The Effect of Laser Offset Welding on Microstructure and Mechanical Properties of 301L to TA2 with and without Cu Intermediate Layer

Abstract

:1. Introduction

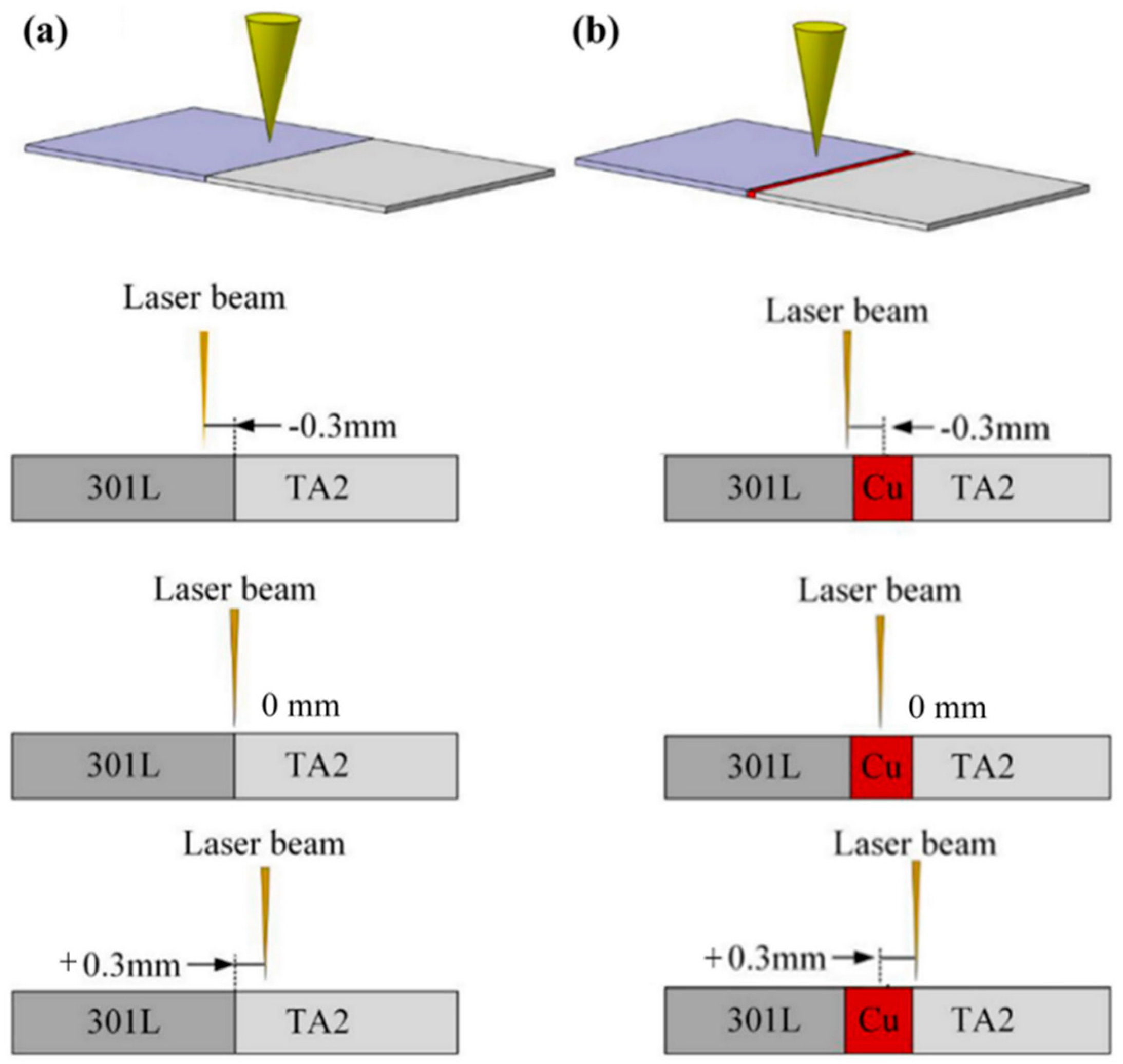

2. Materials and Methods

3. Results and Discussions

3.1. Characterization of 301L/TA2 Welded Joint

3.1.1. Surface Morphologies

3.1.2. Microstructures and Elements Distribution

3.1.3. Microhardness

3.1.4. Tensile Strength and Fracture Surface Observation

3.2. Characterization of 301L/Cu/TA2 Welded Joint

3.2.1. Surface Morphologies

3.2.2. Microstructures and Elements Distribution

3.2.3. Microhardness

3.3. Tensile Strength and Fracture Surface Observation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schutz, R.W.; Watkins, H.B. Recent developments in titanium alloy application in the energy industry. Mater. Sci. Eng. A 1998, 243, 305–315. [Google Scholar] [CrossRef]

- Chen, H.C.; Bi, G.J.; Lee, B.Y.; Cheng, C.K. Laser welding of CP Ti to stainless steel with different temporal pulse shapes. J. Mater. Process. Technol. 2016, 231, 58–65. [Google Scholar] [CrossRef]

- Xian, A.P.; Si, Z.Y. Interlayer design for joining pressureless sintered sialon ceramic and 40Cr steel brazing with Ag57Cu38Ti5 filler metal. J. Mater. Sci. 1992, 27, 1560–1566. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Z.; Zou, L.; Liu, X.; Chai, C.; Zhao, H.; Yan, Y.; Wang, C. Quality evaluation of Apocyni Veneti folium from different habitats and commercial herbs based on simultaneous determination of multiple bioactive constituents combined with multivariate statistical analysis. Molecules 2018, 23, 1–14. [Google Scholar]

- Ridha Mohammed, G.; Ishak, M.; Ahmad, S.N.A.S.; Abdulhadi, H.A. Fiber laser welding of dissimilar 2205/304 stainless steel plates. Metals 2017, 7, 546. [Google Scholar] [CrossRef] [Green Version]

- Landowski, M.; Świerczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous fiber laser welding of 316L austenitic and 2304 lean duplex stainless steels. Materials 2020, 13, 2930. [Google Scholar] [CrossRef] [PubMed]

- Cao, F.J.; Zhang, Y.; Shen, Y.F.; Jin, Y.J.; Li, J.P.; Hou, W.T. Effects of beam offset on the macro defects, microstructure and mechanical behaviors in dissimilar laser beam welds of SDSS2507 and Q235. J. Manuf. Processes 2020, 55, 335–347. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Microstructure and mechanical properties of diffusion bonded joints between titanium and stainless steel with copper interlayer. Sci. Technol. Weld. Joining 2007, 12, 572–578. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, M.; Huang, J.; Cui, C.; Zhang, H.; Zhao, X. Microstructures and mechanical property of laser buttwelding of titanium alloy to stainless steel. Mater. Des. 2014, 53, 504–511. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Wang, L.; Chen, Q.F. Revisions of the diterpenoid alkaloids reported in a JNP paper. Tetrahedron 2013, 69, 5859–5866. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J. Mater. Process. Technol. 2009, 209, 2746–2752. [Google Scholar] [CrossRef]

- Zhang, B.G.; Zhao, J.; Li, X.P.; Feng, J.C. Electron beam welding of 304 stainless steel to QCr0.8 copper alloy with copper filler wire. Trans. Nonferrous Met. Soc. China 2014, 24, 4059–4066. [Google Scholar] [CrossRef]

- Pardal, G.; Ganguly, S.; Williams, S.; Vaja, J. Dissimilar metal joining of stainless steel and titanium using copper as transition metal. Int. J. Adv. Manuf. Technol. 2016, 86, 1139–1150. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Sun, D.Q.; Gu, X.Y.; Li, H. Characterization of laser-welded Ti alloy and stainless steel joint using Cu interlayer. J. Mater. Eng. Perform. 2019, 28, 6092–6101. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, D.Q.; Gu, X.Y.; Liu, Y.J. Nd/YAG pulsed laser welding of TC4 titanium alloy to 301L stainless steel via pure copper interlayer. Int. J. Adv. Manuf. Technol. 2016, 90, 1–9. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, L.; Zhang, Q. Analysis of TA2 hot deformation behavior and corrected TA2 constitutive model based on dynamic recrystallization. Mater. Res. Express 2019, 6, 046531. [Google Scholar] [CrossRef]

- Wesemann, I.; Hoffmann, A.; Mrotzek, T.; Martin, U. Investigation of solidsolution hardening in molybdenum alloys. Int. J. Refract. Met. Hard Mater. 2010, 28, 709–715. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, T.; Chen, G.; Feng, J. Contact reactive joining of TA15 and 304 stainless steel via a copper interlayer heated by electron beam with a beam deflection. J. Mater. Eng. Perform. 2012, 21, 2067–2073. [Google Scholar] [CrossRef]

- Kurt, B.; Orhan, N.; Evin, E.; Calik, A. Diffusion bonding between Ti-6Al-4V alloy and ferritic stainless steel. Mater. Lett. 2007, 61, 1747–1750. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Wang, L.; Zeng, X. Laser-arc hybrid welding of dissimilar titanium alloy and stainless steel using copper wire. Metall. Mater. Trans. A 2015, 46, 2007–2020. [Google Scholar] [CrossRef]

- Hao, X.; Li, P.; Xia, Y.; Dong, H.; Wang, P.; Yan, D. Microstructure and mechanical properties of dissimilar TC4 titanium alloy/304 stainless steel joint using copper filler wire. Metall. Mater. Trans. A 2019, 50, 688–703. [Google Scholar] [CrossRef]

- Song, Y.Q.; Li, S.C.; Du, G.H. Microstructure and forming rule of Ti/Cu diffusion solution zone. Mater. Sci. Technol. 2010, 18, 420–424. [Google Scholar]

| C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0–18.0 | 6.0–8.0 | Base |

| Fe | N | H | O | Ti |

|---|---|---|---|---|

| 0.045 | 0.018 | 0.0013 | 0.124 | Base |

| Material | Melting Point (°C) | Tensile Strength (MPa) | Specific Heat Capacity (J·kg−1·K−1) | Thermal Conductivity (W·m−1·K−1) | Linear Expansion Coefficient (10−6·K−1) |

|---|---|---|---|---|---|

| 301L | 1450 | 550 | 500 | 16.3 | 16.3 |

| TA2 | 1668 | 500 | 522 | 15.04 | 8.4 |

| Spot | Composition (at.%) | Potential Phases | |||

|---|---|---|---|---|---|

| Fe | Cr | Ni | Ti | ||

| Spot A in Figure 3d | 72.18 | 17.33 | 5.15 | 3.97 | γ-Fe |

| Spot B in Figure 3d | 61.65 | 16.46 | 0.93 | 20.27 | FeTi + γ-Fe |

| Spot C in Figure 3e | 56.78 | 7.33 | 3.00 | 30.55 | Fe2Ti |

| Spot D in Figure 3f | 24.10 | 6.46 | 2.04 | 68.18 | β-Ti |

| Region | Composition (%) | Potential Phases | ||||

|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Cu | Ti | ||

| A | 70.10 | 14.44 | 1.77 | 3.56 | 1.0 | γ-Fe |

| B | 45.97 | 11.45 | 3.61 | 16.70 | 21.45 | Fe2Ti + Cu |

| C | 24.33 | 5.06 | 2.47 | 42.10 | 26.14 | Cu2Ti |

| D | 18.66 | 2.23 | 1.11 | 67.90 | 10.09 | Cu + TiFe2 |

| E | 7.91 | 1.33 | 0.62 | 81.90 | 8.21 | Cu |

| F | 2.60 | 0.83 | 0.39 | 42.87 | 52.80 | TiCu |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Shi, Z.; Deng, C.; Liu, Y.; Li, X. The Effect of Laser Offset Welding on Microstructure and Mechanical Properties of 301L to TA2 with and without Cu Intermediate Layer. Metals 2020, 10, 1138. https://doi.org/10.3390/met10091138

Zhao X, Shi Z, Deng C, Liu Y, Li X. The Effect of Laser Offset Welding on Microstructure and Mechanical Properties of 301L to TA2 with and without Cu Intermediate Layer. Metals. 2020; 10(9):1138. https://doi.org/10.3390/met10091138

Chicago/Turabian StyleZhao, Xiaohui, Zhenfu Shi, Chao Deng, Yu Liu, and Xin Li. 2020. "The Effect of Laser Offset Welding on Microstructure and Mechanical Properties of 301L to TA2 with and without Cu Intermediate Layer" Metals 10, no. 9: 1138. https://doi.org/10.3390/met10091138

APA StyleZhao, X., Shi, Z., Deng, C., Liu, Y., & Li, X. (2020). The Effect of Laser Offset Welding on Microstructure and Mechanical Properties of 301L to TA2 with and without Cu Intermediate Layer. Metals, 10(9), 1138. https://doi.org/10.3390/met10091138