Hot Deformation Behavior and Processing Map of High-Strength Nickel Brass

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

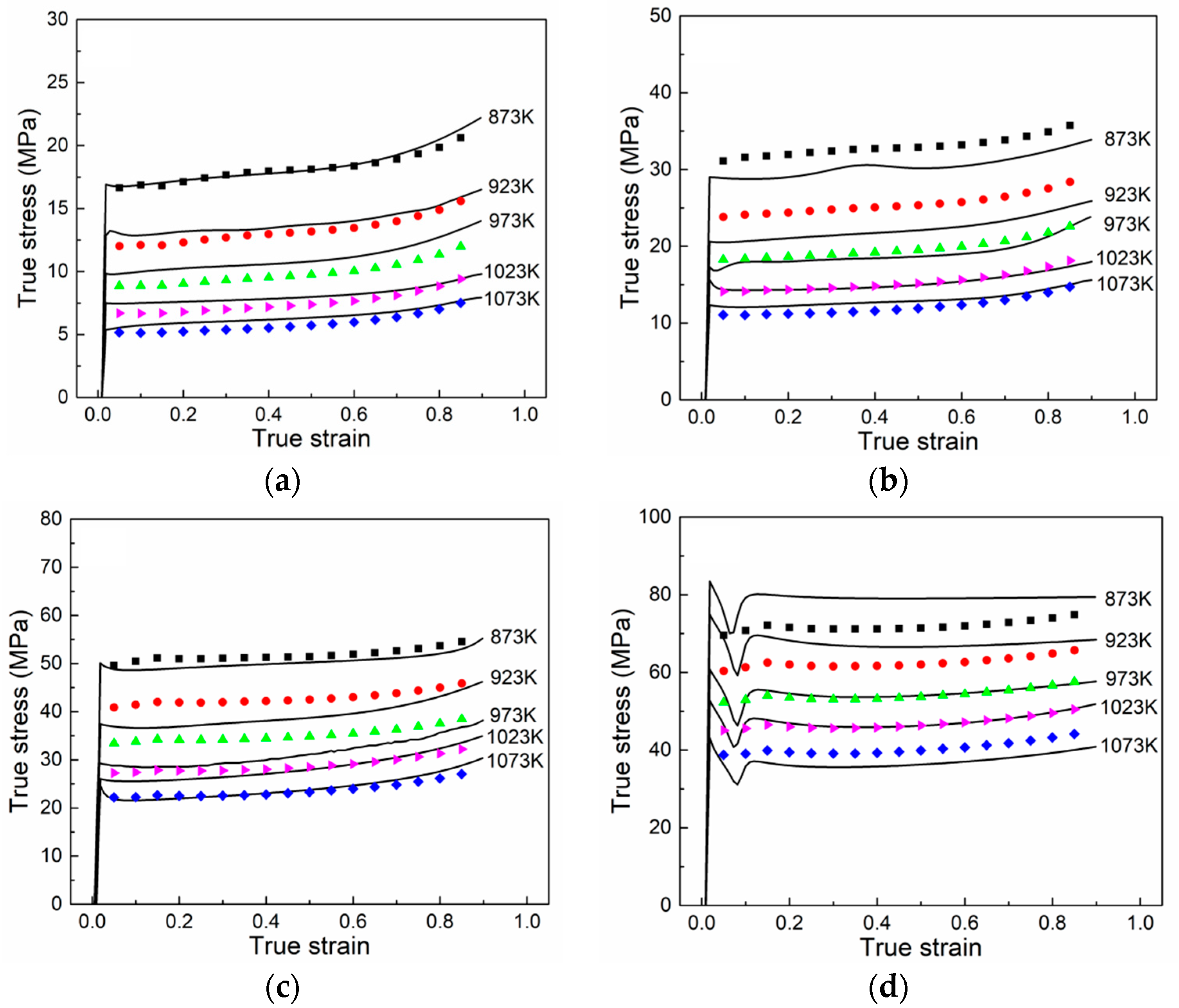

3.1. True Stress and True Strain Curves

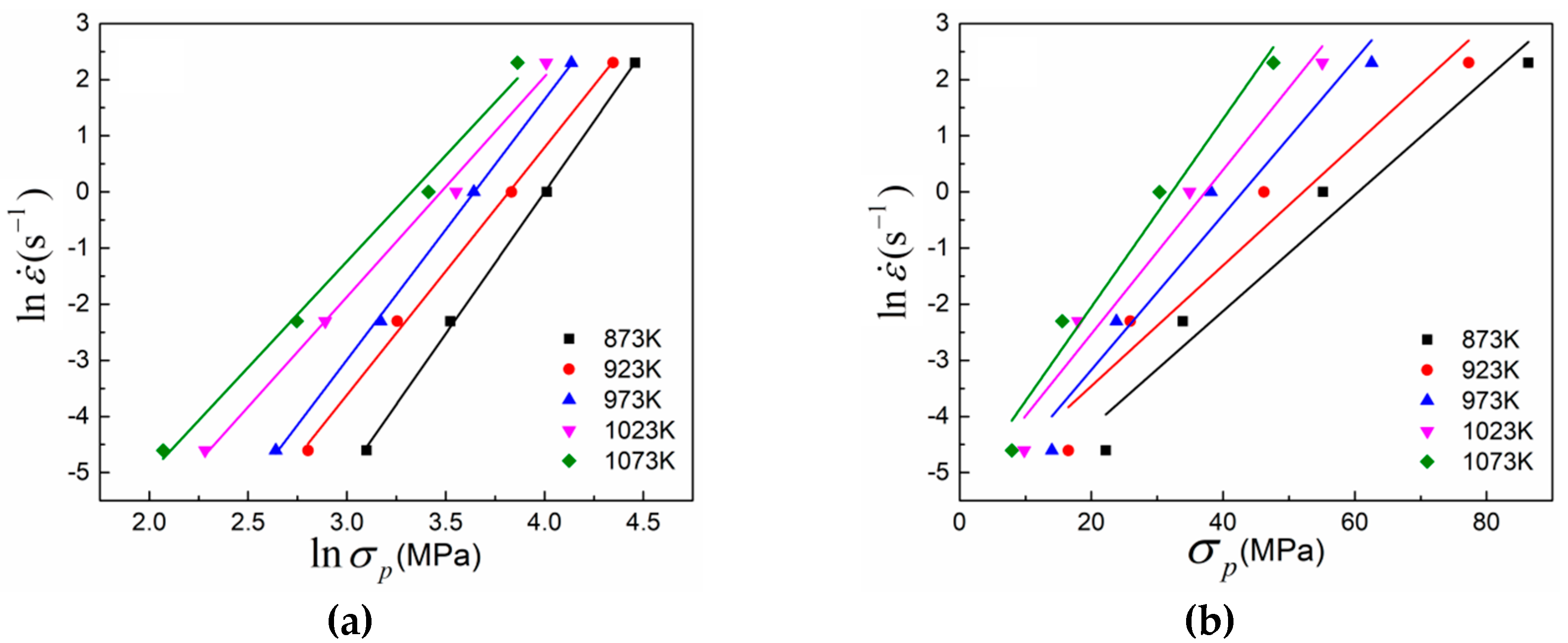

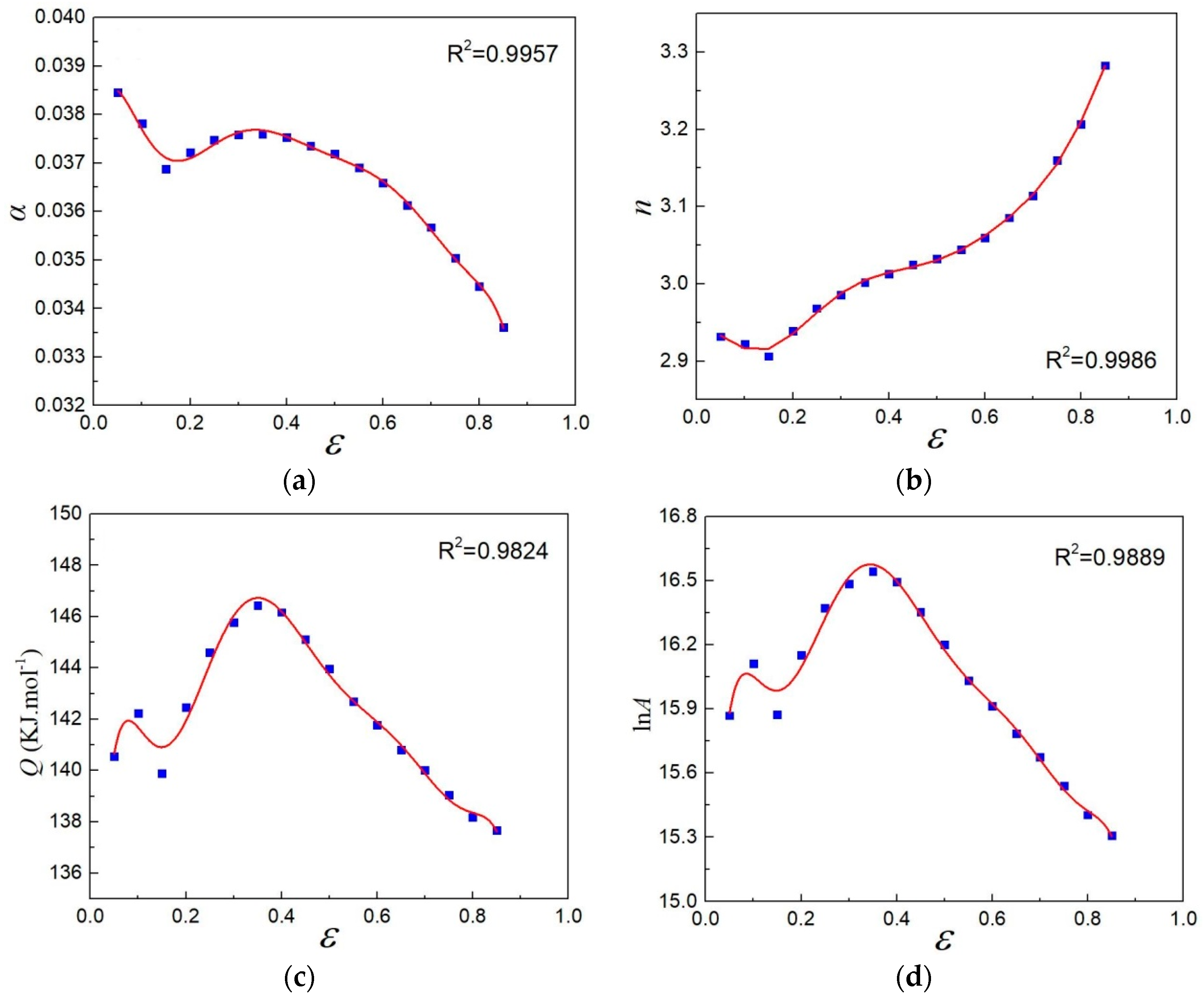

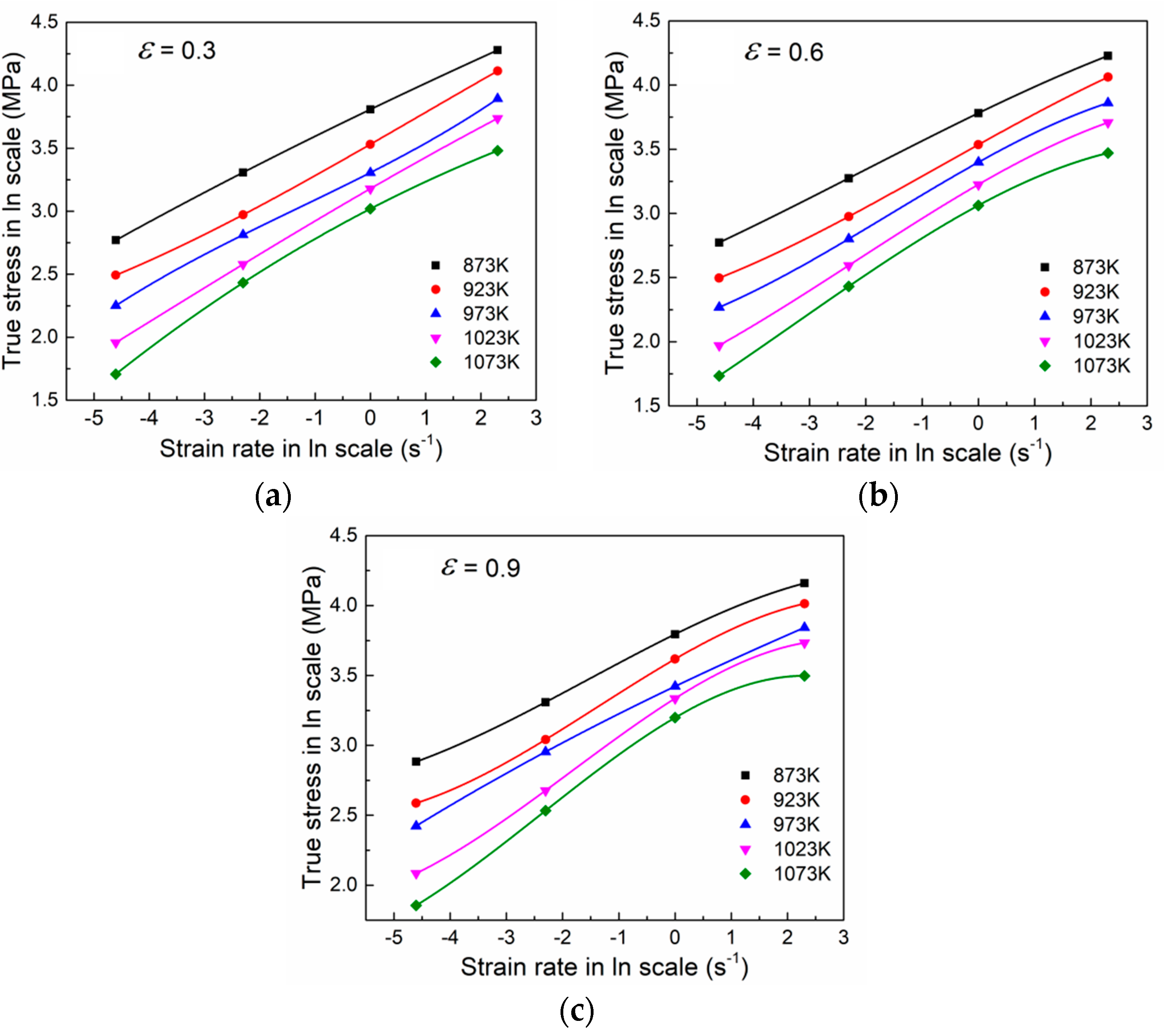

3.2. Arrhenius Model

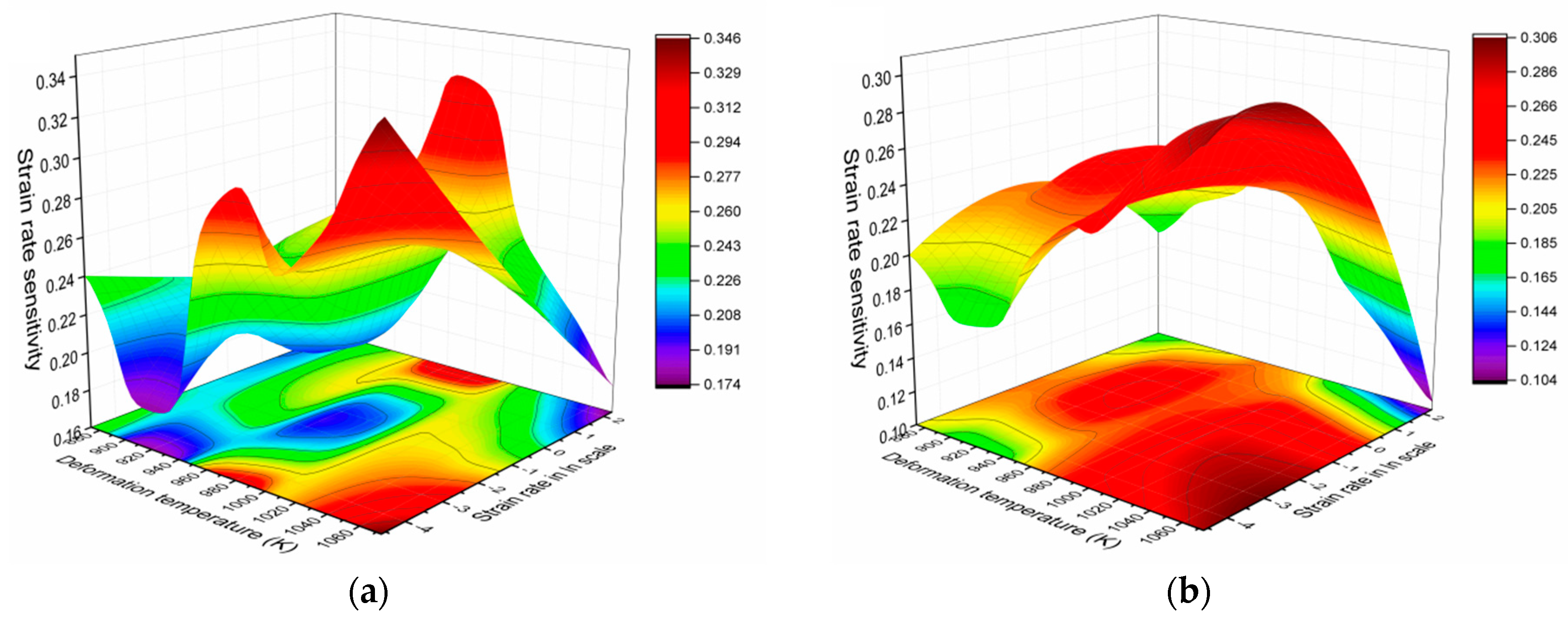

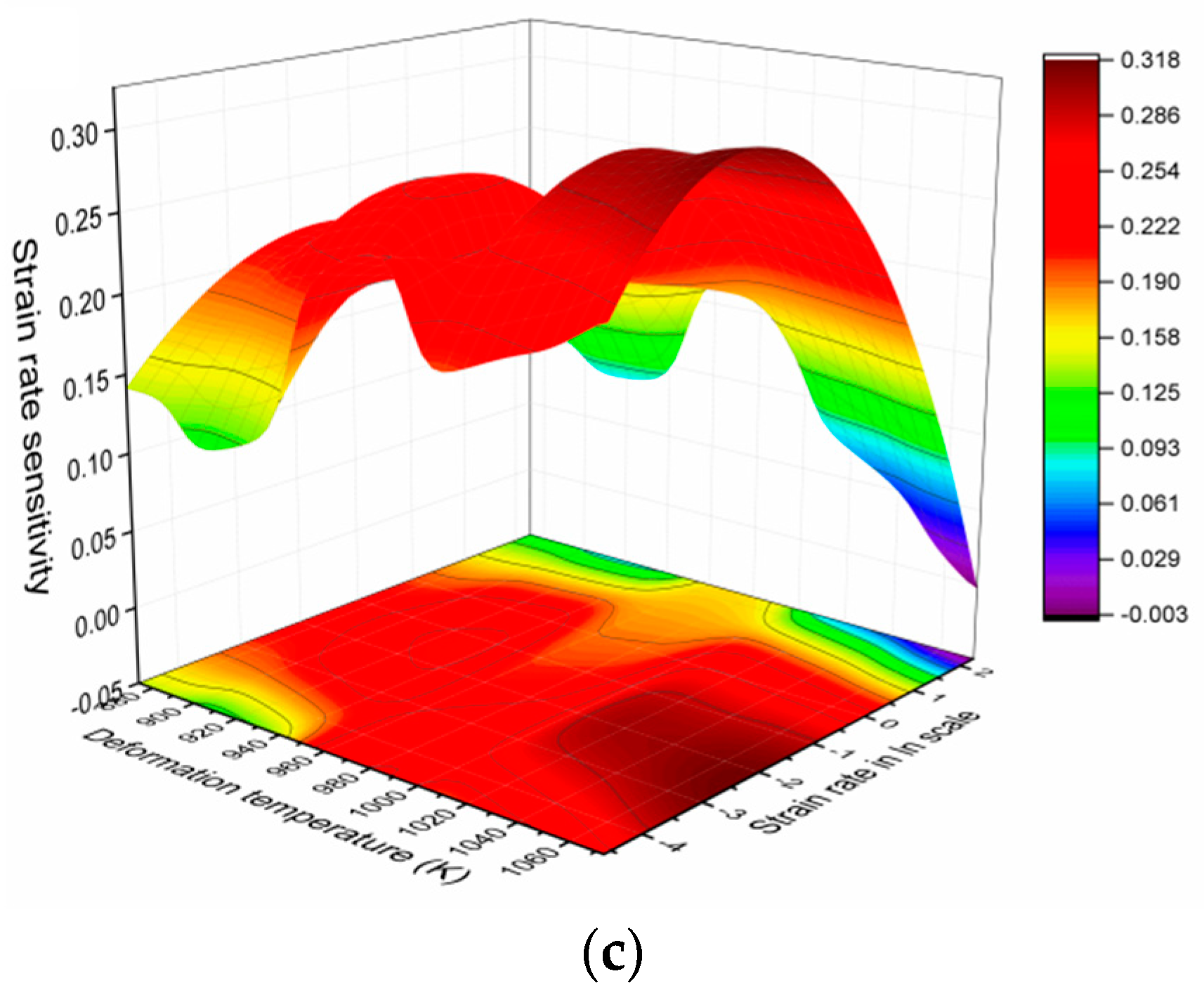

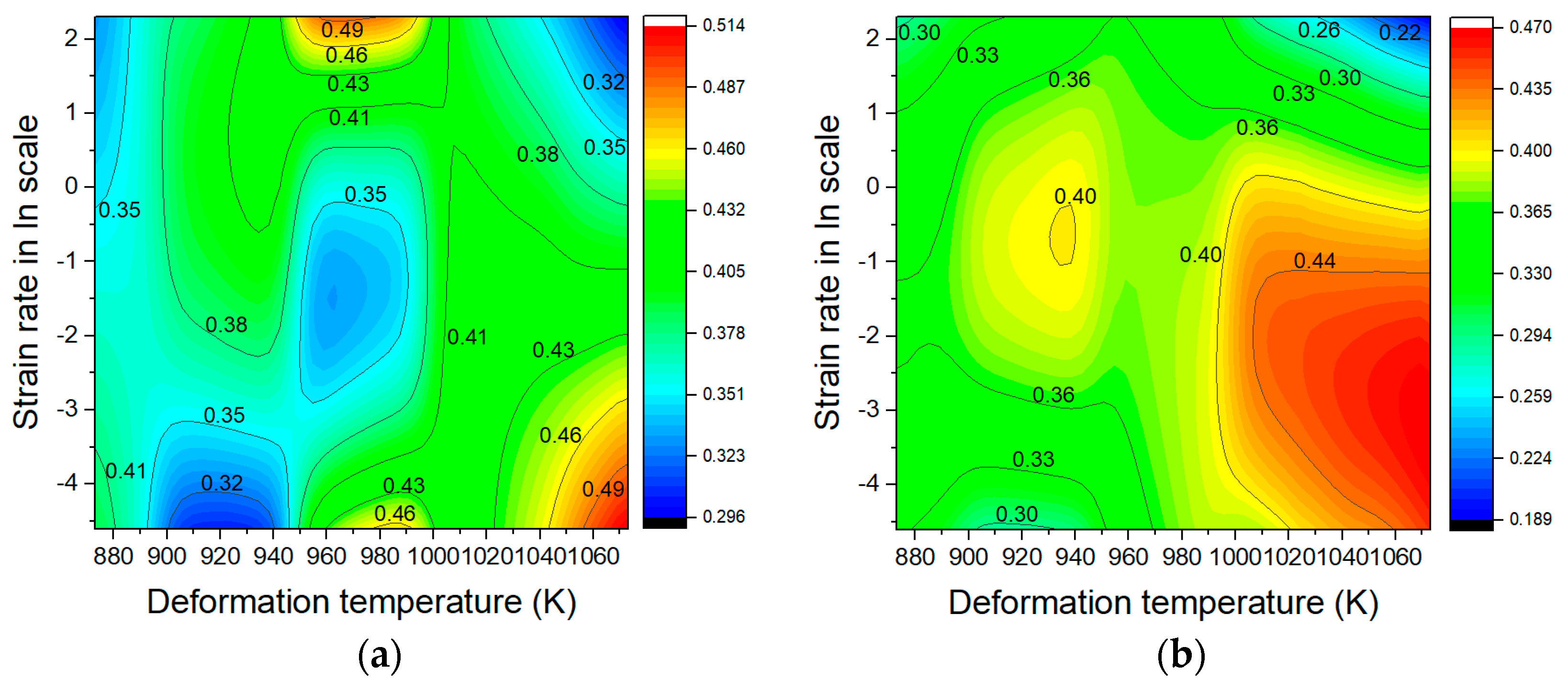

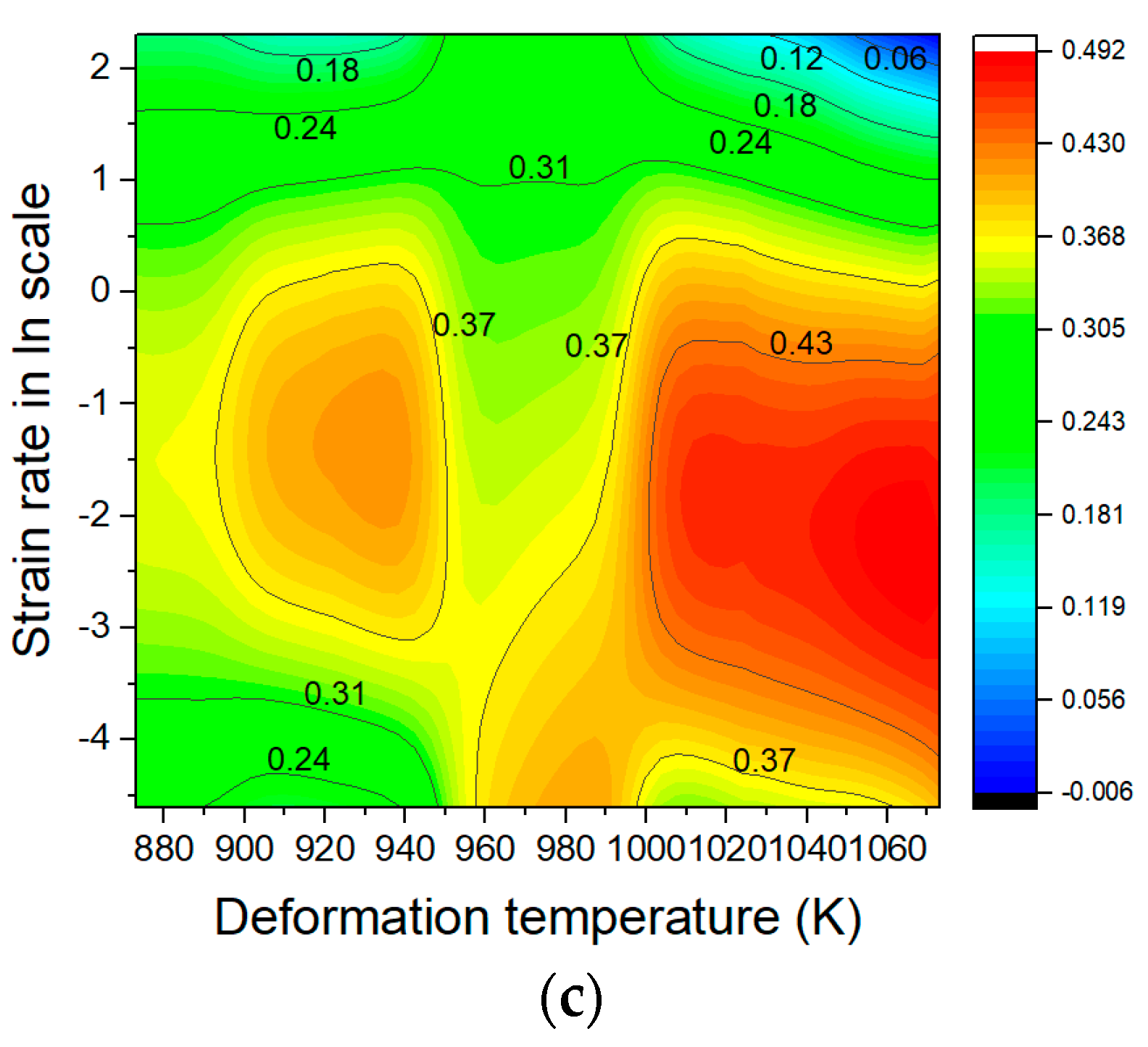

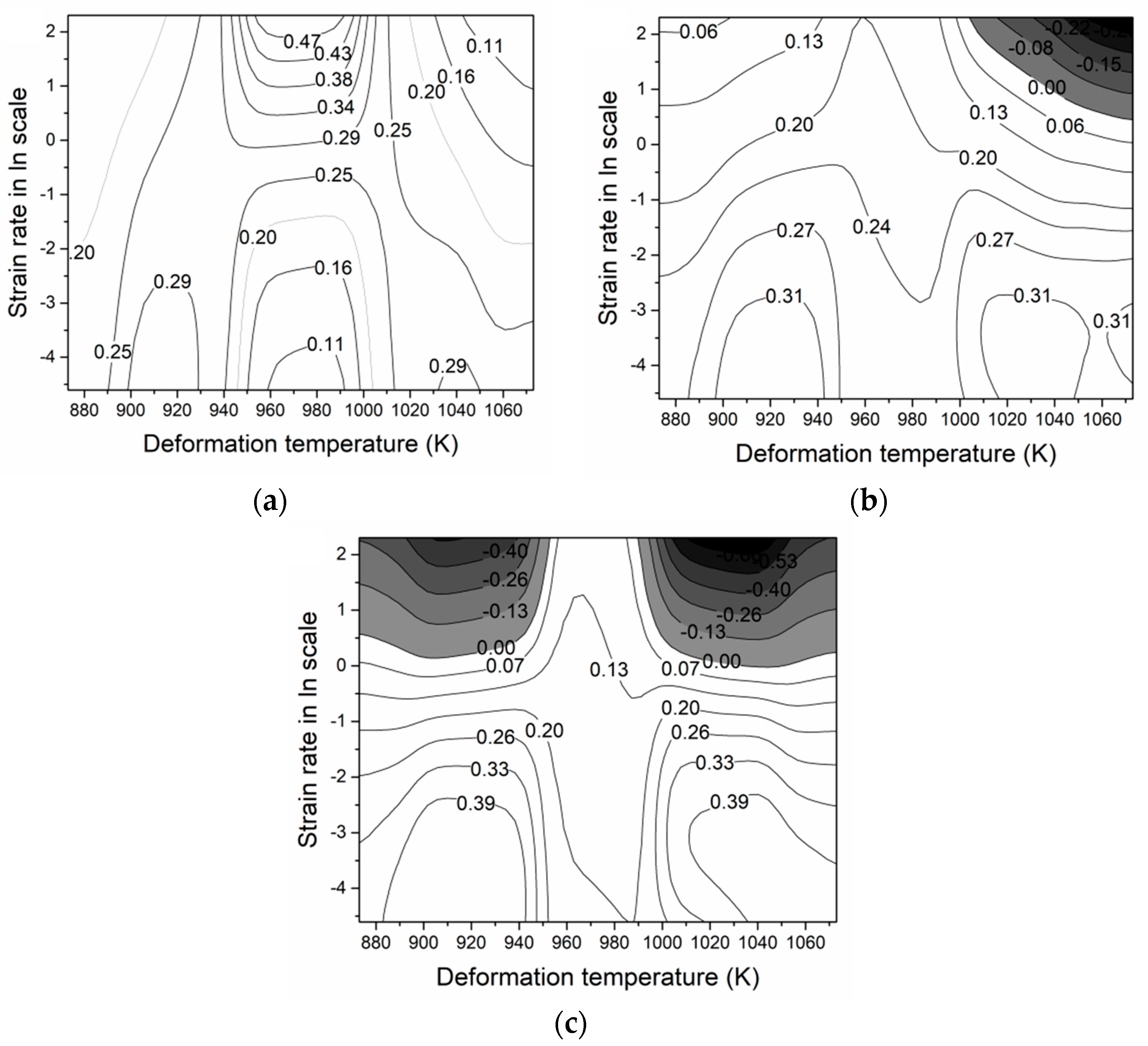

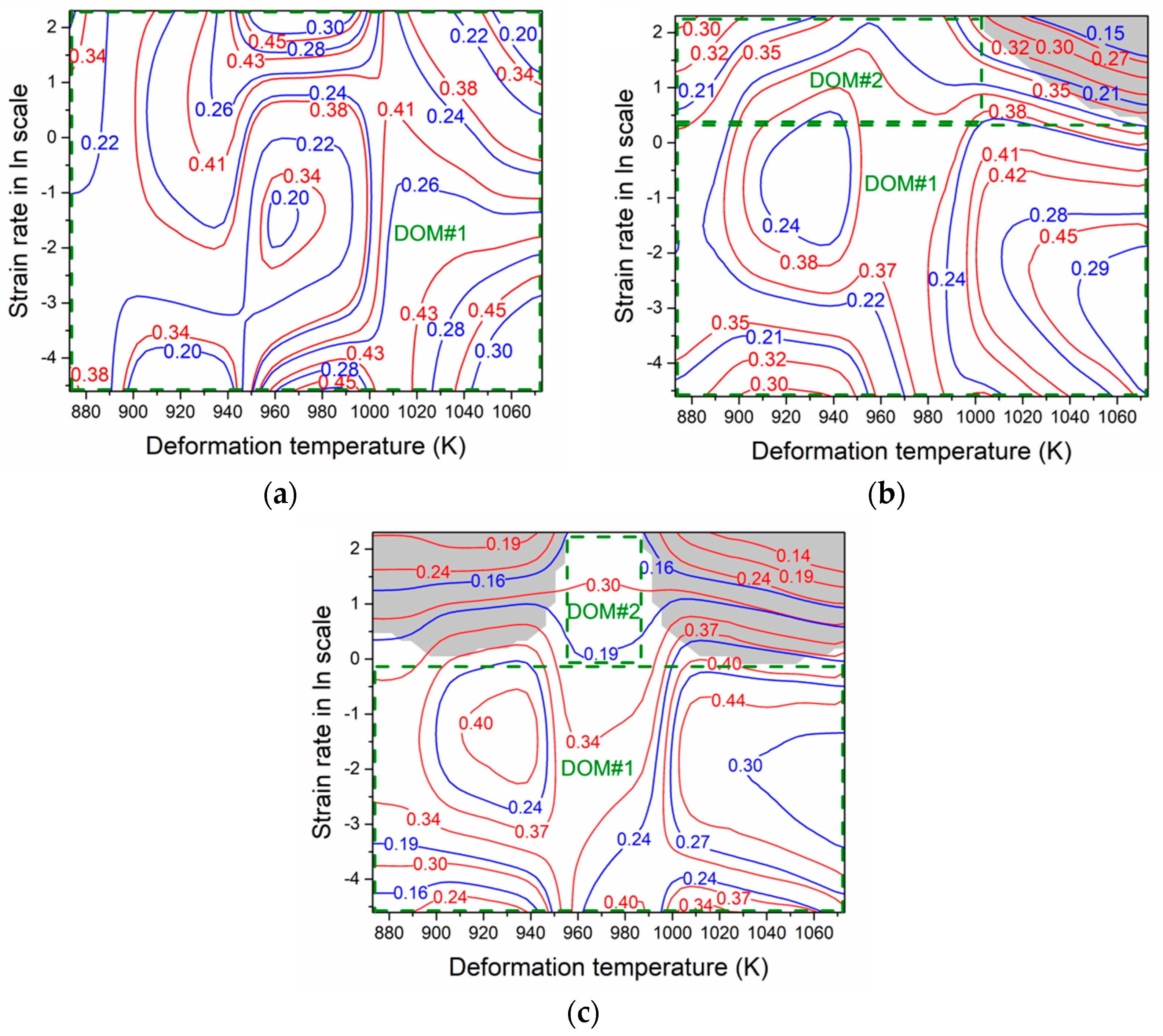

3.3. Processing Map

3.3.1. The Principle of the Processing Map

3.3.2. Construction of Processing Map

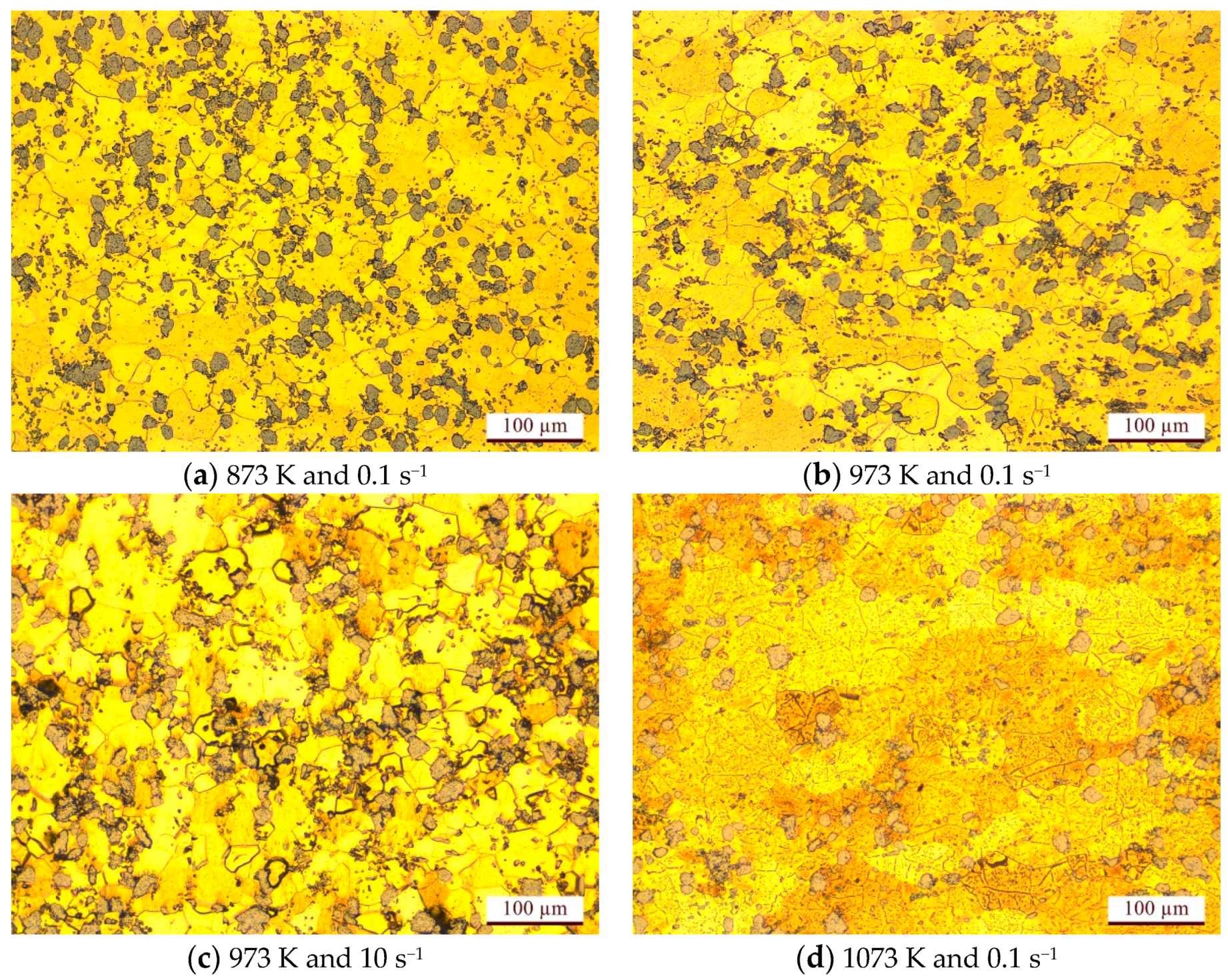

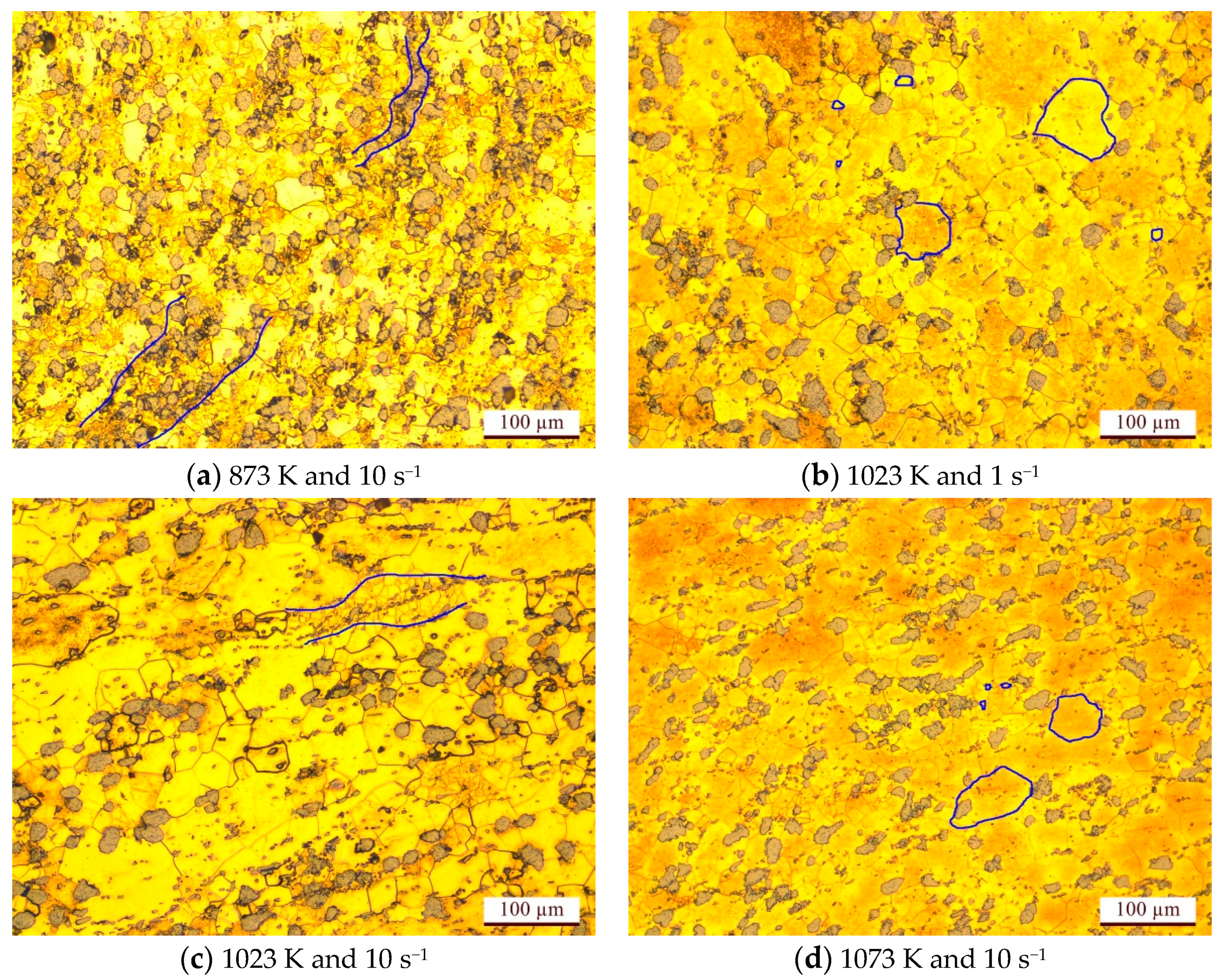

3.4. Microstructure Observations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol/Acronym | Full Name | Symbol/Acronym | Full Name |

| OM | Optical microscope | Flow stress (MPa) | |

| DMM | Dynamic material model | Strain rate (s−1) | |

| β | Brass beta-phase (bcc) | True strain | |

| R | Gas constant (8.314 J.mol-1.K-1) | A, A1, A2, n, n1, α, β, S | Material constants |

| T | Deformation temperature (K) | Q | Deformation activation energy (KJ·mol−1) |

| P | Power dissipation | G | Heat generation |

| J | Microstructural changes | Instability parameter | |

| m | Strain rate sensitivity index | η | Power dissipation index |

References

- Mindivan, H.; Çimenoǧlu, H.; Kayali, E.S. Microstructures and wear properties of brass synchroniser rings. Wear 2003, 254, 532–537. [Google Scholar] [CrossRef]

- Shufeng, L.; Hisashi, I.; Katsuyoshi, K. Microstructure, Phase Transformation, Precipitation Behavior and Mechanical Properties of P/M Cu40Zn–1.0 wt.% Ti Brass Alloy via Spark Plasma Sintering and Hot Extrusion. J. Mater. Sci. Technol. 2013, 11, 16–22. [Google Scholar]

- Padmavardhani, D.; Prasad, Y.V.R.K. Characterization of hot deformation behavior of brasses using processing maps: Part II. β Brass and α-β brass. Metall. Trans. A 1991, 22, 2993–3001. [Google Scholar] [CrossRef]

- Padmavardhani, D.; Prasad, Y.V.R.K. Effect of zinc content on the processing map for hot working of α brass. Mater. Sci. Eng., A 1992, 157, 43–51. [Google Scholar] [CrossRef]

- Pernis, R.; Kasala, J.; Bořuta, J. High temperature plastic deformation of CuZn30 brass-Calculation of the activation energy. Kovove Mater. 2010, 48, 41–46. [Google Scholar] [CrossRef]

- Spigarelli, S.; Mehtedi, M.E.; Cabibbo, M.; Gabrielli, F.; Ciccarelli, D. High temperature processing of brass: Constitutive analysis of hot working of Cu–Zn alloys. Mater. Sci. Eng., A 2014, 615, 331–339. [Google Scholar] [CrossRef]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; Kwame, J.; Aksenov, S. Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling. Materials 2019, 12, 1756. [Google Scholar] [CrossRef] [PubMed]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; Pourcelot, T.; Aksenov, S.; Kwame, J.; Portnoy, V. Modelling of the Superplastic Deformation of the Near-α Titanium Alloy (Ti-2.5Al-1.8Mn) Using Arrhenius-Type Constitutive Model and Artificial Neural Network. Metals 2017, 7, 568. [Google Scholar] [CrossRef]

- Zhi, C.; Ma, L.; Jia, W.; Huo, X.; Fan, Q.; Huang, Z.; Le, Q.; Lin, J. Dependence of deformation behaviors on temperature for twin-roll casted AZ31 alloy by processing maps. J. Mater. Res. Technol. 2019, 8, 5217–5232. [Google Scholar] [CrossRef]

- Srinivasan, N.; Prasad, Y.V.R.K.; Rama Rao, P. Hot deformation behaviour of Mg–3Al alloy—A study using processing map. Mater. Sci. Eng., A 2008, 476, 146–156. [Google Scholar] [CrossRef]

- Ding, X.; Zhao, F.; Shuang, Y.; Ma, L.; Chu, Z.; Zhao, C. Characterization of hot deformation behavior of as-extruded AZ31 alloy through kinetic analysis and processing maps. J. Mater. Process. Technol. 2020, 276, 116325. [Google Scholar] [CrossRef]

- Cheng, W.; Bai, Y.; Ma, S.; Wang, L.; Wang, H.; Yu, H. Hot deformation behavior and workability characteristic of a fine-grained Mg‒8Sn‒2Zn‒2Al alloy with processing map. J. Mater. Sci. Technol. 2019, 35, 1198–1209. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Q.; Niu, Y.; Jia, Y.; Le, Q.; Ning, S.; Hu, C.; Hu, K.; Yu, F. Comparison study of hot deformation behavior and processing map of AZ80 magnesium alloy casted with and without ultrasonic vibration. J. Alloys Compd. 2019, 803, 585–596. [Google Scholar] [CrossRef]

- Guo, Y.; Xuanyuan, Y.; Lia, C.; Sen, Y. Characterization of Hot Deformation Behavior and Processing Maps of Mg-3Sn-2Al-1Zn-5Li Magnesium Alloy. Metals 2019, 9, 1262. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, C.; Lin, Q.; Xiao, Y.; Xu, J.; Kang, W. Study on hot deformation behavior and intrinsic workability of 6063 aluminum alloys using 3D processing map. J. Alloys Compd. 2017, 713, 212–221. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Mo, Y.; Wang, H.; Xu, J. Hot deformation and processing maps of Al–Zn–Mg–Cu alloy under coupling-stirring casting. J. Mater. Res. Technol. 2019, 8, 1224–1234. [Google Scholar] [CrossRef]

- Lin, X.; Dong, F.; Zhang, Y.; Yuan, X.; Huang, H.; Zheng, B.; Wang, L.; Wang, X.; Luo, L.; Su, Y.; et al. Hot-deformation behaviour and hot-processing map of melt-hydrogenated Ti6Al4V/(TiB + TiC). Int. J. Hydrogen Energy 2019, 44, 8641–8649. [Google Scholar] [CrossRef]

- Liu, Q.; Hui, S.; Tong, K.; Yu, Y.; Ye, W.; Song, S.-Y. Investigation of high temperature behavior and processing map of Ti-6Al-4V-0.11Ru titanium alloy. J. Alloys Compd. 2019, 787, 527–536. [Google Scholar] [CrossRef]

- Long, S.; Xia, Y.-F.; Wang, P.; Zhou, Y.-T.; Gong-ye, F.-J.; Zhou, J.; Zhang, J.-S.; Cui, M.-L. Constitutive modelling, dynamic globularization behavior and processing map for Ti-6Cr-5Mo-5V-4Al alloy during hot deformation. J. Alloys Compd. 2019, 796, 65–76. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Bai, X. Constitutive modeling and processing map for hot deformation of Ti–15Mo–3Al-2.7Nb-0.2Si. J. Alloys Compd. 2019, 808, 151759. [Google Scholar] [CrossRef]

- Wu, F.; Xu, W.; Jin, X.; Zhong, X.; Wan, X.; Shan, D.; Guo, B. Study on Hot Deformation Behavior and Microstructure Evolution of Ti55 High-Temperature Titanium Alloy. Metals 2017, 7, 319. [Google Scholar]

- Srinivasa, N.; Prasad, Y.V.R.K. Hot working characteristics of nimonic 75, 80A and 90 superalloys: A comparison using processing maps. J. Mater. Process. Technol. 1995, 51, 171–192. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Li, C.; Xia, X.; Huang, Y.; Li, H.; Wang, H. Deformation behavior and processing maps of Ni3Al-based superalloy during isothermal hot compression. J. Alloys Compd. 2017, 712, 687–695. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, X.; Yang, H.; Ning, Y. The Deformation Behavior, Microstructural Mechanism, and Process Optimization of PM/Wrought Dual Superalloys for Manufacturing the Dual-Property Turbine Disc. Metals 2019, 9, 1127. [Google Scholar] [CrossRef]

- Cai, Z.; Ji, H.; Pei, W.; Tang, X.; Huang, X.; Liu, J. Hot workability, constitutive model and processing map of 3Cr23Ni8Mn3N heat resistant steel. Vacuum 2019, 165, 324–336. [Google Scholar] [CrossRef]

- Li, N.; Zhao, C.; Jiang, Z.; Zhang, H. Flow behavior and processing maps of high-strength low-alloy steel during hot compression. Mater. Charact. 2019, 153, 224–233. [Google Scholar] [CrossRef]

- Łukaszek-Sołek, A.; Krawczyk, J.; Śleboda, T.; Grelowski, J. Optimization of the hot forging parameters for 4340 steel by processing maps. J.Mater. Res. Technol. 2019, 8, 3281–3290. [Google Scholar] [CrossRef]

- Fu, X.-Y.; Bai, P.-C.; Yang, J.-C. Hot Deformation Characteristics of 18Cr-5Ni-4Cu-N Stainless Steel Using Constitutive Equation and Processing Map. Metals 2020, 10, 82. [Google Scholar] [CrossRef]

- Jeong, H.T.; Park, H.K.; Park, K.; Na, T.W.; Kim, W.J. High-temperature deformation mechanisms and processing maps of equiatomic CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2019, 756, 528–537. [Google Scholar] [CrossRef]

- Kim, W.J.; Jeong, H.T.; Park, H.K.; Park, K.; Na, T.W.; Choi, E. The effect of Al to high-temperature deformation mechanisms and processing maps of Al0.5CoCrFeMnNi high entropy alloy. J. Alloys Compd. 2019, 802, 152–165. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, P.; Tian, B.; Liu, Y.; Li, R.; Xu, Q. Hot deformation behavior and processing map of Cu-Ni-Si-P alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 2341–2347. [Google Scholar] [CrossRef]

- Lin, Y.C.; Nong, F.-Q.; Chen, X.-M.; Chen, D.-D.; Chen, M.-S. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 2017, 137, 104–114. [Google Scholar] [CrossRef]

- Quan, G.; Tong, Y.; Luo, G.; Zhou, J. A characterization for the flow behavior of 42CrMo steel. Comput. Mater. Sci. 2010, 50, 167–171. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.-S.; Zhang, J. Modeling of flow stress of 42CrMo steel under hot compression. Mater. Sci. Eng. A 2009, 499, 88–92. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.-C.; Chen, X.-M.; Chen, M.-S. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate. Comput. Mater. Sci. 2010, 50, 227–233. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P. Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300–950 °C. Mater. Sci. Eng. A 2005, 391, 141–150. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. On the development of instability criteria during hotworking with reference to IN 718. Mater. Sci. Eng. A 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Long, S.; Xia, Y.-F.; Hu, J.-C.; Zhang, J.-S.; Zhou, J.; Zhang, P.; Cui, M.-L. Hot deformation behavior and microstructure evolution of Ti-6Cr-5Mo-5V-4Al alloy during hot compression. Vacuum 2019, 160, 171–180. [Google Scholar] [CrossRef]

| Elements | Cu | Ni | Al | Si | Fe | Zn |

|---|---|---|---|---|---|---|

| Mass fraction (wt.%) | 54~56 | 6~7.3 | 3~4.3 | 2~2.5 | 0.5~1 | Rest |

| α | Value | n | Value | Q | Value | lnA | Value |

|---|---|---|---|---|---|---|---|

| B0 | 0.03728 | C0 | 2.92090 | D0 | 123.98543 | E0 | 13.94705 |

| B1 | 0.07507 | C1 | 1.20573 | D1 | 669.68819 | E1 | 75.97630 |

| B2 | −1.48702 | C2 | −29.70380 | D2 | −9346.20325 | E2 | −1031.15598 |

| B3 | 11.32611 | C3 | 253.75623 | D3 | 62,537.37801 | E3 | 6797.12177 |

| B4 | −43.91601 | C4 | −1012.34798 | D4 | −224,395.85636 | E4 | −24,157.72629 |

| B5 | 95.56359 | C5 | 2187.15643 | D5 | 459,440.69083 | E5 | 49,073.23415 |

| B6 | −118.39965 | C6 | −2644.25515 | D6 | −539,568.91491 | E6 | −57,213.34877 |

| B7 | 78.04056 | C7 | 1687.53405 | D7 | 338,812.43677 | E7 | 35,676.65667 |

| B8 | −21.24861 | C8 | −443.12339 | D8 | −88,246.43448 | E8 | −9230.40473 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Q.; Liu, X.; Li, P.; Zhang, X. Hot Deformation Behavior and Processing Map of High-Strength Nickel Brass. Metals 2020, 10, 782. https://doi.org/10.3390/met10060782

Liang Q, Liu X, Li P, Zhang X. Hot Deformation Behavior and Processing Map of High-Strength Nickel Brass. Metals. 2020; 10(6):782. https://doi.org/10.3390/met10060782

Chicago/Turabian StyleLiang, Qiang, Xin Liu, Ping Li, and Xianming Zhang. 2020. "Hot Deformation Behavior and Processing Map of High-Strength Nickel Brass" Metals 10, no. 6: 782. https://doi.org/10.3390/met10060782

APA StyleLiang, Q., Liu, X., Li, P., & Zhang, X. (2020). Hot Deformation Behavior and Processing Map of High-Strength Nickel Brass. Metals, 10(6), 782. https://doi.org/10.3390/met10060782