Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

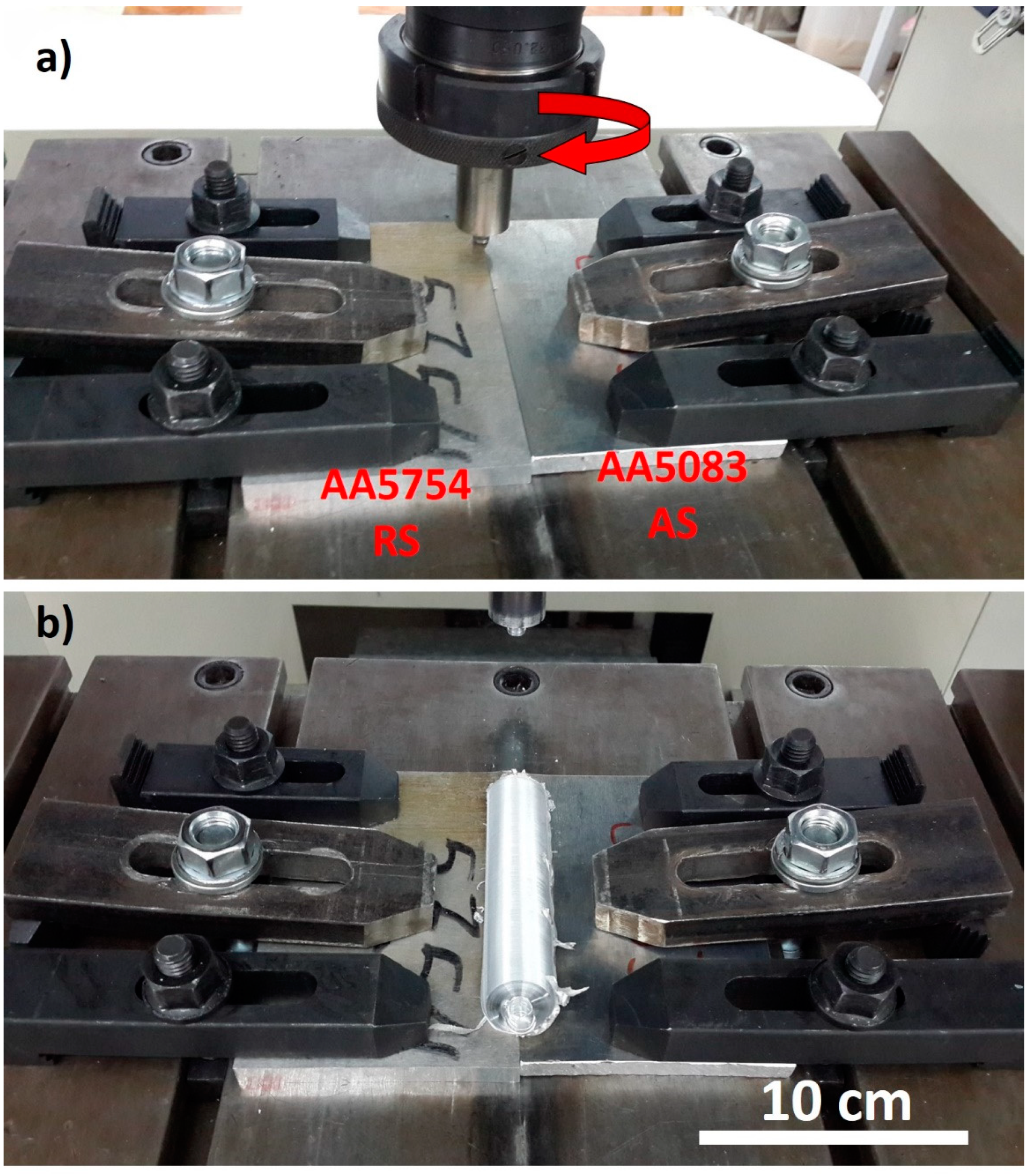

2.2. Friction Stir Welding Procedure

2.3. Macrostructural Investigation

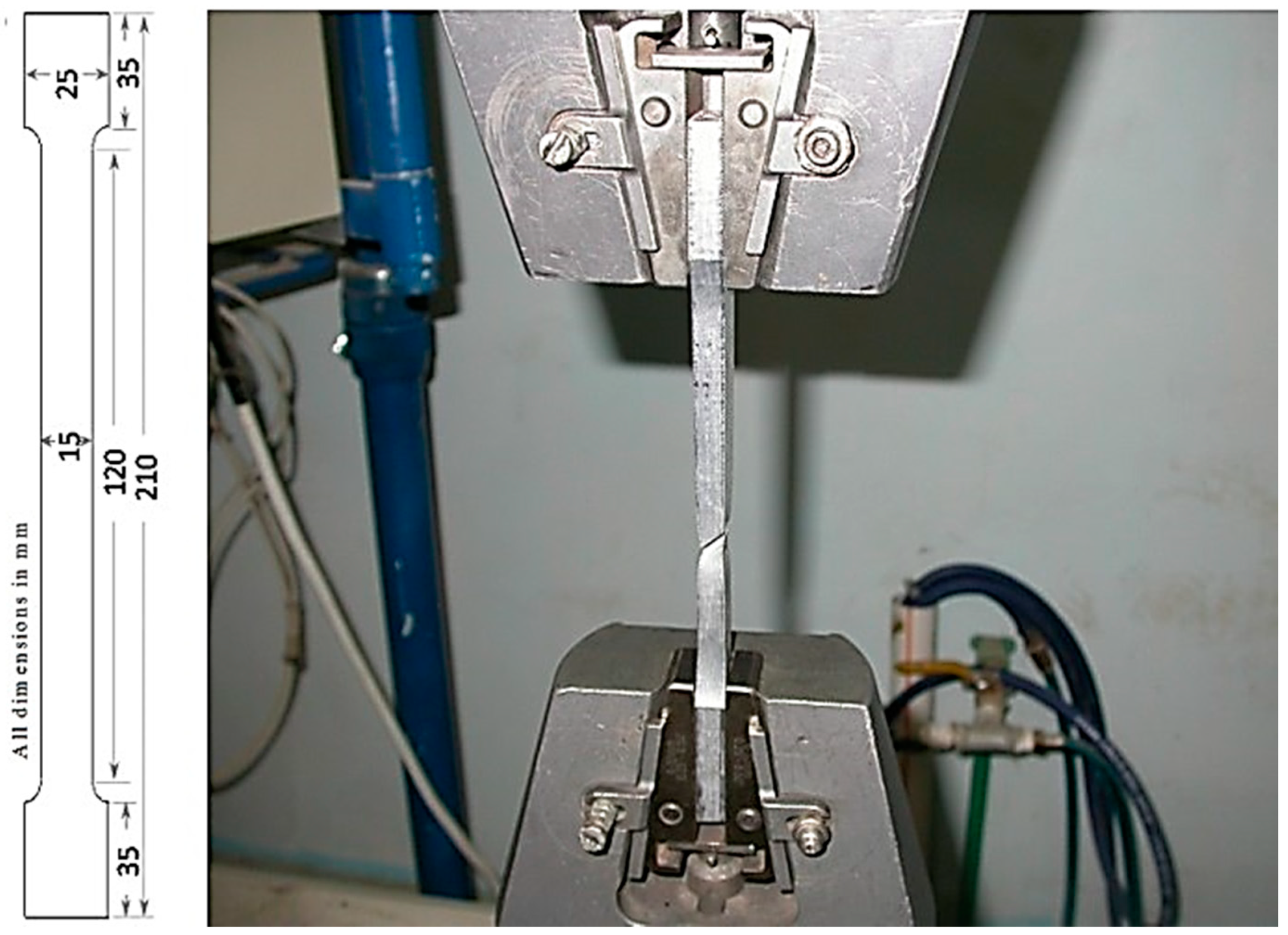

2.4. Mechanical Properties

3. Results and Discussion

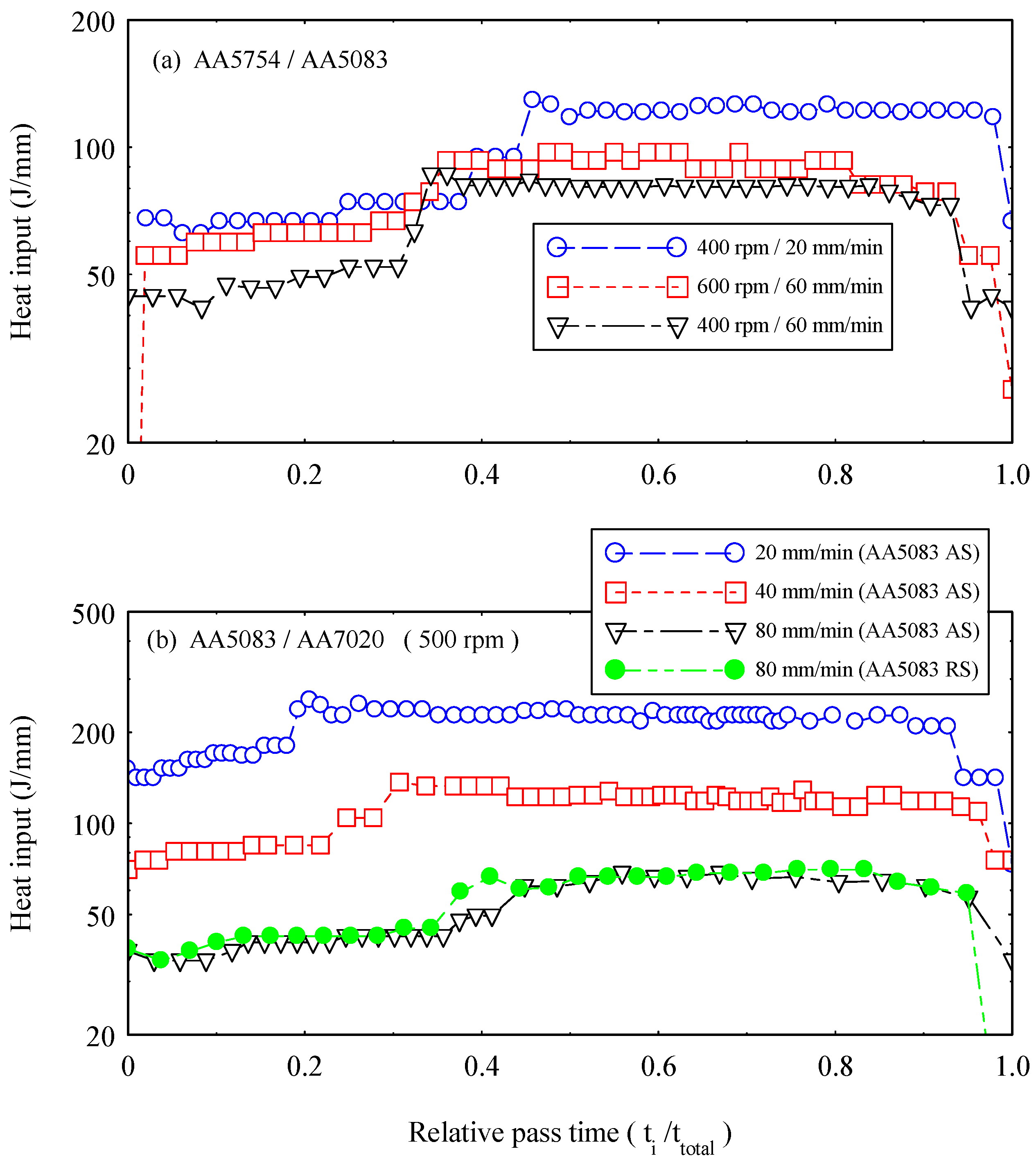

3.1. Effect of FSW Parameters on the Heat Input

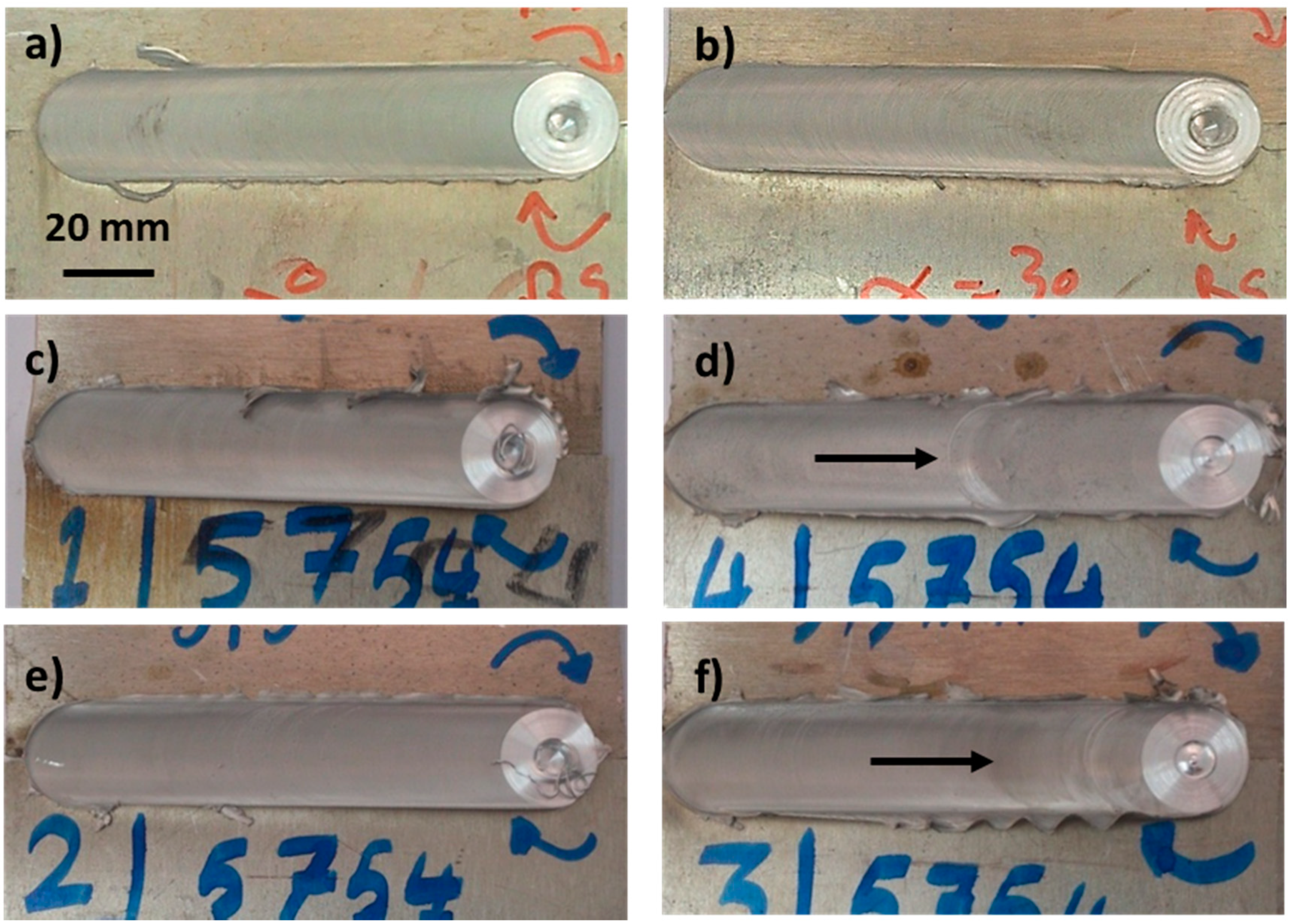

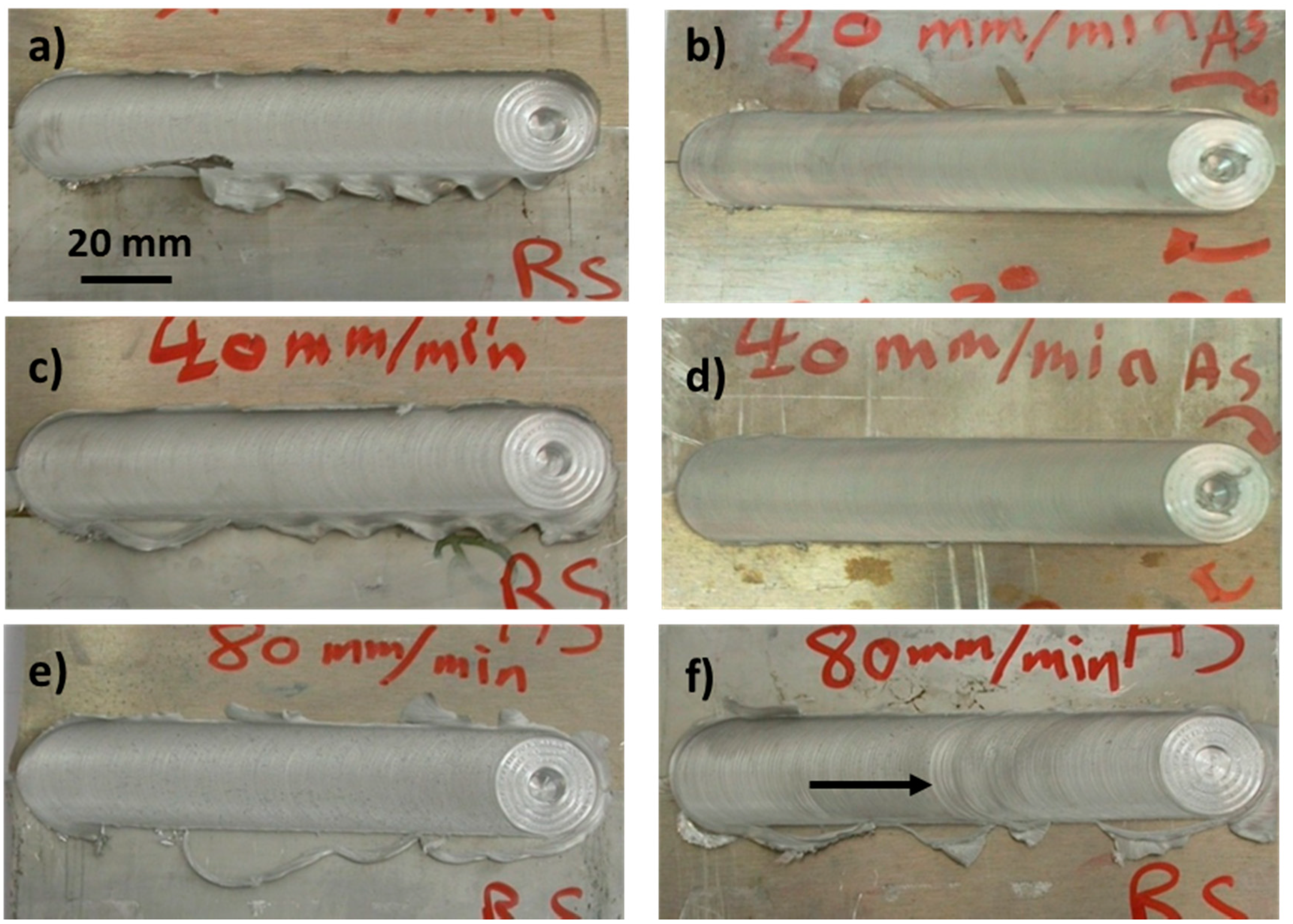

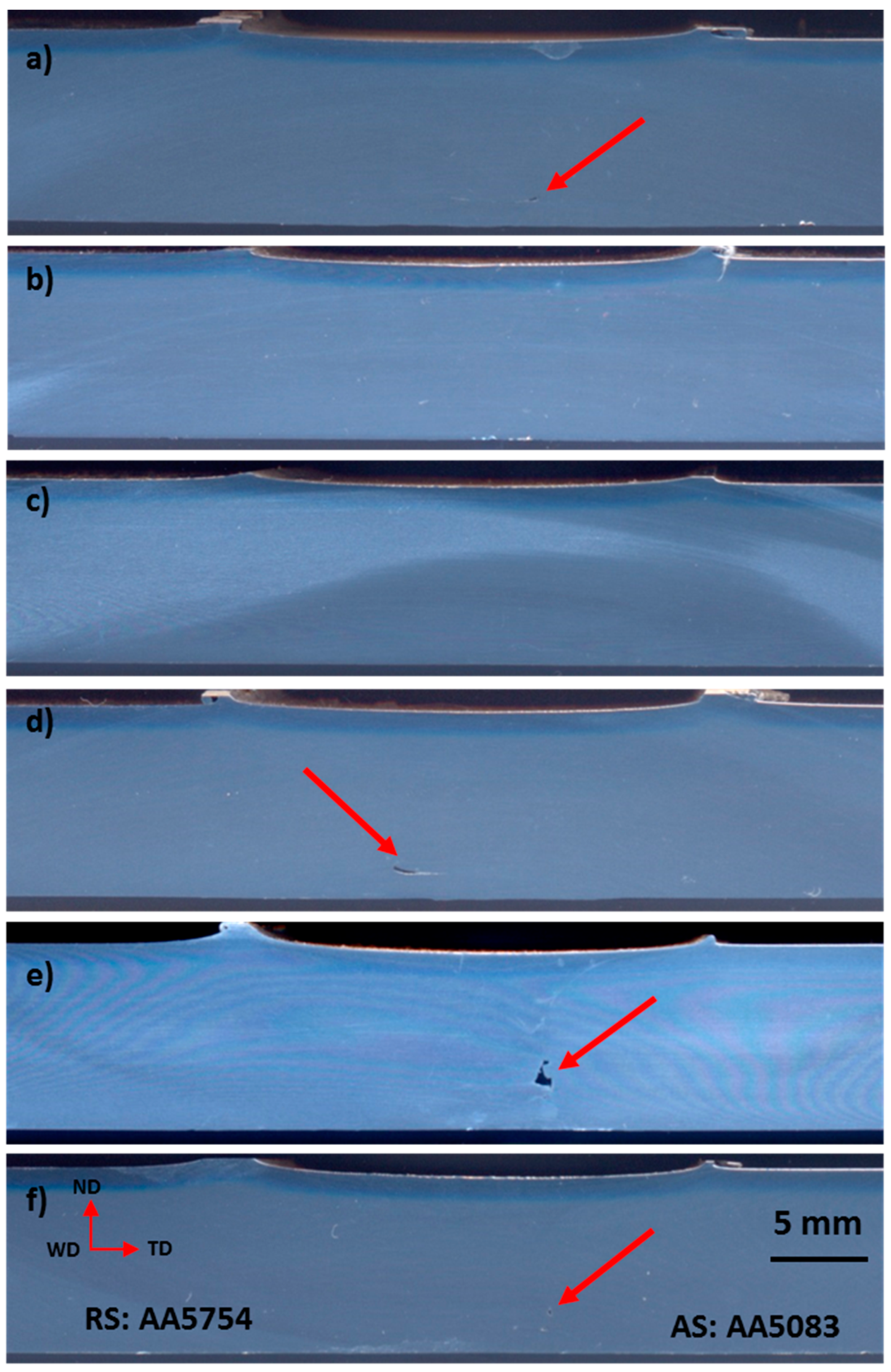

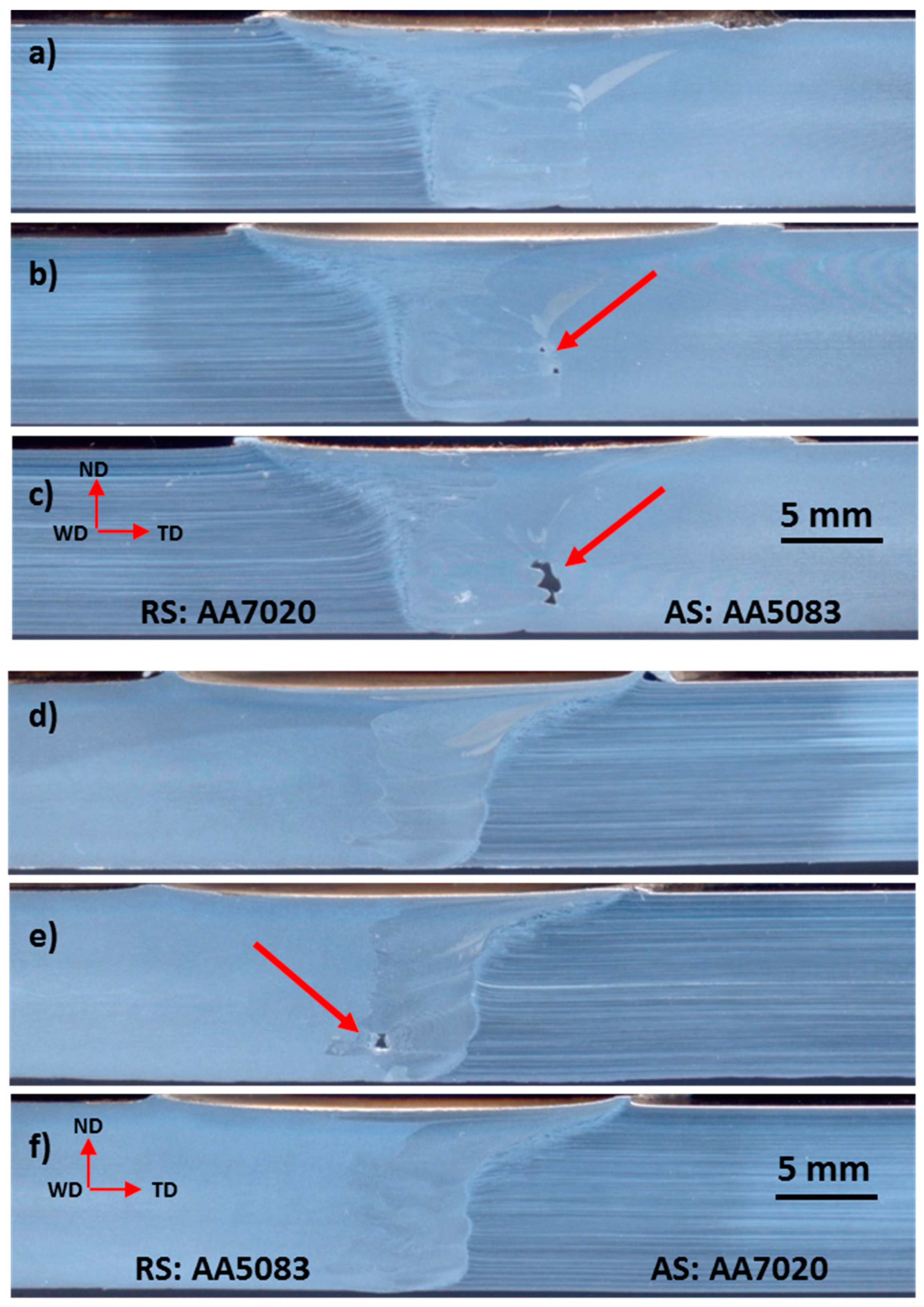

3.2. Joint Appearance and Internal Quality

3.3. Mechanical Properties

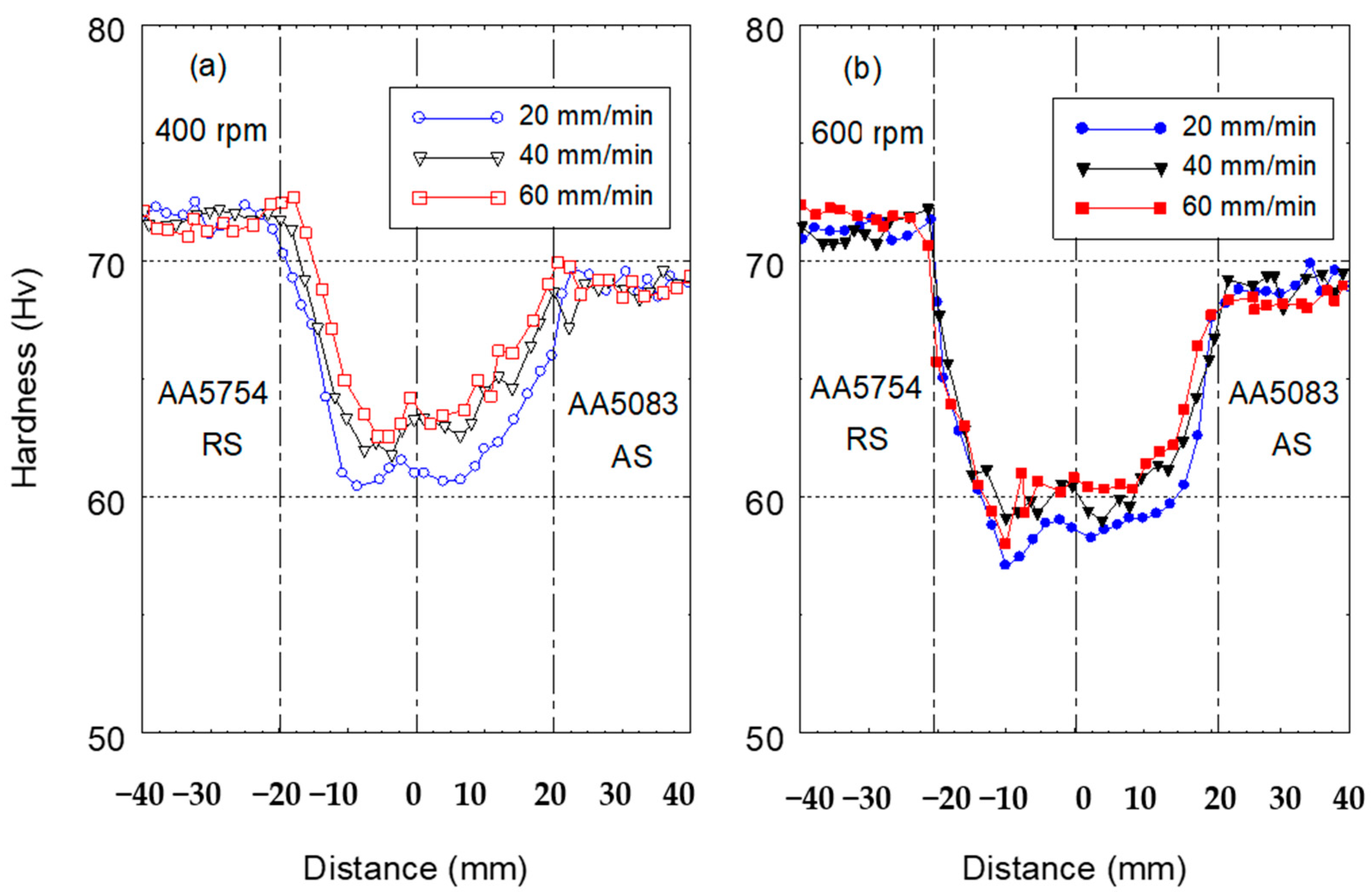

3.3.1. Macro-Hardness Distribution

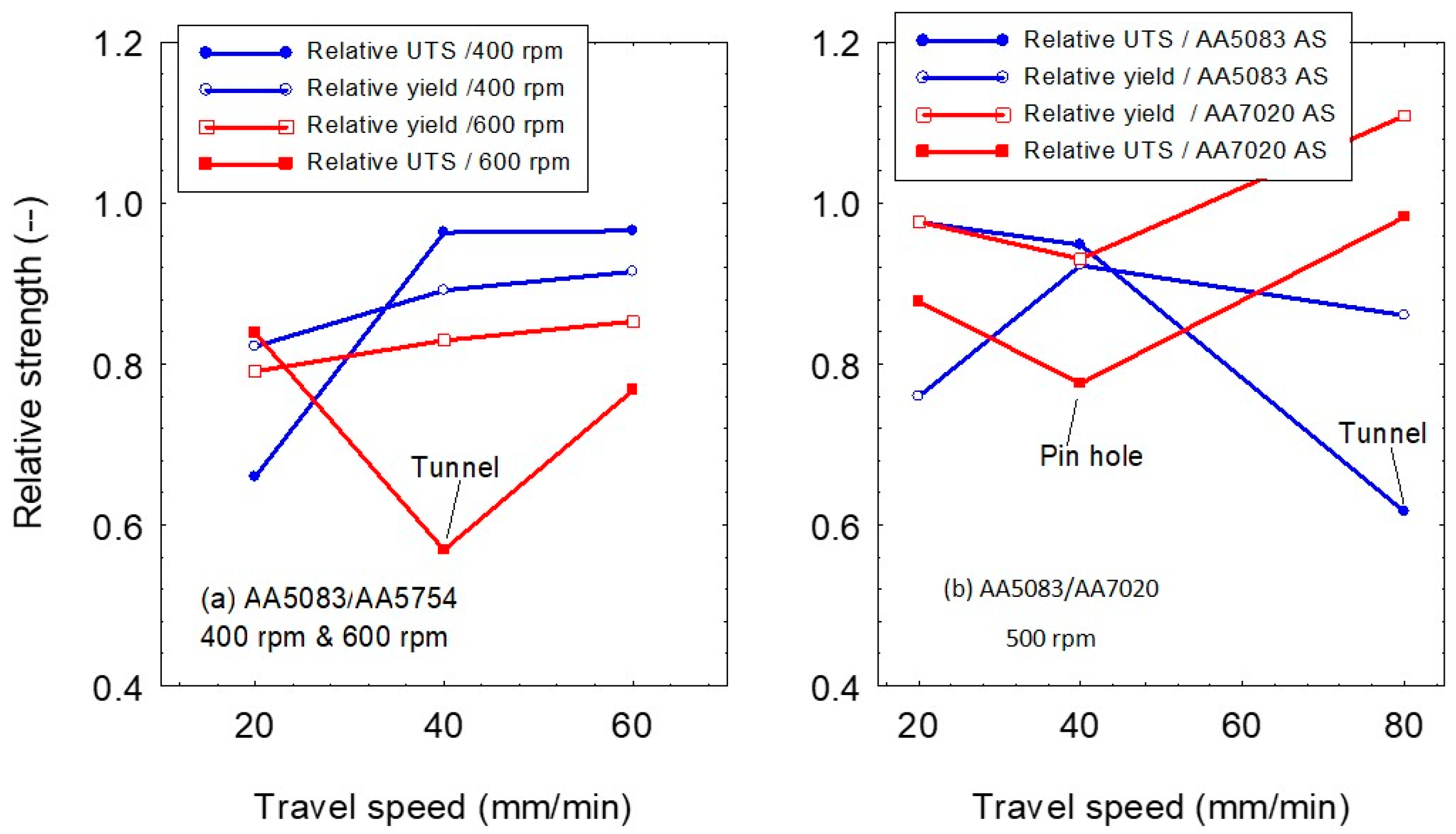

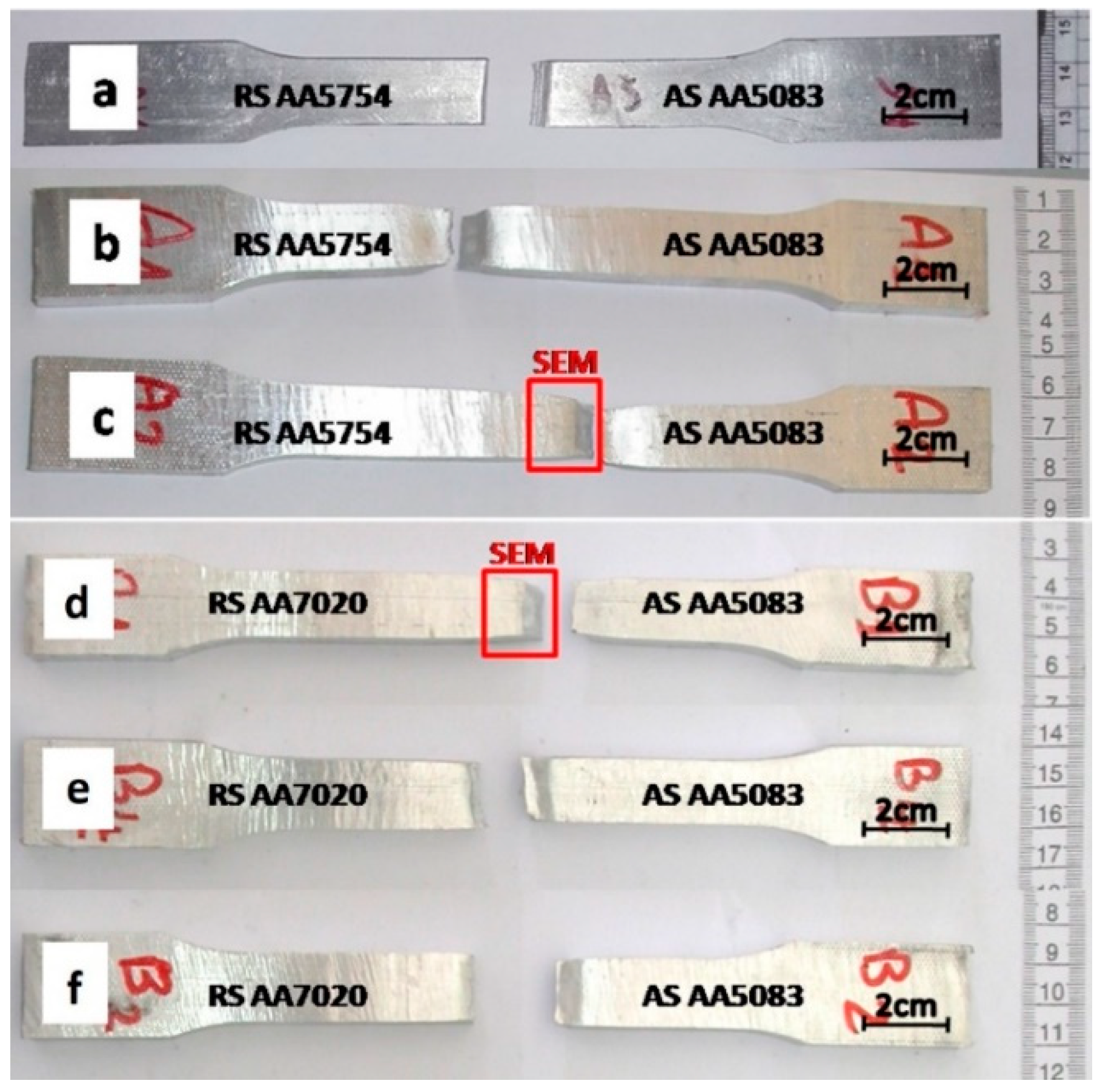

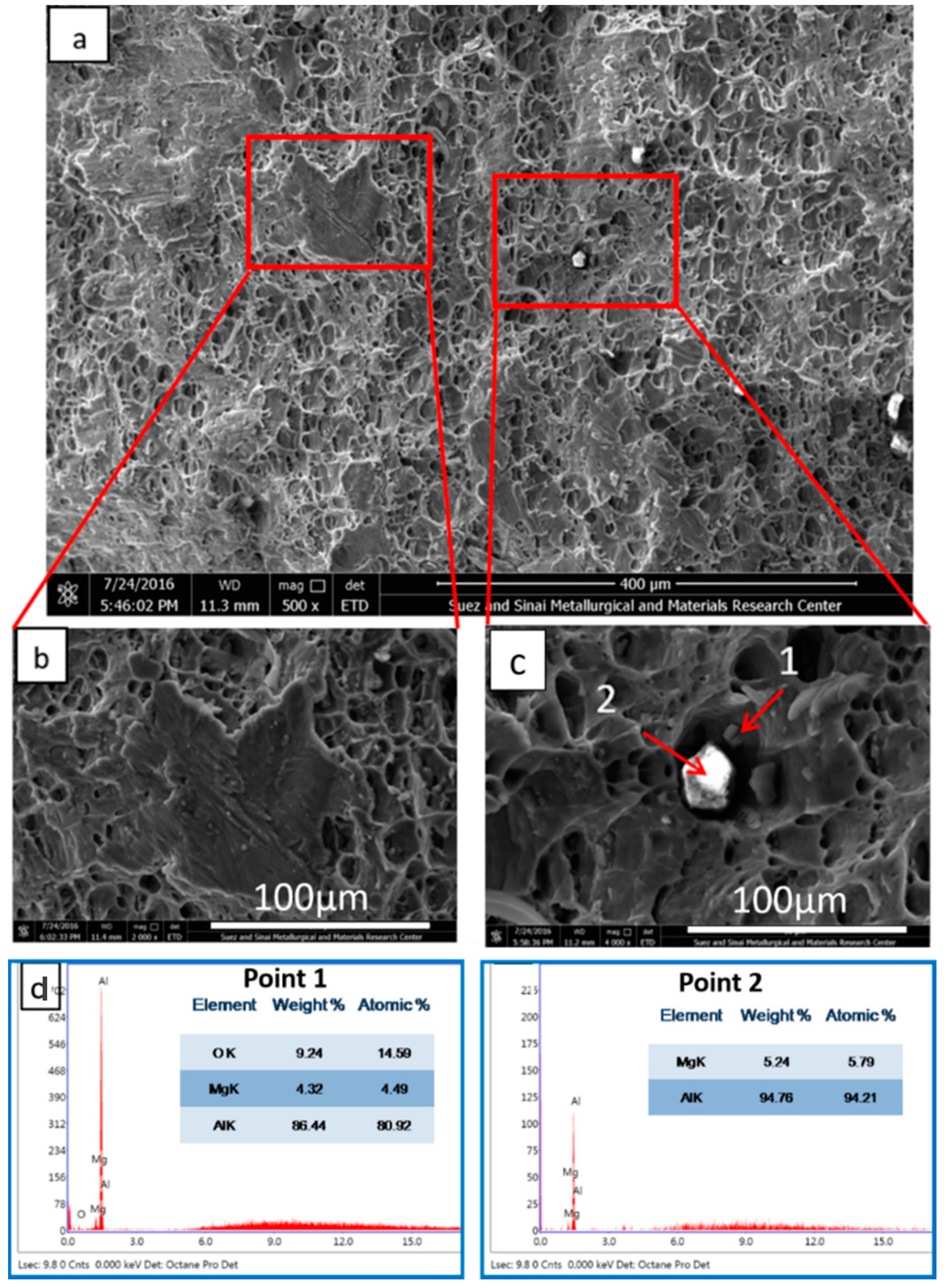

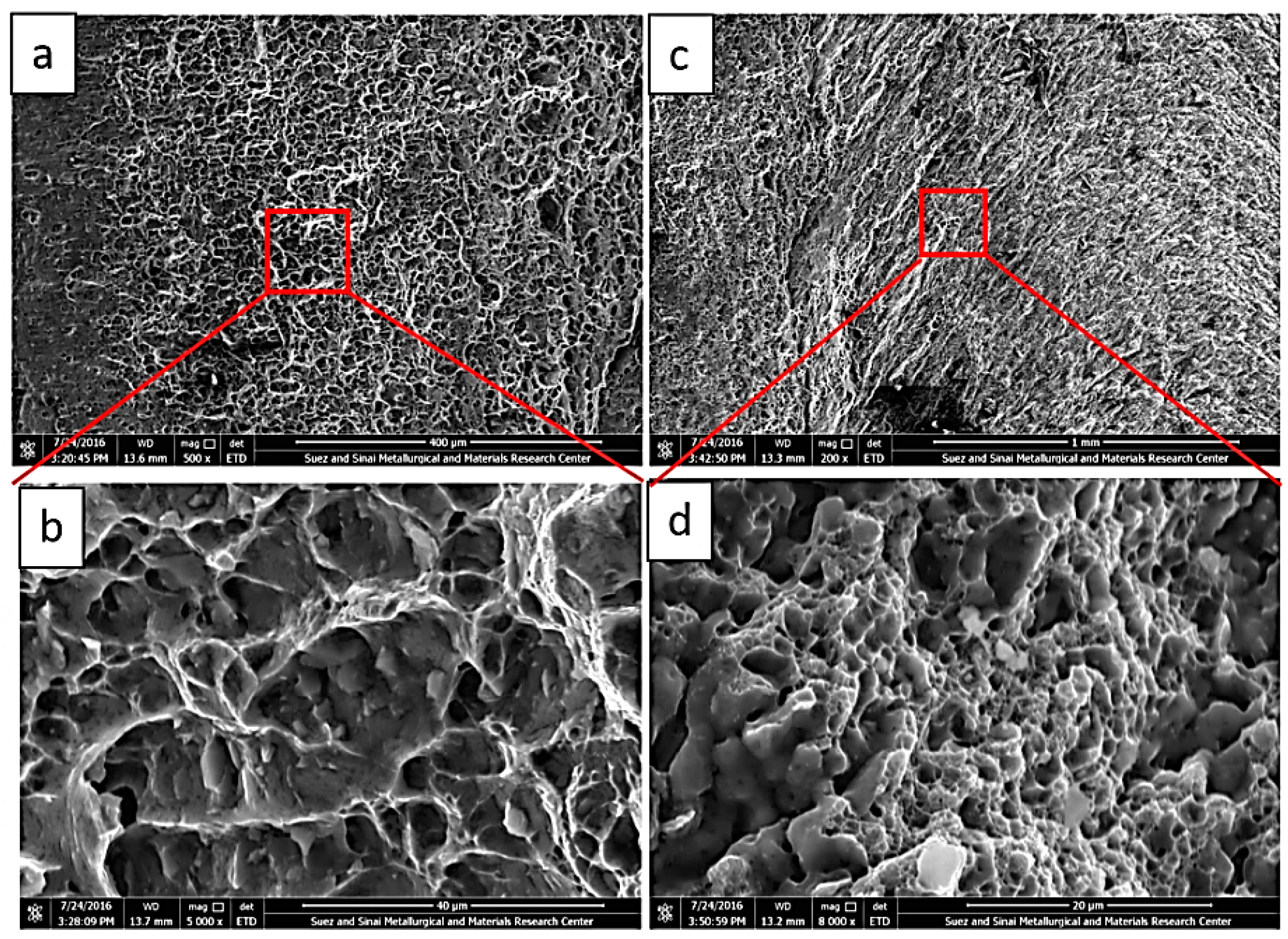

3.3.2. Tensile Properties Analysis

4. Conclusions

- −

- Sound joints are obtained at the low heat input FSW parameters investigated while increasing the heat input results in tunnel defects.

- −

- The hardness profile obtained in the dissimilar AA5083/AA5754 joints is the typical FSW hardness profile of these alloys that reduced in the NG zone due to the loss of the cold deformation strengthening. However, the profile of the dissimilar AA5083/AA7020 showed increase in the hardness in the NG due to the intimate mixing the high strength alloy with the low strength alloy.

- −

- The sound joints in both groups of the dissimilar joints showed very high joint strength with efficiency up to 97 and 98%. Having the high strength alloy at the advancing sides gives high joint strength and efficiency.

- −

- The sound joints showed ductile fracture mechanism with clear dimple features, and significant plastic deformation occurred before fracture. Moreover, the fracture in these joints occurred in the base materials. On the other hand, the joints with tunnel defect showed some features of brittle fracture due the acceleration of the existing crack propagation upon tensile loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ω: | rotational speed, rpm |

| η: | efficiency of heat transfer, % |

| σ0.2%: | 0.2 offset yield stress, MPa |

| σUTS: | Ultimate tensile strength, MPa |

| AA: | Aluminum alloy |

| AS: | advancing side |

| BM: | Base Material |

| EDX: | Energy Dispersive X-Ray |

| FSW: | Friction stir welding |

| FSWed: | Friction Stir Welded |

| HAZ: | Heat affected zone |

| HI: | Heat Input, J/mm |

| HP: | Horsepower |

| HRC: | Hardness Rockwell C |

| HV: | Hardness Vickers |

| NG: | Nugget zone |

| Rpm: | Revolution per minute |

| RS: | retreating side |

| SEM: | Scanning electron microscope |

| SZ: | stirred zone |

| T: | Torque, N∙m |

| TMAZ: | Thermomechanical affected zone |

| v: | welding speed, mm/min |

| WN: | Welding nugget |

References

- Kasman, Ş.; Yenier, Z. Analyzing dissimilar friction stir welding of AA5754/AA7075. Int. J. Adv. Manuf. Technol. 2014, 70, 145–156. [Google Scholar] [CrossRef]

- El Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-Mawla, M.M. Effect of Feed Rate in FSW on the Mechanical and Microstructural Properties of AA5754 Joints. Adv. Mater. Sci. Eng. 2019, 2109, 4156176. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, H.; Cai, Z.; Zhao, J.; Li, J. Microstructural and Mechanical Characterization of a Dissimilar Friction Stir-Welded AA5083-AA7B04 Butt Joint. J. Mater. Eng. Perform. 2017, 26, 530–539. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction stir welding of dissimilar aluminum alloy combinations: State-of-the-art. Metals 2019, 9, 270. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.Y.; Abd-Rabou, M. Finite element modeling of aluminum alloy AA5083-O friction stir welding process. J. Mater. Process. Technol. 2018, 252, 13–24. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Duarte, J.F.; Inácio, P.; Schell, N.; Miranda, R.M.; Santos, T.G. Production of Al/NiTi composites by friction stir welding assisted by electrical current. Mater. Des. 2017, 113, 311–318. [Google Scholar] [CrossRef]

- Safeen, M.W.; Spena, P.R. Main issues in quality of friction stir welding joints of aluminum alloy and steel sheets. Metals 2019, 9, 610. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Ahmed, M.M.Z.; Martin, J.P.; Perrett, J.G.; Wynne, B.P. The use of bobbin tools for friction stir welding of aluminium alloys. Mater. Sci. Forum 2010, 638, 1179–1184. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; El-Sayed Seleman, M.M.; Rainforth, W.M. A comparison of crystallographic texture and grain structure development in aluminum generated by friction stir welding and high strain torsion. Mater. Des. 2016, 103, 259–267. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Hamilton, C.; Kopyściański, M.; Miara, D.; Krasnowski, K. Microstructure and Mechanical Properties of Friction Stir Welded 5083 and 7075 Aluminum Alloys. J. Mater. Eng. Perform. 2017, 26, 1032–1043. [Google Scholar] [CrossRef]

- Vilaa, P.; Santos, T.G. Non-Destructive Testing Techniques for Detecting Imperfections in Friction Stir Welds of Aluminium Alloys. In Aluminium Alloys, Theory and Applications; IntechOpen Limited: London, UK, 2011. [Google Scholar]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Martin, J. Crystallographic texture investigation of thick section friction stir welded AA6082 and AA5083 using EBSD. Key Eng. Mater. 2019, 786, 44–51. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Shazly, M.; Attallah, M.M.; Ahmed, E. Microstructural Development and Mechanical Properties of Friction Stir Welded Ferritic Stainless Steel AISI 409. J. Mater. Eng. Perform. 2019, 28. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ahmed, E.; Hamada, A.S.; Khodir, S.A.; El-Sayed Seleman, M.M.; Wynne, B.P. Microstructure and mechanical properties evolution of friction stir spot welded high-Mn twinning-induced plasticity steel. Mater. Des. 2016, 91. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N.; Dinaharan, I. Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater. Des. 2012, 40, 7–16. [Google Scholar] [CrossRef]

- Kailainathan, S.; Sundaram, S.K.; Nijanthan, K. Influence of Friction Stir Welding Parameter on Mechanical Properties in Dissimilar (AA6063-AA8011) Aluminium Alloys. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 15691–15695. [Google Scholar] [CrossRef]

- Jannet, S.; Mathews, P.K. Effect of welding parameters on mechanical and microstructural properties of dissimilar aluminum alloy joints produced by friction stir welding. In Applied Mechanics and Materials; Trans Tech Publications: Zurich, Switzerland, March 2014. [Google Scholar]

- Park, S.K.; Hong, S.T.; Park, J.H.; Park, K.Y.; Kwon, Y.J.; Son, H.J. Effect of material locations on properties of friction stir welding joints of dissimilar aluminium alloys. Sci. Technol. Weld. Join. 2010, 15, 331–336. [Google Scholar] [CrossRef]

- Leitao, C.; Leal, R.M.; Rodrigues, D.M.; Loureiro, A.; Vilaça, P. Mechanical behaviour of similar and dissimilar AA5182-H111 and AA6016-T4 thin friction stir welds. Mater. Des. 2009, 30, 101–108. [Google Scholar] [CrossRef]

- Khanna, N.; Sharma, P.; Bharati, M.; Badheka, V.J. Friction stir welding of dissimilar aluminium alloys AA 6061-T6 and AA 8011-h14: A novel study. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 7. [Google Scholar] [CrossRef]

- Abd Elnabi, M.M.; Elshalakany, A.B.; Abdel-Mottaleb, M.M.; Osman, T.A.; El Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454-AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Cole, E.G.; Fehrenbacher, A.; Duffie, N.A.; Zinn, M.R.; Pfefferkorn, F.E.; Ferrier, N.J. Weld temperature effects during friction stir welding of dissimilar aluminum alloys 6061-t6 and 7075-t6. Int. J. Adv. Manuf. Technol. 2014, 71, 643–652. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Kovacevic, R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys. J. Mater. Eng. Perform. 2002, 11, 51–63. [Google Scholar] [CrossRef]

- Gérard, H.; Ehrström, J.C. Friction stir welding of dissimilar alloys for aircraft. In Proceedings of the 5th International Friction Stir Welding Symposium, Metz, France, 14–16 September 2004. [Google Scholar]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Kim, N.K.; Kim, B.C.; An, Y.G.; Jung, B.H.; Song, S.W.; Kang, C.Y. The effect of material arrangement on mechanical properties in friction stir welded dissimilar A5052/A5J32 aluminum alloys. Met. Mater. Int. 2009, 15, 671–675. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials. Scr. Mater. 2003, 49, 423–428. [Google Scholar] [CrossRef]

- Jonckheere, C.; De Meester, B.; Denquin, A.; Simar, A. Dissimilar friction stir welding of 2014 to 6061 aluminum alloys. Advanced Mater. Res. Trans Tech Publ. Switz. 2012, 409, 269–274. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Dissimilar Friction Stir Welds in AA2219-AA5083 Aluminium Alloys: Effect of Process Parameters on Material Inter-Mixing, Defect Formation, and Mechanical Properties. Trans. Indian Inst. Met. 2016, 69, 1397–1415. [Google Scholar] [CrossRef]

- Essa, A.R.S.; Ahmed, M.M.Z.; Mohamed, A.K.Y.A.; El-Nikhaily, A.E. An analytical model of heat generation for eccentric cylindrical pin in friction stir welding. J. Mater. Res. Technol. 2016, 5, 234–240. [Google Scholar] [CrossRef]

- ASTM International. ASTM E3-11(2017) Preparation of Metallographic Specimens 1; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Metall. Mater. Trans. A 2018, 50, 271–284. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Pandey, S. Process forces and heat input as function of process parameters in AA5083 friction stir welds. Trans. Nonferrous Met. Soc. China 2012, 22, 288–298. [Google Scholar] [CrossRef]

- Costa, A.M.S.; Oliveira, J.P.; Pereira, V.F.; Nunes, C.A.; Ramirez, A.J.; Tschiptschin, A.P. Ni-based Mar-M247 superalloy as a friction stir processing tool. J. Mater. Process. Technol. 2018, 262, 605–614. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Akinlabi, S.A. Effect of Heat Input on the Properties of Dissimilar Friction Stir Welds of Aluminium and Copper. Am. J. Mater. Sci. 2012, 2, 147–152. [Google Scholar] [CrossRef]

- Schneider, J.; Beshears, R.; Nunes, A.C. Interfacial sticking and slipping in the friction stir welding process. Mater. Sci. Eng. A 2006, 435, 297–304. [Google Scholar] [CrossRef]

- Fall, A.; Jahazi, M.; Khdabandeh, A.R.; Fesharaki, M.H. Effect of process parameters on microstructure and mechanical properties of friction stir-welded ti–6al–4v joints. Int. J. Adv. Manuf. Technol. 2017, 91, 2919–2931. [Google Scholar] [CrossRef]

- Leitão, C.; Louro, R.; Rodrigues, D.M. Analysis of high temperature plastic behaviour and its relation with weldability in friction stir welding for aluminium alloys AA5083-H111 and AA6082-T6. Mater. Des. 2012, 37, 402–409. [Google Scholar] [CrossRef]

- Etter, A.L.; Baudin, T.; Fredj, N.; Penelle, R. Recrystallization mechanisms in 5251 H14 and 5251 O aluminum friction stir welds. Mater. Sci. Eng. A 2007, 445, 94–99. [Google Scholar] [CrossRef]

- Jia, Y.; Lin, S.; Liu, J.; Qin, Y.; Wang, K. The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys. Metals 2019, 9, 1162. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction stir welding of similar and dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242. [Google Scholar] [CrossRef]

- Ilangovan, M.; Rajendra Boopathy, S.; Balasubramanian, V. Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA 6061–AA 5086 aluminium alloy joints. Def. Technol. 2015, 11, 174–184. [Google Scholar] [CrossRef]

| Alloy | Elements in wt.% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Al | |

| AA5083 | 0.40 | 0.40 | 0.10 | 0.4–1.0 | 4.0–4.9 | 0.25 | 0.05–0.25 | 0.15 | Bal. |

| AA5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6–3.6 | 0.20 | 0.30 | <0.15 | Bal. |

| AA7020 | 0.35 | 0.40 | 0.20 | 0.05–0.50 | 1.0–1.4 | 4.50 | 0.1–0.35 | <0.35 | Bal. |

| Alloy | Condition | Tensile Strength, MPa | Hardness, HV |

|---|---|---|---|

| AA5083-O | Annealed | 233 | 68 |

| AA5754-H14 | Strain hardened-1/2 hard | 251 | 74 |

| AA7020-T6 | Solution heat treated and artificially aged | 364 | 117 |

| AA5083/AA5754 | AA5083/AA7020 | ||||

|---|---|---|---|---|---|

| Rotation Speed (rpm) | Travel Speed (mm/min) | Position | Rotation Speed (rpm) | Travel Speed (mm/min) | Position |

| 400 | 20 | AA5083 AS | 500 | 20 | AA5083 AS |

| 40 | AA5083 AS | 40 | AA5083 AS | ||

| 60 | AA5083 AS | 80 | AA5083 AS | ||

| 600 | 20 | AA5083 AS | 500 | 20 | AA7020 AS |

| 40 | AA5083 AS | 40 | AA7020 AS | ||

| 60 | AA5083 AS | 80 | AA7020 AS | ||

| Joint AS-RS | ω (rpm) | v (mm/min) | ω/v | Torque (N∙m) | HI (J/mm) | Heat Index ω2/v |

|---|---|---|---|---|---|---|

| AA5083-AA5754 | 400 | 20 | 20.0 | 91 | 171 | 8000 |

| 400 | 40 | 10.0 | 117 | 110 | 4000 | |

| 400 | 60 | 6.7 | 116 | 73 | 2666 | |

| AA5083-AA5754 | 600 | 20 | 30.0 | 73 | 206 | 18,000 |

| 600 | 40 | 15.0 | 87 | 123 | 9000 | |

| 600 | 60 | 10.0 | 85 | 80 | 6000 | |

| AA5083-AA7020 | 500 | 20 | 25.0 | 87 | 205 | 12,500 |

| 500 | 40 | 12.5 | 91 | 107 | 6250 | |

| 500 | 80 | 6.3 | 65 | 39 | 3125 | |

| AA7020-AA5083 | 500 | 20 | 25.0 | 101 | 238 | 12,500 |

| 500 | 40 | 12.5 | 85 | 100 | 6250 | |

| 500 | 80 | 6.3 | 104 | 62 | 3125 |

| Joint | ω (rpm) | v (mm/min) | ω/v | Surface Thin Flash and Track Lines | Internal Defect |

|---|---|---|---|---|---|

| AA5083/AA5754 | 400 | 20 | 20 | - | - |

| 400 | 40 | 10 | thin flash | - | |

| 400 | 60 | 6.66 | - | - | |

| 600 | 20 | 30 | - | pin hole | |

| 600 | 40 | 15 | track lines, thin flash | tunnel | |

| 600 | 60 | 10 | thin flash | - | |

| AA5083/AA7020 | 500 | 20 | 25 | thick flash | - |

| 500 | 40 | 12.5 | thick flash | - | |

| 500 | 80 | 6.25 | thin flash | tunnel | |

| AA7020/AA5083 | 500 | 20 | 25 | thin flash | - |

| 500 | 40 | 12.5 | - | pin hole | |

| 500 | 80 | 6.25 | track lines, thin flash | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals 2021, 11, 68. https://doi.org/10.3390/met11010068

Ahmed MMZ, Ataya S, El-Sayed Seleman MM, Mahdy AMA, Alsaleh NA, Ahmed E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals. 2021; 11(1):68. https://doi.org/10.3390/met11010068

Chicago/Turabian StyleAhmed, Mohamed M. Z., Sabbah Ataya, Mohamed M. El-Sayed Seleman, Abdalla M. A. Mahdy, Naser A. Alsaleh, and Essam Ahmed. 2021. "Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020" Metals 11, no. 1: 68. https://doi.org/10.3390/met11010068

APA StyleAhmed, M. M. Z., Ataya, S., El-Sayed Seleman, M. M., Mahdy, A. M. A., Alsaleh, N. A., & Ahmed, E. (2021). Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals, 11(1), 68. https://doi.org/10.3390/met11010068