Wear Characteristics of Superalloy and Hardface Coatings in Gas Turbine Applications–A Review

Abstract

1. Introduction

2. Gas Turbine Superalloy

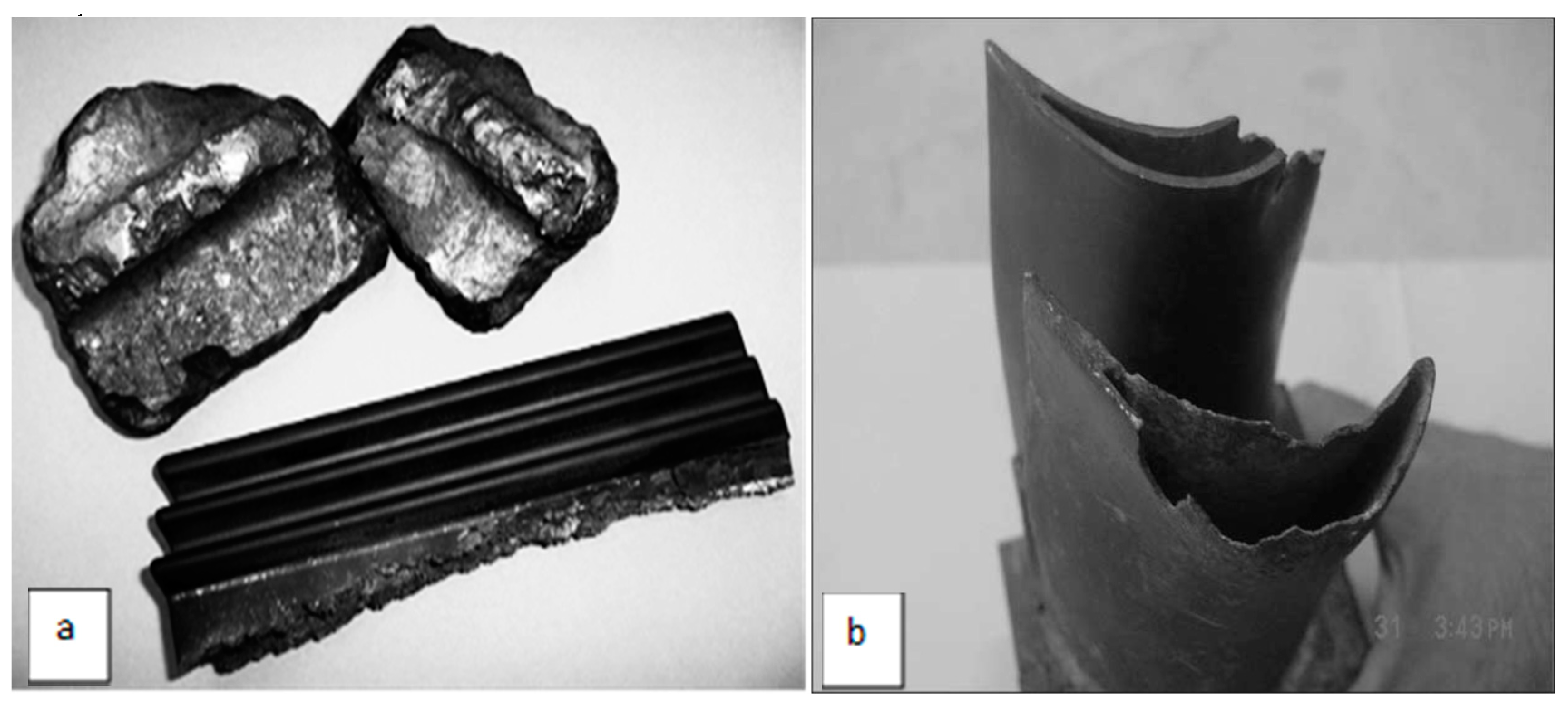

3. Relation of Wear to the Hot-Gas-Path Components of Gas Turbines

4. Relation of Wear to the Hot-Gas-Path Components of Gas Turbines

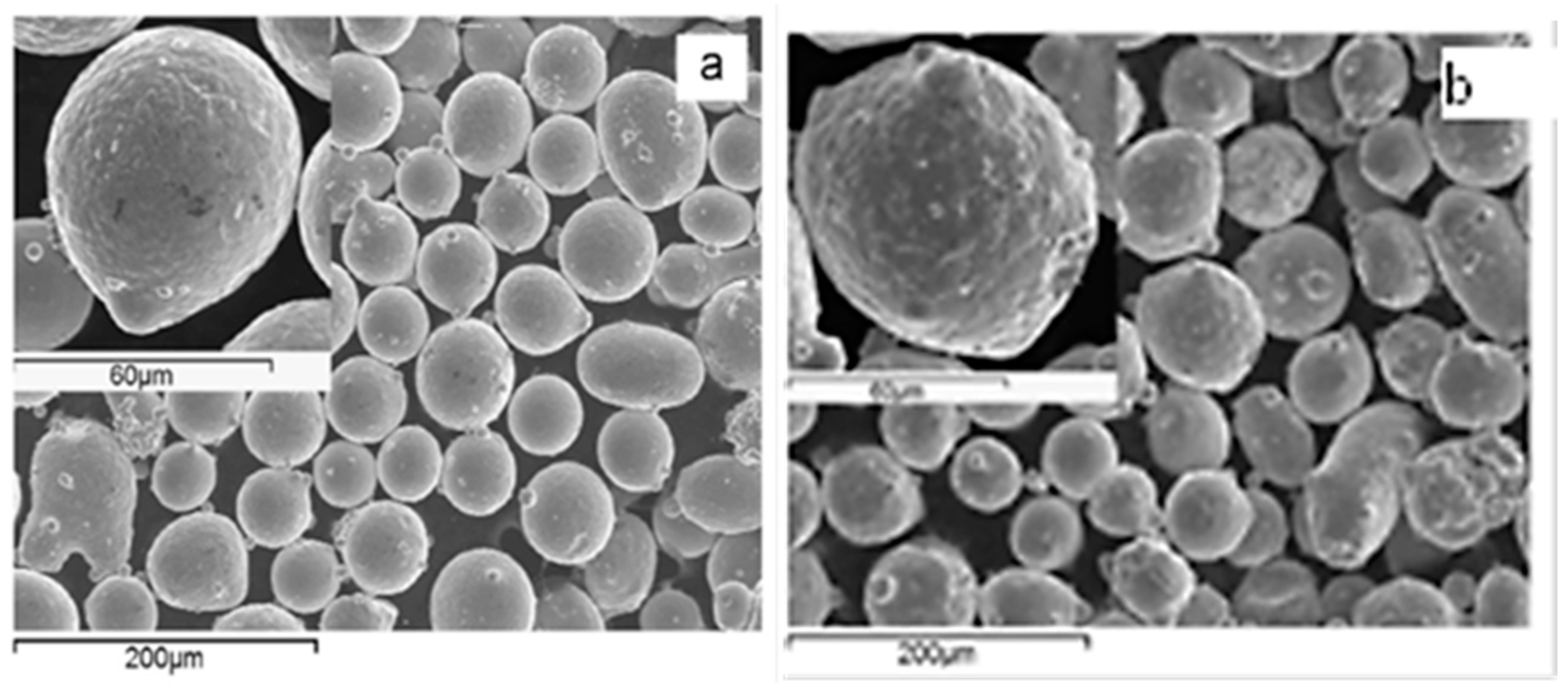

4.1. Wear-Protection Coatings

4.2. Erosion-Protection Coatings

4.3. Current Developments in Combination Wear-Resistant Coatings

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Calindro, A. Performance Analysis and Economic Effects of Maintenance and Hot Gas Path Inspection of a Combined Cycle Power Plant. In Corso Di Laurea Magistrale In Ingegneria Meccanica; Seconda Università degli Studi di Napoli: Caserta, Italy, 2015. [Google Scholar]

- Bloch, H.P.; Geitner, F.K. Major Process Equipment Maintenance and Repair; Gulf Publishing Company: Houston, TX, USA, 1997. [Google Scholar]

- Bohidar, S.K.; Dewangan, R.; Kaurase, P.R. Advanced Materials used for different components of Gas Turbine. Int. J. Sci. Res. Manag. 2013, 1, 366–370. [Google Scholar]

- Singh, K. Advanced Materials for Land Based Gas Turbines. Trans. Indian Inst. Met. 2014, 67, 601–615. [Google Scholar] [CrossRef]

- Zohuri, B. Gas Turbine Working Principles. In Combined Cycle Driven Efficiency for Next Generation Nuclear Power Plants; Springer: Cham, Switzerland, 2015; pp. 147–171. [Google Scholar]

- Vishwanathan, R. Damage Mechanisms and Life Assessment of High. Temperature Components, 4th ed.; ASM International: Novelty, OH, USA, 2006; pp. 415–417. [Google Scholar]

- Office of Fossil Energy. How Gas. Turbine Power Plant. Works; Office of Fossil Energy, Energy Government: Washington, DC, USA, 2017.

- Soares, C. Gas Turbine. A Handbook of Air, Land and Sea Application; BH Elsevier: Oxford, UK, 2017; 1020p. [Google Scholar]

- Scherer, L.G.; Tambara, R.V.; de Carmago, R.F. Gas Turbine Applications. IET Renew. Power Generat. 2015. [Google Scholar]

- Elizarasn, C.; Kumar, V.S.S.; Velayudham, A. An experimental analysis and measurement of process performances in machining of nimonic C-263 super alloy. Measurement 2013, 46, 185–189. [Google Scholar]

- Lee, J.W.; Kuo, Y.C. A study on the microstructure and cyclic oxidation behavior of the pack aluminized Hastelloy X at 1100 °C. Surf. Coat. Tech. 2006, 201, 3867–3871. [Google Scholar] [CrossRef]

- Mazur, Z.; Luna-Ramirez, A.; Islas, J.A.J.; Compos-Amezcua, A. Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Engin. Fail. Anal. 2005, 12, 474–486. [Google Scholar] [CrossRef]

- Kurz, R.; Homji, C.M.; Brun, K. Gas Turbine Degradation. In Proceedings of the 43rd Turbomachinery & 30th Pump Users Symposia, Houston, TX, USA, 23–25 September 2014; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2014; pp. 1–36. [Google Scholar]

- Laguna-Camachoa, J.R.; Villagrán-Villegasa, L.Y.; Martínez-Garcíaa, H.; Juárez-Moralesa, G.; Cruz-Orduñaa, M.I.; Vite-Torresb, M.; Ríos-Velascoc, L.; Hernández-Romeroc, I. A study of the wear damage on gas turbine blades. Engin. Fail. Anal. 2016, 61, 88–99. [Google Scholar] [CrossRef]

- Ghazali, M.J.; Forghani, S.M.; Hasanuddin, N.; Muctar, A.; Daud, A.R. Comparative wear study of plasma sprayed TiO2 & Al2O3-TiO2 on mild steels. Tribol. Int. 2015, 93, 681–686. [Google Scholar]

- Choteborsky, R.; Hrabě, P.; Müller, M.; Válek, R. Effect of carbide size in hardfacing on abrasive wear. Res. Gate 2009, 4, 149–158. [Google Scholar] [CrossRef]

- Vencl, A.; Gligorijević, B.R.; Katavić, B.; Nedic, B. Abrasive wear resistance of the iron-and WC-based hardfaced coatings evaluated with scratch test method. In Tribology in Industry; Faculty of Engineering: Kragujevac, Serbia, 2013; Volume 35, pp. 75–79. [Google Scholar]

- Zamana, H.A.; Sharifb, S.; Kimc, D.W.; Idris, M.H.; Suhaimib, M.A.; Tumurkhuyag, Z. Machinability of Cobalt-based and Cobalt Chromium Molybdenum Alloys—A Review. Proc. Manuf. 2017, 11, 563–570. [Google Scholar] [CrossRef]

- Jeshvaghania, R.A.; Shamanianb, M.; Jaberzadehb, M. Enhancement of wear resistance of ductile iron surface alloyed by stellite 6. Mater. Des. 2011, 32, 2028–2033. [Google Scholar] [CrossRef]

- Sen, S. Influence of chromium carbide coating on tribological performance of steel. Mater. Des. 2006, 27, 85–91. [Google Scholar] [CrossRef]

- Bernstein, H.L. Materials Issues for User of Gas Turbines; Texas A&M University: College Station, TX, USA, 1999; pp. 197–204. [Google Scholar]

- Ahmadi, A.; Sadeghi, F.; Shaffer, S. In-situ friction and fretting wear measurements of Inconel 617 at elevated temperatures. Wear 2018, 410, 110–118. [Google Scholar] [CrossRef]

- Prasanna, N.D.; Siddaraju, C.; Shetty, G.; Ramesh, M.R.; Reddy, M. Studies on the role of HVOF coatings to combat erosion in turbine alloys. Mater. Today Proc. 2018, 5, 3130–3136. [Google Scholar] [CrossRef]

- Rajendran, R. Gas turbine coatings—An overview. Engin. Fail. Anal. 2012, 26, 355–369. [Google Scholar] [CrossRef]

- Kesavan, D.; Kamaraj, M. The microstructure and high temperature wear performance of a nickel base hardfaced coating. Surf. Coat. Technol. 2010, 204, 4034–4043. [Google Scholar] [CrossRef]

- Zikin, A.; Hussainov, I.; Katsich, C.; Badisch, E.; Tomastik, C. Advanced chromium carbide-based hardfacings. Surf. Coat. Technol. 2012, 206, 4270–4278. [Google Scholar] [CrossRef]

- Blau, P.J. Elevated-temperature tribology of metallic materials. Tribol. Int. 2010, 43, 1203–1208. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Maziasz, P.J.; Swindeman, R.W.; Montague, J.P.; Fitzpatrick, M.; Browning, P.F.; Grubb, J.F.; Klug, R.C. Improved creep-resistance of austenitic stainless steel for compact gas turbine recuperators. J. Mater. High. Temp. 1999, 16, 207–212. [Google Scholar] [CrossRef]

- Zhao, J.C.; Larsen, M.; Ravikumar, V. Phase precipitation and time–temperature-transformation diagram of Hastelloy X. Mater. Sci. Engin. A 2000, 293, 112–119. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Chen, M.S.; Lid, H.B.; Wen, D.X.; Zhang, J.L.; Hea, M. Microstructural evolution of a nickel-based superalloy during hot deformation. Mater. Des. 2015, 77, 41–49. [Google Scholar] [CrossRef]

- Roche, R.; Idoumghar, L.; Suryanarayanan, S.; Daggag, M.; Solacolu, C.A.; Miraoui, A. A flexible and efficient multi-agent gas turbine power plant energy management system with economic and environmental constraints. Appl. Energy 2013, 11, 644–654. [Google Scholar] [CrossRef]

- Pouranvari, M.; Ekrami, A.; Kokabi, A.H. Microstructure development during transient liquid phase bonding of GTD-111 nickel-based superalloy. J. Alloy. Compd. 2008, 461, 641–647. [Google Scholar] [CrossRef]

- Eliaz, N.; Shemesh, G.; Latanision, R.M. Hot corrosion in gas turbine components. Engin. Fail. Anal. 2002, 9, 31–34. [Google Scholar] [CrossRef]

- Ennis, P.J.; Filemonowicz, C. Recent advances in creep-resistant steels for power plant applications. Sadhana 2003, 28, 709–730. [Google Scholar] [CrossRef]

- Caron, P.; Khan, T. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Khazaei, B.A.; Jahanbakhsh, A.; Bakhtiari, R. TLP bonding of dissimilar FSX-414/IN-738 system with MBF-80 interlayer: The effect of homogenizing treatment on microstructure and mechanical properties. Mater. Sci. Engin. A 2016, 65, 93–101. [Google Scholar]

- El-Awadi, G.A.; Abdel-Samad, S.; Elshazly, E.S. Hot corrosion behavior of Ni based Inconel 617 and Inconel 738 superalloys. Appl. Surf. Sci. 2016, 378, 224–273. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Microstructure of nickel-base superalloy MAR-M247 additively manufactured through scanning laser epitaxy (SLE). J. Alloy. Compd. 2017, 705, 806–816. [Google Scholar] [CrossRef]

- Koiprasert, H.; Dumrongrattana, S.; Niranatlumpong, P. Thermally sprayed coatings for protection of fretting wear in land-based gas-turbine engine. Wear 2004, 257, 1–7. [Google Scholar] [CrossRef]

- Done, V.; Kesavan, D.; Krishna, M.R.; Chaise, T.; Nelias, D. Semi analytical fretting wear simulation including wear debris. Tribol. Int. 2017, 109, 1–9. [Google Scholar] [CrossRef]

- Tzimasa, E.; Müllejans, H.; Peteves, S.D.; Bressers, J.; Stamm, W. Failure of thermal barrier coating systems under cyclic thermomechanical loading. Acta Mater. 2000, 48, 4699–4707. [Google Scholar] [CrossRef]

- Su, Y.; Han, Q.N.; Zhang, C.C.; Shi, H.J.; Niu, L.S.; Deng, G.J.; Ruia, S.S. Effects of secondary orientation and temperature on the fretting fatigue behaviors of Ni-based single crystal superalloys. Tribol. Int. 2019, 130, 9–18. [Google Scholar] [CrossRef]

- Ilieva, G.I. Erosion failure mechanisms in turbine stage with twisted rotor blade. Engin. Fail. Anal. 2016, 70, 90–104. [Google Scholar] [CrossRef]

- Barella, S.; Boniardi, M.; Cincera, S.; Pellin, P.; Degive, X.; Gijbels, S. Failure analysis of a third stage gas turbine blade. Engin. Fail. Anal. 2020, 18, 386–393. [Google Scholar] [CrossRef]

- Khajavi, M.R.; Shariat, M.H. Failure of first stage gas turbine blades. Engin. Fail. Anal. 2004, 11, 589–597. [Google Scholar] [CrossRef]

- Kim, M.N.; Yun, N.; Jeon, Y.H.; Lee, D.H.; Cho, H.H. Failure analysis in after shell section of gas turbine combustion liner under base-load operation. Engin. Fail. Anal. 2004, 17, 848–856. [Google Scholar]

- Torshizi, S.E.M.; Ebrahimic, M. Failure analysis of gas turbine transition pieces, leading to a solution for prevention. Engin. Fail. Anal. 2013, 32, 402–411. [Google Scholar] [CrossRef]

- Nicolaus, M.; Möhwald, K.; Maier, H.J. A Combined Brazing and Aluminizing Process for Repairing Turbine Blades by Thermal Spraying Using the Coating System NiCrSi/NiCoCrAlY/Al. J. Spray Technol. 2017, 26, 1659–1668. [Google Scholar] [CrossRef]

- Sahraoui, T.; Fenineche, N.E.; Montavon, G.; Coddet, C. Alternative to chromium: Characteristics and wear behavior of HVOF coatings for gas turbine shafts repair (heavy-duty). J. Mater. Process. Technol. 2004, 152, 43–45. [Google Scholar] [CrossRef]

- Schlobohm, J.; Bruchwald, O.; Frąckowiak, W.; Li, Y.; Kästner, M.; Pösch, A.; Reimche, W.; Maier, H.J.; Reithmeier, E. Advanced Characterization Techniques for Turbine Blade Wear and Damage. Procedia CIRP 2017, 59, 83–88. [Google Scholar] [CrossRef]

- Chan, K.S.; Enright, M.P.; Moody, J.; Golden, P.J.; Chandra, R.; Pentz, A.C. Residual Stress Profiles for Mitigating Fretting Fatigue in Gas Turbine Engine Disks. Int. J. Fatigue 2010, 32, 815–823. [Google Scholar] [CrossRef]

- Chandra, S.; Golden, P.; Enright, M.P.; Chan, K.S. Fretting Fatigue-Based Risk Assessment of Gas Turbine Engine Disks. In Proceedings of the Structures, Structural Dynamics, and Materials Conference, Schaumbug, IL, USA, 7–10 April 2008. [Google Scholar]

- Mandard, R.; Witz, J.-F.; Boidin, X.; Fabis, J.; Desplanques, Y.; Mériaux, J. Interacting Force Estimation During blade/Seal Rubs. Tribol. Int. 2015, 82, 504–513. [Google Scholar] [CrossRef]

- Lavella, M. Contact Properties and Wear Behaviour of Nickel Based Superalloy René 80. Metals 2016, 6, 159. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced Characterization Methods for Wear Resistant Hard Coatings: A Review on Recent Progress. Surf. Coatings Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Sahraoui, T.; Fenineche, N.-E.; Montavon, G.; Coddet, C. Structure and Wear Behaviour of HVOF Sprayed Cr3C2–NiCr and WC–Co Coatings. Mater. Des. 2003, 24, 309–313. [Google Scholar] [CrossRef]

- Feng, K.; Chen, Y.; Deng, P.; Li, Y.; Zhao, H.; Lu, F.; Li, R.; Huang, J.; Li, Z. Improved High-Temperature Hardness and Wear Resistance of Inconel 625 Coatings Fabricated by Laser Cladding. J. Mater. Process. Technol. 2017, 243, 82–91. [Google Scholar] [CrossRef]

- Yunus, S.M.; Ghazali, M.J.; Zamri, W.F.H.W.; Pauzi, A.A.; Husin, S. Characterisation of chromium carbide-based coated combustion liner for gas turbines. J. Teknol. 2015, 76, 33–36. [Google Scholar]

- Hussainova, I.; Pirso, J.; Antonov, M.; Juhani, K.; Letunovits, S. Erosion and Abrasion of Chromium Carbide Based Cermets Produced by Different Methods. Wear 2007, 263, 905–911. [Google Scholar] [CrossRef]

- Kerr, C.; Barker, D.; Walsh, F.; Archer, J. The Electrodeposition of Composite Coatings Based on Metal Matrix-Included Particle Deposits. Trans. IMF 2000, 78, 171–178. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, C.-H.; Hwang, S.-Y. Superhard Nano WC–12%Co Coating by Cold Spray Deposition. Mater. Sci. Eng. A 2005, 391, 243–248. [Google Scholar] [CrossRef]

- Yaghtin, A.; Salahinejad, E.; Khosravifard, A.; Araghi, A.; Akhbarizadeh, A. Corrosive Wear Behavior of Chromium Carbide Coatings Deposited by Air Plasma Spraying. Ceram. Int. 2015, 41, 7916–7920. [Google Scholar] [CrossRef]

- Fang, W.; Cho, T.Y.; Yoon, J.; Song, K.; Hur, S.; Youn, S.; Chun, H. Processing Optimization, Surface Properties and Wear Behavior of HVOF Spraying WC–CrC–Ni Coating. J. Mater. Process. Technol. 2009, 209, 3561–3567. [Google Scholar] [CrossRef]

- Tang, J.; Saha, G.C.; Richter, P.; Kondas, J.; Colella, A.; Matteazzi, P. Effects of Post-spray Heat Treatment on Hardness and Wear Properties of Ti-WC High-Pressure Cold Spray Coatings. J. Therm. Spray Technol. 2018, 27, 1153–1164. [Google Scholar] [CrossRef]

- Jafari, M.; Enayati, M.H.; Salehi, M.; Nahvi, S.; Park, C.-G. Microstructural and mechanical characterizations of a novel HVOF-sprayed WC-Co coating deposited from electroless Ni–P coated WC-12Co powders. Mater. Sci. Engin. A 2013, 578, 46–53. [Google Scholar] [CrossRef]

- Yin, X.; Gotman, I.; Klinger, L.; Gutmanas, E. Formation of titanium carbide on graphite via powder immersion reaction assisted coating. Mater. Sci. Engin. A 2005, 392, 107–114. [Google Scholar] [CrossRef]

- Neuman, E.W.; Hilmas, G.E.; Fahrenholtz, W.G. A high strength alumina-silicon carbide-boron carbide triplex ceramic. Ceram. Int. 2017, 43, 7958–7962. [Google Scholar] [CrossRef]

- Rani, S.; Agrawal, A.K.; Rastogi, V. Failure investigations of a first stage Ni based super alloy gas turbine blade. Mater. Today Proc. 2018, 5, 477–486. [Google Scholar] [CrossRef]

- Xue, W.; Gao, S.; Duan, D.; Zhang, J.; Liu, Y.; Li, S. Effects of blade material characteristics on the high-speed rubbing behavior between Al-hBN abradable seal coatings and blades. Wear 2018, 410, 25–33. [Google Scholar] [CrossRef]

- Venkatesh, L.N.; Venkataraman, B.; Tak, M.; Sivakumar, G.; Gundakaram, R.C.; Joshi, S.; Samajdar, I. Room temperature and 600 °C erosion behaviour of various chromium carbide composite coatings. Wear 2019, 422, 44–53. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Syarif, J.; Daud, A.R. Development of an application of tool wear: A review of the characterisation of TiC-based cermets with different binders. Chem. Engin. J. 2012, 255, 445–452. [Google Scholar] [CrossRef]

- Siow, P.C.; Ghani, J.A.; Rizal, M.; Jaafar, T.R.; Ghazali, M.J.; Che Haron, C.H. The study on the properties of TiC x N 1−x coatings processed by cathodic arc physical vapour deposition. Tribol. Mater. Surf. Interf. 2019, 13, 58–66. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J. Quantitative analyses of TiC nanopowders via mechanical alloying method. Ceram. Int. 2017, 43, 14233–14243. [Google Scholar] [CrossRef]

- Maiti, A.; Mukhopadhyay, N.; Raman, R. Effect of adding WC powder to the feedstock of WC–Co–Cr based HVOF coating and its impact on erosion and abrasion resistance. Surf. Coat. Technol. 2007, 201, 7781–7788. [Google Scholar] [CrossRef]

- Fellows, L.; Nowell, D.; Hills, D. On the initiation of fretting fatigue cracks. Wear 1997, 205, 120–129. [Google Scholar] [CrossRef]

- Souza, C.; Ribeiro, D.V.; Kiminami, C.S. Corrosion resistance of Fe-Cr-based amorphous alloys: An overview. J. Non Crystal. Solids 2016, 442, 6–66. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. High temperature erosion–oxidation of Cr3C2–NiCr thermal spray coatings under simulated turbine conditions. Corros. Sci. 2013, 70, 203–2011. [Google Scholar] [CrossRef]

- Cernuschi, F.; Lorenzoni, L.; Capelli, S.; Guardamagna, C.; Karger, M.; Vaßen, R.; Von Niessen, K.; Markocsan, N.; Menuey, J.; Giolli, C. Solid particle erosion of thermal spray and physical vapour deposition thermal barrier coatings. Wear 2011, 271, 2909–2918. [Google Scholar] [CrossRef]

- Corsini, A.; Marchegiani, A.; Rispoli, F.; Venturini, P.; Sheard, A.G. Predicting Blade Leading Edge Erosion in an Axial Induced Draft Fan. J. Engin. Gas Turbin. Power 2012, 134, 042601. [Google Scholar] [CrossRef]

- Abbasi, F.; Majzoobi, G. An investigation into the effect of elevated temperatures on fretting fatigue response under cyclic normal contact loading. Theor. Appl. Fract. Mech. 2018, 93, 144–154. [Google Scholar] [CrossRef]

- Kirk, A.M.; Shipway, P.H.; Sun, W.; Bennett, C.J. Debris development in fretting contacts—Debris particles and debris beds. Tribol. Int. 2019, 149, 105592. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, X. Fretting fatigue analysis of FGM coating under out-of-phase loadings. Trobol. Int. 2019, 134, 165–167. [Google Scholar] [CrossRef]

- Venkatesh, B.; Sriker, K.; Prabhakar, V. Wear Characteristics of Hardfacing Alloys: State-of-the-art. Proc. Mater. Sci. 2015, 10, 527–532. [Google Scholar] [CrossRef]

- Torgerson, T.; Harris, M.; Alidokht, S.A.; Scharf, T.; Aouadi, S.; Chromik, R.; Zabinski, J.; Voevodin, A. Room and elevated temperature sliding wear behavior of cold sprayed Ni-WC composite coatings. Surf. Coat. Technol. 2018, 350, 136–145. [Google Scholar] [CrossRef]

- Koga, G.Y.; Wolf, W.; Schulz, R.; Savoie, S.; Bolfarini, C.; Kiminami, C.S.; Botta, W. Corrosion and wear properties of FeCrMnCoSi HVOF coatings. Surf. Coat. Technol. 2019, 357, 993–1003. [Google Scholar] [CrossRef]

- Borisyuk, Y.; Oreshnikova, N.; Berdnikova, M.; Tumarkin, A.; Khodachenko, G.V.; Pisarev, A. Plasma Nitriding of Titanium Alloy Ti5Al4V2Mo. Phys. Proc. 2015, 71, 105–109. [Google Scholar] [CrossRef]

- Xu, P.; Lin, C.-X.; Zhou, C.; Yi, X. Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings. Surf. Coat. Technol. 2014, 238, 9–14. [Google Scholar] [CrossRef]

- Bartkowski, D.; Młynarczak, A.; Piasecki, A.; Dudziak, B.; Gościański, M.; Bartkowska, A. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 2015, 68, 191–201. [Google Scholar] [CrossRef]

- Li, B.; Jin, Y.; Yao, J.; Li, Z.; Zhang, Q. Solid-state fabrication of WCp-reinforced Stellite-6 composite coatings with supersonic laser deposition. Surf. Coat. Technol. 2017, 321, 386–396. [Google Scholar] [CrossRef]

- Wang, B.Q.; Shui, Z.R. The hot erosion behavior of HVOF chromium carbide-metal cermet coatings sprayed with different powders. Wear 2012, 274, 550–557. [Google Scholar] [CrossRef]

- Szymański, K.; Hernas, A.; Moskal, G.; Myalska, H. Thermally sprayed coatings resistant to erosion and corrosion for power. Surf. Coat. Technol. 2015, 268, 153–164. [Google Scholar] [CrossRef]

- Pereira, J.; Zambrano, J.; Licausi, M.; Tobar, M.; Amigó, V. Tribology and high temperature friction wear behavior of MCrAlY laser cladding coatings on stainless steel. Wear 2015, 330, 280–287. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pauzi, A.A.; Ghazali, M.J.; W. Zamri, W.F.H.; Rajabi, A. Wear Characteristics of Superalloy and Hardface Coatings in Gas Turbine Applications–A Review. Metals 2020, 10, 1171. https://doi.org/10.3390/met10091171

Pauzi AA, Ghazali MJ, W. Zamri WFH, Rajabi A. Wear Characteristics of Superalloy and Hardface Coatings in Gas Turbine Applications–A Review. Metals. 2020; 10(9):1171. https://doi.org/10.3390/met10091171

Chicago/Turabian StylePauzi, Ahmad Afiq, Mariyam Jameelah Ghazali, Wan Fathul Hakim W. Zamri, and Armin Rajabi. 2020. "Wear Characteristics of Superalloy and Hardface Coatings in Gas Turbine Applications–A Review" Metals 10, no. 9: 1171. https://doi.org/10.3390/met10091171

APA StylePauzi, A. A., Ghazali, M. J., W. Zamri, W. F. H., & Rajabi, A. (2020). Wear Characteristics of Superalloy and Hardface Coatings in Gas Turbine Applications–A Review. Metals, 10(9), 1171. https://doi.org/10.3390/met10091171