Hydraulic Modeling on Flow Behavior in High-Speed Billet Continuous Casting Mold Considering Hydrostatic Pressure and Solidified Shell

Abstract

:1. Introduction

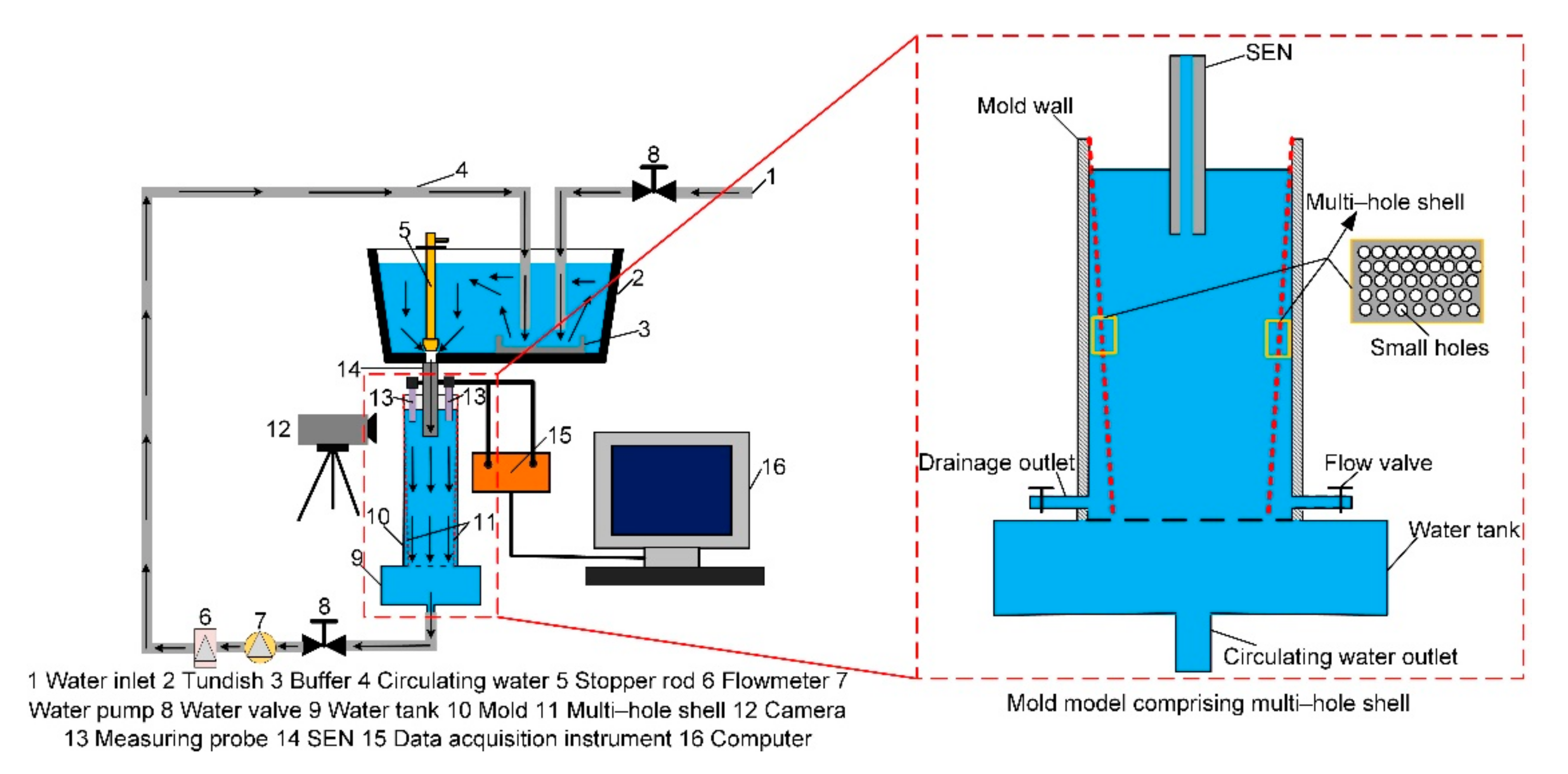

2. Hydraulic Model and Experiment Method

2.1. Establishment of Hydraulic Model

- (1)

- This paper only focused on the steady continuous casting process.

- (2)

- Hydraulic modeling was conducted under ambient temperature (about 300.15 K), regarding the parameters of the fluid as constant.

- (3)

- The solidified shell grows uniformly around the mold.

- (4)

- The influence of the arc structure on the solidified shell thickness was not considered, assuming the solidified shell increased linearly from the meniscus to the mold outlet.

- (5)

- The solidified shell thickness was 10 mm at the mold outlet.

- (6)

- The material thickness of the shell itself is 2 mm, and this paper will consider it into the part of the no solidified fluid. Therefore, the material thickness is much less than the size of the flowing region, and so it can be neglected.

- (7)

- The small size deviation caused by manual operation in the design of multi-hole shell is ignored.

2.2. Arrangement of Small Holes on Solidified Shell

2.3. Experimental Scheme

3. Results and Discussion

3.1. Fluid Flow in the Mold

3.2. Level Fluctuation in the Free Surface of the Mold

3.3. Dsitribution of Liquid Slag in the Mold

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Fr | A dimensionless criterion for characterizing the relative magnitude of inertial force and gravity of the fluid |

| Re | A dimensionless criterion for characterizing the relative magnitude of inertial force and viscous force of the fluid |

| D | The thickness of the solidified shell at the cross section (mm) |

| Doutlet | The thickness of the solidified shell at the mold outlet (mm) |

| Z | The distance of the cross section from the mold meniscus (mm) |

| H | The effective height of the mold (mm) |

| Q | The volume flux converted into the solidified shell at the cross section (ml/s) |

| v | The casting speed of the strand (mm/s) |

| Qhole | The volume flux of a single hole with a diameter d (ml/s) |

| μslag, μsteel, μoil and μwater | The dynamic viscosities of liquid slag, molten steel, mixed oil, and water, respectively (kg·m−1·s−1) |

Appendix A

References

- Yuan, Q.; Thomas, B.G.; Vanka, S.P. Study of transient flow and particle transport in continuous steel caster molds: Part I. Fluid flow. Metall. Mater. Trans. B 2004, 35, 685–702. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Li, B.; Liu, Z.; Niu, R.; Liu, Y.; Zhao, C.; Huang, C.; Qiao, H.; Yuan, T. Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in a Continuous Casting Mold. Metals 2018, 9, 7. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-E.; Han, H.N.; Oh, K.H.; Yoon, J.-K. A Fully Coupled Analysis of Fluid Flow, Heat Transfer and Stress in Continuous Round Billet Casting. ISIJ Int. 1999, 39, 435–444. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Chen, W.; Scheller, P.R.; Ren, Y.; Zhang, L. Mathematical Modeling of Initial Solidification and Slag Infiltration at the Meniscus of Slab Continuous Casting Mold. JOM 2018, 71, 78–87. [Google Scholar] [CrossRef]

- Thomas, B.G.; Yuan, Q.; Mahmood, S.; Liu, R.; Chaudhary, R. Transport and Entrapment of Particles in Steel Continuous Casting. Met. Mater. Trans. A 2013, 45, 22–35. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, W.; Ren, Y.; Zhang, L. Mathematical Modeling on the Influence of Casting Parameters on Initial Solidification at the Meniscus of Slab Continuous Casting. Metall. Mater. Trans. A 2019, 50, 1444–1460. [Google Scholar] [CrossRef]

- Meng, Y.; Thomas, B.G. Heat-transfer and solidification model of continuous slab casting: CON1D. Metall. Mater. Trans. A 2003, 34, 685–705. [Google Scholar] [CrossRef]

- Long, M.; Chen, H.; Chen, D.; Yu, S.; Liang, B.; Duan, H. A Combined Hybrid 3-D/2-D Model for Flow and Solidification Prediction during Slab Continuous Casting. Metals 2018, 8, 182. [Google Scholar]

- Srinivas, P.S.; Mishra, D.K.; Gupta, R.; Korath, J.M.; Jana, A.K. Vortex characteristics due to nozzle clogging in water caster mould: Modelling and validation. Can. Metall. Q. 2018, 58, 308–324. [Google Scholar] [CrossRef]

- Szekely, J.; Yadoya, R.T. The physical and mathematical modeling of the flow field in the mold region in continuous casting systems: Part I. Model studies with aqueous systems. Metall. Mater. Trans. A 1972, 3, 2673–2680. [Google Scholar] [CrossRef]

- Gupta, D.; Lahiri, A.K. Water-Modeling Study of the Surface Disturbances in Continuous Slab Caster. Metall. Mater. Trans. A 1994, 25, 227–233. [Google Scholar] [CrossRef]

- Gupta, D.; Lahiri, A.K. A water model study of the flow asymmetry inside a continuous slab casting mold. Metall. Mater. Trans. A 1996, 27, 757–764. [Google Scholar] [CrossRef]

- Gupta, D.; Chakraborty, S.; Lahiri, A.K. Asymmetry and Oscillation of the Fluid Flow Pattern in a Continuous Casting Mould: A Water Model Study. ISIJ Int. 1997, 37, 654–658. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Sung, H.J.; Lee, S. Flow Oscillations and Meniscus Fluctuations in a Funnel-Type Water Mold Model. Metall. Mater. Trans. A 2009, 41, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Chen, D.F.; Zhang, D.J.; Xie, X.; Bi, Y.Y. Water model study on fluid flow in slab continuous casting mould with solidified shell. Ironmak. Steelmak. 2011, 38, 155–159. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, J.; Cui, H.; Xiao, C. Analysis of Meniscus Fluctuation in a Continuous Casting Slab Mold. Metall. Mater. Trans. A 2018, 49, 1174–1184. [Google Scholar] [CrossRef]

- Szekely, J.; Yadoya, R.T. The physical and mathematical modeling of fluid field in the mold region in continuous casting systems: Part II. The mathematical representation of the turbulent flow field. Metall. Trans. 1973, 4, 1379–1388. [Google Scholar] [CrossRef]

- Lan, X.K.; Khodadadi, J.M.; Shen, F. Evaluation of six k-ε turbulence model predictions of flow in a continuous casting billet-mold water model using laser doppler velocimetry measurements. Metall. Mater. Trans. A 1997, 28, 321–332. [Google Scholar] [CrossRef]

- Ramos-Banderas, A.; Sánchez-Pérez, R.; Demedices-García, L.; Palafox-Ramos, J.; Díaz-Cruz, M.; Morales, R.D. Mathematical simulation and physical modeling of unsteady fluid flows in a water model of a slab mold. Metall. Mater. Trans. B 2004, 35, 449–460. [Google Scholar] [CrossRef]

- Miranda, R.; Barron, M.A.; Barreto, J.; Hoyos, L.; Gonzalez, J. Experimental and Numerical Analysis of the Free Surface in a Water Model of a Slab Continuous Casting Mold. ISIJ Int. 2005, 45, 1626–1635. [Google Scholar] [CrossRef]

- Liu, Z.; Li, B.; Vakhrushev, A.; Wu, M.; Ludwig, A. Physical and Numerical Modeling of Exposed Slag Eye in Continuous Casting Mold using Euler–Euler Approach. Steel Res. Int. 2018, 90, 1800117. [Google Scholar] [CrossRef]

- Huang, J.; Yuan, Z.; Shi, S.; Wang, B.; Liu, C. Flow Characteristics for Two-Strand Tundish in Continuous Slab Casting Using PIV. Metals 2019, 9, 239. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.W.; Wang, Z.L.; Xu, C.J.; Li, S.L.; Ai, X.G.; Li, J. A vertical continuous casting machine for large blooms. Ironmak. Steelmak. 2017, 46, 742–746. [Google Scholar] [CrossRef]

- Chen, H.; Long, M.; Chen, D.; Liu, T.; Duan, H. Numerical study on the characteristics of solute distribution and the formation of centerline segregation in continuous casting (CC) slab. Int. J. Heat Mass Transf. 2018, 126, 843–853. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Mold Section (mm × mm) | 160 × 160 |

| Mold Length (mm) | 1000 |

| Mold Radius (mm) | 8000 |

| Clearance Height (mm) | 70 |

| SEN Type | Straight Through |

| SEN Inner Diameter (mm) | 40 |

| SEN Outer Diameter (mm) | 83 |

| SEN Insertion Depth (mm) | 120 |

| Casting Speed (m/min) | 3.0, 3.5, 4.0, 4.5 |

| Mixed Oil Density (kg/m3) | 821 |

| Mixed Oil Viscosity (kg·m−1·s−1) | 0.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, P.; Chen, D.; Du, Y.; Yu, H.; Long, M.; Liu, P.; Duan, H.; Yang, J. Hydraulic Modeling on Flow Behavior in High-Speed Billet Continuous Casting Mold Considering Hydrostatic Pressure and Solidified Shell. Metals 2020, 10, 1226. https://doi.org/10.3390/met10091226

Xu P, Chen D, Du Y, Yu H, Long M, Liu P, Duan H, Yang J. Hydraulic Modeling on Flow Behavior in High-Speed Billet Continuous Casting Mold Considering Hydrostatic Pressure and Solidified Shell. Metals. 2020; 10(9):1226. https://doi.org/10.3390/met10091226

Chicago/Turabian StyleXu, Pei, Dengfu Chen, Yizhe Du, Hengsong Yu, Mujun Long, Peng Liu, Huamei Duan, and Jie Yang. 2020. "Hydraulic Modeling on Flow Behavior in High-Speed Billet Continuous Casting Mold Considering Hydrostatic Pressure and Solidified Shell" Metals 10, no. 9: 1226. https://doi.org/10.3390/met10091226

APA StyleXu, P., Chen, D., Du, Y., Yu, H., Long, M., Liu, P., Duan, H., & Yang, J. (2020). Hydraulic Modeling on Flow Behavior in High-Speed Billet Continuous Casting Mold Considering Hydrostatic Pressure and Solidified Shell. Metals, 10(9), 1226. https://doi.org/10.3390/met10091226