. Warm redrawing of AA6082 sheets and investigations into the effect of aging heat treatment on cup wall strength. Mater. Sci. Eng. A 2019, 768, 138445. [Google Scholar] [CrossRef]

- Hussaini, S.M.; Krishna, G.; Gupta, A.K.; Singh, S.K. Development of experimental and theoretical forming limit diagrams for warm forming of austenitic stainless steel 316. J. Manuf. Process. 2015, 18, 151–158. [Google Scholar] [CrossRef]

- Keum, Y.T.; Han, B.Y. Springback of FCC sheet in warm forming. J. Ceram. Process. Res. 2002, 3, 159–165. [Google Scholar]

- Chen, F.K.; Huang, T.B. Formability of stamping magnesium-alloy AZ31 sheets. J. Mater. Process. Technol. 2003, 142, 643–647. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Alves, J.L.; Chaparro, B.M.; Menezes, L.F. Study on the influence of work-hardening modeling in springback prediction. Int. J. Plast. 2007, 23, 516–543. [Google Scholar] [CrossRef] [Green Version]

- Billur, E. Warm Hydroforming Characteristics of Stainless Steel Sheet Metals. Master’s Thesis, Virginia University, Richmond, VA, USA, 2018. [Google Scholar]

- Laurent, H.; Coër, J.; Manach, P.Y.; Oliveira, M.C.; Menezes, L.F. Experimental and numerical studies on the warm deep drawing of an Al–Mg Allom. Int. J. Mech. Sci. 2015, 93, 59–72. [Google Scholar] [CrossRef]

- Harrison, N.R.; Friedman, P.A. Warm forming die design, Part II: Parting surface temperature response characterization of a novel thermal finite element modeling code. J. Manuf. Process. 2014, 16, 312–319. [Google Scholar] [CrossRef]

- Harrison, N.R.; Friedman, P.A.; Pan, J. Warm forming die design, Part III: Design and validation of a warm forming die. J. Manuf. Process. 2015, 20, 356–366. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Specialty Handbook: Heat-Resistant Materials; ASM International: Materials Park, OH, USA, 1997; pp. 3–66. [Google Scholar]

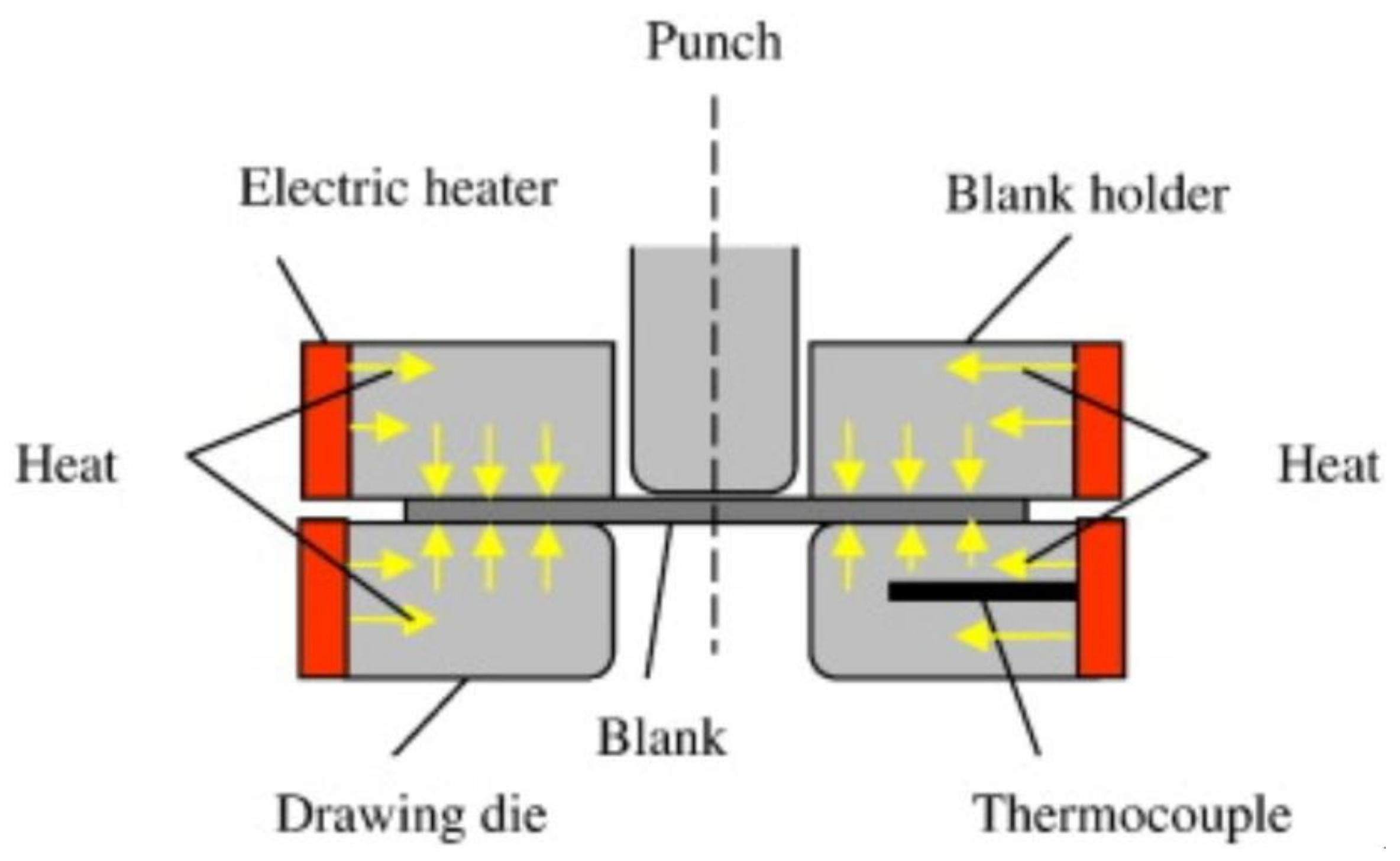

- Martins, J.M.P.; Alves, J.L.; Neto, D.M.; Oliveira, M.C.; Menezes, L.F. Numerical analysis of different heating systems for warm sheet metal forming. Int. J. Adv. Manuf. Technol. 2016, 83, 897–909. [Google Scholar] [CrossRef] [Green Version]

- Hasanuzzaman, M.; Rahim, N.A.; Hosenuzzaman, M.; Saidur, R.; Mahbubul, I.M.; Rashid, M.M. Energy savings in the combustion based process heating in industrial sector. Renew. Sustain. Energy Rev. 2012, 16, 4527–4536. [Google Scholar] [CrossRef]

- Harrison, N.R.; Ilinich, A.; Friedman, P.; Singh, J.; Verma, R. Optimization of high-volume warm forming for lightweight sheet. SAE Tech. Pap. 2013, 2013-01-1170. [Google Scholar] [CrossRef] [Green Version]

- Bong, H.J.; Barlat, F.; Ahn, D.C.; Kim, H.Y.; Lee, M.G. Formability of austenitic and ferritic stainless steels at warm forming temperature. Int. J. Mech. Sci. 2013, 75, 94–109. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Niechajowicz, A.; Kuziak, R.; Krawczyk, J.; Polak, S. The effect of the strain rate on the stress-strain curve and microstructure of AHSS. J. Mater. Process. Technol. 2017, 242, 246–259. [Google Scholar] [CrossRef]

- Wiewiórowska, S.; Muskalski, Z. The application of low and medium carbon steel with multiphase TRIP structure in drawing industry. Procedia Manuf. 2015, 2, 181–185. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Wan, M.; Liu, Z.; Wu, X.; Ma, B.; Cheng, C. Thermal-mechanical behaviors of dual-phase steel sheet under warm-forming conditions. Int. J. Mech. Sci. 2017, 126, 79–94. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.; Nagai, T. Improvement in formability by control of temperature in hot stamping of ultra-high strength steel parts. CIRP Ann. 2014, 63, 301–304. [Google Scholar] [CrossRef]

- Tokita, Y.; Nakagaito, T.; Tamai, Y.; Urabe, T. Stretch formability of high strength steel sheets in warm forming. J. Mater. Process. Technol. 2017, 246, 77–84. [Google Scholar] [CrossRef]

- Saito, N.; Fukahori, M.; Hisano, D.; Hamasaki, H.; Yoshida, F. Effects of temperature, forming speed and stress relaxation on springback in warm forming of high strength steel sheet. Procedia Eng. 2017, 207, 2394–2398. [Google Scholar] [CrossRef]

- Kumar, M.; Sotirov, N.; Chimani, C.M. Investigations on warm forming of AW-7020-T6 alloy sheet. J. Mater. Process. Technol. 2014, 214, 1769–1776. [Google Scholar] [CrossRef]

- Grimes, R.; Janik, V. Automotive applications for magnesium. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D.E., Kobayashi, T., Vaughan, N., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 3101–3123. [Google Scholar]

- Zhang, R.; Shao, Z.; Lin, J. A review on modelling techniques for formability prediction of sheet metal forming. Int. J. Light. Mater. Manuf. 2018, 1, 115–125. [Google Scholar] [CrossRef]

- Martins, J.M.P.; Neto, D.M.; Alves, J.L.; Oliveira, M.C.; Laurent, H.; Andrade-Campos, A.; Menezes, L.F. A new staggered algorithm for thermomechanical coupled problems. Int. J. Solids Struct. 2017, 122–123, 42–58. [Google Scholar] [CrossRef]

- Harrison, N.R.; Rubek, V.; Friedman, P.A. Warm forming die design, part I: Experimental validation of a novel thermal finite element modeling code. J. Manuf. Process. 2013, 15, 263–272. [Google Scholar] [CrossRef]

- Abovyan, T.; Kridli, G.T.; Friedman, P.A.; Ayoub, G. Formability prediction of aluminum sheet alloys under isothermal forming conditions. J. Manuf. Process. 2015, 20, 406–413. [Google Scholar] [CrossRef]

- Neto, D.M.; Martins, J.M.P.; Cunha, P.M.; Alves, J.L.; Oliveira, M.C.; Laurent, H.; Menezes, L.F. Thermo-mechanical finite element analysis of the AA5086 alloy under warm forming conditions. Int. J. Solids Struct. 2017, 151, 99–117. [Google Scholar] [CrossRef] [Green Version]

- Panicker, S.S.; Singh, H.G.; Panda, S.K.; Dashwood, R. Characterization of tensile properties, limiting strains, and deep drawing behavior of AA5754-H22 sheet at elevated temperature. J. Mater. Eng. Perform. 2015, 24, 4267–4282. [Google Scholar] [CrossRef]

- Pourboghrat, F.; Venkatesan, S.; Carsley, J.E. LDR and hydroforming limit for deep drawing of AA5754 aluminum sheet. J. Manuf. Process. 2013, 15, 600–615. [Google Scholar] [CrossRef]

- Wang, W.; Huang, L.; Tao, K.; Chen, S.; Wei, X. Formability and numerical simulation of AZ31B magnesium alloy sheet in warm stamping process. Mater. Des. 2015, 87, 835–844. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Room temperature formability of a magnesium AZ31 alloy: Examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. A 2008, 488, 406–414. [Google Scholar] [CrossRef]

- Uemori, T.; Katahira, T.; Naka, T.; Tada, N.; Yoshida, F. Cyclic stress and strain responses of AZ31 magnesium alloy sheet metal at elevated temperatures. Procedia Manuf. 2018, 15, 1792–1799. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Anand, L. Plasticity of initially textured hexagonal polycrystals at high homologous temperatures: Application to titanium. Acta Mater. 2002, 50, 133–148. [Google Scholar] [CrossRef]

- Maksoud, I.A.; Ahmed, H.; Rödel, J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy. Mater. Sci. Eng. A 2009, 504, 40–48. [Google Scholar] [CrossRef]

- Liang, S.J.; Liu, Z.Y.; Wang, E.D. Simulation of extrusion process of AZ31 magnesium alloy. Mater. Sci. Eng. A 2009, 499, 221–224. [Google Scholar] [CrossRef]

- Ramezani, M.; Neitzert, T.; Pasang, T.; Sellès, M.A. Characterization of friction behaviour of AZ80 and ZE10 magnesium alloys under lubricated contact condition by strip draw and bend test. Int. J. Mach. Tools Manuf. 2014, 85, 70–78. [Google Scholar] [CrossRef]

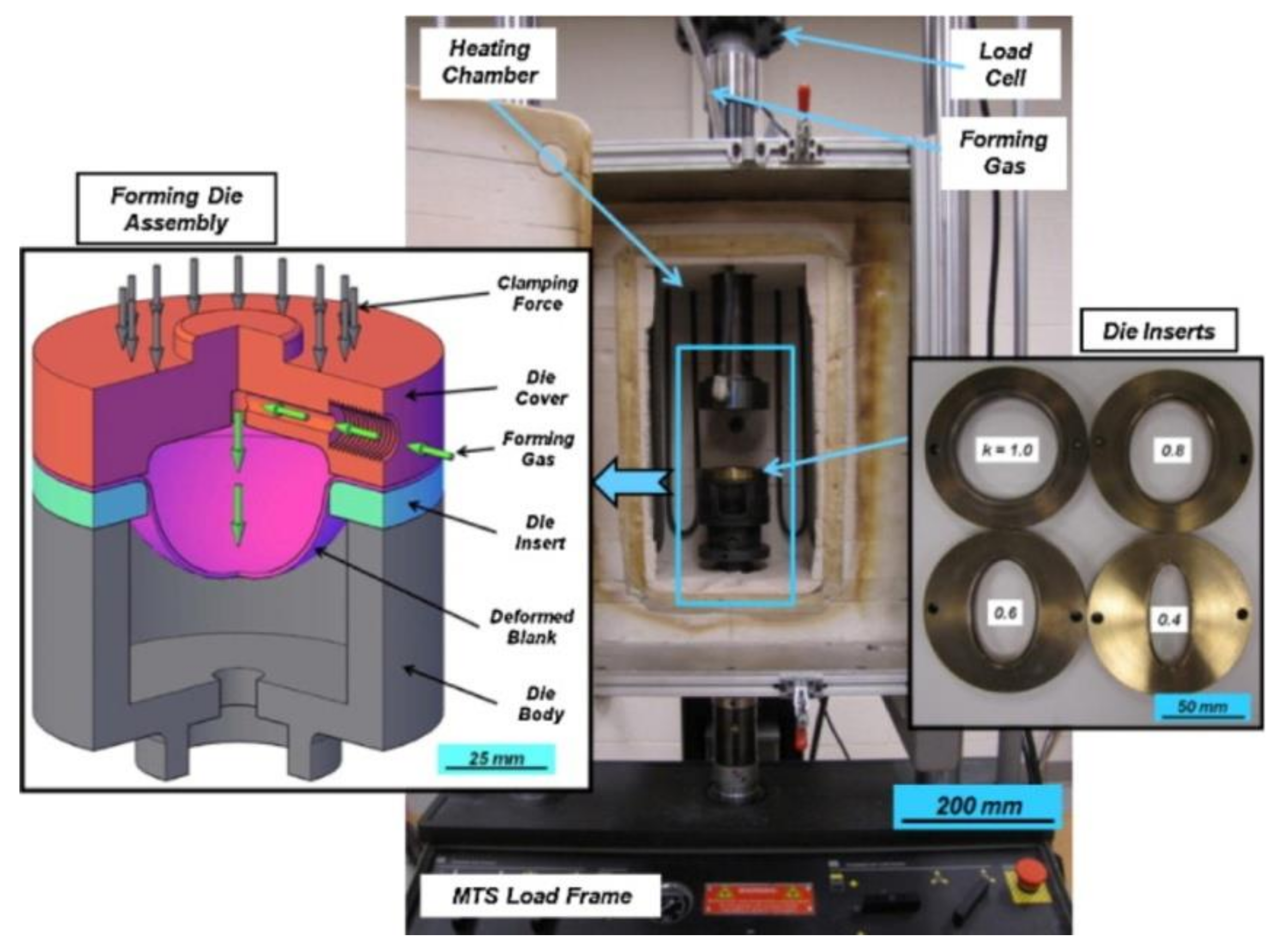

- Abu-Farha, F.; Verma, R.; Hector, L.G. High temperature composite forming limit diagrams of four magnesium AZ31B sheets obtained by pneumatic stretching. J. Mater. Process. Technol. 2014, 212, 1414–1429. [Google Scholar] [CrossRef]

- Atrian, A.; Fereshteh-Saniee, F. Deep drawing process of steel/brass laminated sheets. Compos. Part. B 2013, 47, 75–81. [Google Scholar] [CrossRef]

- Rajabi, A.; Kadkhodayan, M.; Manoochehri, M.; Farjadfar, R. Deep-drawing of thermoplastic metal-composite structures: Experimental investigations, statistical analyses and finite element modeling. J. Mater. Process. Technol. 2015, 215, 159–170. [Google Scholar] [CrossRef]

- Gali, O.A.; Riahi, A.R.; Alpas, A.T. The tribological behaviour of AA5083 alloy plastically deformed at warm forming temperatures. Wear 2016, 302, 1257–1267. [Google Scholar] [CrossRef]

- Jaworski, J.; Kluz, R.; Trzepieciński, T. Operational tests of wear dynamics of drills made of low-alloy high-speed hs2-5-1 steel. Eksploat. i Niezawodn.-Maint. Reliab. 2016, 18, 271–277. [Google Scholar] [CrossRef]

- Pelcastre, L. Hot Forming Tribology: Galling of Tools and Associated Problems. Licentiate Thesis, Luleå University of Technology, Lulea, Sweden, 2011. [Google Scholar]

- Kondratiuk, J.; Kuhn, P. Tribological investigations on friction and wear behaviour of coatings for hot sheet metal forming. Wear 2011, 270, 839–849. [Google Scholar] [CrossRef]

- Wu, C.; Qu, P.; Zhang, L.; Li, S.; Jiang, Z. A Numerical and experimental study on the interface friction of ball-on-disc test under high temperature. Wear 2017, 376–377, 433–442. [Google Scholar] [CrossRef]

- Venema, J.; Matthews, D.T.A.; Hazrati, J.; Wörmann, J.; van den Boogaard, A.H. Friction and wear mechanisms during hot stamping of AlSi coated press hardening steel. Wear 2017, 380–381, 137–145. [Google Scholar] [CrossRef]

- Uda, K.; Azushima, A.; Yanagida, A. Development of new lubricants for hot stamping of Al-coated 22MnB5 steel. J. Mater. Process. Technol. 2016, 228, 112–116. [Google Scholar] [CrossRef]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally benign tribo-systems for metal forming. CIRP Ann. 2010, 59, 760–780. [Google Scholar] [CrossRef] [Green Version]

- Dohda, K.; Boher, C.; Reza-Aria, F.; Mahayotsanun, N. Tribology in metal forming at elevated temperatures. Friction 2015, 3, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Leszak, E. Apparatus and Process for Incremental Dieless Forming. U.S. Patent 3342051A1, 19 September 1967. [Google Scholar]

- Pathak, J. A brief review on incremental sheet metal forming. Int. J. Latest Eng. Manag. Res. 2017, 2, 35–43. [Google Scholar]

- Xu, D.K.; Lu, B.; Cao, T.T.; Zhang, H.; Chen, J.; Hong, H.; Cao, J. Enhancement of process capabilities in electrically-assisted double sided incremental forming. Mater. Des. 2016, 92, 268–280. [Google Scholar] [CrossRef]

- Vahdati, M.; Mahdavinejad, R.; Amini, S. Investigation of the ultrasonic vibration effect in incremental sheet metal forming process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 971–998. [Google Scholar] [CrossRef]

- Amini, S.; Gollo, A.H.; Paktinat, H. An investigation of conventional and ultrasonic-assisted incremental forming of annealed AA1050 sheet. Int. J. Adv. Manuf. Technol. 2017, 90, 1569–1578. [Google Scholar] [CrossRef]

- Al-Obaidai, A.; Kunke, A.; Kräusel, V. Hot single-point incremental forming of glass-fiber-reinforced polymer(PA6GF47) supported by hot air. J. Manuf. Process. 2019, 43, 17–25. [Google Scholar] [CrossRef]

- Ai, S.; Long, H. A review on material fracture mechanism in incremental sheet forming. Int. J. Adv. Manuf. Technol. 2019, 104, 33–61. [Google Scholar] [CrossRef] [Green Version]

- Xiao, X.; Kim, C.; Lv, X.; Hwang, T.S.; Kim, Y.S. Formability and forming force in incremental sheet forming of AA7075-T6 at different temperatures. J. Mech. Sci. Technol. 2019, 33, 3795–3802. [Google Scholar] [CrossRef]

- Kumar, A.; Gulati, V.; Kumar, P.; Singh, H. Forming force in incremental sheet forming: A comparative analysis of the state of the art. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 251. [Google Scholar] [CrossRef]

- Fan, G.; Gao, L.; Hussain, G.; Wu, Z. Electric hot incremental forming: A novel technique. Int. J. Mach. Tool. Manuf. 2008, 48, 1688–1692. [Google Scholar] [CrossRef]

- Kurra, S.; Rahman, N.; Regalla, S.; Gupta, A. Modeling and optimization of surface roughness in single point incremental forming process. J. Mater. Res. Technol. 2015, 4, 304–313. [Google Scholar] [CrossRef] [Green Version]

- Rauch, M.; Hascoet, J.; Hamann, J.; Plenel, Y. Tool path programming optimization for incremental sheet forming applications. Comput. Aided Des. 2009, 41, 877–885. [Google Scholar] [CrossRef]

- Oleksik, V. Influence of Geometrical Parameters, Wall Angle and Part Shape on Thickness Reduction of Single Point Incremental Forming. Procedia Eng. 2014, 81, 2280–2285. [Google Scholar] [CrossRef]

- Al-Ghamdi, K.A.; Hussain, G. On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals 2019, 9, 553. [Google Scholar] [CrossRef] [Green Version]

- Slota, J.; Krasowski, B.; Kubit, A.; Trzepiecinski, T.; Bochnowski, W.; Dudek, K.; Neslušan, M. Residual stresses and surface roughness analysis of truncated cones of steel sheet made by single point incremental forming. Metals 2020, 10, 237. [Google Scholar] [CrossRef] [Green Version]

- Jadhav, S. Basic Investigations of the Incremental Sheet Metal Forming Process on a CNC Milling Machine; Shaker Verlag GmbH: Aachen, Germany, 2004. [Google Scholar]

- Hirt, G.; Ames, J.; Bambach, M. Basic investigation into the characteristics of dies and support tools used in CNC-incremental sheet forming. In Proceedings of the 25th IDDRG Conference, Porto, Portugal, 19–21 June 2006; pp. 341–348. [Google Scholar]

- Martins, P.A.F.; Bay, N.; Skjoedt, M.; Silva, M.B. Theory of single point incremental forming. CIRP Ann. Manuf. Technol. 2008, 57, 247–252. [Google Scholar] [CrossRef]

- Behera, A.K.; de Sousa, R.A.; Ingarao, G.; Oleksik, V. Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef] [Green Version]

- Durante, M.; Formisano, A.; Langella, A.; Minutolo, F. The influence of tool rotation on an incremental forming process. J. Mater. Process. Technol. 2009, 209, 4621–4626. [Google Scholar] [CrossRef]

- Obikawa, T.; Satou, S.; Hakutani, T. Dieless incremental micro-forming of miniature shell objects of aluminium foils. Int. J. Mach. Tool. Manuf. 2009, 49, 906–915. [Google Scholar] [CrossRef]

- Duflou, J.R.; Callebaut, B.; Verbert, J.; De Baerdemaeker, D. Laser assisted incremental forming: Formability and accuracy improvement. CIRP Ann. 2007, 56, 273–276. [Google Scholar] [CrossRef]

- Göttmann, A.; Diettrich, J.; Bergweiler, G.; Bambach, M.; Hirt, G.; Loosen, P.; Poprawe, R. Laser-assisted asymmetric incremental sheet forming of titanium sheet metal parts. Prod. Eng. 2011, 5, 263–271. [Google Scholar] [CrossRef]

- Göttmann, A.; Bailly, D.; Bergweiler, G.; Bambach, M.; Stollenwerk, J.; Hirt, G.; Loosen, P. A novel approach for temperature control in ISF supported by laser and resistance heating. Int. J. Adv. Manuf. Technol. 2013, 67, 2195–2205. [Google Scholar] [CrossRef]

- Mohammadi, A.; Vanhove, H.; Van Bael, A.; Duflou, J.R. Towards accuracy improvement in single point incremental forming of shallow parts formed under laser assisted conditions. Int. J. Mater. Form. 2016, 9, 339–351. [Google Scholar] [CrossRef]

- Mohammadi, A.; Qin, L.; Vanhove, H.; Seefeldt, M.; Van Bael, A.; Duflou, J.R. Single point incremental forming of an aged AL-Cu-Mg alloy: Influence of pre-heat treatment and warm forming. J. Mater. Eng. Perform. 2016, 25, 2478–2488. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, Y.S.; Kang, S.H.; Lee, J.H. Incremental forming of Mg alloy sheet at elevated temperatures. J. Mech. Sci. Technol. 2007, 21, 1518–1522. [Google Scholar] [CrossRef]

- Galdos, L.; Argandona, E.S.D.; Ulacia, I.; Arruebarrena, G. Warm incremental forming of magnesium alloys using hot fluid as heating media. Key Eng. Mater. 2012, 504–506, 815–820. [Google Scholar] [CrossRef]

- Al-Obaidi, A.; Kräusel, V.; Landgrebe, D. Hot single-point incremental forming assisted by induction heating. Int. J. Adv. Manuf. Technol. 2015, 82, 1163–1171. [Google Scholar] [CrossRef]

- Al-Obaidi, A.; Kräusel, V.; Landgrebe, D. Induction Heating Validation of Dieless Single-Point Incremental Forming of AHSS. J. Manuf. Mater. Process. 2017, 1, 5. [Google Scholar] [CrossRef]

- Baharudin, B.; Azpen, Q.; Sulaima, S.; Mustapha, F. Experimental Investigation of Forming Forces in Frictional Stir Incremental Forming of Aluminum Alloy AA6061-T6. Metals 2017, 7, 484. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.W.; Lee, Y.S.; Kwon, Y.N.; Lee, J.H. A Study on Warm Incremental Forming of AZ31 Alloy Sheet. Trans. Mater. Process. 2008, 17, 373–379. [Google Scholar]

- Ji, Y.H.; Park, J.J. Incremental forming of free surface with magnesium alloy AZ31 sheet at warm temperatures. Trans. Nonferrous Met. Soc. China 2008, 18, s165–s169. [Google Scholar] [CrossRef]

- Ji, Y.H.; Park, J.J. Formability of magnesium AZ31 sheet in the incremental forming at warm temperature. J. Mater. Process. Technol. 2008, 201, 354–358. [Google Scholar] [CrossRef]

- Xu, D.; Lu, B.; Cao, T.; Chen, J.; Long, H.; Cao, J. A comparative study on process potentials for frictional stir- and electric hot-assisted incremental sheet forming. Procedia Eng. 2014, 81, 2324–2329. [Google Scholar] [CrossRef] [Green Version]

- Ambrogio, G.; Gagliardi, F. Temperature variation during high speed incremental forming on different lightweight alloys. Int. J. Adv. Manuf. Technol. 2015, 76, 1819–1825. [Google Scholar] [CrossRef]

- Ambrogio, G.; Gagliardi, F.; Chamanfar, A.; Misiolek, W.Z.; Filice, L. Induction heating and cryogenic cooling in single point incremental forming of Ti-6Al-4V: Process setup and evolution of microstructure and mechanical properties. Int. J. Adv. Manuf. Technol. 2017, 91, 803–812. [Google Scholar] [CrossRef]

- Ambrogio, G.; Gagliardi, F.; Bruschi, S.; Filice, L. On the high-speed single point incremental forming of titanium alloys. CIRP Ann. 2013, 62, 243–246. [Google Scholar] [CrossRef]

- Buffa, G.; Campanella, D.; Fratini, L. On the improvement of material formability in SPIF operation through tool stirring action. Int. J. Adv. Manuf. Technol. 2013, 66, 1343–1351. [Google Scholar] [CrossRef]

- Davarpanah, M.A.; Mirkouei, A.; Yu, X.; Malhotra, R.; Pilla, S. Effects of incremental depth and tool rotation on failure modes and microstructural properties in single point incremental forming of polymers. J. Mater. Process. Technol. 2015, 222, 287–300. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Jiang, H. Effects of forming parameters on temperature in frictional stir incremental sheet forming. J. Mech. Sci. Technol. 2016, 30, 2163–2169. [Google Scholar] [CrossRef]

- Liu, Z. Friction stir incremental forming of AA7075-O sheets: Investigation on process feasibility. Procedia Eng. 2017, 207, 783–788. [Google Scholar] [CrossRef]

- Uheida, E.H.; Oosthuizen, G.A.; Dimitrov, D.M.; Bezuidenhout, M.B.; Hugo, P.A. Effects of the relative tool rotation direction on formability during the incremental forming of titanium sheets. Int. J. Adv. Manuf. Technol. 2018, 96, 3311–3319. [Google Scholar] [CrossRef] [Green Version]

- Adams, D.; Jeswiet, J. Single point incremental forming of 6061-T6 using electrically assisted forming methods. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2014, 228, 757–764. [Google Scholar] [CrossRef]

- Bao, W.; Chu, X.; Lin, S.; Gao, J. Experimental investigation on formability and microstructure of AZ31B alloy in electropulse-assisted incremental forming. Mater. Des. 2015, 87, 632–639. [Google Scholar] [CrossRef]

- Honarpisheh, M.; Abdolhoseini, M.J.; Amini, S. Experimental and numerical investigation of the hot incremental forming of Ti-6Al-4V sheet using electrical current. Int. J. Adv. Manuf. Technol. 2016, 83, 2027–2037. [Google Scholar] [CrossRef]

- Khazaali, H.; Fereshteh-Saniee, F. A comprehensive experimental investigation on the influences of the process variables on warm incremental forming of Ti-6Al-4V titanium alloy using a simple technique. Int. J. Adv. Manuf. Technol. 2016, 87, 2911–2923. [Google Scholar] [CrossRef]

- Liu, R.; Lu, B.; Xu, D.; Chen, J.; Chen, F.; Ou, H.; Long, H. Development of novel tools for electricity-assisted incremental sheet forming of titanium alloy. Int. J. Adv. Manuf. Technol. 2016, 85, 1137–1144. [Google Scholar] [CrossRef]

- Najafabady, S.A.; Ghaei, A. An experimental study on dimensional accuracy, surface quality, and hardness of Ti-6Al-4 V titanium alloy sheet in hot incremental forming. Int. J. Adv. Manuf. Technol. 2016, 87, 3579–3588. [Google Scholar] [CrossRef]

- Li, Z.; Lu, S.; Zhang, T.; Zhang, C.; Mao, Z. 1060 Al electric hot incremental sheet forming process: Analysis of dimensional accuracy and temperature. Trans. Indian Inst. Met. 2018, 71, 961–970. [Google Scholar] [CrossRef]

- Li, Z.; Lu, S.; Zhang, T.; Zhang, C.; Mao, Z. Electric assistance hot incremental sheet forming: An integral heating design. Int. J. Adv. Manuf. Technol. 2018, 96, 3209–3215. [Google Scholar] [CrossRef]

- Magnus, C.S. Joule heating of the forming zone in incremental sheet metal forming: Part 1. Int. J. Adv. Manuf. Technol. 2017, 91, 1309–1319. [Google Scholar] [CrossRef]

- Magnus, C.S. Joule heating of the forming zone in incremental sheet metal forming: Part 2. Int. J. Adv. Manuf. Technol. 2017, 89, 295–309. [Google Scholar] [CrossRef]

- Min, J.; Seim, P.; Störkle, D.; Thyssen, L.; Kuhlenkötter, B. Thermal modeling in electricity assisted incremental sheet forming. Int. J. Mater. Form. 2017, 10, 729–739. [Google Scholar] [CrossRef]

- Pacheco, P.A.P.; Silveira, M.E. Numerical simulation of electric hot incremental sheet forming of 1050 aluminum with and without preheating. Int. J. Adv. Manuf. Technol. 2017, 94, 3097–3108. [Google Scholar] [CrossRef]

- Palumbo, G.; Brandizzi, M. Experimental investigations on the single point incremental forming of a titanium alloy component combining static heating with high tool rotation speed. Mater. Des. 2012, 40, 43–51. [Google Scholar] [CrossRef]

- Liu, Z. Heat-assisted incremental sheet forming: A state-of-the-art review. Int. J. Adv. Manuf. Technol. 2018, 98, 2987–3003. [Google Scholar] [CrossRef]

- Albakri, M.; Abu-Farha, F.; Khraisheh, M. A new combined experimental–numerical approach to evaluate formability of rate dependent materials. Int. J. Mech. Sci. 2013, 66, 55–66. [Google Scholar] [CrossRef]

- Wang, L.; Strangwood, M.; Balint, D.; Lin, J.; Dean, T. Formability and failure mechanisms of AA2024 under hot forming conditions. Mater. Sci. Eng. A 2011, 528, 2648–2656. [Google Scholar] [CrossRef]

- Hmida, R.; Thibaud, S.; Gilbin, A.; Richard, F. Influence of the initial grain size in single point incremental forming process for thin sheets metal and microparts: Experimental investigations. Mater. Des. 2013, 45, 155–165. [Google Scholar] [CrossRef]

- Ambrogio, G.; Ciancio, C.; Filice, L.; Gagliardi, F. Theoretical model for temperature prediction in Incremental Sheet Forming-Experimental validation. Int. J. Mech. Sci. 2016, 108, 39–48. [Google Scholar]

- Bhattacharya, A.; Maneesh, K.; Reddy, N.; Cao, J. Formability and surface finish studies in single point incremental forming. J. Manuf. Sci. Eng. 2011, 133, 061020. [Google Scholar] [CrossRef]

- Bagudanch, I.; Garcia-Romeu, M.L.; Centeno, G.; Elías-Zúñiga, A.; Ciurana, J. Forming force and temperature effects on single point incremental forming of polyvinylchloride. J. Mater. Process. Technol. 2015, 219, 221–229. [Google Scholar] [CrossRef]

- Bagudanch, I.; Vives-Mestres, M.; Sabater, M.; Garcia-Romeu, M. Polymer incremental sheet forming process: Temperature analysis using response surface methodology. Mater. Manuf. Process. 2017, 32, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Medina-Sanchez, G.; Garcia-Collado, A.; Carou, D.; Dorado-Vicente, R. Force Prediction for Incremental Forming of Polymer Sheets. Materials 2018, 11, 1597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clavijo-Chaparro, S.L.; Iturbe-Ek, J.; Lozano-Sánchez, L.M.; Sustaita, A.O.; Elías-Zúñiga, A. Plasticized and reinforced poly(methyl methacrylate) obtained by a dissolution-dispersion process for single point incremental forming: Enhanced formability towards the fabrication of cranial implants. Polym. Test. 2018, 68, 39–45. [Google Scholar] [CrossRef]

- Medina-Sánchez, G.; Torres-Jimenez, E.; Lopez-Garcia, R.; Dorado-Vicente, R.; Cazalla-Moral, R. Temperature influence on Single Point Incremental Forming of PVC parts. Procedia Manuf. 2017, 13, 335–342. [Google Scholar] [CrossRef]

- Shim, M.; Park, J. The formability of aluminum sheet in incremental forming. J. Mater. Process. Technol. 2001, 113, 654–658. [Google Scholar] [CrossRef]

- Kim, Y.; Park, J. Effect of process parameters on formability in incremental forming of sheet metal. J. Mater. Process. Technol. 2002, 130, 42–46. [Google Scholar] [CrossRef]

- Hussain, G.; Gao, L.; Hayat, N.; Cui, Z.; Pang, Y.; Dar, N. Tool and lubrication for negative incremental forming of a commercially pure titanium sheet. J. Mater. Process. Technol. 2008, 203, 193–201. [Google Scholar] [CrossRef]

- Lu, B.; Fang, Y.; Xu, D.; Chen, J.; Ou, H.; Moser, N.; Cao, J. Mechanism investigation of friction-related effects in single point incremental forming using a developed oblique roller-ball tool. Int. J. Mach. Tools Manuf. 2014, 85, 14–29. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J. Asymmetric single point incremental forming of sheet metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Malhotra, R.; Bhattacharya, A.; Kumar, A.; Reddy, N.; Cao, J. A new methodology for multi-pass single point incremental forming with mixed toolpaths. CIRP Ann. 2011, 60, 323–326. [Google Scholar] [CrossRef]

- López, C.; Elías-Zúñiga, A.; Jiménez, I.; Martínez-Romero, O.; Siller, H.R.; Diabb, J.M. Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process. Materials 2018, 11, 2542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hajavifard, R.; Maqbool, F.; Schmiedt-Kalenborn, A.; Buhl, J.; Bambach, M.; Walther, F. Integrated Forming and Surface Engineering of Disc Springs by Inducing Residual Stresses by Incremental Sheet Forming. Materials 2019, 12, 1646. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; He, T.; Miwa, H.; Nanbu, T.; Murakami, R.; Liu, S.; Cao, J.; Wang, Q.J. A new approach for analyzing the temperature rise and heat partition at the interface of coated tool tip-sheet incremental forming systems. Int. J. Heat Mass Transf. 2019, 129, 1172–1183. [Google Scholar] [CrossRef]

- Araghi, B.T.; Manco, G.L.; Bambach, M.; Hirt, G. Investigation into a new hybrid forming process: Incremental sheet forming combined with stretch forming. CIRP Ann. 2009, 58, 225–228. [Google Scholar] [CrossRef]

- Tandon, P.; Sharma, O.N. Experimental investigation into a new hybrid-forming process: Incremental stretch drawing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 475–486. [Google Scholar] [CrossRef]

- Jagtab, R.; Kumar, S. An experimental investigation on thinning and formability in hybrid incremental sheet forming process. Procedia Manuf. 2019, 30, 71–76. [Google Scholar] [CrossRef]

- Araghi, B.T.; Göttmann, A.; Bambach, M.; Hirt, G.; Bergweiler, G.; Diettrich, J.; Steiners, M.; Saeed-Akbari, A. Review on the development of a hybrid incremental sheet forming system for small batch sizes and individualized production. Prod. Eng. 2011, 5, 393–404. [Google Scholar] [CrossRef]

- Lu, B.; Zhang, H.; Xu, D.K.; Chen, J. A Hybrid Flexible Sheet Forming Approach towards Uniform Thickness Distribution. Procedia CIRP 2014, 18, 244–249. [Google Scholar] [CrossRef] [Green Version]

- Allwood, J.; Braun, D.; Music, O. The effect of partially cut-out blanks on geometric accuracy in incremental sheet forming. J. Mater. Proc. Technol. 2010, 210, 1501–1510. [Google Scholar] [CrossRef]

- Dong, G.J.; Zhao, C.C.; Cao, M.Y. Flexible-die forming process with solid granule medium on sheet metal. Trans. Nonferrous Met. Soc. China 2013, 23, 2666–2677. [Google Scholar] [CrossRef]

- Koç, M.; Billur, E.; Necati, Ö.N. An experimental study on the comparative assessment of hydraulic bulge test analysis methods. Mater. Des. 2011, 32, 272–281. [Google Scholar] [CrossRef]

- Yang, X.Y.; Lang, L.H.; Liu, K.N.; Liu, B.S. Mechanics analysis of axisymmetric thin-walled part in warm sheet hydroforming. Chin. J. Aeronaut. 2015, 28, 1546–1554. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Wang, Y.N.; Lang, L.H. Accuracy analysis of complex curvature parts based on the rigid-flexible hydroforming. Int. J. Adv. Manuf. Technol. 2018, 99, 247–254. [Google Scholar] [CrossRef]

- Woźniak, D.; Głowacki, M.; Hojny, M.; Pieja, T. Application of CAE systems in forming of drawpieces with use rubber-pad forming processes. Arch. Metall. Mater. 2012, 57, 1179–1187. [Google Scholar] [CrossRef] [Green Version]

- Belhassen, L.; Koubaa, S.; Wali, M.; Dammak, F. Numerical prediction of springback and ductile damage in rubber-padforming process of aluminum sheet metal. Int. J. Mech. Sci. 2016, 117, 218–226. [Google Scholar] [CrossRef]

- Irthiea, I.; Green, G.; Hashim, S.; Kriama, A. Experimental and numerical investigation on micro deep drawing process of stainless steel 304 foil using flexible tools. Int. J. Mach. Tools Manuf. 2014, 76, 21–33. [Google Scholar] [CrossRef] [Green Version]

- Trzepiecinski, T.; Malinowski, T.; Pieja, T. Experimental and numerical analysis of industrial warm forming of stainless steel sheet. J. Manuf. Process. 2017, 30, 532–540. [Google Scholar] [CrossRef]

- Chen, L.; Chen, H.; Guo, W.; Chen, G.; Wang, Q. Experimental and simulation studies of springback in rubber forming using aluminium sheet straight flanging process. Mater. Des. 2014, 54, 354–360. [Google Scholar] [CrossRef]

- Jin, C.K.; Jeong, M.G.; Kang, C.G. Effect of rubber forming process parameters on micro-patterning of thin metallic plates. Procedia Eng. 2014, 81, 1439–1444. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Hua, L.; Lan, J.; Wei, X. Studies of the deformation styles of the rubber-pad forming process used for manufacturing metallic bipolar plates. J. Power Sources 2010, 195, 8177–8184. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Z.R.; Dean, T.A. The mechanics of multi-point sandwich forming. Int. J. Mach. Tools Manuf. 2008, 48, 1495–1503. [Google Scholar] [CrossRef]

- Walczyk, D.F.; Hosford, J.F.; Papazian, J.M. Using reconfigurable tooling and surface heating for incremental forming of composite aircraft parts. J. Manuf. Sci. Eng. 2003, 125, 333–343. [Google Scholar] [CrossRef]

- Li, M.Z.; Cai, Z.Y.; Sui, Z.; Yan, Q.G. Multi-point forming technology for sheet metal. J. Mater. Process. Technol. 2002, 129, 333–338. [Google Scholar] [CrossRef]

- Chen, J.J.; Li, M.Z.; Liu, W.; Wang, C.T. Sectional multipoint forming technology fir large-size sheet metal. Int. J. Adv. Manuf. Technol. 2005, 25, 935–939. [Google Scholar] [CrossRef]

- Abosaf, M.; Essa, K.; Alghawail, A.; Tolipov, A.; Su, S.; Pham, D. Optimisation of multi-point forming process parameters. Int. J. Adv. Manuf. Technol. 2017, 92, 1849–1859. [Google Scholar] [CrossRef] [Green Version]

- Nakajima, N. A newly developed technique to fabricate complicated dies and electrodes with wires. J. Jpn. Soc. Mech. Eng. 1969, 72, 498–506. [Google Scholar] [CrossRef]

- Paunoiu, V.; Teodor, V.; Maier, C.; Baroiu, N.; Bercu, G. Study ofthe tool geometry in reconfigurable multipoint forming. Ann. Dunărea de Jos Univ. Galaţi 2011, 11, 139–144. [Google Scholar]

- Sairajan, K.K.; Aglietti, G.S.; Mani, K.M. A review of multifunctional structure technology for aerospace applications. Acta Astronaut. 2016, 120, 30–42. [Google Scholar] [CrossRef]

- Sun, G.Y.; Huo, X.T.; Chen, D.D.; Li, Q. Experimental and numerical study on honey-comb sandwich panels under bending and in-panel compression. Mater. Des. 2017, 133, 154–168. [Google Scholar] [CrossRef]

- Carradò, A.; Faerber, J.; Niemeyer, S.; Ziegmann, G.; Palkowski, H. Metal/polymer/metalhybrid systems: Towards potential formability applications. Compos. Struct. 2011, 93, 715–721. [Google Scholar] [CrossRef]

- Besse, C.C.; Mohr, D. Plasticity of formable all-metal sandwich sheets: Virtual experiments and constitutive modeling. Int. J. Solids Struct. 2012, 49, 2863–2880. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.Y.; Zhang, X.; Liang, X.B. Multi-point forming of sandwich panels with egg-box-like cores andfailure behaviors in forming process: Analytical models, numerical and experimental investigations. Mater. Des. 2018, 160, 1029–1041. [Google Scholar] [CrossRef]

- Liang, X.B.; Cai, Z.Y.; Zhang, X. Forming characteristics analysis and springback predictionof bi-directional trapezoidal sandwich panels in the multi-point bend-forming. Int. J. Adv. Manuf. Technol. 2018, 98, 1709–1720. [Google Scholar] [CrossRef]

- Zhang, S.H.; Chen, S.F.; Ma, Y.; Song, H.W.; Cheng, M. Developments of new sheet metal forming technology and theory in China. Acta Metall. Sin. 2015, 28, 1452–1470. [Google Scholar] [CrossRef]

- Chen, H.; Güner, A.; Khalifa, N.B.; Tekkaya, A.E. Granular media-based tube press hardening. J. Mater. Process. Tech. 2016, 228, 145–159. [Google Scholar] [CrossRef]

- Dong, G.J.; Zhao, C.C.; Cao, M.Y. Process of back pressure deep drawing with solid granule medium on sheet metal. J. Cent. South. Univ. 2014, 21, 2617–2626. [Google Scholar] [CrossRef]

- Psyk, V.; Risch, D.; Kinsey, B.L.; Tekkaya, A.E.; Kleiner, M. Electromagnetic forming—A review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Kim, D.; Park, H.I.; Lee, J.; Kim, J.H.; Lee, M.-G.; Lee, Y. Experimental study on forming behavior of high-strength steel sheets under electromagnetic pressure. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 670–681. [Google Scholar] [CrossRef]

- Long, A.; Wan, M.; Wang, W.; Wu, X.; Cui, X.; Ma, B. Forming methodology and mechanism of a novel sheet metal forming technology-electromagnetic superposed forming(EMSF). Int. J. Solids Struct. 2018, 151, 165–180. [Google Scholar] [CrossRef]

- Lai, Z.; Cao, Q.; Han, X.; Huang, Y.; Deng, F.; Chen, Q.; Li, L. Investigation on plastic deformation behavior of sheet workpiece during radial Lorentz force augmented deep drawing process. J. Mater. Process. Technol. 2017, 245, 193–206. [Google Scholar] [CrossRef]

- Paese, E.; Geier, M.; Homrich, R.P.; Rosa, P.; Rossi, R. Sheet metal electromagnetic forming using a flat spiral coil: Experiments, modeling, and validation. J. Mater. Process. Technol. 2019, 263, 408–422. [Google Scholar] [CrossRef]

- Thibaudeau, E.; Kinsey, B.L. Analytical design and experimental validation of uniform pressure actuator for electromagnetic forming and welding. J. Mater. Process. Technol. 2015, 215, 251–263. [Google Scholar] [CrossRef]

- Psyk, V.; Kurka, P.; Kimme, S.; Werner, M.; Landgrebe, D.; Ebert, A.; Schwarzendahl, M. Structuring by electromagnetic forming and by forming with an elastomer punch as a tool for component optimisation regarding mechanical stiffness and acoustic performance. Manuf. Rev. 2015, 2, 23. [Google Scholar] [CrossRef] [Green Version]

- Mamalis, A.G.; Manolakos, D.E.; Kladas, A.G.; Koumoutsos, A.K.; Ovchinnikov, S.G. Electromagnetic forming of aluminum alloy sheet using a grooved die: Numerical modelling. Phys. Met. Metall. 2006, 102, 590–593. [Google Scholar] [CrossRef]

- Golovashchenko, S.F. Material formability and coil design in electromagnetic forming. J. Mater. Eng. Perform. 2007, 16, 314–320. [Google Scholar] [CrossRef]

- Balanethiram, V.S.; Hu, X.; Altynova, M.; Daehn, G.S. Hyperplasticity: Enhanced formability at high rates. J. Mater. Process. Technol. 1994, 45, 595–600. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, Z.; Yu, H.; Xiao, X.; Cheng, Y. Springback Calibration of a U-Shaped Electromagnetic Impulse Forming Process. Metals 2019, 9, 603. [Google Scholar] [CrossRef] [Green Version]

- Xiong, W.R.; Wang, W.P.; Wan, M.; Li, X.J. Geometric issues in V-bending electromagnetic forming process of 2024-T3 aluminum alloy. J. Manuf. Process. 2015, 19, 171–182. [Google Scholar] [CrossRef]

- Yu, H.; Chen, J.; Liu, W.; Yin, H.; Li, C. Electromagnetic forming of aluminum circular tubes into square tubes: Experiment and numerical simulation. J. Manuf. Process. 2018, 31, 613–623. [Google Scholar] [CrossRef]

- Su, H.; Huang, L.; Li, J.; Ma, F.; Huang, P.; Feng, F. Two-step electromagnetic forming: A new forming approach to local features of large-size sheet metal parts. Int. J. Mach. Tools Manuf. 2018, 124, 99–116. [Google Scholar] [CrossRef]

- Kamal, M.; Shang, J.; Cheng, V.; Hatkevich, S.; Daehn, G.S. Agile manufacturing of a micro-embossed case by a two-step electromagnetic forming process. J. Mater. Process. Technol. 2007, 190, 41–50. [Google Scholar] [CrossRef]

- Imbert, J.; Worswick, M. Electromagnetic reduction of a pre-formed radius on AA 5754 sheet. J. Mater. Process. Technol. 2011, 211, 896–908. [Google Scholar] [CrossRef]

- Li, J.; Qiu, W.; Huang, L.; Su, H.; Tao, H.; Li, P. Gradient electromagnetic forming (GEMF): A new forming approach for variable-diameter tubes by use of sectional coil. Int. J. Mach. Tools Manuf. 2018, 135, 65–77. [Google Scholar] [CrossRef]

- Centeno, G.; Martínez-Donaire, A.J.; Bagudanch, I.; Morales-Palma, D.; Garcia-Romeu, M.L.; Vallellano, C. Revisiting Formability and Failure of AISI304 Sheets in SPIF: Experimental Approach and Numerical Validation. Metals 2017, 7, 531. [Google Scholar] [CrossRef] [Green Version]

- Centeno, G.; Martínez-Donaire, A.J.; Morales-Palma, D.; Vallellano, C.; Martins, P.A.F. Novel experimental techniques for the determination of the forming limits at necking and fracture. In Materials Forming and Machining; Davim, P., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 1–24. [Google Scholar]

- Cui, X.H.; Mo, J.H.; Li, J.J.; Zhao, J.; Zhu, Y.; Huang, L.; Li, W.Z.; Zhong, K. Electromagnetic incremental forming (EMIF): A novel aluminum alloy sheet and tube forming technology. J. Mater. Process. Technol. 2014, 214, 409–427. [Google Scholar] [CrossRef]

- Lai, Z.; Cao, Q.; Han, X.; Liu, N.; Li, X.; Huang, Y.; Chen, M.; Cai, H.; Wang, G.; Liu, L.; et al. A comprehensive electromagnetic forming approach for large sheet metal forming. Procedia Eng. 2017, 207, 54–59. [Google Scholar] [CrossRef]

- Tan, J.; Zhan, M.; Gao, P.; Li, H. Electromagnetic forming rules of a stiffened panel with grid ribs. Metals 2017, 7, 559. [Google Scholar] [CrossRef] [Green Version]

- Cao, T.; Lu, B.; Ou, H.; Long, H.; Chen, J. Investigation on a new hole-flanging approach by incremental sheet forming through a featured tool. Int. J. Mach. Tools Manuf. 2016, 110, 1–17. [Google Scholar] [CrossRef]

- Li, C.; Liu, D.; Yu, H.; Ji, Z. Research on formability of 5052 aluminum alloy sheet in a quasi-static-dynamic tensile process. Int. J. Mach. Tools Manuf. 2009, 49, 117–124. [Google Scholar] [CrossRef]

- Kacem, A.; Krichen, A.; Manach, P.Y.; Thuillier, S.; Yoon, J.W. Failure prediction in the hole-flanging process of aluminium alloys. Eng. Fract. Mech. 2013, 99, 251–265. [Google Scholar] [CrossRef]

- Krichen, A.; Kacem, A.; Hbaieb, M. Blank-holding effect on the hole-flanging process of sheet aluminum alloy. J. Mater. Process. Technol. 2011, 211, 619–626. [Google Scholar] [CrossRef]

- Su, H.; Huang, L.; Li, J.; Ma, F.; Ma, H.; Huang, P.; Zhu, H.; Feng, F. Inhomogeneous deformation behaviors of oblique hole-flanging parts during electromagnetic forming. J. Manuf. Process. 2020, 52, 1–11. [Google Scholar] [CrossRef]

- Feng, F.; Li, J.; Yuan, P.; Zhang, Q.; Huang, P.; Su, H.; Chen, R. Application of a GTN Damage Model Predicting the Fracture of 5052-O Aluminum Alloy High-Speed Electromagnetic Impaction. Metals 2018, 8, 761. [Google Scholar] [CrossRef] [Green Version]

- Gillard, A.J.; Golovashchenko, S.F.; Mamutov, A.V. Effect of quasi-static prestrain on the formability of dual phase steels in electrohydraulic forming. J. Manuf. Process. 2013, 15, 201–218. [Google Scholar] [CrossRef]

- Mamutov, A.V.; Golovashchenko, S.F.; Mamutov, V.S.; Bonnen, J.J.F. Modeling of electrohydraulic forming of sheet metal parts. J. Mater. Process. Technol. 2015, 219, 84–100. [Google Scholar] [CrossRef] [Green Version]

- Golovashchenko, S.F.; Gillard, A.J.; Mamutov, A.V. Formability of dual phase steels in electrohydraulic forming. J. Mater. Process. Technol. 2013, 213, 1191–1212. [Google Scholar] [CrossRef]

- Golovashchenko, S.F.; Mamutov, A.V.; Bonnen, J.J.F.; Gillard, A.J. Electrohydraulic forming of sheet metal parts. In Proceedings of the International Conference on the Technology of Plasticity, Aachen, Germany, 25–30 September 2011; pp. 1170–1175. [Google Scholar]

- Golovashchenko, S.F.; Bessonov, N.M.; Ilinich, A.M. Two-step method of forming complex shapes from sheet metal. J. Mater. Process. Technol. 2011, 211, 875–885. [Google Scholar] [CrossRef]

- Samei, J.; Green, D.E.; Golovashchenko, S.; Hassannejadasl, A. Quantitative microstructural analysis of formability enhancement in dual phase steels subject to electrohydraulic forming. J. Mater. Eng. Perform. 2013, 22, 2080–2088. [Google Scholar] [CrossRef]

- Maris, C.; Hassannejadasl, A.; Green, D.E.; Cheng, J.; Golovashchenko, S.F.; Gillard, A.J.; Liang, Y. Comparison of quasi-static and electrohydraulic free forming limits for DP600 and AA5182 sheets. J. Mater. Process. Technol. 2016, 235, 206–219. [Google Scholar] [CrossRef]

- Zia, M.; Fazli, A.; Soltananpour, M. Warm electrohydraulic forming: A novel high speed forming process. Procedia Eng. 2017, 207, 323–328. [Google Scholar] [CrossRef]

- Ahmed, K.I.; Gadala, M.S.; El-Sebaie, M.G. Deep spinning of sheet metals. Int. J. Mach. Tools Manuf. 2015, 97, 72–85. [Google Scholar] [CrossRef]

- Xia, Q.; Shima, S.; Kotera, H.; Yasuhuku, D. A study of the one-path deep drawing spinning of cups. J. Mater. Process. Technol. 2005, 159, 397–400. [Google Scholar] [CrossRef]

- Abd-Alrazzaq, M.; Ahmed, M.; Younes, M. Experimental Investigation on the Geometrical Accuracy of the CNC Multi-Pass Sheet Metal Spinning Process. J. Manuf. Mater. Process. 2018, 2, 59. [Google Scholar] [CrossRef] [Green Version]