Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties of Cold Drawn and Annealed Wires

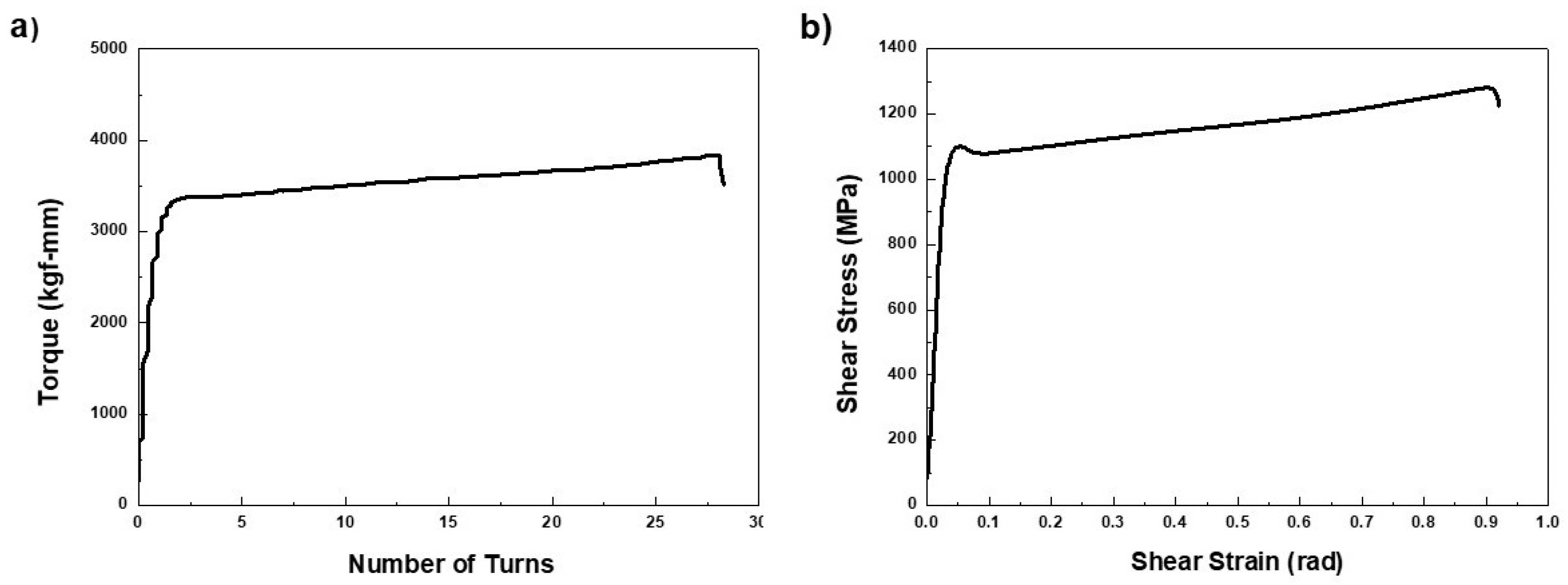

3.2. Torsional Ductility and Work Hardening

4. Conclusions

- In cold drawn wires, the number of turns to failure (NT) increased steadily up to ε = 2.18, showing the maximum peak, and then decreased with drawing strain. The increase of NT with drawing strain was related to the re-alignment of lamellar cementite along the wire axis, and the decrease of NT after the peak was caused by the fracture of lamellar cementite and the occurrence of dynamic aging during wire drawing.

- During the post-deformation annealing at 500 °C, NT of steel wires decreased with annealing time, except for the occurrence of delamination for an annealing time of 10 s. The decrease of NT would be attributed to the microstructural evolutions, accompanying the spheroidization and growth of cementite particles, and the recovery of ferrite in cold drawn steel wires.

- The variations of strain-hardening index, obtained from shear stress–shear strain curves, with drawing strain showed the similar trend to NT of cold drawn and/or annealed steel wires. When the strain-hardening index increases in shear stress–shear strain curves, the further plastic deformation is allowed in a torsion test. The behaviors of NT of cold drawn and/or annealed steel wires could be explained with the variations of mean free path (MPF) of dislocations

- It was found that among microstructural features, the shape and orientation of lamellar cementite showed the significant effect on torsional ductility of cold drawn and annealed hyper-eutectoid steel wires.

- Other ductility parameters of RA and EL showed the different behaviors from NT in cold drawn and/or annealed steel wires. During wire drawing, EL decreased continuously with drawing strain due to work hardening of lamellar ferrite, while the variation of RA with drawing strain was described as the sequential behavior: Increasing, showing the maximum peak, and decreasing continuously after the peak. Meanwhile, during the post-deformation annealing at 500 °C, the increase of annealing time in steel wires drawn with a strain of 1.95 resulted in the increase of EL and the decrease of RA.

Author Contributions

Funding

Conflicts of Interest

References

- Borchers, C.; Kirchheim, R. Cold-drawn Pearlitic Steel Wires. Prog. Mater. Sci. 2016, 82, 405–444. [Google Scholar] [CrossRef]

- Li, Y.J.; Choi, P.; Goto, S.; Borchers, C.; Raabe, D.; Kirchheim, R. Evolution of Strength and Microstructure during Annealing of Heavily Cold-drawn 6.3 GPa Hypereutectoid Pearlitic Steel Wire. Acta Mater. 2012, 60, 4005–4016. [Google Scholar] [CrossRef]

- Zhang, X.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and strengthening Mechanisms in cold-drawn pearlitic steel wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Zhang, X.; Godfrey, A.; Hansen, N.; Huang, X.X. Hierarchical Structures in Cold-drawn Pearlitic Steel Wire. Acta Mater. 2013, 61, 4898–4909. [Google Scholar] [CrossRef] [Green Version]

- Watte, P.; Humbeeck, J.V.; Aernoudt, E.; Lefever, I. Strain Ageing in Heavily Drawn Eutectoid Steel Wires. Scr. Mater. 1996, 34, 85–95. [Google Scholar] [CrossRef]

- Fang, F.; Zhou, L.C.; Hu, X.J.; Zhou, X.F.; Tu, Y.Y.; Xie, Z.H.; Jiang, J.Q. Microstructure and Mechanical Properties of Cold-drawn Pearlitic Wires Affect by Inherited Texture. Mater. Des. 2015, 79, 60–67. [Google Scholar] [CrossRef]

- Toribio, J.; González, B.; Matos, J.C. Analysis of Fatigue Crack Paths in Cold Drawn Pearlitic Steel. Materials 2015, 8, 7439–7446. [Google Scholar] [CrossRef] [Green Version]

- Toribio, J.; González, B.; Matos, J.C. Fatigue crack propagation in cold drawn steel. Mater. Sci. Eng. A 2007, 468–470, 267–272. [Google Scholar] [CrossRef]

- Park, D.B.; Lee, J.W.; Lee, Y.S.; Park, K.T.; Nam, W.J. Effect of the Annealing Temperature and Time on the Microstructural Evolution and Corresponding the Mechanical Properties of Cold-drawn Steel Wires. Met. Mater. Int. 2008, 14, 59–64. [Google Scholar]

- Fang, F.; Hu, J.; Chen, S.H.; Xie, Z.H.; Jiang, J.Q. Revealing Microstructural and Mechanical Characteristics of Cold-drawn Pearlitic Steel Wires undergoing Simulated Galvanization Treatment. Mater. Sci. Eng. A 2012, 547, 51–54. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, J.C.; Lee, Y.S.; Park, K.T.; Nam, W.J. Effects of Post-deformation Annealing Conditions on the Behavior of Lamellar Cementite and the Occurrence of Delamination in Cold-drawn Steel Wires. J. Mater. Process. Technol. 2009, 209, 5300–5304. [Google Scholar] [CrossRef]

- Joung, S.W.; Kang, U.G.; Hong, S.P.; Kim, Y.W.; Nam, W.J. Aging Behavior and Delamination in Cold Drawn and Post-deformation Annealed Hyper-eutectoid Steel Wires. Mater. Sci. Eng. A 2013, 586, 171–177. [Google Scholar] [CrossRef]

- Hono, K.; Ohnuma, M.; Murayama, M.; Nishida, S.; Yoshie, A.; Takahashi, T. Cementite Decomposition in Heavily Drawn Pearlite Steel Wire. Scr. Mater. 2001, 44, 977–983. [Google Scholar] [CrossRef]

- Languillaum, J.; Kapelaki, G.; Baudelet, B. Cementite Dissolution in Heavily Cold-drawn Pearlite Steel Wires. Acta Mater. 1997, 45, 1201–1212. [Google Scholar] [CrossRef]

- Zhou, L.C.; Fang, F.; Wang, L.; Chen, H.Q.; Xie, Z.H.; Jiang, J.Q. Torsion Delamination and Recrystallized Cementite of Heavy Drawing Pearlitic Wires After Low Temperature Annealing. Mater. Sci. Eng. A 2018, 713, 52–60. [Google Scholar] [CrossRef]

- Gondo, S.; Tanemura, R.; Suzuki, S.; Kajino, S.; Asakawa, M.; Takemoto, K.; Tashima, K. Microstructures and Mechanical Properties of Fiber Textures forming Mesoscale Structure of Drawn Fine High Carbon Steel Wire. Mater. Sci. Eng. A 2019, 747, 255–264. [Google Scholar] [CrossRef]

- He, Y.; Xiang, S.; Shi, W.; Liu, J.; Ji, X.; Yu, W. Effect of Microstructure Evolution on Anisotropic Fracture Behaviors of Cold Drawing Pearlitic Steels. Mater. Sci. Eng. A 2017, 683, 153–163. [Google Scholar] [CrossRef]

- Nam, W.J.; Bae, C.M.; Oh, S.J.; Kwon, S.J. Effect of Interlamellar Spacing on Cementite Dissolution during Wire Drawing of Pearlitic Steel Wires. Scr. Mater. 2000, 42, 457–463. [Google Scholar] [CrossRef]

- Li, Y.J.; Choi, P.; Borchers, C.; Chen, Y.Z.; Goto, S.; Raabe, D.; Kirchheim, R. Atom Probe Tomography Characterization of Heavily Cold Drawn Pearlitic Steel Wire. Ultramicroscopy 2011, 111, 628–632. [Google Scholar] [CrossRef]

- Zhao, T.Z.; Zhang, S.H.; Zhang, G.L.; Song, H.W.; Cheng, M. Hardening and Softening Mechanisms of Pearlitic Steel Wire under Torsion. Mater. Des. 2014, 59, 397–405. [Google Scholar] [CrossRef]

- Zelin, M. Microstructure Evolution in Pearlitic Steels during Wire Drawing. Acta Mater. 2002, 50, 4431–4447. [Google Scholar] [CrossRef]

- Lee, S.K.; Ko, D.C.; Ki, B.M. Pass schedule of wire drawing process to prevent delamination for high strength steel cord wire. Mater. Des. 2009, 30, 2919–2927. [Google Scholar] [CrossRef]

- Gelfi, M.; Solazzi, L.; Poli, S. Influence of the Manufacturing Process on Defects in the Galvanized Coating of High Carbon Steel Wires. Materials 2017, 10, 264. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rojas, H.A.G.; Egea, A.J.S.; Hameed, S.; Bolmaro, R. An Ultra-Fast Annealing Treatment by Electropulsing during Pure Copper Wire Drawing. Metals 2019, 9, 1253. [Google Scholar] [CrossRef] [Green Version]

- Egea, A.J.S.; Peiro, J.J.; Signorelli, J.W.; Rojas, H.A.G.; Celentano, D.J. On the Microstructure Effects when using Electropulsing versus Furnace Treatments while Drawing Inox 308L. J. Mater. Res. Technol. 2019, 8, 2269–2279. [Google Scholar] [CrossRef]

- Zhou, L.; Fang, F.; Wang, L.; Hu, X.; Xie, Z.; Jiang, J. Torsion Performance of Pearlitic Steel Wires: Effects of Morphology and Crystallinity of Cementite. Mater. Sci. Eng. A 2019, 743, 425–435. [Google Scholar] [CrossRef]

- Lu, X. Correlation between Microstructural Evolution and Mechanical Properties of 2000 MPa Cold-Drawn Pearlitic Steel Wires during Galvanizing Simulated Annealing. Metals 2019, 9, 326. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Wang, L.; Fang, F.; Ma, Z.; Xie, Z.H.; Jiang, J. Origin and Mechanism of Torsion Fracture in Cold-drawn Pearlitic Steel Wires. J. Mater. Sci. 2013, 48, 5528–5535. [Google Scholar] [CrossRef]

- Das, S.; Koli, P.; Mathur, J.; Dey, A.; Bhattacharyya, T.; Bhattacharyya, S. Failure Analysis of Motor Tire Bead Wires During Torsion Test. J. Fail. Anal. Preven. 2013, 13, 684–688. [Google Scholar] [CrossRef]

- Fan, Z.; Mingzhi, H.; Deke, S. The Relationship between the Strain-hardening Exponent n and the Microstructure of Metals. Mater. Sci. Eng. A 1989, 122, 211–213. [Google Scholar] [CrossRef]

- Lou, S.; Northwood, D.O. Effect of Strain Aging on the Strength Coefficient and Strain-Hardening Exponent of Construction-Grade Steels. JMEPEG 1994, 3, 344–349. [Google Scholar] [CrossRef]

- Takahashi, J.; Kosaka, M.; Kawakami, K.; Tarui, T. Change in Carbon State by Low-temperature Aging in Heavily Drawn Pearlitic Steel Wires. Acta Mater. 2012, 60, 387–395. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, J.Y.; An, K.S.; Park, P.Y.; Nam, W.J. Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires. Metals 2020, 10, 1043. https://doi.org/10.3390/met10081043

Jung JY, An KS, Park PY, Nam WJ. Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires. Metals. 2020; 10(8):1043. https://doi.org/10.3390/met10081043

Chicago/Turabian StyleJung, Jin Young, Kang Suk An, Pyeong Yeol Park, and Won Jong Nam. 2020. "Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires" Metals 10, no. 8: 1043. https://doi.org/10.3390/met10081043

APA StyleJung, J. Y., An, K. S., Park, P. Y., & Nam, W. J. (2020). Effects of Wire Drawing and Annealing Conditions on Torsional Ductility of Cold Drawn and Annealed Hyper-Eutectoid Steel Wires. Metals, 10(8), 1043. https://doi.org/10.3390/met10081043