Abstract

The aim of the research was to characterize the soldering alloy type Zn–Al–Cu and study the fluxless ultrasonic soldering of the combination of aluminum alloy type Al7075 with copper substrate. The Zn–Al–Cu solder is of the close-to-eutectic type with two phase transformations: the eutectic transformation at 378 °C and the eutectoid transformation at 285 °C. The solder microstructure is formed of a matrix composed of the solid solutions of aluminum (Al) and zinc (Zn) in which the copper phases CuZn4 and CuAl2 are precipitated. The shear strength of the soldering alloy type Zn5Al with copper addition reaches values from 167 to 187 MPa and it depends on the copper content in the solder. The bond with aluminum alloy type Al7075 is formed due to the solubility of Al in zinc solder at the formation of solid solution Al. Contrary to this observation, the bond with the copper substrate is in this case formed due to the interaction of zinc and aluminum with the copper substrate. Two new intermetallic phases, namely Al(Cu,Zn)2 and Cu3.2Zn0.7Al4.2, were formed. The average shear strength of Al7075/Zn5Al3Cu/Cu joints attained was 134.5 MPa. For comparison, the Cu/Zn5Al3Cu/Cu joint attained an average shear strength of 136.5 MPa.

1. Introduction

Materials used in certain industrial applications are required to be light, strong, and electrically conductive at the same time. These conditions are met in the case of materials such as copper and aluminum. In the case of Cu/Al joints, many of the properties of both materials are utilized. However, the fabrication of a sound joint of these two materials is a rather tricky matter due to physical differences between the Cu and Al elements. Different welding technologies may be used for joining these metals, such as friction, friction stir welding, laser or cold roll welding [1,2,3,4,5]. However, soldering is also a suitable technology for joining these metals. Moreover, soldering can be applied also for the fabrication of products with intricate shapes as well as for mass production [6,7].

One possible method for soldering the Cu/Al combination is by the application of zinc solders. This concerns solders alloyed with one or more elements. Zn-based solders are a suitable option also in view of their relatively low price and capability to react with the surface of both Al and Cu. The addition of a small amount of suitable alloying elements lowers the melting temperature of these solders and enhances the solderability. Research on Zn-based solders has been carried out by many authors [8,9,10,11,12,13,14]. In their works, they have mainly used solders based on Zn–Al or Zn–Sn with the addition of other elements. Their research was devoted to the effect of the alloying elements on the microstructure, formation of intermetallic phases, or the strength of different combinations of metals or ceramics, and to the study of the corrosion properties of the solders.

Feng, J. et al. [15] focused also on the effect of the Al content on the properties of Zn–Al solder when fabricating Cu/Al joints. In their study, a small amount of Ce was added to the solder and they assessed its effect upon the solderability, the microstructure of the Zn22Al solder, the mechanical properties of the joint, and the structure of the layer formed in the boundary of the Cu/Al joint. Materials such as Al alloy type 1060 and pure copper were used in their experiments and automatic soldering with an oxy-acetylene flame was applied. The Ce content varied from 0.01 to 1 wt. %.

The Zn(4–6)Al(1–5)Cu alloy destined for higher application temperatures was designed with a liquidus point between 382 and 402 °C. The increased Al content improves the spreadability and nominal electric resistance but the Cu content does not significantly affect these properties. The added elements increase the hardness and tensile strength. The study revealed the favorable properties of Zn–Al–Cu alloys such as good solderability, low nominal electric resistance, and good mechanical properties [16]. In [17], Zn–Al–Cu based alloys destined for higher application temperatures were studied, namely the ZCA34 (Zn3Cu4Al), ZCA35 (Zn3Cu5Al), and ZCA36 (Zn3Cu6Al) alloys. The strength of these alloys was measured by SPT (shear punch test) in the temperature range from 25 to 225 °C. Loading with the force of 20 kN at the loading rate of 0.25 mm·min−1 was applied. After loading, the shear strength of the studied specimens was determined. In [18], the authors studied the reactions between the solder types Zn4Al and Zn4Al1Cu for higher application temperatures and copper substrate. The melting point of these solders was 380 and 381 °C, respectively. The addition of 1 wt. % Cu resulted in reduced activation energy, increased growth of the IM (intermetallic) phases of Cu–Zn, and a reduced erosion rate of the Cu substrate. Fei Xing et al. also researched the soldering of Cu using Zn-based solders [19]. Their research included soldering with Zn–Sn–Cu–Bi solders at the temperature of 450 °C with the application of flux type ZnCl2/NH4Cl at different reaction times from 10 to 90 s. They observed the presence of intermetallic phases such as ε-CuZn5, γ-Cu5Zn8, and β-CuZn in the boundary with the Cu substrate. The shear strength of the overlapped joints attained values from 51.6 to 76.5 MPa.

The aim of our study consisted in the soldering of Cu and Al substrates by a fluxless process in air with ultrasound assistance. The contribution presents the characterization of Zn–Al-based solder with Cu addition. Solders with 1, 2, and 3 wt. % Cu were assessed by ICP-AES (inductively coupled plasma-atomic emission spectrometry) and DSC (differential scanning calorimetry) analyses and tensile strength measurements. The soldered joints proper were fabricated using solder type Zn5Al3Cu with 3 wt. % Cu. These joints were subjected to SEM/EDX analysis and a shear strength test.

2. Materials and Methods

After determination of the weight proportions of the prepared experimental alloy, the weighing of individual components was performed. Materials with a high purity of 4N were used as input components for solder manufacture.

Solder manufacture in the as-cast condition was performed in a vacuum oven (PZP KOMPLET a.s., Dobruška, Czech Republic). The procedure was as follows: the calculated charges of solder components were placed in a graphite boat. The boat with the charge was placed in a tube made of siliceous glass 50 mm in diameter. The tube was then inserted into a horizontal vacuum resistance oven so that the boat was situated in the heating zone. The tube could, if necessary, be flushed with Ar by the flange on its inlet and the outlet on its end. In the case of Zn-based solders, it is more suitable to prepare them at Ar overpressure due to solder evaporation. The charge was molten at the specified temperature. Some metals are well soluble in the base matrix. The dissolving and homogenization of the solder components lasted for approximately one hour, until the melt under Ar shielding was freely cooled down. After removal from the oven, the formed alloy was again melted in a graphite crucible, and after thorough stirring, it was cast to a graphite boat where it was cooled down rapidly.

Three soldering alloys based on Zn5Al, with 1, 2, and 3 wt. % Cu were prepared. The chemical composition of these alloys is given in Table 1.

Table 1.

Composition of Sn–Sb–Ti alloy and the results of chemical analysis done by the the ICP-AES method [wt. %].

Chemical analysis of the prepared alloys was performed by the atomic emission spectrometry method with induction coupled plasma (ICP-AES, SPECTRO Analytical Instruments GmbH, Kleve, Germany). The analysis was carried out on the instrument type SPECTRO VISION EOP (SPECTRO Analytical Instruments GmbH, Kleve, Germany). The samples of alloys destined for ICP-AES analysis were dissolved in suitable chemical solutions of acid and bases. The analysis proper was performed on the emission atomic spectrometer (SPECTRO Analytical Instruments GmbH, Kleve, Germany) with a pneumatic atomizer and Scott’s atomizing chamber.

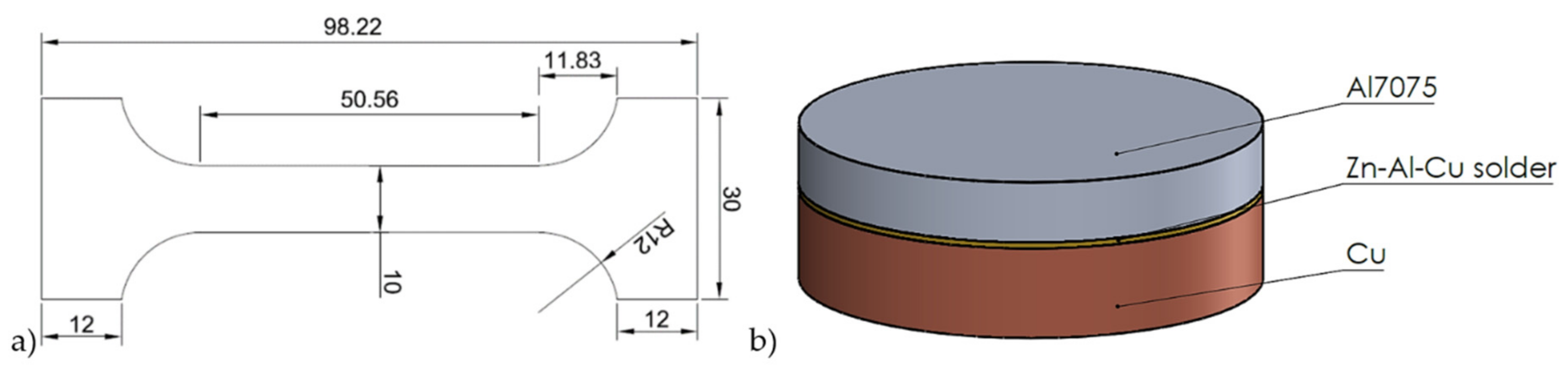

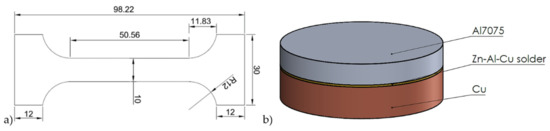

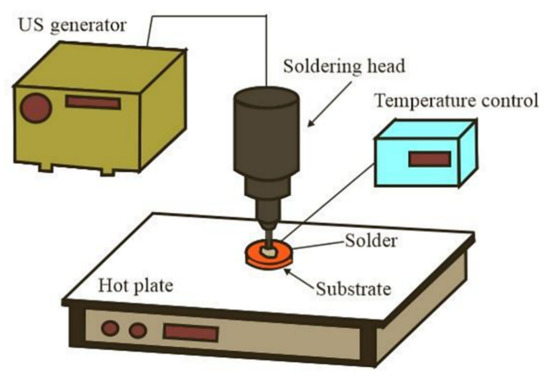

Test pieces for the tensile strength test were then prepared from the soldering alloys (Figure 1a). The dimensions given in Figure 1a are in mm.

Figure 1.

Schematic presentation of test pieces (unit: mm). (a) Tensile strength test piece; (b) assembly of soldered joints.

Substrates of the following materials were used for the experiments:

- metallic Cu substrate of 4N purity in the shape of discs with dimensions Ø 15 mm × 2 mm,

- metallic Al7075 substrate in the shape of discs with dimensions Ø 15 mm × 2 mm.

The scheme of the soldered joints is shown in Figure 1b.

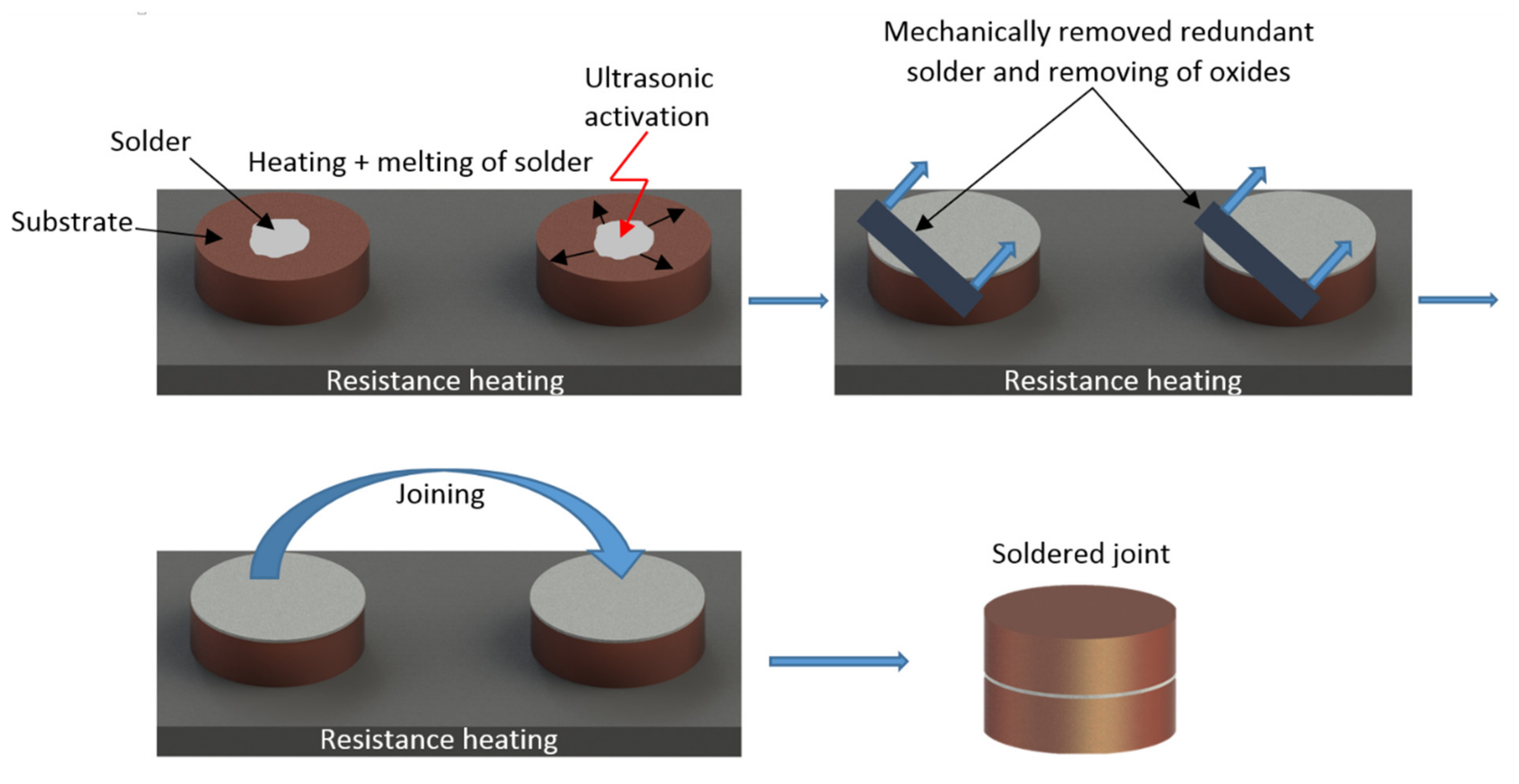

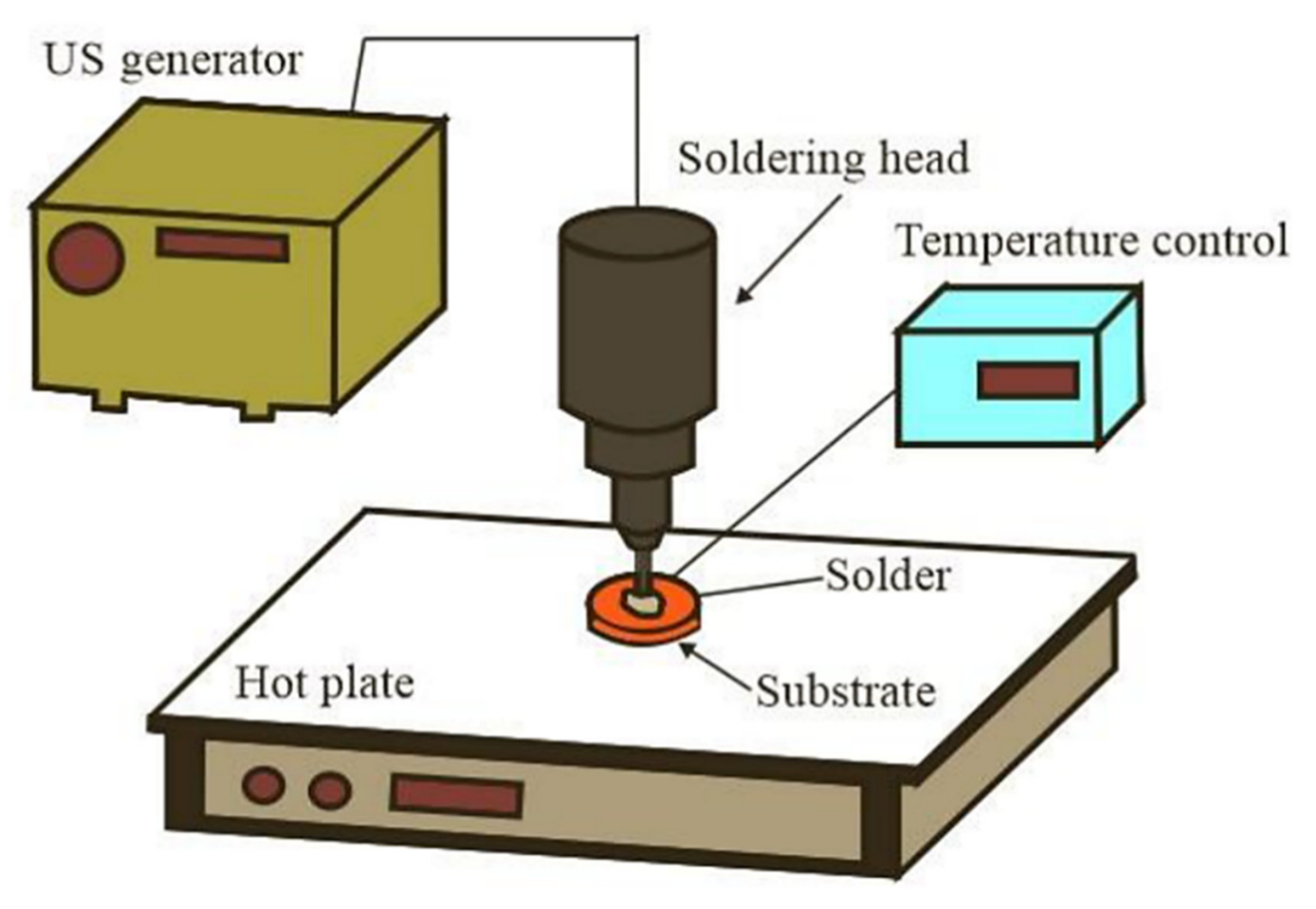

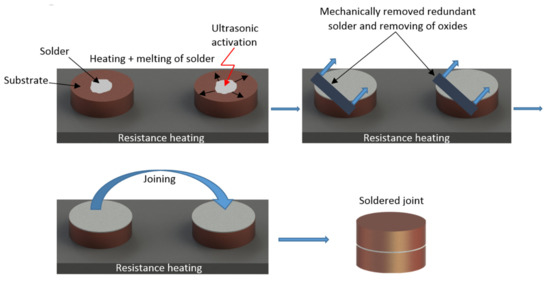

The soldered joints were fabricated using a hot plate with thermostatic temperature control. The Si substrate was placed on the hot plate and then the solder heated to the soldering temperature was placed on it. Soldering was performed using an ultrasonic equipment type Hanuz UT2 (HANUZ s.r.o. Nove Mesto nad Vahom, Slovakia) with the parameters given in Table 2. Solder activation was realized via an encapsulated ultrasonic transducer consisting of a piezo-electric oscillating system and a titanium sonotrode with the end tip diameter of Ø 3 mm. The soldering temperature was approximately 20 °C above the melting point of the soldering alloy. The soldering temperature was checked by continuous temperature measurement on the hot plate using a NiCr/NiSi thermocouple. The ultrasonic power was activated for 5 s. Soldering was realized without the use of flux. After ultrasound activation, the redundant oxide layer on the surface of the molten solder was removed. A similar process was performed also with the other substrate. Then, both substrates with molten solder were laid on each other and thus the soldered joint was formed. The schematic representation of this process is shown in Figure 2 and the set-up scheme for ultrasonic soldering is shown in Figure 3.

Table 2.

Soldering parameters.

Figure 2.

Schematic representation of the soldering process in the presence of ultrasonic power.

Figure 3.

Set-up scheme for ultrasonic soldering.

Metallographic preparation of specimens from the soldered joints was realized by the standard metallographic procedures used for specimen preparation. Grinding was performed using SiC emery papers with 240, 320, and 1200 grains/cm2 granularity. Polishing was performed with diamond suspensions with grain size 9, 6, and 3 μm. Final polishing was performed using polishing emulsion type OP-S (Struers) with 0.2 μm granularity.

The solder microstructure was studied using scanning electron microscopy (SEM) on microscopes of type TESCAN VEGA 3 (Tescan Orsay Holding, Brno, Czech Republic) and JEOL 7600 F (JOEL Ltd., Tokyo, Japan) with an X-ray micro-analyzer type Microspec WDX-3PC (Microspec Ltd., Peterborough, NH, USA) for performing the qualitative and semi-quantitative chemical analysis.

For identification of the phase composition of the solder, X-ray diffraction analysis was used, performed on an XRD diffractometer type PANalytical X’Pert PRO (Malvern Panalytical Ltd., Malvern, UK) with solder specimens of dimensions 10 mm × 10 mm × 2 mm. Step size parameter was 0.013° and scan step time parameter was 29.07 s.

Differential scanning calorimetry, or also differential compensation calorimetry, is a method in which the thermal properties of materials are examined. The DSC analysis of the Zn–Al–Cu solders was performed on equipment type Netzsch STA 409 C/CD (NETZSCH-Gerätebau GmbH, Selb, Germany) under shielding with Ar gas with 6N purity. To determine the mechanical properties of the soldered joints, the shear strength test was performed. The measurement was performed on the following joint:

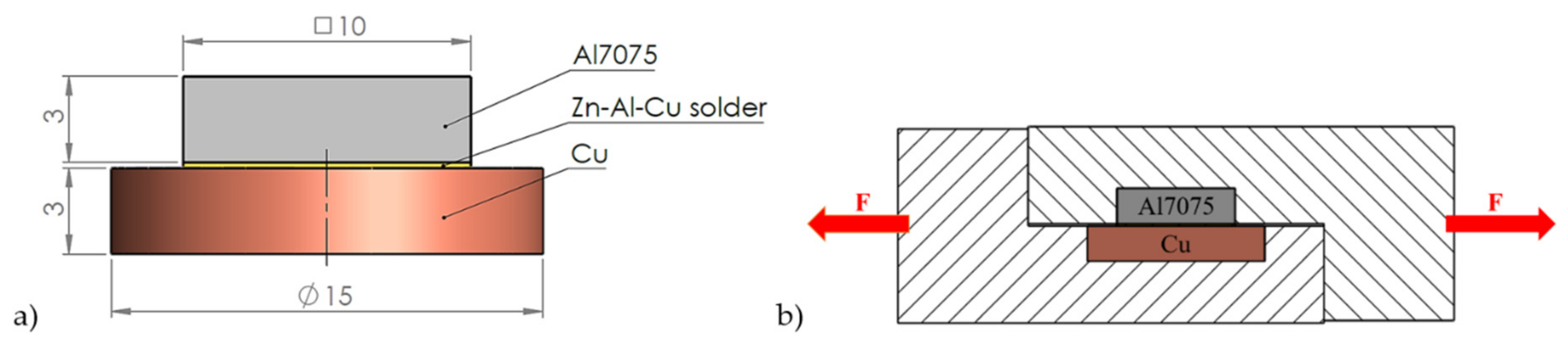

Copper in the shape of discs with dimensions Ø 15 mm × 3 mm/square of Al7075 alloy with dimensions 10 mm × 10 mm × 3 mm.

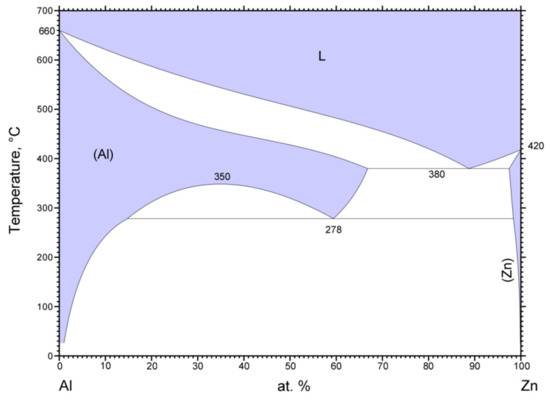

The schematic representation of the specimen is shown in Figure 4a. The shear strength was measured on a versatile testing equipment type LabTest 5.250SP1-VM (Labortech Ltd., Praque, Czech Republic). To change the direction of the axial loading force applied on the test specimen, a special jig was used with the defined shape of the test specimen (Figure 4b). This shearing jig ensures a uniform loading of the specimen by shear in the plane of the solder and substrate boundary.

Figure 4.

Schematic presentation of shear strength measurement. (a) Specimen for shear strength test (unit: mm); (b) scheme of special jig.

3. Results

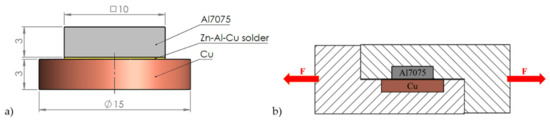

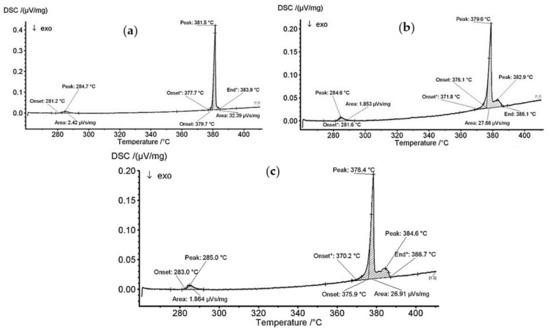

3.1. DSC Analysis

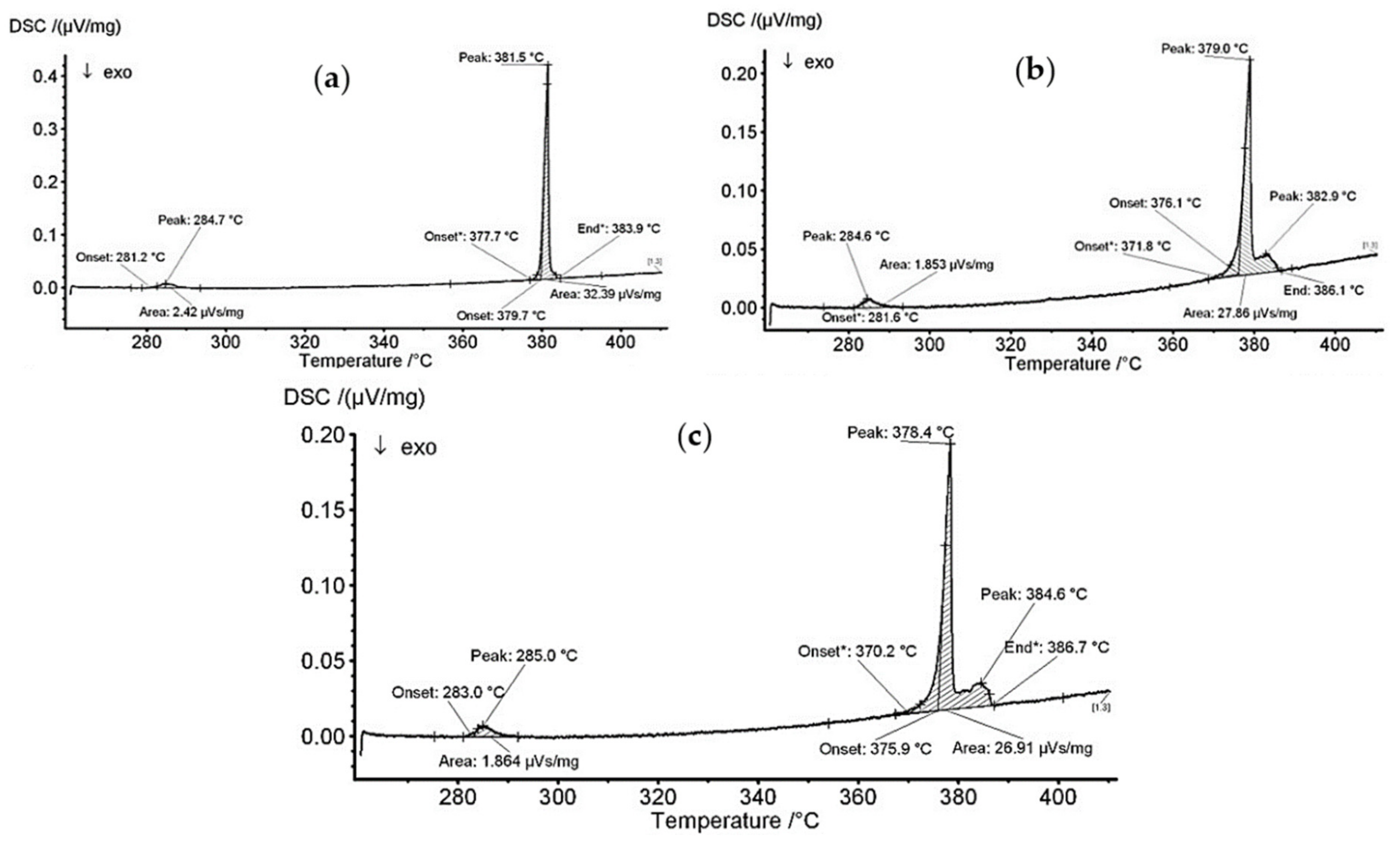

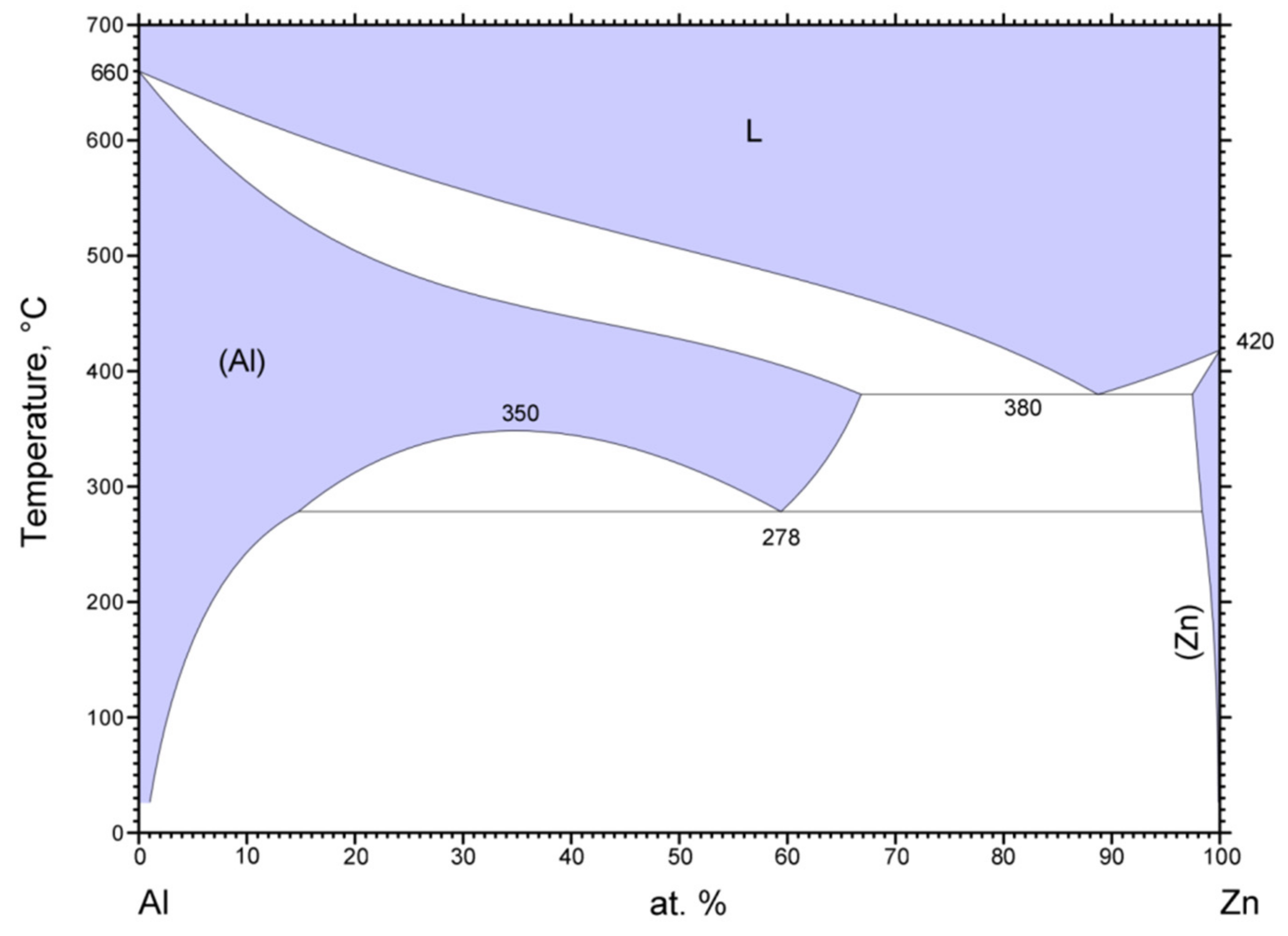

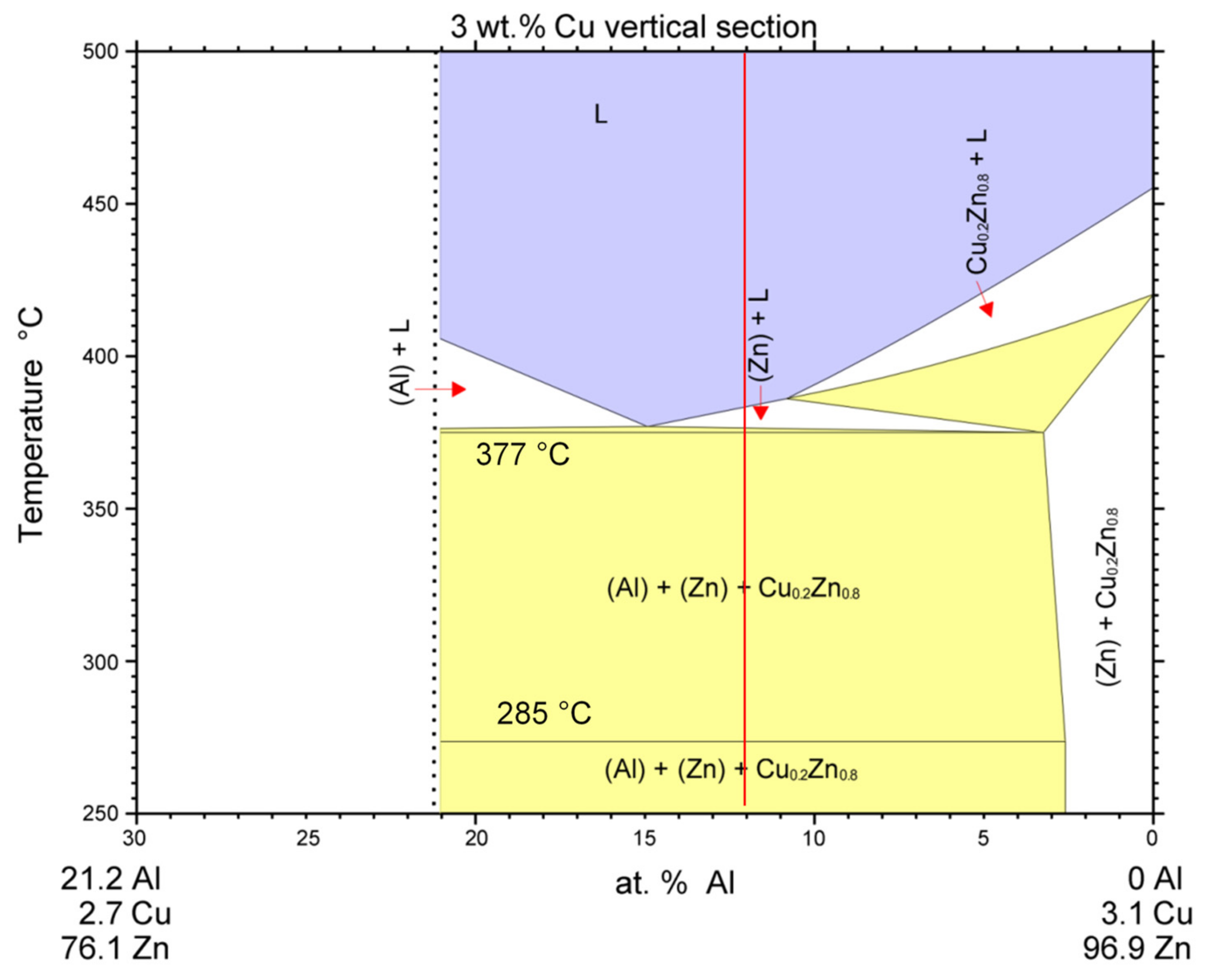

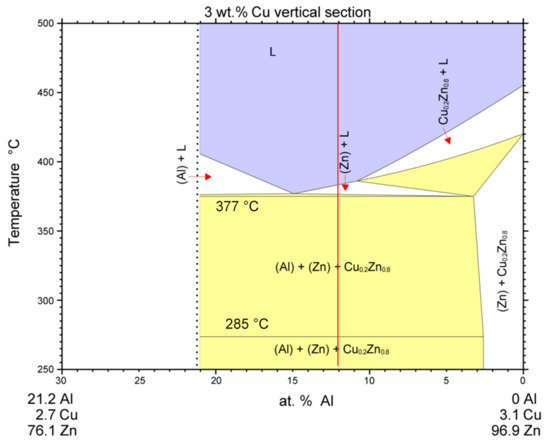

To determine the melting point of the solder, DSC analysis was applied. The DSC curve of soldering alloys of type Zn–Al–Cu typically has two basic peaks. The first peak corresponds to eutectoid transformation and the second pronounced peak corresponds to eutectic transformation (Figure 5). Following the Zn–Al binary diagram, the temperature of eutectoid transformation is around 278 °C (Figure 6). According to [20], the following reaction takes place at this temperature: Al-rich fcc (Al) + hcp (Zn) ↔ Zn-rich fcc (Al). It is obvious from the DSC curve in Figure 7 that the addition of Cu to the solder increases the temperature of this transformation to approximately 285 °C. On the contrary, the temperature of eutectic transformation, which according to the binary diagram equals 381 °C (Figure 6), is slightly reduced with the addition of Cu to the soldering alloy. At 2 wt. % Cu, the maximum temperature of the second peak is 379.0 °C, and at 3 wt. % Cu, the maximum temperature of that peak is 378.4 °C. Since the main base of the Zn5Al solder is close-to-eutectic, at the temperature around 381 °C, it should be completely molten. But the addition of copper to the solder shifts the end temperature towards higher values and extends the lower section of the peak (Figure 5), whereas in the case of Zn5Al2Cu and Zn5Al3Cu solders, a third peak is created. The Zn5Al1Cu solder is totally molten at the temperature of 383.9 °C, whereas in the case of the Zn5Al3Cu solder, melting terminates at 386.7 °C. Table 3 shows the measured solidus and liquidus temperatures of these solders. The soldering temperature is usually selected approximately 20 °C above the melting point of the soldering alloy, so the soldering temperature applied in the experiments was 410 °C.

Figure 5.

DSC curves of soldering alloys: (a) Zn5Al1Cu; (b) Zn5Al2Cu; (c) Zn5Al3Cu, at the heating rate of 1 K·min−1. * manually extrapolated point.

Figure 6.

The binary diagram of Al–Zn [20].

Figure 7.

The phase diagram of Al–Zn–Cu for the concentration of 3 wt. % Cu [20].

Table 3.

Solidus and liquidus temperatures of Zn-Al-Cu solders.

3.2. Microstructure of Solders Type Zn–Al–Cu

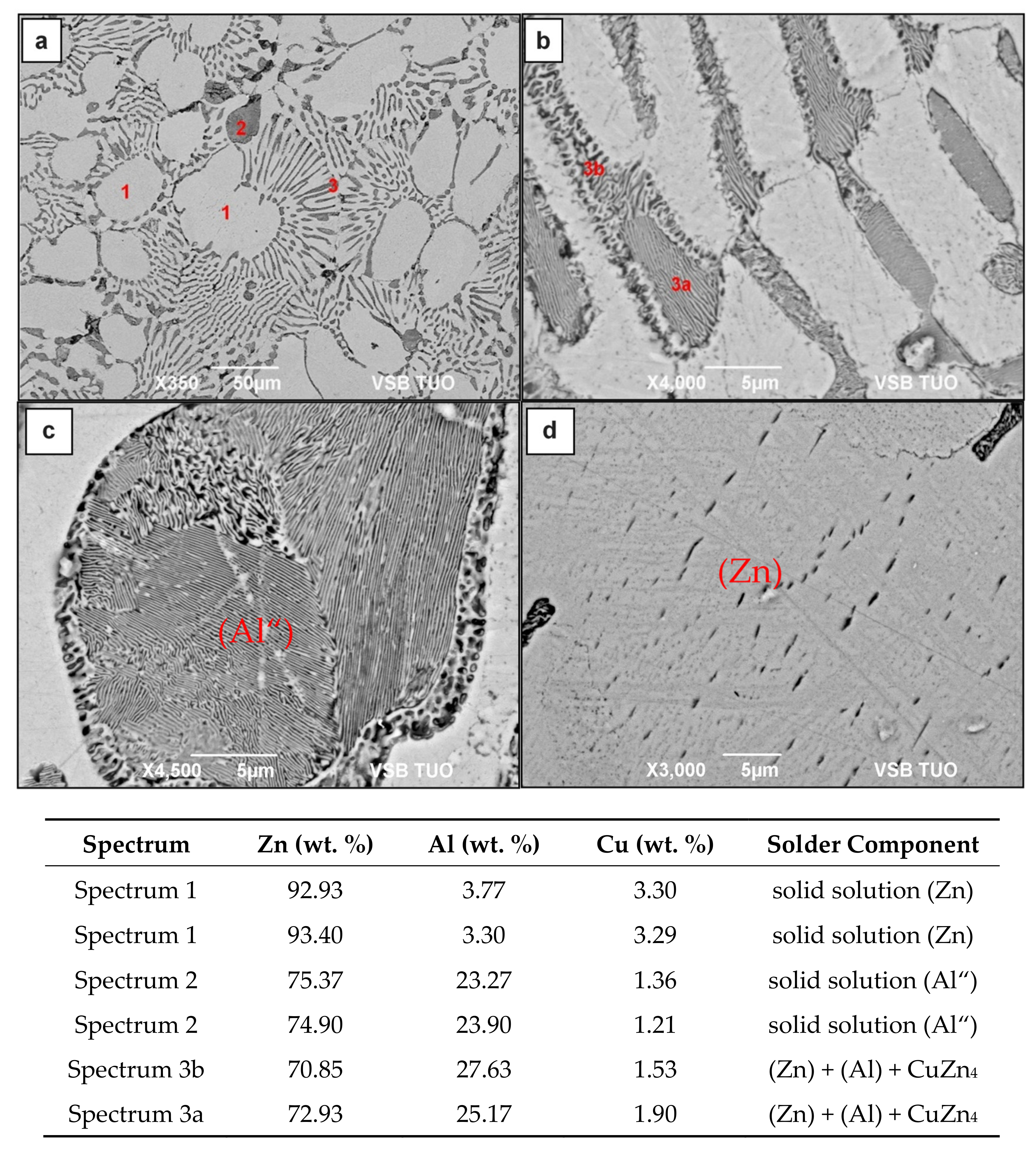

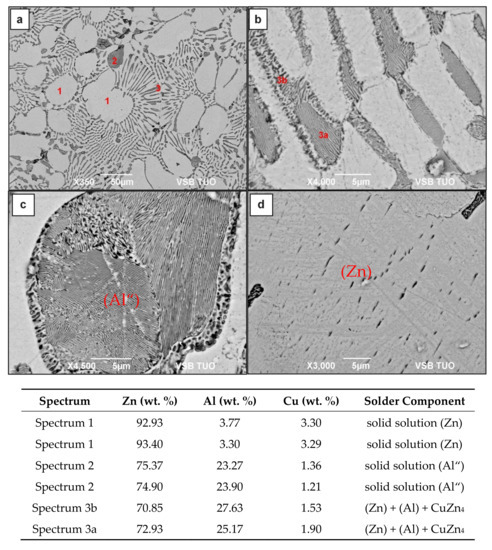

The microstructure was studied by the SEM technique in observing mode BSE (Back-scatter detector). In the BSE mode, the measure of darkening is indirectly proportional to the average atomic weight of the elements present at the given point. The lighter elements are shown as darker—the solid solution Al, while the heavier elements are shown as brighter—the solid solution Zn.

The microstructure of the Zn–Al–Cu solder is shown in Figure 8. The structure is, at first sight, formed of the solid solution Zn and the solid solution Al. According to the phase diagram in Figure 8, the solder matrix contains also the ε-CuZn4 phase (eventually Cu0.2Zn0.8 phase).

Figure 8.

SEM/EDX analysis of ZnAl5Cu3 solder: (a,b) points of measurement in individual spectra; (c) detail of zone 2; (d) detail of zone 1.

For determination of the chemical composition of the individual components of the soldering alloy, local chemical EDX microanalysis was performed. The points of measurement shown in Figure 8a are marked as Spectrum 1 to Spectrum 3. The primary grains (Spectrum 1) in Figure 8a are formed of solid solution Zn, where Cu and Al are partially dissolved. This zone is documented in Figure 8d. Spectrum 2 corresponds by its composition to Al phase with a high Zn content, which is stable above the temperature of 277 °C. Figure 8c suggests that very fine lamellar eutectics is concerned, with a higher content of Zn and lower content of Al than in the case of Spectrum 3. The Spectra 3, 3a, and 3b represent the eutectics with lamellar structure Al + Zn + a minority proportion of ε-CuZn4 phase.

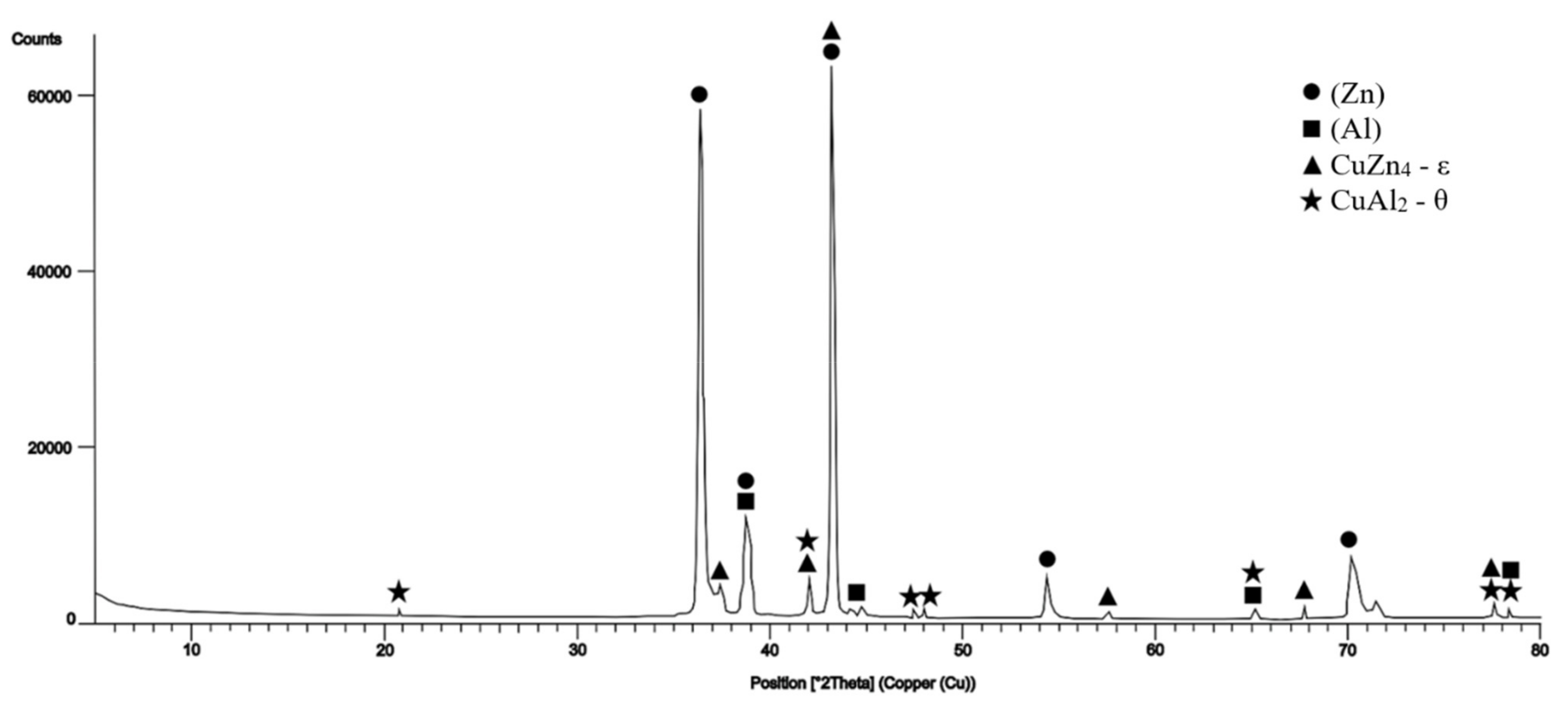

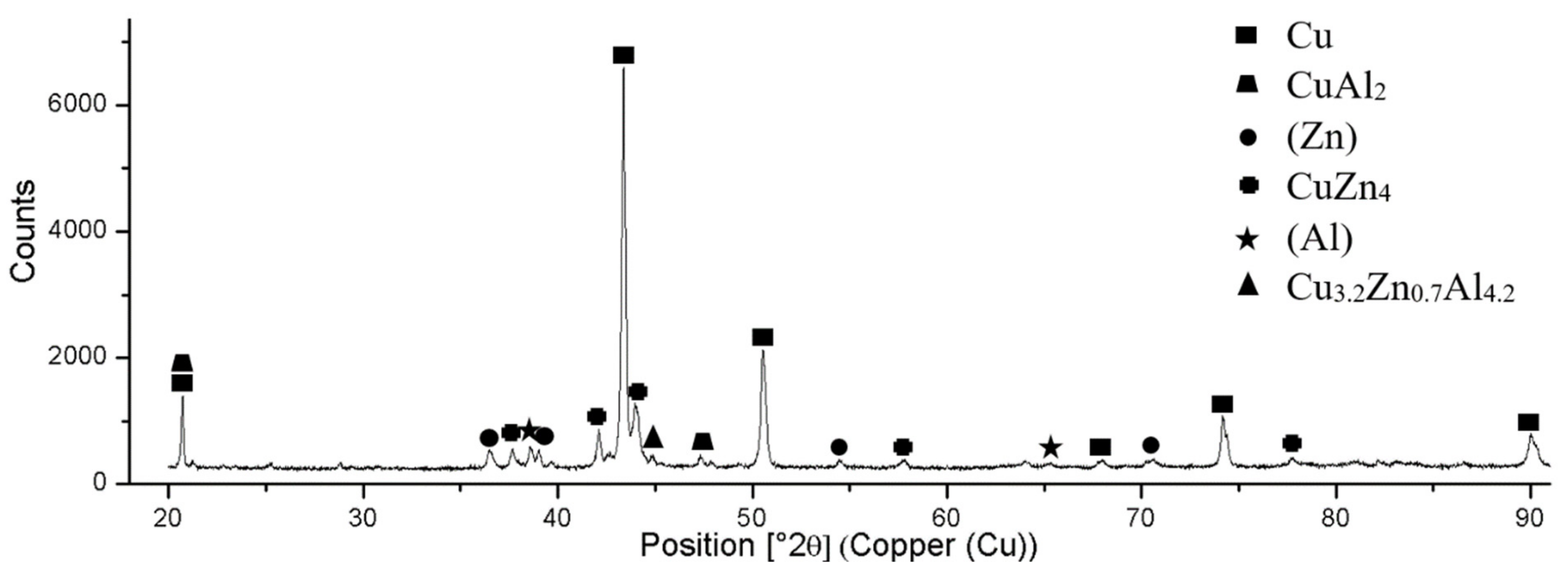

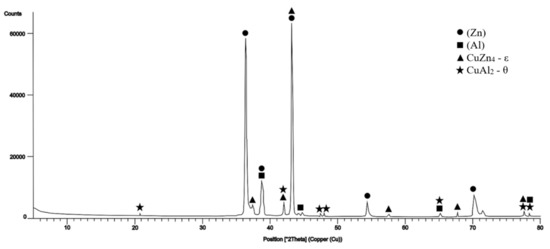

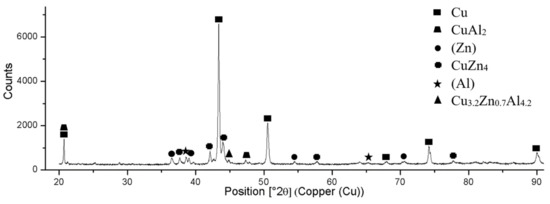

The diffraction XRD analysis of the Zn5Al3Cu solder has proved the presence of solid solution Zn, solid solution Al, and intermetallic phases CuZn4-ɛ and CuAl2-θ. The CuAl2 phase was not identified by EDX analysis. The record from the diffraction analysis is documented in Figure 9.

Figure 9.

Diffraction record of Zn5Al3Cu solder.

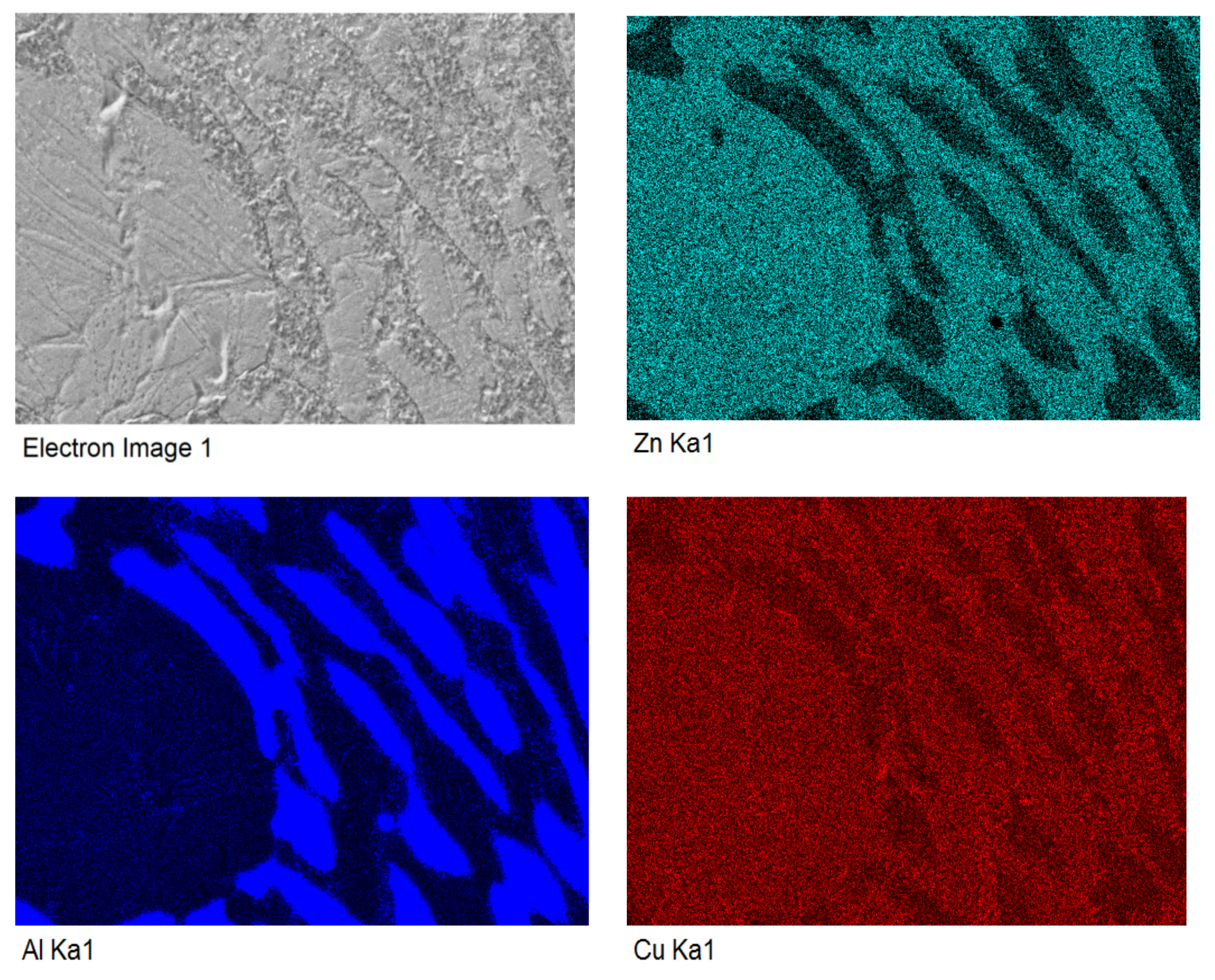

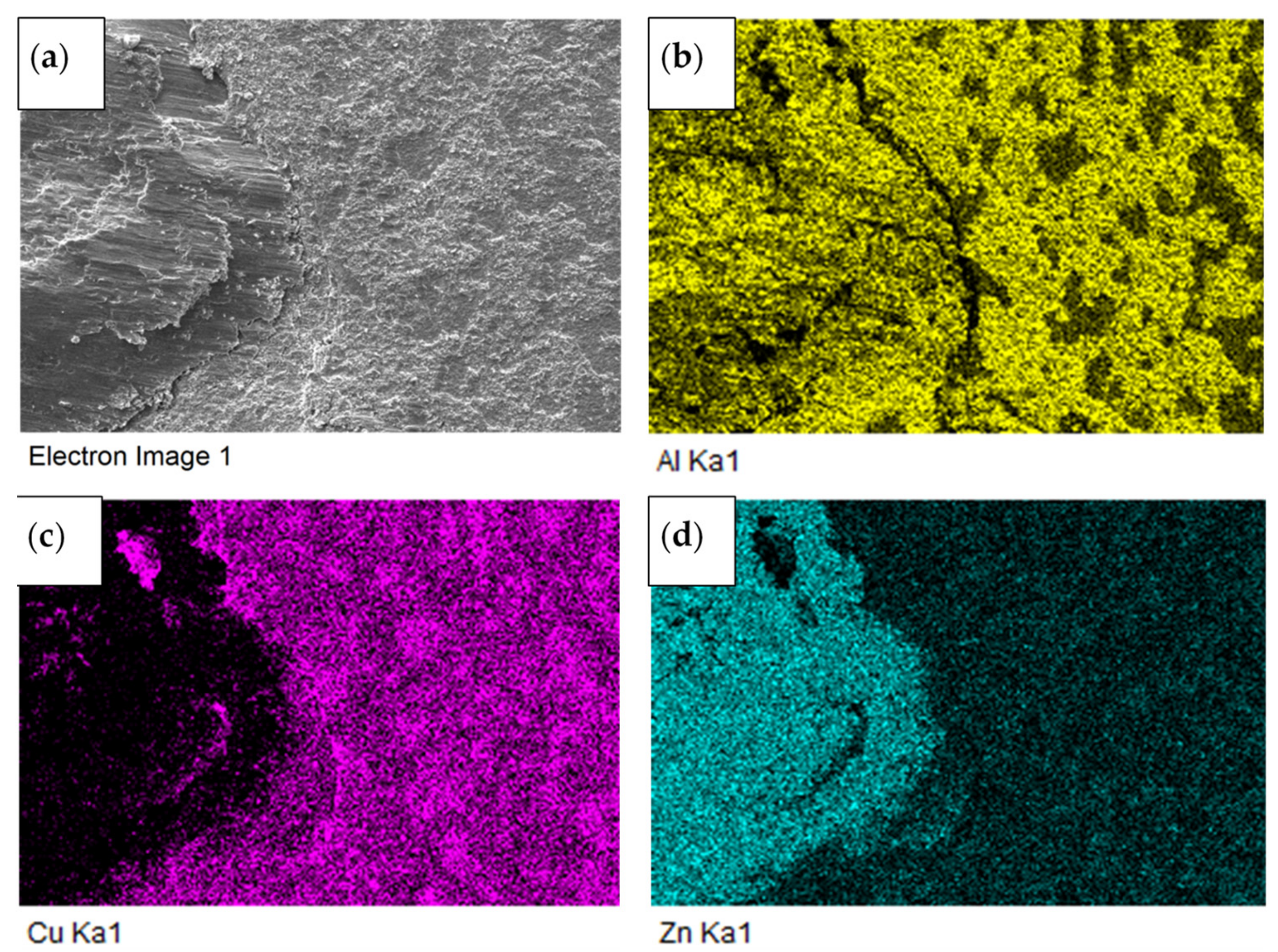

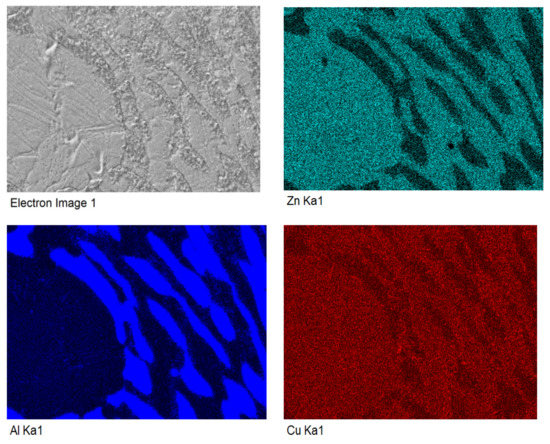

Figure 10 shows the results of planar EDX analysis of this solder, where the solder elements Zn, Al, and Cu are differentiated by color. The grains of solid solution Zn are clearly visible and also the space amongst the grains (light-blue color) filled with solid solution Al. Copper and its phase CuZn4 is dissipated mainly in the solid solution Zn.

Figure 10.

Map of Zn, Al, and Cu elements in the structure of Zn5Al3Cu solder.

3.3. Tensile Strength of Soldering Alloys Type Zn–Al–Cu

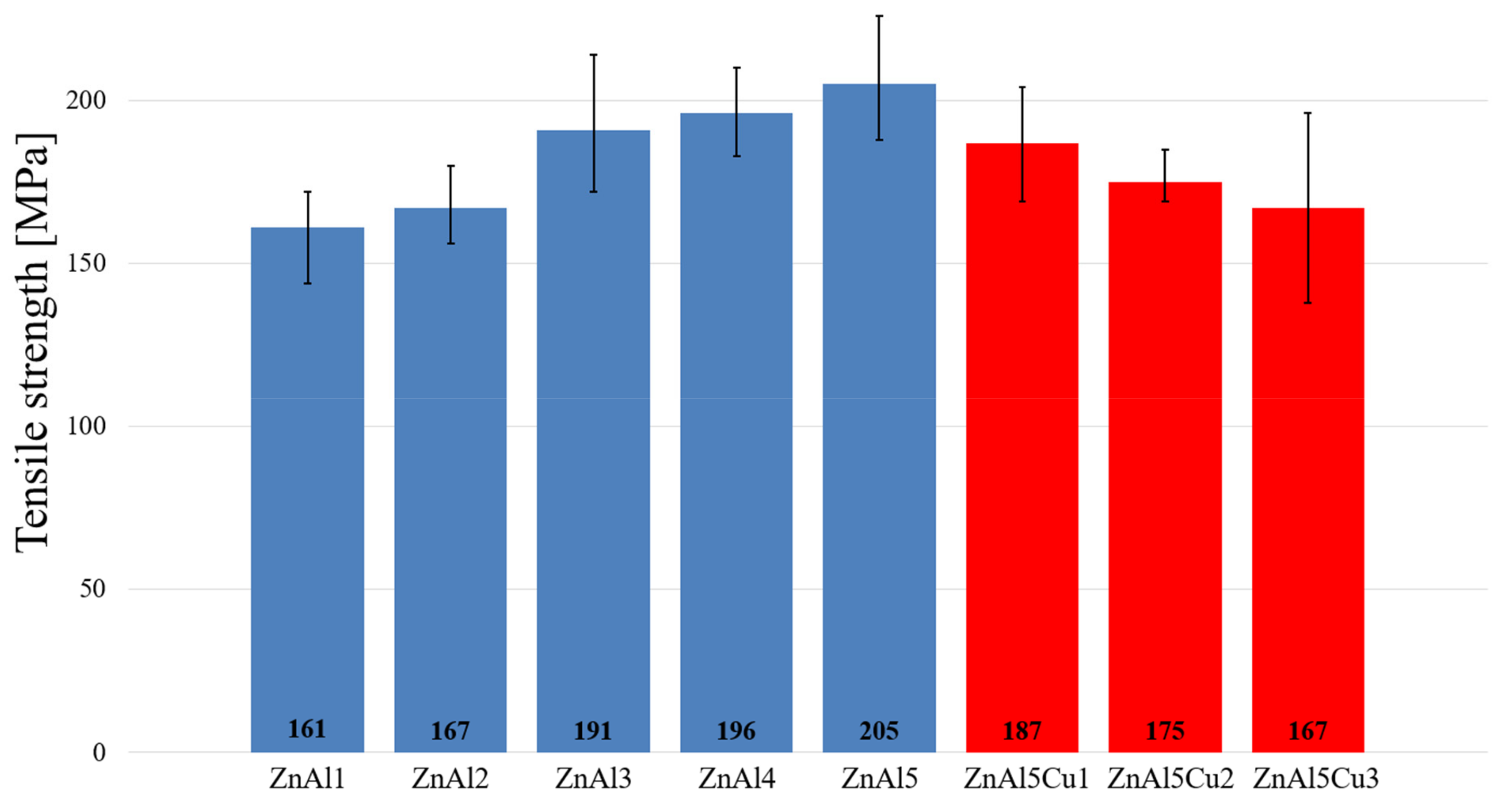

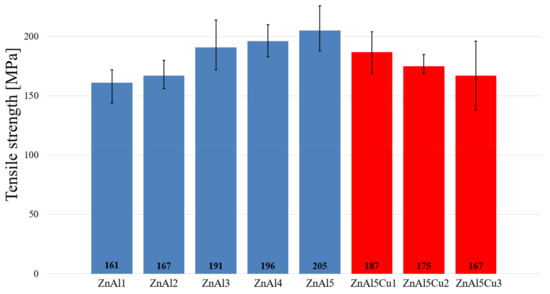

The mechanical tests of Zn–Al–Cu type solders were performed. The dimensions of the test pieces were proposed and calculated. Three specimens of each experimental soldering alloy were used for tensile strength measurement. The loading rate of the test piece was 1 mm·min−1. The tensile strength of the Zn–Al–Cu type solders in dependence on the copper content was determined. The results of the tensile test are documented in the graph in Figure 11.

Figure 11.

Tensile strength of type Zn–Al–Cu soldering alloys in dependence on Al and Cu content.

For comparison, Figure 11 shows the dependence of the tensile strength of the Zn–Al type soldering alloys on the Al content in the solder. It is obvious that with increasing Al content also the tensile strength of the soldering alloy increases. The highest tensile strength of 205 MPa was achieved with Zn5Al solder, which is the main base of Zn5Al–Cu solders. On the contrary, the tensile strength is reduced with the addition of copper. The lowest tensile strength was observed in the case of the solder with the highest copper content. The average tensile strength of Zn5Al3Cu solder is 167 MPa. The highest tensile strength was clearly observed in the solder with the lowest Cu content. The average value of tensile strength of Zn5Al1Cu solder is 187 MPa. These data suggest that the addition of 3 wt. % Cu reduces the average tensile strength of soldering alloys of type Zn–Al–Cu by 38 MPa. This is due to the formation of copper phases such as Cu–Zn and Cu–Al.

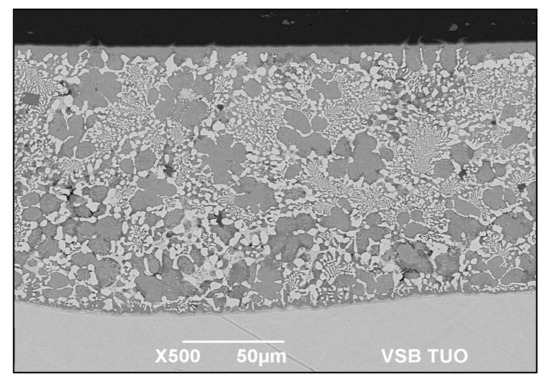

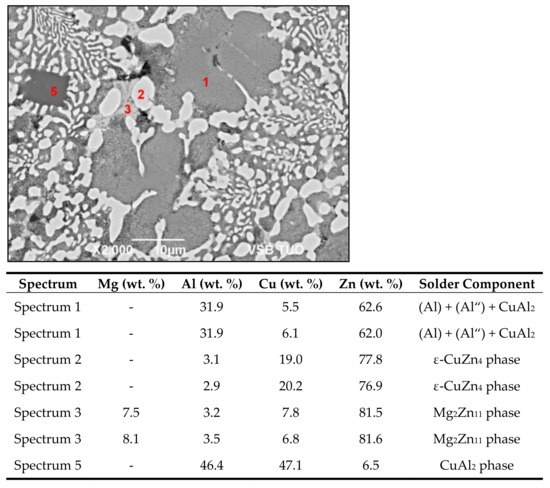

3.4. Microstructure of Al7075/Zn–Al–Cu/Cu Joint

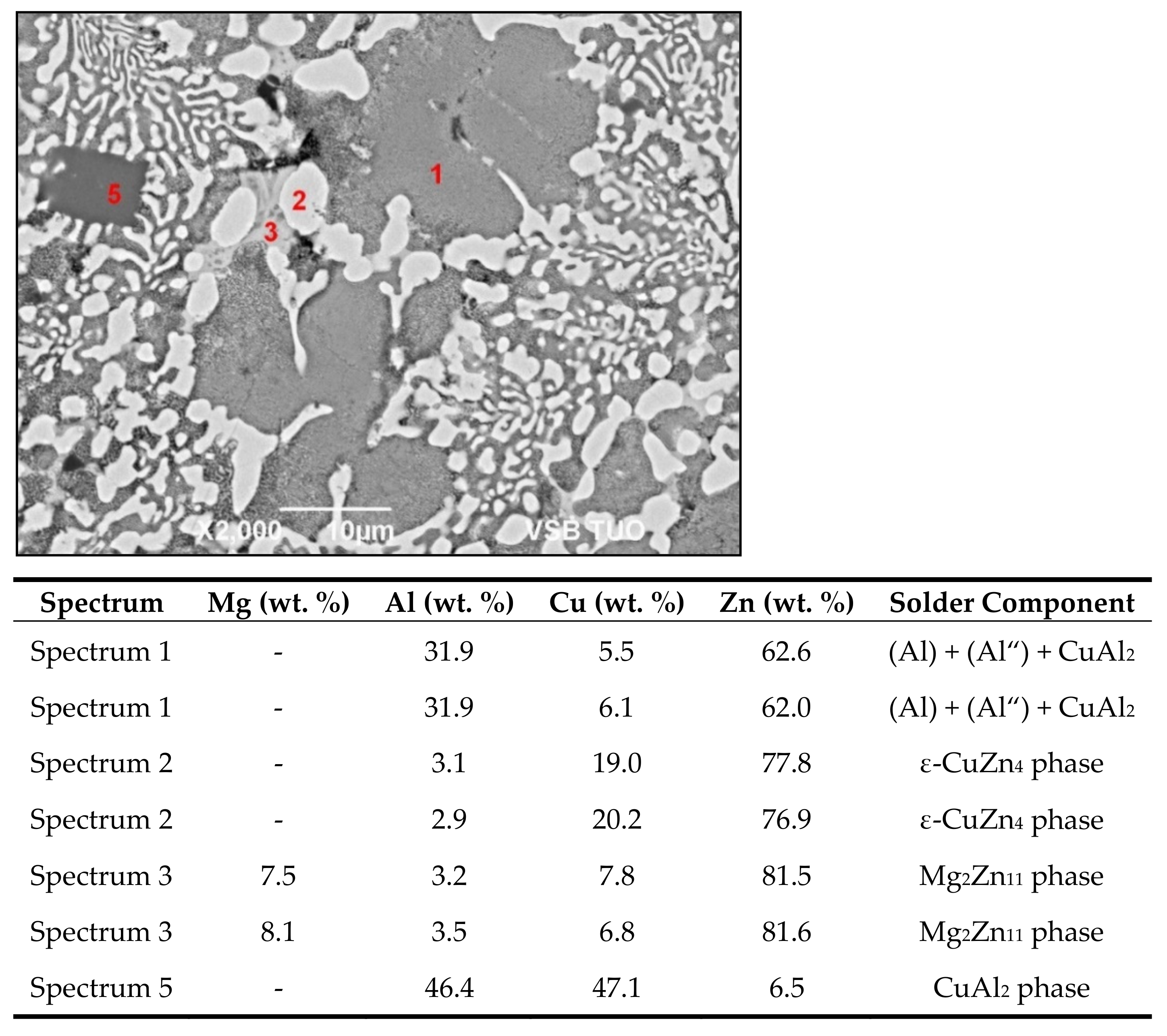

The soldered joint of Al7075/Zn–Al–Cu/Cu was fabricated at the temperature of 410 °C. The boundary of the soldered joint is shown in Figure 12. It is obvious that on both boundaries a new transition zone, formed by new phases, was created. The structural character of the Zn–Al–Cu solder has changed after soldering, therefore the EDX analysis was performed anew. The points of measurement, the individual spectra, are documented in Figure 13. Spectrum 1 is formed of very fine ternary eutectics occurring by eutectic reaction at the temperature around 380 °C and it has remained stable. It is composed of (Al) + (Al“) + CuAl2 mixture with a low portion of Cu. Spectrum 2 corresponds by its composition to the ε-CuZn4 phase (eventually the Cu0.2Zn0.8 phase, when following from Figure 7) with dissolved aluminum at its content of 3 wt. %. The irregular constituents—particles in Spectrum 3, contained magnesium (around 8 wt. %) and zinc (around 81 wt. %), which according to the phase diagram, corresponds to the Mg2Zn11 phase. Moreover, also Al and Cu were partially present. Magnesium comes from Al7075 (Al90Zn5.5Mg2.5Cu1.5Si0.5) alloy. The dark particle of oblong shape—Spectrum 5, has proportions of Al:(Cu + Zn) 2:1, which proves the presence of CuAl2, which contains around 6.5 wt. % of dissolved zinc.

Figure 12.

Microstructure of the boundary in Al7075/Zn5Al3Cu/Cu joint.

Figure 13.

EDX analysis of solder structure in soldered joint of Al7075/Zn5Al3Cu/Cu.

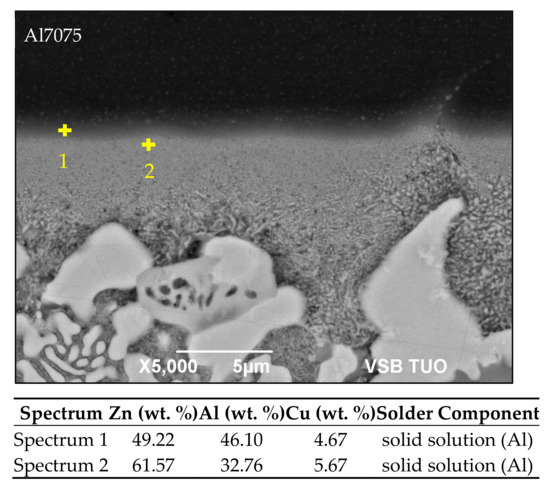

3.5. Microstructure of Boundary in Al7075/Zn5Al3Cu Joint

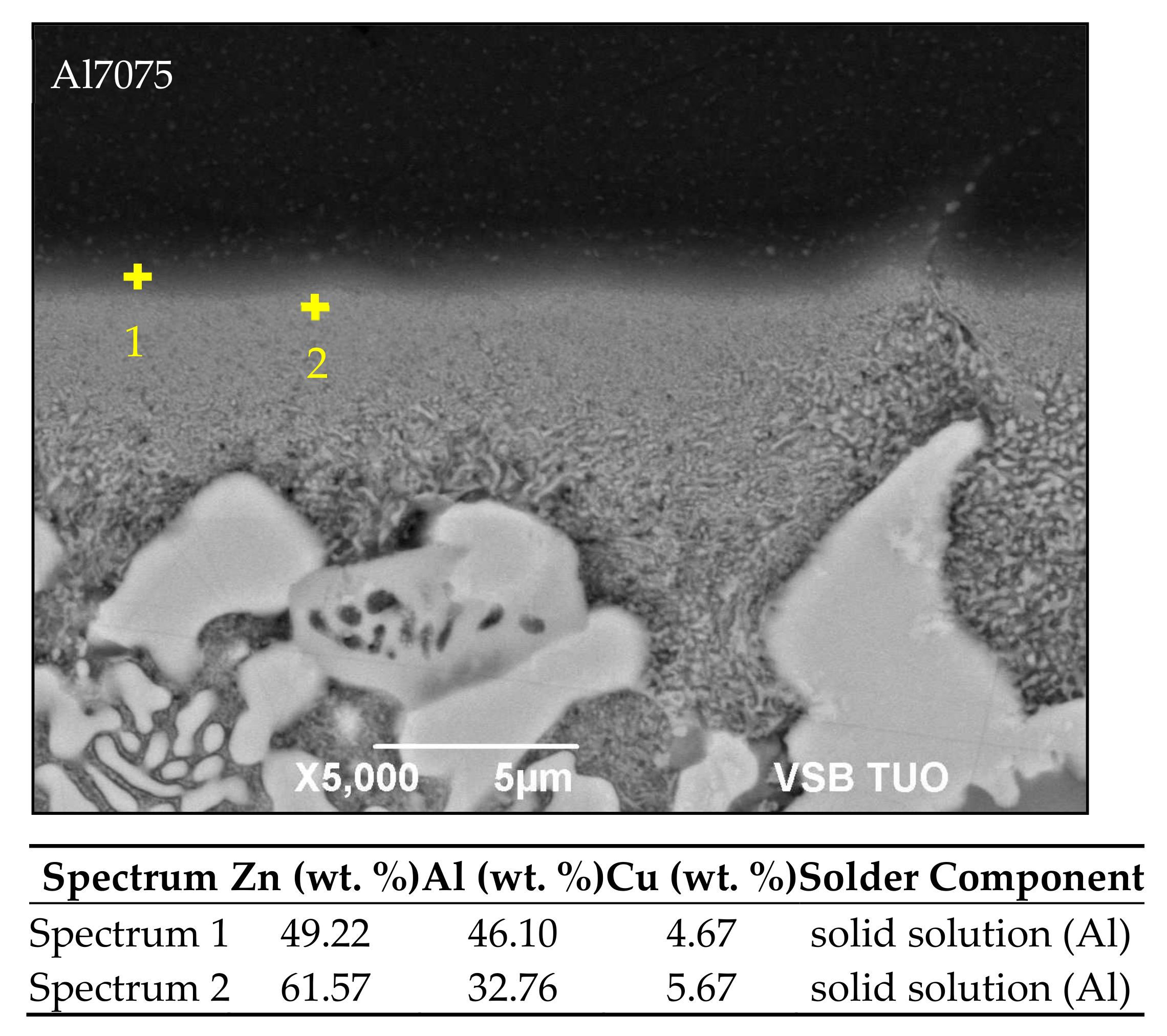

The detail of the boundary in the Al7075/Zn5Al3Cu joint is documented in Figure 14. The solubility band of Al may be observed in the zinc solder, from 5 to 11 µm wide. The EDX analysis of this band was performed at the points Spectrum 1 and Spectrum 2. At both points, a solid solution of aluminum (Al) was identified.

Figure 14.

A detail of the boundary in Al7075/Zn5Al3Cu joint.

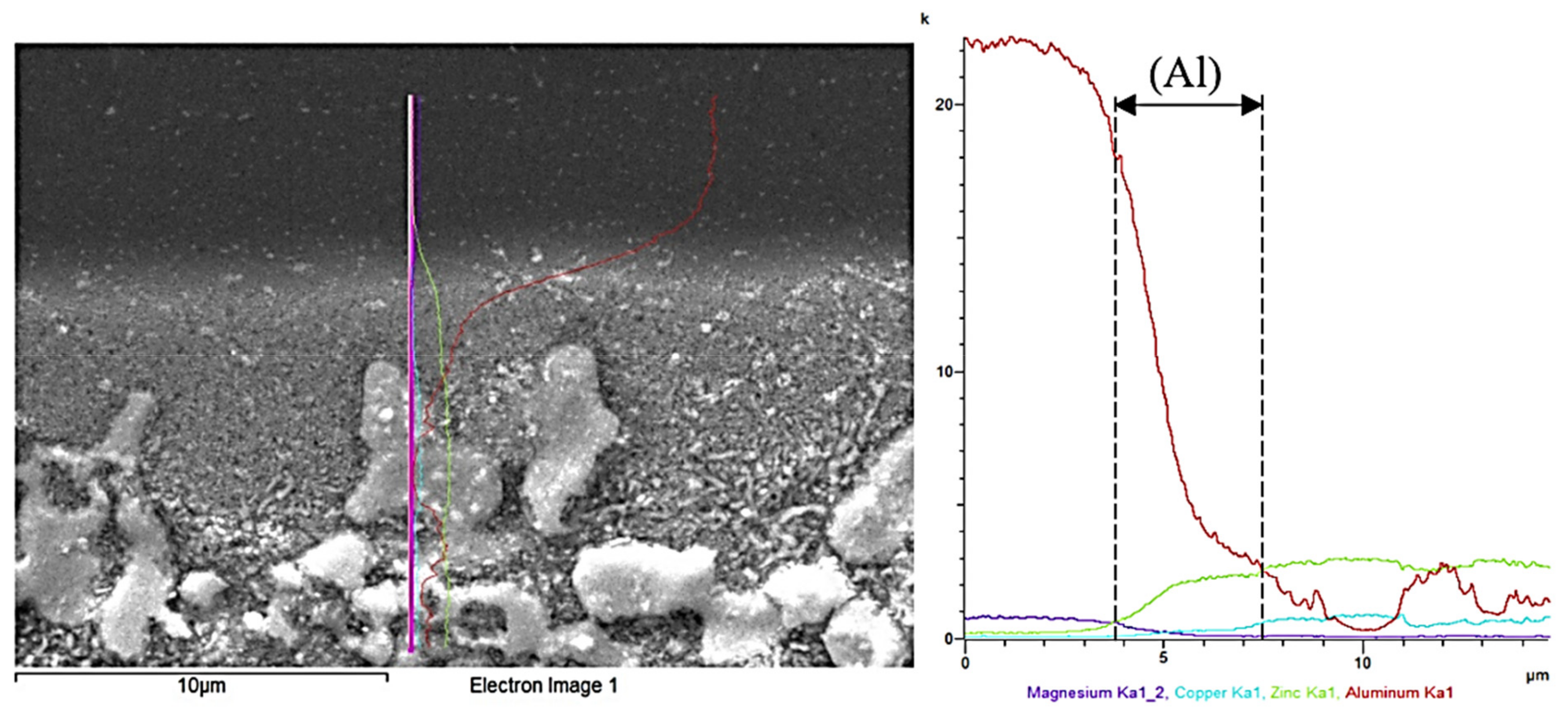

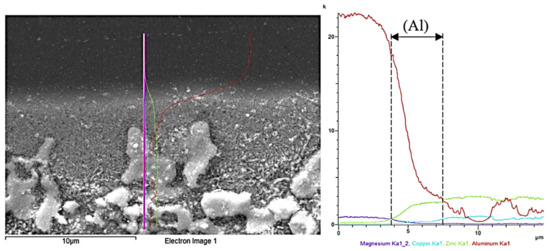

The concentration profiles of the Zn and Al elements shown in Figure 15 prove the presence of solid solution Al, where copper is also partially dissolved in an amount up to 6 wt. %.

Figure 15.

Concentration profiles of Zn, Al, Cu, and Mg elements on the boundary of Al7075/Zn5Al3Cu joint.

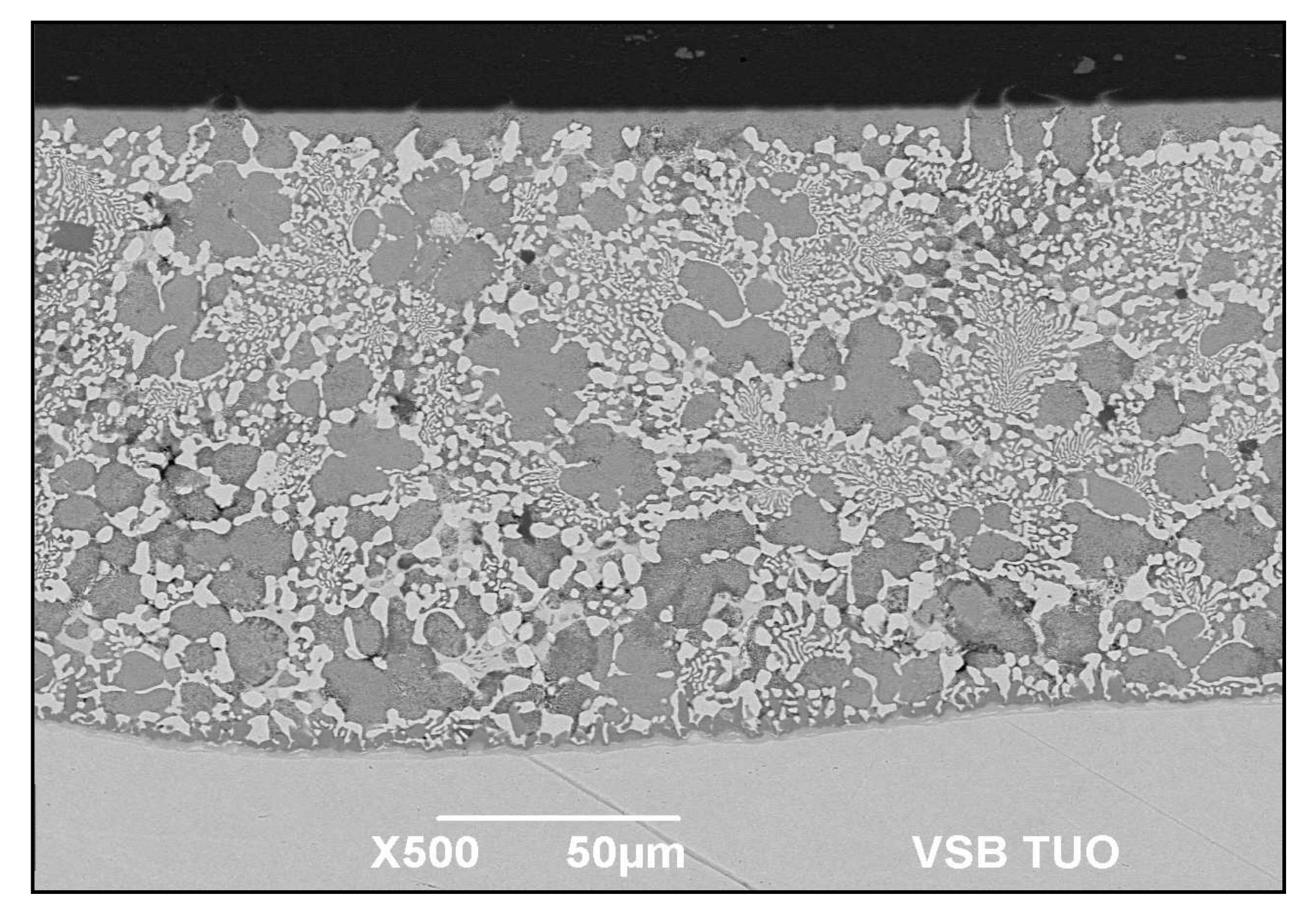

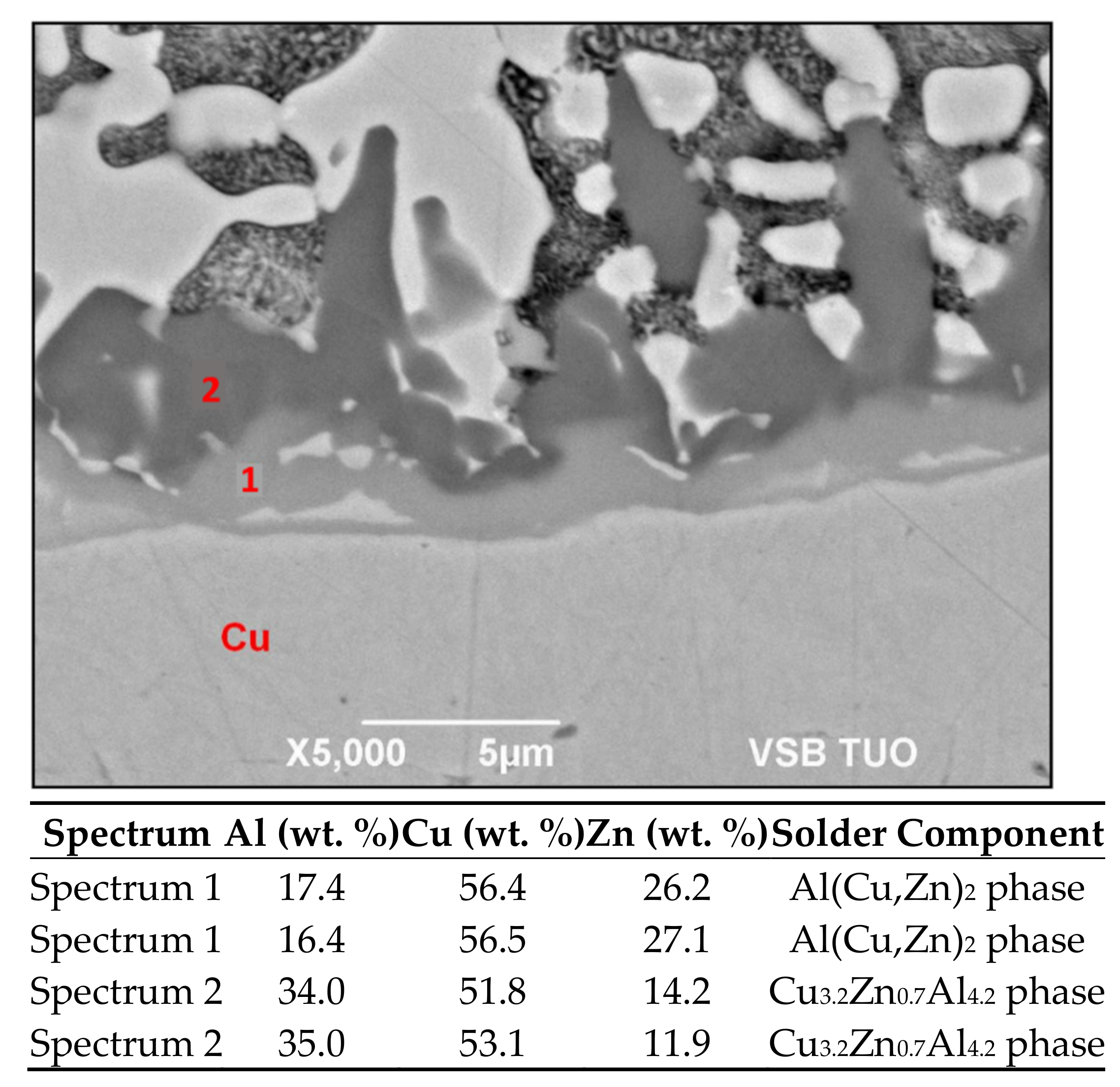

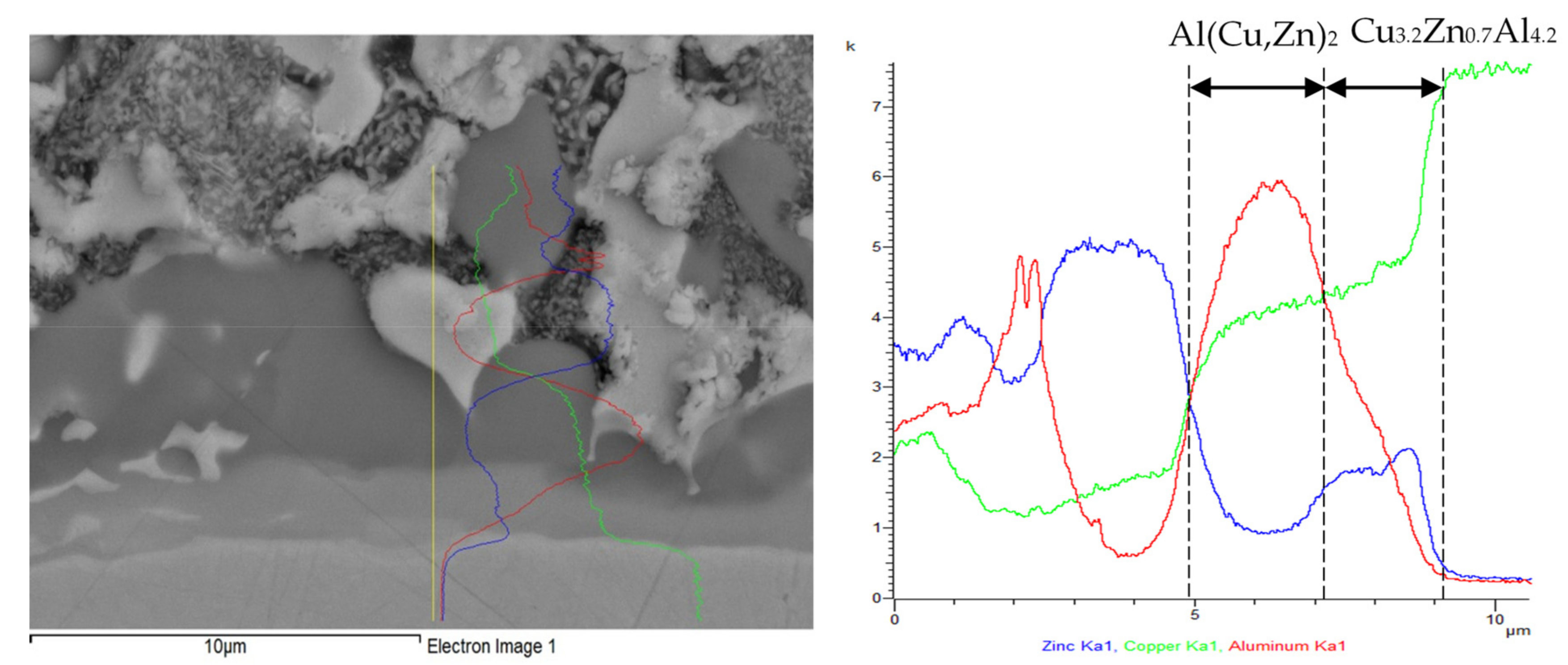

3.6. Microstructure of Boundary in Cu/Zn5Al3Cu Joint

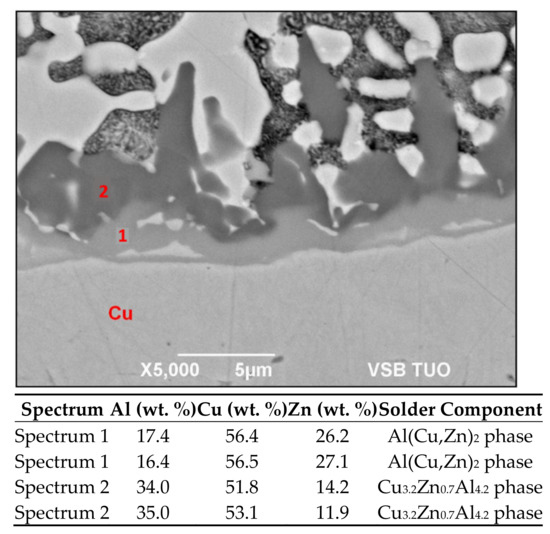

Mainly the transition zone of the joint was analyzed. Two new intermetallic phases can be observed in the boundary of the Cu/Zn5Al3Cu joint. Figure 16 shows the result of the EDX analysis of the transition zones at the points of measurement, Spectrum 1 and Spectrum 2. Spectrum 1 contained around 17 wt. % Al and 56 wt. % Cu + 27 wt. % Zn. This may be considered as a stoichiometric phase type AB2, thus Al(Cu, Zn)2. This phase occurred directly in the Cu/Zn5Al3Cu solder boundary and also aluminum participated in the formation of this phase. The thickness of this phase is 1.5 to 3 µm.

Figure 16.

The point EDX analysis of the Cu/Zn5Al3Cu boundary.

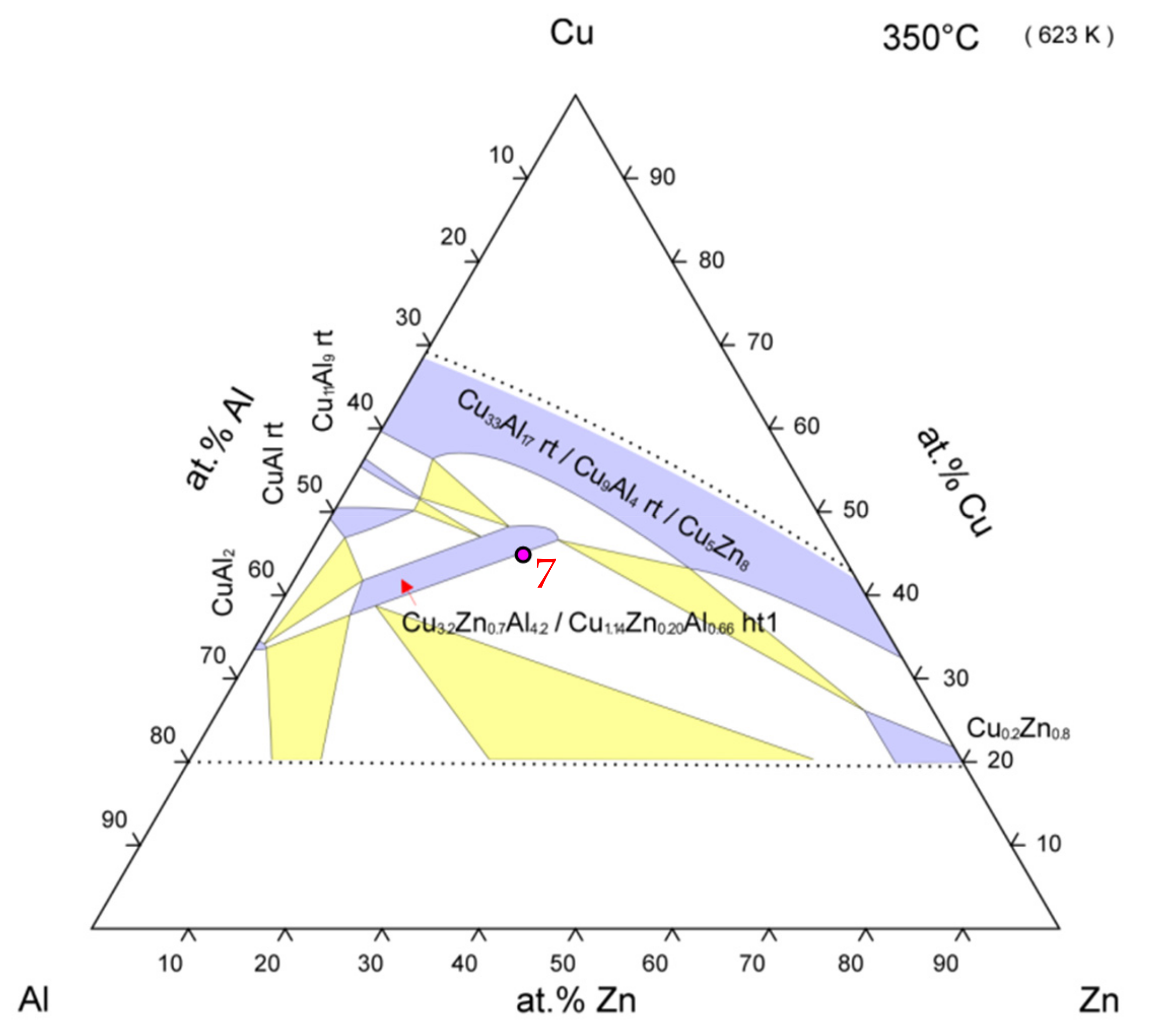

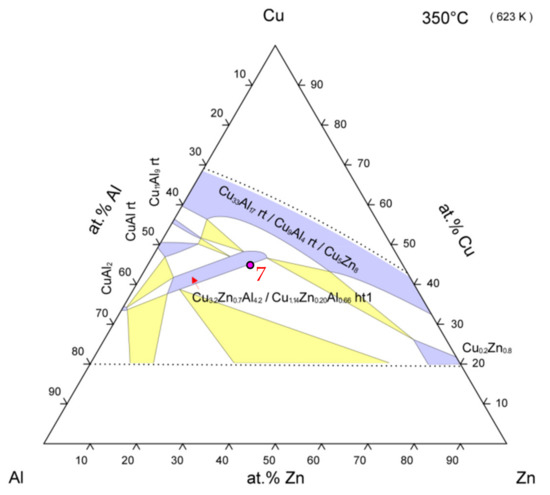

Spectrum 2, with a lower Cu content and higher Al content than in the previous phase, was formed as another layer adjacent to the solder. It corresponds stoichiometrically to the Cu3.2Zn0.7Al4.2 phase, following from the phase diagram in Figure 17. The thickness of this layer is 4.3 to 7.8 µm.

Figure 17.

Isothermal sections in the ternary system of Al–Cu–Zn for the temperature of 350 °C with marked position of Spectrum [20].

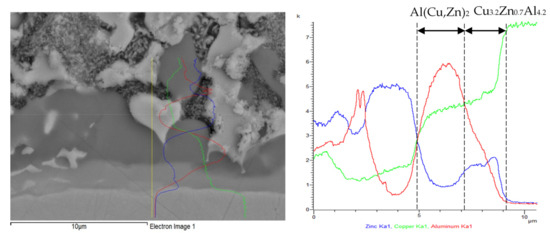

The results of the point EDX analysis are proved also by the course of the concentration profiles of the Zn, Cu, and Al elements. Beside Zn, also Al contributes to bond formation with the Cu substrate, which is significantly represented in the boundary of the Cu/Zn5Al3Cu joint (Figure 18).

Figure 18.

Concentration profiles of Al, Cu, and Zn elements in the Cu/Zn5Al3Cu boundary.

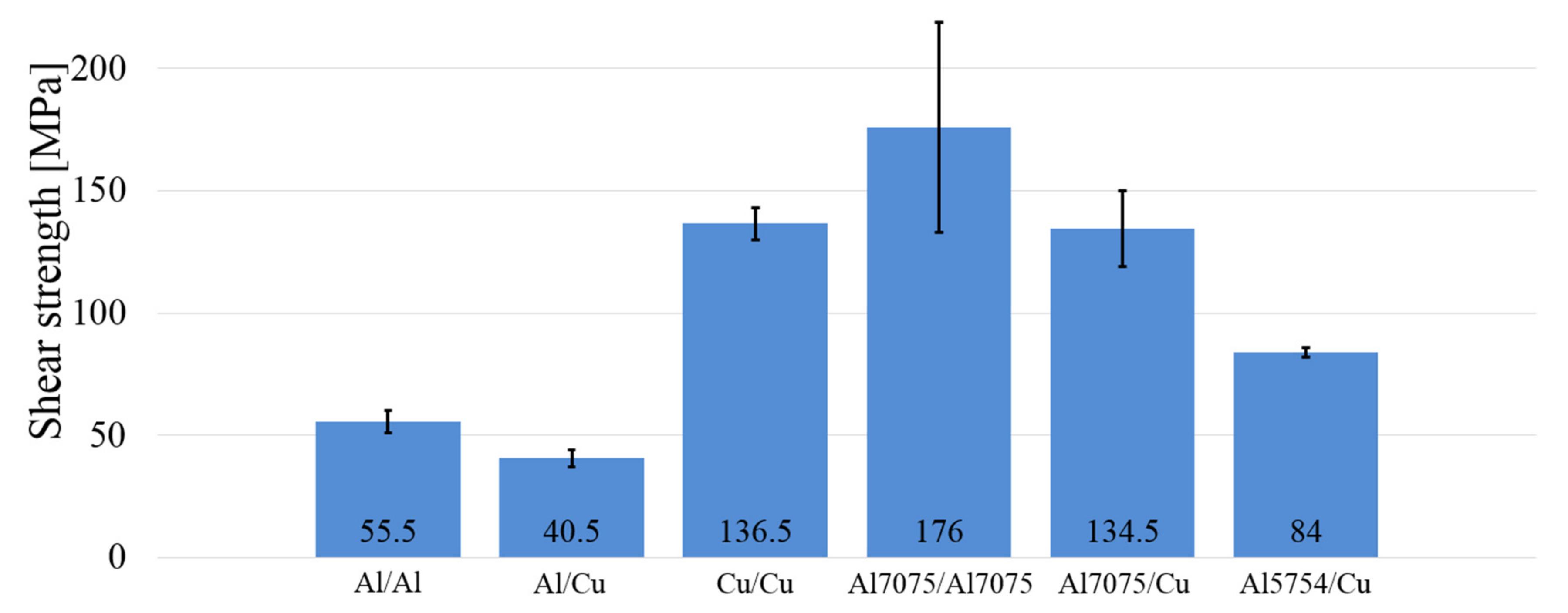

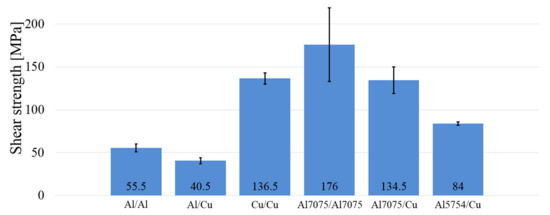

3.7. Shear Strength of Soldered Joints

The research in this study was primarily oriented to soldering the combination of aluminum alloy type Al7075 with a copper substrate using Zn5Al3Cu solder. The measurement of the shear strength of the joints was performed due to the potentially wider application of the results and for comparison purposes was realized also on the combinations of Al7075/Al7075, Al5754/Cu, Al/Al, Cu/Cu, and Al/Cu joints. The measurement was performed on four specimens of each material. The results of the average shear strength of the joints are documented in Figure 19. From the results of the measurements, it is obvious that the stronger the aluminum alloy, the stronger the shear strength of the joint. The tensile strength of pure aluminum is approximately 60 MPa. The strength of Al5754 alloy is 220 MPa and the ultimate strength of Al7075 alloy is 280 MPa. The lowest average shear strength was observed in the case of the Al/Al combination, namely 55.5 MPa, and the highest in the case of the Al7075/Al7075 combination—as much as 176 MPa. This is due to the fact that the fracture did not occur directly in the solder but in the base (aluminum) material. Shearing off of the aluminum material occurred. The difference in the shear strength of the joints in aluminum materials in comparison to combined joints with copper substrate may be explained by the different mechanism of bond formation. In the case of Al, Al5754, and Al7075 materials, the bond is formed due to the dissolution of Al in the Zn solder. However, in the case of copper substrate, the bond is formed due to the interaction of the zinc solder with the copper substrate at the formation of new transition intermetallic phases such as Al(Cu,Zn)2 and Cu3.2Zn0.7Al4.2. It can be generally said that joints with Cu substrate had lower strength values. For example, the Al/Cu joint exerted 15 MPa (27 %) lower shear strength in comparison to the Al/Al joint. The Al7075/Cu joint showed 41 MPa (23.3 %) lower shear strength in comparison to the Al7075/Al7075 joint.

Figure 19.

Shear strength of soldered joints fabricated with Zn5Al3Cu solder.

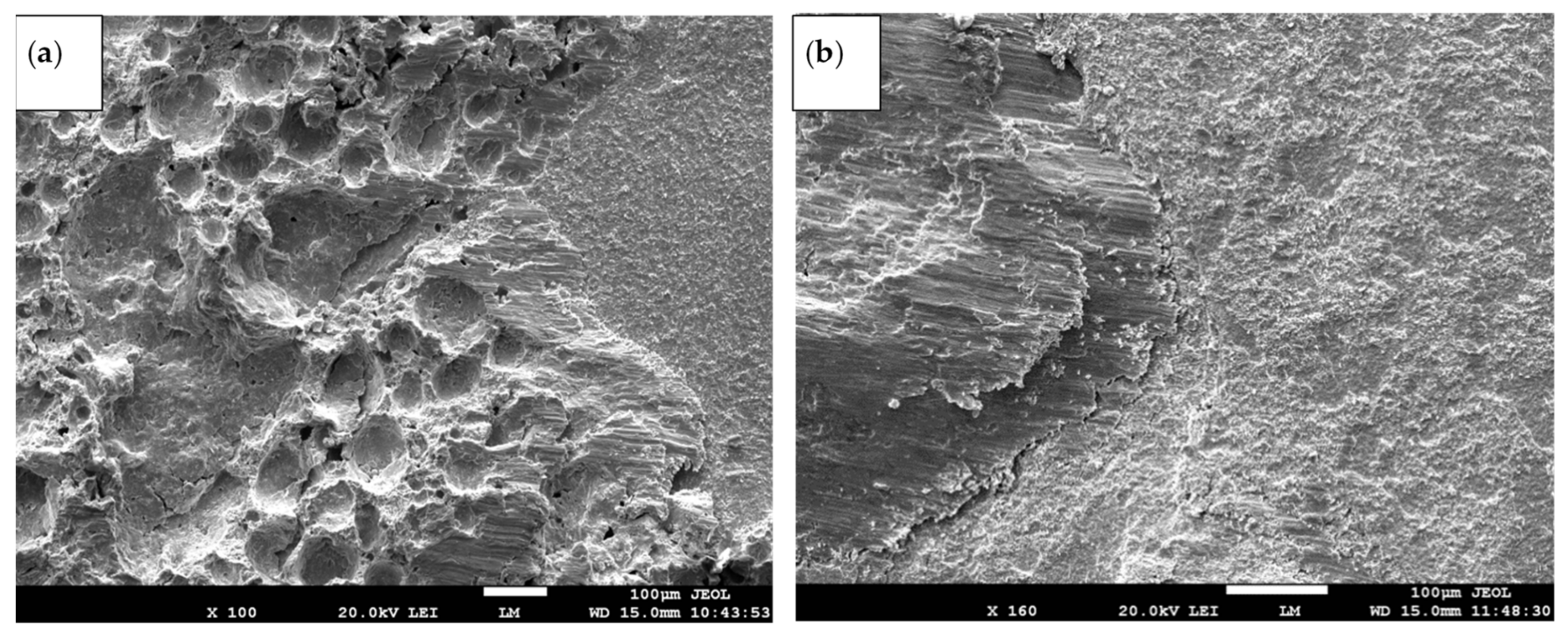

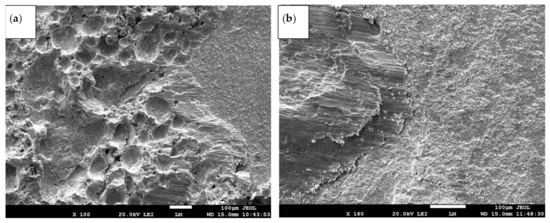

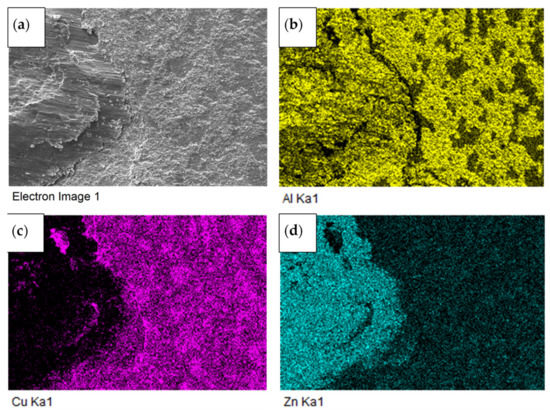

For a more precise identification, the fractured surfaces of the joints were also analyzed. Figure 20a,b shows the fractured surface in the boundary of the Al7075/Zn5Al3Cu/Cu joint. It can be seen that the entire fractured surface remained covered with solder. A ductile fracture occurred in the solder. A planar analysis of the Al, Cu, and Zn elements was performed on the fractured surface and is documented in Figure 21b–d. In the map of the fractured surface, the Al, Cu, and Zn elements prevail. Therefore, the existence of phases of these elements on the fractured surface can be assumed.

Figure 20.

The fractured surface of soldered joint of Al7075/Zn5Al3Cu/Cu: (a) magnification 100×; (b) magnification 160×.

Figure 21.

The fractured surface of soldered joint of Al7075/Zn5Al3Cu/Cu and planar distribution of individual elements: (a) structure of fracture; (b) Al; (c) Cu; (d) Zn.

Regarding this viewpoint, the XDR analysis on the fractured surface of the Al7075/Zn5Al3Cu/Cu joint was performed (Figure 22). The presence of Cu on the fractured surface was thus proved. In addition, observed were solid solutions of aluminum and zinc and newly formed phases of copper—CuZn4, CuAl2, Cu3.2Zn0.7Al4.2, were also observed, which are the result of solder interaction with the copper substrate. All these phases were proved also by EDX analysis.

Figure 22.

The XRD analysis of fractured surface in Al7075/Zn5Al3Cu/Cu joint.

4. Conclusions

The aim of the research was to characterize the soldering alloy of type Zn–Al–Cu and to study whether the selected composition of the soldering alloy is suitable for the combination of copper with aluminum alloy type Al7075 with the application of ultrasonic soldering. The following results were achieved:

- To determine the melting point of the solder, DSC analysis was applied. The DSC curve contains two basic peaks. The first peak corresponds to eutectoid transformation in the Zn–Al system. The second peak corresponds to eutectic transformation in the same system. It was found that the addition of Cu to the solder increases the temperature of eutectoid transformation to approximately 285 °C and, vice versa, the temperature of eutectic transformation is reduced to 378 °C.

- The microstructure of solder of type Zn–Al–Cu is formed of a eutectic mixture of solid solutions Zn + Al + Al“. Two copper phases, CuZn4 and CuAl2, were identified in the solder matrix.

- The average tensile strength of soldering alloys of type Zn–Al–Cu reaches values from 167 to 187 MPa. It was found that the addition of copper partially reduces the tensile strength of soldering alloys of type Zn–Al–Cu. The addition of 3 wt. % Cu to Zn5Al solder will reduce the average tensile strength by 38 MPa. This is caused by the formation of copper phases of type CuZn4 and CuAl2.

- The bond of aluminum alloy with Zn5Al3Cu solder is formed due to the dissolution of Al in zinc solder at the formation of solid solution Al. The width of the solubility band with the solid solution Al was 5 to 11 µm.

- Two new intermetallic phases, namely Al(Cu,Zn)2 and Cu3.2Zn0.7Al4.2, were identified in the boundary of the Cu/Zn5Al3Cu joint, which are the result of interaction of the zinc solder and copper substrate. Beside the interaction of Zn, also a significant effect of Al on bond formation with the copper substrate was proved.

- The average shear strength of the Al7075/Zn5Al3Cu/Cu joint had a value of 134.5 MPa. For comparison, the Cu/Zn5Al3Cu/Cu joint attained an average shear strength of 136.5 MPa.

Author Contributions

Conceptualization, R.K. and I.K.; methodology, R.K.; validation, R.K., I.K. and J.D.; formal analysis, J.D., P.B. and M.S.; investigation, R.K. and I.K.; data curation, I.K.; writing—original draft preparation, R.K.; writing—review and editing, I.K.; visualization, I.K.; supervision, R.K.; project administration, I.K.; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under contract no. APVV-17-0025 and by the scientific grant agency of the Ministry of Education of the Slovak Republic and of Slovak Academy of Sciences under contract no. VEGA 1/0303/20.

Acknowledgments

The paper was also prepared in cooperation with the VSB—Technical University of Ostrava, FMT—Faculty of Materials Science and Technology, Department of Non-ferrous Metals, Refining and Recycling.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, W.-B.; Bang, K.-S.; Jung, S.-B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing. J. Alloy. Compd. 2005, 390, 212–219. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Yarrapareddy, E.; Kovacevic, R. Microstructural evolution in the friction stir welded 6061 aluminum alloy to copper. J. Mater. Process. Technol. 2006, 172, 110–112. [Google Scholar] [CrossRef]

- Sahin, M. Joining of aluminum and copper materials with friction welding. Int. J. Adv. Manuf. Technol. 2009, 49, 527–534. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel-kovar, copper-steel and copper-aluminium. Mater. Sci. Eng. 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Abbasi, M.; Taheri, A.K.; Salehi, M. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloy. Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

- Xia, C.; Li, Y.; Puchkov, U.; Gerasimov, S.; Wang, J. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al–Si filler metal. Vacuum 2008, 82, 799–804. [Google Scholar] [CrossRef]

- Xia, C.Z.; Li, Y.; Puchkov, U.A.; Gerasimov, S.A.; Wang, J. Crack analysis near vacuum brazing interface of Cu/Al dissimilar materials using Al–Si brazing alloy. Mater. Sci. Technol. 2009, 25, 383–387. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Z.; Zhao, D.; Liu, X.; Yan, J. Effects of Zn on intermetallic compounds and strength of Al/Mg joints ultrasonically soldered in air. J. Mater. Process. Technol. 2019, 271, 384–393. [Google Scholar] [CrossRef]

- Lin, J.C.; Liang, C.L.; Lin, K.L. Joint effects of Ti and Cu additions on microstructure and mechanical properties of Zn-25Sn-xCu-yTi high-temperature Pb-free solders. Mater. Sci. Eng. A 2019, 765, 138323. [Google Scholar] [CrossRef]

- Guo, W.T.; Liang, C.L.; Lin, K.L. The effects of Cu alloying on the microstructure and mechanical properties of Zn-25Sn-xCu (x = 0–1.0 wt%) high temperature Pb-free solders. Mater. Sci. Eng. A 2019, 750, 117–124. [Google Scholar] [CrossRef]

- Wu, B.; Leng, X.; Xiu, Z.; Yan, J. Microstructural evolution of SiC joints soldered using Zn–Al filler metals with the assistance of ultrasound. Ultrason. Sonochem. 2018, 44, 280–287. [Google Scholar] [CrossRef] [PubMed]

- Xing, F.; Lu, Y.; Luo, C.; Ruan, Y.; Qiu, X. Coupling modification of microstructure for improving the mechanical properties of Zn-Sn-Cu-Bi high-temperature solder. Mater. Lett. 2016, 181, 42–46. [Google Scholar] [CrossRef]

- Liu, L.; Chen, Z.; Zhou, Z.; Chen, G.; Wu, F.; Liu, C. Diffusion barrier property of electroless Ni-W-P coating in high temperature Zn-5Al/Cu solder interconnects. J. Alloy. Compd. 2017, 722, 746–752. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, C.; Liu, J.; Zhang, G.; Suganuma, K. Corrosion mechanism of Zn-30Sn high-temperature, lead-free solder in neutral NaCl solution. Corros. Sci. 2018, 140, 40–50. [Google Scholar] [CrossRef]

- Feng, J.I.; Xue, S.B.; Lou, J.Y.; Lou, Y.B.; Wang, S.Q. Microstructure and properties of Cu/Al joints brazed with Zn-Al filler metals. Transcations Nonferrous Met. Soc. China 2012, 22, 281–287. [Google Scholar]

- Kang, N.; Na, H.S.; Kim, S.J.; Kang, C.Y. Alloy design of Zn-Al-Cu solder for ultra high temperatures. J. Alloys Compd. 2009, 467, 246–250. [Google Scholar] [CrossRef]

- Mahmudi, R.; Alibabaie, S. Elevated-temperature shear strength and hardness of Zn-3Cu-xAl ultra-high-temperature lead-free solders. Mater. Sci. Eng. 2013, 559, 421–426. [Google Scholar] [CrossRef]

- Takaku, Y.; Felicia, L.; Ohnuma, I.; Kainuma, R.; Ishida, K. Interfacial Reaction Between Cu Substrates and Zn-Al Base High-Temperature Pb-Free Solders. J. Electron. Mater. 2008, 37, 314–323. [Google Scholar] [CrossRef]

- Xing, F.; Yao, J.; Liang, J.; Qiu, X. Influence of intermetallic growth on the mechanical properties of Zn–Sn–Cu–Bi/Cu solder joints. J. Alloys Compd. 2015, 649, 1053–1059. [Google Scholar] [CrossRef]

- Okamoto, H.; Massalski, T.B. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).