Interface of a Al6061/Ti Composite Prepared by Field Assisted Sintering Technique

Abstract

:1. Introduction

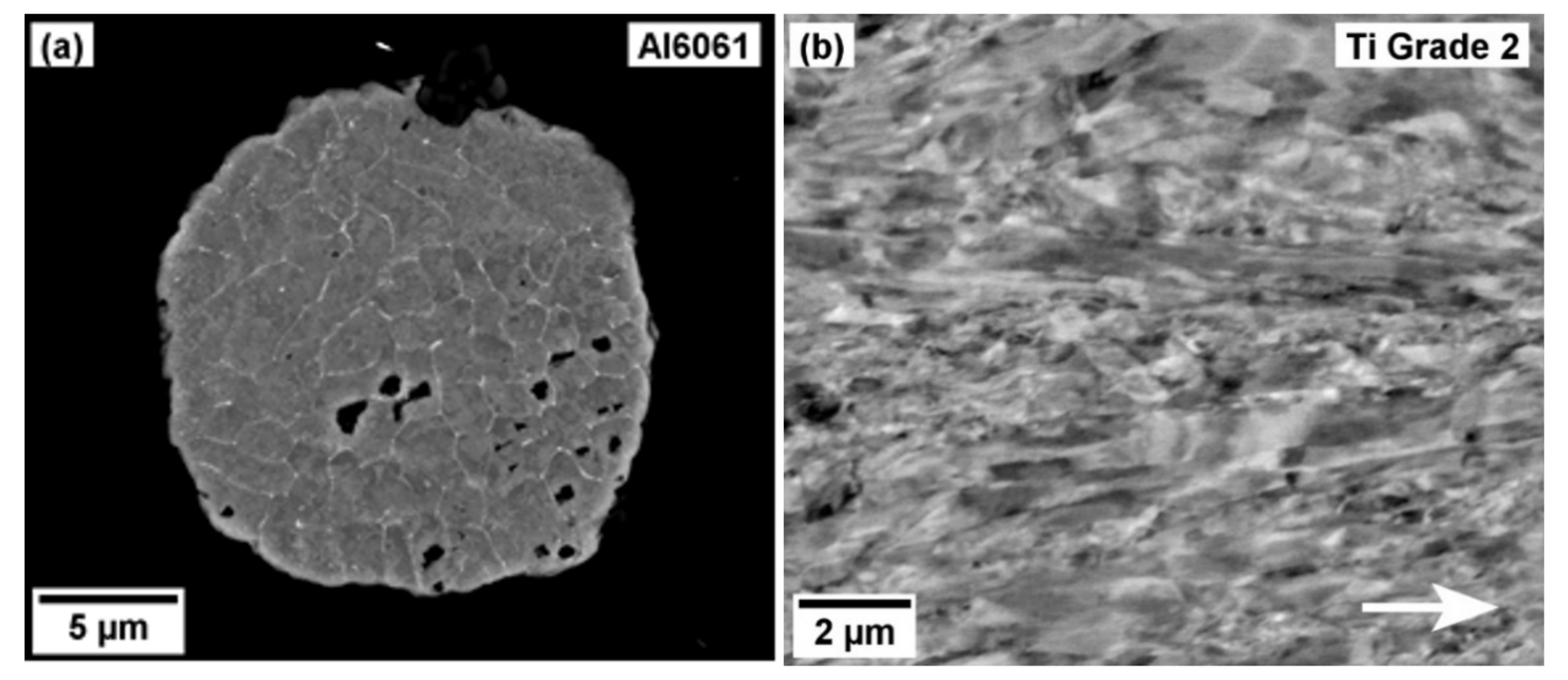

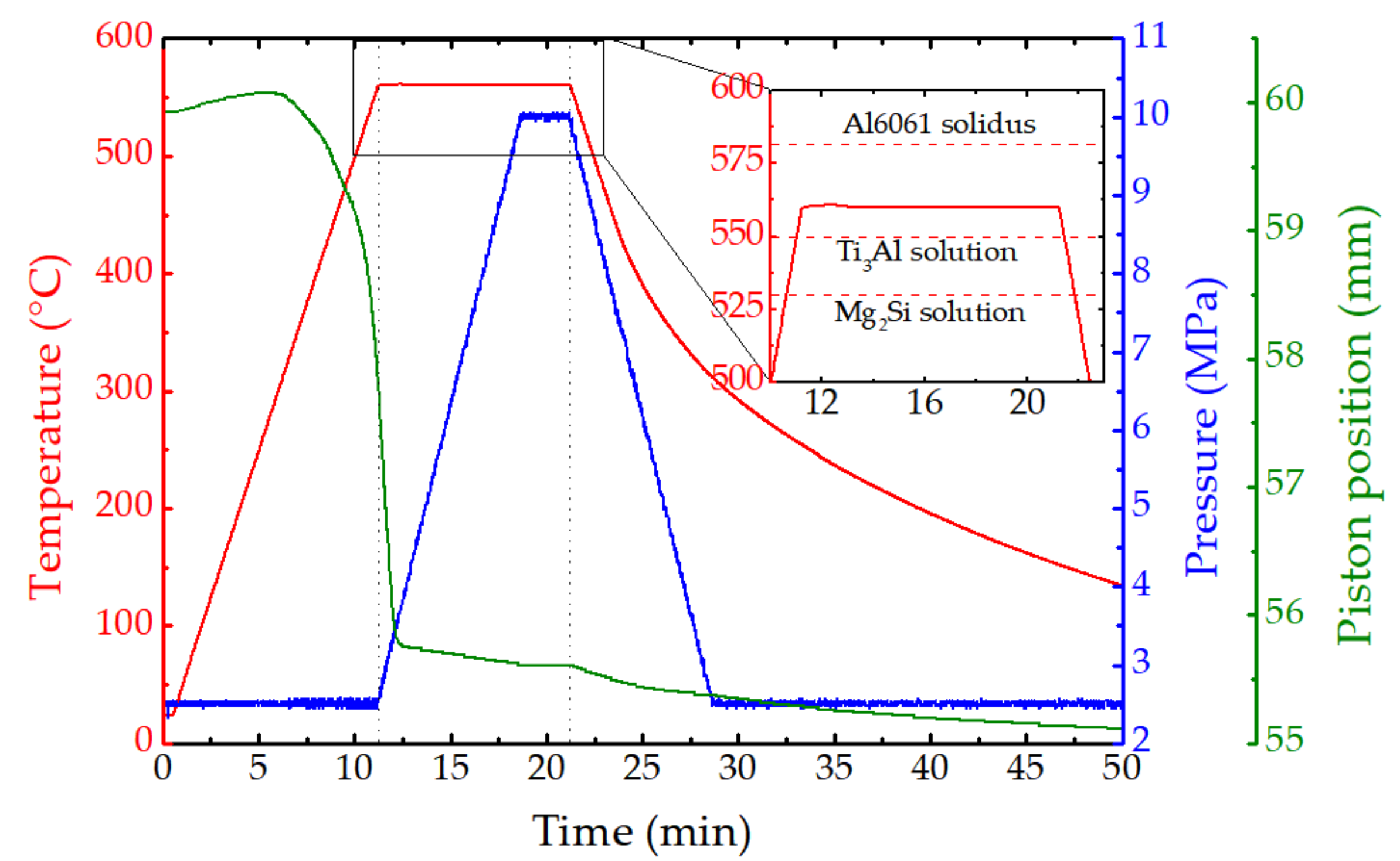

2. Materials and Methods

- 1.

- The temperature must be as high as possible to promote diffusion between the matrix and reinforcement.

- 2.

- The temperature has to be below the solidus temperature of Al6061 alloy (582 °C, [27]) to prevent melting.

- 3.

- The temperature should be above the solvus temperature of various intermetallic phases which can be created (Mg2Si, Ti3Al) [28].

- 4.

- The piston pressure should be kept low and applied slowly to promote plastic deformation of the Al6061 particles, while suppressing the deformation of the reinforcement wireframe structure.

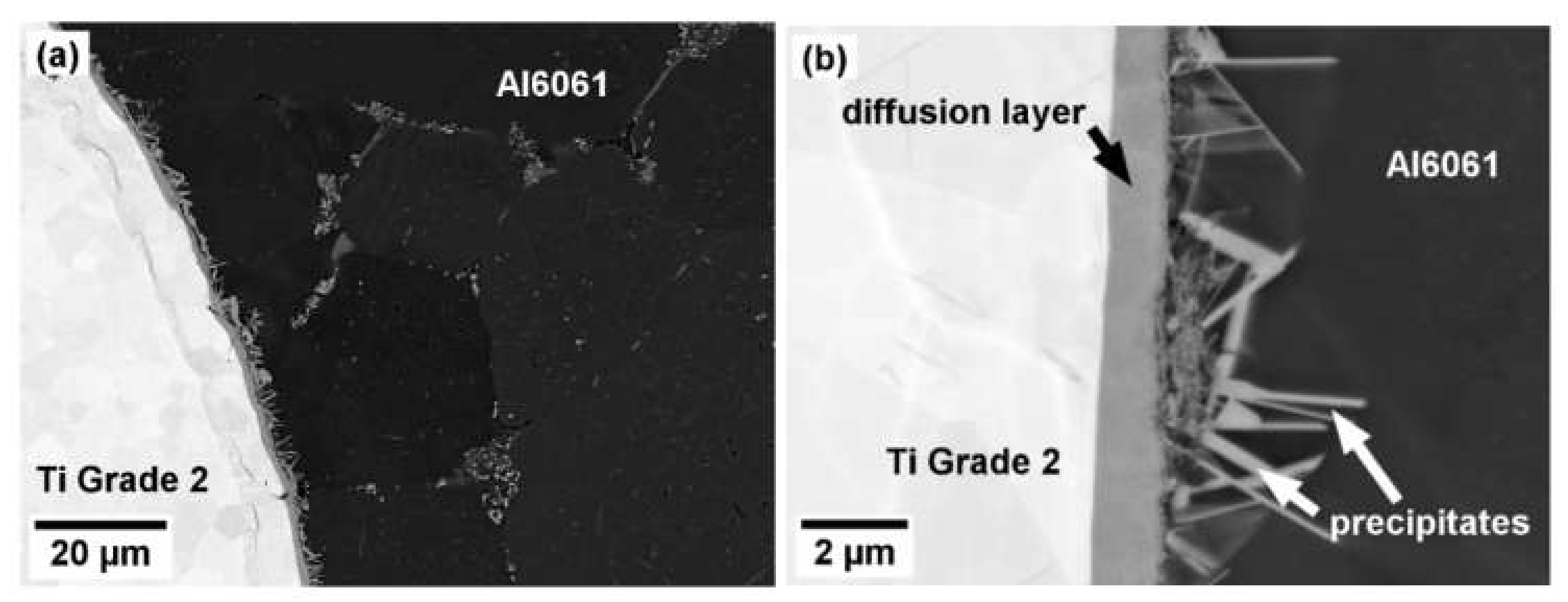

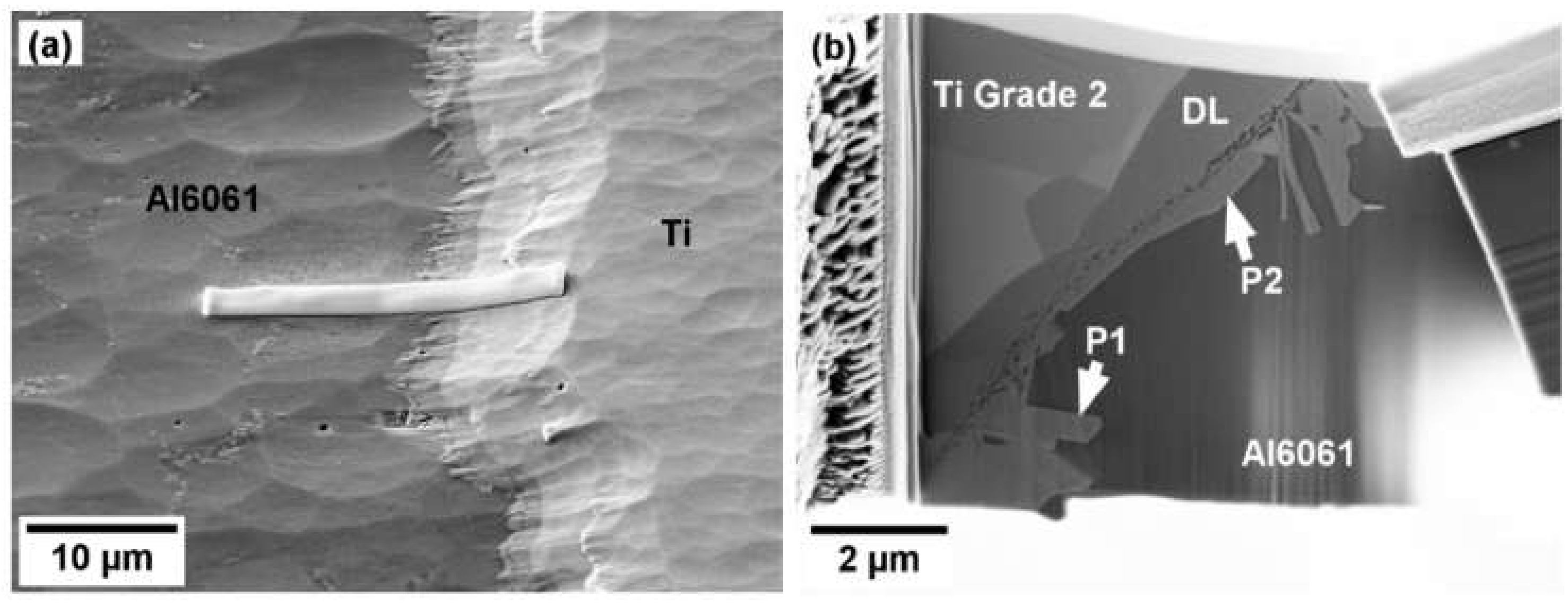

3. Results

4. Discussion

5. Conclusions

- Heterogeneous composite material was manufactured from Ti Grade 2 bulk and Al6061 alloy powder by FAST at 560 °C for 10 min.

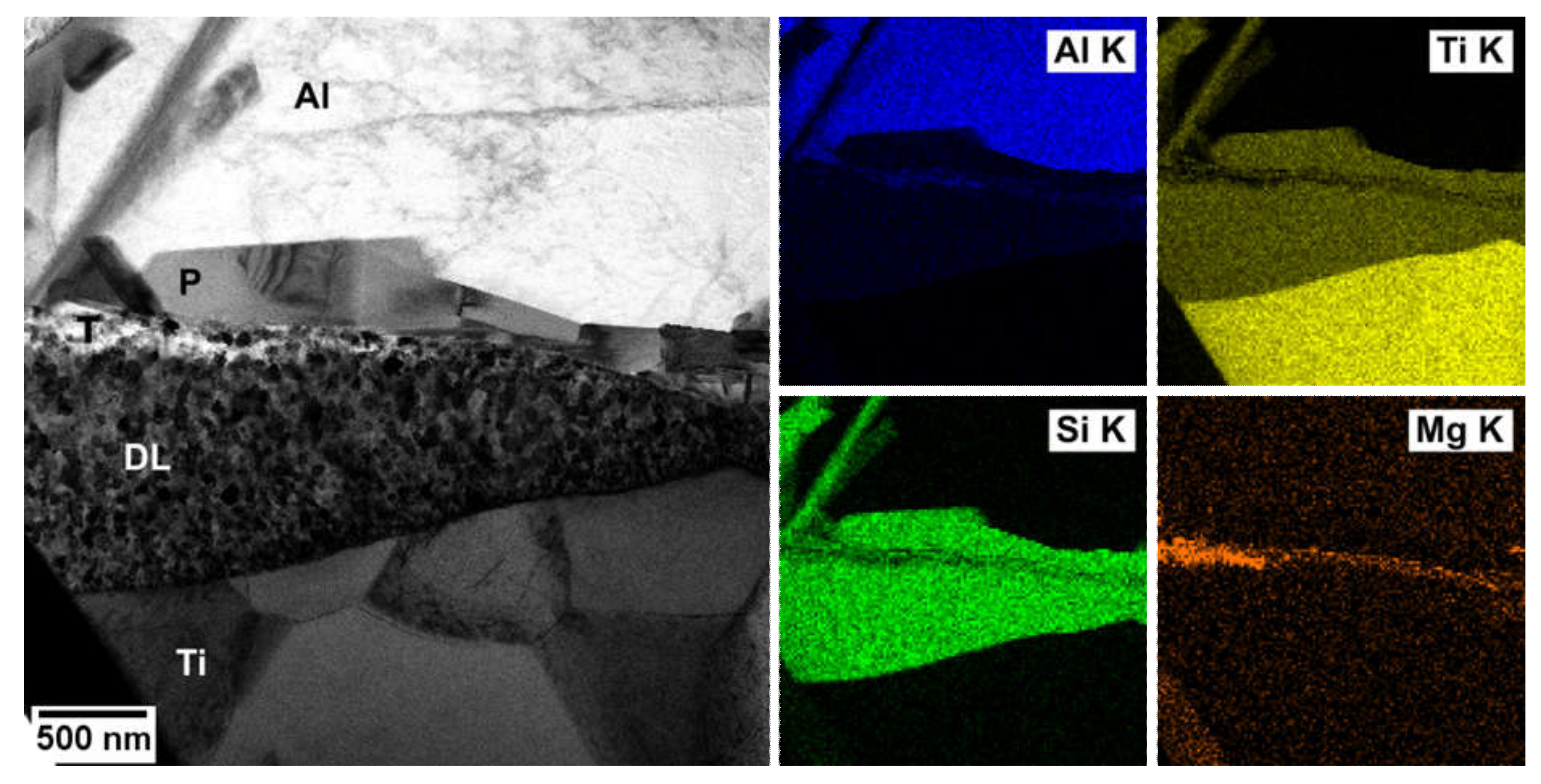

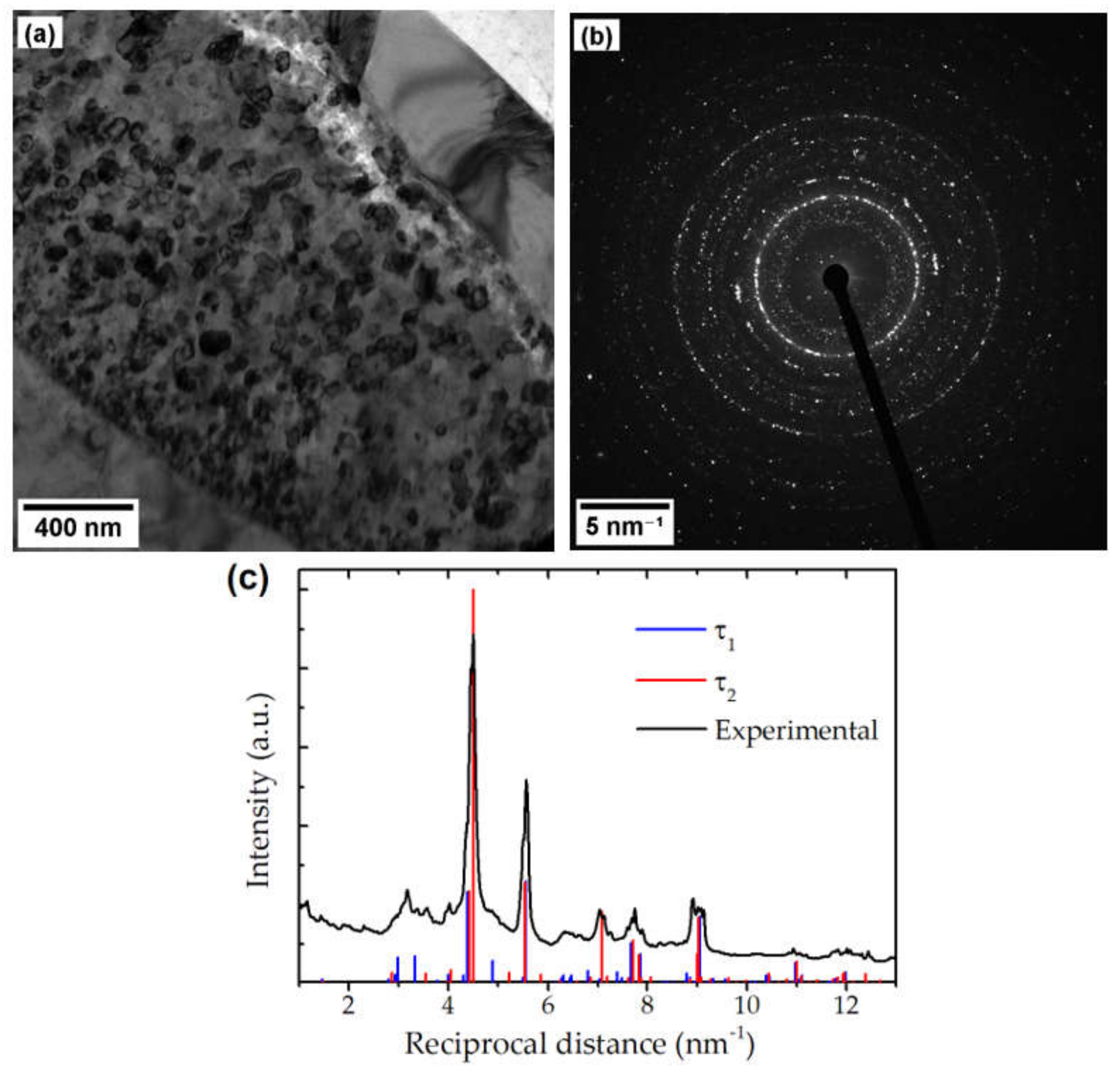

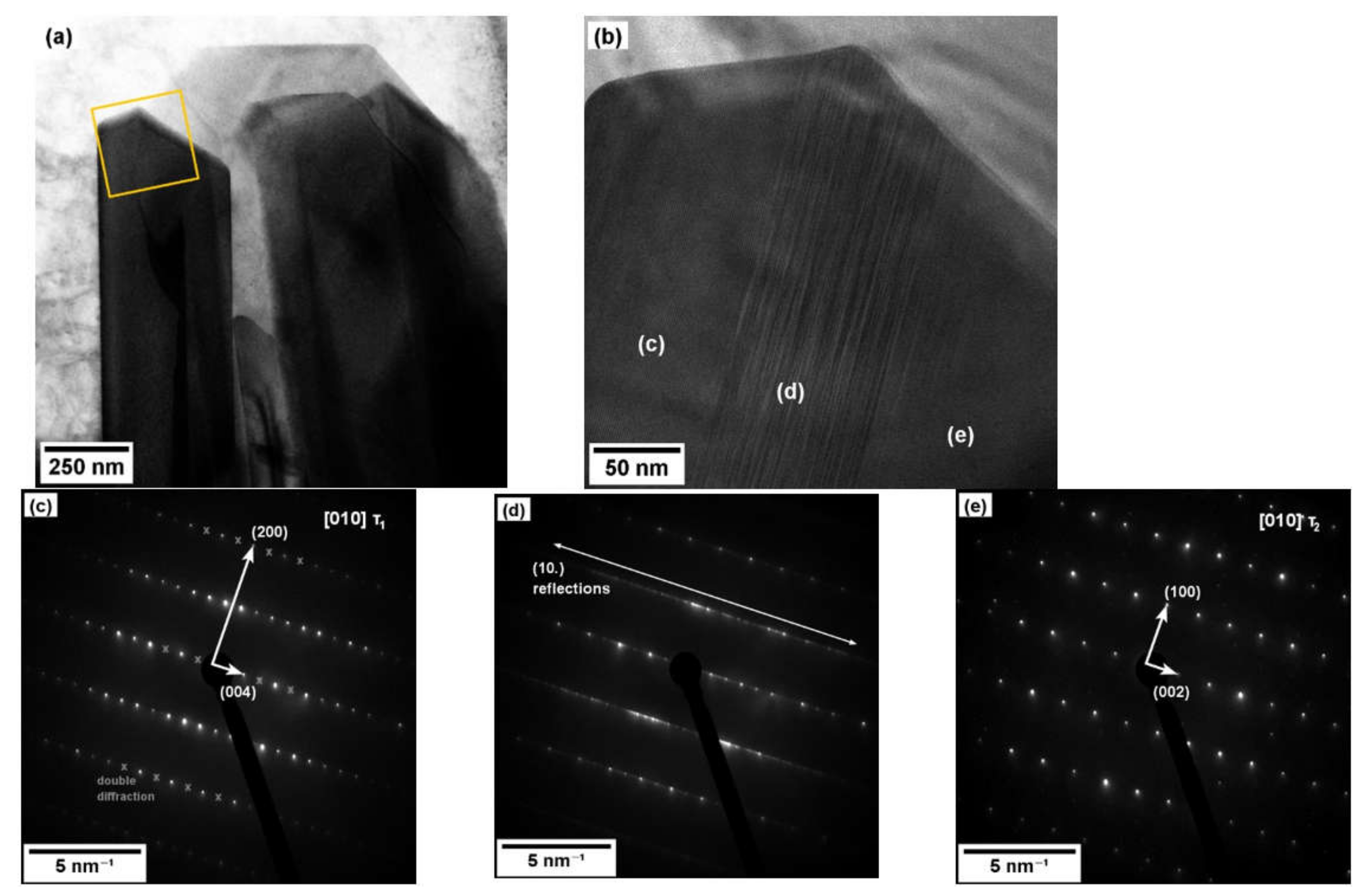

- Diffusion layer is continuous with the thickness of approx. 1–2 µm and consists of ternary Al-Si-Ti τ1 and τ2 phases.

- Si significantly affects the formation of the diffusion layer due to its high inter-diffusion coefficient in Al. Similar diffusion layers in terms of width have been observed after diffusion bonding of Ti and Al alloys.

- TEM analysis showed a modulated τ1/τ2 structure resembling the LPSO phase.

- FAST is capable of manufacturing heterogeneous composites from dissimilar materials.

Author Contributions

Funding

Conflicts of Interest

References

- Aksit, M.; Altstädt, V. Hybrid Materials-Historical Perspective and Current Trends. COJ Rev. Res. 2020, 2, 17. [Google Scholar]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Estrin, Y.; Bréchet, Y.; Dunlop, J.; Fratzl, P. (Eds.) Architectured Materials in Nature and Engineering: Archimats; Springer Series in Materials Science; Springer Nature Switzerland AG: Cham, Switzerland, 2019; ISBN 978-3-030-11941-6. [Google Scholar]

- Ashby, M.F.; Bréchet, Y.J.M. Designing hybrid materials. Acta. Mater. 2003, 51, 5801–5821. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Savio, G.; Rosso, S.; Meneghello, R.; Concheri, G. Geometric Modeling of Cellular Materials for Additive Manufacturing in Biomedical Field: A Review. Available online: https://www.hindawi.com/journals/abb/2018/1654782/ (accessed on 18 November 2020).

- Schaedler, T.A.; Carter, W.B. Architected Cellular Materials. Annu. Rev. Mater. Res. 2016, 46, 187–210. [Google Scholar] [CrossRef]

- Williams, C.B.; Cochran, J.K.; Rosen, D.W. Additive manufacturing of metallic cellular materials via three-dimensional printing. Int. J. Adv. Manuf. Technol. 2011, 53, 231–239. [Google Scholar] [CrossRef]

- Cakmak, E.; Sridharan, N.; Venkatakrishnan, S.V.; Bilheux, H.Z.; Santodonato, L.J.; Shyam, A.; Babu, S.S. Feasibility Study of Making Metallic Hybrid Materials Using Additive Manufacturing. Metall. Mater. Trans. A 2018, 49, 5035–5041. [Google Scholar] [CrossRef]

- Annamalai, A.R.; Srikanth, M.; Muthuchamy, A.; Acharya, S.; Khisti, A.; Agrawal, D.K.; Jen, C.-P. Spark Plasma Sintering and Characterization of Al-TiB2 Composites. Metals 2020, 10, 1110. [Google Scholar] [CrossRef]

- Firestein, K.L.; Corthay, S.; Steinman, A.E.; Matveev, A.T.; Kovalskii, A.M.; Sukhorukova, I.V.; Golberg, D.; Shtansky, D.V. High-strength aluminum-based composites reinforced with BN, AlB2 and AlN particles fabricated via reactive spark plasma sintering of Al-BN powder mixtures. Mater. Sci. Eng. A 2017, 681, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Pellizzari, M.; Cipolloni, G. Spark Plasma Sintering of Copper Matrix Composites Reinforced with TiB2 Particles. Materials 2020, 13, 2602. [Google Scholar] [CrossRef]

- Sweet, G.A.; Brochu, M.; Hexemer, R.L.; Donaldson, I.W.; Bishop, D.P. Consolidation of aluminum-based metal matrix composites via spark plasma sintering. Mater. Sci. Eng. A 2015, 648, 123–133. [Google Scholar] [CrossRef]

- Martin, G.; Fabrègue, D.; Mercier, F.; Chafino-Aixa, J.-A.; Dendievel, R.; Blandin, J.-J. Coupling electron beam melting and spark plasma sintering: A new processing route for achieving titanium architectured microstructures. Scr. Mater. 2016, 122, 5–9. [Google Scholar] [CrossRef]

- de Lama, M.A.; Balden, M.; Greuner, H.; Höschen, T.; Matejicek, J.; You, J.H. Microstructural stability of spark-plasma-sintered Wf/W composite with zirconia interface coating under high-heat-flux hydrogen beam irradiation. Nucl. Mater. Energy 2017, 13, 74–80. [Google Scholar] [CrossRef]

- Trzaska, Z.; Couret, A.; Monchoux, J.-P. Spark plasma sintering mechanisms at the necks between TiAl powder particles. Acta Mater. 2016, 118, 100–108. [Google Scholar] [CrossRef]

- Trzaska, Z.; Bonnefont, G.; Fantozzi, G.; Monchoux, J.-P. Comparison of densification kinetics of a TiAl powder by spark plasma sintering and hot pressing. Acta Mater. 2017, 135, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Trzaska, Z.; Monchoux, J.-P. Electromigration experiments by spark plasma sintering in the silver–zinc system. J. Alloys Compd. 2015, 635, 142–149. [Google Scholar] [CrossRef]

- Pripanapong, P.; Umeda, J.; Imai, H.; Takahashi, M.; Kondoh, K. Tensile Strength of Ti/Mg Alloys Dissimilar Bonding Material Fabricated by Spark Plasma Sintering. IJEIR 2016, 5, 253–259. [Google Scholar]

- Cooke, K.O.; Atieh, A.M. Current Trends in Dissimilar Diffusion Bonding of Titanium Alloys to Stainless Steels, Aluminium and Magnesium. J. Manuf. Mater. Process. 2020, 4, 39. [Google Scholar] [CrossRef]

- Fuji, A. In situ observation of interlayer growth during heat treatment of friction weld joint between pure titanium and pure aluminium. Sci. Technol. Weld. Join. 2002, 7, 413–416. [Google Scholar] [CrossRef]

- Fuji, A.; Ikeuchi, K.; Sato, Y.S.; Kokawa, H. Interlayer growth at interfaces of Ti/Al–1%Mn, Ti/Al–4·6%Mg and Ti/pure Al friction weld joints by post-weld heat treatment. Sci. Technol. Weld. Join. 2004, 9, 507–512. [Google Scholar] [CrossRef]

- Hamajima, T.; Ameyama, K.; Fuji, A. Microstructural Change of Weld Interface in Ti/Al Friction Weld during Heat Treatment. J. Soc. Mater. Sci. Jpn. 1995, 44, 1224–1230. [Google Scholar] [CrossRef]

- Ma, Z.; Jin, Y.; Ji, S.; Meng, X.; Ma, L.; Li, Q. A general strategy for the reliable joining of Al/Ti dissimilar alloys via ultrasonic assisted friction stir welding. J. Mater. Sci. Technol. 2019, 35, 94–99. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Diffusion bonding of titanium and AA 7075 aluminum alloy dissimilar joints—process modeling and optimization using desirability approach. Int. J. Adv. Manuf. Technol. 2016, 86, 1095–1112. [Google Scholar] [CrossRef]

- AlHazaa, A.; Khan, T.I.; Haq, I. Transient liquid phase (TLP) bonding of Al7075 to Ti–6Al–4V alloy. Mater. Charact. 2010, 61, 312–317. [Google Scholar] [CrossRef]

- ASM Handbook, Volume 2: Properties of Wrought Aluminum and Aluminum Alloys; ASM International: Russel Township, OH, USA, 1990; ISBN 978-1-62708-162-7.

- ASM Handbook, Volume 4: Heat Treating of Aluminum Alloys; ASM Internationa: Russel Township, OH, USA, 1991; Volume 4.

- Welsch, G.; Boyer, R.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International Russel Township: Russel Township, OH, USA, 1993; ISBN 978-0-87170-481-8. [Google Scholar]

- Al6061-T6, Al6061-T651. Available online: http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6061T6 (accessed on 22 November 2020).

- Zháňal, P.; Václavová, K.; Hadzima, B.; Harcuba, P.; Stráský, J.; Janeček, M.; Polyakova, V.; Semenova, I.; Hájek, M.; Hajizadeh, K. Thermal stability of ultrafine-grained commercial purity Ti and Ti–6Al–7Nb alloy investigated by electrical resistance, microhardness and scanning electron microscopy. Mater. Sci. Eng. A 2016, 651, 886–892. [Google Scholar] [CrossRef]

- Ti Grade 2. Available online: http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MTU020 (accessed on 22 November 2020).

- Räisänen, J.; Anttila, A.; Keinonen, J. Diffusion of aluminum in ion-implanted α-Ti. J. Appl. Phys. 1985, 57, 613–614. [Google Scholar] [CrossRef]

- Diffusion in Dilute Substitutional Alloys. In Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-Controlled Processes; Mehrer, H. (Ed.) Springer Series in Solid-State Sciences; Springer: Berlin, Heidelberg, 2007; pp. 327–339. ISBN 978-3-540-71488-0. [Google Scholar]

- Räisänen, J.; Keinonen, J. Annealing behavior of Si in ion-implanted α-Ti. Appl. Phys. Lett. 1986, 49, 773–775. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.-Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Murray, J.L. The Mg−Ti (Magnesium-Titanium) system. Bull. Alloy Phase Diagr. 1986, 7, 245–248. [Google Scholar] [CrossRef]

- Li, Z.; Liao, C.; Liu, Y.; Wang, X.; Wu, Y.; Zhao, M.; Long, Z.; Yin, F. 700 °C Isothermal Section of the Al-Ti-Si Ternary Phase Diagram. J. Phase Equilibria Diffus. 2014, 35, 564–574. [Google Scholar] [CrossRef]

- Schubert, K.; Frank, K.; Gohle, R.; Maldonado, A.; Meissner, H.G.; Raman, A.; Rossteutscher, W. Einige Strukturdaten metallischer Phasen (8). Naturwissenschaften 1963, 50, 41. [Google Scholar] [CrossRef]

- Raman, A.; Schubert, K. Über den Aufbau einiger zu TiAl3 verwandter Legierungsreihen. II. Untersuchungen in einigen T-Al-Si- und T4...6-In-Systemen. Z. Für Met. 1965, 56, 44–52. [Google Scholar]

- Momma, K.; Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Wilden, J.; Bergmann, J.P.; Herz, S. Properties of diffusion welded hybrid joints titanium/aluminum. In Proceedings of the 3rd International Brazing and Soldering Conference, San Antonio, TX, USA, 24–26 April 2006; Stephens, J.J., Weil, K.S., Eds.; ASM Int.: Materials Park, OH, USA, 2006; pp. 338–343, ISBN 978-0-87170-838-0. [Google Scholar]

- Wang, J.; Liu, Y.; Liu, Y.; Wu, C.; Su, X. The Isothermal Section of the Al-Si-Ti Ternary System at 550 °C. J. Phase Equilibria Diffus. 2019, 40, 810–819. [Google Scholar] [CrossRef]

- Luo, Q.; Li, Q.; Zhang, J.-Y.; Chen, S.-L.; Chou, K.-C. Experimental investigation and thermodynamic calculation of the Al–Si–Ti system in Al-rich corner. J. Alloys Compd. 2014, 602, 58–65. [Google Scholar] [CrossRef]

- Egusa, D.; Abe, E. The structure of long period stacking/order Mg–Zn–RE phases with extended non-stoichiometry ranges. Acta Mater. 2012, 60, 166–178. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zheng, M.; Zhong, H.; Gu, J. Alternative-band microstructure and LPSO phase in TiAl alloy produced by direct laser deposition. Mater. Charact. 2020, 164, 110315. [Google Scholar] [CrossRef]

| Element | Si | Mg | Fe | Cu | Cr | Ti | Mn | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.75 | 0.93 | 0.30 | 0.33 | 0.21 | 0.01 | 0.05 | <0.002 | bal. |

| at.% | 0.72 | 1.04 | 0.15 | 0.14 | 0.11 | 0.01 | 0.02 | <0.001 | bal. |

| Material | Al6061 | Ti Grade 2 |

|---|---|---|

| Microhardness (HV0.5) | 57 ± 2 | 128 ± 3 |

| In α Titanium | In Aluminium | ||||||

|---|---|---|---|---|---|---|---|

| D (m2/s) | L (nm) | Reference | D (m2/s) | L (nm) | Reference | ||

| Al | 1.17 × 10−20 | 3 | [33] | Ti | 5.69 × 10−13 | 58 | [34] |

| Si | 1.12 × 10−17 | 82 | [35] | Si | 5.84 × 10−13 | 1.9 × 104 | [36] |

| Mg | insoluble | - | [20,37] | Mg | 4.15 × 10−13 | 1.5 × 104 | [36] |

| Analyzed Region | Mg (at.%) | Al (at.%) | Si (at.%) | Ti (at.%) |

|---|---|---|---|---|

| Diffusion layer (DL) | 0.07 | 10.1 | 47.5 | 42.4 |

| Precipitate 1 (P1) | 0.07 | 9.5 | 38.1 | 52.4 |

| Precipitate 2 (P2) | 0.08 | 12.2 | 46.9 | 40.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlík, J.; Veselý, J.; Stráský, J.; Chráska, T.; Janeček, M. Interface of a Al6061/Ti Composite Prepared by Field Assisted Sintering Technique. Metals 2021, 11, 73. https://doi.org/10.3390/met11010073

Kozlík J, Veselý J, Stráský J, Chráska T, Janeček M. Interface of a Al6061/Ti Composite Prepared by Field Assisted Sintering Technique. Metals. 2021; 11(1):73. https://doi.org/10.3390/met11010073

Chicago/Turabian StyleKozlík, Jiří, Jozef Veselý, Josef Stráský, Tomáš Chráska, and Miloš Janeček. 2021. "Interface of a Al6061/Ti Composite Prepared by Field Assisted Sintering Technique" Metals 11, no. 1: 73. https://doi.org/10.3390/met11010073

APA StyleKozlík, J., Veselý, J., Stráský, J., Chráska, T., & Janeček, M. (2021). Interface of a Al6061/Ti Composite Prepared by Field Assisted Sintering Technique. Metals, 11(1), 73. https://doi.org/10.3390/met11010073