Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy

Abstract

:1. Introduction

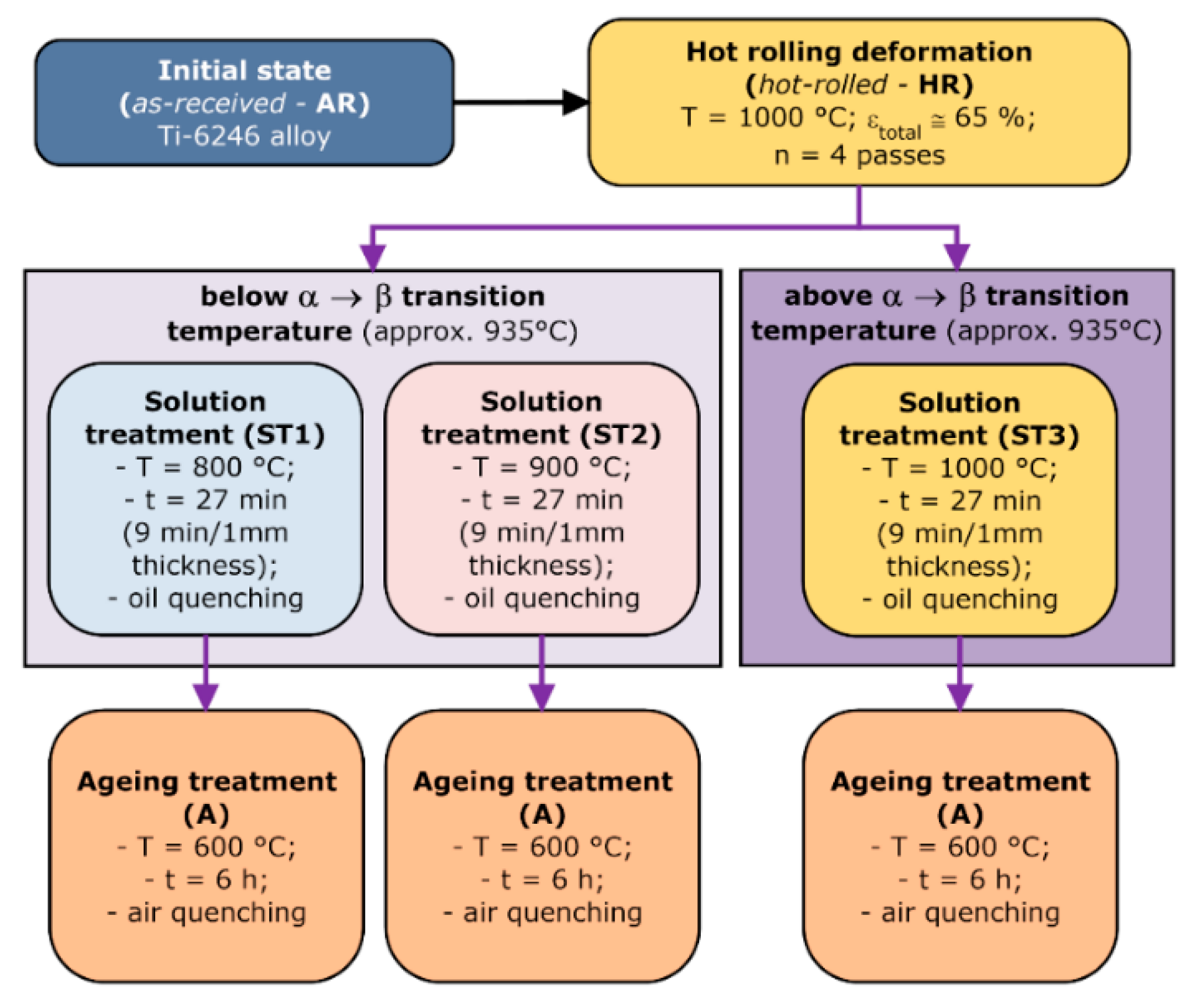

2. Materials and Methods

3. Results and Discussion

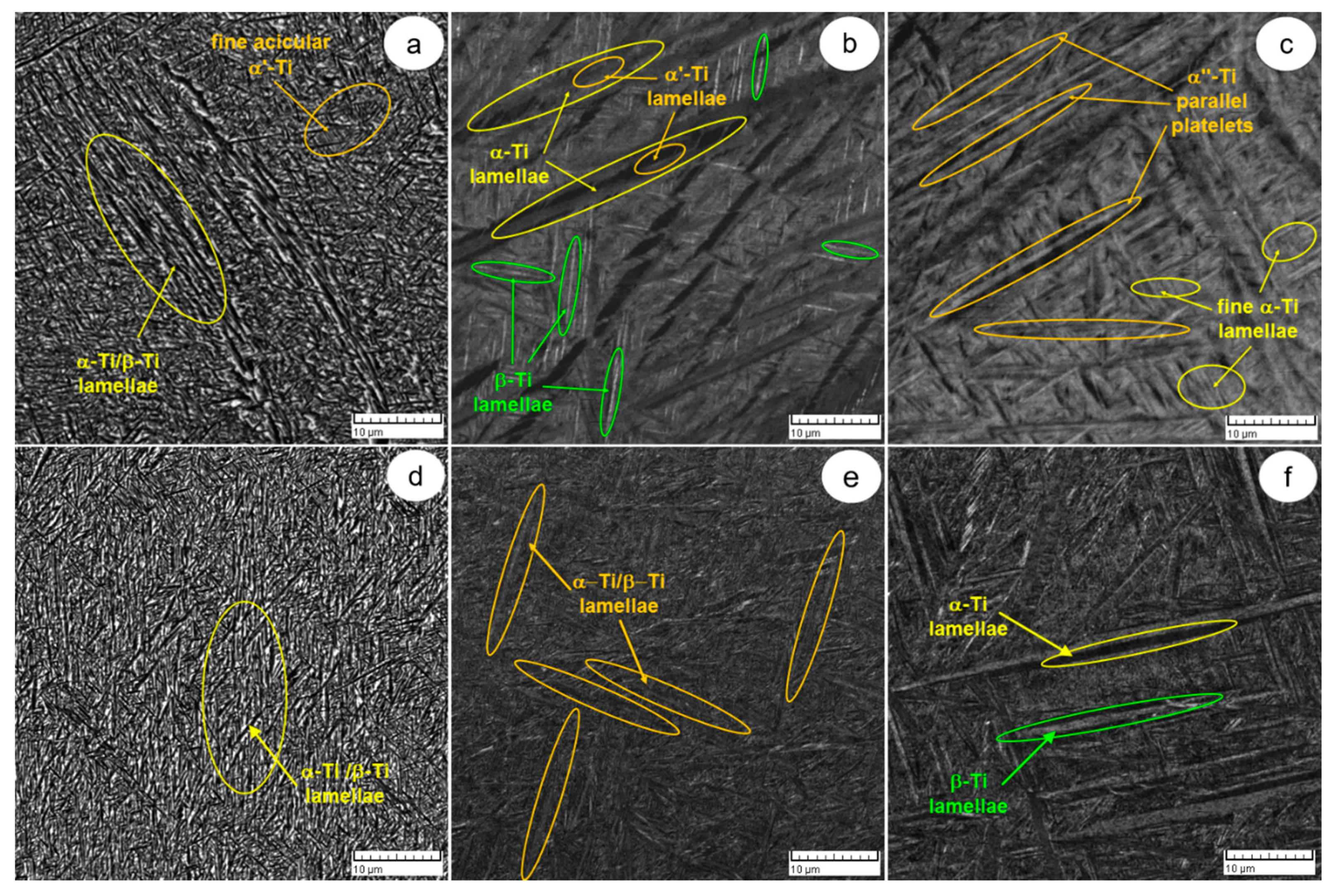

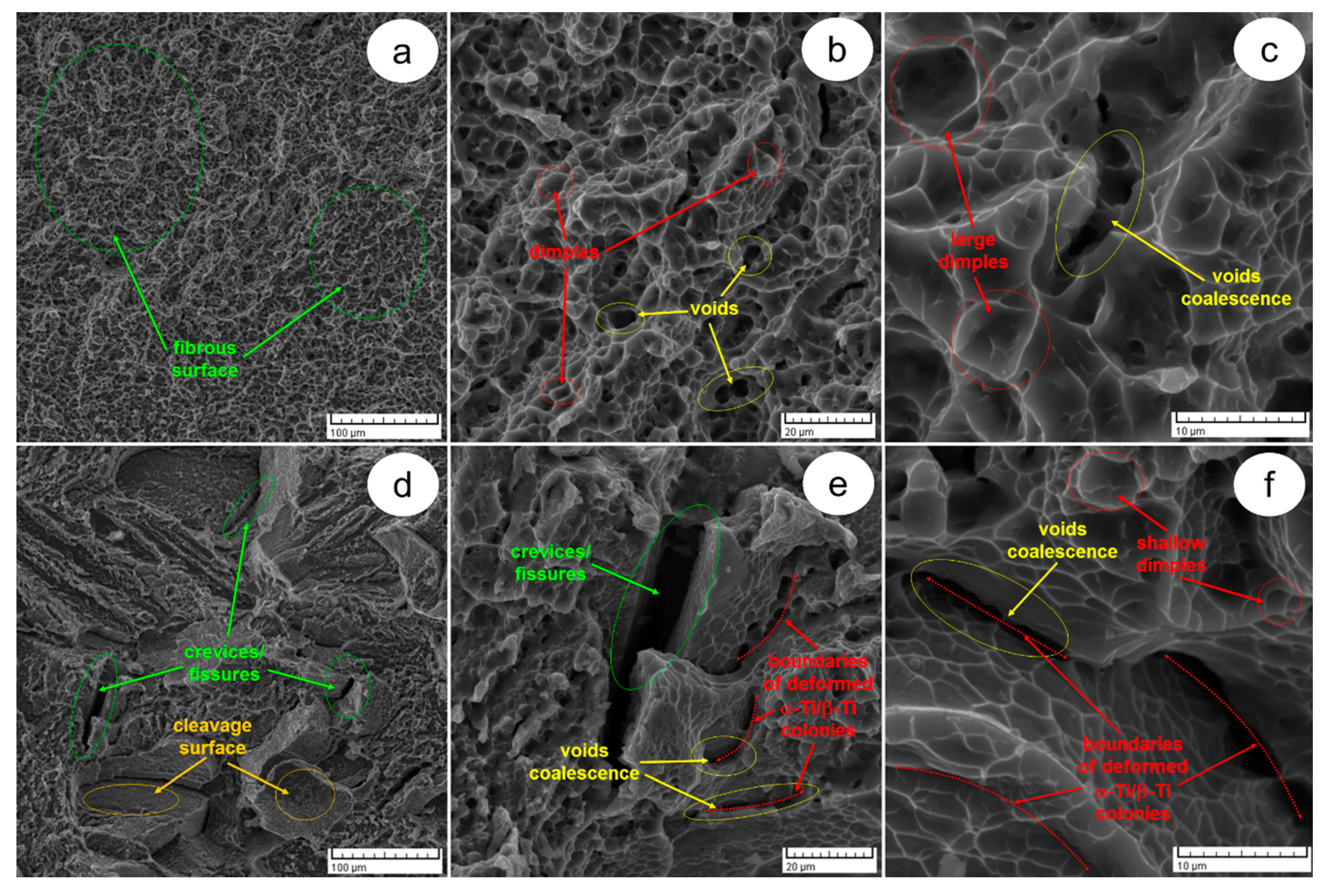

3.1. Microstructure Evolution during TM Processing of Ti-6246 Alloy

3.2. Mechanical Behaviour during TM Processing of Ti-6246 Alloy

4. Conclusions

- The main positive effect of applying solution and ageing treatments is represented by the possibility to control exhibited mechanical behaviour of Ti-6246 alloy;

- A solution treatment temperature below β-transus induces the formation of α′-Ti phase, influencing the alloy’s mechanical behaviour by increasing both strength and ductility properties in comparison with the hot-deformed state; the Ti-6246 alloy shows the highest strength and ductility when solution treatment is performed close to β-transus temperature;

- A solution treatment temperature above β-transus induces the formation of α″-Ti phase, influencing the alloy’s mechanical behaviour by decreasing both strength and ductility properties;

- During ageing treatment α′-Ti/α″-Ti → α-Ti/β-Ti and β-Ti → α-Ti/ω-Ti transformations occur, influencing the alloy’s mechanical behaviour by increasing the strength, ductility and microhardness due to the stress relieving and dispersion precipitation strengthening mechanisms.

Author Contributions

Funding

Conflicts of Interest

References

- Fanning, J.C.; Boyer, R.R. Properties of TIMETAL 555—A new near-beta titanium alloy for airframe components. In Ti-2003 Science and Technology, Proceedings of the 10th World Conference on Titanium, Hamburg, Germany, 13–18 July 2003; Lütjering, G., Albrecht, J., Eds.; Wiley-VCH: Hamburg, Germany, 2003; Volume IV, pp. 2643–2650. [Google Scholar]

- Nyakana, S.L.; Fanning, J.C.; Boyer, R.R. Quick reference guide for β titanium alloys in the 00 s. J. Mater. Eng. Perform. 2005, 14, 799–811. [Google Scholar] [CrossRef]

- Cotton, J.D.; Boyer, R.R.; Briggs, R.D.; Baggerly, R.G.; Meyer, C.A.; Carter, M.D.; Wood, W.; Tewksbury, G.; Li, V.; Yao, X.; et al. Phase transformations in Ti-5Al-5Mo-5V-3Cr-0.5Fe. In Ti-2007 Science and Technology Proceedings of the 11th World Conference on Titanium, Kyoto, Japan, 3–7 June 2007; Niinomi, M., Akiyama, S., Hagiwara, M., Ikeda, M., Maruyama, K., Eds.; The Japan Institute of Metals: Kyoto, Japan, 2007; Volume I, pp. 471–474. [Google Scholar]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Manda, P.; Ghosal, P.; Chakkingal, U.; Singh, A.K. Effect of alloying elements in hot-rolled metastable β-titanium alloys: Part I. evolution of microstructure and texture. Metall. Mater. Trans. A 2015, 46, 2646–2663. [Google Scholar] [CrossRef]

- Ma, Y.; Du, Z.; Cui, X.; Cheng, J.; Liu, G.; Gong, T.; Liu, H.; Wang, X.; Chen, Y. Effect of cold rolling process on microstructure and mechanical properties of high strength β titanium alloy thin sheets. Prog. Nat. Sci. Mater. Int. 2018, 28, 711–717. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y.; Wang, L. Surface modification of titanium and titanium alloys: Technologies, developments, and future interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Froes, F.H. Titanium: Physical Metallurgy, Processing and Applications, 1st ed.; ASM International: Cleveland, OH, USA, 2015; p. 417. [Google Scholar]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. Light Alloys: Metallurgy of the Light Metals, 5th ed.; Matthew Deans: Oxford, UK, 2017; p. 533. [Google Scholar]

- Liu, S.; Liu, J.; Wang, L.; Ma, R.L.W.; Zhong, Y.; Lu, W.; Zhang, L.C. Superelastic behavior of in-situ eutectic-reaction manufactured high strength 3D porous NiTi-Nb scaffold. Scr. Mater. 2020, 181, 121–126. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Ready, A.J.; Haynes, P.D.; Grabowski, B.; Rugg, D.; Sutton, A.P. The role of molybdenum in suppressing cold dwell fatigue in titanium alloys. Proc. R. Soc. A Maths. Phys. Eng. Sci. 2017, 473, 1–15. [Google Scholar] [CrossRef]

- Froes, F.H.; Highberger, W.T. Synthesis of corona 5 (Ti-4.5 Al-5Mo-1.5Cr). JOM 1980, 32, 57–64. [Google Scholar] [CrossRef]

- Weiss, I.; Froes, F.H.; Eylon, D.; Welsch, G.E. Modification of alpha morphology in Ti-6Al-4V by thermomechanical processing. Metall. Mater. Trans. A 1986, 17, 1935–1947. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.K.; Kumar, A.; Parihar, M.S. Investigations on the effect of heating temperature and cooling rate on evolution of microstructure in an α + β titanium alloy. Mater. Res. Soc. 2018, 33, 946–957. [Google Scholar] [CrossRef]

- Dąbrowski, R. The kinetics of phase transformations during continuous cooling of the Ti6Al4V alloy from the singlephase β range. Arch. Metall. Mater. 2011, 56, 703–707. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Zeng, W.; Zhao, Y.; Sun, X.; Du, Z. Influence of cooling rate following heat treatment on microstructure and phase transformation for a two-phase alloy. J. Alloy. Compd. 2016, 688, A301–A309. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; p. 449. [Google Scholar]

- Zhang, J.; Tasan, C.C.; Lai, M.J.; Dippel, A.-C.; Raabe, D. Complexion-mediated martensitic phase transformation in titanium. Nat. Commun. 2017, 8, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Duerig, T.W.; Terlinde, G.T.; Williams, J.C. Phase transformations and tensile properties of Ti-10V-2Fe-3Al. Metall. Mater. Trans. A 1980, 11, 1987–1998. [Google Scholar] [CrossRef]

- Menon, E.S.K.; Chakravartty, J.K.; Wadekar, S.L.; Banerjee, S. Stress induced martensitic transformation in Ti-20V. J. Phys. Colloq. 1982, 43, C321–C326. [Google Scholar] [CrossRef]

- Ninomi, M.; Kobayashi, T.; Inagaki, I.; Thompson, A.W. The effect of deformation-induced transformation on the fracture toughness of commercial titanium alloys. Metall. Mater. Trans. A 1990, 21, 1733–1744. [Google Scholar] [CrossRef]

- Ishiyama, S.; Hanada, S.; Izumi, O. Effect of Zr, Sn and Al additions on deformation mode and beta phase stability of metastable beta Ti alloys. ISIJ Int. 1991, 31, 807–813. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.Y.; Miyazaki, S. Ni-Free Ti-Based Shape Memory Alloys, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 1–52. [Google Scholar]

- He, J.; Li, D.; Jiang, W.; Ke, L.; Qin, G.; Ye, Y.; Qin, Q.; Qiu, D. The martensitic transformation and mechanical properties of Ti6Al4V prepared via selective laser melting. Materials 2019, 12, 321. [Google Scholar] [CrossRef] [Green Version]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Cleveland, OH, USA, 2000; p. 216. [Google Scholar]

- El-Hadad, S.; Nady, M.; Khalifa, W.; Shash, A. Influence of heat treatment conditions on the mechanical properties of Ti-6Al-4V alloy. Can. Metall. Q. 2018, 57, 186–193. [Google Scholar] [CrossRef]

- ASM International Handbook Committee. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th ed.; ASM International: Cleveland, OH, USA, 1992; p. 3470. [Google Scholar]

- El-Hadad, S.; Mhaede, M.; Ibrahiem, K.M. Microstructural effects on corrosion behavior of investment cast Ti-6.5Al-3.4Mo-1.7Zr alloy. Int. J. Cast Met. Res. 2016, 29, 243–250. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef] [Green Version]

- TIMETAL 6-2-4-6 Data Sheet. Available online: https://www.timet.com/assets/local/documents/datasheets/alphaandbetaalloys/6246.pdf (accessed on 9 July 2020).

- Zhang, X.D.; Evans, D.J.; Baeslack, W.A.; Fraser, H.L. Effect of long term aging on the microstructural stability and mechanical properties of Ti-6Al-2Cr-2Mo-2Sn-2Zr alloy. Mater. Sci. Eng. A 2003, 344, 300–311. [Google Scholar] [CrossRef]

- Wu, C.; Zhan, M. Microstructural evolution, mechanical properties and fracture toughness of near β titanium alloy during different solution plus aging heat treatments. J. Alloy. Compd. 2019, 805, 1144–1160. [Google Scholar] [CrossRef]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy Ti-5Al-5V-5Mo-3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Jia, W.J.; Zeng, W.D.; Yu, H.Q. Effect of aging on the tensile properties and microstructures of a near-alpha titanium alloy. Mater. Des. 2014, 58, 108–115. [Google Scholar] [CrossRef]

- Du, Z.; Xiao, S.; Xu, L.; Tian, J.; Kong, F.; Chen, Y. Effect of heat treatment on microstructure and mechanical properties of a new high strength titanium alloy. Mater. Des. 2014, 55, 183–190. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The thermomechanical processing of alpha/beta titanium alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Weiss, I.; Semiatin, S.L. Thermomechanical processing of alpha titanium alloys—An overview. Mater. Sci. Eng. A 1999, 263, 243–256. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Knisley, S.L.; Fagin, P.N.; Barker, D.R.; Zhang, F. Microstructure evolution during alpha-beta heat treatment of Ti-6Al-4V. Metall. Mater. Trans. A 2003, 34, 2377–2386. [Google Scholar] [CrossRef]

- Dabrowski, R. The kinetics of phase transformations during continuous cooling of Ti-6Al-4V alloy from the diphase α + β range. Arch. Metall. Mater. 2011, 56, 217–221. [Google Scholar]

- Krakhmalev, P.; Fredriksson, G.; Yadroitsava, I.; Kazantseva, N.; Du Plessis, A.; Yadroitsev, I. Deformation behavior and microstructure of Ti6Al4V manufactured by SLM. Phys. Procedia 2016, 83, 778–788. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; To, A.C. Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting. Addit. Manuf. 2017, 16, 58–64. [Google Scholar] [CrossRef]

- Mantri, S.A.; Banerjee, R. Microstructure and micro-texture evolution of additively manufactured β-Ti alloys. Addit. Manuf. 2018, 23, 86–98. [Google Scholar] [CrossRef]

- Yamanaka, K.; Saito, W.; Mori, M.; Matsumoto, H.; Chiba, A. Preparation of weak-textured commercially pure titanium by electron beam melting. Addit. Manuf. 2015, 8, 105–109. [Google Scholar] [CrossRef]

- Ji, X.; Gutierrez-Urrutia, I.; Emura, S.; Liu, T.; Hara, T.; Min, X.; Ping, D.; Tsuchiya, K. Twinning behavior of orthorhombic-α martensite in a Ti-7.5Mo alloy. Sci. Technol. Adv. Mater. 2019, 20, 401–411. [Google Scholar] [CrossRef] [Green Version]

- Hafeez, N.; Liu, J.; Wang, L.; Wei, D.; Tang, Y.; Lu, W.; Zhang, L.C. Superelastic response of low-modulus porous beta-type Ti-35Nb-2Ta-3Zr alloy fabricated by laser powder bed fusion. Addit. Manuf. 2020, 34, 101264. [Google Scholar] [CrossRef]

- Chong, Y.; Deng, G.; Gao, S.; Yi, J.; Shibata, A.; Tsuji, N. Yielding nature and Hall-Petch relationships in Ti-6Al-4V alloy with fully equiaxed and bimodal microstructures. Scr. Mater. 2019, 172, 77–82. [Google Scholar] [CrossRef]

- Yu, Y.; Hui, S.; Ye, W.; Xiong, B. Mechanical properties and microstructure of an α + β titanium alloy with high strength and fracture toughness. Rare Met. 2009, 28, 346–349. [Google Scholar] [CrossRef]

- Padmalatha, T.S.R.V.; Chakkingal, U. The effect of heat treatment and the volume fraction of the alpha phase on the workability of Ti-5Al-5Mo-5V-3Cr alloy. J. Mater. Eng. Perform. 2019, 28, 5352–5360. [Google Scholar] [CrossRef]

- Guo, Y.; Jung, T.; Chiu, Y.L.; Li, H.; Bray, S.; Bowen, P. Microstructure and microhardness of Ti6246 linear friction weld. Mater. Sci. Eng. A 2013, 562, 17–24. [Google Scholar] [CrossRef]

- Chamanfar, A.; Pasang, T.; Ventura, A.; Misiolek, W.Z. Mechanical properties and microstructure of laser welded Ti–6Al–2Sn–4Zr–2Mo (Ti6242) titanium alloy. Mater. Sci. Eng. A 2016, 663, 213–224. [Google Scholar] [CrossRef] [Green Version]

- Xu, P.; Zhou, L.; Han, M.; Wei, Z.; Liang, Y. Flash-butt welded Ti6242 joints preserved base-material strength and ductility. Mater. Sci. Eng. A 2020, 774, 138915. [Google Scholar] [CrossRef]

- Tang, B.; Chu, Y.; Zhang, M.; Meng, C.; Fan, J.; Kou, H.; Li, J. The ω phase transformation during the low temperature aging and low rate heating process of metastable β titanium alloys. Mater. Chem. Phys. 2020, 239, 122–125. [Google Scholar] [CrossRef]

- Ali, T.; Wang, L.; Cheng, X.; Liu, A.; Xu, X. Omega phase formation and deformation mechanism in heat treated Ti-5553 alloy under high strain rate compression. Mater. Lett. 2019, 236, 163–166. [Google Scholar] [CrossRef]

- Jones, N.G.; Dashwood, R.J.; Jackson, M.; Dye, D. Beta phase decomposition in Ti-5Al-5Mo-5V-3Cr. Acta Mater. 2009, 57, 3830–3839. [Google Scholar] [CrossRef]

- Li, M.J.; Min, X.H.; Yao, K.; Ye, F. Novel insight into the formation of alpha-martensite and omega-phase with cluster structure in metastable Ti-Mo alloys. Acta Mater. 2019, 164, 322–333. [Google Scholar] [CrossRef]

- Chen, W.; Cao, S.; Kou, W.J.; Zhang, J.Y.; Wang, Y.; Zha, Y.; Pan, Y.; Hu, Q.M.; Sun, Q.Y.; Sun, J. Origin of the ductile-to-brittle transition of metastable beta-titanium alloys: Self-hardening of omega-precipitates. Acta Mater. 2019, 170, 187–204. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. Omega-assisted nucleation and growth of alpha precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe beta titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Shi, R.; Zheng, Y.; Banerjee, R.; Fraser, H.L.; Wang, Y. ω-Assisted α nucleation in a metastable β titanium alloy. Scr. Mater. 2019, 171, 62–66. [Google Scholar] [CrossRef]

- Gao, J.; Knowles, A.J.; Guan, D.; Rainforth, W.M. ω phase strengthened 1.2 GPa metastable β titanium alloy with high ductility. Scr. Mater. 2019, 162, 77–81. [Google Scholar] [CrossRef]

| Element | wt.% | at.% | Abs. Error (%) | Rel. Error (%) |

|---|---|---|---|---|

| Titanium | 81.54 | 82.55 | 2.44 | 2.76 |

| Aluminium | 6.33 | 11.36 | 0.33 | 4.77 |

| Tin | 1.85 | 0.75 | 0.05 | 2.94 |

| Zirconium | 3.91 | 2.08 | 0.16 | 3.79 |

| Molybdenum | 6.24 | 3.15 | 0.24 | 3.54 |

| Iron | 0.14 | 0.12 | 0.12 | 2.77 |

| Structural State | Mechanical Properties | |||

|---|---|---|---|---|

| Ultimate Sensile Strength, σUTS (MPa) | 0.2 Yield Strength, σ0.2 (MPa) | Elongation to Fracture, εf (%) | Microhardness, HV1 | |

| As-received (AR) | 1057 ± 14 | 967 ± 11 | 12.9 ± 1.8 | 305.2 ± 16.9 |

| Hot-deformed at 1000 °C (HR) | 1012 ± 11 | 902 ± 14 | 3.2 ± 0.6 | 417.8 ± 6.1 |

| Solution treated at T = 800 °C (ST1) | 1113 ± 14 | 985 ± 10 | 5.3 ± 0.8 | 385.1 ± 10.1 |

| Solution treated at T = 900 °C (ST2) | 1205 ± 12 | 1014 ± 13 | 8.1 ± 1.2 | 312.4 ± 17.1 |

| Solution treated at T = 1000 °C (ST3) | 961 ± 12 | 747 ± 15 | 7.2 ± 0.9 | 339.8 ± 21.3 |

| Solution treated at T = 800 °C + ageing treated at T = 600 °C (ST1 + A) | 1144 ± 13 | 991 ± 12 | 6.5 ± 0.9 | 325.2 ± 11.9 |

| Solution treated at T = 900 °C + ageing treated at T = 600 °C (ST2 + A) | 1279 ± 15 | 1161 ± 14 | 10.1 ± 1.3 | 425.2 ± 4.5 |

| Solution treated at T = 1000 °C + ageing treated at T = 600 °C (ST3 + A) | 1044 ± 12 | 919 ± 13 | 5.7 ± 0.9 | 442.6 ± 9.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alluaibi, M.H.I.; Cojocaru, E.M.; Rusea, A.; Șerban, N.; Coman, G.; Cojocaru, V.D. Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy. Metals 2020, 10, 1114. https://doi.org/10.3390/met10091114

Alluaibi MHI, Cojocaru EM, Rusea A, Șerban N, Coman G, Cojocaru VD. Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy. Metals. 2020; 10(9):1114. https://doi.org/10.3390/met10091114

Chicago/Turabian StyleAlluaibi, Mohammed Hayder Ismail, Elisabeta Mirela Cojocaru, Adrian Rusea, Nicolae Șerban, George Coman, and Vasile Danut Cojocaru. 2020. "Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy" Metals 10, no. 9: 1114. https://doi.org/10.3390/met10091114

APA StyleAlluaibi, M. H. I., Cojocaru, E. M., Rusea, A., Șerban, N., Coman, G., & Cojocaru, V. D. (2020). Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy. Metals, 10(9), 1114. https://doi.org/10.3390/met10091114