Processing Tests, Adjusted Cost Models and the Economies of Reprocessing Copper Mine Tailings in Chile

Abstract

1. Introduction

2. Materials and Methods

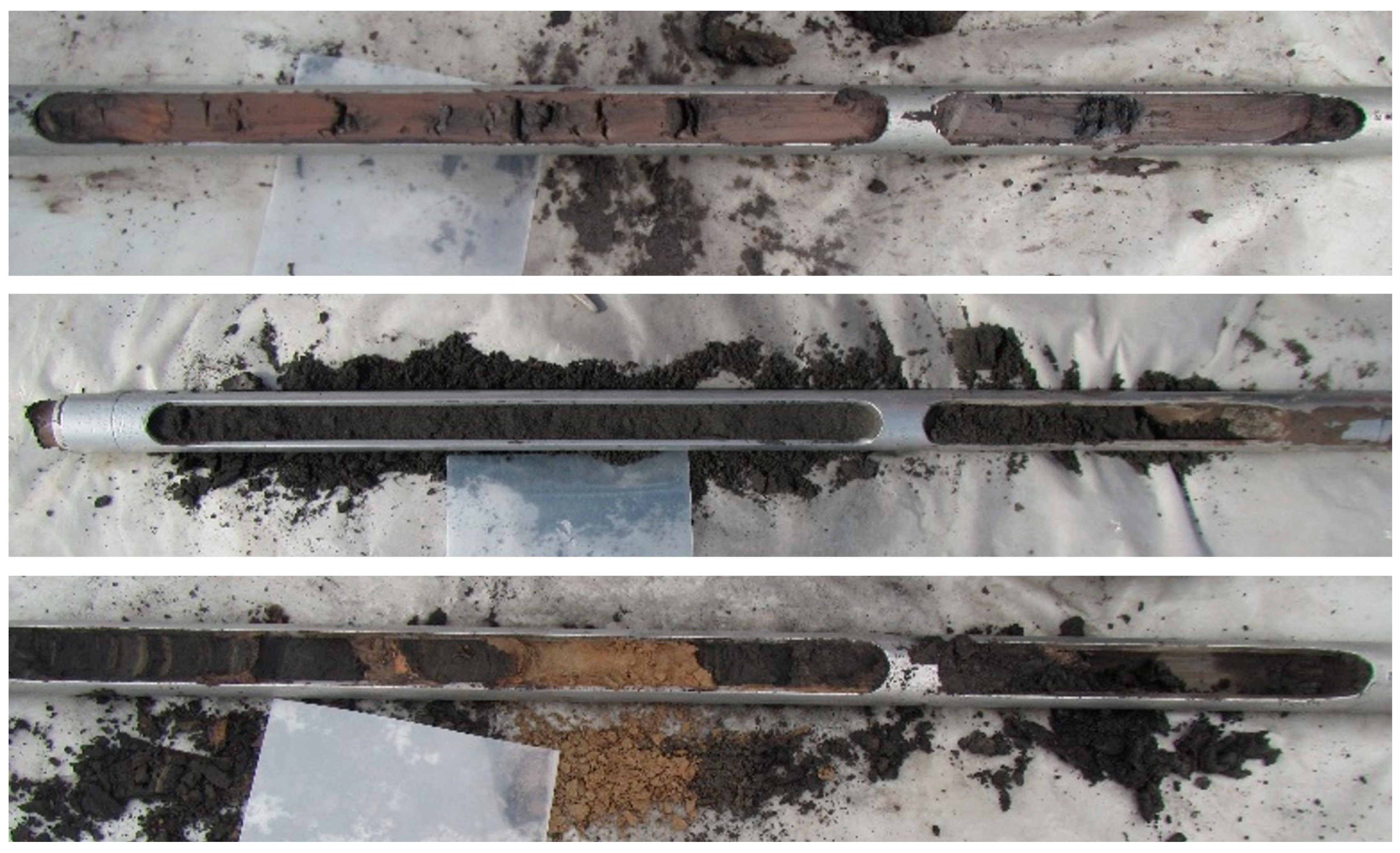

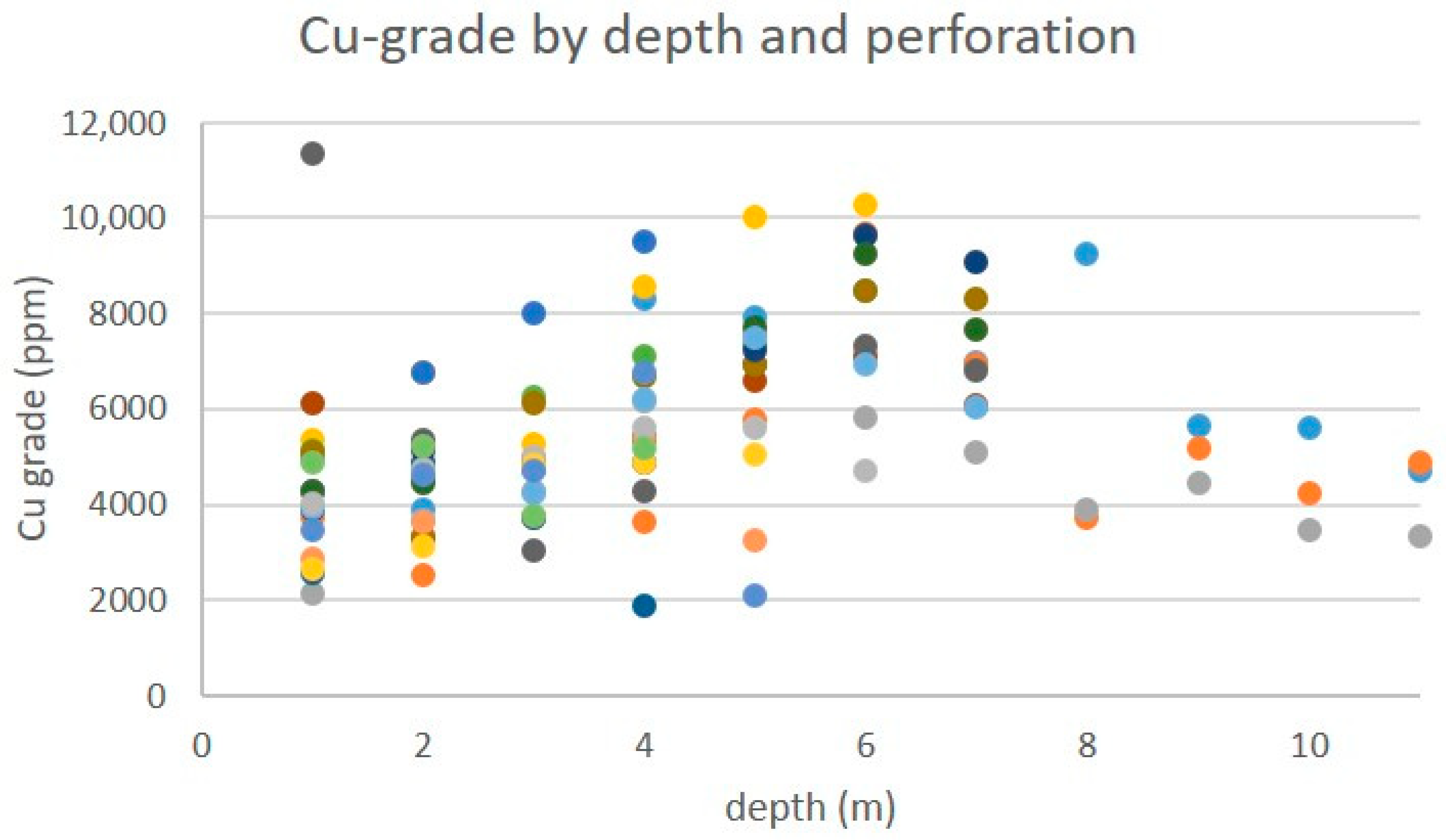

2.1. Tailings Material and Sampling

2.2. Geochemical and Mineralogical Analysis

2.3. Magnetic Separation

2.4. Flotation

2.5. Conventional Sulfuric Acid Chemical Leaching

2.6. Methodological Approach Used for the Economic Assessment

3. Results and Discussion

3.1. Mineralogy

3.2. Semi Technical Processing Tests

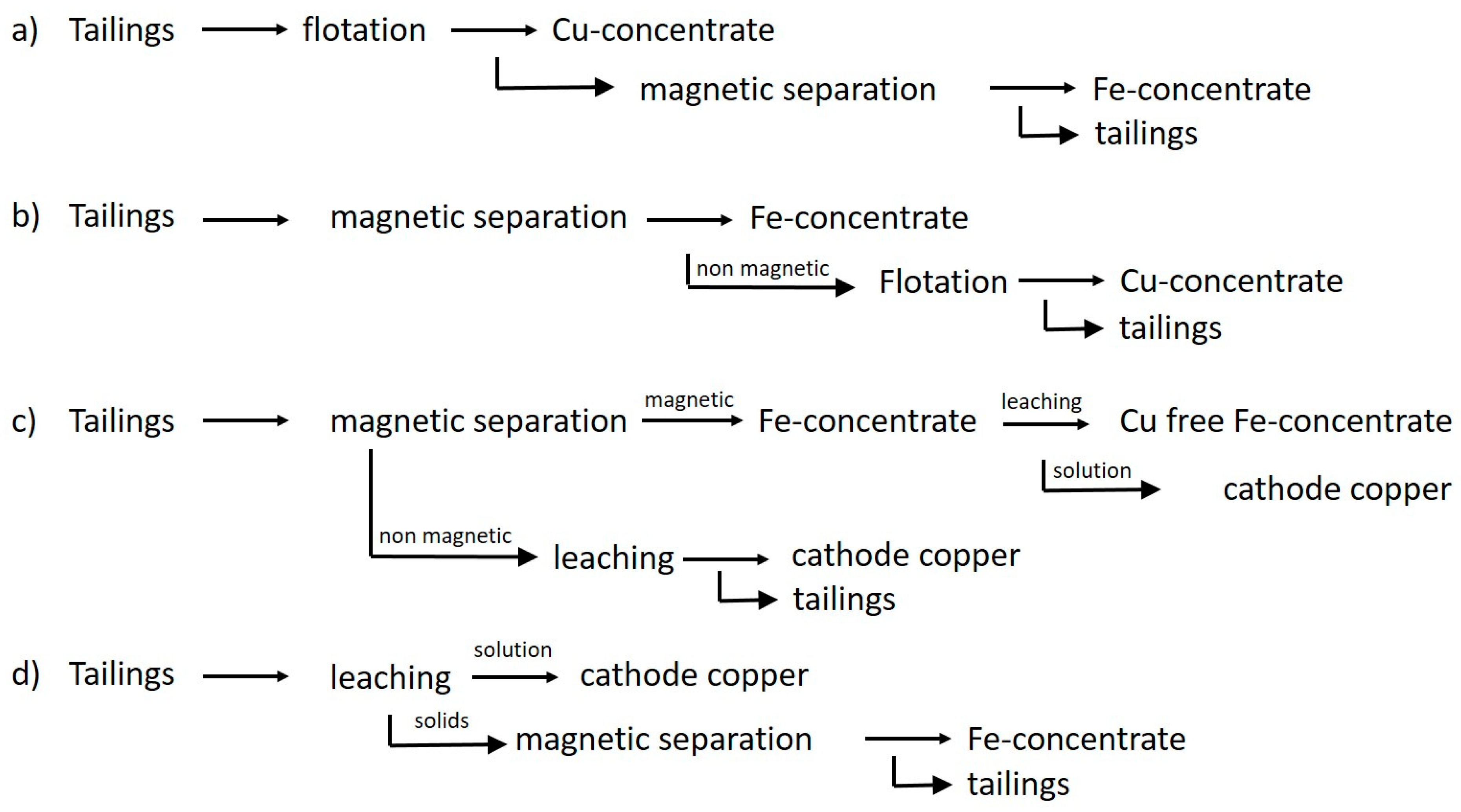

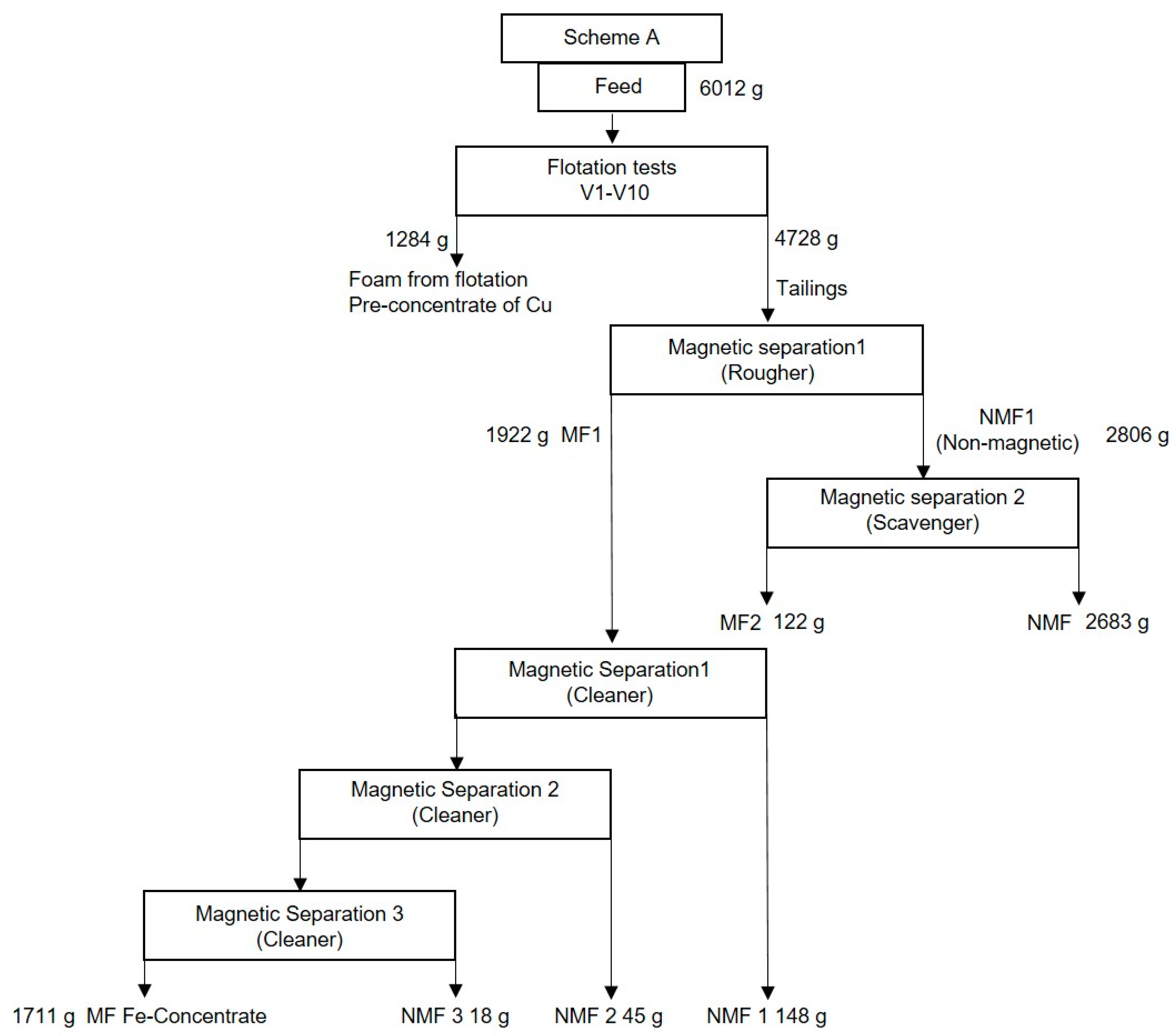

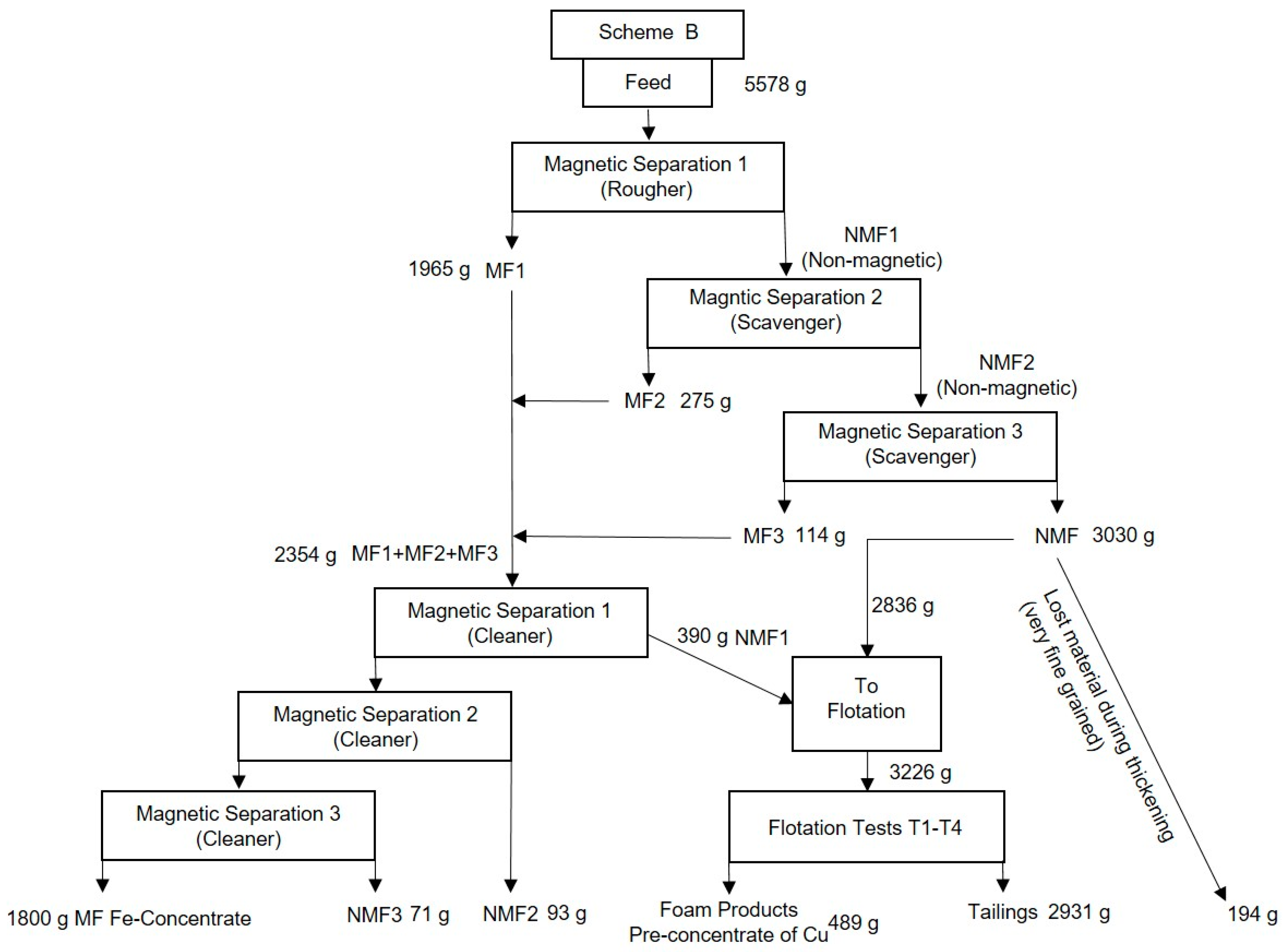

3.2.1. Flotation–Magnetic Separation and Magnetic Separation–Flotation (Figure 5a,b)

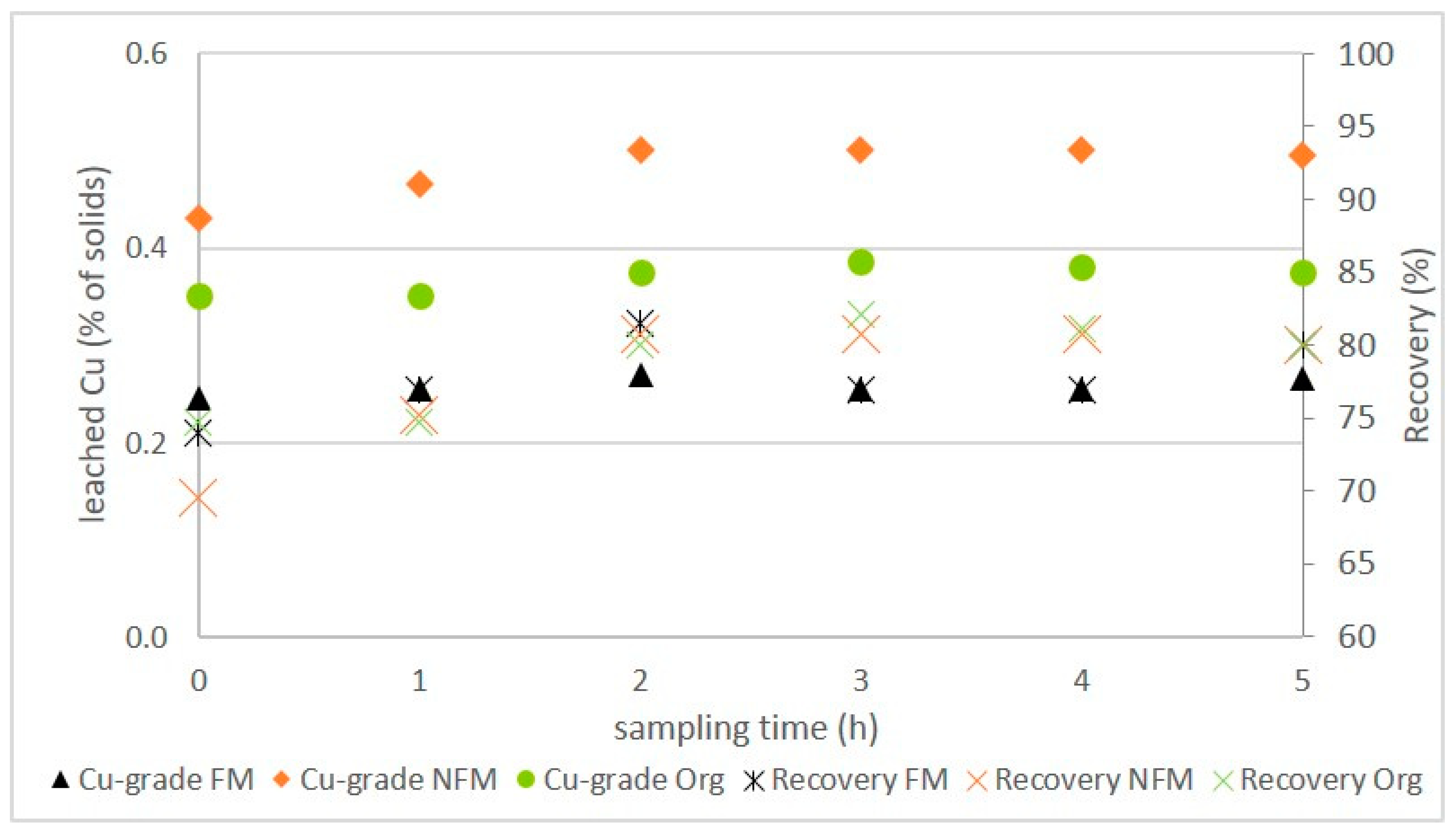

3.2.2. Leaching–Magnetic Separation and Magnetic Separation–Leaching (Figure 5c,d)

3.3. Introduction of Adjusted Cost Models

- Magnetic separation into FM and NFM fraction, including magnetic cleaner steps

- Separate leaching of the FM and NFM material in stirred tank or horizontal rotary reactor with dilute sulfuric acid (below 5%) in continuous or batch mode (for several hours)

- Final production of an Fe-concentrate (Cl-, S-, P- and Cu-grades could be an issue)

- Hydrocyclone and/or settling to separate solids and liquids (Cu-rich solution)

- Washing of solids to remove rests of copper (dilute Cu-solution)

- Deposition of the NFM fraction (finer-grained than original tailings material)

- Further concentration and cleaning of Cu-solution to produce intermediate products, or cathodes by electrowinning

3.4. Comparison of Cost Models and NPV

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Drobe, M. Vorkommen und Produktion Mineralischer Rohstoffe—Ein Ländervergleich. 2020. Available online: https://www.bgr.bund.de/DE/Themen/Min_rohstoffe/Downloads/studie_Laendervergleich_2017.pdf?__blob=publicationFile&v=7 (accessed on 1 July 2020).

- Lottermoser, B. Mine Wastes: Characterization, Treatment, and Environmental Impacts, 3rd ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- SERNAGEOMIN. Anuario de la Minería de Chile 2019. Available online: https://www.sernageomin.cl/pdf/anuario_2019_act100720.pdf (accessed on 14 July 2020).

- Alcalde, J.; Kelm, U.; Vergara, D. Historical assessment of metal recovery potential from old mine tailings: A study case for porphyry copper tailings, Chile. Miner. Eng. 2018, 127, 334–338. [Google Scholar] [CrossRef]

- Nikonow, W.; Rammlmair, D.; Furche, M. A multidisciplinary approach considering geochemical reorganization and internal structure of tailings impoundments for metal exploration. J. Appl. Geochem. 2019, 104, 51–59. [Google Scholar] [CrossRef]

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards mine tailings valorization: Recovery of critical materials from Chilean mine tailings. J. Clean. Prod. 2020, 263, 121555. [Google Scholar] [CrossRef]

- Giurco, D.; Prior, T.; Mudd, G.; Mason, L.; Behrisch, J. Peak Minerals in Australia: A Review of Changing Impacts and Benefits; Department of Civil Engineering, Monash University: Clayton, Australia, 2010; Available online: https://opus.lib.uts.edu.au/bitstream/10453/31155/1/2009003150OK.pdf (accessed on 15 September 2020).

- Gordon, R.B. Production residues in copper technological cycles. Resour. Conserv. Recycl. 2002, 36, 87–106. [Google Scholar] [CrossRef]

- Evdokimov, S.I.; Evdokimov, V.S. Metal recovery from old tailings. J. Min. Sci. 2014, 50, 800–808. [Google Scholar] [CrossRef]

- Yin, Z.; Sun, W.; Hu, Y.; Zhang, C.; Guan, Q.; Wu, K. Evaluation of the possibility of copper recovery from tailings by flotation through bench-scale, commissioning, and industrial tests. J. Clean. Prod. 2018, 171, 1039–1048. [Google Scholar] [CrossRef]

- Mackay, I.; Videla, A.R.; Brito-Parade, P.R. The link between particle size and froth stability—Implications for reprocessing of flotation tailings. J. Clean. Prod. 2020, 242, 118436. [Google Scholar] [CrossRef]

- Schippers, A.; Hedrich, S.; Vasters, J.; Drobe, M.; Sand, W.; Willscher, S. Biomining: Metal Recovery from Ores with Microorganisms. In Geobiotechnology I. Advances in Biochemical Engineering/Biotechnology; Schippers, A., Glombitza, F., Sand, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 141, pp. 1–47. [Google Scholar] [CrossRef]

- Xie, Y.; Xu, Y.; Yan, L.; Yang, R. Recovery of nickel, copper and cobalt from low-grade Ni-Cu sulfide tailings. Hydrometallurgy 2005, 80, 54–58. [Google Scholar] [CrossRef]

- Olson, G.J.; Brierley, C.L.; Briggs, A.P.; Calmet, E. Biooxidation of thiocyanate-containing refractory gold tailings from Minacalpa, Peru. Hydrometallurgy 2006, 81, 159–166. [Google Scholar] [CrossRef]

- Schippers, A.; Nagy, A.A.; Kock, D.; Melcher, F.; Gock, E.-D. The use of FISH and real-time PCR to monitor the biooxidation and cyanidation for gold and silver recovery from a mine tailings concentrate (Ticapampa, Peru). Hydrometallurgy 2008, 94, 77–81. [Google Scholar] [CrossRef]

- Marrero, J.; Coto, O.; Goldmann, S.; Graupner, T.; Schippers, A. Recovery of nickel and cobalt from laterite tailings by reductive dissolution under aerobic conditions using Acidithiobacillus species. Environ. Sci. Technol. 2015, 49, 6674–6682. [Google Scholar] [CrossRef] [PubMed]

- Falagán, C.; Grail, B.M.; Johnson, D.B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Dold, B.; Fondbote, L. Element cycling and secondary mineralogy in porphyry copper tailings as a function of climate, primary mineralogy, and mineral processing. J. Geochem. Explor. 2001, 77, 3–55. [Google Scholar] [CrossRef]

- S&P Global. SNL Database. Commercial Online-Databank. Available online: https://platform.marketintelligence.spglobal.com/web/client#dashboard/metalsAndMining (accessed on 14 July 2020).

- Lottermoser, B.G. Recycling, reuse and rehabilitation of mine wastes. Elements 2011, 7, 405–410. [Google Scholar] [CrossRef]

- Wellmer, F.W.; Dalheimer, M.; Wagner, M. Economic Evaluations in Exploration, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2008; p. 250. [Google Scholar] [CrossRef]

- Wellmer, F.W.; Drobe, M. A quick estimation of the economics of exploration projects—Rules of thumb for mine capacity revisited—The input for estimating capital and operating costs. Bol. Geol. Min. 2019, 130, 7–26. [Google Scholar] [CrossRef]

- SERNAGEOMIN. Datos de Geoquímica de Depósitos de Relaves de Chile (actualización: 13/01/2020). Available online: https://www.sernageomin.cl/datos-publicos-deposito-de-relaves/ (accessed on 15 June 2020).

- Vick, S.G. Planning, Design, and Analysis of Tailings Dams; Wiley: New York, NY, USA, 1983; p. 369. [Google Scholar]

- Bussière, B. Colloquium 2004: Hydrogeotechnical properties of hard rock tailings from metal mines and emerging geoenvironmental disposal approaches. Can. Geotech. J. 2007, 44, 1019–1052. [Google Scholar] [CrossRef]

- Blight, G.; Bentel, G. The behaviour of mine tailings during hydraulic deposition. J. S. Afr. Inst. Min. Metall. 1983, 83, 73–86. [Google Scholar]

- Long, K.R.; Singer, D.A. A Simplified Economic Filter for Open-Pit Mining and Heap-Leach Recovery of Copper in the United States. In USGS Open-File Rep.; 2001; 01-218. Available online: https://pubs.usgs.gov/of/2001/0218/pdf/of01-218.pdf (accessed on 15 September 2020).

- b2bmetal (2020). Online Metal Marketplace with Requirements for Several Steel Grades Including Mechanical Properties, Chemical Composition and Grade Equivalents. Available online: http://www.b2bmetal.eu/en/pages/index/index/id/141/ (accessed on 20 November 2020).

- Long, K.R. A Test and Re-Estimation of Taylor’s Empirical Capacity-Reserve Relationship. Nat. Resour. Res. 2009, 18, 57–63. [Google Scholar] [CrossRef]

- Dhawan, N.; Sadegh Safarzadeh, M.; Miller, J.D.; Moats, M.S.; Rajaman, R.K. Crushed ore agglomeration and its control for heap leach operations. Miner. Eng. 2013, 41, 53–70. [Google Scholar] [CrossRef]

- ACH Minerals 2016. Appendix 2: Capital and Operating Cost Estimate—GR Engineering Services. Available online: https://consultation.epa.wa.gov.au/seven-day-comment-on-referrals/ravensthorpe-gold-copper-project/supporting_documents/CMS16331%20%20Referral%20%20Appendix%202%20Captial%20and%20Operating%20Cost%20Estimate.pdf (accessed on 29 July 2020).

- Conić, V.; Stanković, S.; Marković, B.; Božić, D.; Stojanović, J.; Sokić, M. Investigation of optimal technology for copper leaching from old flotation tailings of the copper mine Bor (Serbia). Metall. Mater. Eng. 2020, 26, 209–222. [Google Scholar] [CrossRef]

- Kuhn, K.; Meima, J.A. Characterization and Economic Potential of Historic Tailings from Gravity Separation: Implications from a Mine Waste Dump (Pb-Ag) in the Harz Mountains Mining District, Germany. Minerals 2019, 9, 303. [Google Scholar] [CrossRef]

- Nevskaya, M.A.; Seleznev, S.G.; Masloboev, V.A.; Klyuchnikova, E.M.; Makarov, D.V. Environmental and Business Challenges Presented by Mining and Mineral Processing Waste in the Russian Federation. Minerals 2019, 9, 445. [Google Scholar] [CrossRef]

- Figueiredo, J.; Vila, M.C.; Góis, J.; Pavani Biju, B.; Futuro, A.; Martins, D.; Dinis, M.L.; Fiúza, A. Bi-level depth assessment of an abandoned tailings dam aiming its reprocessing for recovery of valuable metals. Miner. Eng. 2019, 133, 1–9. [Google Scholar] [CrossRef]

| Reagents | Type | Comments | |

|---|---|---|---|

| PAX | potassium amyl xanthate | promoter | collector for sulfide and oxide Cu-Minerals after sulfidization |

| AERO 238 | sodium di-sec-butyl phosphorodithioate | promoter | collector for sulfide and oxide Cu-Minerals after sulfidization |

| AERO 404 | dithiophosphate and mercaptobenzothiazole | promotor | collector for sulfide and oxide Cu-Minerals after sulfidization |

| AERO OX-100 | hydroxamic acid | promoter | collector for oxide Cu-minerals without sulfidization |

| CuSO4 | copper (II)sulfate | activator | activator for sulfides |

| CaO | lime | pH-regulation | pH-regulation |

| MIBC | methylisobutylcarbinol | frother | frother |

| NaHS∙H2O | sodium hydrosulfide hydrate | modifier | sulfidizer |

| Na2S∙9H2O | sodium sulfide | modifier | sulfidizer |

| - | Quartz | Magnetite | Gypsum | Amphibole | Calcite | Hematite | Muscovite | Plagioclase | Chlorite |

|---|---|---|---|---|---|---|---|---|---|

| coarse | 13 | 22 | 3 | 10 | 3 | 6 | 8 | 23 | 12 |

| fine | 15 | 15 | 4 | 8 | 4 | 8 | 15 | 19 | 12 |

| - | Pyrite | Apatite | Atacamite | Halite | Ankerite | Chalcopyrite |

|---|---|---|---|---|---|---|

| homogenized sample material | 1.0 | 0.5 | 0.4 | 0.4 | 0.4 | 0.2 |

| Test | Tailings | Pre-Concentrate of Cu | ||

|---|---|---|---|---|

| Mass (g) | Mass (g) | Grade (%) | Recovery (%) | |

| 1 | 936 | 182.3 | 1.2 | 45.9 |

| 2 | 490 | 67.5 | 1.9 | 56.6 |

| 3 | 490 | 105.4 | 1.5 | 73.1 |

| 4 | 487 | 80.8 | 1.3 | 48.0 |

| 5 | 486 | 94.5 | 1.6 | 65.1 |

| 6 | 485 | 67.7 | 2.2 | 65.1 |

| 7 | 483 | 75.0 | 1.9 | 66.2 |

| 8 | 501 | 71.9 | 2.2 | 65.7 |

| 9 | 487 | 66.6 | 2.0 | 60.2 |

| 10 | 1445 | 472.4 | 0.9 | 64.2 |

| Product | Mass (g) | Recovery (%) | Cu Grade (%) | Recovery (%) | Fe Grade (%) | Recovery (%) | S Grade (%) | Recovery (%) |

|---|---|---|---|---|---|---|---|---|

| Feed | 6012 | 100 | 0.45 | 100 | 26.7 | 100 | 0.04 | 100 |

| Flotation (pre)concentrate | 1284 | 21.4 | 1.37 | 65.1 | 20.6 | 16.5 | 0.16 | 88.1 |

| Fe-concentrate | 1711 | 28.5 | 0.08 | 4.8 | 60.0 | 64.1 | 0.01 | 3.6 |

| tailings | 3016 | 50.2 | 0.27 | 30.1 | 10.3 | 19.4 | 0.01 | 8.3 |

| Product | Mass (g) | Recovery (%) | Cu Grade (%) | Recovery (%) | Fe Grade (%) | Recovery (%) | S Grade (%) | Recovery (%) |

|---|---|---|---|---|---|---|---|---|

| Feed | 5384 | 100 | 0.42 | 100 | 26.9 | 100 | 0.0 | 100 |

| Fe-concentrate | 1800 | 33.4 | 0.14 | 11.2 | 59.8 | 74.4 | 0.0 | 6.6 |

| Flotation (pre)concentrate | 489 | 9.1 | 2.04 | 44.2 | 12.4 | 4.2 | 0.2 | 67.3 |

| tailings | 3095 | 57.5 | 0.32 | 44.6 | 10.0 | 21.4 | 0.0 | 26.1 |

| Test | Tailings | Pre-Concentrate of Cu | ||

|---|---|---|---|---|

| Mass (g) | Mass (g) | Grade (%) | Recovery (%) | |

| 1 | 499 | 62.0 | 2.2 | 50.9 |

| 2 | 501 | 72.1 | 2.1 | 52.7 |

| 3 | 501 | 56.4 | 2.4 | 47.6 |

| 4 | 501 | 95.7 | 1.7 | 57.1 |

| total | - | 286.2 | 2.1 | 52.1 |

| Capacity | Original Opex | Adjusted Opex | Original Capex | Adjusted Capex | |

|---|---|---|---|---|---|

| flotation | 500 t/d | 22.3 USD/t | 13.2 USD/t | 15.7 M USD | 9.4 M USD |

| magnetic separation | 500 t/d | - | 10 USD/t incl. fr. | - | 1 M USD |

| agitated leaching | 500 t/d | 40 USD/t | 16 USD/t | 19.4 USD/t | 9.3 M USD |

| Flotation-Magnetic Separation | Mass (M t) | Fe Grade (%) | Fe Recovery (%) | Cu Grade (%) | Flotation Recovery (%) | Cu in Concentrate (t) | Metal Value in Concentrate (M USD) | Capex and Opex (M USD) |

|---|---|---|---|---|---|---|---|---|

| tailings mass | 2.0 | 27 | - | 0.45 | - | - | - | - |

| Cu (pre)concentrate | 0.43 | - | - | 1.37 | 65 | 6020 | 33.1 | 35.8 |

| Fe concentrate | 0.57 | 60 | 64 | 0.08 | - | - | 37.0 | 20.2 |

| Magnetic Separation-Flotation | Mass (M t) | Fe Grade (%) | Fe Recovery (%) | Cu Grade (%) | Flotation Recovery (%) | Cu in Concentrate (t) | Metal Value in Concentrate (M USD) | Capex and Opex (M USD) |

|---|---|---|---|---|---|---|---|---|

| tailings mass | 2.0 | 27 | - | 0.45 | - | 9000 | - | - |

| Fe- concentrate | 0.66 | 60 | 74 | 0.14 | - | - | 42.9 | 21.7 |

| Cu (pre)concentrate | 0.18 | - | - | 2.04 | 44 | 3700 | 20.4 | 26.7 |

| Leaching-Magnetic Separation | Mass (M t) | Fe Grade (%) | Fe Recovery (%) | Cu Grade (%) | Leaching Recovery (%) | Cu Leached (t) | Metal Value in Leachate (M USD) | Capex and Opex (M USD) |

|---|---|---|---|---|---|---|---|---|

| magnetic separation | 0.6 | 60 | 64 | - | - | - | 39.0 | 20.7 |

| leaching with dilute sulfuric acid | 2.0 | - | - | 0.56 | 80 | 8930 | 49.1 | 41.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drobe, M.; Haubrich, F.; Gajardo, M.; Marbler, H. Processing Tests, Adjusted Cost Models and the Economies of Reprocessing Copper Mine Tailings in Chile. Metals 2021, 11, 103. https://doi.org/10.3390/met11010103

Drobe M, Haubrich F, Gajardo M, Marbler H. Processing Tests, Adjusted Cost Models and the Economies of Reprocessing Copper Mine Tailings in Chile. Metals. 2021; 11(1):103. https://doi.org/10.3390/met11010103

Chicago/Turabian StyleDrobe, Malte, Frank Haubrich, Mariano Gajardo, and Herwig Marbler. 2021. "Processing Tests, Adjusted Cost Models and the Economies of Reprocessing Copper Mine Tailings in Chile" Metals 11, no. 1: 103. https://doi.org/10.3390/met11010103

APA StyleDrobe, M., Haubrich, F., Gajardo, M., & Marbler, H. (2021). Processing Tests, Adjusted Cost Models and the Economies of Reprocessing Copper Mine Tailings in Chile. Metals, 11(1), 103. https://doi.org/10.3390/met11010103