Fatigue Crack Initiation and Propagation at High Temperature of New-Generation Bearing Steel

Abstract

:1. Introduction

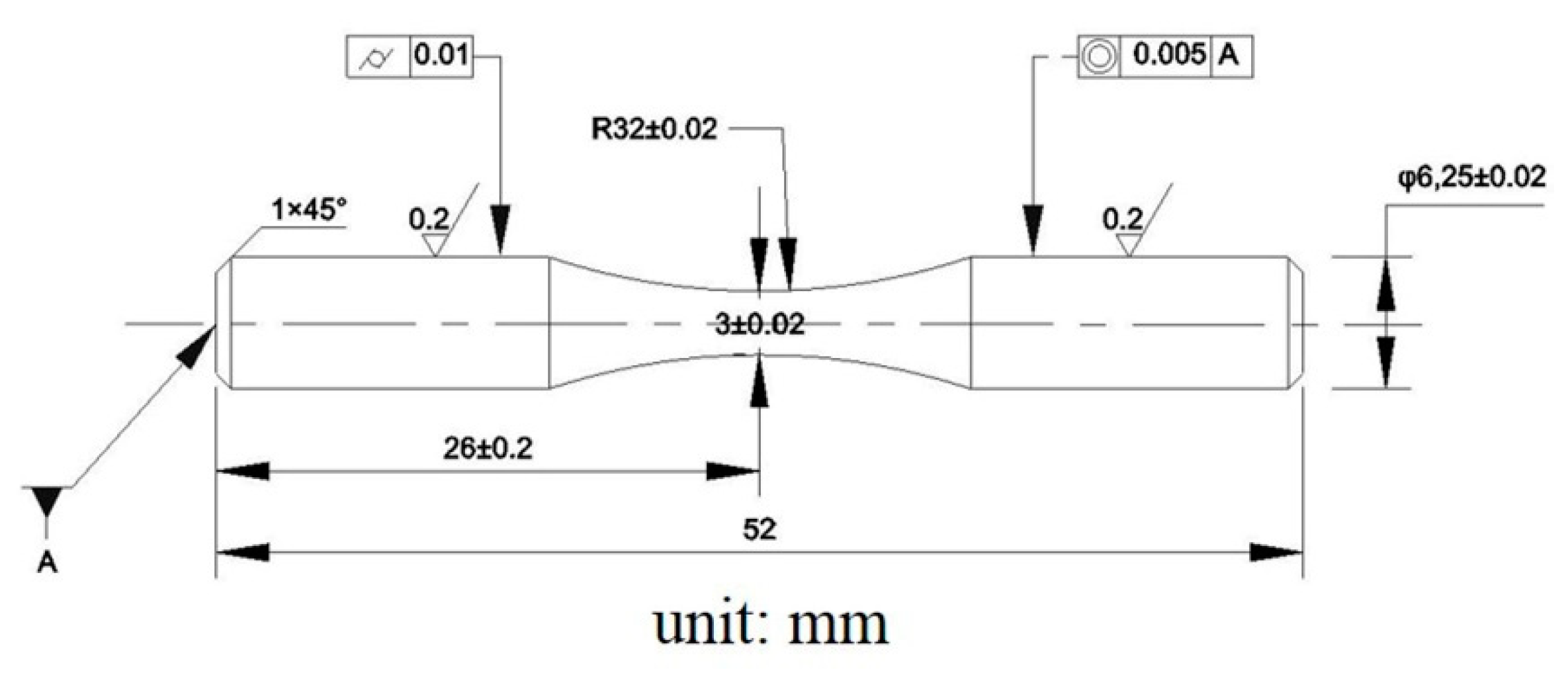

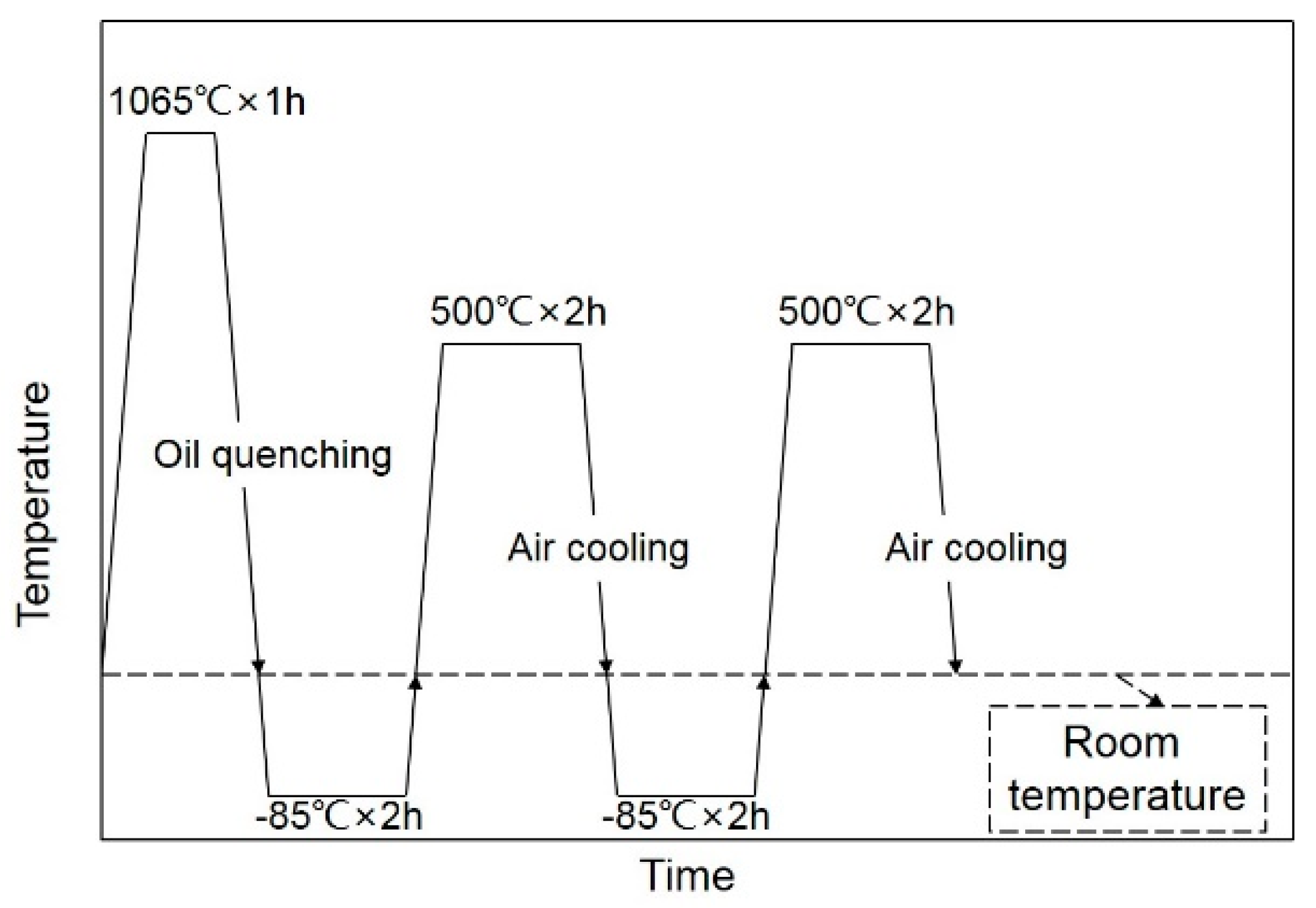

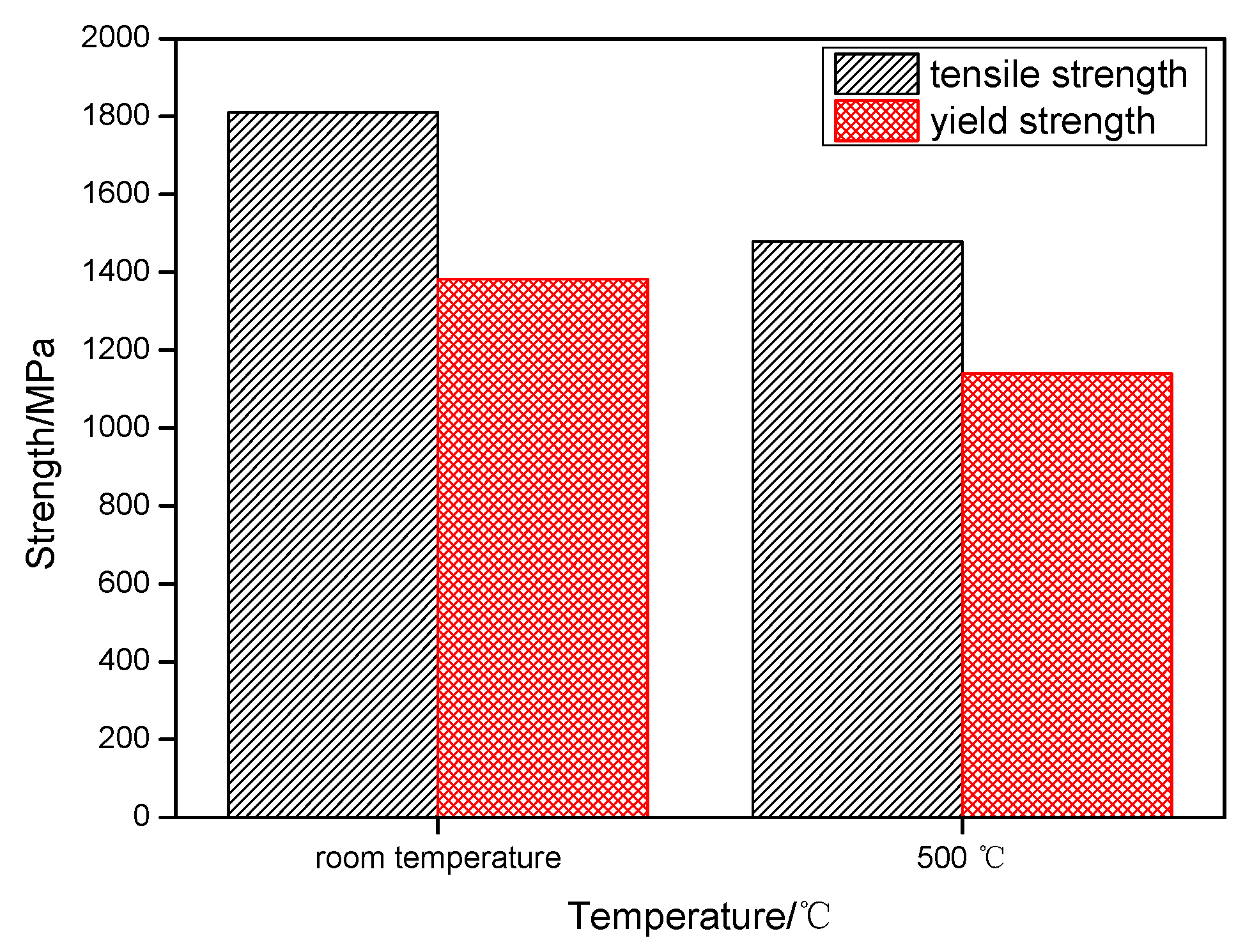

2. Materials and Methods

3. Experimental Results

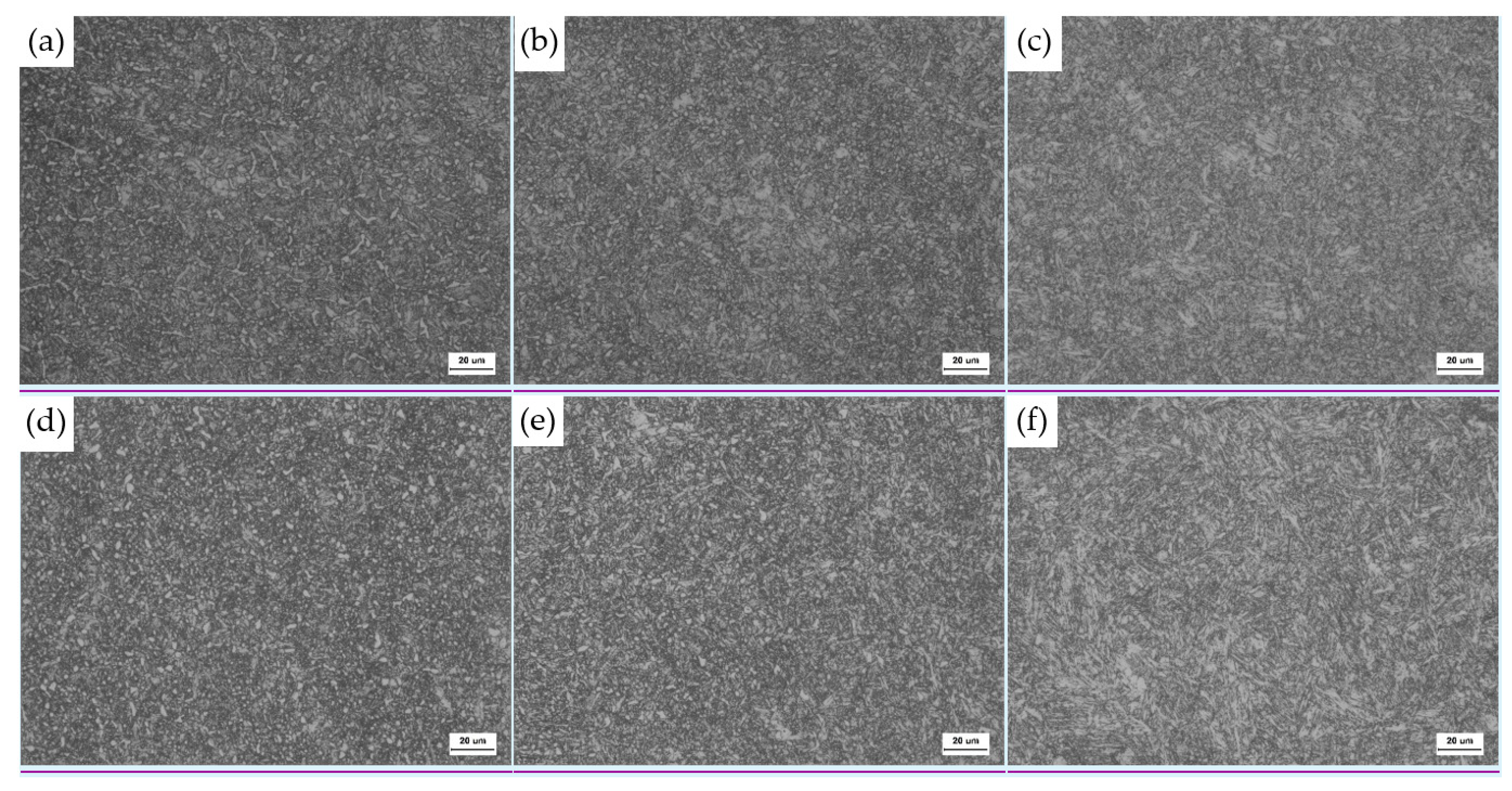

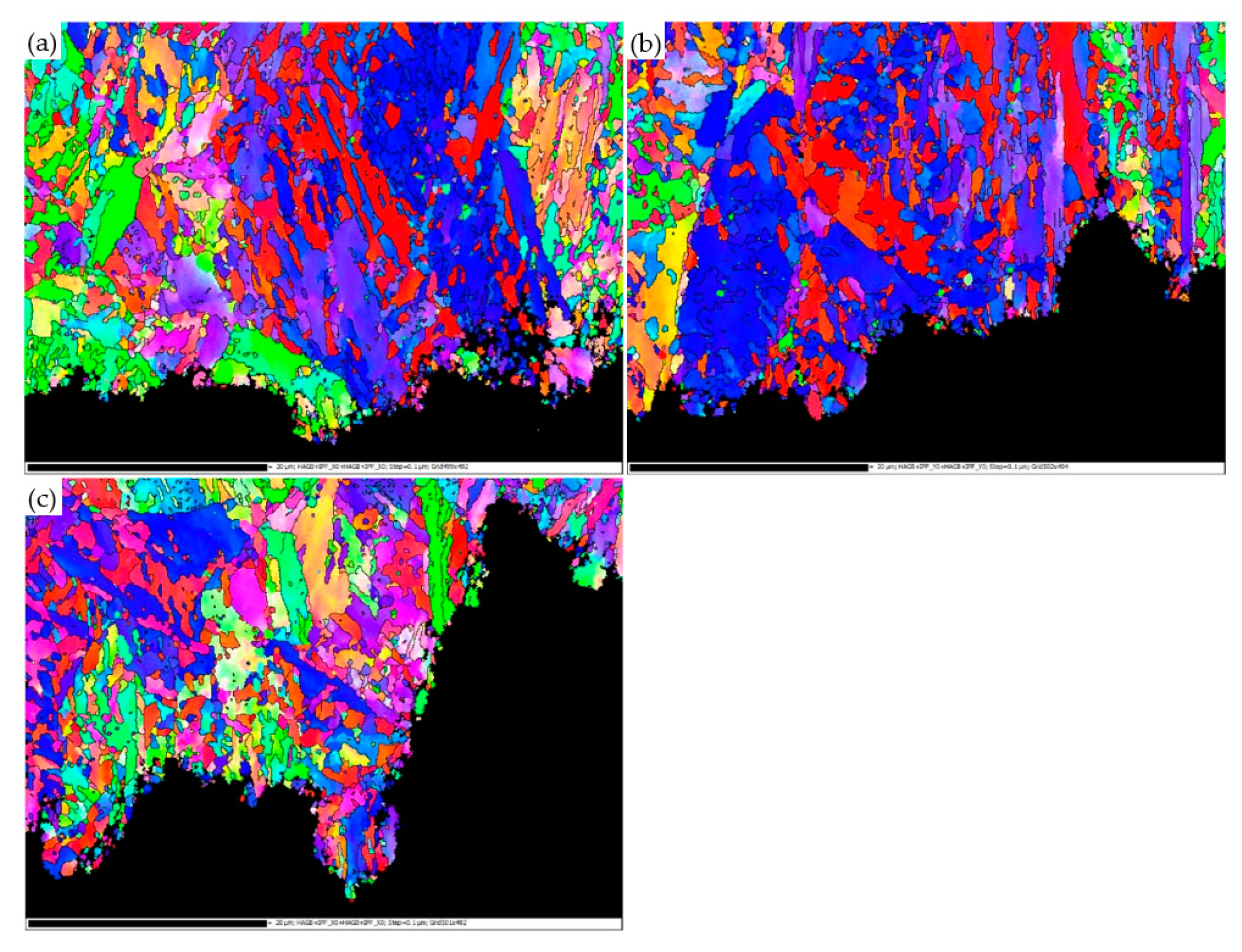

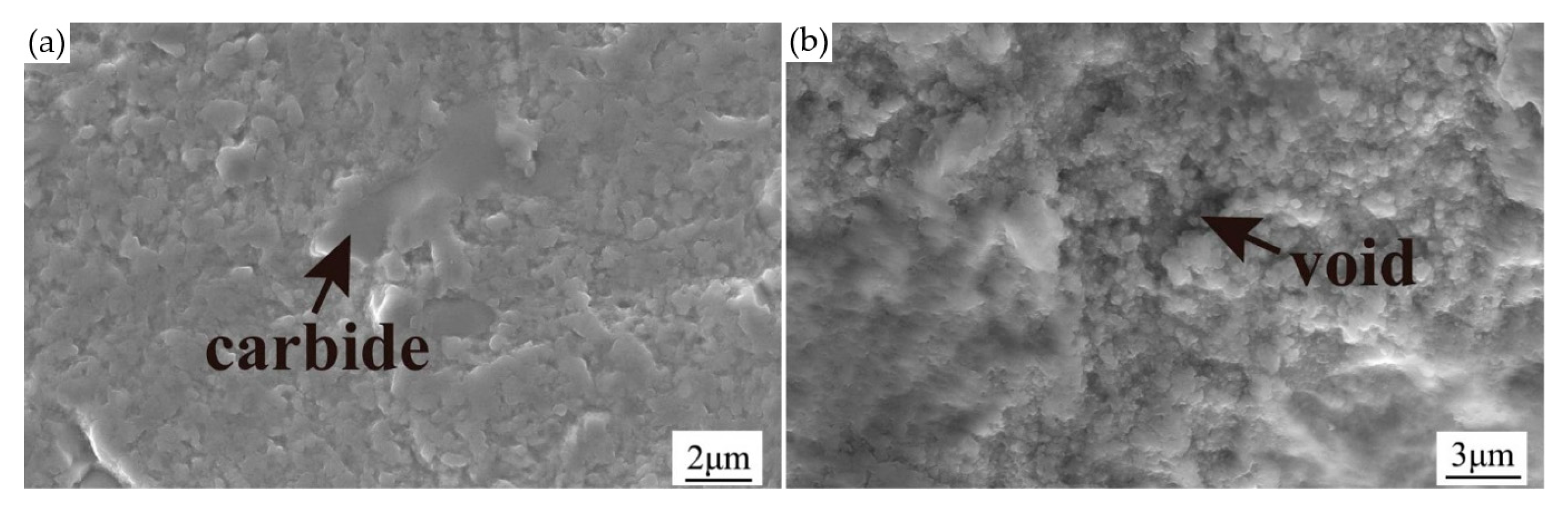

3.1. Microstructural Characterization of the Carburized Case

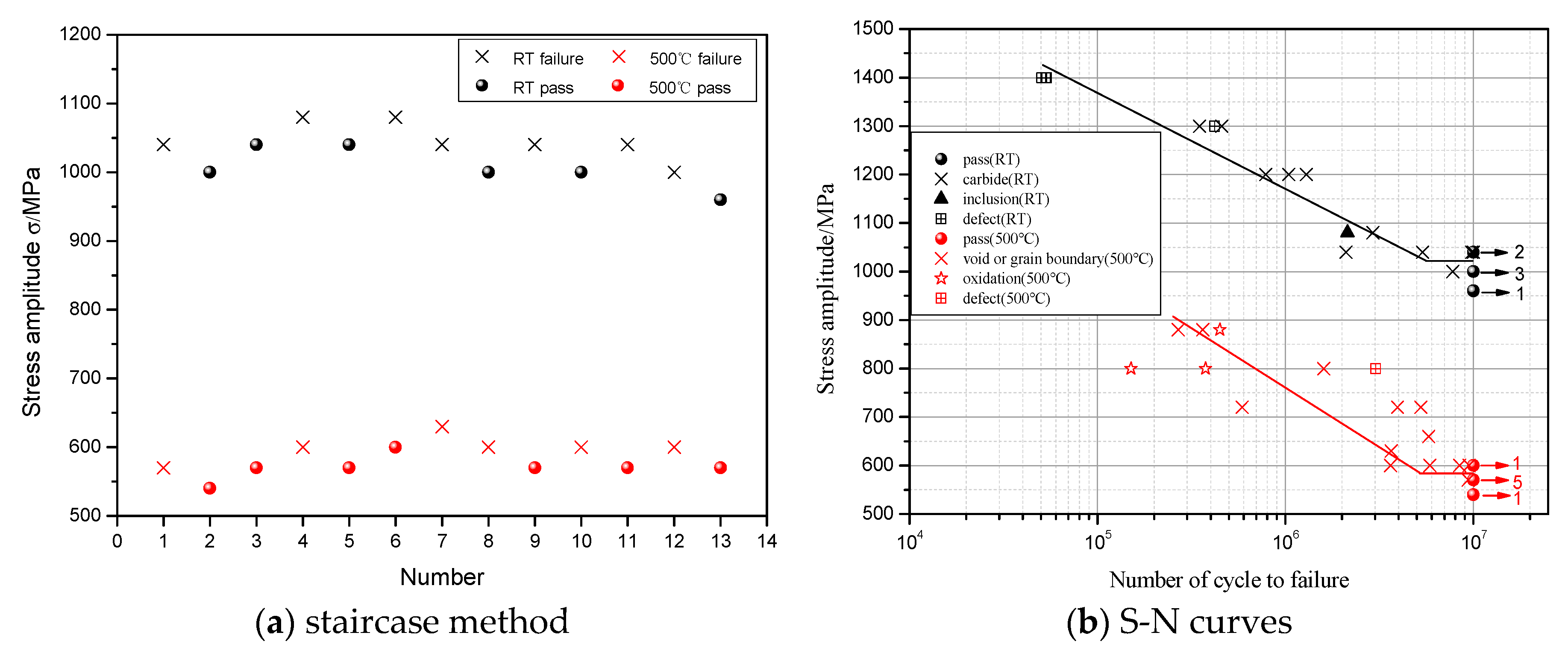

3.2. Staircase Method and S-N Curves

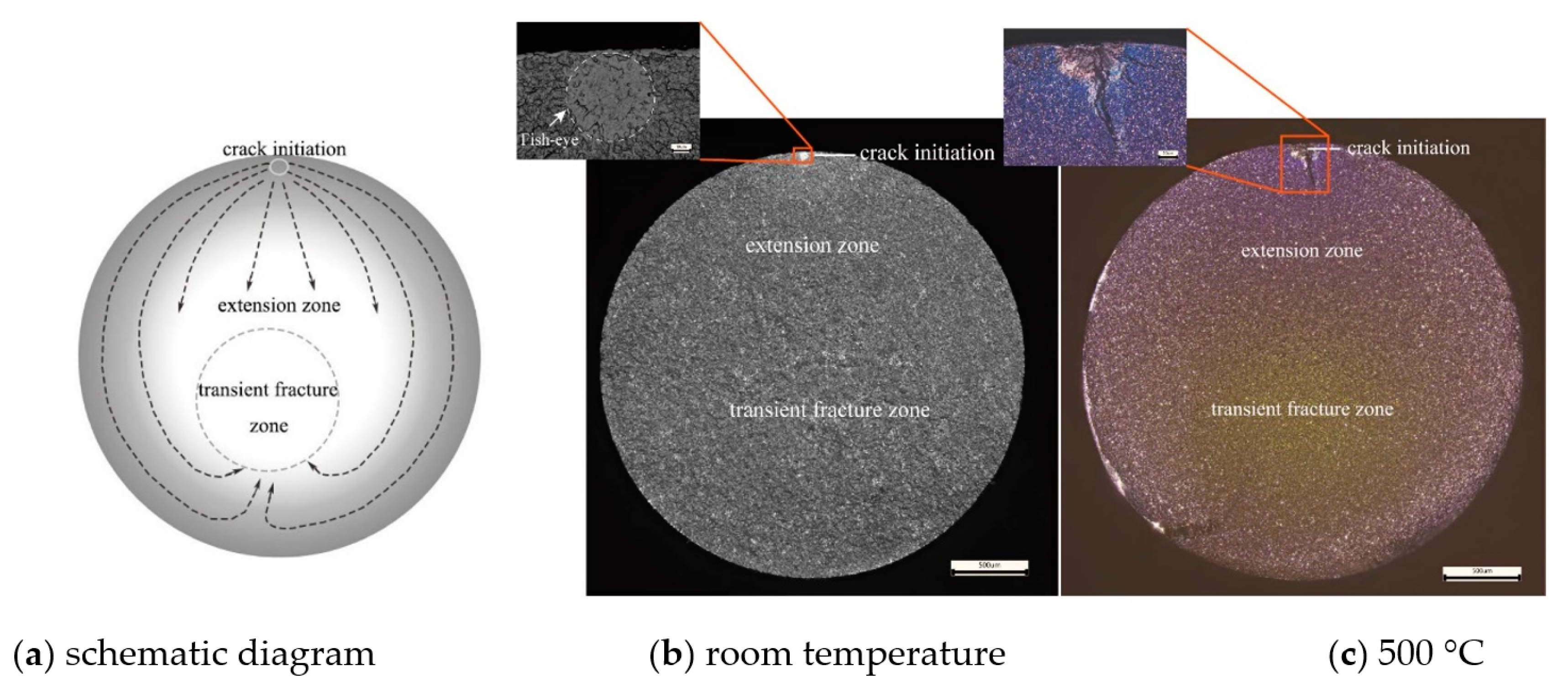

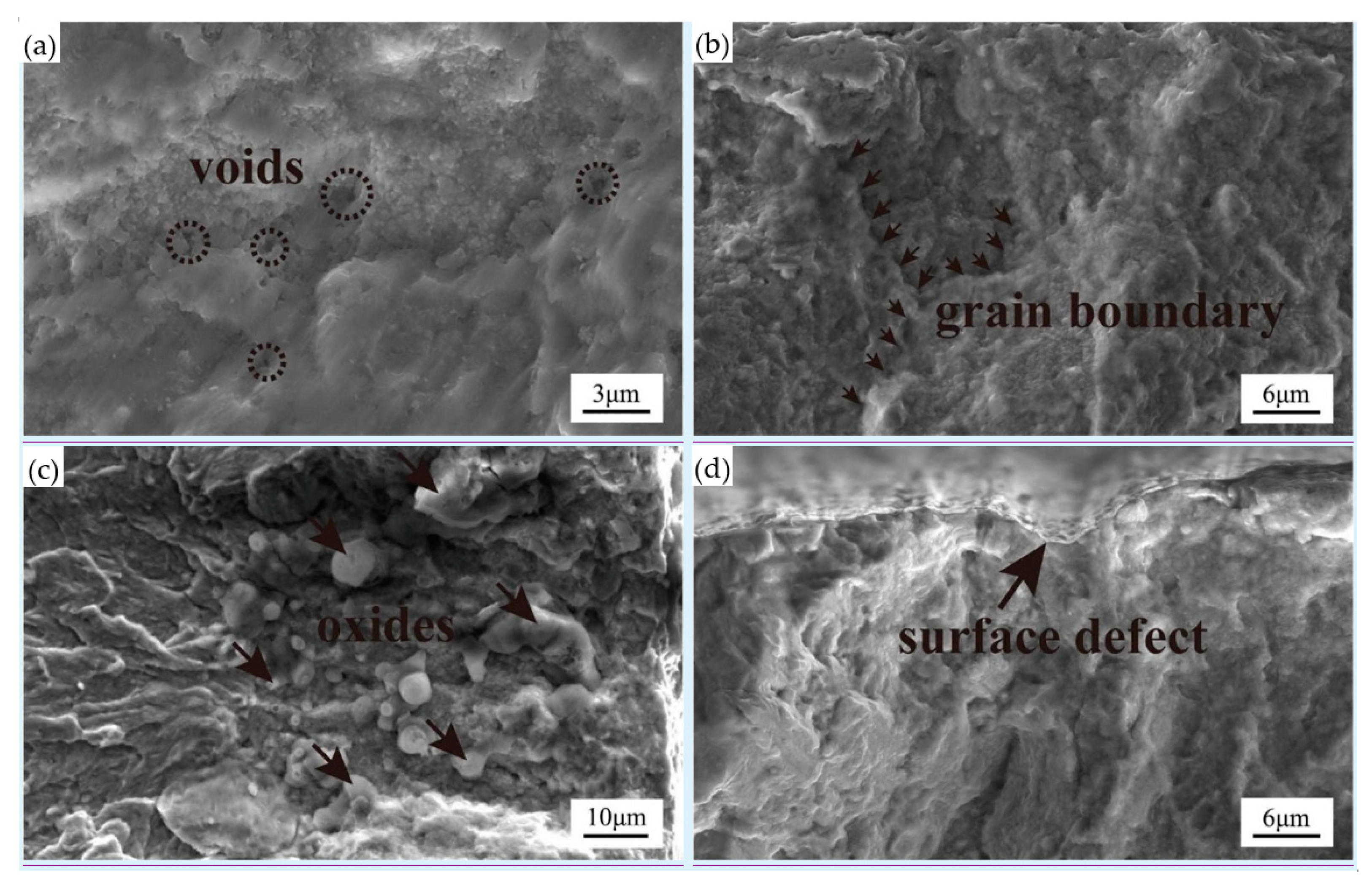

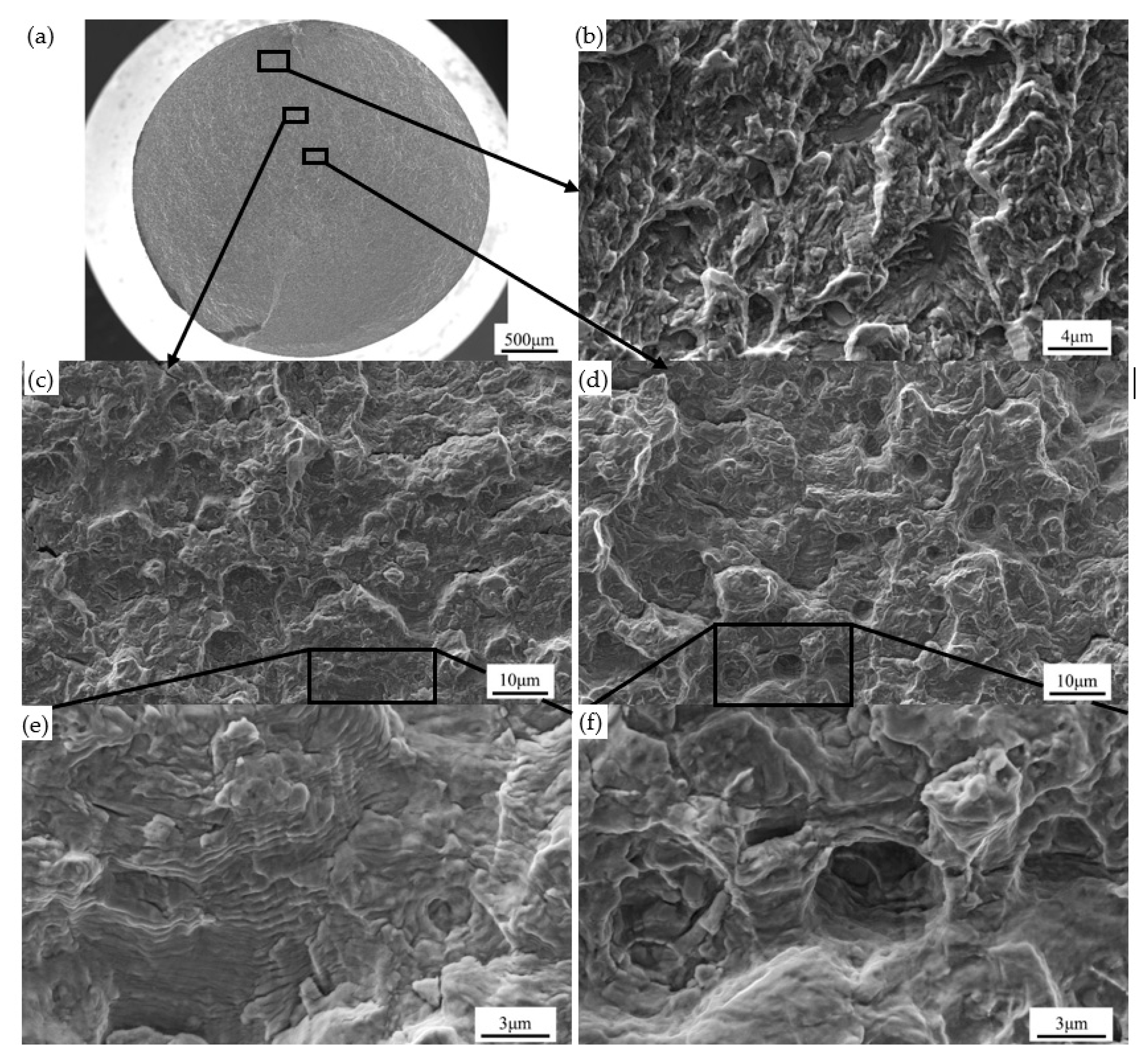

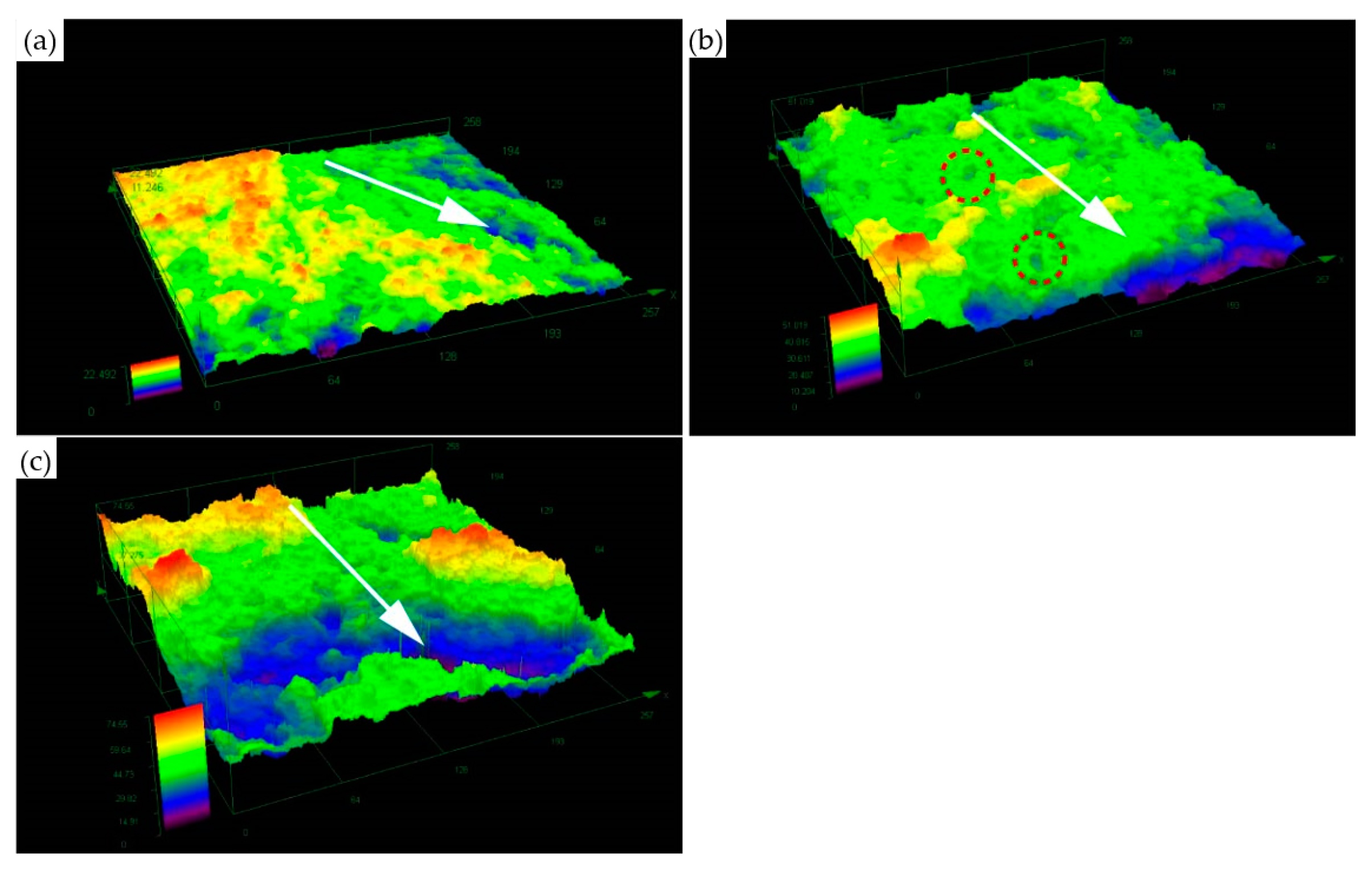

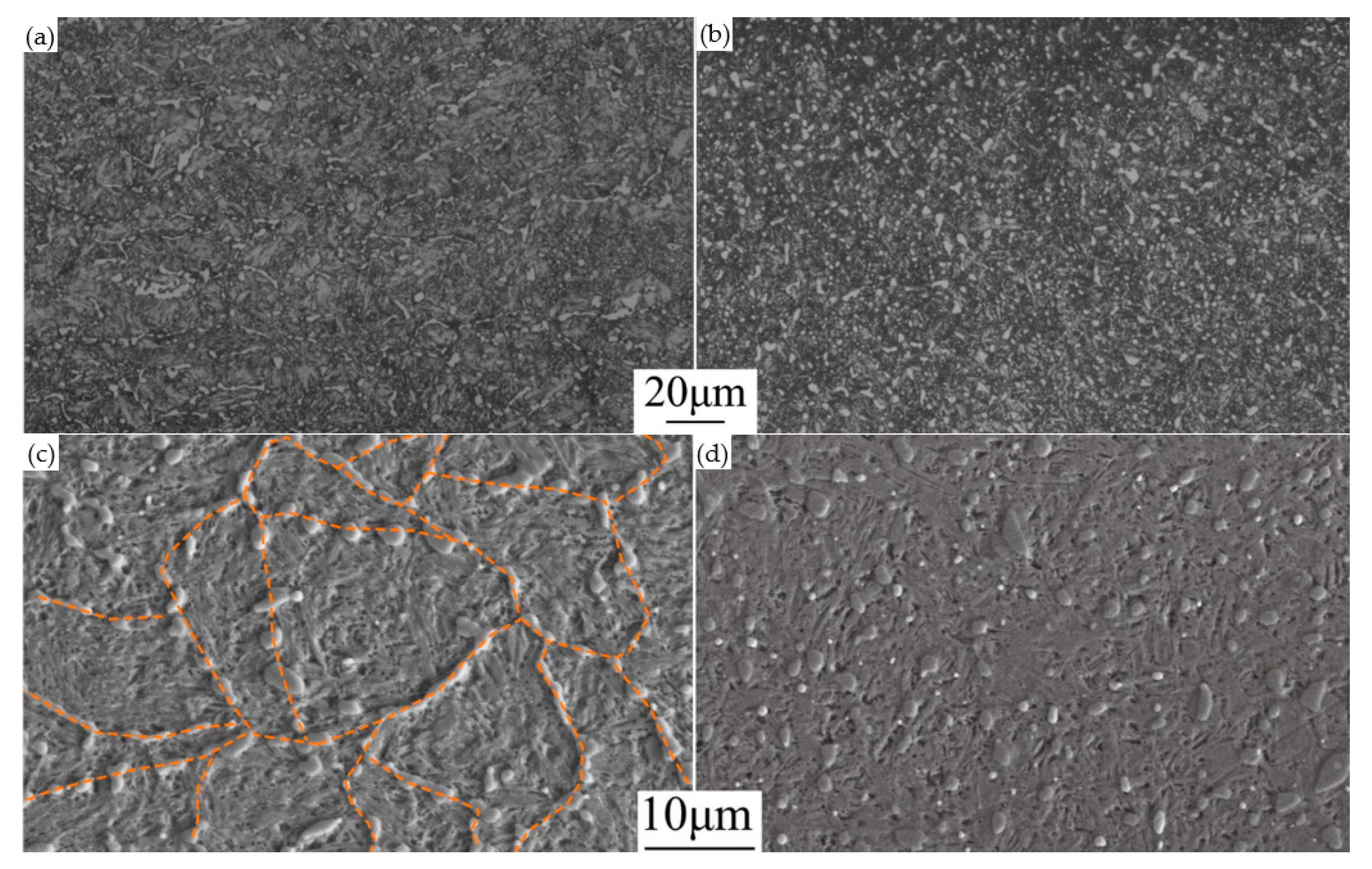

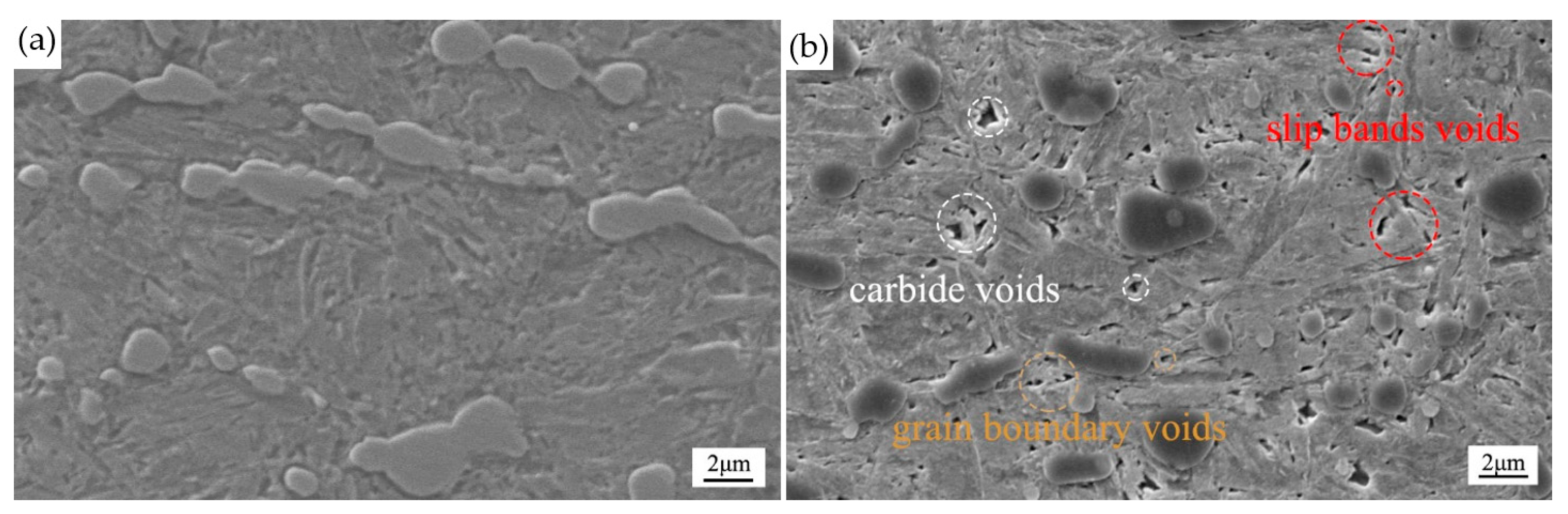

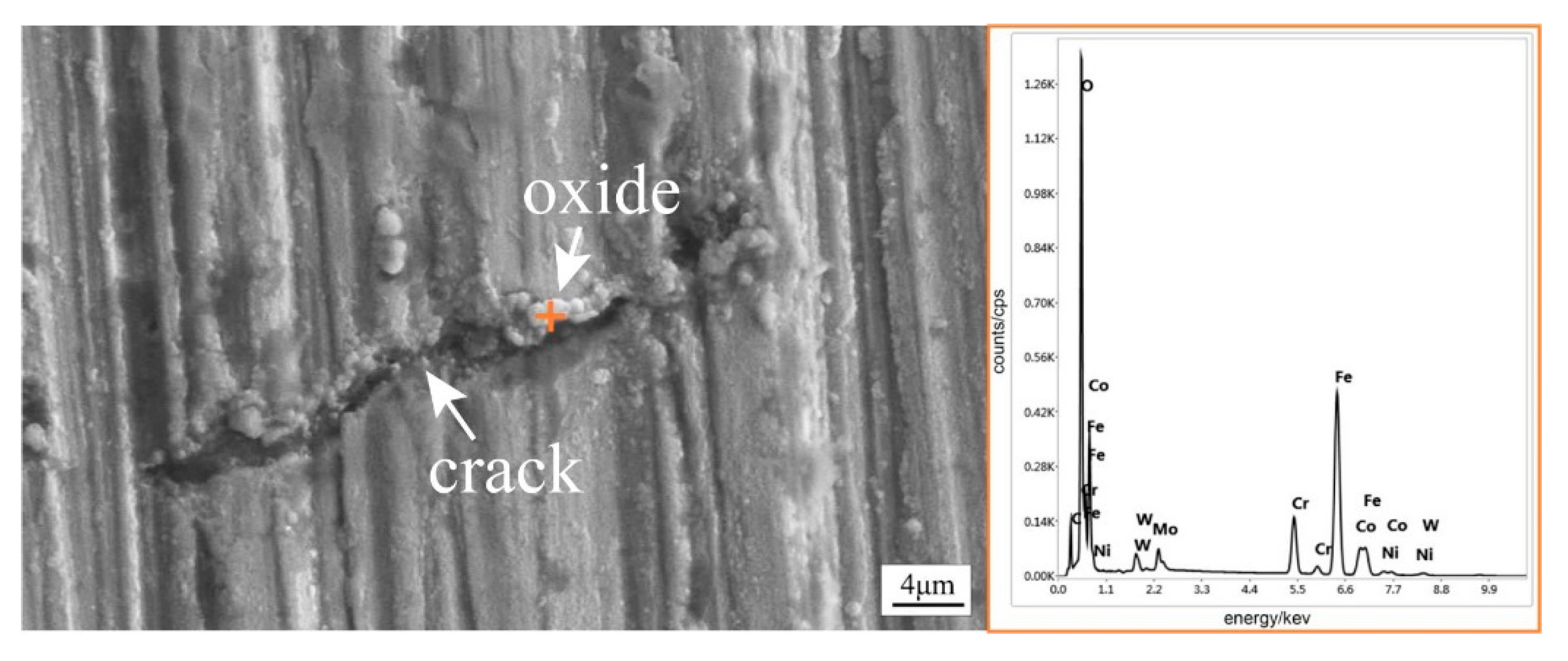

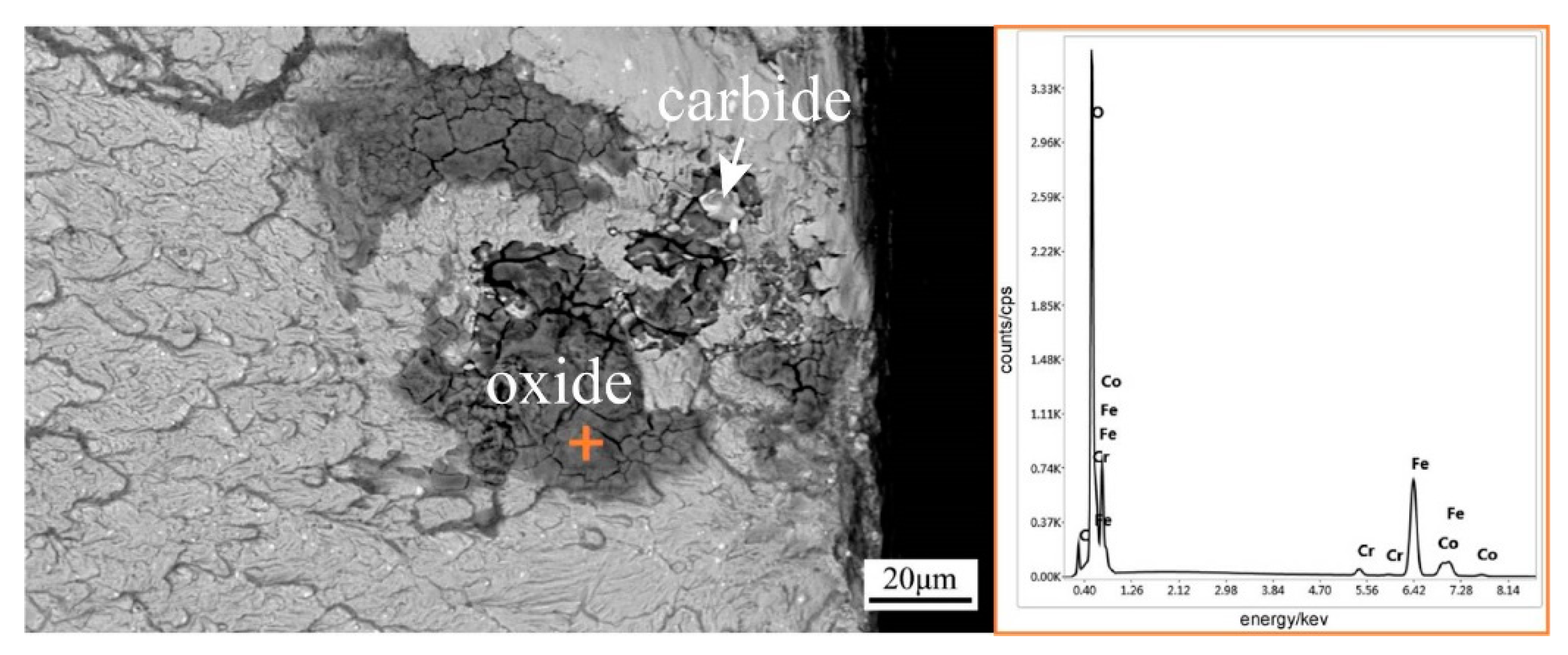

3.3. The Fracture Morphology

4. Discussion

4.1. Effect of Voids on Rotating Bending Fatigue Properties

4.2. Effect of High-Temperature Oxides on Crack Initiation and Propagation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiao, N.; Hui, W.J.; Zhang, Y.J.; Zhao, X.L.; Chen, Y.; Dong, H. High cycle fatigue behavior of a low carbon alloy steel: The influence of vacuum carburizing treatment. Eng. Fail. Anal. 2020, 109, 104215. [Google Scholar] [CrossRef]

- Huang, S.; Zhsng, G.Q.; Wang, M.Q.; Tan, H.L. Fatigue properties of heavy-duty gear steel with different carburized depth. J. Iron Steel Res. Int. 2012, 24, 34–38. [Google Scholar] [CrossRef]

- Wang, B.; Yang, M.S.; Zhao, K.Y. Fatigue resistance of Surface-Carburized Cr-Co-Mo-Ni bearing steel refined by vacuum melting. J. Vac. Sci. Technol. 2016, 36, 838–843. [Google Scholar] [CrossRef]

- Zhang, J.S. High Temperature Deformation and Fracture of Materials, 1st ed.; Science Press: Beijing, China, 2007; pp. 100–107. [Google Scholar]

- Hou, Z.P.; Yang, M.S.; Zhao, K.Y.; Bai, L.G. Microstructure evolution research of Cr-Co-Mo-Ni gear and bearing steel under action of temperature and stress coupling. Iron Steel 2014, 49, 80–85. [Google Scholar] [CrossRef]

- Xie, S.X.; Li, J.K.; Hou, F.; Liu, Y.J.; Wang, Q.Y.; Zhang, J.H. Very high cycle fatigue behavior of CrMoW rotor steel at different temperature. Chin. Meas. Test. Technol. 2015, 41, 13–17. [Google Scholar] [CrossRef]

- Geng, S.Y.; Yang, M.S.; Zhao, K.Y. Influence of temperature on high cycle fatigue properties of high cobalt molybdenum stainless bearing steel. Iron Steel 2018, 53, 77–85. [Google Scholar] [CrossRef]

- Lin, H.; Yang, M.S.; Shu, B.P.; Li, J.X.; Luo, Z.Q. High temperature rotating bending fatigue behavior and damage mechanism of high nitrogen stainless bearing. J. Iron Steel Res. 2019, 31, 475–484. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Yang, M.S.; Sun, S.Q.; Li, J.X.; Luo, Z.Q.; Li, N. High temperature fatigue properties and crack initiation and its expansion mechanism of high nitrogen bearing steel. J. Iron Steel Res. 2018, 30, 555–562. [Google Scholar] [CrossRef]

- Li, J.K.; Liu, Y.J.; Wang, Q.Y.; Hou, F. High-cycle rotate bending fatigue behavior of TC17 at elevated temperature. J. Sichuan Univ. Eng. Sci. Ed. 2014, 46, 198–202. [Google Scholar]

- Jeglic, F.; Niessen, P.; Burns, D.J. Temperature dependence of fatigue crack propagation in an Al-2.6Mg alloy. In Fatigue at Elevated Temperatures, 1st ed.; Carden, A.E., Mcevily, A.J., Wells, C.H., Eds.; ASTM International: West Conshohocken, PA, USA, 1973; pp. 139–148. [Google Scholar] [CrossRef]

- Murakam, Y.; Nomoto, T.; Ueda, T. Factors influencing the mechanism of superlong fatigue failure in steels. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 581–590. [Google Scholar] [CrossRef]

- Yang, Z.; Li, S.; Liu, Y.; Li, Y.; Li, G.; Hui, W.; Weng, Y. Estimation of the size of GBF area on fracture surface for high strength steels in very high cycle fatigue regime. Int. J. Fatigue 2008, 30, 1016–1023. [Google Scholar] [CrossRef]

- Shiozawa, K.; Morii, Y.; Nishino, S.; Lu, L. Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime. Int. J. Fatigue 2006, 28, 1521–1532. [Google Scholar] [CrossRef]

- Hong, Y.S.; Liu, X.L.; Lei, Z.Q.; Sun, C.Q. The formation mechanism of characteristic region at crack initiation for very-high-cycle fatigue of high-strength steels. Int. J. Fatigue 2016, 89, 108–118. [Google Scholar] [CrossRef] [Green Version]

- Nishijima, S.; Kanazawa, K. Stepwise S-N curve and fish-eye failure in gigacycle fatigue. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 601–607. [Google Scholar] [CrossRef]

- Reuchet, J.; Remy, L. High temperature low cycle fatigue of MAR-M 509 superalloy II: The influence of oxidation at high temperatures. Mater. Sci. Eng. 1983, 58, 33–42. [Google Scholar] [CrossRef]

| C | Cr | Co | Mo | Ni | S | P |

|---|---|---|---|---|---|---|

| 0.09–0.18 | 11.0–14.0 | 12.0–15.0 | 4.0–6.0 | 1.5–3.0 | ≤0.002 | ≤0.008 |

| Test Temperature/°C | Carbide Diameter d/μm | /% | /μm | Carbide Size Distribution/% | ||

|---|---|---|---|---|---|---|

| d < 1 μm | 1 μm ≤ d ≤ 3 μm | d > 3 μm | ||||

| Room temperature | 1.37 | 5.87 | 5.69 | 32.79 | 63.06 | 4.16 |

| 500 °C | 1.16 | 8.62 | 4.10 | 52.25 | 45.77 | 1.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Yang, M.; Zhao, K. Fatigue Crack Initiation and Propagation at High Temperature of New-Generation Bearing Steel. Metals 2021, 11, 25. https://doi.org/10.3390/met11010025

Wu Z, Yang M, Zhao K. Fatigue Crack Initiation and Propagation at High Temperature of New-Generation Bearing Steel. Metals. 2021; 11(1):25. https://doi.org/10.3390/met11010025

Chicago/Turabian StyleWu, Zhiwei, Maosheng Yang, and Kunyu Zhao. 2021. "Fatigue Crack Initiation and Propagation at High Temperature of New-Generation Bearing Steel" Metals 11, no. 1: 25. https://doi.org/10.3390/met11010025

APA StyleWu, Z., Yang, M., & Zhao, K. (2021). Fatigue Crack Initiation and Propagation at High Temperature of New-Generation Bearing Steel. Metals, 11(1), 25. https://doi.org/10.3390/met11010025