The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process

Abstract

1. Introduction

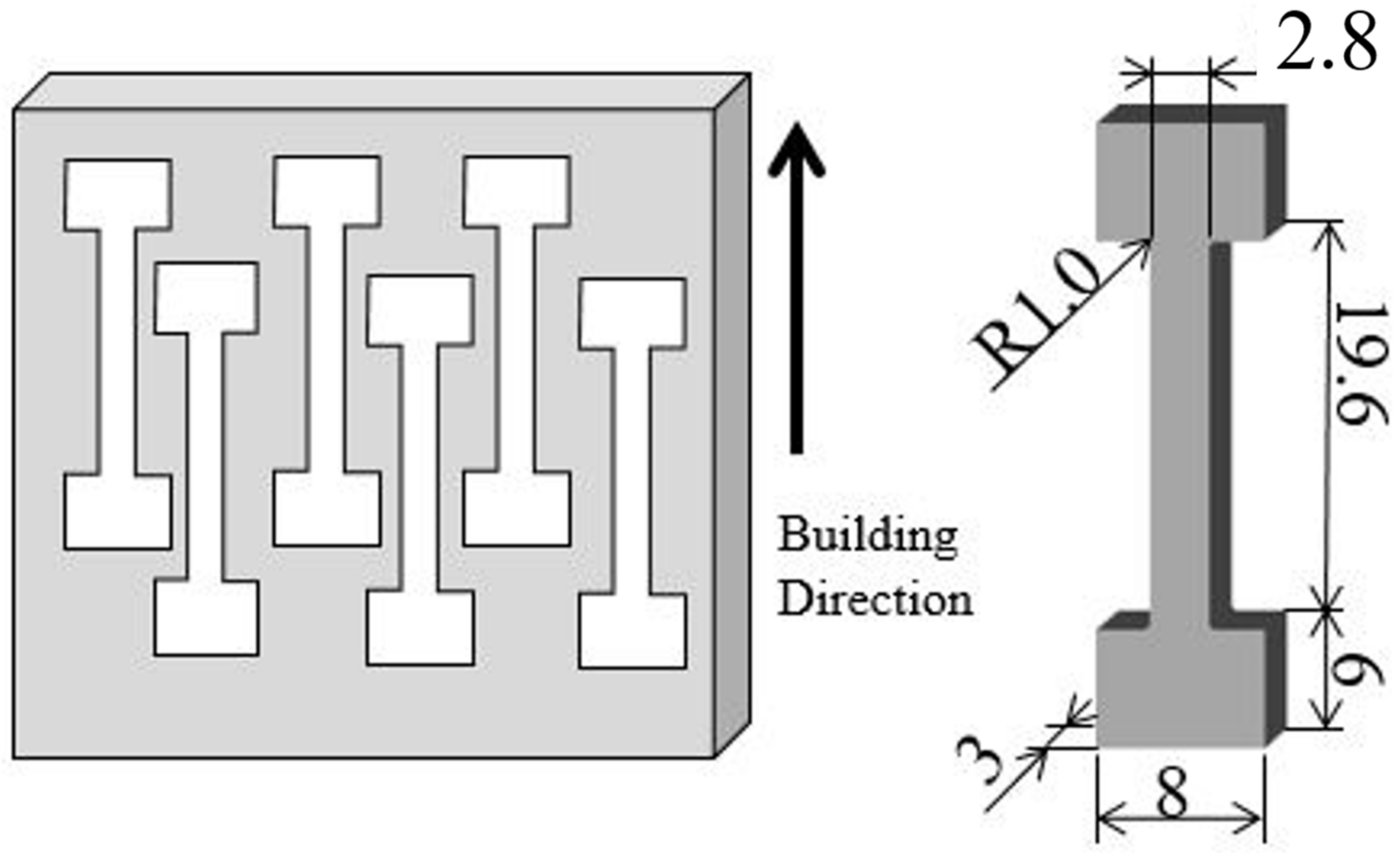

2. Materials and Methods

3. Results

3.1. Microstructural Characterization

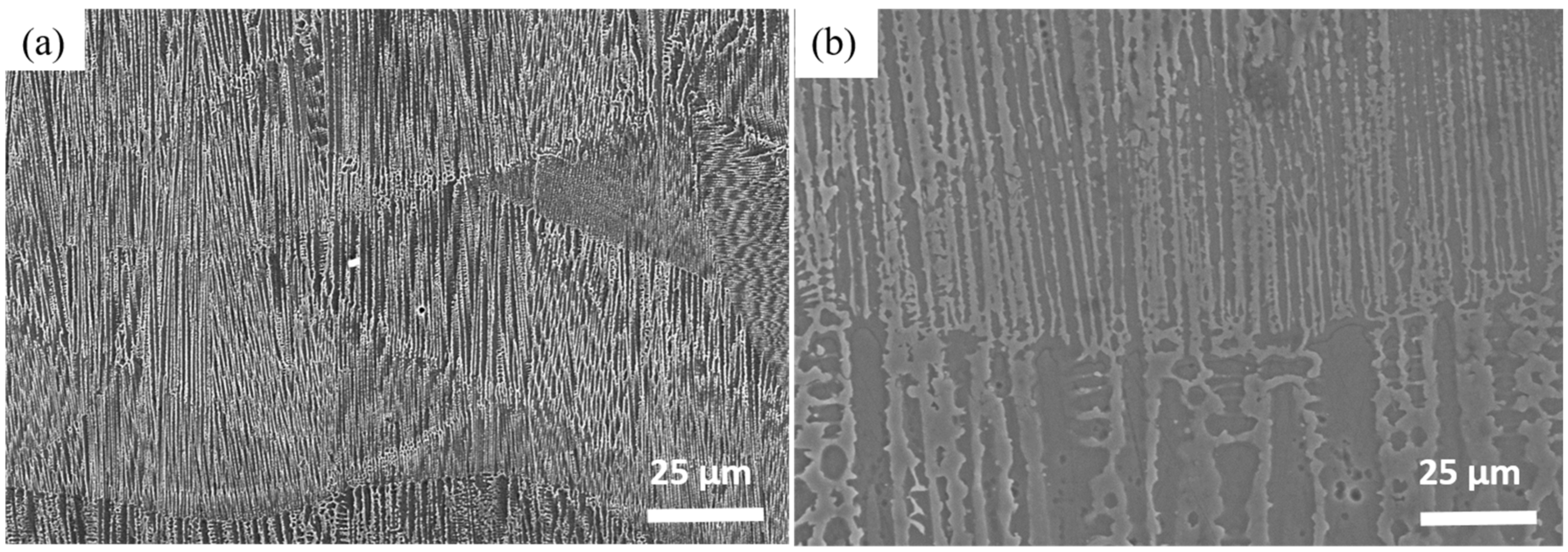

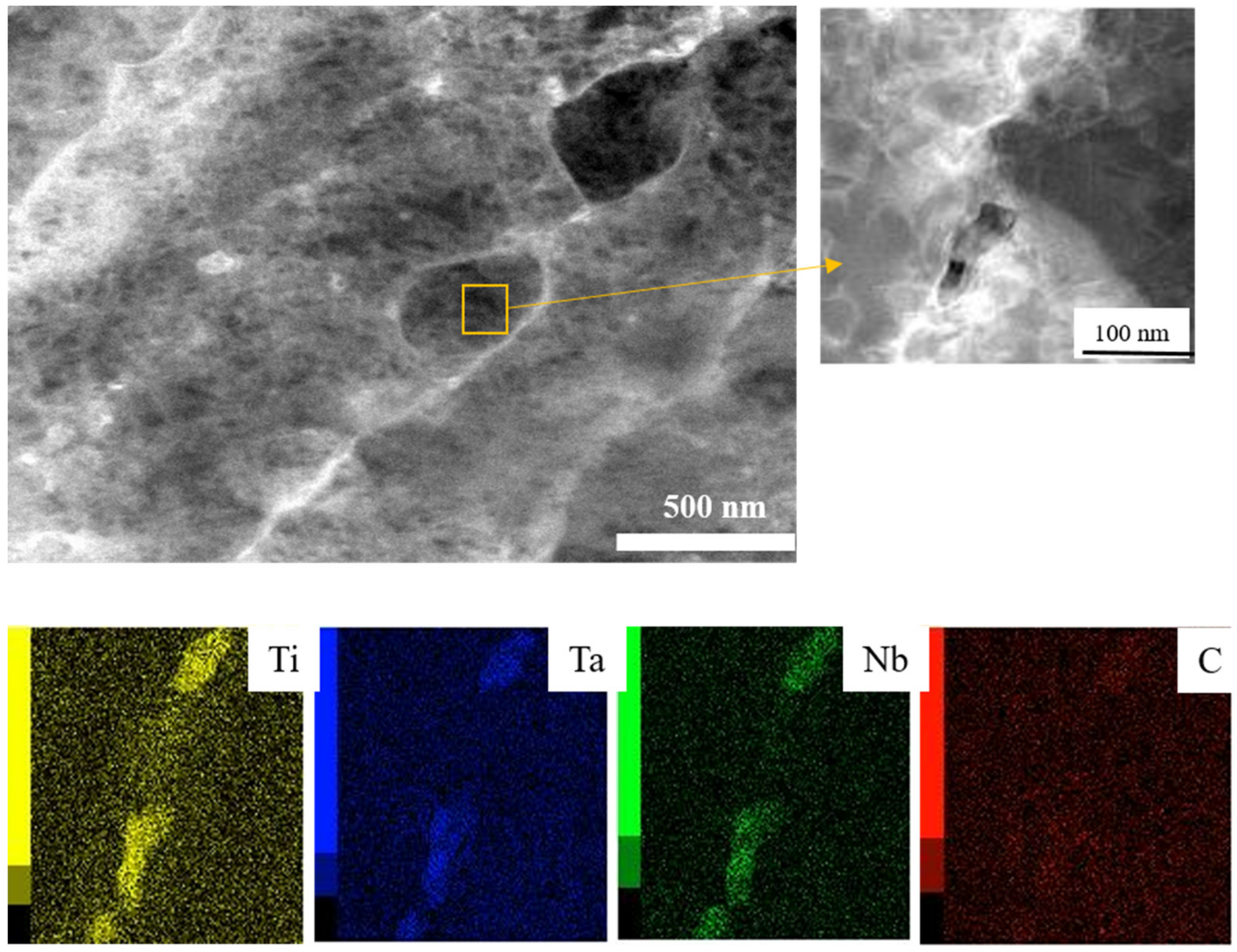

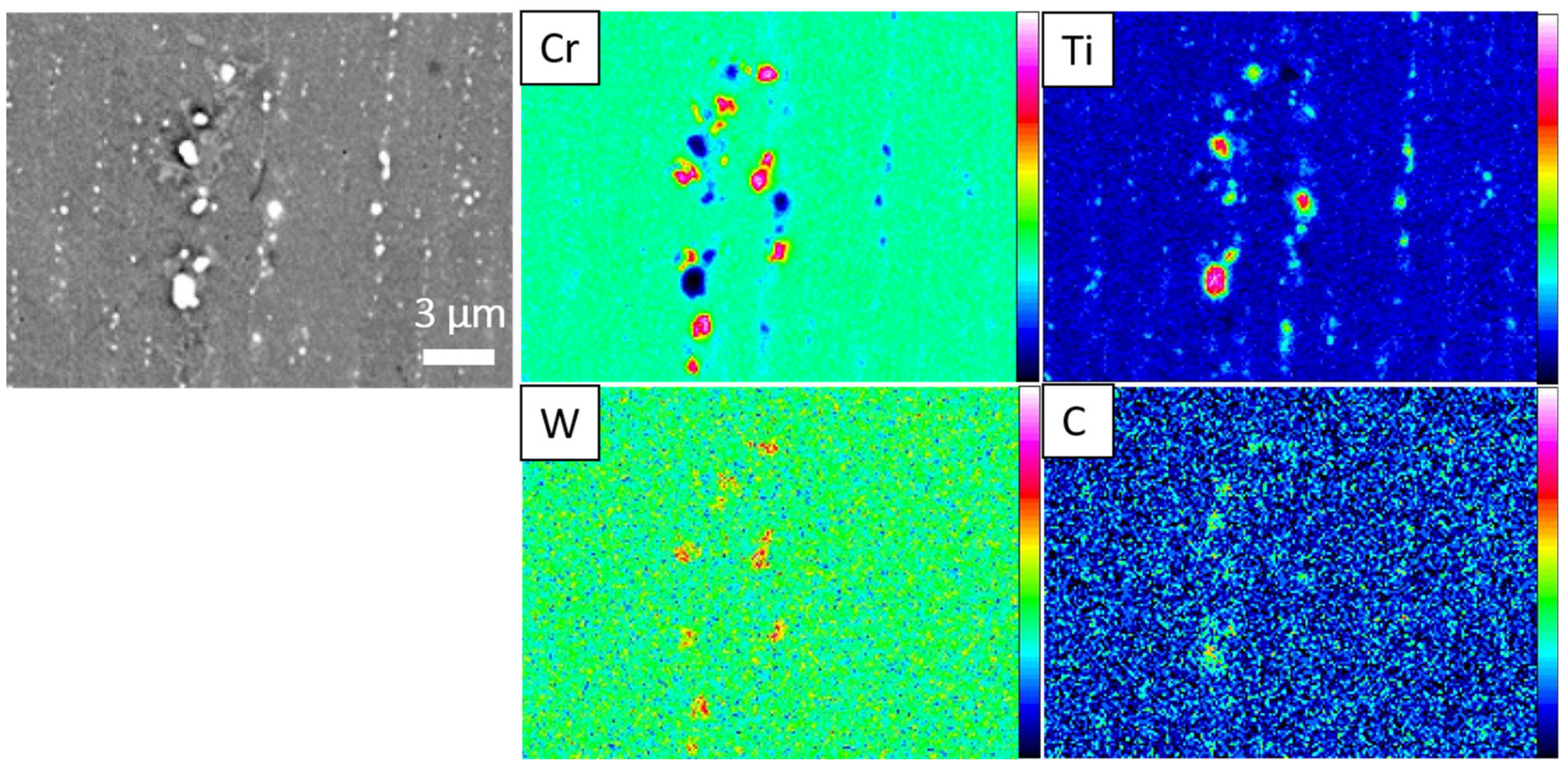

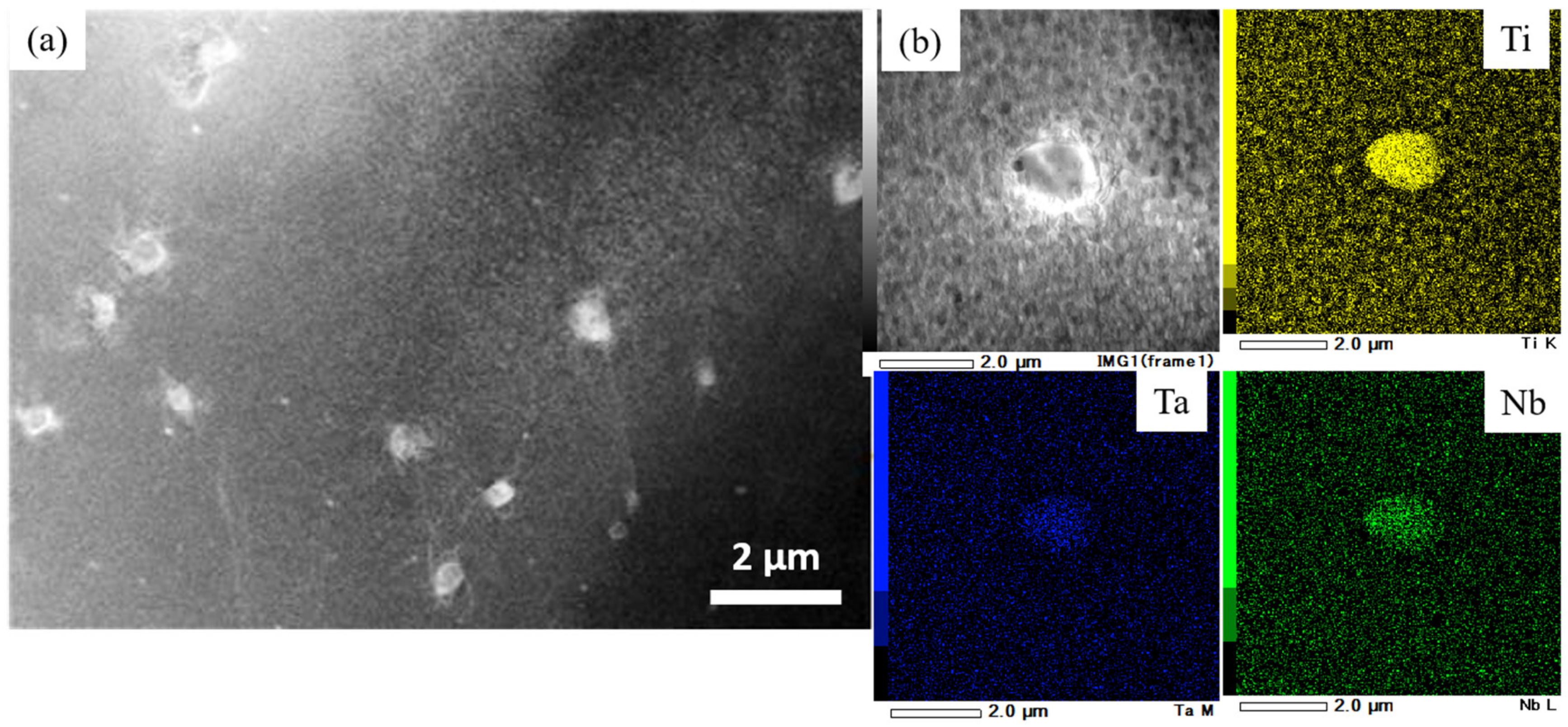

3.1.1. As-Built Specimen

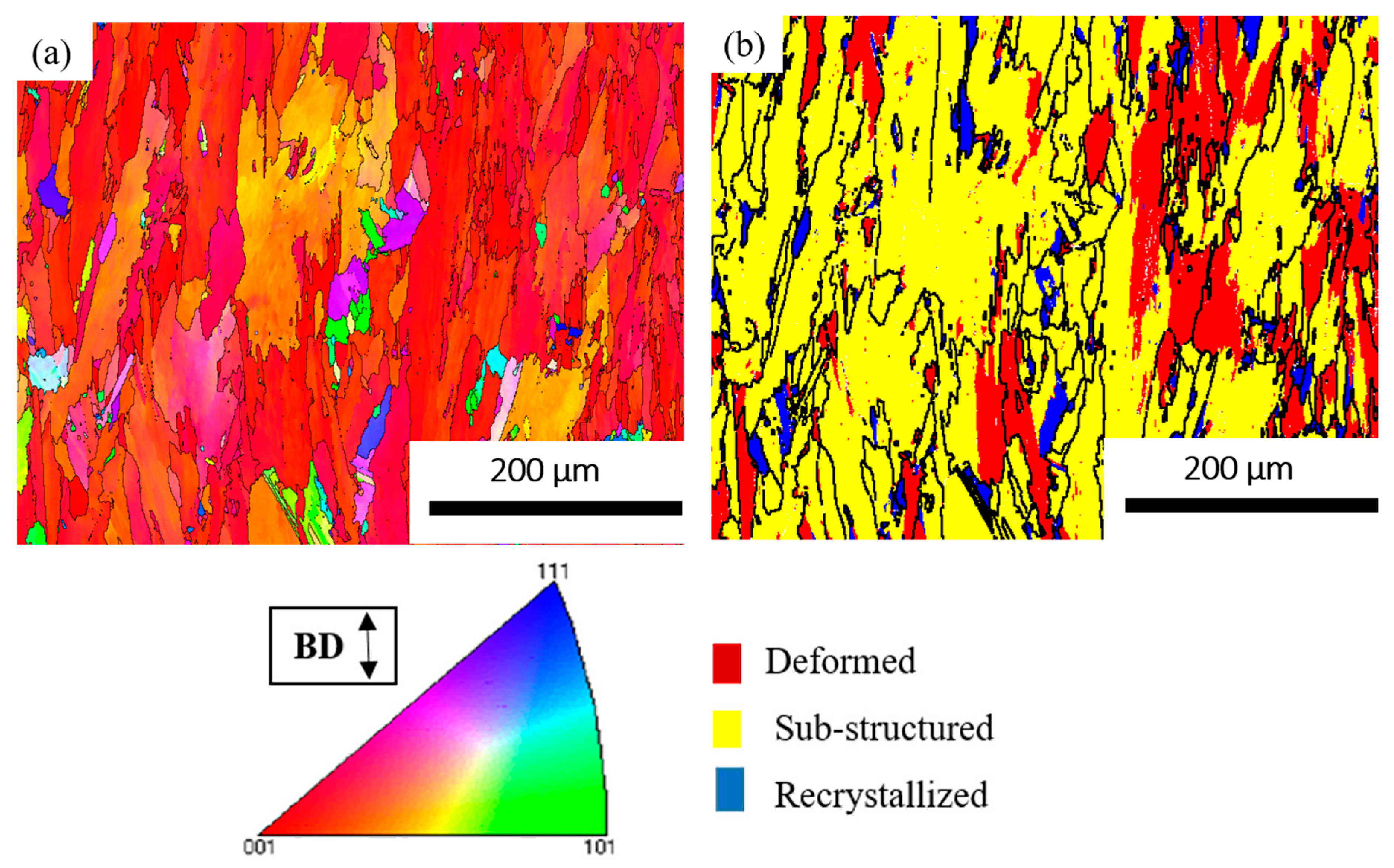

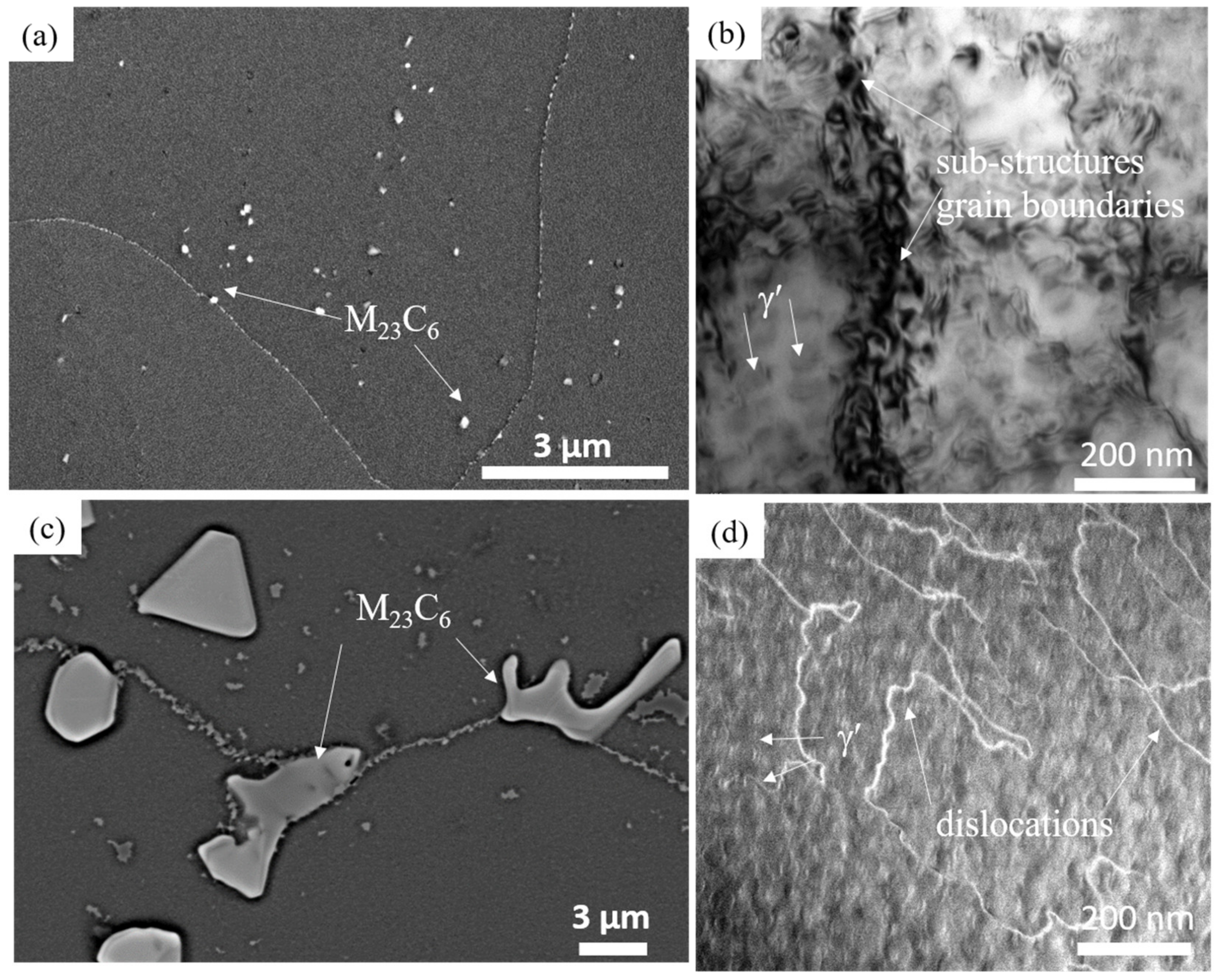

3.1.2. Heat-Treated Specimens

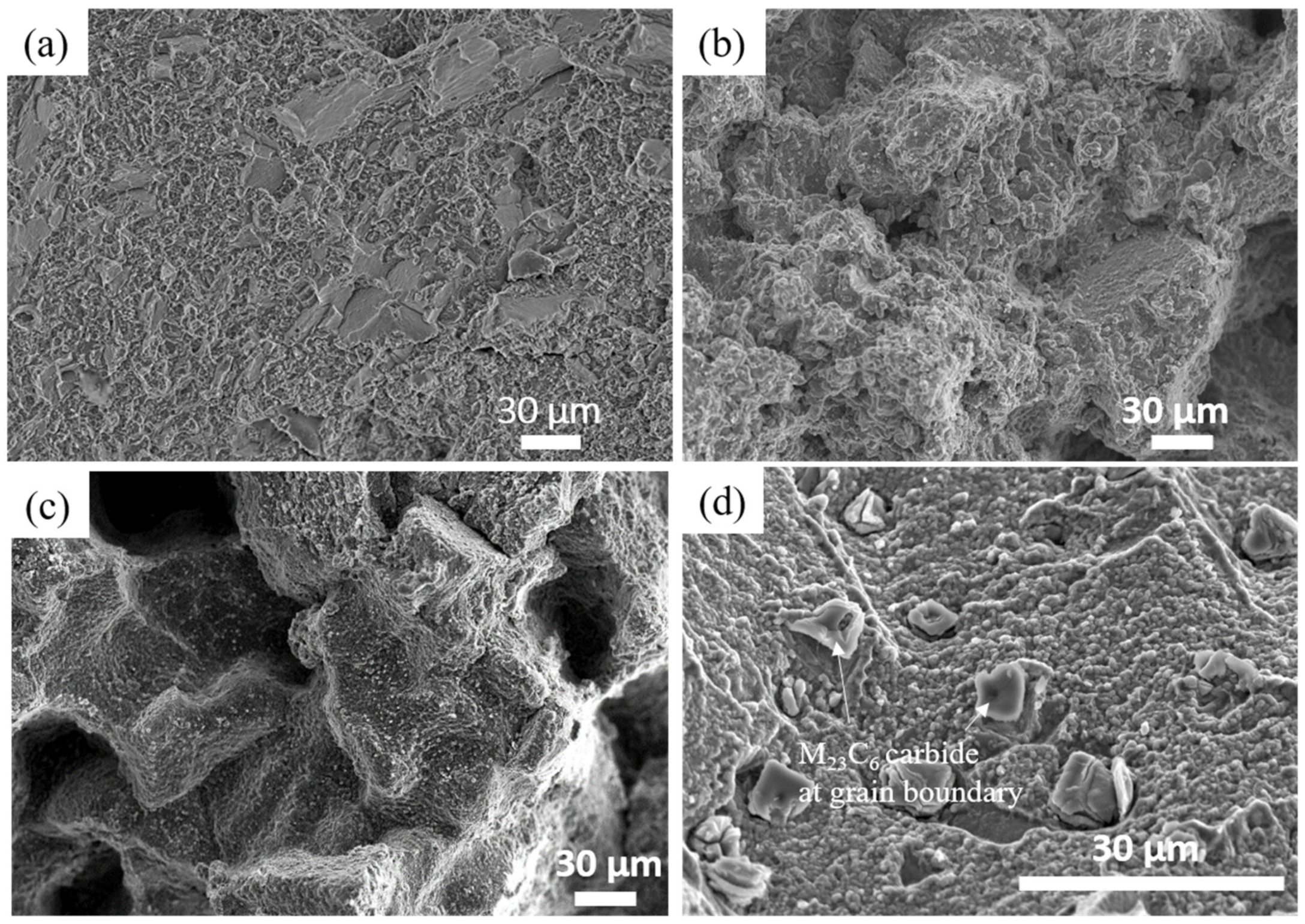

3.2. Creep Properties

4. Discussion

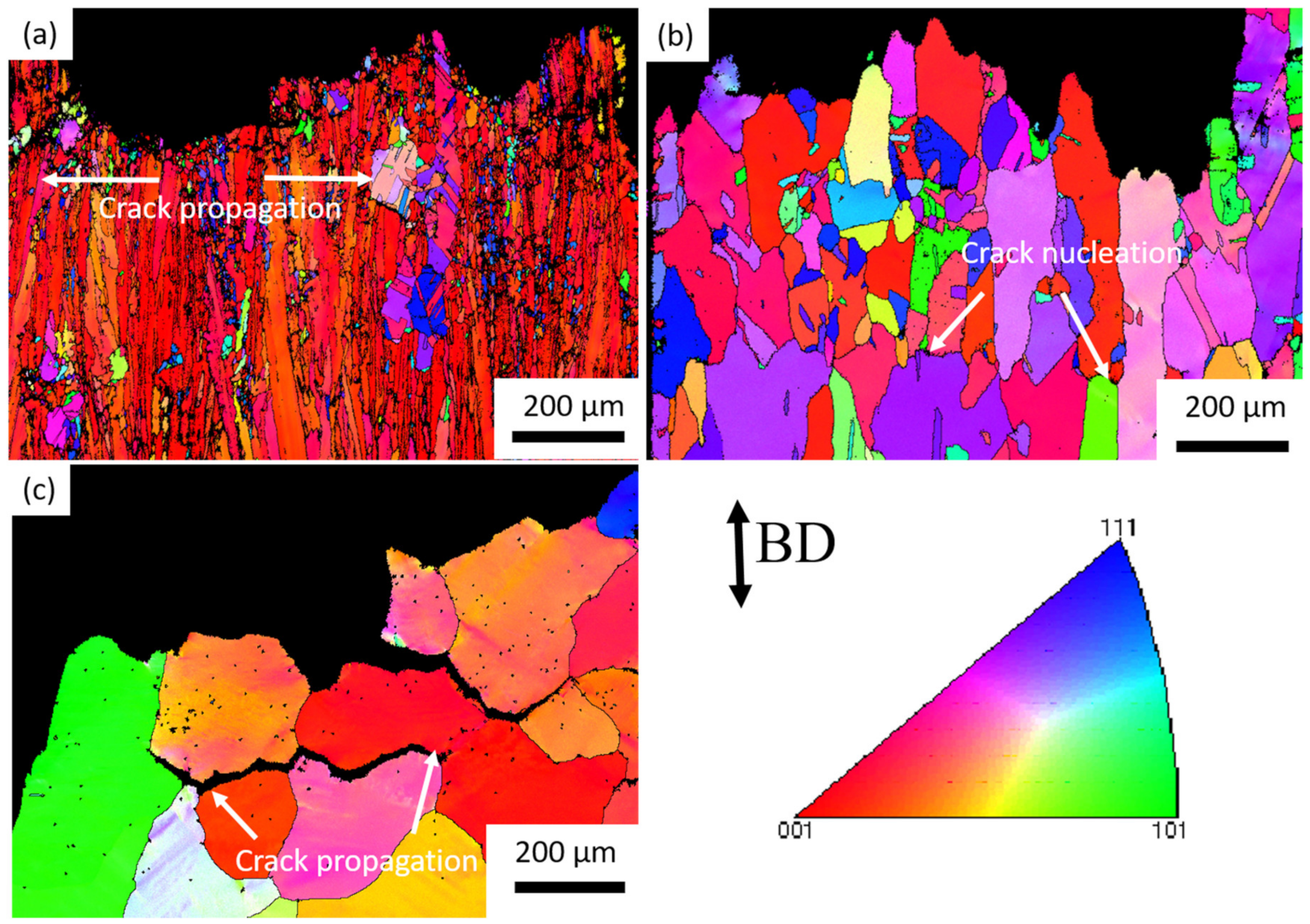

4.1. The Effects of Recrystallization on Creep Properties of SLM Specimen

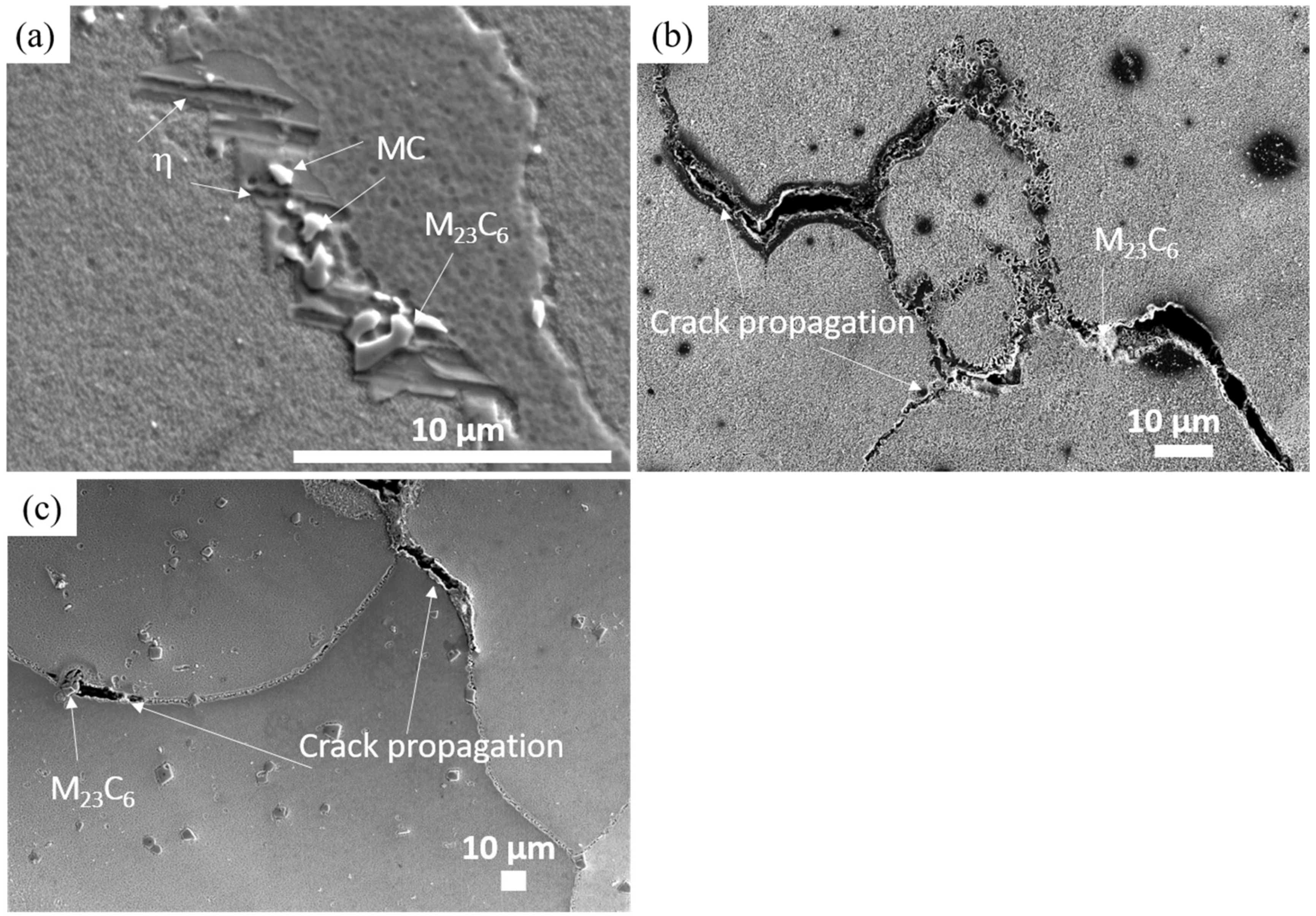

4.2. The Effect of Precipitates and Dislocation Density on Creep Properties

5. Conclusions

- The as-built SLM material showed a columnar grain structure due to the epitaxial growth of dendrite structure. The dislocation density of the as-built condition was high. At the interdendritic region, Ti, Nb, Ta, and C elements were segregated during the solidification.

- In the LTH condition, small, recrystallized grains formed between the columnar grains; as a result, the rupture elongation was large and the creep life was poor. The formation of harmful phases like η also decreased the creep life.

- The creep life of the HTH specimen was 2.7 times longer than that of the LTH specimen due to attaining full recrystallization. In addition, γ′ precipitate size increment during the creep also improved creep life, but ductility was very poor compared to the LTH specimen.

- The cast-LTH specimen showed longer creep life than SLM specimens, mainly because of low creep strain rate, larger grain size, and γ′-phase coarsening during the creep test. In addition, the small size of M23C6 carbides remaining discretely at grain boundaries also improved creep life.

Author Contributions

Funding

Conflicts of Interest

References

- Divya, V.D.; Munoz-Moreno, D.; Messe, O.M.D.M.; Barnard, J.S.; Baker, S.; Illston, T.; Stone, H.J. Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater. Charact. 2016, 114, 62–74. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Kakehi, K. Influence of powder surface contamination in the Ni-based superalloy alloy718 fabricated by selective laser melting and hot isostatic pressing. Metals 2017, 7, 367. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef]

- Islam, M.; Purtonen, T.; Piili, H.; Salminen, A.; Nyrhilä, O. Temperature profile and imaging analysis of laser additive manufacturing of stainless steel. Phys. Procedia 2013, 41, 835–842. [Google Scholar] [CrossRef]

- Järvinen, J.P.; Matilainen, V.; Li, X.; Piili, H.; Salminen, A.; Makela, I.; Nyrhila, O. Characterization of effect of support structures in laser additive manufacturing of stainless steel. Phys. Procedia 2014, 56, 72–81. [Google Scholar] [CrossRef]

- Piili, H.; Happonen, A.; Väistö, T.; Venkataramanan, V.; Partanen, J.; Salminen, A. Cost Estimation of Laser Additive Manufacturing of Stainless Steel. Phys. Procedia 2015, 78, 388–396. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. In Proceedings of the ACME/ISCIE 2012 International Symposium on Flexible automation, St. Louis, MO, USA, 18–20 June 2012; pp. 507–515. [Google Scholar]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Shiva, S.; Palani, I.A.; Mishra, S.K.; Paul, C.P.; Kukreja, L.M. Investigations on the influence of composition in the development of Ni-Ti shape memory alloy using laser based additive manufacturing. Opt. Laser Technol. 2015, 69, 44–51. [Google Scholar] [CrossRef]

- Loeber, L.; Biamino, S.; Ackelid, U.; Sabbadini, S.; Epicoco, P.; Pino, P.; Eckert, J. Comparison of selective laser and electron beam melted titanium. In Proceedings of the 22nd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conerence (SFF 2011), Austin, TX, USA, 8–10 August 2011; pp. 547–556. [Google Scholar]

- Doubenskaia, M.; Domashenkov, A.; Smurov, I.; Petrovskiy, P. Study of Selective Laser Melting of intermetallic TiAl powder using integral analysis. Int. J. Mach. Tools Manuf. 2018, 129, 1–14. [Google Scholar] [CrossRef]

- Gussone, J.; Hagedorn, Y.C.; Gherekhloo, H.; Kasperovich, G.; Merzouk, T.; Hausmann, J. Microstructure of γ-titanium aluminide processed by selected laser melting at elevated temperatures. Intermetallics 2015, 66, 133–140. [Google Scholar] [CrossRef]

- Pinto, I.P.M.S. Additive Manufacturing of Nickel components using CMT process. Master’s Thesis, Instituto Superior Técnico, Lisbon, Portugal, May 2015. [Google Scholar]

- Murr, L.E.; Martinez, E.; Pan, X.M.; Gaytan, S.M.; Castro, J.R.; Terazzas, C.A.; Medina, F.; Wicker, R.B.; Abbott, D.H. Microstructures of Rene 142 nickel-based superalloy fabricated by electron beam melting. Acta Mater 2013, 61, 4289–4296. [Google Scholar] [CrossRef]

- Wang, F. Mechanical property study on rapid additive layer manufacture Hastelloy® X alloy by selective laser melting technology. Int. J. Adv. Manuf. Technol. 2012, 58, 545–551. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Warren, J.; Wei, D.Y. The cyclic fatigue behavior of direct age 718 at 149, 315, 454 and 538 °C. Mater. Sci. Eng. A 2006, 428, 106–115. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Arabi, H.; Boutorabi, S.M.A. Development of wrought precipitation strengthened IN939 superalloy. Mater. Sci. Technol. 2012, 28, 1470–1478. [Google Scholar] [CrossRef]

- Delargy, K.M.; Smith, G.D.W. phase composition and phase stability of a High-Chromium nickel-based superalloy, in939. Metall. Trans. A 1983, 14, 1771–1783. [Google Scholar] [CrossRef]

- Shaw, S.W.K. Response of in-939 To Process Variations. Metals 1980, 275–284. [Google Scholar]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Quested, P.N.; Osgerby, S. Mechanical properties of conventionally cast, directionally solidified, and single-crystal superalloys. Mater. Sci. Technol. 2013, 836. [Google Scholar] [CrossRef]

- Papadaki, C.; Li, W.; Ying, S.; Salvati, E.; Zhang, H.; Romano Brandt, L.; Sui, T.; Korsunsky, A.M. Microstructural Variations During Interrupted Creep Tests on P/M Polycrystalline Nickel-Base Superalloy. In Proceedings of the 14th International Conference on Fracture 2017 (ICF-14), Cassino, Italy, 18–23 June 2017. [Google Scholar]

- Philpott, W.; Jepson, M.A.E.; Thomson, R.C. Comparison of the effects of a conventional heat treatment between cast and selective laser melted IN939 alloy. In Advanced Materials Technology for Fossil Power Plants, Proceedings of the Eight International Conference (EPRI 2016), Albuferia, Portugal, 11–14 October 2016; ASM International: Novelty, OH, USA, 2016; pp. 735–746. [Google Scholar]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Messé, O.M.D.M.; Muñoz-Moreno, R.; Illston, T.; Baker, S.; Stone, H.J. Metastable carbides and their impact on recrystallisation in IN738LC processed by selective laser melting. Addit. Manuf. 2017, 22, 394–404. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Zhang, P.; Liu, M.; Kuang, T. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- Mišković, Z.; Jovanović, M.; Gligić, M.; Lukić, B. Microstructural investigation of IN 939 superalloy. Vacuum 1992, 43, 709–711. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Yang, G.; Song, M.; Chen, J.; Huang, W. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy. Opt. Laser Technol. 2011, 43, 208–213. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Huang, C.; Song, M.; Yang, G.; Cheng, J.; Huang, W. The effect of laser scanning path on microstructures and mechanical properties of laser solid formed nickel-base superalloy Inconel 718. J. Alloys Compd. 2011, 509, 4505–4509. [Google Scholar] [CrossRef]

- Hu, Y.L.; Lin, X.; Lin, Y.L.; Wang, Y.L.; Zhang, S.Y.; Lu, X.F.; Huang, W.D. Effect of heat treatment on the microstructural evolution and mechanical properties of GH4099 additive-manufactured by directed energy deposition. J. Alloys Compd. 2019, 800, 163–173. [Google Scholar] [CrossRef]

- Hutchinson, C.R.; Zurob, H.S.; Sinclair, C.W.; Brechet, Y.J.M. The comparative effectiveness of Nb solute and NbC precipitates at impeding grain-boundary motion in Nb steels. Scr. Mater. 2008, 59, 635–637. [Google Scholar] [CrossRef]

- Guo, J.T.; Yuan, C.; Yang, H.C.; Lupinc, V.; Maldini, M. Creep-rupture behavior of a directionally solidified nickel-base superalloy. Metall. Mater. Trans. A 2001, 32, 1103–1110. [Google Scholar] [CrossRef]

- Thébaud, L.; Villechaise, P.; Crozet, C.; Devaux, A.; Bechet, D.; Franchet, J.-M.; Rouffie, A.-L.; Mills, M.; Cormier, J. Is there an optimal grain size for creep resistance in Ni-based disk superalloys? Mat. Sci. Eng. 2017, 716, 274–283. [Google Scholar] [CrossRef]

- Long, F.; Yoo, Y.S.; Yo, C.Y.; Seo, S.M.; Song, Y.S.; Yin, T.; Hu, Z.Q. Formation of η and σ phase in three polycrystalline superalloys and their impact on tensile properties. Mater. Sci. Eng. A 2009, 527, 361–369. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

| Elements | Cr | Co | Ti | Al | W | Ta | Nb | C | Fe | S | Mg | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| powder | 22.5 | 19 | 3.7 | 1.9 | 2.0 | 1.4 | 1.0 | 0.15 | - | - | - | Bal |

| cast | 22.5 | 19.0 | 3.6 | 1.9 | 2.0 | 1.4 | 1.0 | 0.2 | 0.1 | 0.0002 | 0.0012 | Bal. |

| Specimen | Heat Treatment | Condition | Abbreviation |

|---|---|---|---|

| SLM | 1160 °C/4 h/FC+ 850 °C/16 h/AC | lower temperature heat treatment | LTH |

| SLM | 1240 °C/6 h/FC+ 850 °C/16 h/AC | higher temperature heat treatment | HTH |

| Cast | 1160 °C/4 h/FC+ 850 °C/16 h/AC | lower temperature heat treatment | Cast-LTH |

| Specimen Condition | Average Grain Size (µm) | Recrystallization Fraction (%) |

|---|---|---|

| LTH | 27 | 12.8 |

| HTH | 50 | 66 |

| Cast-LTH | 200 | 99.9 |

| Specimen | Creep Life (h) | Strain (%) |

|---|---|---|

| As-built | 66 | 3 |

| LTH | 203 | 2.7 |

| HTH | 554 | 0.8 |

| Cast-LTH | 931 | 1.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banoth, S.; Li, C.-W.; Hiratsuka, Y.; Kakehi, K. The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process. Metals 2020, 10, 1016. https://doi.org/10.3390/met10081016

Banoth S, Li C-W, Hiratsuka Y, Kakehi K. The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process. Metals. 2020; 10(8):1016. https://doi.org/10.3390/met10081016

Chicago/Turabian StyleBanoth, Santhosh, Chen-Wei Li, Yo Hiratsuka, and Koji Kakehi. 2020. "The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process" Metals 10, no. 8: 1016. https://doi.org/10.3390/met10081016

APA StyleBanoth, S., Li, C.-W., Hiratsuka, Y., & Kakehi, K. (2020). The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process. Metals, 10(8), 1016. https://doi.org/10.3390/met10081016