Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components

Abstract

:1. Introduction

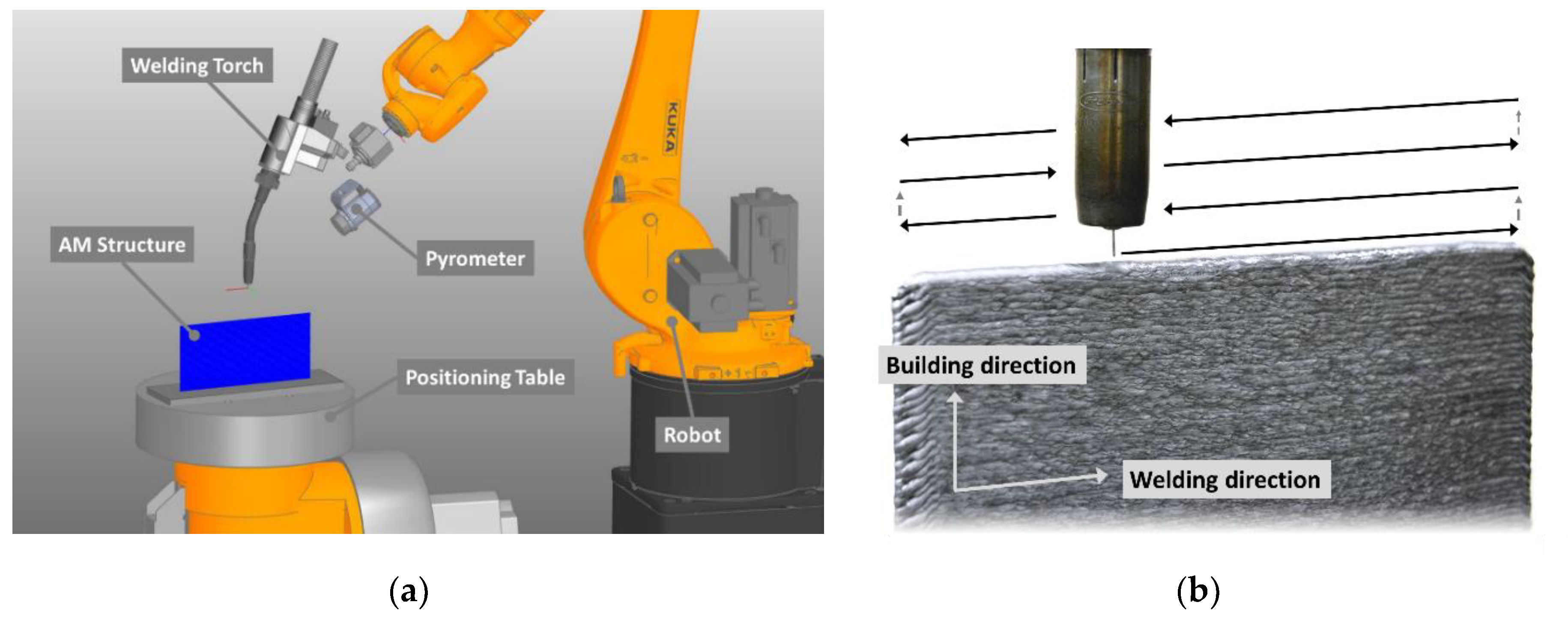

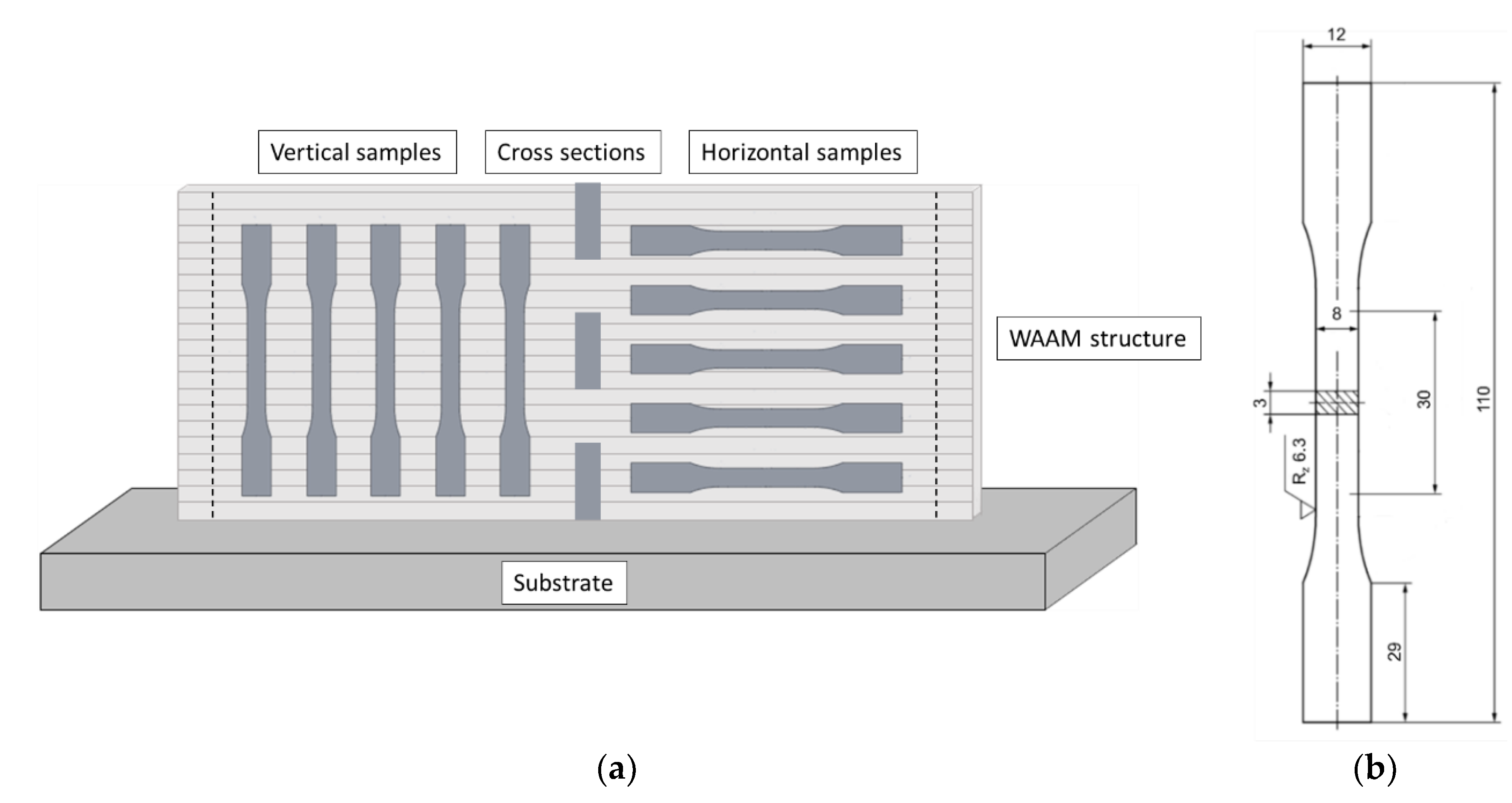

2. Materials and Methods

3. Results

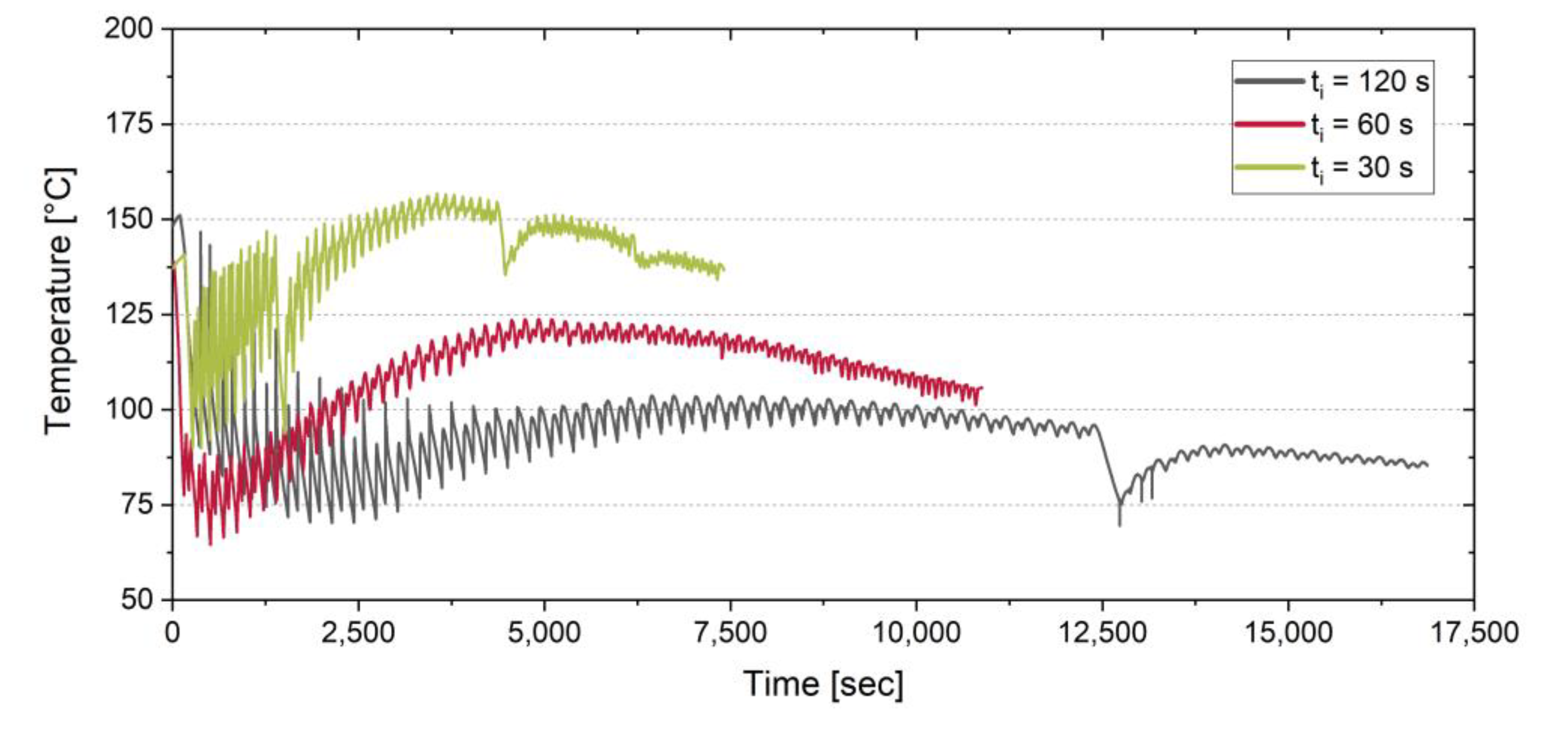

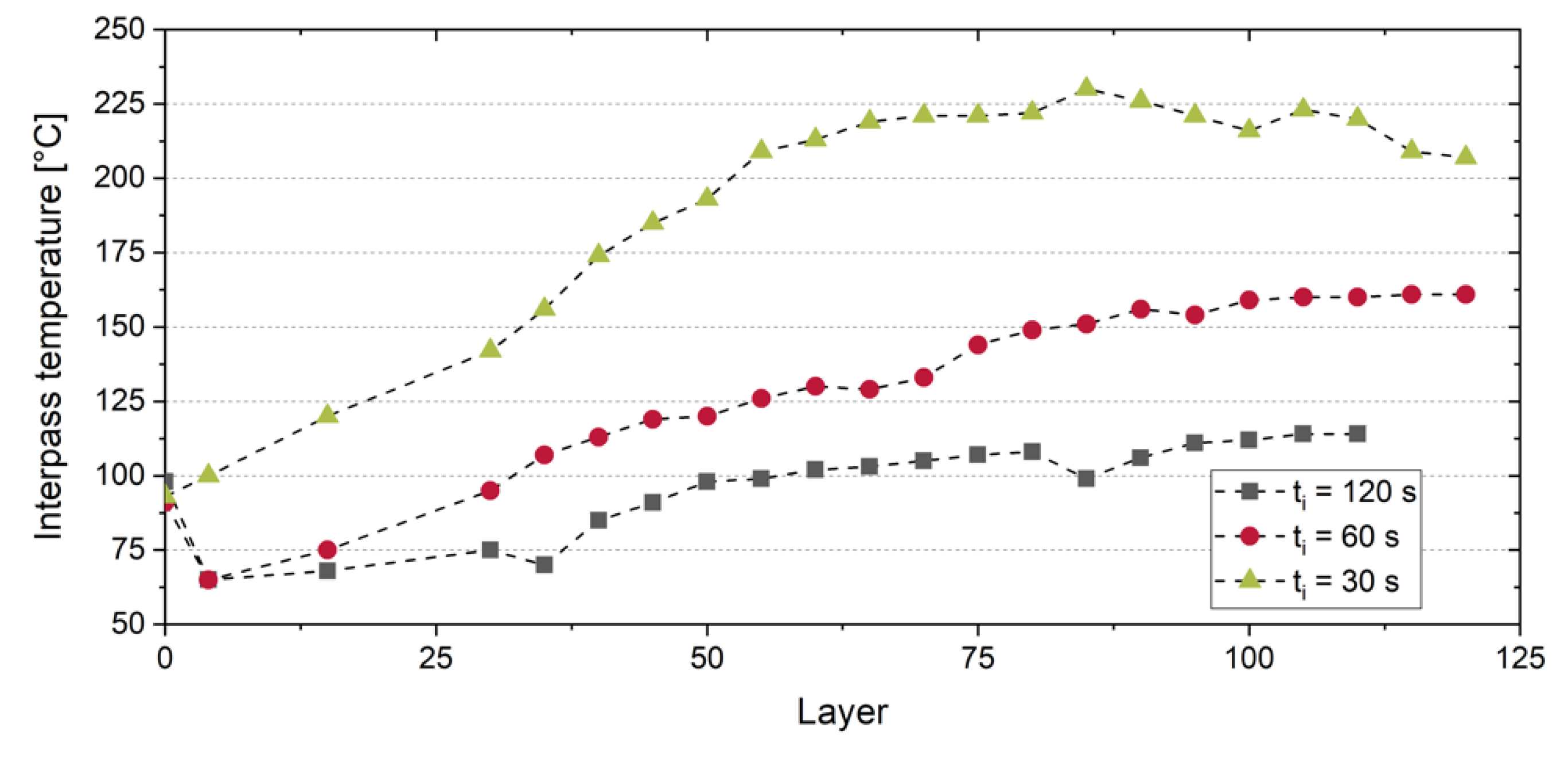

3.1. Temperature Formation During WAAM

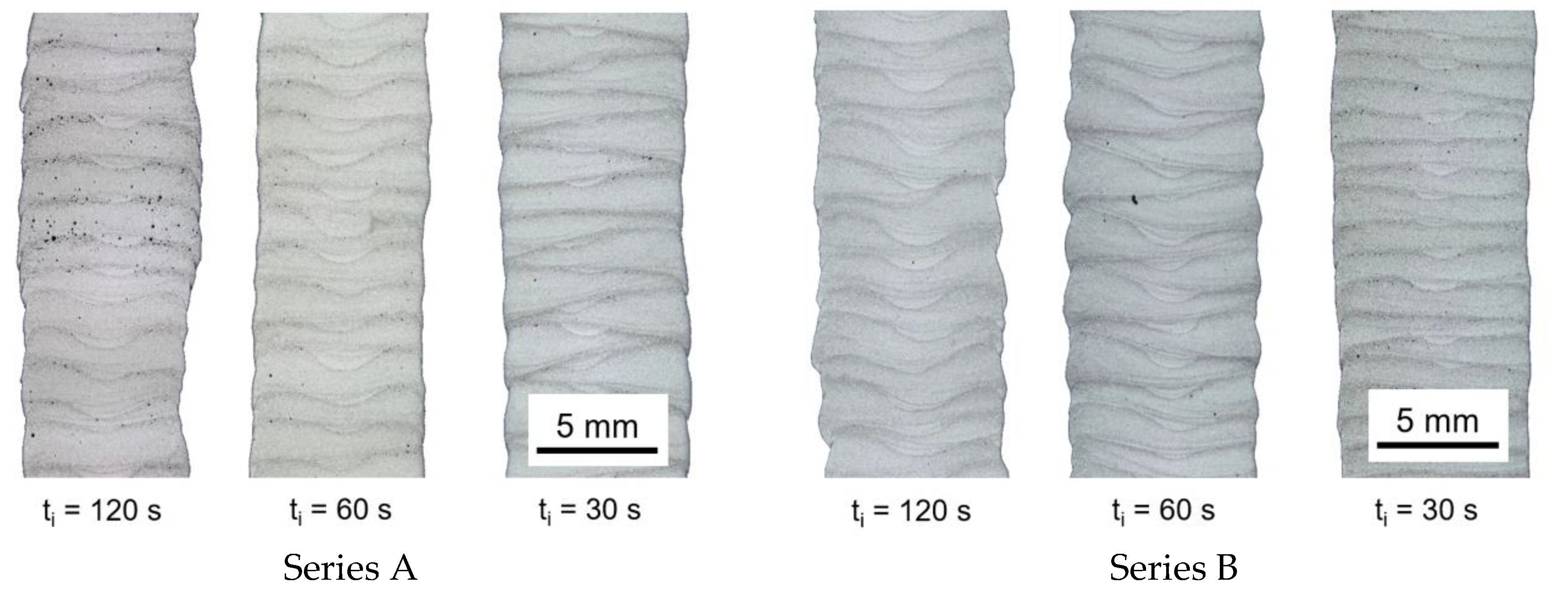

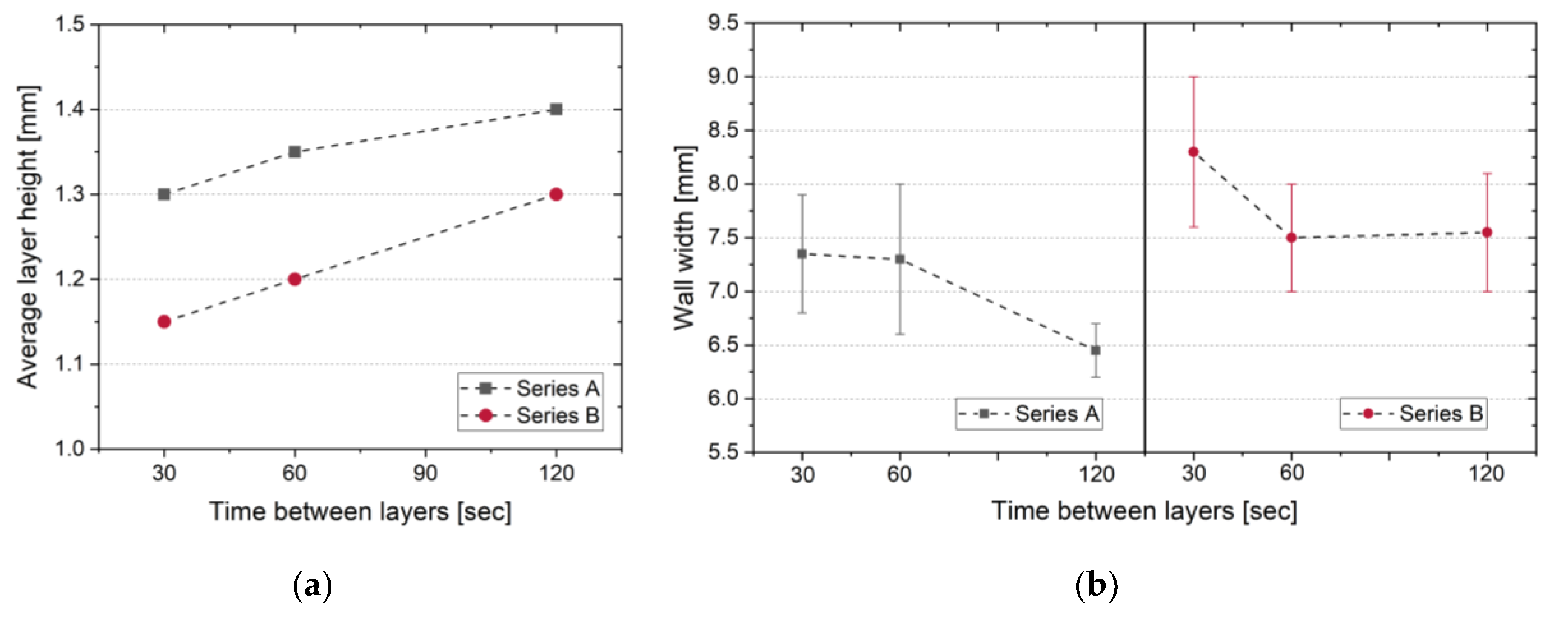

3.2. Effects on Resulting Geometry

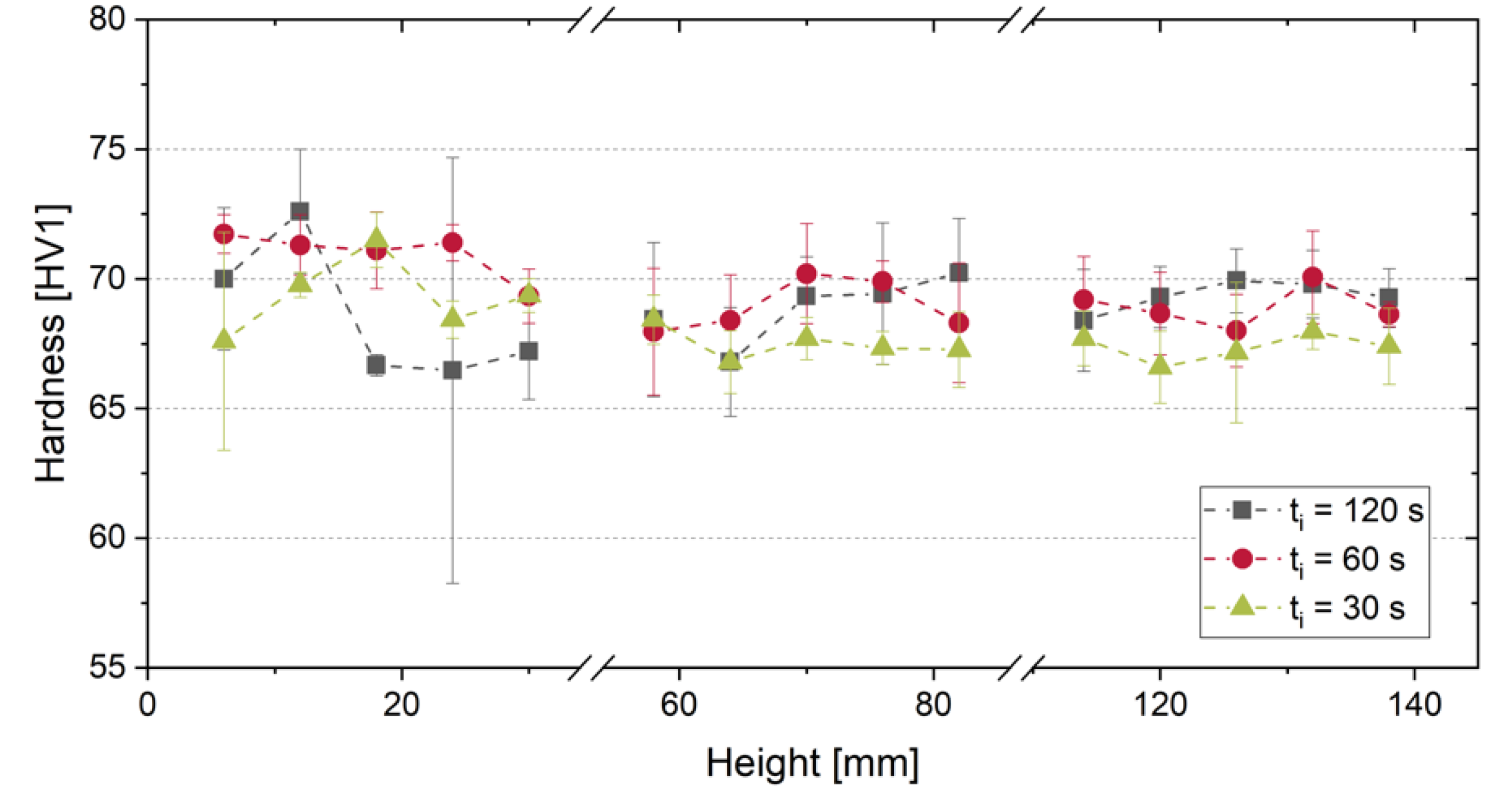

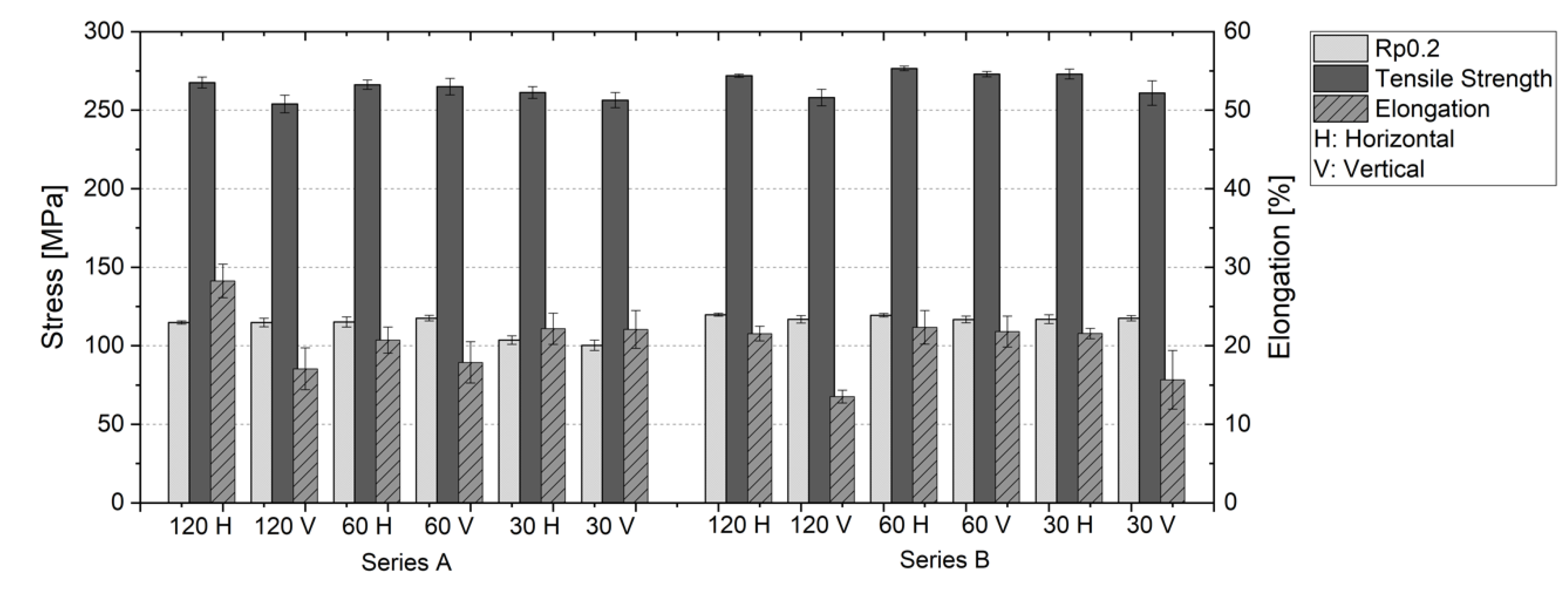

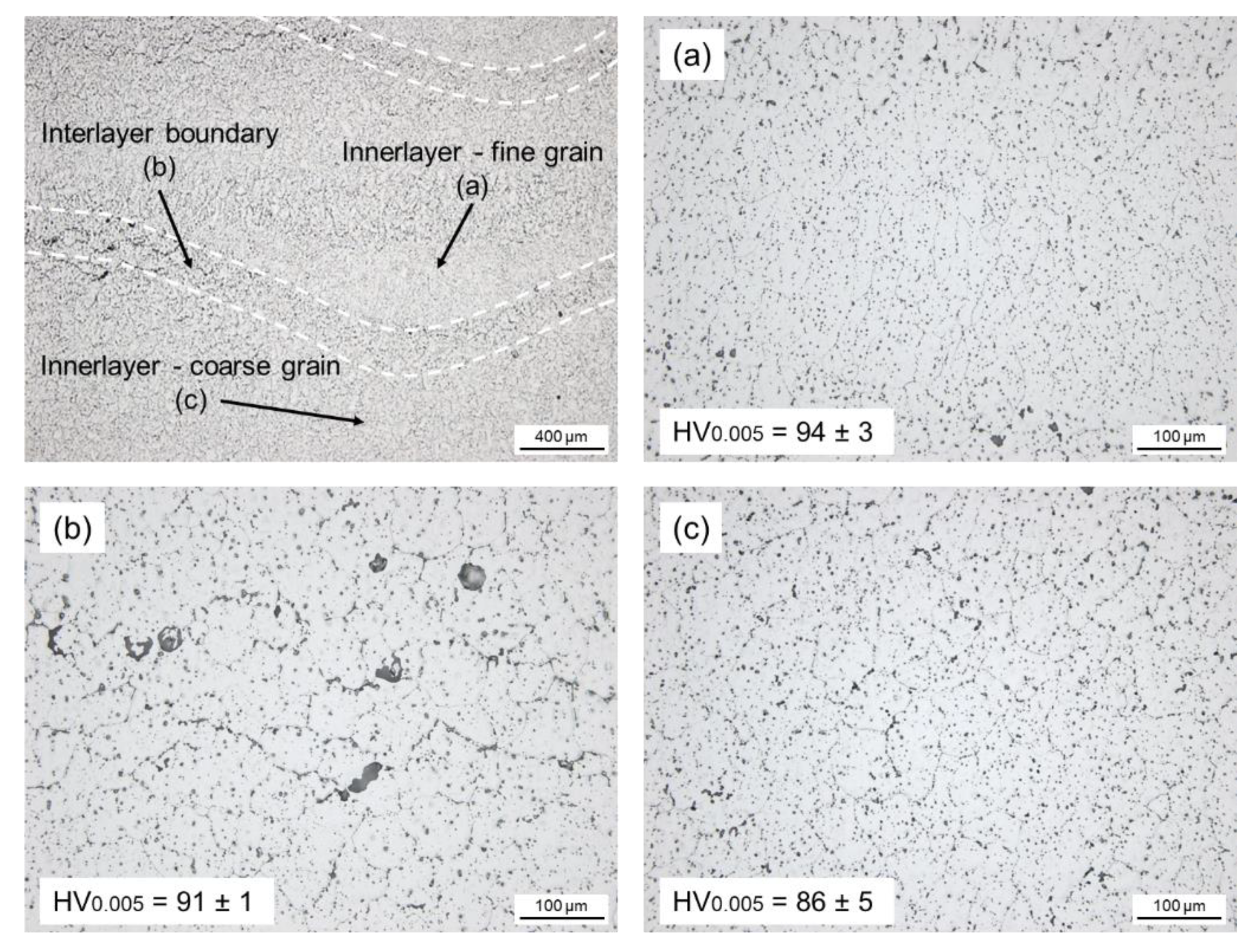

3.3. Residual Stress and Mechanical Properties

4. Conclusions

- Temperature profiles during WAAM processing indicated that the temperature distribution is directly related to the geometry of the additive manufactured component. Due to a continuously changing geometry, a non-steady temperature distribution during WAAM can be assumed. However, steady geometrical build-up results can be expected by obtaining uniform temperature fields.

- Although different process strategies, using the same energy input per length unit, lead to comparable temperature distributions and cooling rates, they showed differences in the resulting geometry of the component. An increase in wire feed and welding speed resulted in lower layer height and increased wall width. Furthermore, higher interpass temperatures led to an increase in wall width and lower layer height.

- Residual stresses in the top layer and on the surface of the wall specimen appeared of low magnitude due to small temperature gradients combined with a comparably low yield strength of the regarded material.

- Material properties were evenly distributed over the build-up geometry with values comparable to AlMg5 wrought material. No significant dependency on the temperature-time regime during processing could be detected. However, the mechanical properties, especially the elongation at fracture, showed dependencies on the loading in relation to the build-up direction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Grunwald, R.; Mayer, M.; Schörghuber, M. WAAM-Technologie und aktuelle Anwendungen: DVS-Berichte Congress 2018. DVS Media GmbH 2018, 344, 97–103. [Google Scholar]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef] [Green Version]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Watts, C.; Drake, R. A review of Additive Manufacturing technology and Cost Estimation techniques for the defense sector. CIRP J. Manuf. Sci. Technol. 2017, 19, 117–128. [Google Scholar] [CrossRef] [Green Version]

- Cunningham, C.; Wikshåland, S.; Xu, F.; Kemakolam, N.; Shokrani, A.; Dhokia, V.; Newman, S. Cost Modelling and Sensitivity Analysis of Wire and Arc Additive Manufacturing. Procedia Manuf. 2017, 11, 650–657. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Thomas-Seale, L.E.J.; Kirkman-Brown, J.C.; Attallah, M.M.; Espino, D.M.; Shepherd, D.E.T. The barriers to the progression of additive manufacture: Perspectives from UK industry. Int. J. Prod. Econ. 2018, 198, 104–118. [Google Scholar] [CrossRef]

- Baufeld, B.; Widdison, R.; Dutilleul, T.; Bridger, K. Electron Beam Additive Manufacturing at the Nuclear AMRC. Elektron. Elektrotech. 2016, 51, 25. [Google Scholar]

- Taminger, K.M.; Hafley, R.A. Electron Beam Freeform Fabrication for Cost Effective Near-Net Shape Manufacturing. In Proceedings of the Meeting on Cost Effective Manufacture via Net Shape Processing, Amsterdam, The Netherlands, 15–17 May 2006. [Google Scholar]

- Liberini, M.; Astarita, A.; Campatelli, G.; Scippa, A.; Montevecchi, F.; Venturini, G.; Durante, M.; Boccarusso, L.; Minutolo, F.M.C.; Squillace, A. Selection of Optimal Process Parameters for Wire Arc Additive Manufacturing. Procedia CIRP 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Hoefer, K.; Haelsig, A.; Mayr, P. Arc-based additive manufacturing of steel components—Comparison of wire-and powder-based variants. Weld World 2018, 62, 243–247. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Oster, L.; Zanders, E. Plasma-Mehrdraht-Schweißen zum Herstellen gradierter Strukturen. In Proceedings of the DVS CONGRESS, Friedrichshafen, Germany, 17–18 September 2018; DVS 344. pp. 109–114. [Google Scholar]

- Fang, X.; Zhang, L.; Li, H.; Li, C.; Huang, K.; Lu, B. Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process. Materials 2018, 11, 812. [Google Scholar] [CrossRef] [Green Version]

- Kazanas, P.; Deherkar, P.; Almeida, P.; Lockett, H.; Williams, S. Fabrication of geometrical features using wire and arc additive manufacture. Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 2012, 226, 1042–1051. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM Deposition Patterns for T-crossing Features. Procedia CIRP 2016, 55, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Workowski, M.; Nitschke-Pagel, T.; Dilger, K. Load induced inhomogeneous plastic deformations in welded aluminium joints. Weld. World 2014, 58, 529–538. [Google Scholar] [CrossRef]

- Ge, J.; Lin, J.; Chen, Y.; Lei, Y.; Fu, H. Characterization of wire arc additive manufacturing 2Cr13 part: Process stability, microstructural evolution, and tensile properties. J. Alloys Compd. 2018, 748, 911–921. [Google Scholar] [CrossRef]

- Suryakumar, S.; Karunakaran, K.P.; Chandrasekhar, U.; Somashekara, M.A. A study of the mechanical properties of objects built through weld-deposition. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1138–1147. [Google Scholar] [CrossRef]

- Henckell, P.; Günther, K.; Ali, Y.; Bergmann, J.P.; Scholz, J.; Forêt, P. The Influence of Gas Cooling in Context of Wire Arc Additive Manufacturing—A Novel Strategy of Affecting Grain Structure and Size. In The Minerals, Metals & Materials Series, TMS 2017 146th Annual Meeting & Exhibition Supplemental Proceedings; BSpringer International Publishing: Cham, Switzerland, 2017; pp. 147–156. [Google Scholar]

- Li, F.; Chen, S.; Shi, J.; Zhao, Y.; Tian, H. Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures. Appl. Sci. 2018, 8, 207. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Li, F.; Chen, S.; Zhao, Y.; Tian, H. Effect of in-process active cooling on forming quality and efficiency of tandem GMAW–based additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 101, 1349–1356. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminium alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, L.; Chen, G.; Dang, X.; Huang, K.; Wang, L.; Lu, B. Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes. Materials 2018, 11, 2075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Derekar, K.; Lawrence, J.; Melton, G.; Addison, A.; Zhang, X.; Xu, L. Influence of Interpass Temperature on Wire Arc Additive Manufacturing (WAAM) of Aluminium Alloy Components. MATEC Web Conf. 2019, 269, 5001. [Google Scholar] [CrossRef]

- Köhler, M.; Tóth, T.; Hensel, J.; Dilger, K. Prozesscharakteristiken bei der lichtbogenbasierten generativen Fertigung metallischer Komponenten. DVS Ber. 39 Assist. Fügetechnik 2019, 356, 96–102. [Google Scholar]

- Köhler, M.; Fiebig, S.; Hensel, J.; Dilger, K. Wire and Arc Additive Manufacturing of Aluminum Components. Metals 2019, 9, 608. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Chemical Composition (wt%) | |||||

|---|---|---|---|---|---|---|

| Al | Mn | Mg | Si | Fe | Cu | |

| Welding Wire: Al-5356 | bal | 0.15 | 5.0 | 0.05 | 0.15 | - |

| Substrate: Al-6082 | bal | 0.4–1.0 | 0.60–1.2 | 0.7–1.3 | <0.5 | <0.1 |

| Parameter | Symbol | Unit | Series A | Series B |

|---|---|---|---|---|

| Wire feed | vW | m/min | 8 | 10 |

| Welding speed | vS | cm/min | 60 | 76 |

| Voltage | I | V | 15.5–16.5 | 16.5–17.5 |

| Current | U | A | 91–92 | 111–112 |

| Time between layers | ti | s | 30/60/120 | 30/60/120 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Köhler, M.; Hensel, J.; Dilger, K. Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components. Metals 2020, 10, 952. https://doi.org/10.3390/met10070952

Köhler M, Hensel J, Dilger K. Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components. Metals. 2020; 10(7):952. https://doi.org/10.3390/met10070952

Chicago/Turabian StyleKöhler, Markus, Jonas Hensel, and Klaus Dilger. 2020. "Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components" Metals 10, no. 7: 952. https://doi.org/10.3390/met10070952

APA StyleKöhler, M., Hensel, J., & Dilger, K. (2020). Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components. Metals, 10(7), 952. https://doi.org/10.3390/met10070952