The Joint Effects of Nitriding and Parameters Related to the Destabilisation of Austenite on Wear Resistance in White Cast Iron with 25% Cr

Abstract

:1. Introduction

2. Materials and Methods

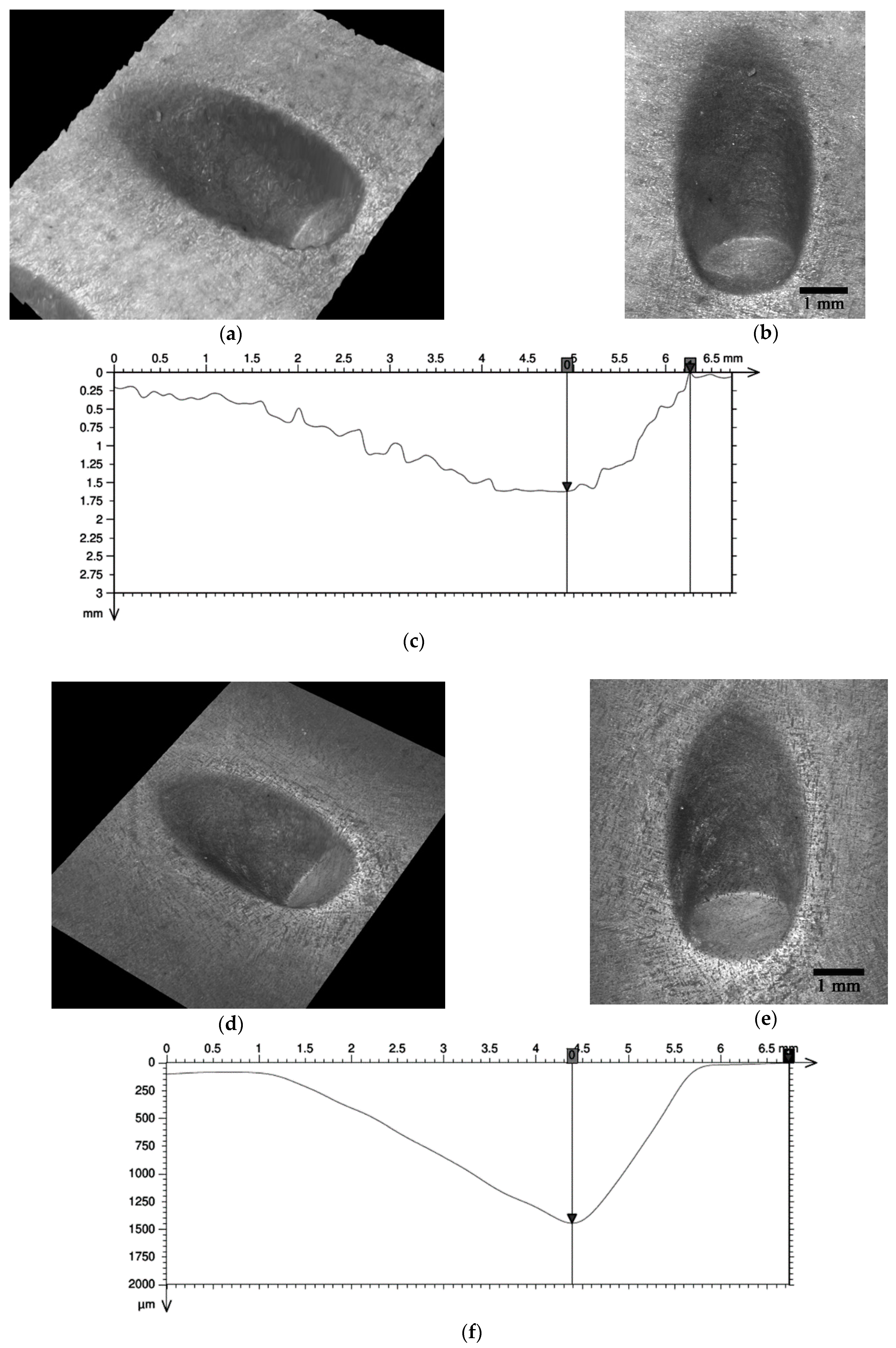

3. Results

4. Conclusions

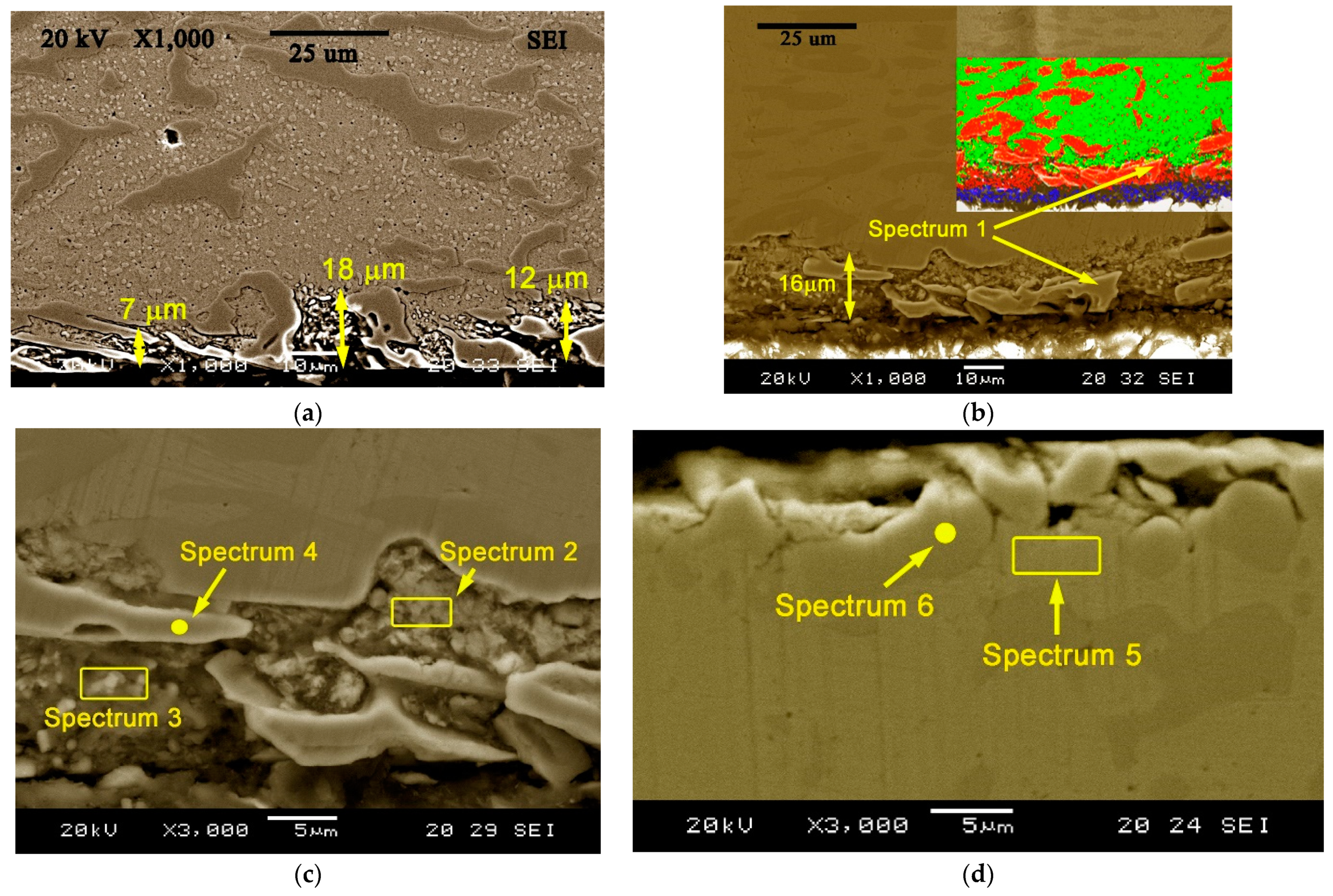

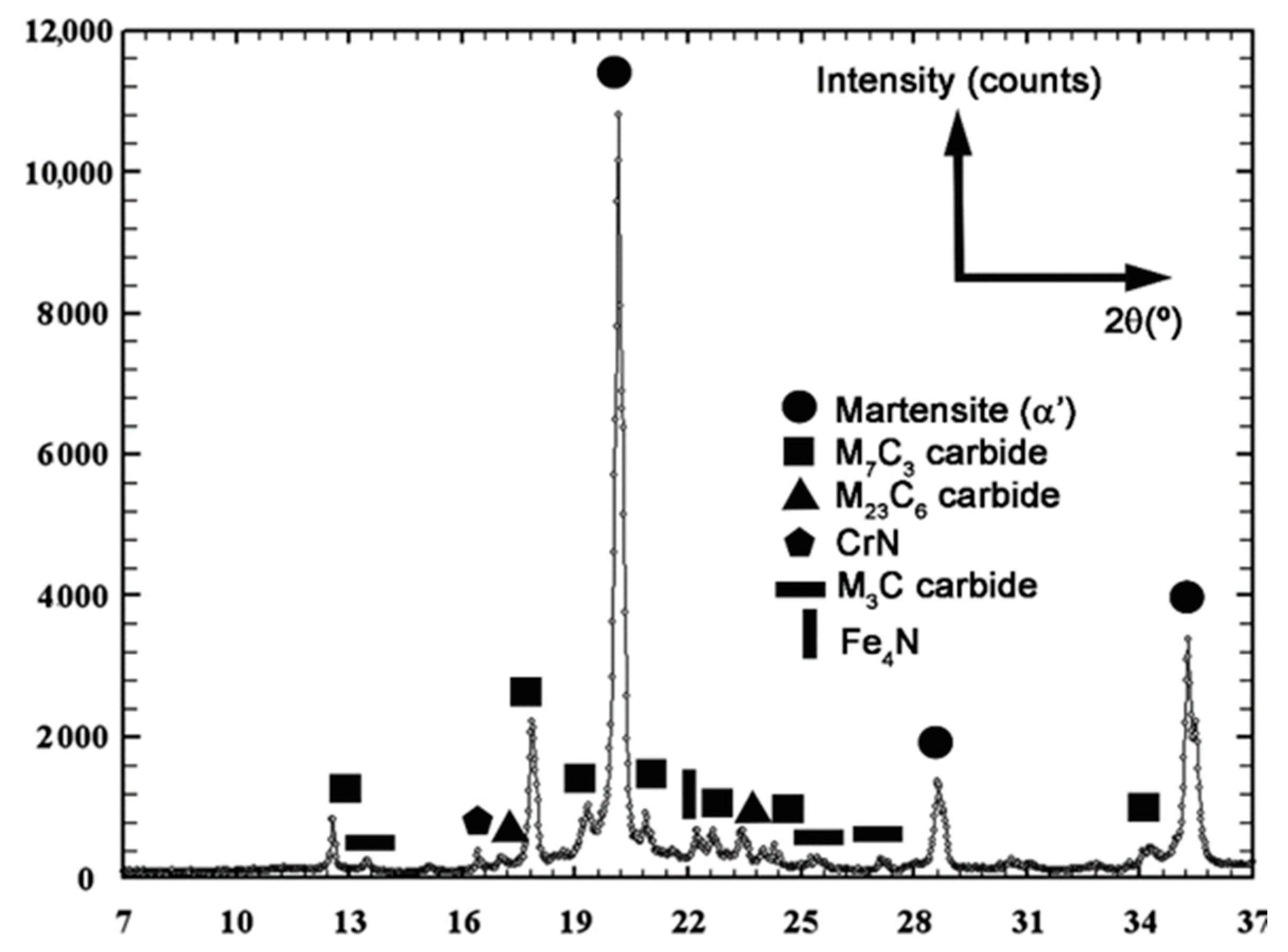

- The thickness of the nitrided layer is much smaller in white cast irons with lower percentages of Cr, not reaching 20 microns in any of the experiments carried out. N has been detected forming very fine nitrides of the type CrN and Fe4N.

- The nitriding treatment entailed a considerable softening of the material, once the nitrided layer was passed. This softening is ‘reduced’ when the temperature of destabilisation of the austenite is at 1100 °C. This temperature accelerates the dissolution of eutectic carbides, precipitated as a consequence of non-equilibrium solidification. The nitriding treatment entails an additional tempering which favours a second destabilisation of the austenite with an additional precipitation of secondary carbides and the transformation of the possible retained austenite into martensite.

- Despite this, the nitriding treatment, together with air-cooling, after the destabilisation of austenite, allows a considerable increase in resistance to erosive wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chung, R.J.; Tang, X.; Li, D.Y.; Hinckley, B.; Dolman, K. Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe-25wt.%Cr-4wt.%C. Wear 2009, 267, 356–361. [Google Scholar] [CrossRef]

- Zhang, Y.; Shimizu, K.; Yaer, X.; Kusumoto, K.; Efremenko, V.G. Erosive wear performance of heat treated multi-component cast iron containing Cr, V, Mn and Ni eroded by alumina spheres at elevated temperatures. Wear 2017, 390–391, 135–145. [Google Scholar] [CrossRef]

- Guitar, M.A.; Suarez, S.; Prat, O.; Guigou, M.D.; Gari, V.; Pereira, G.; Mucklich, F. High Chromium Cast Irons: Destabilized-Subcritical Secondary Carbide Precipitation and Its Effect on Hardness and Wear Properties. J. Mater. Eng. Perform. 2018, 27, 3877–3885. [Google Scholar] [CrossRef]

- Karantzalis, A.E.; Lekatou, A.; Diavati, E. Effect of Destabilization Heat Treatments on the Microstructure of High-Chromium Cast Iron: A Microscopy Examination Approach. J. Mater. Eng. Perform. 2009, 18, 1078–1085. [Google Scholar] [CrossRef]

- Gasan, H.; Erturk, F. Effects of a Destabilization Heat Treatment on the Microstructure and Abrasive Wear Behavior of High-Chromium White Cast Iron Investigated Using Different Characterization Techniques. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44A, 4993–5005. [Google Scholar] [CrossRef]

- Gonzalez-Pociño, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. Erosive Wear Resistance Regarding Diferent Destabilization Heat Treatments of Austenite in High Chromium White Cast Iron, Alloyed with Mo. Metals 2019, 9, 522. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Pocino, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. Optimization of Thermal Processes Applied to Hypoeutectic White Cast Iron containing 25% Cr Aimed at Increasing Erosive Wear Resistance. Metals 2020, 10, 359. [Google Scholar] [CrossRef] [Green Version]

- Ortega-Cubillos, P.; Nannetti-Bernardini, P.A.; Celso-Fredel, M.; Antonio Campos, R. Wear resistance of high chromium white cast iron for coal grinding rolls. Revista Facultad de Ingeniería 2015, 0, 134–142. [Google Scholar] [CrossRef] [Green Version]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Mejia, I.; Zuno-Silva, J.; Rainforth, M. Abrasive wear of V-Nb-Ti alloyed high-chromium white irons. Wear 2015, 332, 1006–1011. [Google Scholar] [CrossRef]

- Gonzalez-Pocino, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. Optimization, by Means of a Design of Experiments, of Heat Processes to Increase the Erosive Wear Resistance of White Hypoeutectic Cast Irons Alloyed with Cr and Mo. Metals 2019, 9, 403. [Google Scholar] [CrossRef] [Green Version]

- Guitar, M.A.; Nayak, U.P.; Britz, D.; Mucklich, F. The Effect of Thermal Processing and Chemical Composition on Secondary Carbide Precipitation and Hardness in High-Chromium Cast Irons. Int. J. Met. 2020, 14, 755–765. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.S.; Wang, J.; Shen, B.L.; Liu, H.H.; Gao, S.J.; Huang, S.J. Effect of cryogenic treatment on the matrix structure and abrasion resistance of white cast iron subjected to destabilization treatment. Wear 2006, 261, 1150–1154. [Google Scholar] [CrossRef]

- Gonzalez-Pocino, A.; Alvarez-Antolin, F.; Asensio-Lozano, J.; Alvarez-Perez, H. Influence of Thermal Processing Factors, Linked to the Destabilisation of Austenite, on the Microstructural Variation of a White Cast Iron Containing 25% Cr and 0.6% Mo. Metals 2020, 10, 832. [Google Scholar] [CrossRef]

- Antolin, J.F.A.; Garrote, L.F.; Lozano, J.A. Application of Rietveld Refinement to the correlation of the microstructure evolution of white cast irons with 18 and 25 %-wt. Cr after oil quench and successive temper treatments, with abrasive wear and bending testing. Revista de Metalurgia 2018, 54, 11. [Google Scholar] [CrossRef] [Green Version]

- Pero-Sanz, J.A. Aceros; Dossat, Ed.; Dossat: Madrid, Spain, 2004; p. 558. [Google Scholar]

- Selte, A.; Ozkal, B.; Arslan, K.; Ulker, S.; Hatman, A. Effect of Nitriding on the Wear Resistance of Tool Powder Steels with Different Contents of V, Cr and Mo. Met. Sci. Heat Treat. 2018, 59, 729–734. [Google Scholar] [CrossRef]

- Binder, C.; Bendo, T.; Hammes, G.; Klein, A.N.; de Mello, J.D.B. Effect of nature of nitride phases on sliding wear of plasma nitrided sintered iron. Wear 2015, 332, 995–1005. [Google Scholar] [CrossRef]

- Gonzalez-Pocino, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. Improvement of Adhesive Wear Behavior by Variable Heat Treatment of a Tool Steel for Sheet Metal Forming. Materials 2019, 12, 2831. [Google Scholar] [CrossRef] [Green Version]

- Garzon, C.M.; Franco, A.R.; Tschiptschin, A.P. Thermodynamic Analysis of M7C3 Carbide Dissolution during Plasma Nitriding of an AISI D2 Tool Steel. ISIJ Int. 2017, 57, 737–745. [Google Scholar] [CrossRef] [Green Version]

- Kallel, M.; Zouch, F.; Antar, Z.; Bahri, A.; Elleuch, K. Hammer premature wear in mineral crushing process. Tribol. Int. 2017, 115, 493–505. [Google Scholar] [CrossRef]

- Al-Bukhaiti, M.A.; Abouel-Kasem, A.; Emara, K.M.; Ahmed, S.M. A Study on Slurry Erosion Behavior of High Chromium White Cast Iron. J. Tribol. Trans. ASME 2017, 139. [Google Scholar] [CrossRef]

- Atapek, S.H.; Fidan, S. Solid-particle erosion behavior of cast alloys used in the mining industry. Int. J. Miner. Metall. Mater. 2015, 22, 1283–1292. [Google Scholar] [CrossRef]

- Prat-Bartés, A.; Tort-Martorell, X.; Grima-Cintas, P.; Pozueta-Fernández, L.; Solé-Vidal, I. Métodos Estadísticos, 2nd ed.; UPC: Barcelona, Spain, 2004; p. 376. [Google Scholar]

| C | Si | Mn | Cr | Mo |

|---|---|---|---|---|

| 2.7 | 1.2 | 0.8 | 25.1 | 0.5 |

| Factors | Levels | ||

|---|---|---|---|

| Code | Thermal Parameter | Level –1 | Level +1 |

| A | Temperature of destabilisation of the austenite (°C) | 1000 | 1100 |

| B | Time of permanence at the destabilisation temperature (h) | 4 | 8 |

| C | Nitriding | no | yes |

| D | Means of cooling in tempering | air | oil |

| E | Temperature of tempering (°C) | 200 | 500 |

| F | Time of permanence in tempering (h) | 3 | 6 |

| Experiment | A | B | C | D | E | F | Confounding Patterns |

|---|---|---|---|---|---|---|---|

| 1 | –1 | –1 | –1 | +1 | +1 | +1 | A + BD + CE B + AD + CF C + AE + BF D + AB + EF E + AC + DF F + BC + DE AF + BE + CD |

| 2 | +1 | –1 | –1 | –1 | –1 | +1 | |

| 3 | –1 | +1 | –1 | –1 | +1 | –1 | |

| 4 | +1 | +1 | –1 | +1 | –1 | –1 | |

| 5 | –1 | –1 | +1 | +1 | –1 | –1 | |

| 6 | +1 | –1 | +1 | –1 | +1 | –1 | |

| 7 | –1 | +1 | +1 | –1 | –1 | +1 | |

| 8 | +1 | +1 | +1 | +1 | +1 | +1 |

| Gas Mixture | 70%N2 + 30%H2 |

|---|---|

| Gas flux (cm3/min) | 500 |

| Temperature (°C) | 540 |

| Pressure (Pa) | 400 |

| Time (min) | 120 |

| Output voltage (V) | 500 |

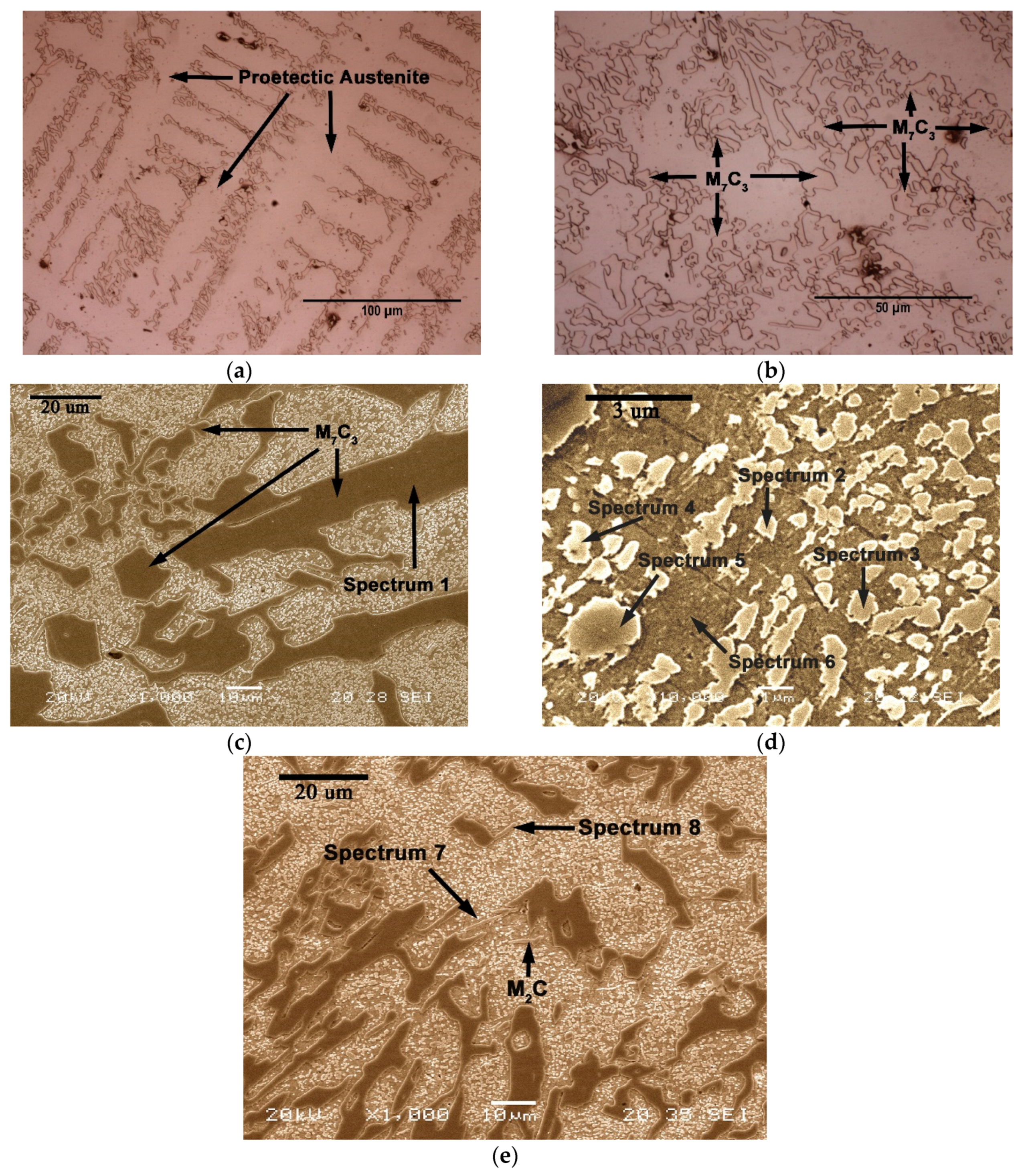

| Spectrum | C | Cr | Fe | Mo | Si |

|---|---|---|---|---|---|

| 1 | 38 | 38 | 23 | 0.8 | - |

| 2 | 30 | 9 | 61 | - | - |

| 3 | 40 | 9 | 51 | - | - |

| 4 | 33 | 7 | 60 | - | - |

| 5 | 36 | 37 | 26 | 0.7 | - |

| 6 | 27 | 6 | 67 | 0.2 | 2 |

| 7 | 26 | 10 | 48 | 16 | - |

| 8 | 28 | 9 | 47 | 16 | - |

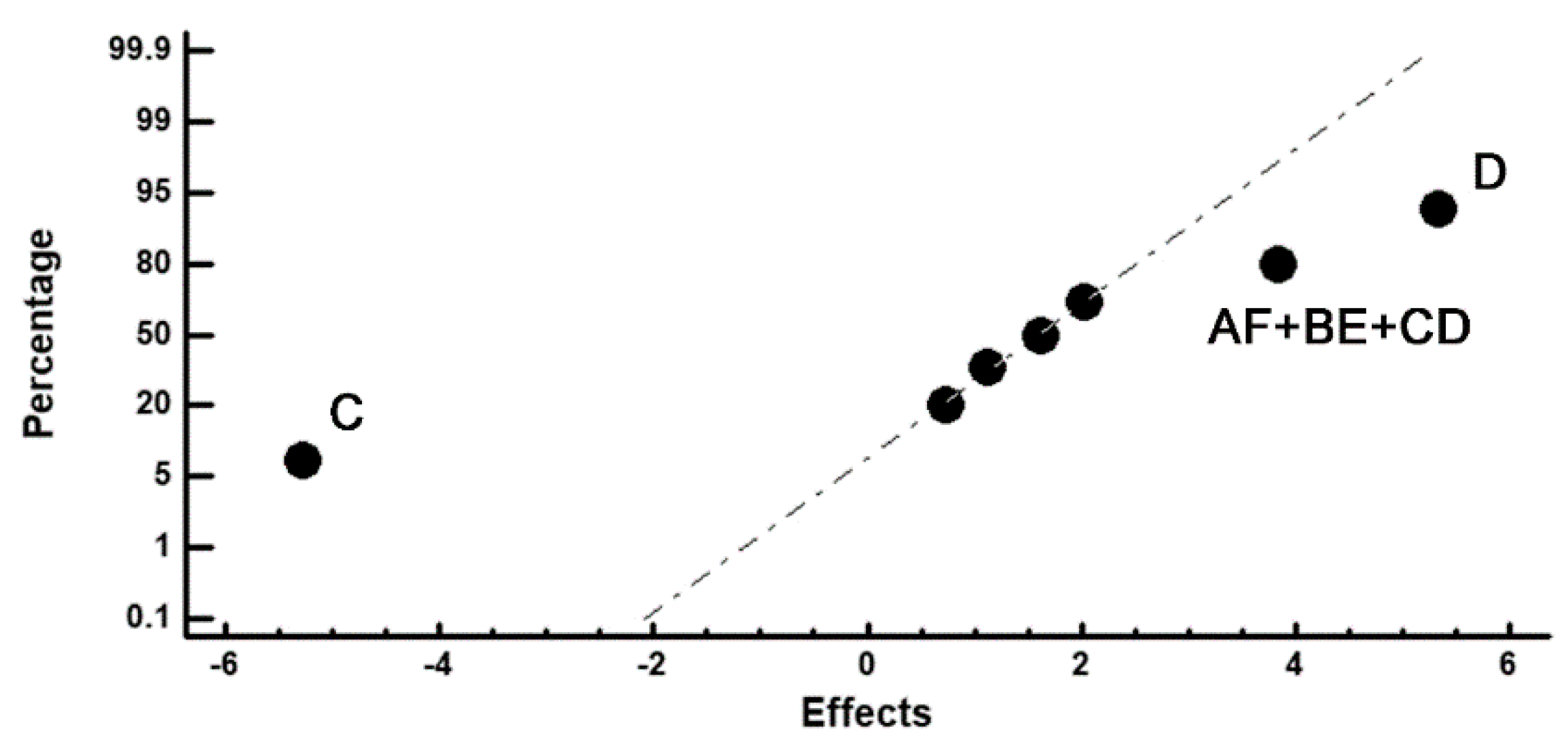

| Experiment | Erosive Wear | Confounding Pattern | |

|---|---|---|---|

| mg | Effect | ||

| 1 | 85.5 | 81.712 | Average |

| 2 | 83.6 | 1.62 | A + BD + CE |

| 3 | 83.6 | 0.72 | B + AD + CF |

| 4 | 84.7 | −5.27 | C + AE + BF |

| 5 | 80.9 | 5.32 | D + AB + EF |

| 6 | 75.4 | 2.02 | E + AC + DF |

| 7 | 73.6 | 1.12 | F + BC + DE |

| 8 | 86.4 | 3.82 | AF + BE + CD |

| Spectrum | C | N | Cr | Fe |

|---|---|---|---|---|

| 1 | 32 | -- | 49 | 19 |

| 2 | 26 | 2 | 14 | 58 |

| 3 | 30 | 10 | 42 | 18 |

| 4 | 32 | -- | 48 | 20 |

| 5 | 32 | 30 | 18 | 20 |

| 6 | 32 | -- | 50 | 18 |

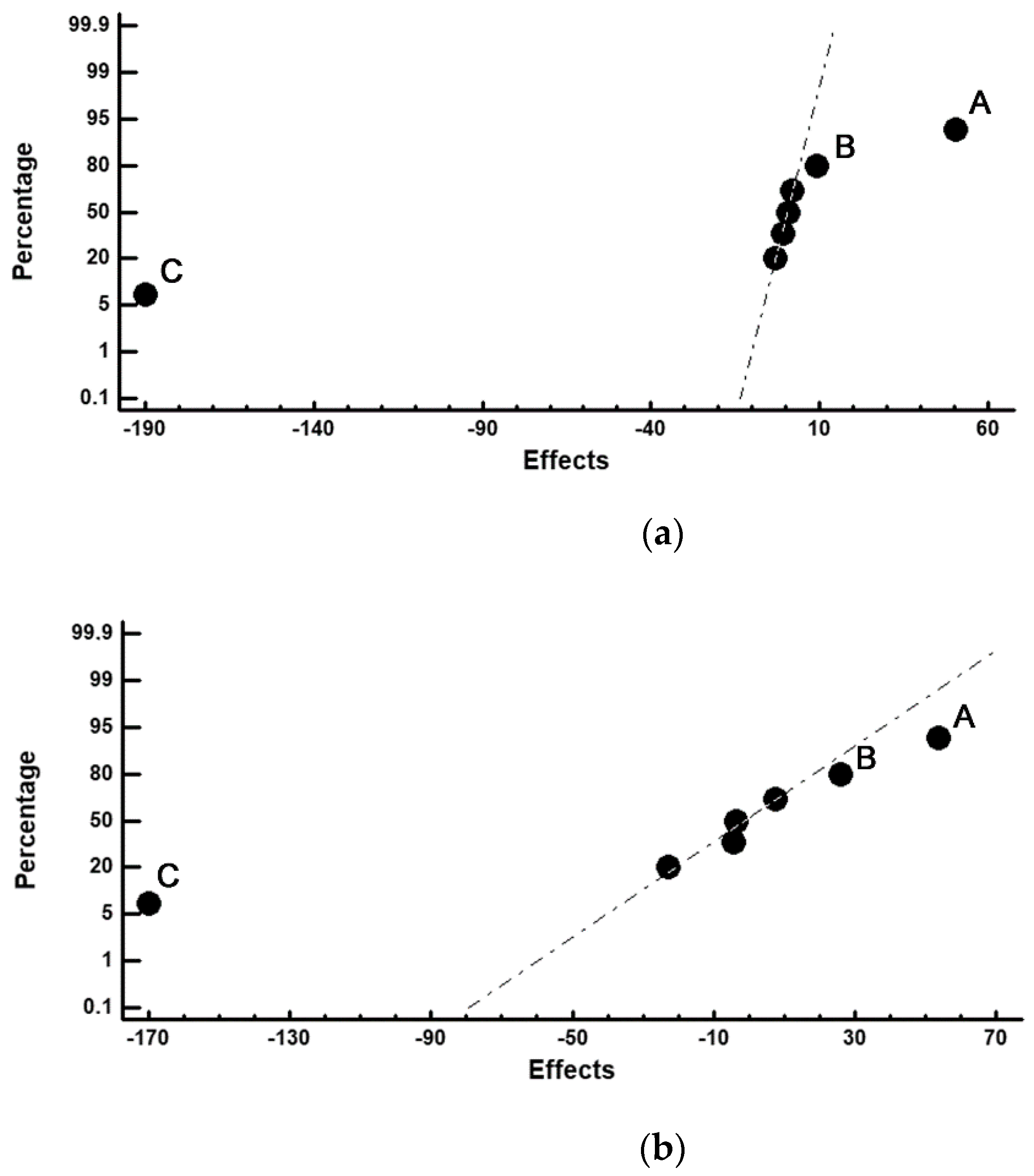

| Experiment | Hardness (HV) | Micro-Hardness (HV) | Confounding Pattern | ||

|---|---|---|---|---|---|

| F = 10 N | Effect | F = 0.5 N | Effect | ||

| 1 | 699 | 633.87 | 645 | 619.00 | Average |

| 2 | 746 | 50.2 | 714 | 53.5 | A + BD + CE |

| 3 | 710 | 9.2 | 706 | 26.0 | B + AD + CF |

| 4 | 760 | −189.7 | 751 | −170.0 | C + AE + BF |

| 5 | 510 | 0.75 | 509 | −4.5 | D + AB + EF |

| 6 | 562 | 1.75 | 556 | −3.5 | E + AC + DF |

| 7 | 516 | −3.25 | 509 | −23.0 | F + BC + DE |

| 8 | 568 | −0.75 | 562 | 7.5 | AF + BE + CD |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Pociño, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. The Joint Effects of Nitriding and Parameters Related to the Destabilisation of Austenite on Wear Resistance in White Cast Iron with 25% Cr. Metals 2021, 11, 85. https://doi.org/10.3390/met11010085

González-Pociño A, Alvarez-Antolin F, Asensio-Lozano J. The Joint Effects of Nitriding and Parameters Related to the Destabilisation of Austenite on Wear Resistance in White Cast Iron with 25% Cr. Metals. 2021; 11(1):85. https://doi.org/10.3390/met11010085

Chicago/Turabian StyleGonzález-Pociño, Alejandro, Florentino Alvarez-Antolin, and Juan Asensio-Lozano. 2021. "The Joint Effects of Nitriding and Parameters Related to the Destabilisation of Austenite on Wear Resistance in White Cast Iron with 25% Cr" Metals 11, no. 1: 85. https://doi.org/10.3390/met11010085

APA StyleGonzález-Pociño, A., Alvarez-Antolin, F., & Asensio-Lozano, J. (2021). The Joint Effects of Nitriding and Parameters Related to the Destabilisation of Austenite on Wear Resistance in White Cast Iron with 25% Cr. Metals, 11(1), 85. https://doi.org/10.3390/met11010085