Laser Powder Bed Fusion of Potential Superalloys: A Review

Abstract

1. Introduction

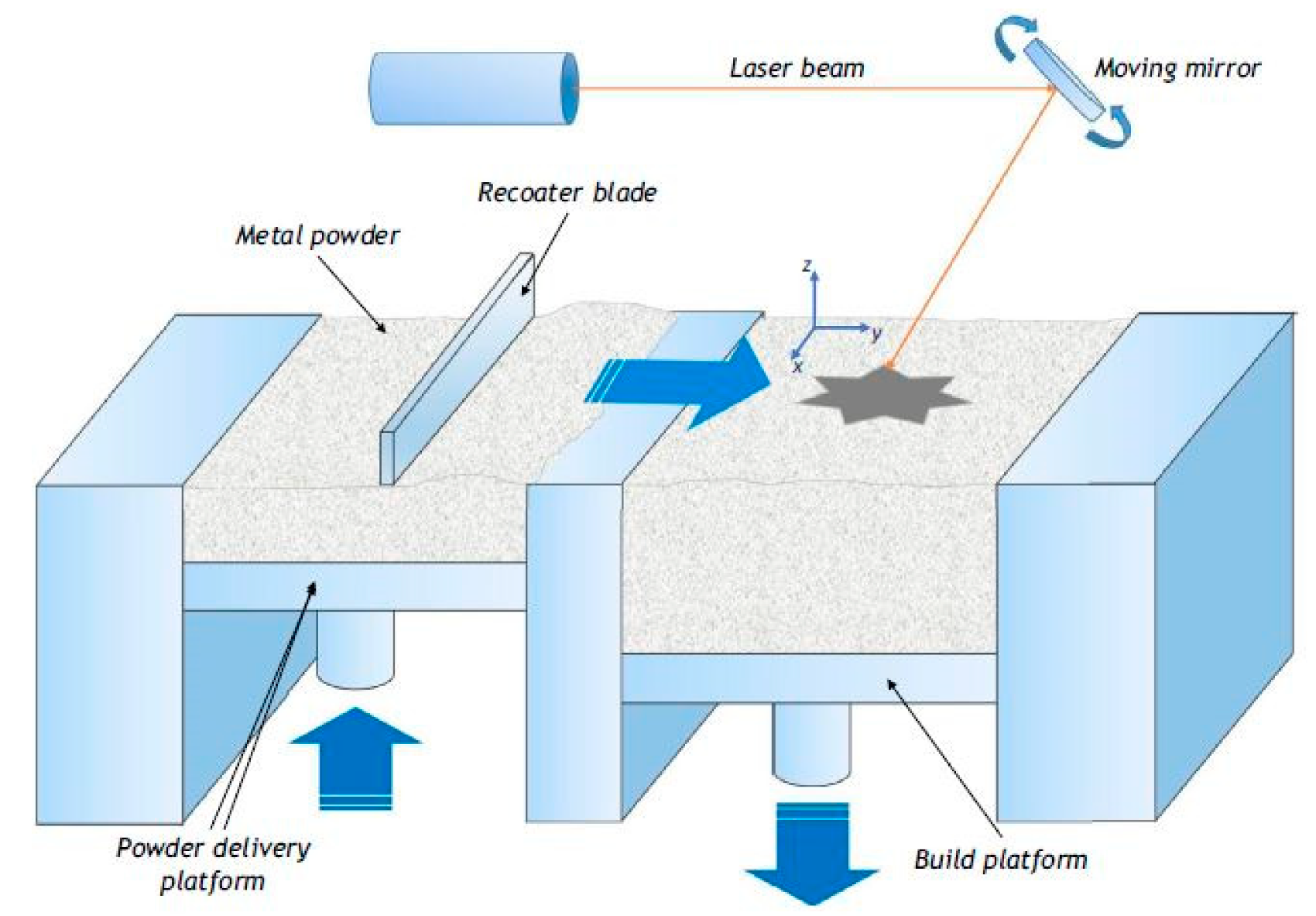

2. Laser Powder Bed Fusion (LPBF)

3. Effects of Process Parameters on the LPBF Process

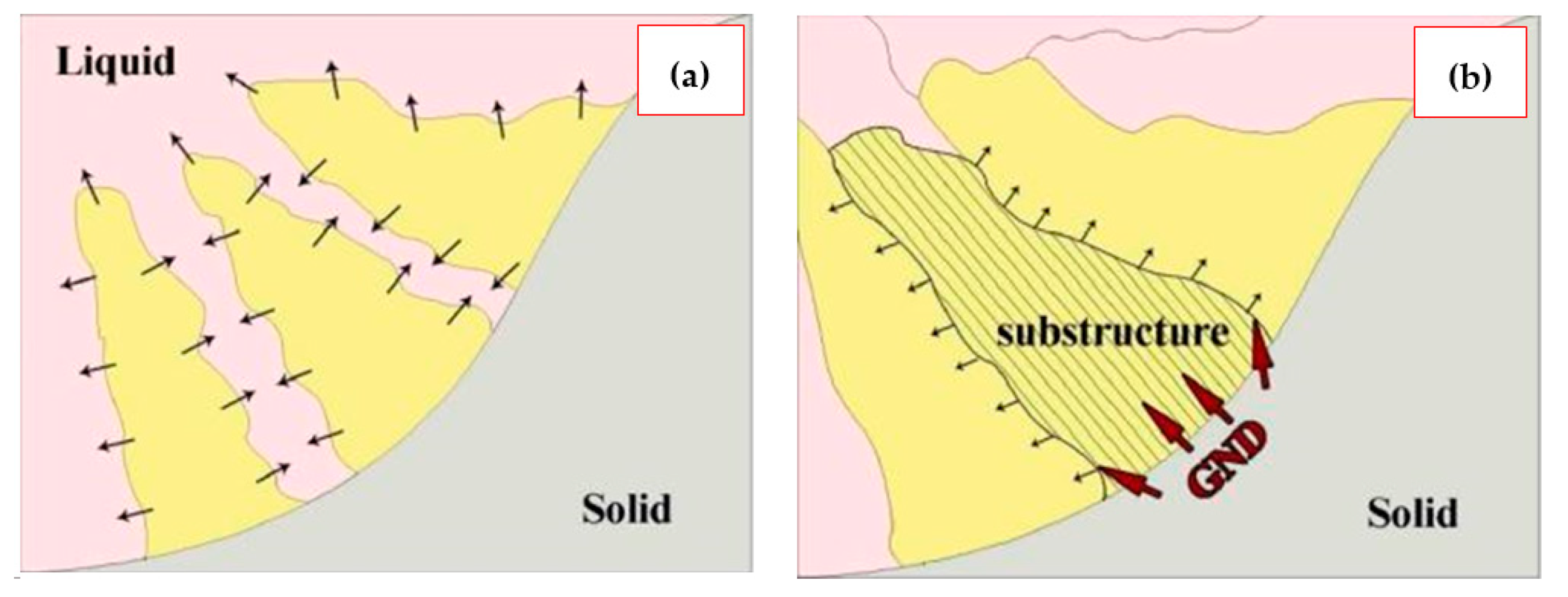

- executing the process in a vacuum or protective atmosphere (in high purity inert gases such as argon or nitrogen) to slow down or render the oxidation process inactive

- alloying additions to disrupt formed surface oxide films

- optimizing processing parameters to minimize the balling phenomenon

- re-scanning of the underlying substrate to break up oxide films to ensure a clean surface at the atomic level between the liquid and the solid

3.1. Laser Types

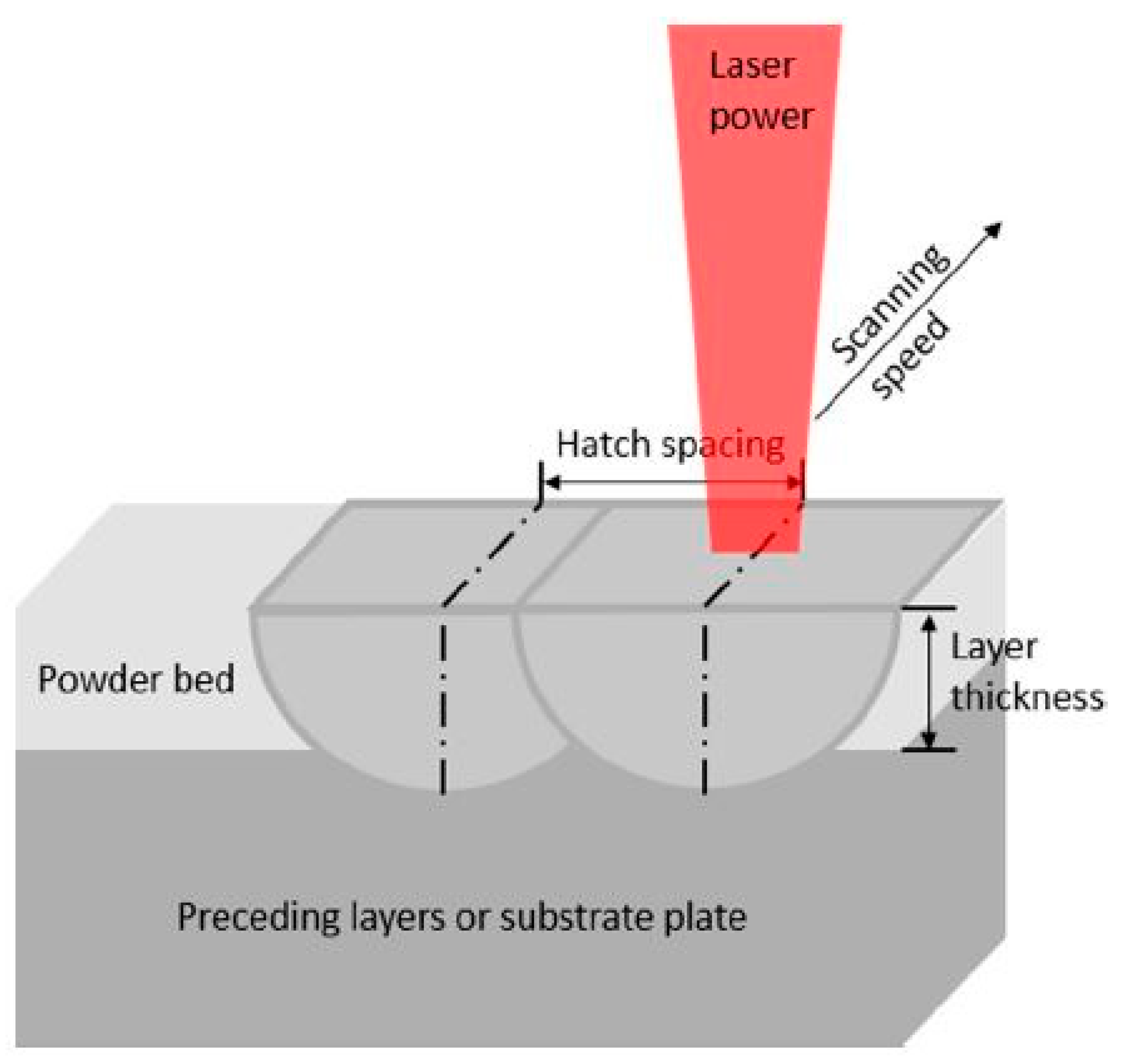

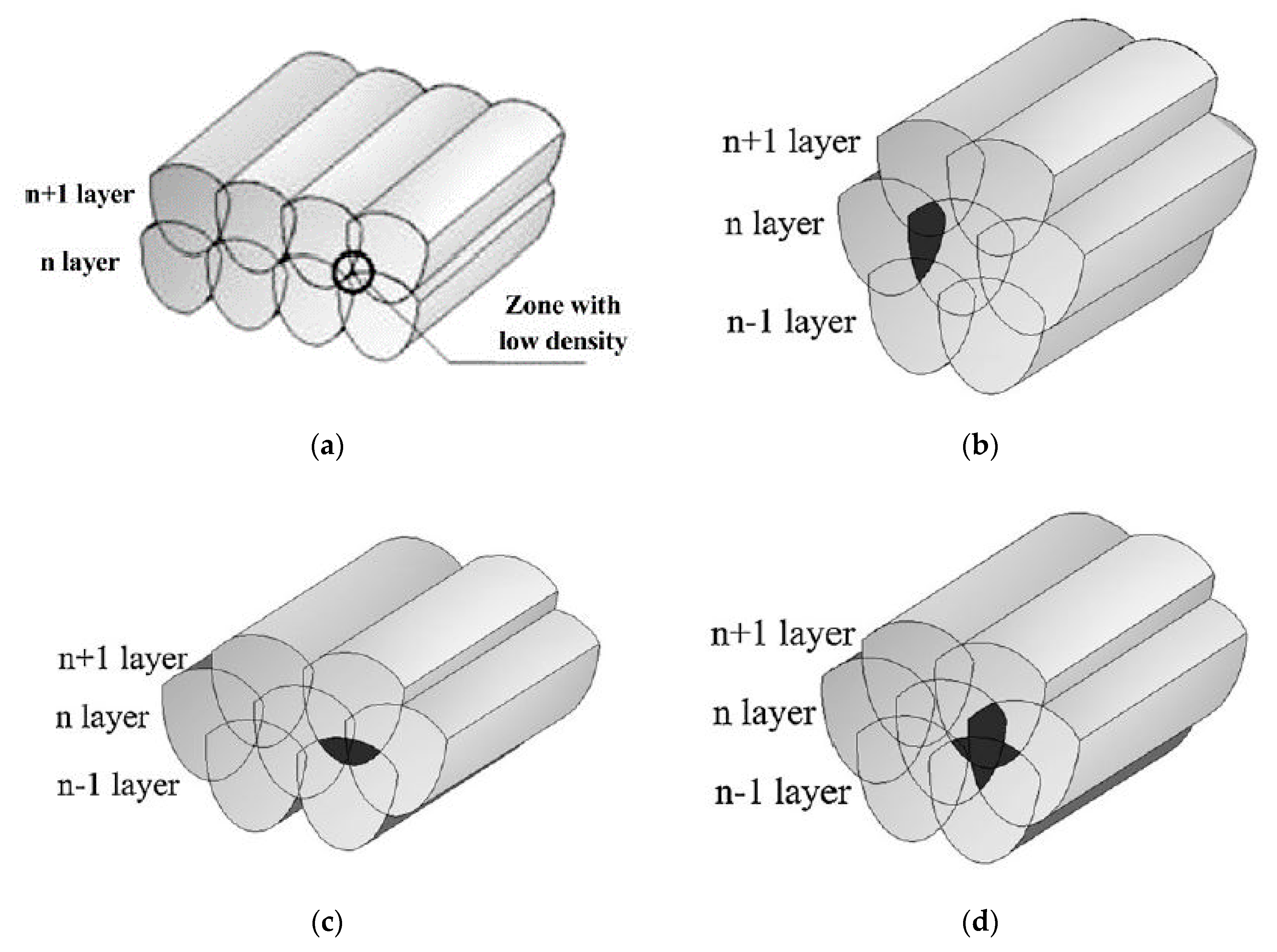

3.2. Effects of Processing Parameters on LPBF (Laser Power, Beam Size, Scanning Speed, Scan Hatch Spacing and Powder Layer Thickness)

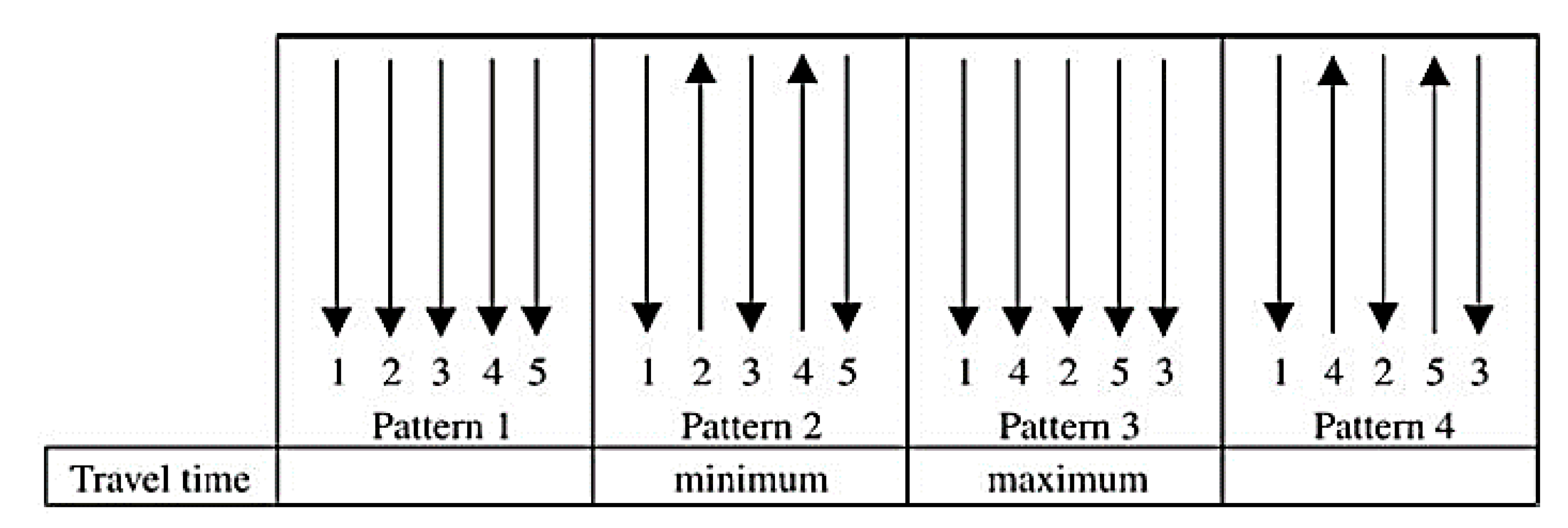

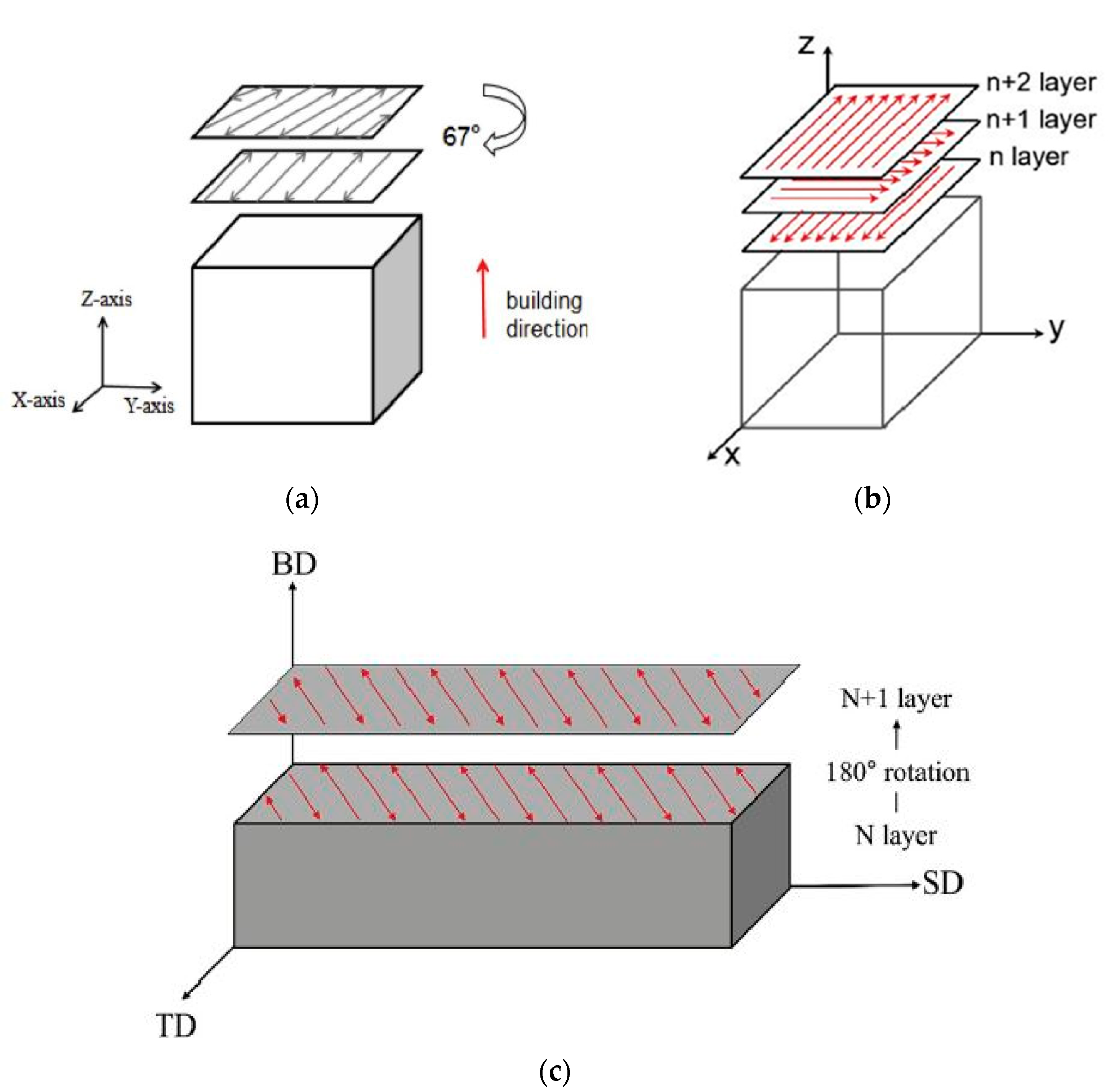

3.3. Effect of Laser Scanning Strategy on the Densification Mechanism

3.4. Effects of the Atmosphere on the LPBF Process

3.5. Effects of Powder Characteristics on the LPBF Process

4. LPBF of TiAl Alloys

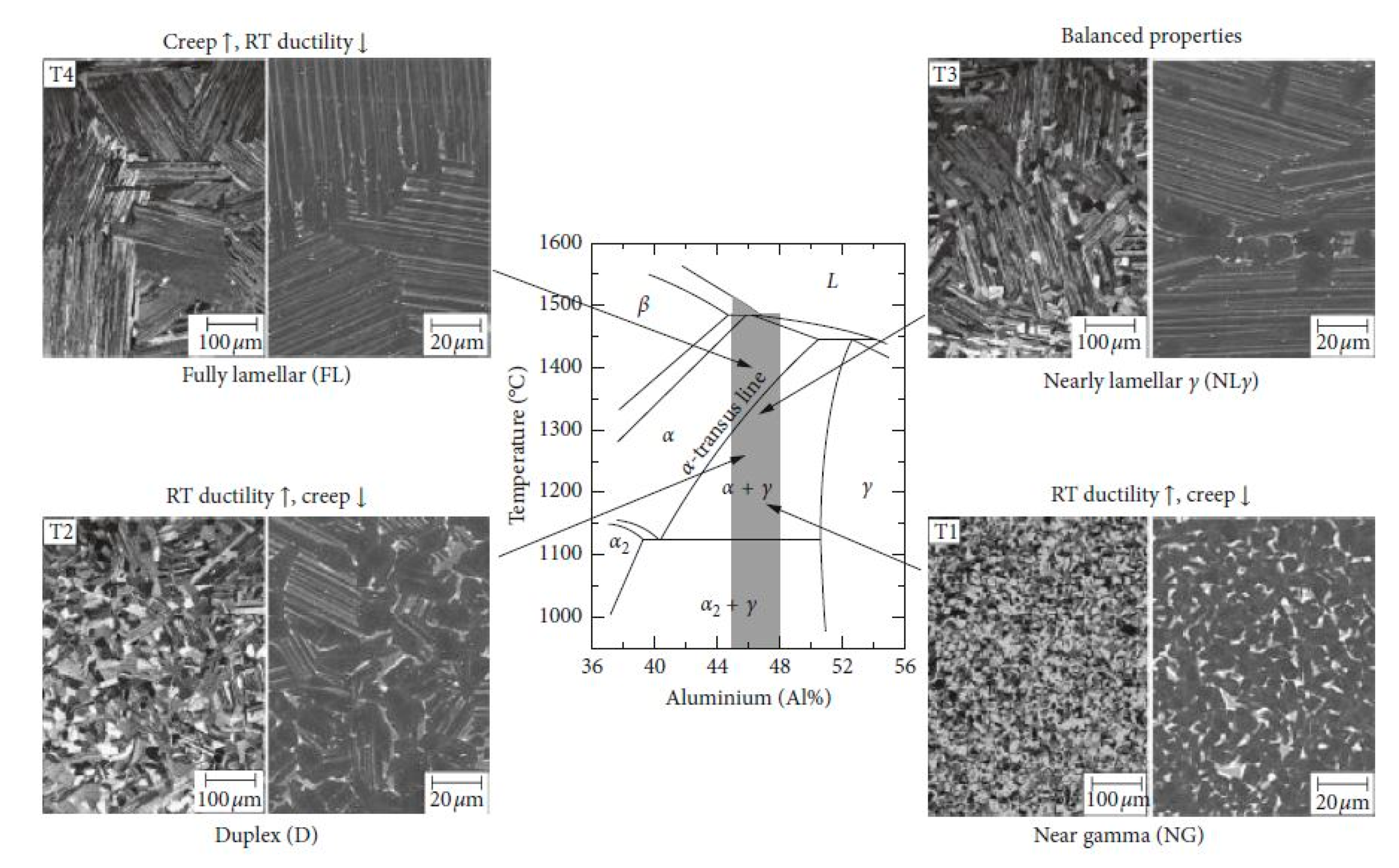

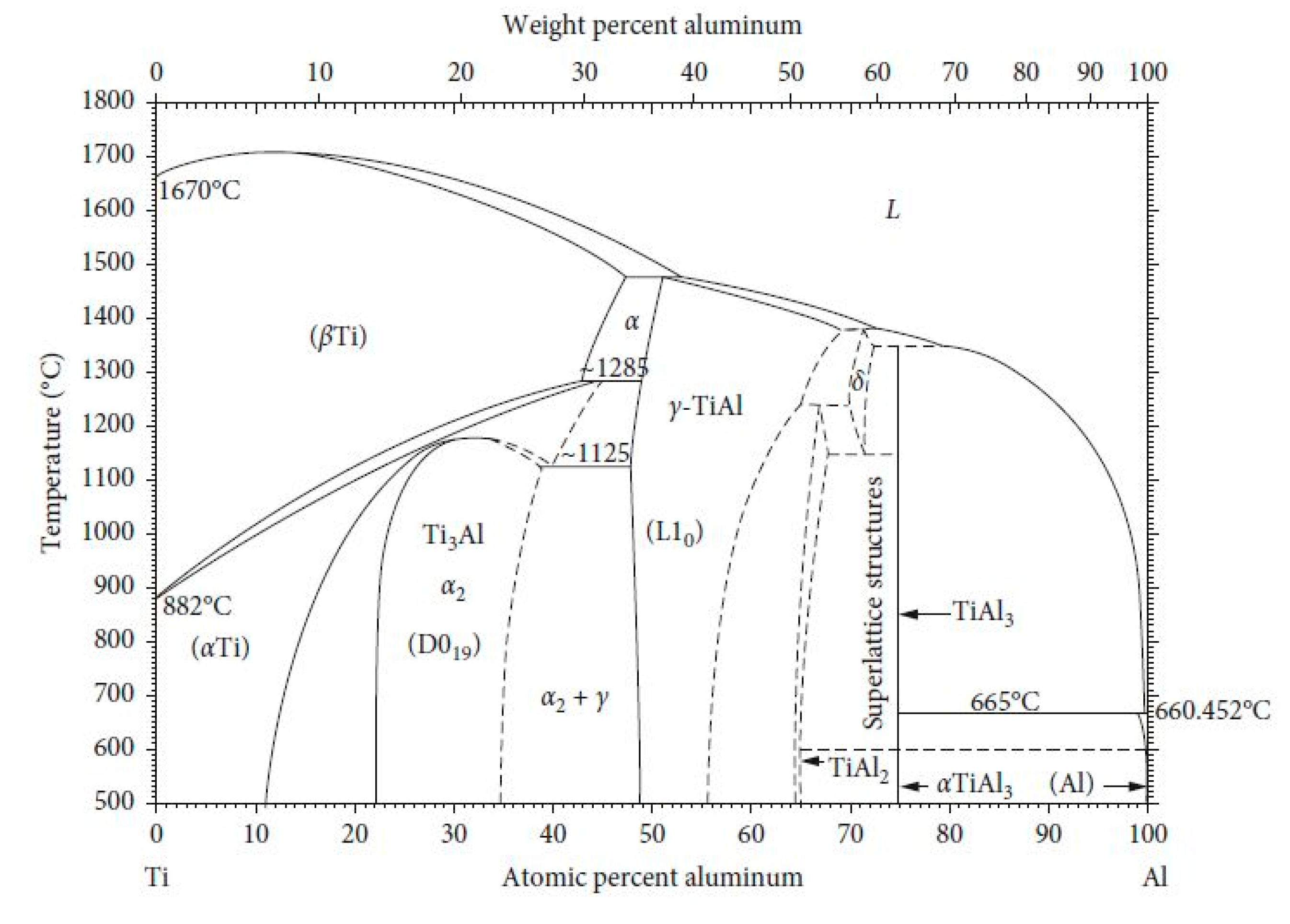

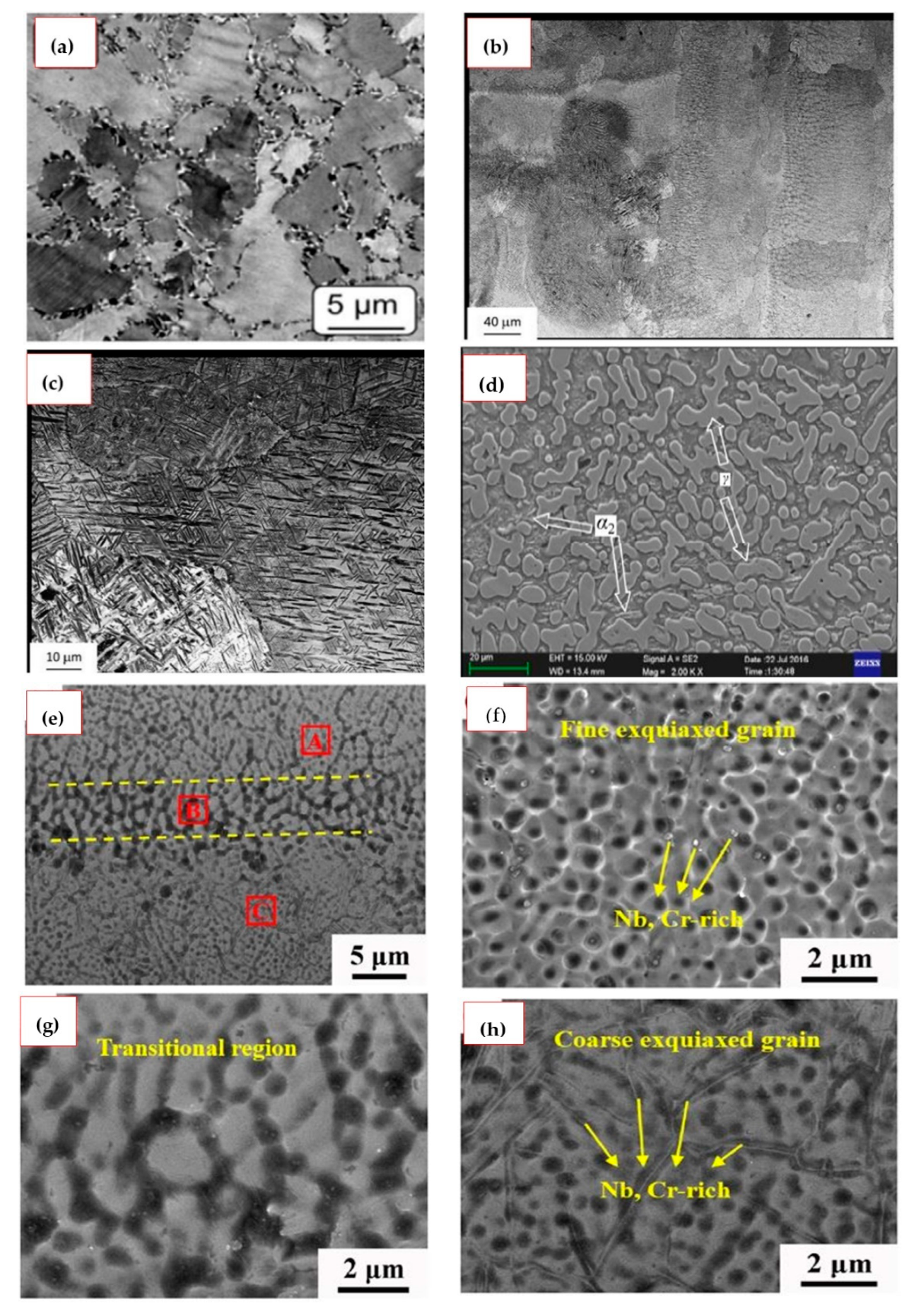

Phase Transformation and Microstructural Evolution of LPBF Built TiAl Alloys

5. LPBF of HEAs

Microstructures of LPBF-Built HEAs

6. Mechanical Properties of LPBF-Processed TiAl-Based Alloys and HEAs

7. Present Research Progress and Future Studies

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Appel, F.; Oehring, M. γ-titanium aluminide alloys: Alloy design and properties. In Titanium and Titanium Alloys. Fundamentals and Applications; Leyens, C., Peters, M., Eds.; WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim: Cologne, Germany, 2003; pp. 89–93. [Google Scholar]

- Bewlay, B.; Nag, S.; Suzuki, A.; Weimer, M. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Senkov, O.; Scott, J.; Senkova, S.; Meisenkothen, F.; Miracle, D.; Woodward, C. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z. A promising new class of high-temperature alloys: Eutectic high-entropy alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef] [PubMed]

- Ding, Q.; Zhang, Y.; Chen, X.; Fu, X.; Chen, D.; Chen, S.; Gu, L.; Wei, F.; Bei, H.; Gao, Y. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 2019, 574, 223–227. [Google Scholar] [CrossRef]

- Chen, J.; Niu, P.; Liu, Y.; Lu, Y.; Wang, X.; Peng, Y.; Liu, J. Effect of Zr content on microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. Mater. Des. 2016, 94, 39–44. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1. 5CrFeNi1. 5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.; Yeh, J.; Tsai, C.; Chuang, A.; Liaw, P. Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 2012, 60, 5723–5734. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, J.; Xia, Z.; Fu, W.; Wu, K.; Liu, G.; Sun, J. Stable nanocrystalline NbMoTaW high entropy alloy thin films with excellent mechanical and electrical properties. Mater. Lett. 2018, 210, 84–87. [Google Scholar] [CrossRef]

- Mishra, R.K.; Shahi, R.R. Phase evolution and magnetic characteristics of TiFeNiCr and TiFeNiCrM (M = Mn, Co) high entropy alloys. J. Magn. Magn. Mater. 2017, 442, 218–223. [Google Scholar] [CrossRef]

- Kai, W.; Li, C.; Cheng, F.; Chu, K.; Huang, R.; Tsay, L.; Kai, J. Air-oxidation of FeCoNiCr-based quinary high-entropy alloys at 700–900 °C. Corros. Sci. 2017, 121, 116–125. [Google Scholar] [CrossRef]

- Kumar, N.; Fusco, M.; Komarasamy, M.; Mishra, R.; Bourham, M.; Murty, K. Understanding effect of 3.5 wt.% NaCl on the corrosion of Al0.1CoCrFeNi high-entropy alloy. J. Nucl. Mater. 2017, 495, 154–163. [Google Scholar] [CrossRef]

- Xie, P.; Yao, Y.; Huang, Z.; Liu, Z.; Zhang, J.; Li, T.; Wang, G.; Shahbazian-Yassar, R.; Hu, L.; Wang, C. Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 2019, 10, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Edalati, P.; Floriano, R.; Mohammadi, A.; Li, Y.; Zepon, G.; Li, H.-W.; Edalati, K. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Scr. Mater. 2020, 178, 387–390. [Google Scholar] [CrossRef]

- Sahlberg, M.; Karlsson, D.; Zlotea, C.; Jansson, U. Superior hydrogen storage in high entropy alloys. Sci. Rep. 2016, 6, 36770. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Bystrzycki, J. Structure and hydrogen storage properties of a high entropy ZrTiVCrFeNi alloy synthesized using Laser Engineered Net Shaping (LENS). Int. J. Hydrog. Energy 2013, 38, 12180–12189. [Google Scholar] [CrossRef]

- Sogabe, R.; Goto, Y.; Mizuguchi, Y. Superconductivity in REO0. 5F0. 5BiS2 with high-entropy-alloy-type blocking layers. Appl. Phys. Express 2018, 11, 053102. [Google Scholar] [CrossRef]

- Chaudhary, V.; Borkar, T.; Mikler, C.; Gwalani, B.; Choudhuri, D.; Soni, V.; Alam, T.; Ramanujan, R.; Banerjee, R. Additively Manufactured Functionally Graded FeNi based High Entropy Magnetic Alloys. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018; p. 1. [Google Scholar]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Güther, V.; Allen, M.; Klose, J.; Clemens, H. Metallurgical processing of titanium aluminides on industrial scale. Intermetallics 2018, 103, 12–22. [Google Scholar] [CrossRef]

- Wang, P.; Huang, P.; Ng, F.L.; Sin, W.J.; Lu, S.; Nai, M.L.S.; Dong, Z.; Wei, J. Additively manufactured CoCrFeNiMn high-entropy alloy via pre-alloyed powder. Mater. Des. 2019, 168, 107576. [Google Scholar] [CrossRef]

- Torralba, J.; Alvaredo, P.; García-Junceda, A. High-entropy alloys fabricated via powder metallurgy. A critical review. Powder Met. 2019, 62, 84–114. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Yeh, J.-W.; Chen, S.-K.; Shun, T.-T. Wear resistance and high-temperature compression strength of Fcc CuCoNiCrAl 0.5 Fe alloy with boron addition. MMTA 2004, 35, 1465–1469. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, J.; Zheng, H.; Li, H.; Liu, S.; Cheng, G.J. A review on microstructures and properties of high entropy alloys manufactured by selective laser melting. Int. J. Extrem. Manuf. 2020, 2, 032003. [Google Scholar] [CrossRef]

- Smith, M.; Cantwell, W.; Guan, Z.; Tsopanos, S.; Theobald, M.; Nurick, G.; Langdon, G. The quasi-static and blast response of steel lattice structures. J. Sandw. Struct. Mater. 2011, 13, 479–501. [Google Scholar] [CrossRef]

- Ushijima, K.; Cantwell, W.; Mines, R.; Tsopanos, S.; Smith, M. An investigation into the compressive properties of stainless steel micro-lattice structures. J. Sandw. Struct. Mater. 2011, 13, 303–329. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010; pp. 1–12. [Google Scholar]

- Doubenskaia, M.; Domashenkov, A.; Smurov, I.; Petrovskiy, P. Study of selective laser melting of intermetallic TiAl powder using integral analysis. Int. J. Mach. Tools Manuf. 2018, 129, 1–14. [Google Scholar] [CrossRef]

- Griffiths, V.; Scanlan, J.P.; Eres, M.H.; Martinez-Sykora, A.; Chinchapatnam, P. Cost-driven build orientation and bin packing of parts in selective laser melting (SLM). Eur. J. Oper. Res. 2019, 273, 334–352. [Google Scholar] [CrossRef]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective laser melting: A manufacturing technology for the future? Laser Tech. J. 2012, 9, 33–38. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Das, S. Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Körner, C.; Bauereiß, A.; Attar, E. Fundamental consolidation mechanisms during selective beam melting of powders. Model. Simul. Mater. Sci. Eng. 2013, 21, 085011. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.; Dalgarno, K. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Lauwers, B.; Kruth, J.-P.; Bonse, J.; Oorts, S.; Froyen, L. Comparison between Nd: YAG and CO2 lasers for use with selective laser sintering of metal powders. Proc. Photomec’99 1999, 1999, 165–173. [Google Scholar]

- Tolochko, N.K.; Khlopkov, Y.V.; Mozzharov, S.E.; Ignatiev, M.B.; Laoui, T.; Titov, V.I. Absorptance of powder materials suitable for laser sintering. Rapid Prototyp. J. 2000, 6, 155–161. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Manna, I. Laser-Assisted Fabrication of Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Cao, X.; Wallace, W.; Poon, C.; Immarigeon, J.-P. Research and progress in laser welding of wrought aluminum alloys. I. Laser welding processes. Mater. Manuf. Process. 2003, 18, 1–22. [Google Scholar] [CrossRef]

- Mueller, R.; Gu, H.; Ferguson, N. Nd: YAG Laser Welding for Automotive Manufacturing Applications; Technical Paper; SAE: Warrendale, PA, USA, 1999. [Google Scholar]

- Morgan, R.H.; Papworth, A.J.; Sutcliffe, C.; Fox, P.; O’Neill, W. High density net shape components by direct laser re-melting of single-phase powders. J. Mater. Sci. 2002, 37, 3093–3100. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Kong, F.; Gu, G.; Hawkins, T.W.; Parsons, J.; Jones, M.; Dunn, C.; Kalichevsky-Dong, M.T.; Wei, K.; Samson, B.; Dong, L. Flat-top mode from a 50 µm-core Yb-doped leakage channel fiber. Opt. Express 2013, 21, 32371–32376. [Google Scholar] [CrossRef]

- Sezerman, O.; Best, G. Accurate alignment preserves polarization. Laser Focus World 1997, 33, 27–30. [Google Scholar]

- Olakanmi, E.; Cochrane, R.; Dalgarno, K. Densification mechanism and microstructural evolution in selective laser sintering of Al–12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsev, I. Microstructure and properties of intermetallic composite coatings fabricated by selective laser melting of Ti–SiC powder mixtures. Intermetallics 2014, 46, 147–155. [Google Scholar] [CrossRef]

- Yuan, W.; Chen, H.; Cheng, T.; Wei, Q. Effects of laser scanning speeds on different states of the molten pool during selective laser melting: Simulation and experiment. Mater. Des. 2020, 189, 108542. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Simchi, A.; Asgharzadeh, H. Densification and microstructural evaluation during laser sintering of M2 high speed steel powder. Mater. Sci. Technol. 2004, 20, 1462–1468. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Su, W.; Erasenthiran, P.; Dickens, P.M. Investigation of fully dense laser sintering of tool steel powder using a pulsed Nd: YAG (neodymium-doped yttrium aluminium garnet) laser. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 127–138. [Google Scholar] [CrossRef]

- Dewidar, M.; Dalgarno, K.; Wright, C. Processing conditions and mechanical properties of high-speed steel parts fabricated using direct selective laser sintering. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 1651–1663. [Google Scholar] [CrossRef]

- Badrossamay, M.; Yasa, E.; Van Vaerenbergh, J.; Kruth, J.-P. Improving productivity rate in SLM of commercial steel powders. Tech. Pap. Soc. Manuf. Eng. 2009, 13, 1–13. [Google Scholar]

- Bourell, D.; Stucker, B.; Spierings, A.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloy. Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Carter, L.; Essa, K.; Attallah, M. Optimisation of selective laser melting for a high temperature Ni-superalloy. Rapid Prototyp. J. 2015, 21, 423–432. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Hagedorn-Hansen, D.; Bezuidenhout, M.; Dimitrov, D.; Oosthuizen, G. The effects of selective laser melting scan strategies on deviation of hybrid parts. S. Afr. J. Ind. Eng. 2017, 28, 200–212. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, J.b.; Luo, Z.Y.; Wang, D. Accuracy and density optimization in directly fabricating customized orthodontic production by selective laser melting. Rapid Prototyp. J. 2012, 18, 482–489. [Google Scholar] [CrossRef]

- Su, X.; Yang, Y. Research on track overlapping during selective laser melting of powders. J. Mater. Process. Technol. 2012, 212, 2074–2079. [Google Scholar] [CrossRef]

- Di, W.; Yongqiang, Y.; Xubin, S.; Yonghua, C. Study on energy input and its influences on single-track, multi-track, and multi-layer in SLM. Int. J. Adv. Manuf. Technol. 2012, 58, 1189–1199. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.-Q.; Huang, Y.-L.; Wu, W.-H.; Sun, T.-T.; He, X.-R. Impact of inter-layer scan strategy on quality of direct fabrication metal parts in SLM process. Laser Technol. 2010, 34, 447–451. [Google Scholar] [CrossRef]

- Wang, Y.; Li, R.; Niu, P.; Zhang, Z.; Yuan, T.; Yuan, J.; Li, K. Microstructures and properties of equimolar AlCoCrCuFeNi high-entropy alloy additively manufactured by selective laser melting. Intermetallics 2020, 120, 106746. [Google Scholar] [CrossRef]

- Luo, S.; Gao, P.; Yu, H.; Yang, J.; Wang, Z.; Zeng, X. Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical behavior. J. Alloy. Compd. 2019, 771, 387–397. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Choe, J.; Lee, K.-A. Selective laser melted equiatomic CoCrFeMnNi high-entropy alloy: Microstructure, anisotropic mechanical response, and multiple strengthening mechanism. J. Alloy. Compd. 2019, 805, 680–691. [Google Scholar] [CrossRef]

- Kenel, C.; Dasargyri, G.; Bauer, T.; Colella, A.; Spierings, A.B.; Leinenbach, C.; Wegener, K. Selective laser melting of an oxide dispersion strengthened (ODS) γ-TiAl alloy towards production of complex structures. Mater. Des. 2017, 134, 81–90. [Google Scholar] [CrossRef]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rashid, R.R.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J.P. The investigation of the influence of laser remelting on density, surface quality and microstructure of selective laser melting parts. Rapid Prototyp. J. 2011, 17, 312–327. [Google Scholar] [CrossRef]

- Lamikiz, A.; Sanchez, J.; de Lacalle, L.L.; Arana, J. Laser polishing of parts built up by selective laser sintering. Int. J. Mach. Tools Manuf. 2007, 47, 2040–2050. [Google Scholar] [CrossRef]

- Kang, N.; Fu, Y.; Coddet, P.; Guelorget, B.; Liao, H.; Coddet, C. On the microstructure, hardness and wear behavior of Al-Fe-Cr quasicrystal reinforced Al matrix composite prepared by selective laser melting. Mater. Des. 2017, 132, 105–111. [Google Scholar] [CrossRef]

- Ferrar, B.; Mullen, L.; Jones, E.; Stamp, R.; Sutcliffe, C. Gas flow effects on selective laser melting (SLM) manufacturing performance. J. Mater. Process. Technol. 2012, 212, 355–364. [Google Scholar] [CrossRef]

- Ladewig, A.; Schlick, G.; Fisser, M.; Schulze, V.; Glatzel, U. Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit. Manuf. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Huang, H.-Y. Effects of shielding gas composition and activating flux on GTAW weldments. Mater. Des. 2009, 30, 2404–2409. [Google Scholar] [CrossRef]

- Masmoudi, A.; Bolot, R.; Coddet, C. Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J. Mater. Process. Technol. 2015, 225, 122–132. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Effect of metal vaporization behavior on keyhole-mode surface morphology of selective laser melted composites using different protective atmospheres. Appl. Surf. Sci. 2015, 355, 310–319. [Google Scholar] [CrossRef]

- Vilaro, T.; Kottman-Rexerodt, V.; Thomas, M.; Colin, C.; Bertrand, P.; Thivillon, L.; Abed, S.; Ji, V.; Aubry, P.; Peyre, P. Direct fabrication of a Ti-47Al-2Cr-2Nb alloy by selective laser melting and direct metal deposition processes. Adv. Mater. Res. 2010, 89, 586–591. [Google Scholar]

- Ismaeel, A.; Wang, C.-S. Effect of Nb additions on microstructure and properties of γ-TiAl based alloys fabricated by selective laser melting. Trans. Nonferrous Met. Soc. China 2019, 29, 1007–1016. [Google Scholar] [CrossRef]

- Baudana, G.; Biamino, S.; Klöden, B.; Kirchner, A.; Weißgärber, T.; Kieback, B.; Pavese, M.; Ugues, D.; Fino, P.; Badini, C. Electron beam melting of Ti-48Al-2Nb-0.7 Cr-0.3 Si: Feasibility investigation. Intermetallics 2016, 73, 43–49. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.; Ceylan, A.; Martinez, E.; Martinez, J.; Hernandez, D.; Machado, B.; Ramirez, D.; Medina, F.; Collins, S. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

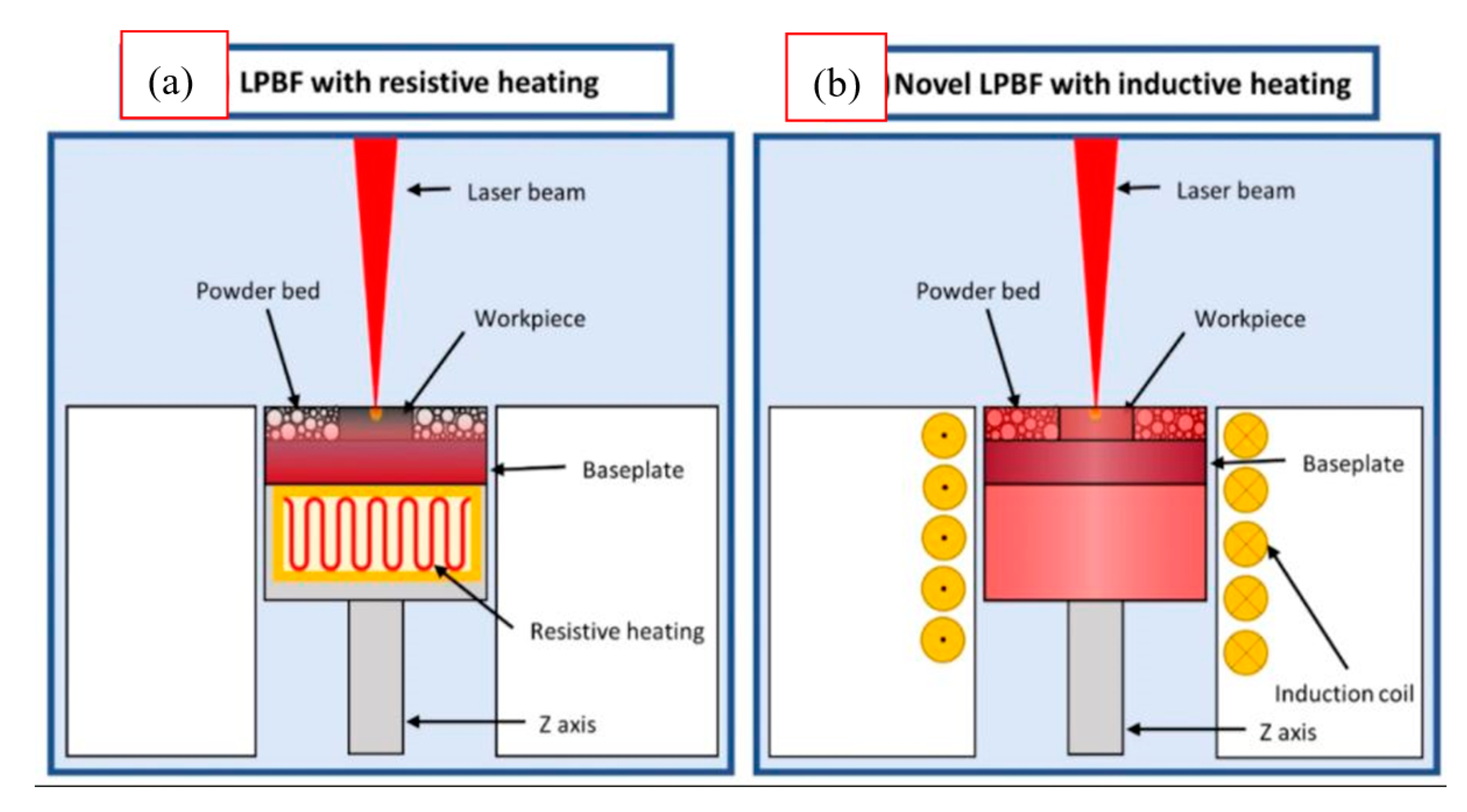

- Caprio, L.; Demir, A.G.; Chiari, G.; Previtali, B. Defect-free laser powder bed fusion of Ti–48Al–2Cr–2Nb with a high temperature inductive preheating system. J. Phys. Photonics 2020, 2, 024001. [Google Scholar] [CrossRef]

- Biamino, S.; Penna, A.; Ackelid, U.; Sabbadini, S.; Tassa, O.; Fino, P.; Pavese, M.; Gennaro, P.; Badini, C. Electron beam melting of Ti–48Al–2Cr–2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics 2011, 19, 776–781. [Google Scholar] [CrossRef]

- Terner, M.; Biamino, S.; Epicoco, P.; Penna, A.; Hedin, O.; Sabbadini, S.; Fino, P.; Pavese, M.; Ackelid, U.; Gennaro, P. Electron beam melting of high niobium containing TiAl alloy: Feasibility investigation. Steel Res. Int. 2012, 83, 943–949. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Dzogbewu, T.C. Additive manufacturing of TiAl-based alloys. Manuf. Rev. 2020, 7, 35. [Google Scholar] [CrossRef]

- Gussone, J.; Hagedorn, Y.-C.; Gherekhloo, H.; Kasperovich, G.; Merzouk, T.; Hausmann, J. Microstructure of γ-titanium aluminide processed by selective laser melting at elevated temperatures. Intermetallics 2015, 66, 133–140. [Google Scholar] [CrossRef]

- Löber, L.; Schimansky, F.P.; Kühn, U.; Pyczak, F.; Eckert, J. Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy. J. Mater. Process. Technol. 2014, 214, 1852–1860. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Domashenkov, A.; Smurov, I.; Petrovskiy, P. Comprehensive analysis of selective laser melting of TiAl powder. In Proceedings of the Lasers Manufacture Conference, München, Germany, 26–29 June 2017. [Google Scholar]

- Mogale, N.F.; Matizamhuka, W.R. Spark plasma sintering of titanium aluminides: A progress review on processing, structure-property relations, alloy development and challenges. Metals 2020, 10, 1080. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Crystal orientation, crystallographic texture and phase evolution in the Ti–45Al–2Cr–5Nb alloy processed by selective laser melting. Mater. Charact. 2016, 113, 125–133. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Zhou, Y.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Effect of substrate preheating on the texture, phase and nanohardness of a Ti–45Al–2Cr–5Nb alloy processed by selective laser melting. Scr. Mater. 2016, 118, 13–18. [Google Scholar] [CrossRef]

- Okamoto, H.; Okamoto, H. Phase Diagrams for Binary Alloys; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Li, W.; Liu, J.; Zhou, Y.; Li, S.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Effect of laser scanning speed on a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting: Microstructure, phase and mechanical properties. J. Alloy. Compd. 2016, 688, 626–636. [Google Scholar] [CrossRef]

- Gussone, J.; Garces, G.; Haubrich, J.; Stark, A.; Hagedorn, Y.-C.; Schell, N.; Requena, G. Microstructure stability of γ-TiAl produced by selective laser melting. Scr. Mater. 2017, 105, 110–113. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q. Parameter optimization for Ti-47Al-2Cr-2Nb in selective laser melting based on geometric characteristics of single scan tracks. Opt. Laser Technol. 2017, 90, 71–79. [Google Scholar] [CrossRef]

- Shi, X.; Wang, H.; Feng, W.; Zhang, Y.; Ma, S.; Wei, J. The crack and pore formation mechanism of Ti–47Al–2Cr–2Nb alloy fabricated by selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 91, 105247. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Liu, J.; Zhou, Y.; Li, M.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Enhanced nanohardness and new insights into texture evolution and phase transformation of TiAl/TiB2 in-situ metal matrix composites prepared via selective laser melting. Acta Mater. 2017, 136, 90–104. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, S.; Hou, Y.; Wang, D.; Zhou, P.; Han, P.; Li, Y.; Yan, M. Layered surface structure of gas-atomized high Nb-containing TiAl powder and its impact on laser energy absorption for selective laser melting. Appl. Surf. Sci. 2018, 441, 210–217. [Google Scholar] [CrossRef]

- Praveen, S.; Kim, H.S. High-entropy alloys: Potential candidates for high-temperature applications–An overview. Adv. Eng. Mater. 2018, 20, 1700645. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Cheng, X.; Wu, C.; Cheng, B.; Xu, Z. The microstructure and mechanical properties of refractory high-entropy alloys with high plasticity. Materials 2018, 11, 208. [Google Scholar] [CrossRef] [PubMed]

- Ogura, M.; Fukushima, T.; Zeller, R.; Dederichs, P.H. Structure of the high-entropy alloy AlxCrFeCoNi: Fcc versus bcc. J. Alloy. Compd. 2017, 715, 454–459. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- MacKay, R.A.; Gabb, T.P.; Smialek, J.L.; Nathal, M.V. A new approach of designing superalloys for low density. JOM 2010, 62, 48–54. [Google Scholar] [CrossRef]

- Yeh, A.; Tsao, T.; Chang, Y.; Chang, K.; Yeh, J.; Chiou, M.; Jian, S.; Kuo, C.; Wang, W.; Murakami, H. Developing new type of high temperature alloys–High entropy superalloys. Int. J. Metall. Mater. Eng. 2015, 1, 4. [Google Scholar]

- Yeh, A.-C.; Chang, Y.-J.; Tsai, C.-W.; Wang, Y.-C.; Yeh, J.-W.; Kuo, C.-M. On the solidification and phase stability of a Co-Cr-Fe-Ni-Ti high-entropy alloy. MMTA 2014, 45, 184–190. [Google Scholar] [CrossRef]

- Manzoni, A.M.; Singh, S.; Daoud, H.M.; Popp, R.; Völkl, R.; Glatzel, U.; Wanderka, N. On the path to optimizing the Al-Co-Cr-Cu-Fe-Ni-Ti high entropy alloy family for high temperature applications. Entropy 2016, 18, 104. [Google Scholar] [CrossRef]

- Tsao, T.K.; Yeh, A.C.; Kuo, C.M.; Murakami, H. On the superior high temperature hardness of precipitation strengthened high entropy Ni-based alloys. Adv. Eng. Mater. 2017, 19, 1600475. [Google Scholar] [CrossRef]

- Ranganathan, S. Alloyed pleasures: Multimetallic cocktails. Curr. Sci. 2003, 85, 1404–1406. [Google Scholar]

- Miracle, D.; Miller, J.; Senkov, O.; Woodward, C.; Uchic, M.; Tiley, J. Exploration and development of high entropy alloys for structural applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.-W.; Ranganathan, S.; Bhattacharjee, P. High-Entropy Alloys; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Guo, J.; Goh, M.; Zhu, Z.; Lee, X.; Nai, M.L.S.; Wei, J. On the machining of selective laser melting CoCrFeMnNi high-entropy alloy. Mater. Des. 2018, 153, 211–220. [Google Scholar] [CrossRef]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Piglione, A.; Dovgyy, B.; Liu, C.; Gourlay, C.M.; Hooper, P.A.; Pham, M.S. Printability and microstructure of the CoCrFeMnNi high-entropy alloy fabricated by laser powder bed fusion. Mater. Lett. 2018, 224, 22–25. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, K.; Kokawa, H.; Han, B.; Li, Z. Cracking mechanism and mechanical properties of selective laser melted CoCrFeMnNi high entropy alloy using different scanning strategies. Mater. Sci. Eng. A 2020, 789, 139672. [Google Scholar] [CrossRef]

- Zhu, Z.; An, X.; Lu, W.; Li, Z.; Ng, F.; Liao, X.; Ramamurty, U.; Nai, S.; Wei, J. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy. Mater. Res. Lett. 2019, 7, 453–459. [Google Scholar] [CrossRef]

- Chen, P.; Li, S.; Zhou, Y.; Yan, M.; Attallah, M.M. Fabricating CoCrFeMnNi high entropy alloy via selective laser melting in-situ alloying. J. Mater. Sci. Technol. 2020, 43, 40–43. [Google Scholar] [CrossRef]

- Chen, P.; Yang, C.; Li, S.; Attallah, M.M.; Yan, M. In-situ alloyed, oxide-dispersion-strengthened CoCrFeMnNi high entropy alloy fabricated via laser powder bed fusion. Mater. Des. 2020, 194, 108966. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloy. Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Jing, H.; Han, Y.; Zhao, L.; Minami, F. Effects of annealing on the structure and mechanical properties of FeCoCrNi high-entropy alloy fabricated via selective laser melting. Addit. Manuf. 2020, 32, 101058. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.P.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Lim, C.S. Revealing hot tearing mechanism for an additively manufactured high-entropy alloy via selective laser melting. Scr. Mater. 2019, 168, 129–133. [Google Scholar] [CrossRef]

- Fujieda, T.; Chen, M.; Shiratori, H.; Kuwabara, K.; Yamanaka, K.; Koizumi, Y.; Chiba, A.; Watanabe, S. Mechanical and corrosion properties of CoCrFeNiTi-based high-entropy alloy additive manufactured using selective laser melting. Addit. Manuf. 2019, 25, 412–420. [Google Scholar] [CrossRef]

- Park, J.M.; Choe, J.; Park, H.K.; Son, S.; Jung, J.; Kim, T.-S.; Yu, J.-H.; Kim, J.G.; Kim, H.S. Synergetic strengthening of additively manufactured (CoCrFeMnNi)99C1 high-entropy alloy by heterogeneous anisotropic microstructure. Addit. Manuf. 2020, 35, 101333. [Google Scholar]

- Park, J.M.; Choe, J.; Kim, J.G.; Bae, J.W.; Moon, J.; Yang, S.; Kim, K.T.; Yu, J.-H.; Kim, H.S. Superior tensile properties of 1% C-CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting. Mater. Res. Lett. 2020, 8, 1–7. [Google Scholar] [CrossRef]

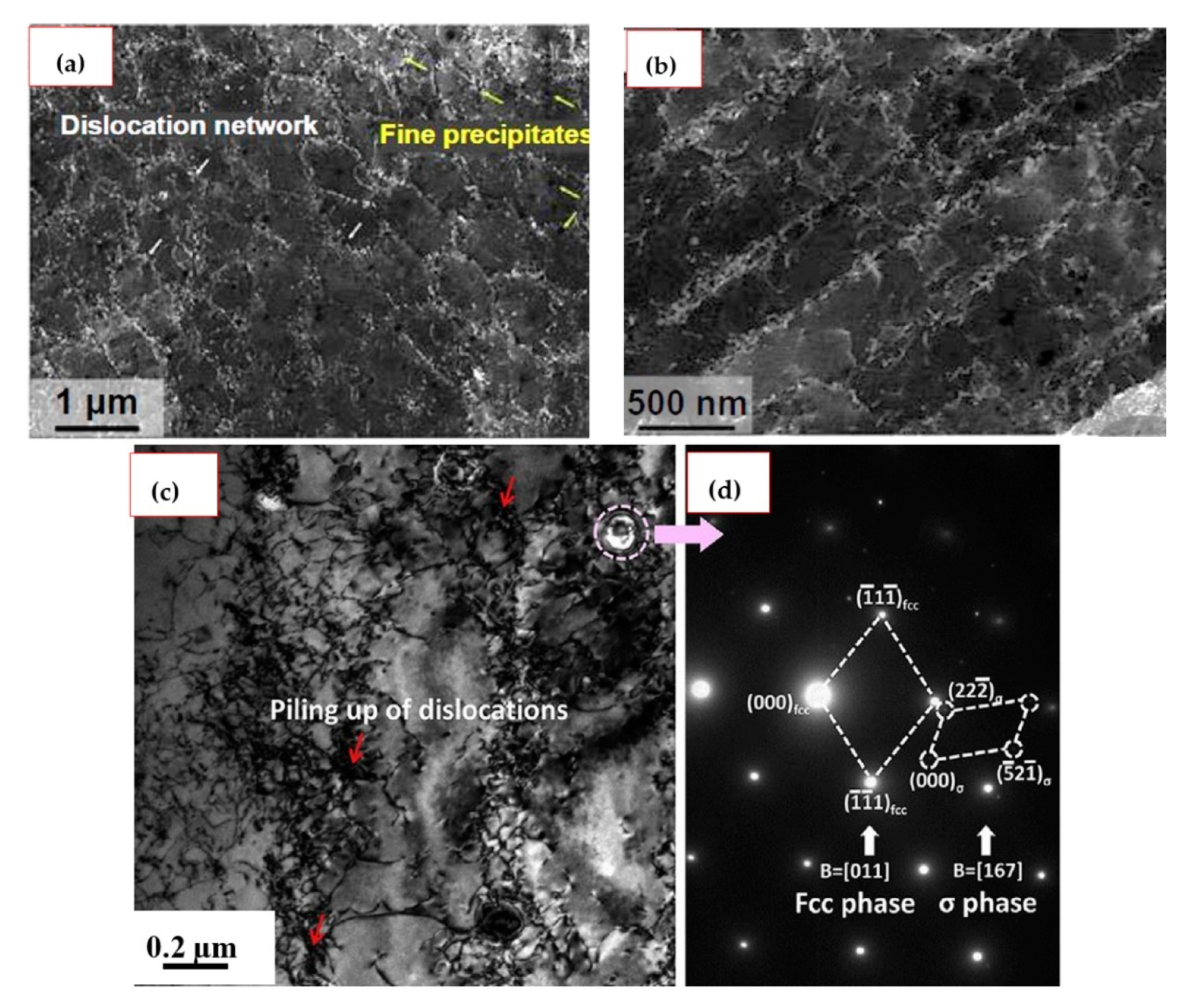

- Wu, W.; Zhou, R.; Wei, B.; Ni, S.; Liu, Y.; Song, M. Nanosized precipitates and dislocation networks reinforced C-containing CoCrFeNi high-entropy alloy fabricated by selective laser melting. Mater. Charact. 2018, 144, 605–610. [Google Scholar] [CrossRef]

- Zhou, R.; Liu, Y.; Zhou, C.; Li, S.; Wu, W.; Song, M.; Liu, B.; Liang, X.; Liaw, P. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics 2018, 94, 165–171. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Li, X.; Jing, H.; Qin, G.; Pang, H.; Minami, F. A Si-containing FeCoCrNi high-entropy alloy with high strength and ductility synthesized in situ via selective laser melting. Addit. Manuf. 2020, 35, 101340. [Google Scholar] [CrossRef]

- Luo, S.; Zhao, C.; Su, Y.; Liu, Q.; Wang, Z. Selective laser melting of dual phase AlCrCuFeNix high entropy alloys: Formability, heterogeneous microstructures and deformation mechanisms. Addit. Manuf. 2020, 31, 100925. [Google Scholar] [CrossRef]

- Yao, H.; Tan, Z.; He, D.; Zhou, Z.; Zhou, Z.; Xue, Y.; Cui, L.; Chen, L.; Wang, G.; Yang, Y. High strength and ductility AlCrFeNiV high entropy alloy with hierarchically heterogeneous microstructure prepared by selective laser melting. J. Alloy. Compd. 2020, 813, 152196. [Google Scholar] [CrossRef]

- Peyrouzet, F.; Hachet, D.; Soulas, R.; Navone, C.; Godet, S.; Gorsse, S. Selective laser melting of Al0.3CoCrFeNi high-entropy alloy: Printability, microstructure, and mechanical properties. JOM 2019, 71, 3443–3451. [Google Scholar] [CrossRef]

- Zhou, P.; Xiao, D.; Wu, Z.; Ou, X. Al0.5FeCoCrNi high entropy alloy prepared by selective laser melting with gas-atomized pre-alloy powders. Mater. Sci. Eng. A 2019, 739, 86–89. [Google Scholar] [CrossRef]

- Karlsson, D.; Marshal, A.; Johansson, F.; Schuisky, M.; Sahlberg, M.; Schneider, J.M.; Jansson, U. Elemental segregation in an AlCoCrFeNi high-entropy alloy–A comparison between selective laser melting and induction melting. J. Alloy. Compd. 2019, 784, 195–203. [Google Scholar] [CrossRef]

- Niu, P.; Li, R.; Yuan, T.; Zhu, S.; Chen, C.; Wang, M.; Huang, L. Microstructures and properties of an equimolar AlCoCrFeNi high entropy alloy printed by selective laser melting. Intermetallics 2019, 104, 24–32. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Kim, H.S. High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties. Prog. Mater. Sci. 2020, 100709, in press. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Nguyen, Q.B.; Ng, F.L.; An, X.H.; Liao, X.Z.; Liaw, P.K.; Nai, S.M.L.; Wei, J. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 2018, 154, 20–24. [Google Scholar] [CrossRef]

- Beyramali Kivy, M.; Asle Zaeem, M. Generalized stacking fault energies, ductilities, and twinnabilities of CoCrFeNi-based face-centered cubic high entropy alloys. Scr. Mater. 2017, 139, 83–86. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C.; Du, Z.; Hou, Z.; Lin, P.; Chen, Y. Microstructure and tensile properties of hot fogred high Nb containing TiAl based alloy with initial near lamellar microstructure. Mater. Sci. Eng. A 2015, 642, 16–21. [Google Scholar] [CrossRef]

- Jabbar, H.; Monchoux, J.-P.; Houdellier, F.; Dollé, M.; Schimansky, F.-P.; Pyczak, F.; Thomas, M.; Couret, A. Microstructure and mechanical properties of high niobium containing TiAl alloys elaborated by spark plasma sintering. Intermetallics 2010, 18, 2312–2321. [Google Scholar] [CrossRef][Green Version]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Kim, J.; Wakai, A.; Moridi, A. Materials and manufacturing renaissance: Additive manufacturing of high-entropy alloys. J. Mater. Res. 2020, 35, 1963–1983. [Google Scholar] [CrossRef]

- Löber, L.; Biamino, S.; Ackelid, U.; Sabbadini, S.; Epicoco, P.; Fino, P.; Eckert, J. Comparison of selective laser and electron beam melted titanium aluminides. In Proceedings of the Conference Paper of 22nd International Symposium “Solid Freeform Fabrication Proceedings”, Austin, TX, USA, 8–10 August 2011; pp. 547–556. [Google Scholar]

- Yang, Y.; Wen, S.; Wei, Q.; Li, W.; Liu, J.; Shi, Y. Effect of scan line spacing on texture, phase and nanohardness of TiAl/TiB2 metal matrix composites fabricated by selective laser melting. J. Alloy. Compd. 2017, 728, 803–814. [Google Scholar] [CrossRef]

- Kenel, C.; Leinenbach, C. Influence of Nb and Mo on microstructure formation of rapidly solidified ternary Ti–Al- (Nb, Mo) alloys. Intermetallics 2016, 69, 82–89. [Google Scholar] [CrossRef]

- Kenel, C.; Leinenbach, C. Influence of cooling rate on microstructure formation during rapid solidification of binary TiAl alloys. J. Alloy. Compd. 2015, 637, 242–247. [Google Scholar] [CrossRef]

| LPBF Processing Parameters | Materials Characteristics |

|---|---|

| Type of commercial equipment | Particle morphology |

| Laser type | Particle size and distribution |

| Laser power | Chemical composition |

| Scan speed | Absorptivity (or reflectivity) |

| Scan radius | Melting temperature |

| Scan Hatch spacing | Specific heat |

| Scan vector length | Thermal conductivity |

| Layer thickness | Viscosity |

| Processing environment | Surface tension |

| Gas flow | Emissivity |

| Heaters (bed temperature) | Component ratio |

| Scan strategy | Boiling point |

| Material | CO2 Laser (λ = 10.6 µm) | Nd:YAG Laser (λ = 1.06 µm) |

|---|---|---|

| Cu | 0.26 | 0.59 |

| Fe | 0.45 | 0.64 |

| Sn | 0.23 | 0.66 |

| Ti | 0.59 | 0.77 |

| Pb | - | 0.79 |

| Cu-10Al (wt.%) | 0.32 | 0.63 |

| Co-alloy (1% C; 28% Cr; 4% W) | 0.25 | 0.58 |

| Ni-alloy I (13% Cr; 3% B; 4% Si; 0.6% C) | 0.64 | 0.42 |

| Ni-alloy II (15% Cr; 3.1% Si; 4%; 0.8% C) | 0.72 | 0.51 |

| Fe-3C-3Cr-12 V + 10TiC (wt.%) | 0.39 | 0.65 |

| Fe-0.6C-4Cr-2Mo-1Si + 15TiC (wt.%) | 0.42 | 0.71 |

| Fe-1C-14Cr-10Mn-6Ti + 66TiC (wt.%) | 0.44 | 0.79 |

| TiAl-Based Alloy Composition (at.%) | Phase Composition | LPBF Process Parameters | Reported Relative Density | Microstructure | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Laser Power (W) | Scanning Speed (mm·s−1) | Hatch Scan Distance (µm) | Layer Thickness (µm) | Scan Strategy | |||||

| Ti-48Al-2Cr-2Nb | 90 | 600 | 90 | 60 | 90° | 93% ± 2% | Lamellar | [33] | |

| 0 | 90 | 77% ± 2% | |||||||

| 1000 | 80 | 84% ± 3% | |||||||

| 1400 | 80 | 78% ± 4% | |||||||

| Ti-47Al-2Cr-2Nb | 200 | 20 | - | 100 | - | 98.95% | - | [105] | |

| 0.3 | cross scanning | 94.1% | Near-lamellar | [106] | |||||

| 30 | 0.25 | 94.3% | |||||||

| 250 | 30 | 0.3 | 92.5% | ||||||

| 40 | 0.25 | 93.4% | |||||||

| 300 | 40 | 0.3 | 89.3% | ||||||

| 50 | 0.25 | 91.0% | |||||||

| Ti-47Al-2Cr-2Nb | (as built); (after heat treatment) | 50 | 50 | 160 | - | - | - | mixed (as built); duplex or fully lamellar (after heat treatments) | [86] |

| Ti-44.8Al-6Nb-1.0Mo-0.1B | 80 | 450 | 100 | 30 | cross-hatching scan strategy with zigzag scan vectors | mixed | [95,104] | ||

| Ti-45Al-2Cr-5Nb | 250 | 500 | 100 | 20 | long bidirectional scanning vectors with 90° rotation between consecutive layers | 97.18% | mixed | [100] | |

| 300 | - | ||||||||

| 350 | - | ||||||||

| 200 | 400 | 100 | 30 | - | [101] | ||||

| 500 | 92.25% | equiaxed | [103] | ||||||

| 600 | 91.79% | ||||||||

| 700 | 91.33% | ||||||||

| 800 | 90.68% | ||||||||

| Ti-45Al-2Cr-5Nb + (0 wt.% TiB2) | 300 | 800 | 100 | 30 | 93.44% | [107] | |||

| Ti-45Al-2Cr-5Nb + (1 wt.% TiB2) | 92.18% | ||||||||

| Ti-45Al-2Cr-5Nb + (2 wt.% TiB2) | 91.33% | ||||||||

| Ti-45Al-2Cr-5Nb + (3 wt.% TiB2) | 85.16% | ||||||||

| Ti-28.9Al-9.68Nb-2.26Mo-0.024B wt.% | 100 | 50 | 300 | 75 | stripe hatching | 99.0% | fine grained nearly lamellar | [96] | |

| 175 | 1000 | ||||||||

| Ti-45Al-8Nb | - | 180 | 550 | 120 | 30 | - | 98.70% | - | [108] |

| HEA Composition | Lattice Structure | LPBF Process Parameters | Reported Relative Density (or Max Density Achieved) | Microstructure | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Laser Power (W) | Scanning Speed (mm·s−1) | Hatch Scan Distance (µm) | Layer Thickness (µm) | Scan Strategy | |||||

| CoCrFeNiMn | FCC | 240 | 2000 | 50 | 40 | - | 99.2% | - | [121] |

| FCC | 200 | - | 125 | 60 | unidirectional | 99.29% | columnar | [123] | |

| FCC | 240 | 2000 | 50 | 40 | 90° | 99.2% | mixed | [125] | |

| FCC | 240 | 2500 | 50 | 40 | 90° | 97.1% | mixed | ||

| FCC | 280 | 800 | 60 | 30 | Chessboard pattern | 7.89 g·cm−3 | columnar | [126,127] | |

| FCC | 160 | 1200 | 50 | 30 | 0°, 67°, 90° | - | columnar | [124] | |

| FCC + tetragonal σ | 400 | 2000 | 90 | 30 | 67° | 98.2% | mixed | [128] | |

| CoCrFeNi | FCC | 200 | 740 | 40 | 40 | 67° | 99.71% ± 0.25% | mixed | [129] |

| FCC | 200 | 300 | - | 20 | - | - | - | [122] | |

| FCC | 150 | 270 | 100 | 50 | chessboard and stripe/bi-directional | 98.7% | columnar | [130] | |

| Co1.5CrFeNi1.5Ti0.5Mo0.1 | SC + FCC | 160 | 650 | 100 | 40 | - | 99.3% | columnar | [131] |

| (CoCrFeMnNi)99C1 | FCC + Mn-rich oxide and sulfide, Cr-rich carbide | 90 | 600 | 80 | 25 | 180° with raster scanning pattern | - | mixed | [132] |

| 90 | 200 | 80 | 25 | - | columnar | [133] | |||

| CoCrFeNiC0.05 | FCC | 400 | 800 | 110 | 50 | 67° | 99% | - | [134,135] |

| CoCrFeNiSi1.5 | FCC | 197 | - | 41 | 40 | 67° | 99.01 ± 0.11 | mixed | [136] |

| 133 | - | 97 | 40 | 99.85 ± 0.13 | |||||

| AlCoCrCuFeNi | FCC + BCC | 300 | 1600 | 90 | 40 | 67° | 7.08 g·cm−3 | mixed | [73] |

| AlCrCuFeNix (x = 2.0, 2.5, 2.75,3.0) | FCC + BCC (B2) (of nanoscale lamellar or cellular structures) | 200 | 400 | 80 | 20 | 90° | >99.7% | mixed | [137] |

| AlCrCuFeNi | BCC (containing B2 + Cu-rich nano precipitates) | 300 | 600 | 80 | 40 | 90° | >99.7% | columnar | [74] |

| Al0.5Cr0.9FeNi2.5V0.2 | FCC + L12 | 140 | 900 | 50 | 30 | 67° | 99.88% | mixed | [138] |

| Al0.3CrFeCoNi | FCC | 160 | 1100 | 45 | 25 | 67° | 99.9% | columnar | [139] |

| Al0.5CrFeCoNi | FCC | 400 | 1600 | 90 | 40 | 67° | - | mixed | [140] |

| AlCoCrFeNi | BCC + B2 | 98 | 2000 | 52 | 20 | 67° | - | equiaxed | [141] |

| AlCoCrFeNi | BCC + B2 | 400 | 1000 | 90 | 40 | 67° | 98.4% | mixed | [142] |

| Fe49.5Mn30Co10Cr10C0.5 | FCC | 180 | 1000 | 55 | 40 | 67° | - | mixed | [125] |

| TiAl-Based Alloy Composition (at.%) | Mechanical Property Evaluated | Main Findings | Reference |

|---|---|---|---|

| Ti- 48Al-2Cr-2Nb | Compression |

| [150] |

| Ti-44.8Al-6Nb-1.0Mo-0.1B | Tensile at room and high temperature (850 °C) |

| [95] |

| (47- x)Ti- 48Al-2Mn-xNb (x = 3, 4, 5, 6, 7) | Microhardness, compression, and friction-wear |

| [87] |

| Ti-45Al-2Cr-5Nb | Nanohardness |

| [101] |

| Ti-45Al-2Cr-5Nb + (xTiB2) (x = 1, 2, 3 wt.%) | Nanohardness |

| [106] |

| Ti- 48Al-2Cr-2Nb | Microhardness |

| [33] |

| Ti-28.9Al-9.68Nb-2.26Mo-0.024B wt.% | Compression |

| [96] |

| Ti-45Al-2Cr-5Nb + (1 wt.% TiB2) | Nanohardness |

| [151] |

| HEA Composition | Reported Relative Density (or Max Density Achieved) | Mechanical Properties Evaluated | Main Findings | Reference |

|---|---|---|---|---|

| CoCrFeNiMn | 99.2% | Microhardness |

| [121] |

| 99.2% | Tensile |

| [144] | |

| - | Compression |

| [75] | |

| 7.89 g.cm−3 | Microhardness, tensile |

| [126,127] | |

| 98.2% | Tensile |

| [128] | |

| CoCrFeNi | 99.71% ± 0.25% | Microhardness, tensile and impact toughness |

| [129] |

| 98.7% | Tensile |

| [130] | |

| Co1.5CrFeNi1.5Ti0.5Mo0.1 | 99.3% | Tensile | As-built

| [131] |

| (CoCrFeMnNi)99C1 | - | Tensile |

| [132] |

| [133] | |||

| CoCrFeNiC0.05 | 99% | Tensile |

| [134,135] |

| AlCoCrCuFeNi | 7.08 g.cm−3 | Microhardness |

| [73] |

| AlCrCuFeNix (x=2.0, 2.5. 2.75,3.0) | > 99.7% | Tensile |

| [137] |

| AlCrCuFeNi | > 99.7% | Compression |

| [74] |

| Al0.5Cr0.9FeNi2.5V0.2 | 99.88% | Tensile |

| [138] |

| Al0.3CrFeCoNi | 99.9% | Tensile |

| [139] |

| Al0.5CrFeCoNi | - | Microhardness, tensile |

| [140] |

| AlCoCrFeNi | 98.4% | Microhardness |

| [142] |

| Fe49.5Mn30Co10Cr10C0.5 | - | Tensile |

| [125] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2021, 11, 58. https://doi.org/10.3390/met11010058

Cobbinah PV, Nzeukou RA, Onawale OT, Matizamhuka WR. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals. 2021; 11(1):58. https://doi.org/10.3390/met11010058

Chicago/Turabian StyleCobbinah, Prince Valentine, Rivel Armil Nzeukou, Omoyemi Temitope Onawale, and Wallace Rwisayi Matizamhuka. 2021. "Laser Powder Bed Fusion of Potential Superalloys: A Review" Metals 11, no. 1: 58. https://doi.org/10.3390/met11010058

APA StyleCobbinah, P. V., Nzeukou, R. A., Onawale, O. T., & Matizamhuka, W. R. (2021). Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals, 11(1), 58. https://doi.org/10.3390/met11010058