Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel

Abstract

:1. Introduction

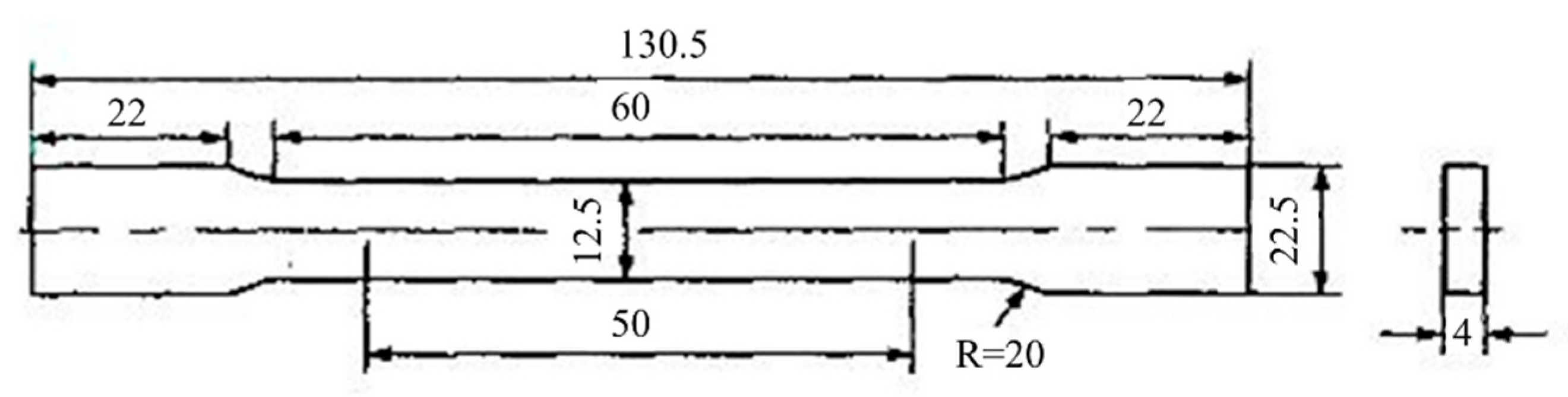

2. Experimental Procedure

3. Results

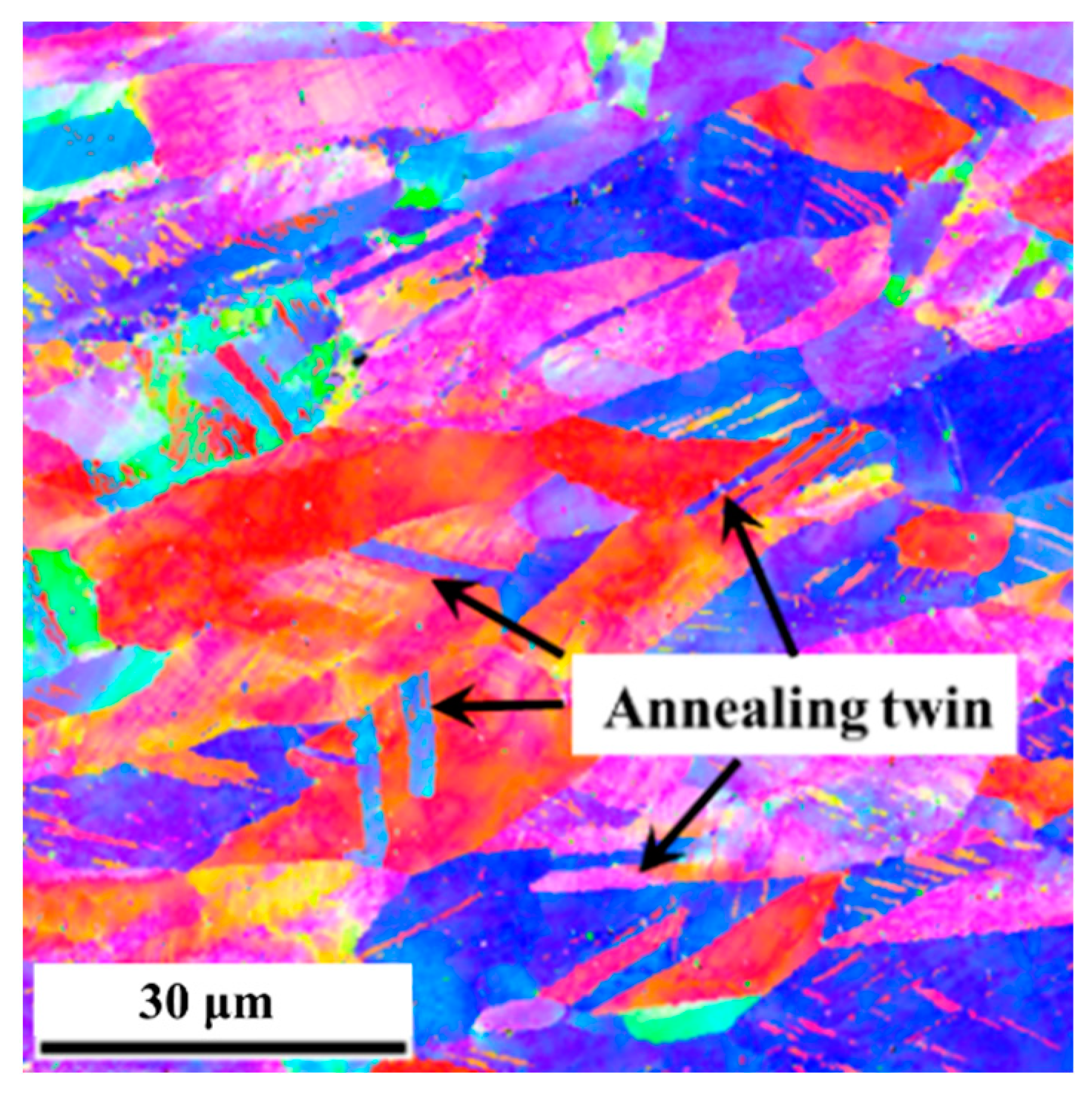

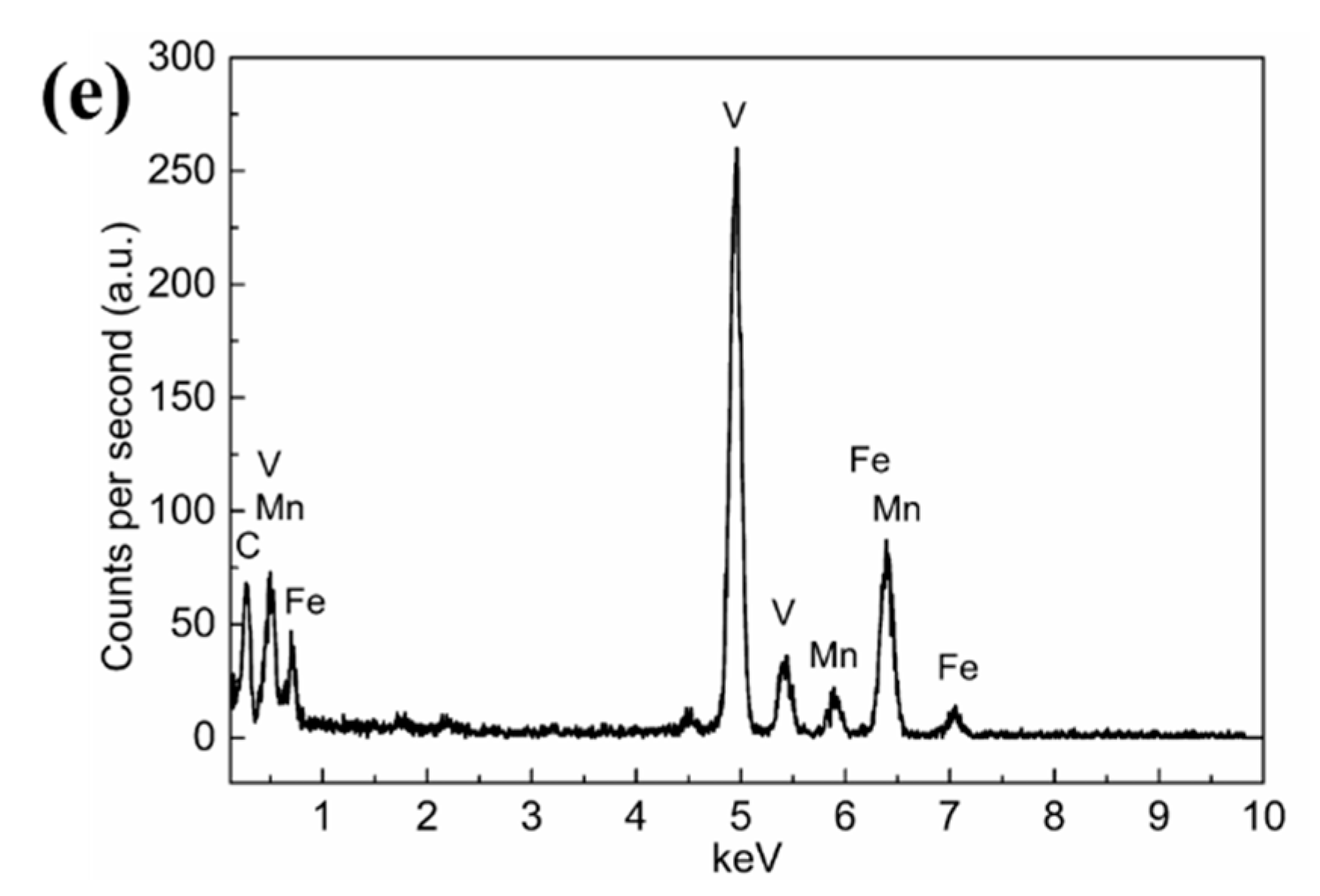

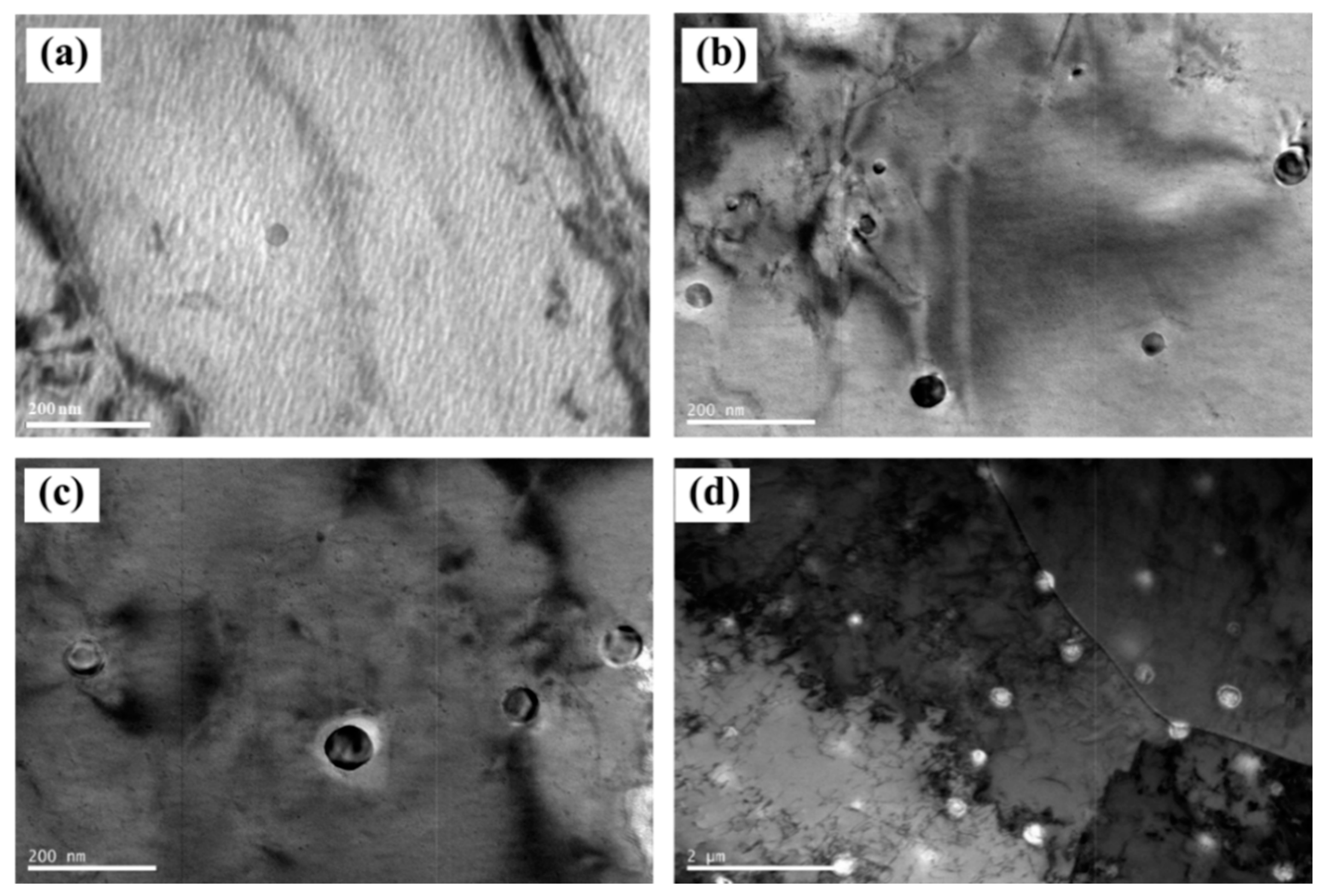

3.1. Microstructure Change before and after Aging Process

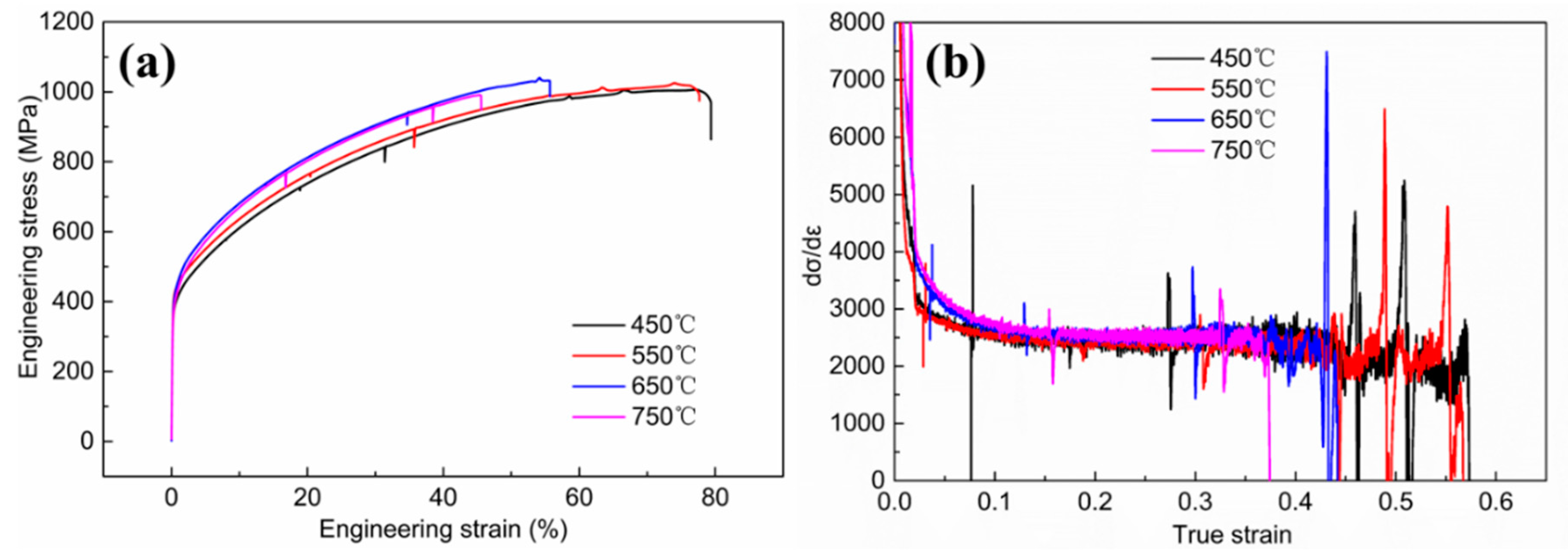

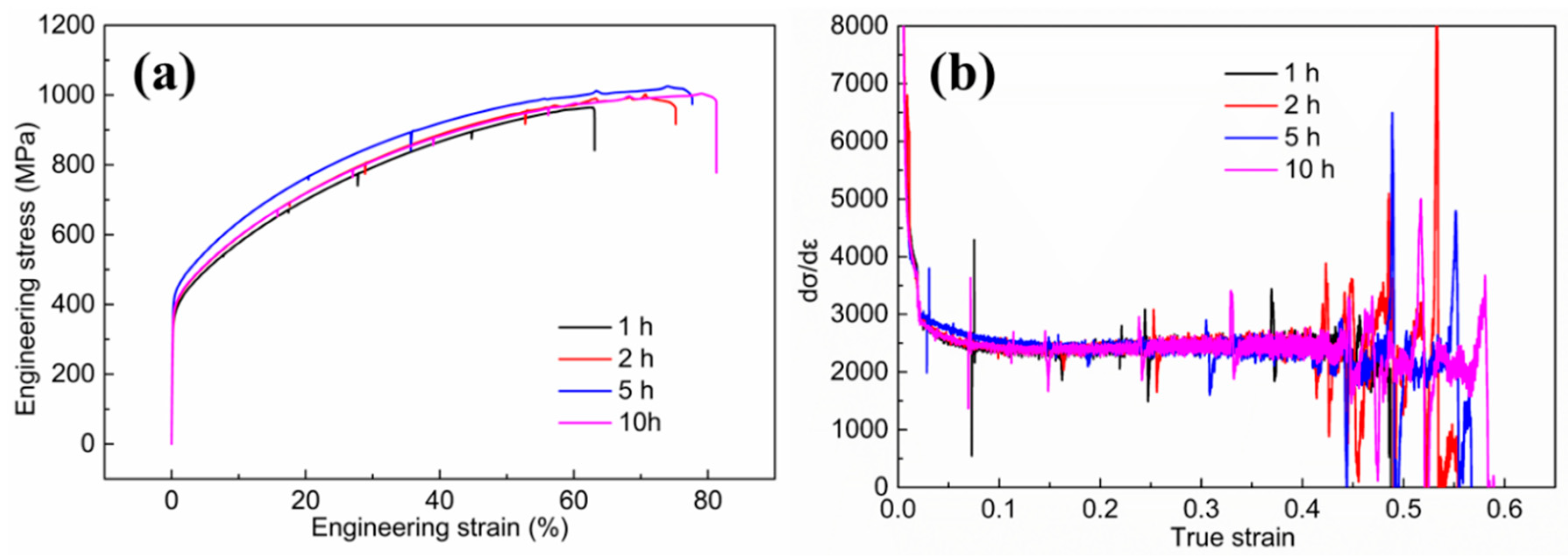

3.2. Effect of Aging Process on Tensile Behavior

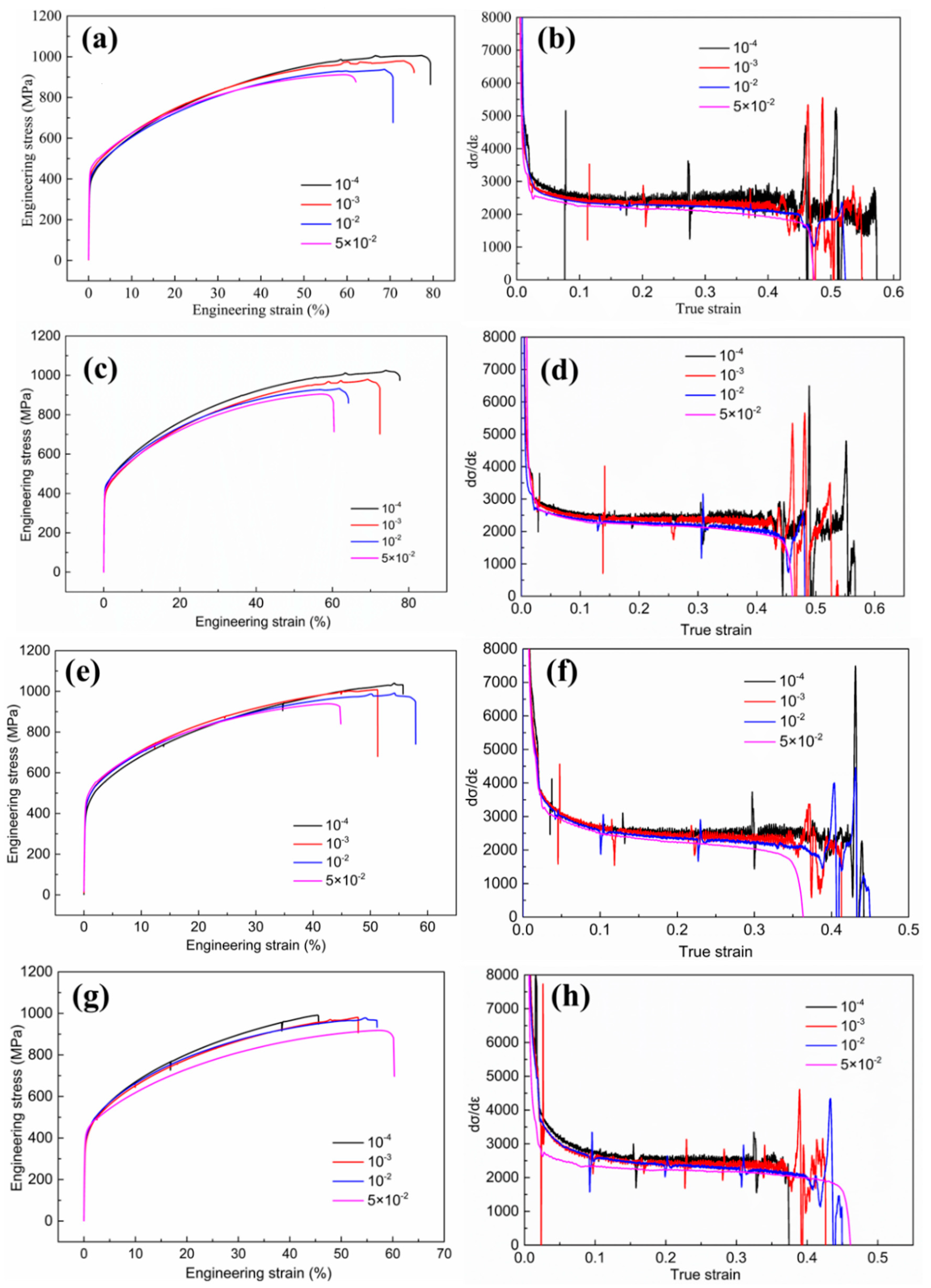

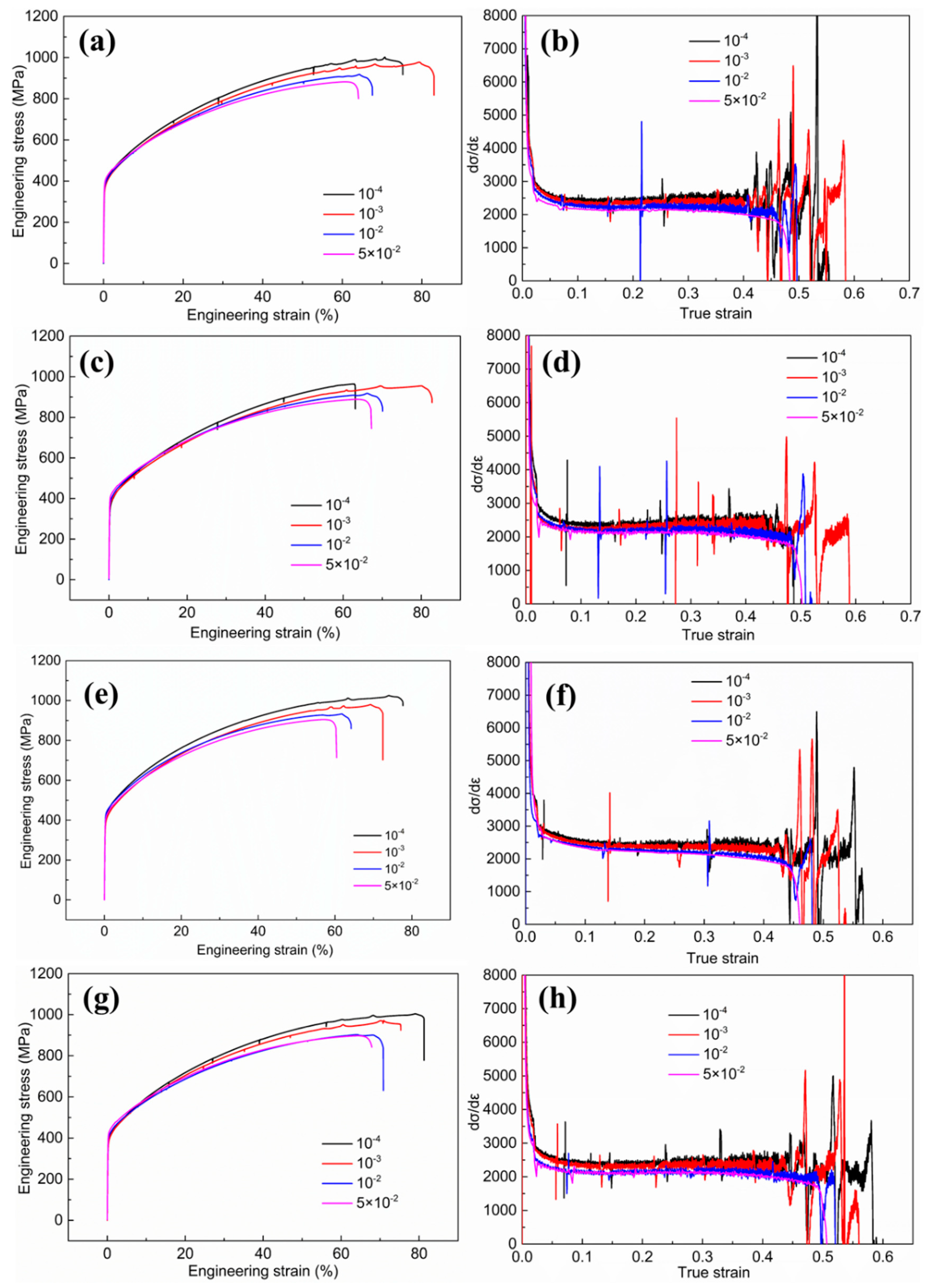

3.3. Effect of Strain Rate on Tensile Behavior

4. Discussion

4.1. Aging Strengthening

4.2. Strain Rate Sensitivity

4.3. Adiabatic Heating

4.4. Dynamic Strain Aging (DSA)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, B.; Krieger, W.; Rohwerder, M.; Ponge, D.; Raabe, D. Dependence of hydrogen embrittlement mechanisms on microstructure-Driven hydrogen distribution in medium Mn steels. Acta Mater. 2020, 183, 313–328. [Google Scholar] [CrossRef]

- Sun, B.; Palanisamy, D.; Ponge, D.; Gault, B.; Fazeli, F.; Scott, C.; Yue, S.; Raabe, D. Revealing fracture mechanisms of medium manganese steels with and without delta-Ferrite. Acta Mater. 2019, 164, 683–696. [Google Scholar] [CrossRef]

- Cooman, B.C.D.; Estrin, Y.; Kim, S.K. Twinning-Induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Scott, C.; Remy, B.; Collet, J.-L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Kang, S.; Jung, J.; Kang, M.; Woo, W.; Lee, Y. The effects of grain size on yielding, strain hardening, and mechanical twinning in Fe–18Mn–0.6C–1.5Al twinning-Induced plasticity steel. Mater. Sci. Eng. A 2016, 652, 212–220. [Google Scholar] [CrossRef]

- Hamada, A.S.; Järvenpää, A.; Honkanen, M.; Jaskari, M.; Porter, D.A.; Karjalainen, L.P. Effects of Cyclic Pre-Straining on Mechanical Properties of an Austenitic Microalloyed High-Mn Twinning-Induced Plasticity Steel. Procedia Eng. 2014, 74, 47–52. [Google Scholar] [CrossRef] [Green Version]

- Yen, H.; Huang, M.; Scott, C.P.; Yang, J. Interactions between deformation-Induced defects and carbides in a vanadium-CONTAINING TWIP steel. Scr. Mater. 2012, 66, 1018–1023. [Google Scholar] [CrossRef]

- Chateau, J.P.; Dumay, A.; Allain, S.; Jacques, A. Precipitation hardening of a FeMnC TWIP steel by vanadium carbides. J. Phys. Conf. Ser. 2010, 240, 12023. [Google Scholar] [CrossRef]

- Kwon, Y.A.; Zargaran, A.A.; Ryu, J.H.A.; Kim, N.J.A.N. Effect of annealing conditions on the microstructure and tensile properties of 0.5 V containing Fe-16Mn-0.8C-0.5Si steel. Scr. Mater. 2019, 172, 125–129. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, A.A.Z.U.; Wu, Q. Effect of strain rate on the work-Hardening rate in high-Mn steel. Mater. Sci. Technol. 2017, 33, 1306–1311. [Google Scholar] [CrossRef]

- Xu, M.; Mi, Z.; Li, H.; Tang, D.; Jiang, H. Deformation mechanism transition in Fe–17Mn–0.4C–0.06V TWIP steel with different strain rates. Mater. Sci. Technol. 2018, 34, 242–251. [Google Scholar] [CrossRef]

- Yin, F.; Hu, S.; Xu, R.; Han, X.; Qian, D.; Wei, W.; Hua, L.; Zhao, K. Strain rate sensitivity of the ultrastrong gradient nanocrystalline 316L stainless steel and its rate-Dependent modeling at nanoscale. Int. J. Plast. 2020, 129, 102696. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, C.; Wang, J.; Ren, Z.; Shi, W. Effect of annealing treatment on the microstructure and mechanical properties of Fe-18Mn-0.8 C-0.2 V TWIP steel. Mater. Res. Expr. 2020, 6, 1265h4. [Google Scholar] [CrossRef]

- Han, G.M.; Tian, C.G.; Chu, Z.K.; Cui, C.Y.; Hu, Z.Q.; Sun, X.F. Activation energy calculations for the Portevin–Le Chatelier effect in nimonic 263 superalloy. Met. Mater. Trans. A 2015, 46, 4629–4635. [Google Scholar] [CrossRef]

- Yong, Q. Secondary Phase in Steels; Press of Metallurgy Industry: Beijing, China, 2006. [Google Scholar]

- Sun, S.; Xue, Z.; An, L.; Chen, X.; Liu, Y. A novel design to enhance the mechanical properties in Cu-Bearing antibacterial stainless steel. Materials 2020, 13, 403. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.F.; Jia, N.; Misra, R.D.K.; Zuo, L. Softening behavior by excessive twinning and adiabatic heating at high strain rate in a Fe–20Mn–0.6 C TWIP steel. Acta Mater. 2016, 103, 229–242. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, C.R.; Lopes, A.B.; Grácio, J.J.; Barlat, F. Strain hardening rate sensitivity and strain rate sensitivity in TWIP steels. Mater. Sci. Eng. A 2015, 629, 54–59. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Yang, H.K.; Zhang, Z.J.; Dong, F.Y.; Duan, Q.Q.; Zhang, Z.F. Strain rate effects on tensile deformation behaviors for Fe–22Mn–0.6C–(1.5Al) twinning-Induced plasticity steel. Mater. Sci. Eng. A 2014, 607, 551–558. [Google Scholar] [CrossRef]

- Chen, L.; Kim, H.S.; Kim, S.K. Localized deformation due to Portevin–LeChatelier effect in 18Mn–0.6 C TWIP austenitic steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef] [Green Version]

- Yoshinaga, H.; Morozumi, S. A Portevin-Le Chatelier effect expected from solute atmosphere dragging. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1971, 186, 1351–1366. [Google Scholar] [CrossRef]

- Qian, K.; Li, X.; Xiao, L.; Chen, W.; Zhang, H.; Peng, K. Dynamic strain aging phenomenon in metals and alloys. J. Fuzhou Univ. (Nat. Sci. Ed.) 2001, 6, 8–23. [Google Scholar]

- Kawakami, K.; Matsumiya, T. Numerical analysis of hydrogen trap state by TiC and V4C3 in bcc-Fe. ISIJ Int. 2012, 52, 1693–1697. [Google Scholar] [CrossRef] [Green Version]

- Hu, G.; Wang, X.; Rong, Y. Fundamentals of Materials Science; Shanghai Jiao Tong University Press: Shanghai, China, 2010. [Google Scholar]

| Elements | C | V | Mn | Fe | Total |

|---|---|---|---|---|---|

| wt.% | 12.11 | 61.28 | 4.28 | 22.33 | 100 |

| at.% | 37.50 | 44.74 | 2.90 | 14.87 | 100 |

| Strain Rate | 450 °C | 550 °C | 650 °C | 750° C |

|---|---|---|---|---|

| 10−4 | 1006 ± 17 | 1025 ± 14 | 1040 ± 18 | 991 ± 15 |

| 10−3 | 980 ± 14 | 980 ± 26 | 1008 ± 13 | 981 ± 12 |

| 10−2 | 938 ± 21 | 933 ± 22 | 991 ± 21 | 978 ± 27 |

| 0.05 | 912 ± 11 | 905 ± 14 | 939 ± 16 | 918 ± 23 |

| Temperature | 450 °C | 550 °C | 650 °C | 750 °C |

|---|---|---|---|---|

| m | −0.0161 | −0.0202 | −0.0151 | −0.0105 |

| Strain Rate | 1 h | 2 h | 5 h | 10 h |

|---|---|---|---|---|

| 10−4 | 964 ± 14 | 1002 ± 11 | 1025 ± 14 | 1004 ± 16 |

| 10−3 | 955 ± 20 | 977 ± 24 | 980 ± 26 | 971 ± 14 |

| 10−2 | 918 ± 18 | 918 ± 16 | 933 ± 22 | 902 ± 21 |

| 0.05 | 889 ± 16 | 882 ± 21 | 905 ± 14 | 897 ± 15 |

| Time | 1 h | 2 h | 5 h | 10 h |

|---|---|---|---|---|

| m | −0.0133 | −0.0211 | −0.0202 | −0.0199 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Xue, Z. Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel. Metals 2021, 11, 126. https://doi.org/10.3390/met11010126

Sun S, Xue Z. Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel. Metals. 2021; 11(1):126. https://doi.org/10.3390/met11010126

Chicago/Turabian StyleSun, Shaoheng, and Zhiyong Xue. 2021. "Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel" Metals 11, no. 1: 126. https://doi.org/10.3390/met11010126

APA StyleSun, S., & Xue, Z. (2021). Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel. Metals, 11(1), 126. https://doi.org/10.3390/met11010126