A Study on the Damping Capacities of Mg–Zn–Y-Based Alloys with Lamellar Long Period Stacking Ordered Phases by Preparation Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

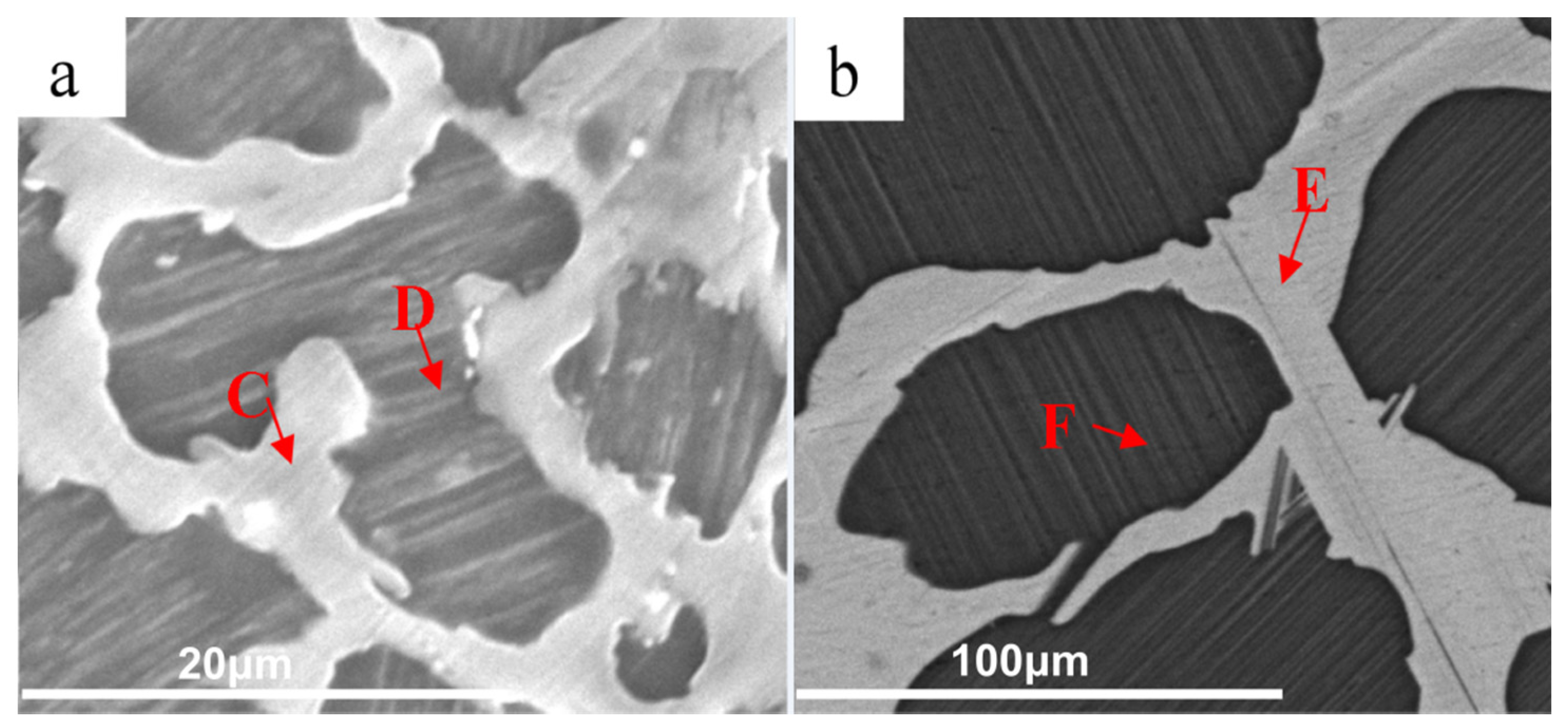

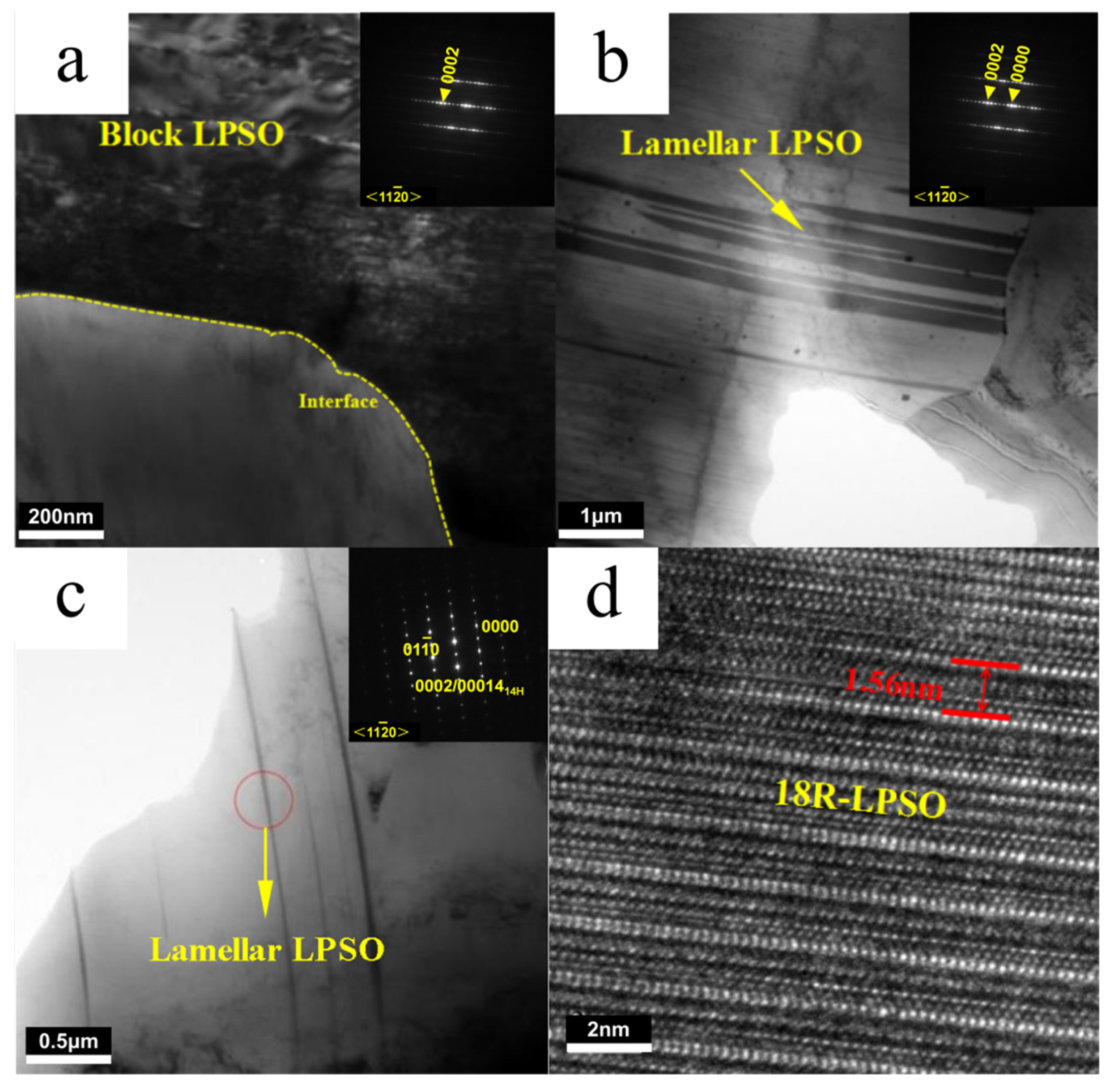

3.1. Microstructure

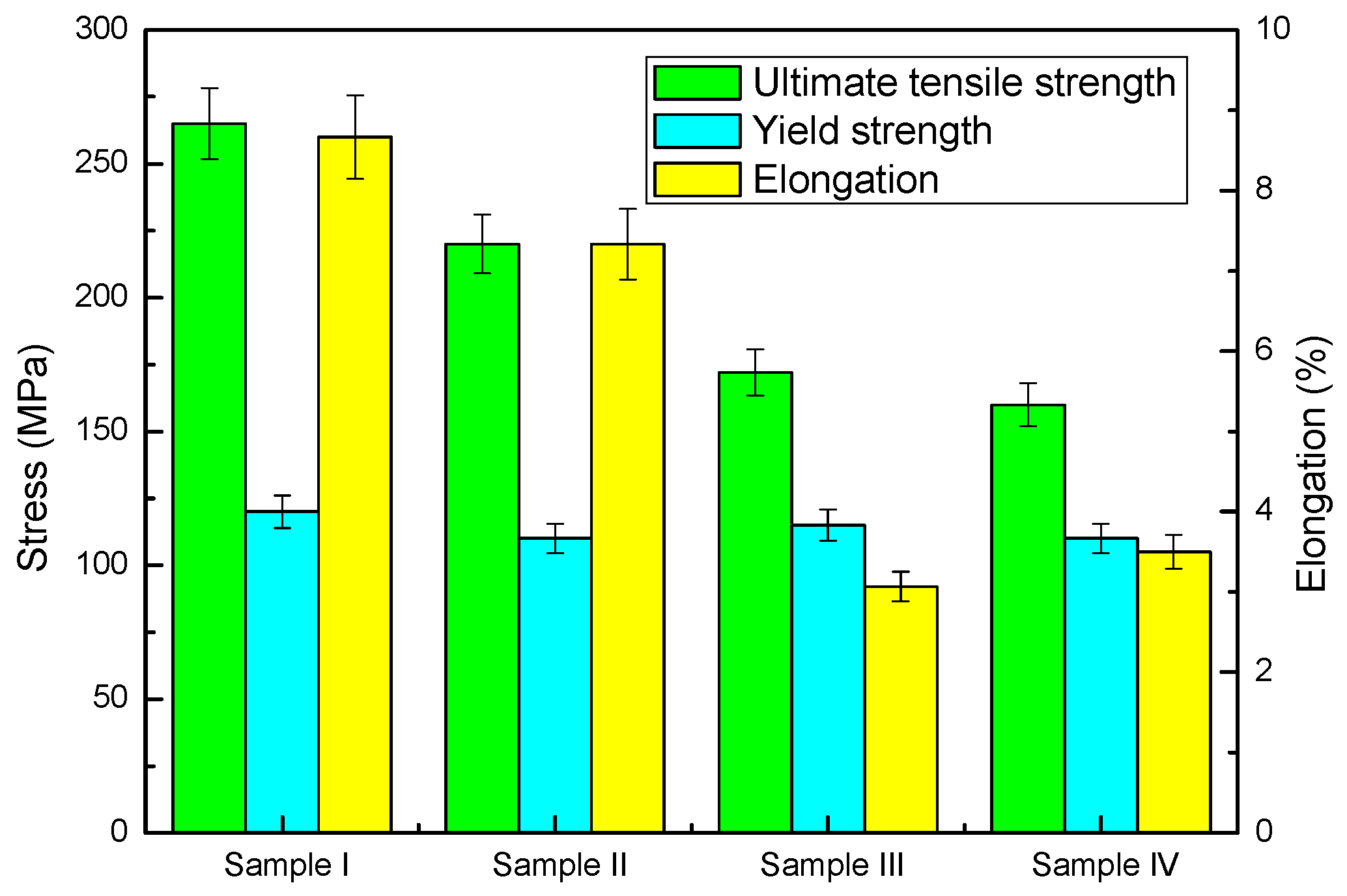

3.2. Properties

3.3. Discussion

C1 = (ρFBLN3)/(6bELC2)

C2 = FB/bELC

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys. 2013, 1, 2–22. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.J.; Liu, C.Y.; Zhang, B.; Xue, P.; Ma, Z.Y.; Luo, K.; Ma, M.Z.; Liu, R.P. Simultaneously improving mechanical properties and damping capacity of Al-Mg-Si alloy through friction stir processing. Mater. Charact. 2017, 131, 425–430. [Google Scholar] [CrossRef]

- Wan, D.Q. Near spherical α-Mg dendrite morphology and high damping of low-temperature casting Mg-1wt.%Ca alloy. Mater. Charact. 2011, 62, 8–11. [Google Scholar]

- Yan, B.S.; Dong, X.P.; Ma, R.; Chen, S.Q.; Pan, Z.; Ling, H.J. Effects of heat treatment on microstructure, mechanical properties and damping capacity of Mg-Zn-Y-Zr alloy. Mater. Sci. Eng. A 2014, 594, 168–177. [Google Scholar] [CrossRef]

- Wan, D.Q.; Wang, H.B.; Ye, S.T.; Hu, Y.L.; Li, L.L. The damping and mechanical properties of magnesium alloys balanced by aluminum addition. J. Alloys Compd. 2019, 782, 421–426. [Google Scholar] [CrossRef]

- Niu, R.L.; Yan, F.G.; Duan, D.P.; Yang, X.M. Effect of yttrium addition on microstructures, damping properties and mechanical properties of as-cast Mg−based ternary alloys. J. Alloys Compd. 2019, 785, 1270–1278. [Google Scholar] [CrossRef]

- Cheng, P.; Zhao, Y.H.; Lu, R.P.; Hou, H.; Bu, Z.Q.; Yan, F. Effect of Ti addition on the microstructure and mechanical properties of cast Mg-Gd-Y-Zn alloys. Mater. Sci. Eng. A 2017, 708, 482–491. [Google Scholar] [CrossRef]

- Cheng, P.; Zhao, Y.H.; Lu, R.P.; Hou, H. Effect of the morphology of long-period stacking ordered phase on mechanical properties and corrosion behavior of cast Mg-Zn-Y-Ti alloy. J. Alloys Compd. 2018, 764, 226–238. [Google Scholar] [CrossRef]

- Ding, Z.B.; Zhao, Y.H.; Lu, R.P.; Pei, H.X.; Hou, H. Microstructure evolution and mechanical properties of Mg-10Gd-3Y-xZn-0.6Zr alloys. J. Mater. Res. 2018, 33, 1797–1805. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly Solidified Powder Metallurgy MgZn1Y2Alloys with Excellent Tensile Yield Strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef] [Green Version]

- Itoi, T.; Seimiya, T.; Kawamura, Y.; Hirohashi, M. Long period stacking structures observed in Mg97Zn1Y2 alloy. Scripta Mater. 2004, 51, 107–111. [Google Scholar] [CrossRef]

- Wang, J.F.; Gao, S.; Song, P.F.; Huang, X.F.; Shi, Z.Z.; Pan, F.S. Effects of phase composition on the mechanical properties and damping capacities of as-extruded Mg-Zn-Y-Zr alloys. J. Alloys. Compd. 2011, 509, 8567–8572. [Google Scholar] [CrossRef]

- Wang, J.F.; Lu, R.P.; Wei, W.W.; Huang, X.F.; Pan, F.S. Effect of long period stacking ordered structure on the damping capacities of Mg–Ni–Y alloys. J. Alloys Compd. 2012, 537, 1–5. [Google Scholar] [CrossRef]

- Qin, D.Z.; Wang, J.F.; Chen, Y.L.; Lu, R.P.; Pan, F.S. Effect of long period stacking ordered structure on the damping capacities of Mg–Ni–Y alloys. Mater. Sci. Eng. A 2015, 624, 9–13. [Google Scholar] [CrossRef]

- Tang, Y.X.; Li, B.; Tang, H.X.; Xu, Y.C.; Gao, Y.P.; Wang, L.H.; Guan, J.Y. Effect of long period stacking ordered structure on mechanical and damping properties of as-cast Mg–Zn–Y–Zr alloy. Mater. Sci. Eng. A 2015, 640, 287–294. [Google Scholar] [CrossRef]

- Yuan, J.W.; Li, T.; Zhang, K.; Li, M.; Li, X.G.; Li, Y.J.; Ma, M.L.; Shi, G.L. Effect of Zn content on the microstructures, mechanical properties, and damping capacities of Mg–7Gd–3Y–1Nd–0.5Zr based alloys. J. Alloys Compd. 2019, 773, 919–926. [Google Scholar] [CrossRef]

- Schaller, R. Metal matrix composites, a smart choice for high damping materials. J. Alloys Compd. 2003, 355, 131–135. [Google Scholar] [CrossRef]

- Ren, L.B.; Quan, G.F.; Xu, Y.G.; Yin, D.D.; Lu, J.W.; Dang, J.T. Effect of heat treatment and pre-deformation on damping capacity of cast Mg-Y binary alloys. J. Alloys Compd. 2017, 699, 976–982. [Google Scholar] [CrossRef]

- González-Martínez, R.; Göken, J.; Letzig, D.; Steinhoff, K.; Kainer, K.U. Influence of aging on damping of the magnesium-aluminium-zinc series. J. Alloys Compd. 2007, 437, 127–132. [Google Scholar] [CrossRef]

- Lu, R.P.; Wang, J.F.; Chen, Y.L.; Qin, D.Z.; Yang, W.X.; Wu, Z.S. Effects of heat treatment on the morphology of long-period stacking ordered phase, the corresponding damping capacities and mechanical properties of Mg-Zn-Y alloys. J. Alloys Compd. 2015, 639, 541–546. [Google Scholar] [CrossRef]

- Yamasaki, M.; Anan, T.; Yoshimoto, S.; Kawamura, Y. Mechanical properties of warm-extruded Mg–Zn–Gd alloy with coherent 14H long periodic stacking ordered structure precipitate. Scripta Mater. 2005, 53, 799–803. [Google Scholar] [CrossRef]

- Oñorbe, E.; Garcés, G.; Pérez, P.; Cabezas, S.; Klaus, M.; Genzel, C.; Frutos, E.; Adeva, P. The evolution of internal strain in Mg-Y-Zn alloys with a long period stacking ordered structure. Scripta Mater. 2011, 65, 719–722. [Google Scholar] [CrossRef]

- Shi, X.; Long, Y.; Zhang, H.; Chen, L.; Zhou, Y.; Yu, X.; Yu, X.; Cai, L.; Leng, Z. Role of LPSO Phase in Crack Propagation Behavior of an As-Cast Mg-Y-Zn Alloy Subjected to Dynamic Loadings. Materials 2019, 12, 498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gröbner, J.; Kozlov, A.; Fang, X.Y.; Geng, J.; Nie, J.F.; Schmid-Fetzer, R. Phase equilibria and transformations in ternary Mg-rich Mg–Y–Zn alloys. Acta Mater. 2012, 60, 5948–5962. [Google Scholar] [CrossRef]

- Huang, S.; Wang, J.F.; Hou, F.; Huang, X.H.; Pan, F.S. Effect of Gd and Y contents on the microstructural evolution of long period stacking ordered phase and the corresponding mechanical properties in Mg–Gd–Y–Zn–Mn alloys. Mater. Sci. Eng. A 2014, 612, 363–370. [Google Scholar] [CrossRef]

- Yamasaki, M.; Sasaki, M.; Nishijima, M.; Hiraga, K.; Kawamura, Y. Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg-Zn-Gd alloys during isothermal aging at high temperature. Acta Mater. 2007, 55, 6798–6805. [Google Scholar] [CrossRef]

- Yoshimoto, S.; Yamasaki, M.; Kawamura, Y. Microstructure and Mechanical Properties of Extruded Mg-Zn-Y Alloys with 14H Long Period Ordered Structure. Mater. Trans. 2006, 47, 959. [Google Scholar] [CrossRef] [Green Version]

- Granato, K.L. Theory of Mechanical Damping Due to Dislocations. J. Appl. Phys. 1956, 27, 583. [Google Scholar] [CrossRef]

- Granato, K.L. Application of Dislocation Theory to Internal Friction Phenomena at High Frequencies. J. Appl. Phys. 1956, 27, 789. [Google Scholar] [CrossRef]

- Sugimoto, K.; Niiya, K.; Okamoto, T.; Kishitake, K. A Study of Damping Capacity in Magnesium Alloys. Trans. JIM 1977, 18, 277. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.M.; Morton, A.J.; Nie, J.F. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys. Acta Mater. 2010, 58, 2936–2947. [Google Scholar] [CrossRef]

- Egusa, D.; Abe, E. The structure of long period stacking/order Mg-Zn-RE phases with extended non-stoichiometry ranges. Acta Mater. 2012, 60, 166–178. [Google Scholar] [CrossRef]

- Gao, X.; Nie, J.F. Enhanced precipitation-hardening in Mg–Gd alloys containing Ag and Zn. Scripta Mater. 2008, 58, 619–622. [Google Scholar] [CrossRef]

- Chino, M.; Mabuchi, S.H.; Iwasaki, H.; Yamamoto, A.; Tsubakino, H. Novel equilibrium two phase Mg alloy with the long-period ordered structure. Scripta Mater. 2004, 51, 711–714. [Google Scholar] [CrossRef]

- Garcésa, G.; Oñorbea, E.; Dobesb, F.; Péreza, P.; Antoranzc, J.M.; Adevaa, P. Effect of microstructure on creep behaviour of cast Mg97Y2Zn1 (at.%) alloy. Mater. Sci. Eng. A 2012, 539, 48–55. [Google Scholar] [CrossRef]

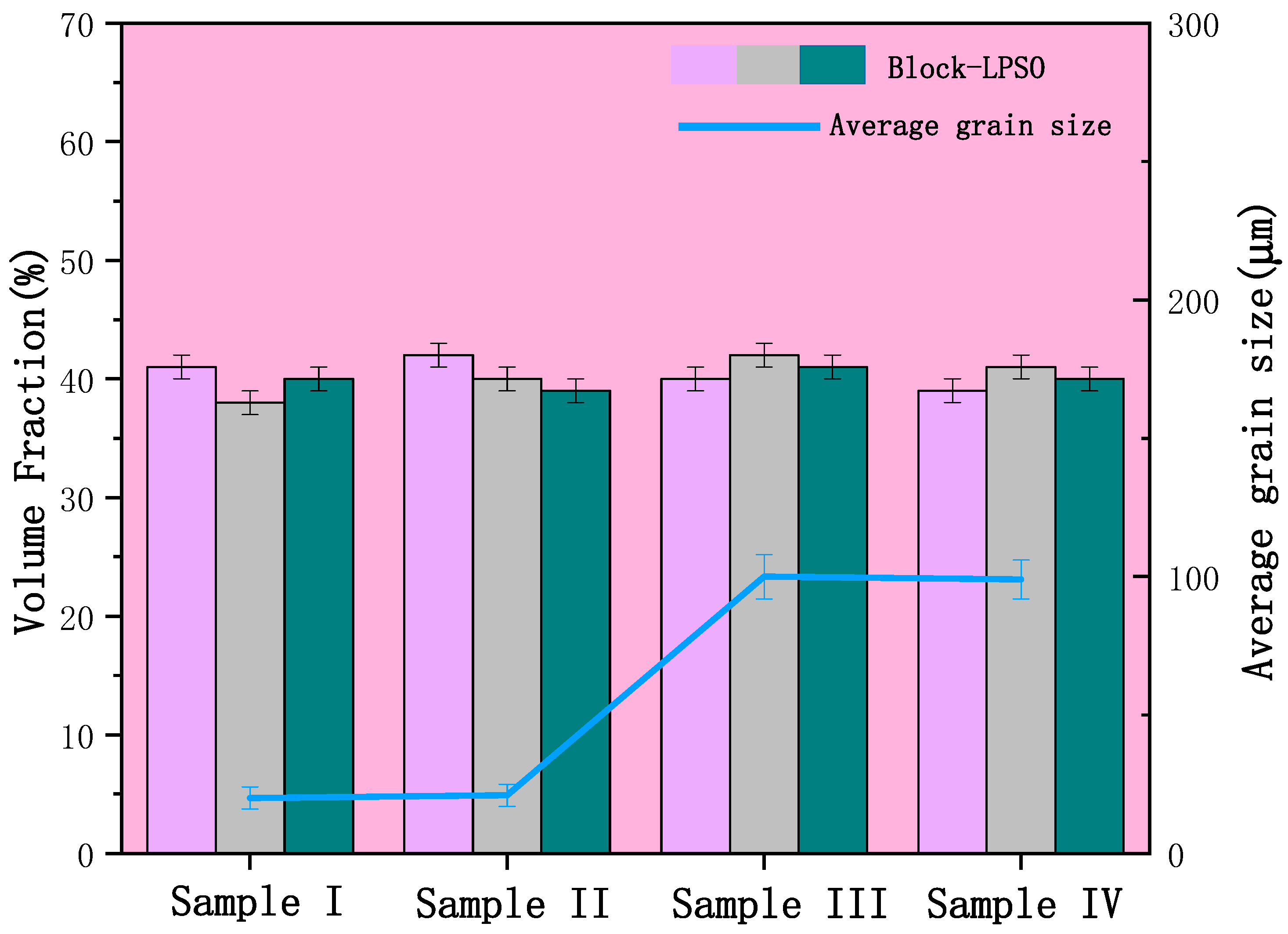

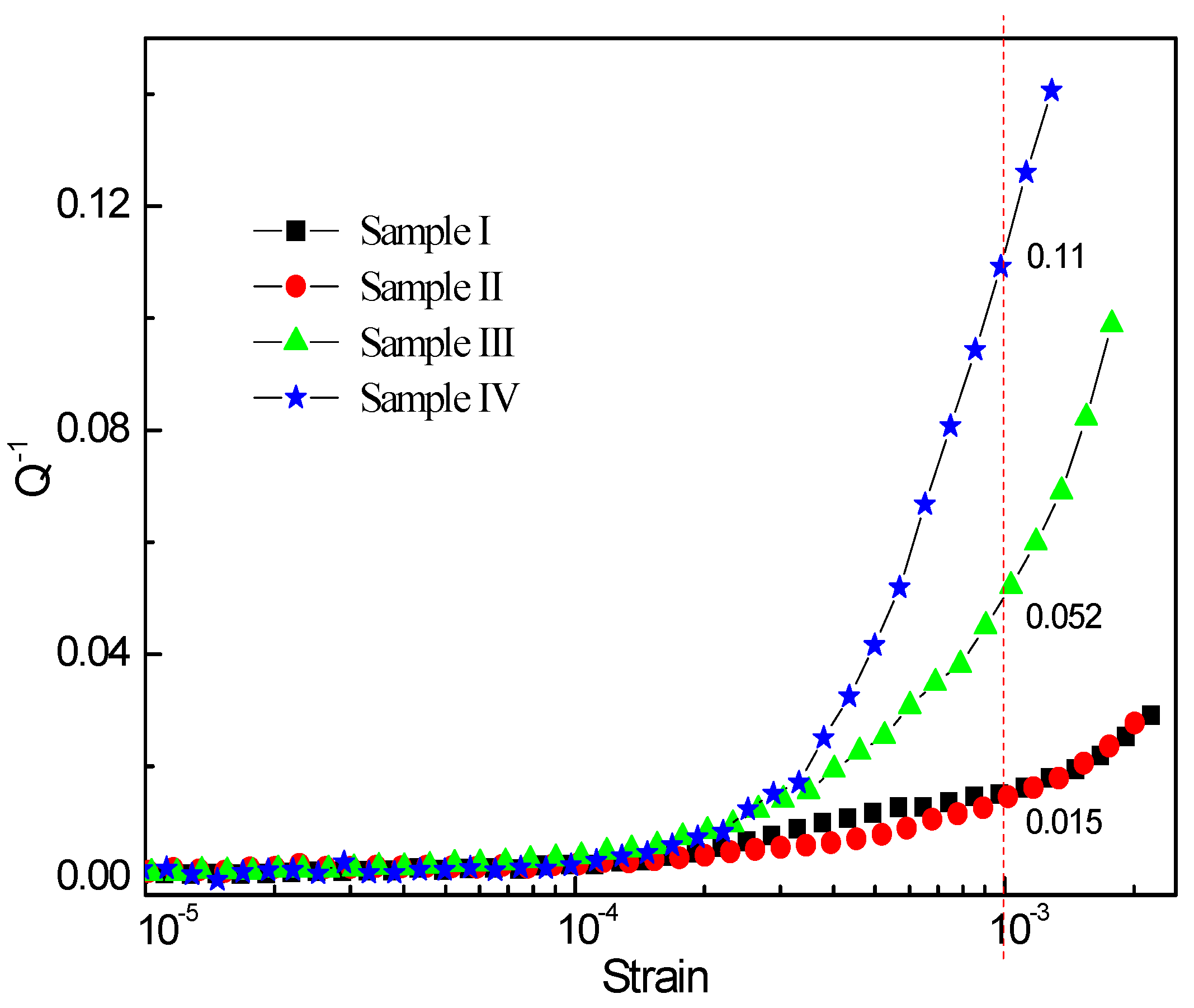

| Alloy | Craft | Grain Size/μm | Main Second Phase |

|---|---|---|---|

| Sample I | Cast alloy cooling in salt water | ~20 | Block LPSO phase |

| Sample II | Cast alloy heat treatment at 673 K × 10 h + cooling in salt water | ~20 | Block LPSO phase + Dense lamellar LPSO phases |

| Sample III | Cast alloy cooling in air | ~100 | Block LPSO phase |

| Sample IV | Cast alloy heat treatment at 673 K × 10 h + cooling in air | ~100 | Block LPSO phase + Sparse lamellar LPSO phases |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, R.; Jiao, K.; Zhao, Y.; Li, K.; Yao, K.; Hou, H. A Study on the Damping Capacities of Mg–Zn–Y-Based Alloys with Lamellar Long Period Stacking Ordered Phases by Preparation Process. Metals 2021, 11, 79. https://doi.org/10.3390/met11010079

Lu R, Jiao K, Zhao Y, Li K, Yao K, Hou H. A Study on the Damping Capacities of Mg–Zn–Y-Based Alloys with Lamellar Long Period Stacking Ordered Phases by Preparation Process. Metals. 2021; 11(1):79. https://doi.org/10.3390/met11010079

Chicago/Turabian StyleLu, Ruopeng, Kai Jiao, Yuhong Zhao, Kun Li, Keyu Yao, and Hua Hou. 2021. "A Study on the Damping Capacities of Mg–Zn–Y-Based Alloys with Lamellar Long Period Stacking Ordered Phases by Preparation Process" Metals 11, no. 1: 79. https://doi.org/10.3390/met11010079