Effect of Gas Nitriding on Interface Adhesion and Surface Damage of CL60 Railway Wheels under Rolling Contact Conditions

Abstract

1. Introduction

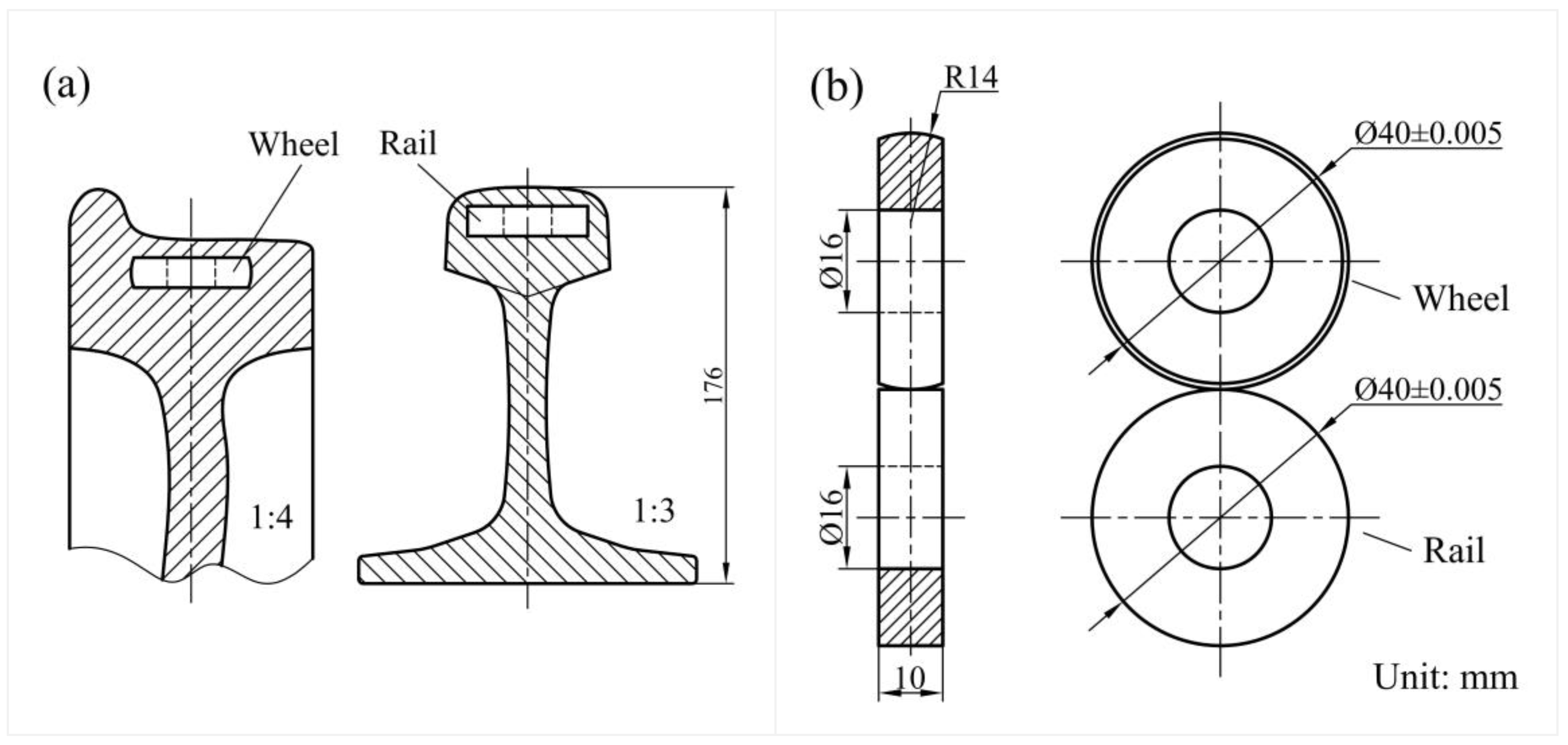

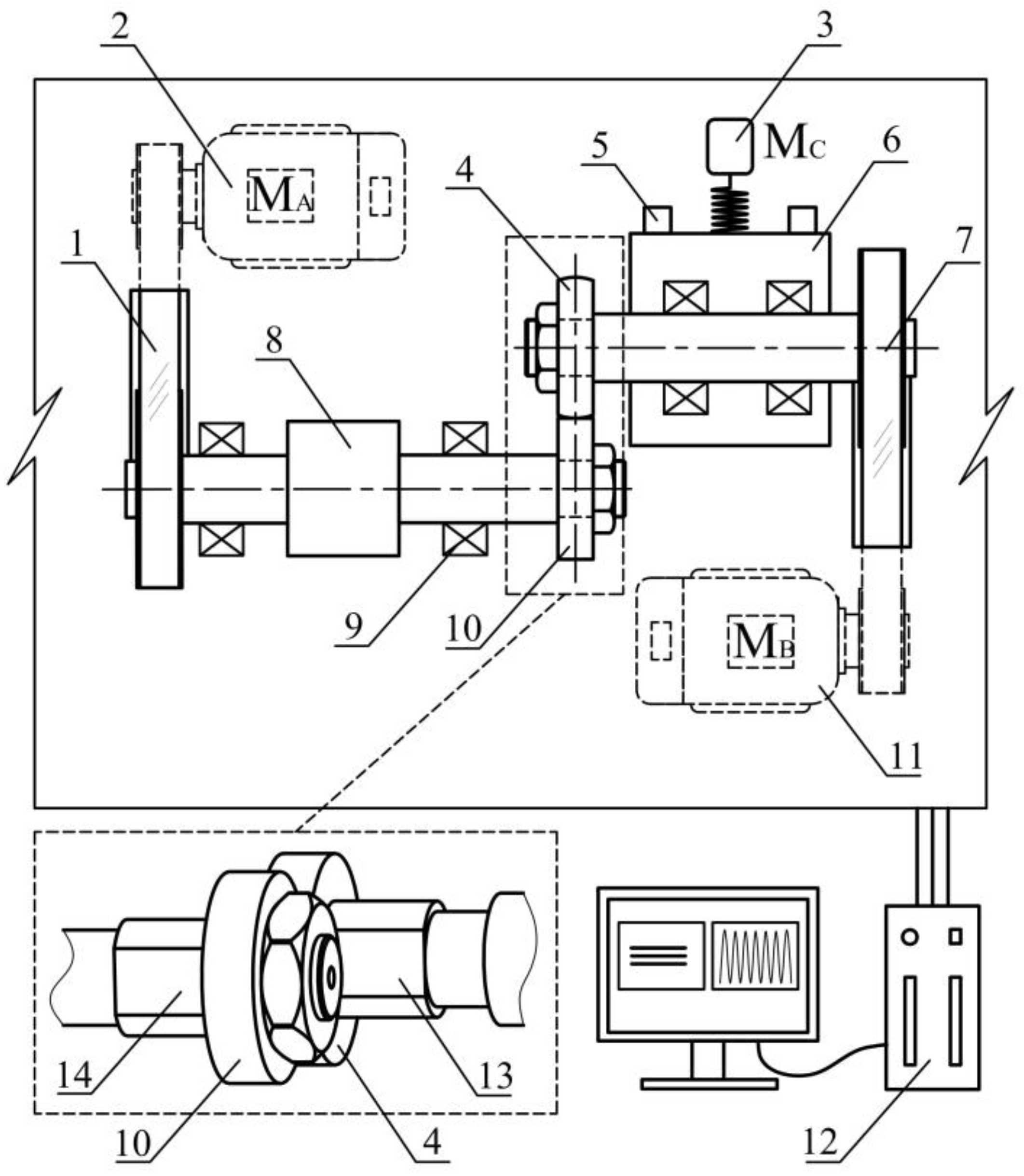

2. Materials and Methods

2.1. Test Materials

2.2. Gas Nitriding Processes

2.3. Test Method and Program

3. Results and Discussion

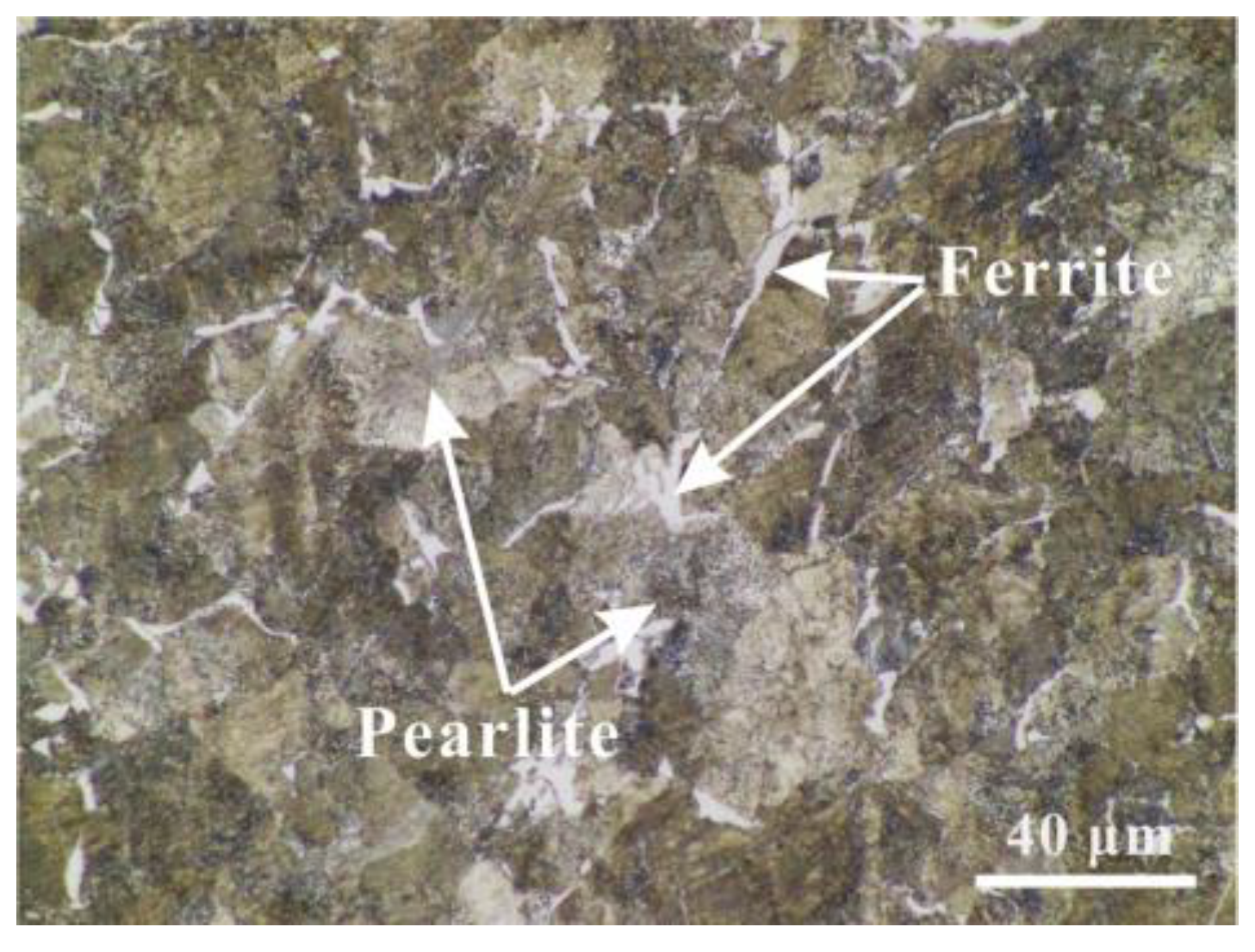

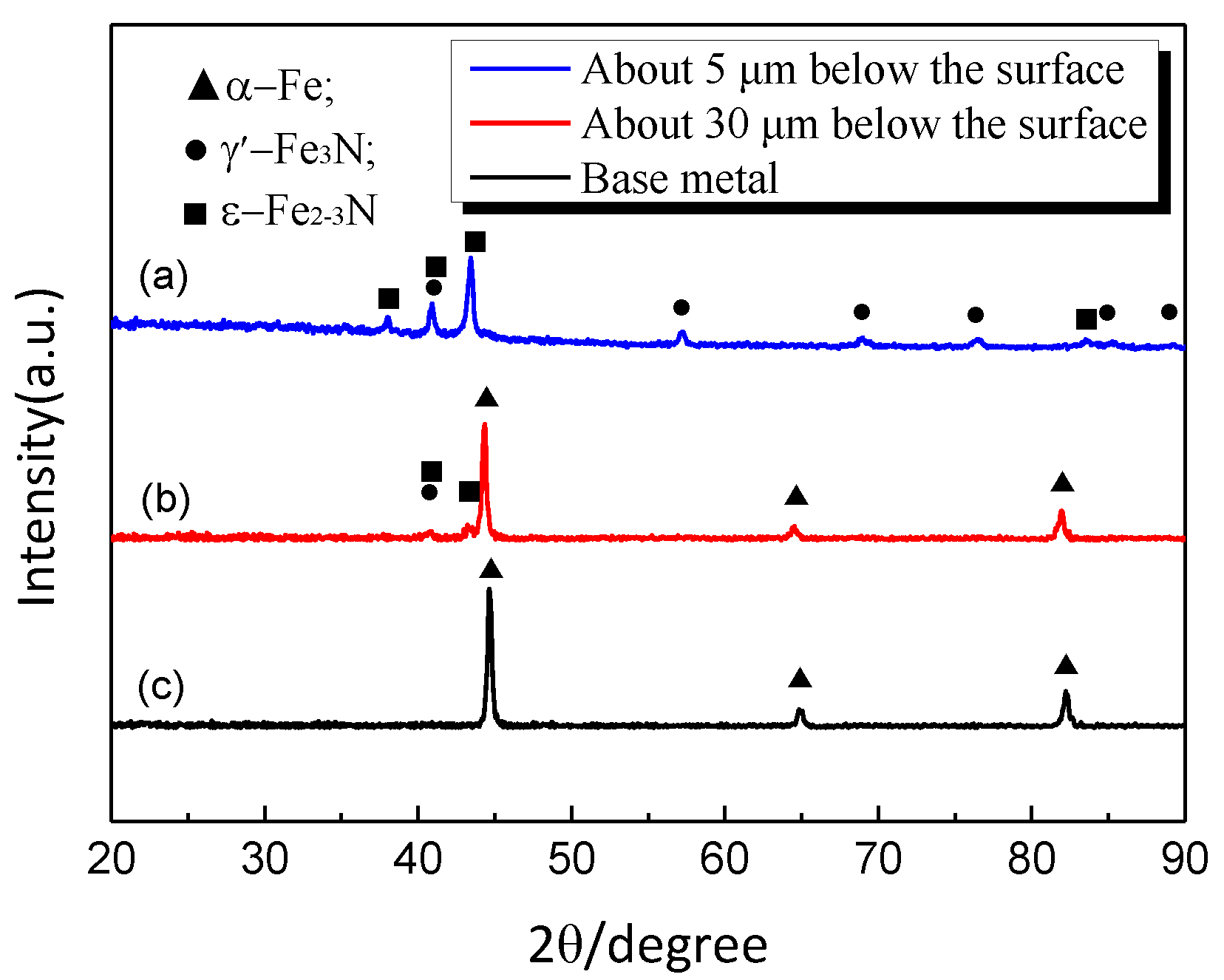

3.1. Microstructure and Mechanical Properties

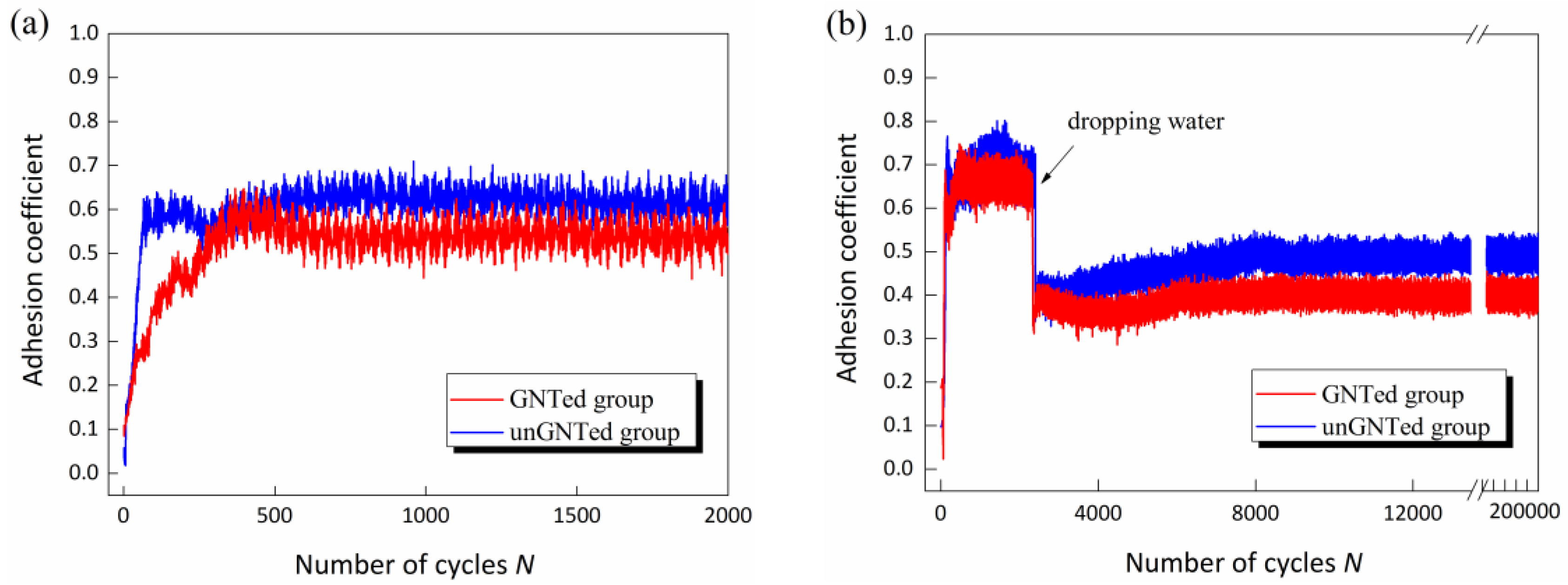

3.2. Analysis on Adhesion Characteristics of Wheel and Rail

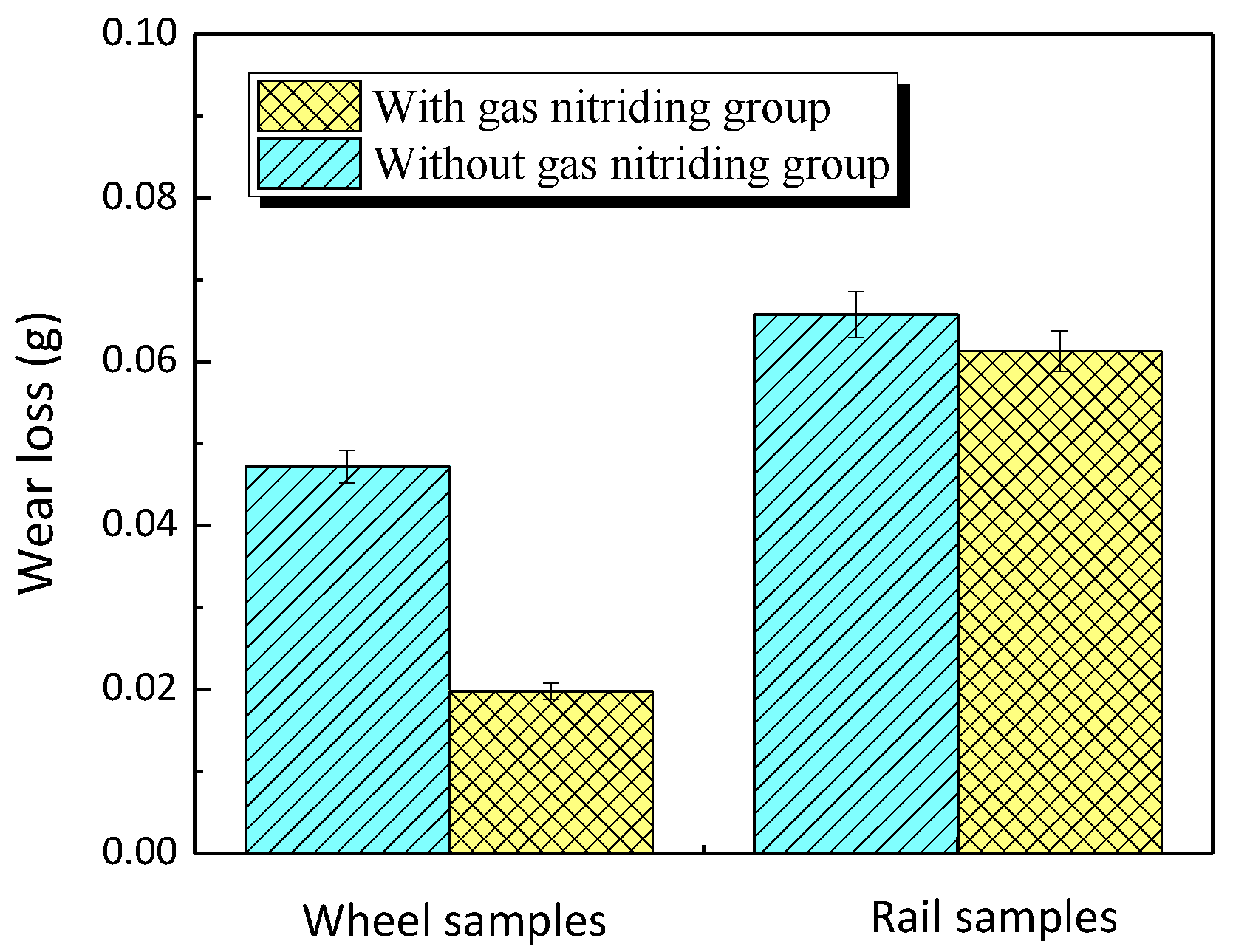

3.3. Evaluation of Wear Amount

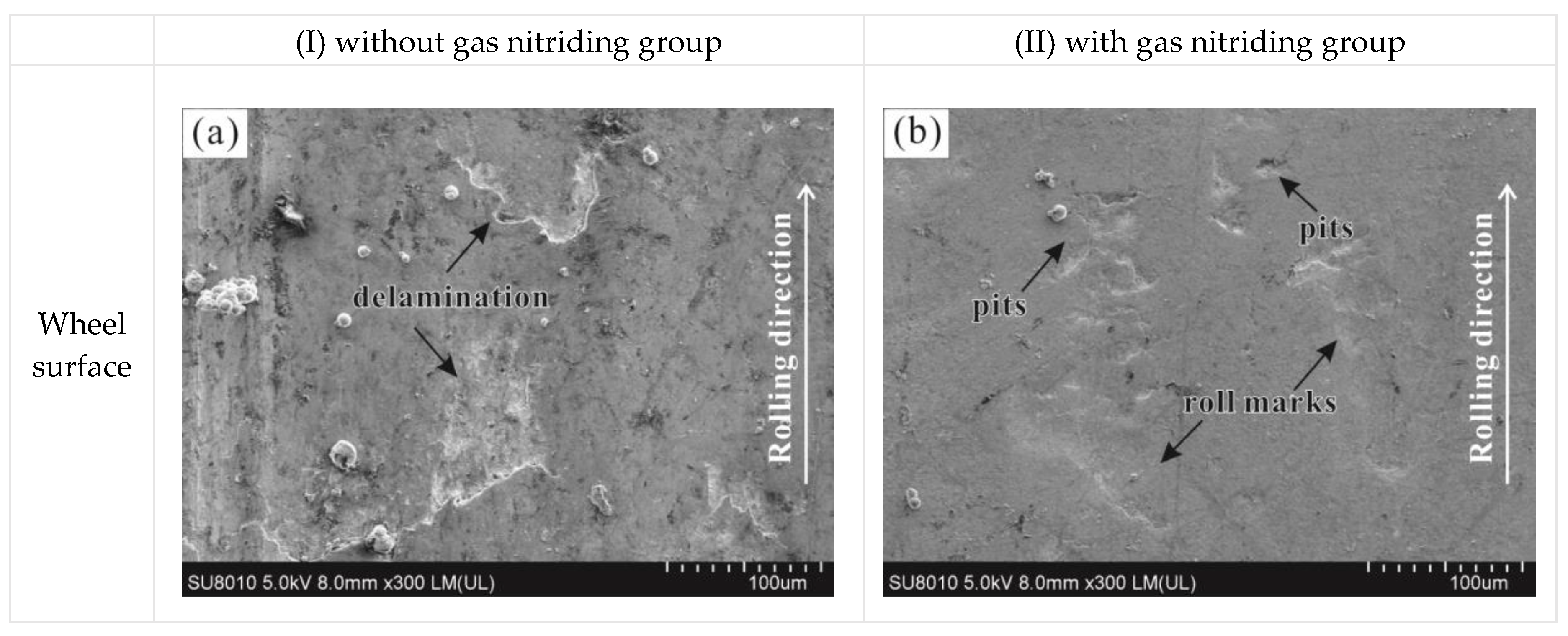

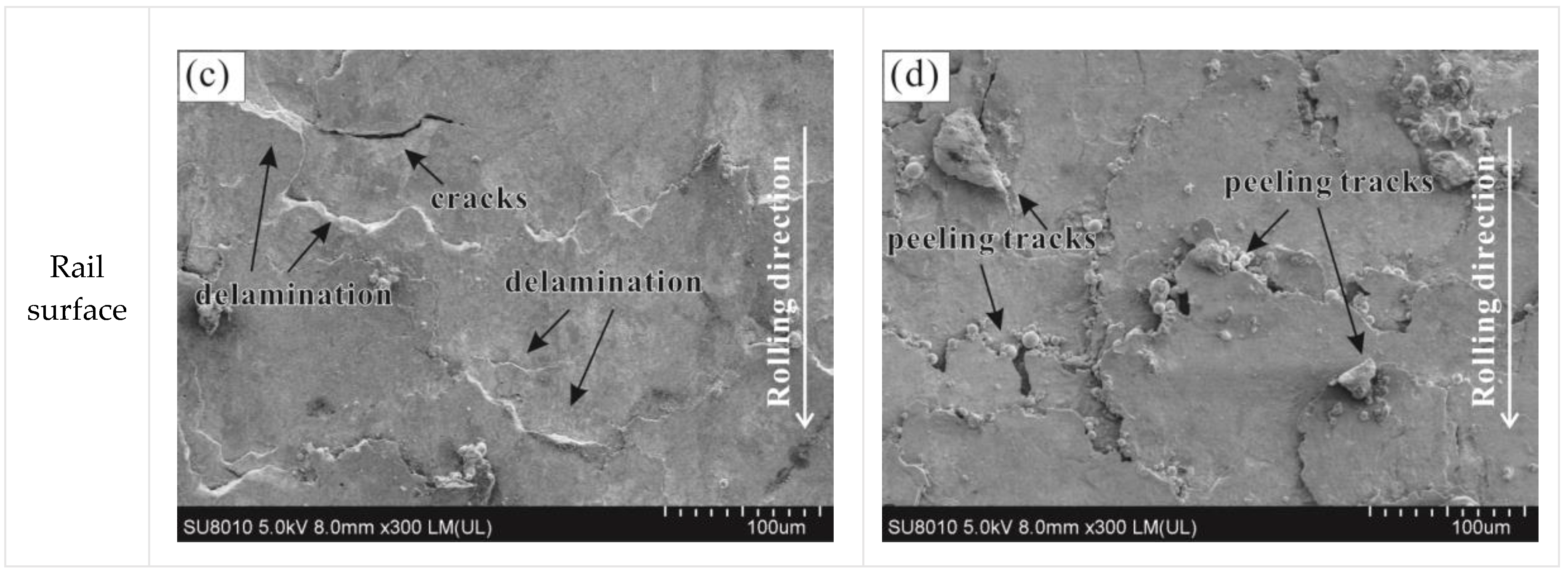

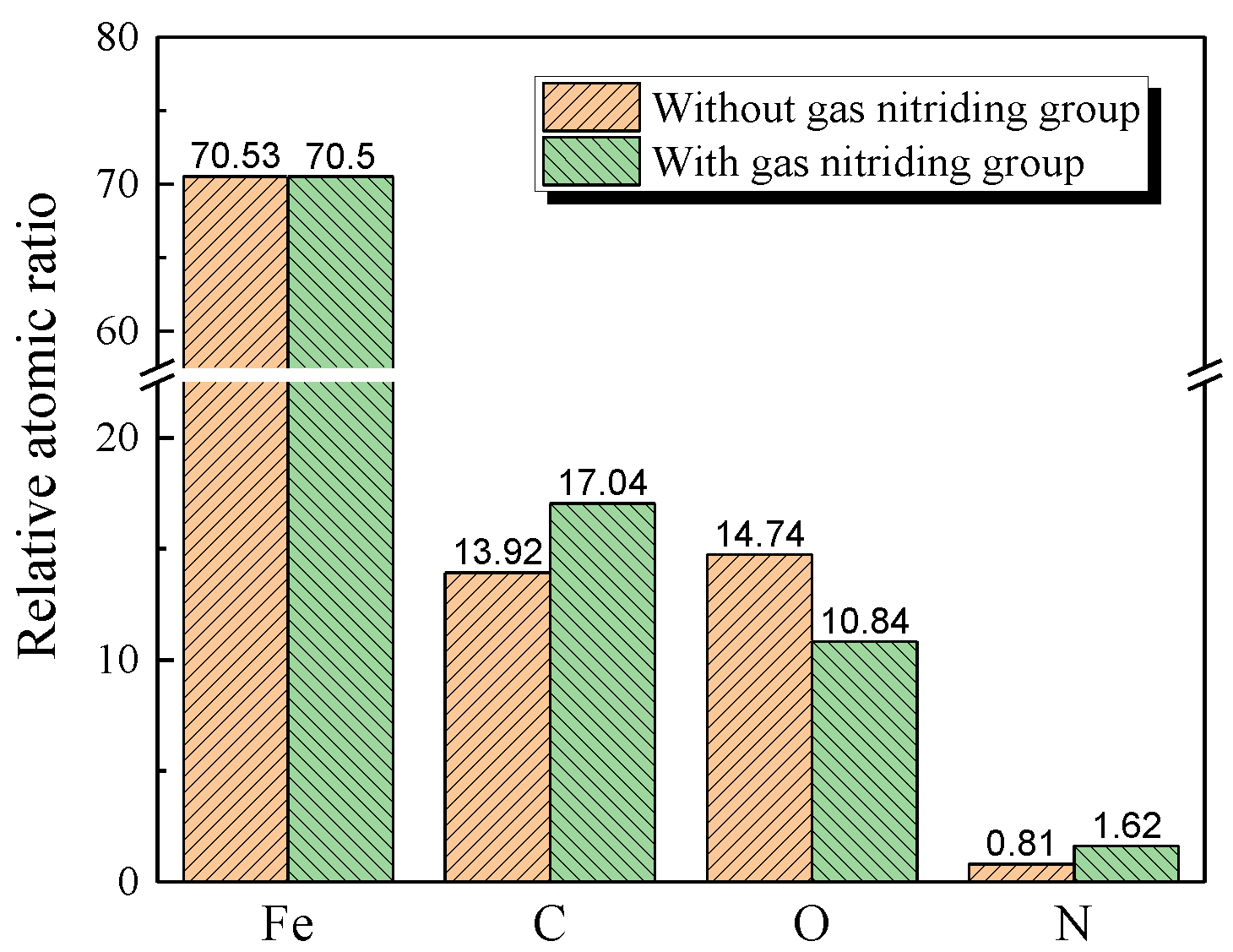

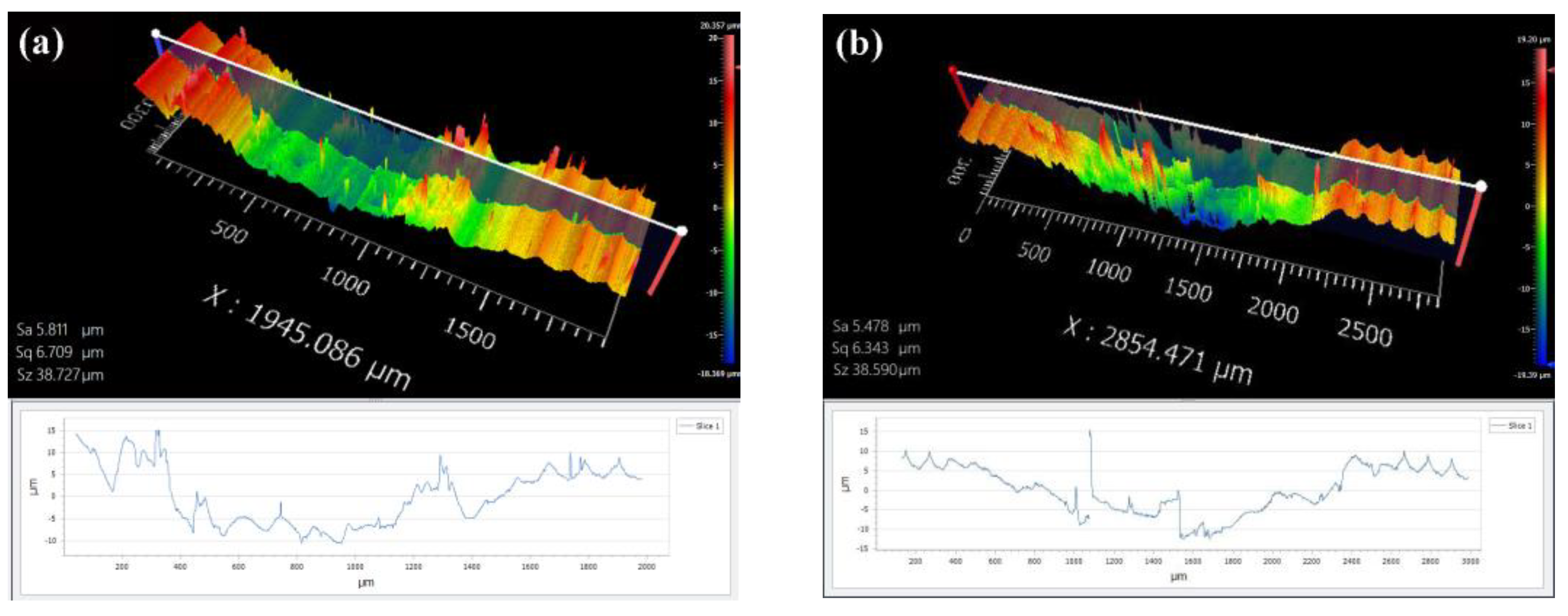

3.4. Wear Surface Morphology

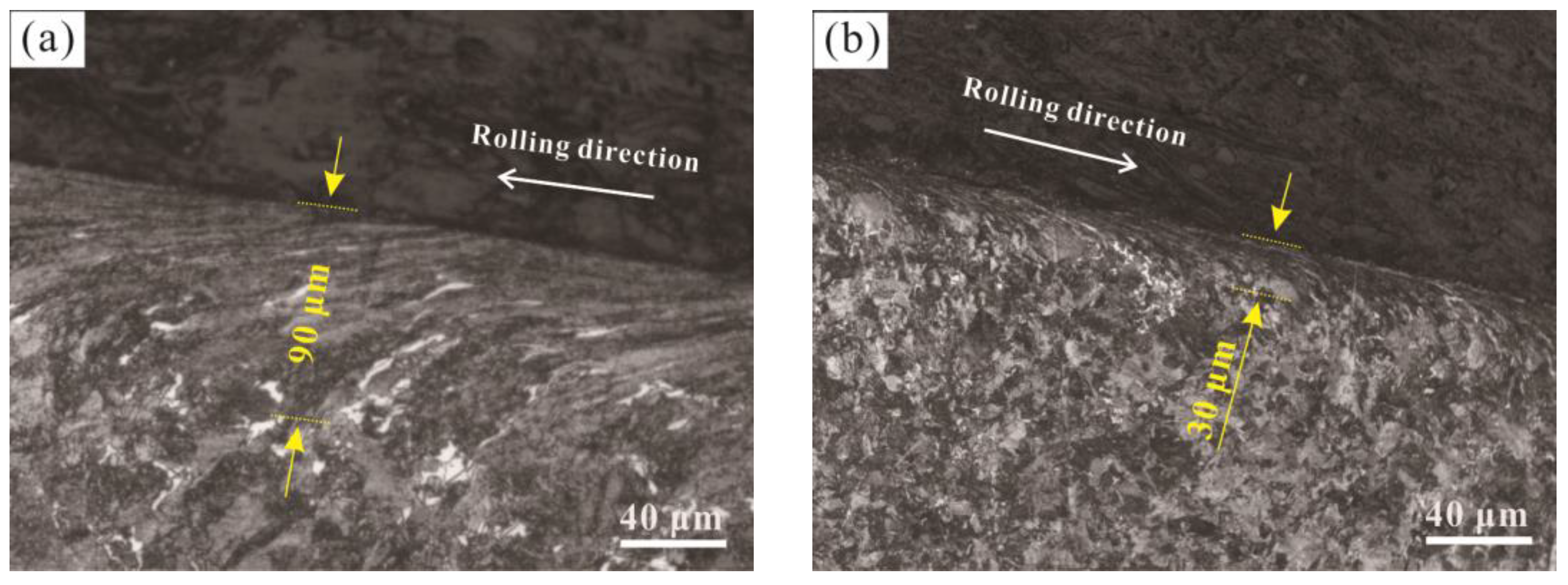

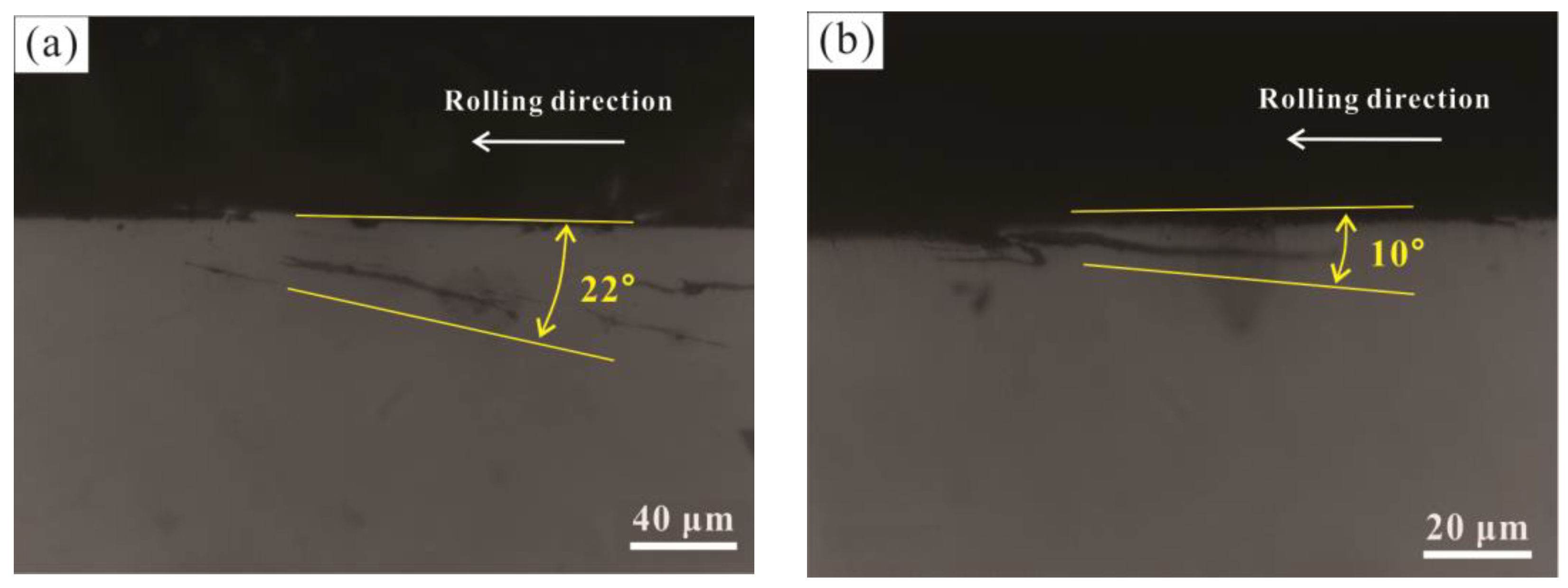

3.5. Plastic Deformation and Fatigue Crack Evaluation

4. Conclusions

- (1)

- The microhardness on the nitrided surface is improved significantly due to the formation of iron nitrides such as γ′-Fe4N and ε-Fe2–3N after gas nitriding. The compound layer consists of a white bright layer with a thickness of about 20 μm and a diffusion layer with a thickness of about 70 μm. The white bright layer was not easily corroded and had good wear resistance, and the nitrogen content of the diffusion layer gradually decreased along the depth direction. The gas nitriding could increase the surface hardness of the specimen by more than 40%.

- (2)

- The gas nitriding on the wheel surface reduced the adhesion coefficient between the wheel and the rail by 11.7% (in dry condition) and 18.4% (in water condition). However, the wheel surface with nitriding treatment could still maintain a high adhesion coefficient between the wheel and the rail, avoiding the occurrence of wheel slippage, etc. The gas nitriding on the wheel surface not only significantly improved the wear resistance of the wheel surface, but also effectively reduced the wear amount of the rail specimen, and the loss was reduced by 58.05% and 10.77%, respectively.

- (3)

- After the gas nitriding for the wheel surface, the surface peeling phenomenon was reduced, the surface damage was slight, no peeling characteristics were observed except for the indentation caused by the rolling, and the surface roughness was reduced. At the same time, the plastic deformation of the wheel surface and the crack propagation angle were reduced after gas nitriding, thus gas nitriding can effectively improve the fatigue resistance of the wheel material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hao, H.; Liu, Z.W.; Zhao, F.Q. An overview of energy efficiency standards in China’s transport sector. Renew. Sustain. Energy Rev. 2017, 67, 246–256. [Google Scholar] [CrossRef]

- Davydov, Y.; Kalikina, T.; Plyaskin, A.; Keyno, M. The Heavy Haul Train Service on the Eastern Section of the Baikal-Amur Mainline. Procedia Eng. 2017, 187, 769–774. [Google Scholar] [CrossRef]

- Wang, W.J.; Guo, H.M.; Du, X.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Investigation on the damage mechanism and prevention of heavy-haul railway rail. Eng. Fail. Anal. 2013, 35, 206–218. [Google Scholar] [CrossRef]

- Lima, E.A.; Martins, T.S.; Santos, A.A. Effect of manufacturing residual stress on the fatigue life of railway wheels for heavy-haul transportation. Procedia Struct. Integr. 2019, 17, 246–253. [Google Scholar] [CrossRef]

- Grassie, S.; Nilsson, P.; Bjurstrom, K.; Frick, A.; Hansson, L.G. Alleviation of rolling contact fatigue on Sweden’s heavy haul railway. Wear 2002, 253, 42–53. [Google Scholar] [CrossRef]

- Thairon, R.; Abreu, L.E.D.; Felipe, B.; Antunes, D.S.J.A. Progression of plastic strain on heavy-haul railway rail under random pure rolling and its influence on crack initiation. Adv. Eng. Softw. 2018, 124, 10–21. [Google Scholar]

- Zhong, W.; Hu, J.J.; Shen, P.; Wang, C.Y.; Liu, Q.Y. Experimental investigation between rolling contact fatigue and wear of high-speed and heavy-haul railway and selection of rail material. Wear 2011, 271, 2485–2493. [Google Scholar] [CrossRef]

- Smitirupa, P.; Arun, K.S.; Ranjan, B. Prediction of railway wheel wear and its influence on the vehicle dynamics in a specific operating sector of Indian railways network. Wear 2018, 406, 92–104. [Google Scholar]

- Zhu, Y.; Yang, Y.; Mu, X.; Wang, W.J.; Yao, Z.; Yang, H.Y. Study on wear and RCF performance of repaired damage railway wheels: Assessing laser cladding to repair local defects on wheels. Wear 2019, 430, 126–136. [Google Scholar] [CrossRef]

- Piao, Z.Y.; Xu, B.S.; Wang, H.D.; Yu, X.X. Rolling Contact Fatigue Behavior of Thermal-Sprayed Coating: A Review. Crit. Rev. Solid State Mater. Sci. 2019. [Google Scholar] [CrossRef]

- Roy, T.; Paradowska, A.; Abrahams, R.; Law, M.; Mutton, P.; Soodi, M.; Yan, W.Y. Residual stress in laser cladded heavy-haul rails investigated by neutron diffraction. J. Mater. Process. Technol. 2020, 278, 116511. [Google Scholar] [CrossRef]

- Meng, L.; Zhao, W.F.; Hou, K.L.; Kou, D.H.; Yuan, Z.H.; Zhang, X.; Xu, J.L.; Hu, Q.W.; Wang, D.Z.; Zeng, X.Y. A comparison of microstructure and mechanical properties of laser cladding and laser-induction hybrid cladding coatings on full-scale rail. Mater. Sci. Eng. A 2019, 748, 1–15. [Google Scholar] [CrossRef]

- Cao, X.; Shi, L.B.; Cai, Z.B.; Liu, Q.Y.; Zhou, Z.R.; Wang, W.J. Investigation on the microstructure and damage characteristics of wheel and rail materials subject to laser dispersed quenching. Appl. Surf. Sci. 2018, 450, 468–483. [Google Scholar] [CrossRef]

- Su, C.R.; Shi, L.B.; Wang, W.J.; Wang, D.Z.; Cai, Z.B.; Liu, Q.Y.; Zhou, Z.R. Investigation on the rolling wear and damage properties of laser dispersed quenched rail materials treated with different ratios. Tribol. Int. 2019, 135, 488–499. [Google Scholar] [CrossRef]

- Zhang, G.S.; Cui, H.Z.; Zhang, H.Y.; Cheng, G.Q. Micro-porous layer generated during gas nitriding and induction quenching compound treatment affects tribological properties. Tribol. Int. 2018, 120, 226–232. [Google Scholar] [CrossRef]

- Jegou, S.; Barrallier, L.; Fallot, G. Gaseous nitriding behaviour of 33CrMoV12-9 steel: Evolution of the grain boundaries precipitation and influence on residual stress development. Surf. Coat. Technol. 2018, 339, 78–90. [Google Scholar] [CrossRef]

- Zhang, J.W.; Lu, L.T.; Shiozawa, K.; Zhou, W.N.; Zhang, W.H. Effects of nitrocarburizing on fatigue property of medium carbon steel in very high cycle regime. Mater. Sci. Eng. A 2011, 528, 7060–7067. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, Y.H.; Wang, H.X.; Zhu, H.Y.; Ji, R.J.; Liu, Z.K.; Shen, Y. Research on the effect of gas nitriding treatment on the wear resistance of ball seat used in multistage fracturing. Mater. Des. 2015, 70, 45–52. [Google Scholar] [CrossRef]

- Wang, W.J.; Wang, H.; Wang, H.Y.; Guo, J.; Liu, Q.Y.; Zhu, M.H.; Jin, X.S. Sub-scale simulation and measurement of railroad wheel/rail adhesion under dry and wet conditions. Wear 2013, 302, 1461–1467. [Google Scholar] [CrossRef]

- Ding, H.H.; He, C.G.; Ma, L.; Guo, J.; Liu, Q.Y.; Wang, W.J. Wear mapping and transitions in wheel and rail materials under different contact pressure and sliding velocity conditions. Wear 2016, 352, 1–8. [Google Scholar] [CrossRef]

- Link, R.E.; Fletcher, D.I.; Beynon, J.H. Development of a Machine for Closely Controlled Rolling Contact Fatigue and Wear Testing. J. Test. Eval. 2000, 28, 267–275. [Google Scholar]

- Tjong, S.C.; Lau, K.C. Properties and abrasive wear of TiB2/Al-4% Cu composites produced by hot isostatic pressing. Compos. Sci. Technol. 1999, 59, 2005–2013. [Google Scholar] [CrossRef]

- Wang, W.J.; Lewis, R.; Evans, M.D.; Liu, Q.Y. Influence of different application of lubricants on wear and pre-existing rolling contact fatigue cracks of rail materials. Tribol. Lett. 2017, 65, 58–72. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| Wheel Rail | 0.55–0.62 0.78–0.80 | 0.55–0.70 0.95–1.0 | 0.18–0.25 0.60–0.70 | 0.035 ≤0.03 | 0.04 ≤0.03 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Qin, T.; Shen, M.; Rong, K.; Xiong, G.; Peng, J. Effect of Gas Nitriding on Interface Adhesion and Surface Damage of CL60 Railway Wheels under Rolling Contact Conditions. Metals 2020, 10, 911. https://doi.org/10.3390/met10070911

Wu Q, Qin T, Shen M, Rong K, Xiong G, Peng J. Effect of Gas Nitriding on Interface Adhesion and Surface Damage of CL60 Railway Wheels under Rolling Contact Conditions. Metals. 2020; 10(7):911. https://doi.org/10.3390/met10070911

Chicago/Turabian StyleWu, Qiang, Tao Qin, Mingxue Shen, Kangjie Rong, Guangyao Xiong, and Jinfang Peng. 2020. "Effect of Gas Nitriding on Interface Adhesion and Surface Damage of CL60 Railway Wheels under Rolling Contact Conditions" Metals 10, no. 7: 911. https://doi.org/10.3390/met10070911

APA StyleWu, Q., Qin, T., Shen, M., Rong, K., Xiong, G., & Peng, J. (2020). Effect of Gas Nitriding on Interface Adhesion and Surface Damage of CL60 Railway Wheels under Rolling Contact Conditions. Metals, 10(7), 911. https://doi.org/10.3390/met10070911