Effect of Backing Plate Materials in Micro-Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminum Alloys

Abstract

:1. Introduction

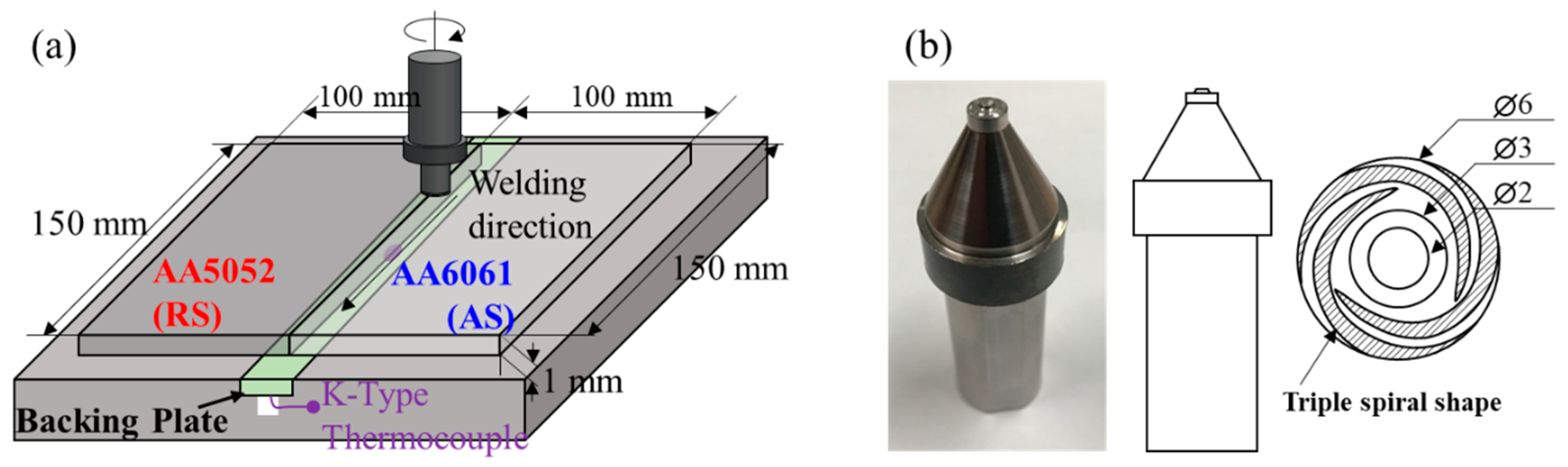

2. Materials and Methods

3. Results

3.1. Welding Temperature

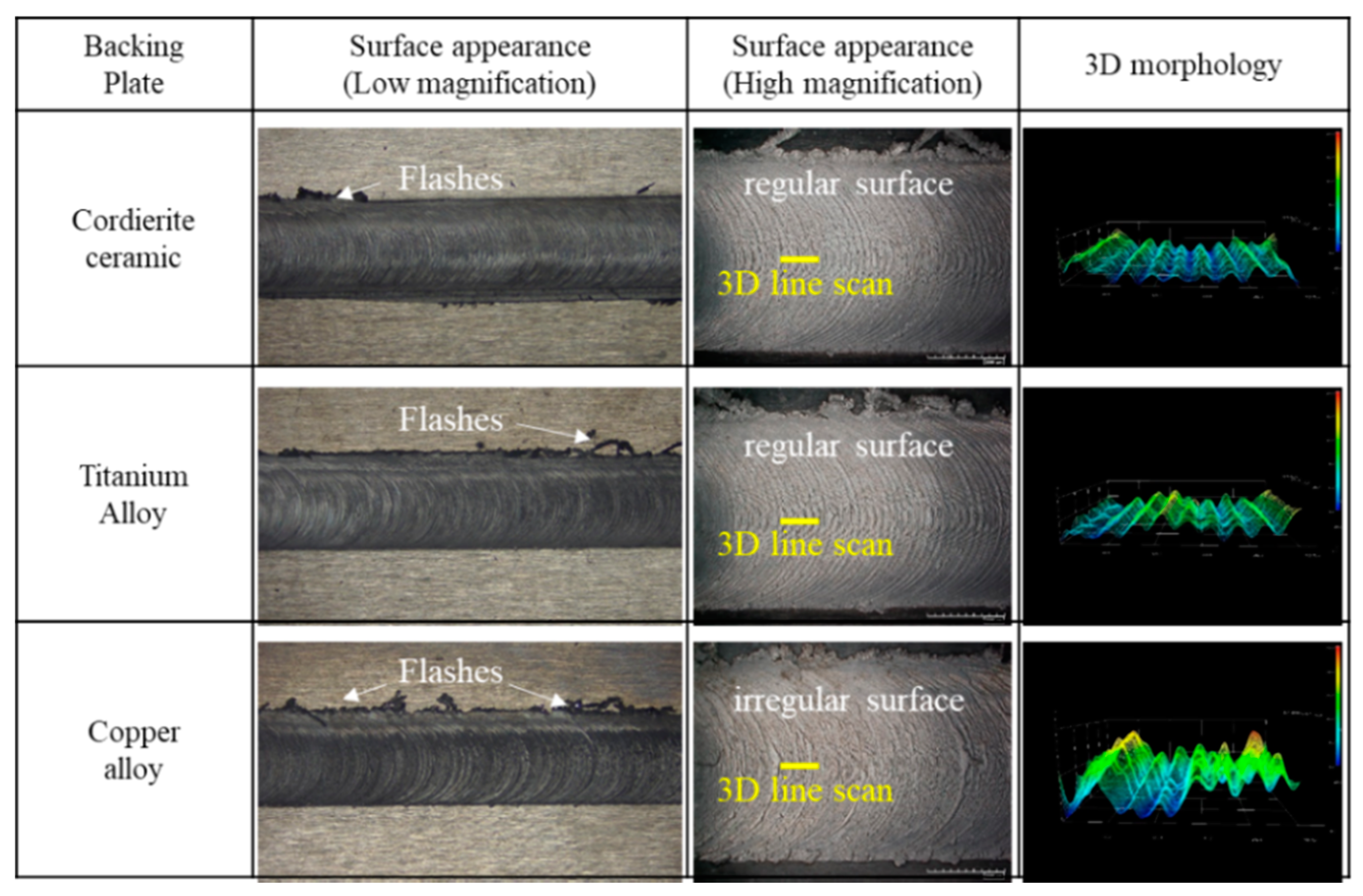

3.2. Microstructure of the Joint Surface and Cross Section

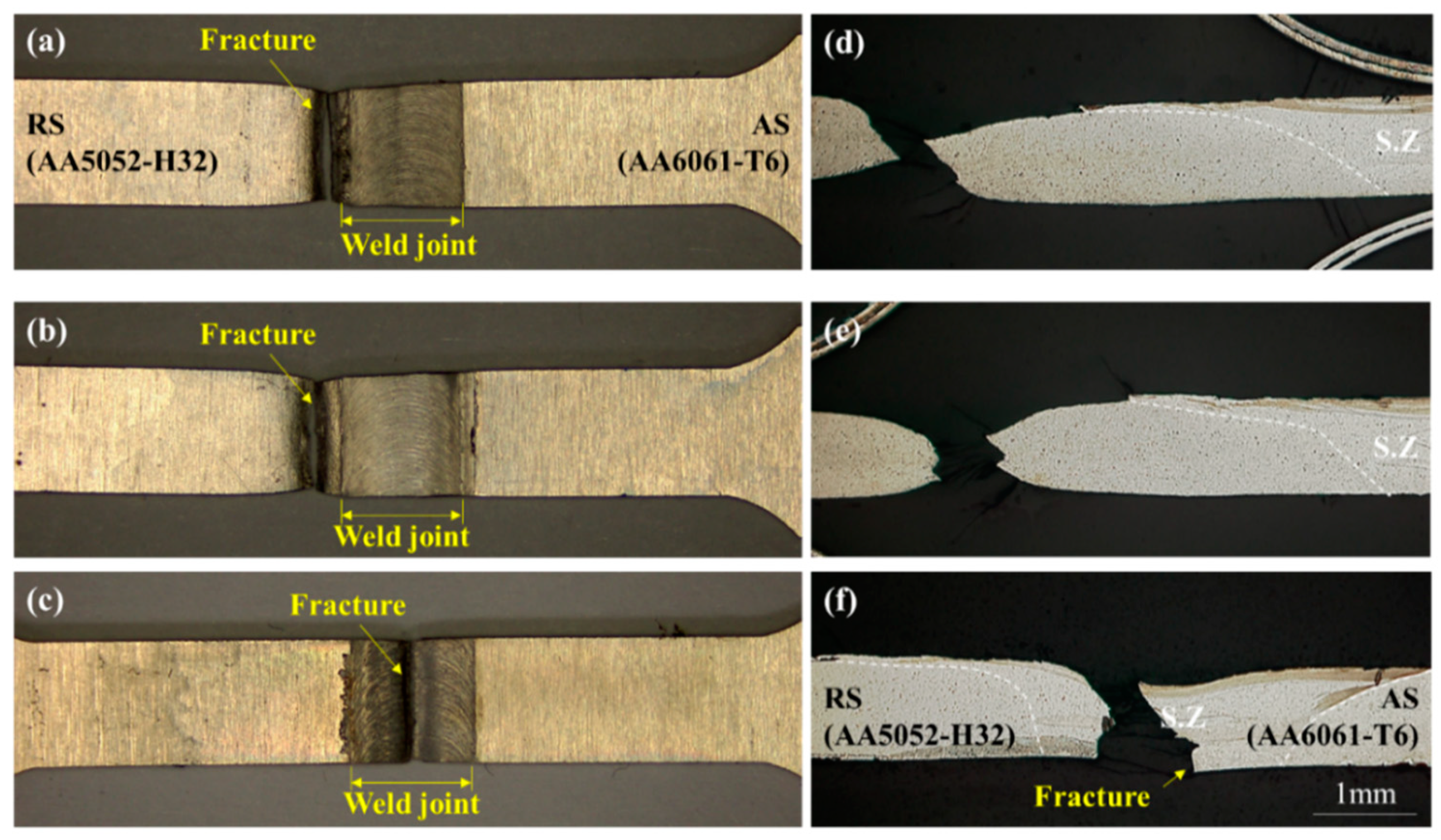

3.3. Mechanical Properties

3.4. Fractography Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huang, Y.; Meng, X.; Lu, Z.; Huang, T.; Zhang, Y.; Cao, J.; Zhou, L.; Feng, J. Microstructures and mechanical properties of micro friction stir welding (µFSW) of 6061-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 1084–1091. [Google Scholar] [CrossRef]

- Yumei, Y.; Guoqiang, W.; Kang, Y.; Baosheng, W.; Dejun, Y. Friction stir butt welding thin aluminum alloy sheets. Int. J. Adv. Manuf. Technol. 2018, 96, 3139–3147. [Google Scholar]

- Park, J.H.; Park, S.H.; Park, S.H.; Joo, Y.H.; Kang, M. Evaluation of Mechanical Properties with Tool Rotational Speed in Dissimilar Cast Aluminum and High-Strength Steel of Lap Jointed Friction Stir Welding. J. Korean Soc. Manuf. Process. Eng. 2019, 18, 90–96. [Google Scholar] [CrossRef]

- Joo, Y.H.; Park, Y.C.; Lee, Y.M.; Kim, K.H.; Kang, M.C. The Weldability of a Thin Friction Stir Welded Plate of Al5052-H32 using High Frequency Spindle. J. Korean Soc. Manuf. Process. Eng. 2017, 16, 90–95. [Google Scholar] [CrossRef]

- Sattari, S.; Bisadi, H.; Sajed, M. Mechanical properties and temperature distributions of thin friction stir welded sheets of AA5083. Int. J. Mech. Appl. 2012, 2, 1–6. [Google Scholar] [CrossRef]

- Teh, N.J.; Goddin, H.; Whitaker, A. Developments in micro applications of friction stir welding. Dense 2012, 1–18. Available online: https://www.twi-global.com/technical-knowledge/published-papers/developments-in-micro-applications-of-friction-stir-welding.

- Leitao, C.; Leal, R.; Rodrigues, D.; Loureiro, A.; Vilaca, P. Mechanical behavior of similar and dissimilar AA5182-H111 and AA6061-T4 thin friction stir welds. Mater. Des. 2009, 30, 101–108. [Google Scholar] [CrossRef] [Green Version]

- Leal, R.; Leitao, C.; Loureiro, A.; Rodrigues, D.; Vilaca, P. Material flow heterogeneous friction stir welding of thin aluminium sheets: Effect of shoulder geometry. Mater. Sci. Eng. A 2008, 498, 384–391. [Google Scholar] [CrossRef] [Green Version]

- Parwez, A.M.; Sinha, A.N. Experimental and numerical analysis of the effect of preheating in friction stir welding. Int. J. Innov. Tech. Explor. Eng. 2019, 8, 1665–1669. [Google Scholar]

- Costa, M.I.; Leitao, C.; Rodrigues, D.M. Influence of the aluminium alloy type on defects formation in friction stir lap welding of thin sheets. Soldag. Insp. 2018, 23, 32–42. [Google Scholar] [CrossRef]

- Babu, N.; Susenthirar, R.; Karunakaran, N. Microstructural and mechanical properties of solid state welded dissimilar aluminum alloy joints. Int. J. Chem. Sci. 2016, 14, 2958–2966. [Google Scholar]

- Sithole, K.; Rao, V.V. Recent developments in micro friction stir welding: A review. Mat. Sci. Eng. 2016, 114, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Upadhyay, P.; Reynolds, A.P. Effects of forge axis force and backing plate thermal diffusivity on FSW of AA6056. Mat. Sci. Eng. A. 2012, 558, 394–402. [Google Scholar] [CrossRef]

- Ghetiya, N.D.; Pate, K.M. Numerical simulation of an effect of backing plates on joint temperature and weld quality in air and immersed FSW of AA2014-T6. Int. J. Adv. Manuf. Technol. 2018, 99, 1937–1951. [Google Scholar] [CrossRef]

- Liu, F.; Fu, L.; Chen, H. Microstructure evolution and mechanical properties of high-speed friction stir welded aluminum alloy thin plate joints. J. Mat. Eng. Perform. 2018, 27, 3590–3599. [Google Scholar] [CrossRef]

- Liu, Z.; Ji, S.; Meng, X.; Huang, R. Improving joint formation and tensile properties of friction stir welded ultra-thin Al/Mg alloy sheets using a pinless tool assisted by a stationary shoulder. Int. J. Adv. Manuf. Technol. 2017, 93, 2071–2079. [Google Scholar] [CrossRef]

- Murr, L.E.; Liu, G.; McClure, J.C. A TEM study of precipitation and related microstructures in friction-stir-welded 6061 aluminium. J. Mater. Sci. 1998, 33, 1243–1251. [Google Scholar] [CrossRef]

| BP Material | Thermal Conductivity (W/(mK)) | Density (g/cm3) |

|---|---|---|

| Cordierite Ceramic | 2.3 | 2.3 |

| Titanium Alloy | 4.48 | 15.6 |

| Copper Alloy | 9.96 | 388.0 |

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| AA5052-H32 | 0.25 | 0.4 | 0.1 | 0.1 | 2.5 | 0.1 | 0.15 | Bal. |

| AA6061-T6 | 0.66 | 0.48 | 0.29 | 0.15 | 1.02 | 0.05 | 0.20 | Bal. |

| BP Material | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| Base Metal (AA6061-T6) | 306.99 | 14.08 |

| Base Metal (AA5052-H32) | 256.82 | 17.75 |

| Cordierite Ceramic | 222.63 | 10.37 |

| Titanium Alloy | 220.23 | 10.25 |

| Copper Alloy | 208.70 | 4.37 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Joo, Y.; Kang, M. Effect of Backing Plate Materials in Micro-Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminum Alloys. Metals 2020, 10, 933. https://doi.org/10.3390/met10070933

Park S, Joo Y, Kang M. Effect of Backing Plate Materials in Micro-Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminum Alloys. Metals. 2020; 10(7):933. https://doi.org/10.3390/met10070933

Chicago/Turabian StylePark, SeongHwan, YoungHwan Joo, and Myungchang Kang. 2020. "Effect of Backing Plate Materials in Micro-Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminum Alloys" Metals 10, no. 7: 933. https://doi.org/10.3390/met10070933

APA StylePark, S., Joo, Y., & Kang, M. (2020). Effect of Backing Plate Materials in Micro-Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminum Alloys. Metals, 10(7), 933. https://doi.org/10.3390/met10070933